wheels SUZUKI SWIFT 2008 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 541 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-2

General Description

ABS DescriptionS7RS0B4501001

The ABS (Antilock Brake System) controls the fluid

pressure applied to the wheel cylinder of each brake

from the master cylinder so that each wheel is not locked

even when hard braking is applied.

This ABS has also the following function.

While braking is applied, but before ABS control

becomes effective, braking force is distributed between

the front and rear so as to prevent the rear wheels from

being locked too early for better stability of the vehicle.

The main component parts of this ABS include the

following parts in addition to those of the conventional

brake system.

• Wheel speed sensor which senses revolution speed of each wheel and outputs its signal.

• ABS warning light which light s to inform abnormality

when system fails to operate properly.

• ABS hydraulic unit / cont rol module assembly is

incorporated ABS co ntrol module, ABS hydraulic unit

(actuator assembly), solenoid valve power supply

driver (transistor), solenoid valve driver (transistor),

pump motor driver (transistor).

– ABS control module which sends operation signal to ABS hydraulic unit to control fluid pressure

applied to each wheel cylinder based on signal

from each wheel speed sensor so as to prevent

wheel from locking.

– ABS hydraulic unit which operates according to signal from ABS control module to control fluid

pressure applied to wheel cylinder of each 4

wheels.

– Solenoid valve power supp ly driver (transistor)

which supplies power to solenoid valve in ABS

hydraulic unit.

– Solenoid valve driver (transistor) which controls each solenoid valves in ABS hydraulic unit.

– Pump motor driver (transistor) which supplies power to pump motor in ABS hydraulic unit.

This ABS is equipped with Electronic Brake force

Distribution (EBD) system that controls a fluid pressure

of rear wheels to best condition, which is the same

function as that of proportion ing valve, by the signal from

wheel sensor independently of change of load due to

load capacity and so on. An d if the EBD system fails to

operate properly, the brake warning light lights to inform

abnormality.

ABS Hydraulic Unit / Control Module Assembly

Description

S7RS0B4501002

ABS control module is a component of ABS hydraulic

unit / control module asse mbly and has the following

functions.

Self-Diagnosis Function

ABS control module diagnose s conditions of the system

component parts (whether or not there is any

abnormality) all the time and indicates the results

(warning of abnormality occurrence and DTC) through

the ABS warning light as described.

• When ignition switch is turned ON, ABS warning light lights for 2 seconds to check its circuit.

• When no abnormality has been detected (the system is in good condition), ABS warning light turns OFF

after 2 seconds.

• When an abnormality in th e system is detected, ABS

warning light lights and the area where that

abnormality lies is stored in the memory of EEPROM

in ABS control module.

1

I4RS0A450001-01

Page 551 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-12

DTC ClearanceS7RS0B4504006

WARNING!

When performing a driving test, select a safe

place where there is neither any traffic nor

any traffic accident possibility and be very

careful during testing to avoid occurrence of

an accident.

After repair or replace malfunction part(s), clear all DTCs

by performing the following procedure or using SUZUKI

scan tool.

1) Connect SUZUKI scan tool to data link connector in the same manner as when making this connection

for DTC check.

2) Turn ignition switch to ON position.

3) Erase DTC according to instructions displayed on scan tool. Refer to scan tool operator’s manual for

further derails.

NOTE

For DTC C 1021, C1022, C1025, C1026, C1031,

C1032, C1035, C1036 and C1061, confirm that

ABS warning light turns off after performing

Step 2 of “Test Driving” under “ABS Check”,

and then clear the DTCs.

4) After completing the clear ance, turn ignition switch

OFF and disconnect scan tool from data link

connector.

5) Perform “Driving Test” (S tep 2 of “ABS Check”) and

“DTC Check” and confirm that NO DTC is displayed

on scan tool.

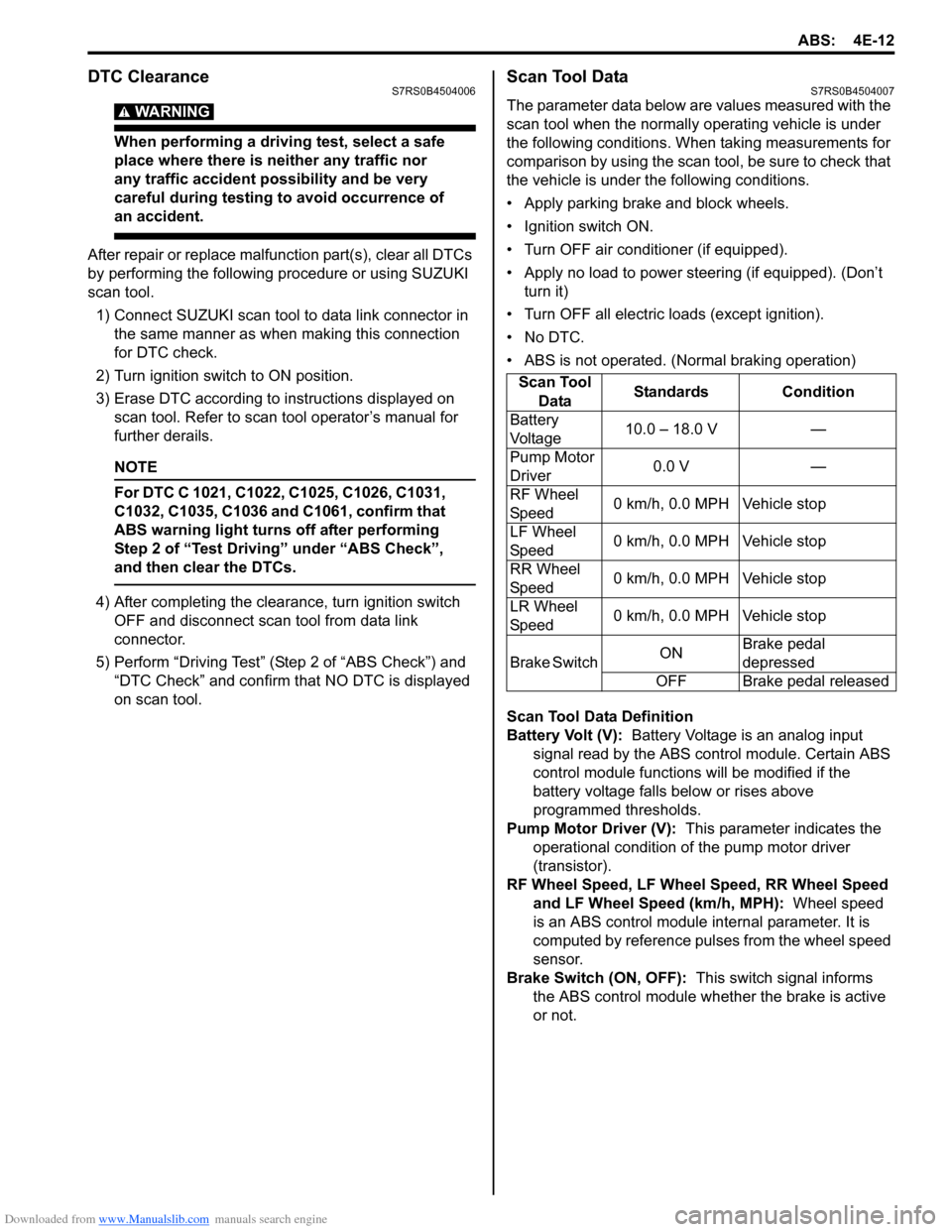

Scan Tool DataS7RS0B4504007

The parameter data below are values measured with the

scan tool when the normally operating vehicle is under

the following conditions. When taking measurements for

comparison by using the scan tool, be sure to check that

the vehicle is under the following conditions.

• Apply parking brake and block wheels.

• Ignition switch ON.

• Turn OFF air conditioner (if equipped).

• Apply no load to power steering (if equipped). (Don’t turn it)

• Turn OFF all electric loads (except ignition).

• No DTC.

• ABS is not operated. (N ormal braking operation)

Scan Tool Data Definition

Battery Volt (V): Battery Voltage is an analog input

signal read by the ABS control module. Certain ABS

control module function s will be modified if the

battery voltage falls below or rises above

programmed thresholds.

Pump Motor Driver (V): This parameter indicates the

operational condition of the pump motor driver

(transistor).

RF Wheel Speed, LF Wheel Speed, RR Wheel Speed and LF Wheel Speed (km/h, MPH): Wheel speed

is an ABS control module inte rnal parameter. It is

computed by reference pulses from the wheel speed

sensor.

Brake Switch (ON, OFF): This switch signal informs

the ABS control modu le whether the brake is active

or not.

Scan Tool

Data Standards Condition

Battery

Voltage 10.0 – 18.0 V —

Pump Motor

Driver 0.0 V —

RF Wheel

Sp ee d 0 km/h, 0.0 MPH Vehicle stop

LF Wheel

Sp ee d 0 km/h, 0.0 MPH Vehicle stop

RR Wheel

Sp ee d 0 km/h, 0.0 MPH Vehicle stop

LR Wheel

Sp ee d 0 km/h, 0.0 MPH Vehicle stop

Brake Switch ONBrake pedal

depressed

OFF Brake pedal released

Page 567 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-28

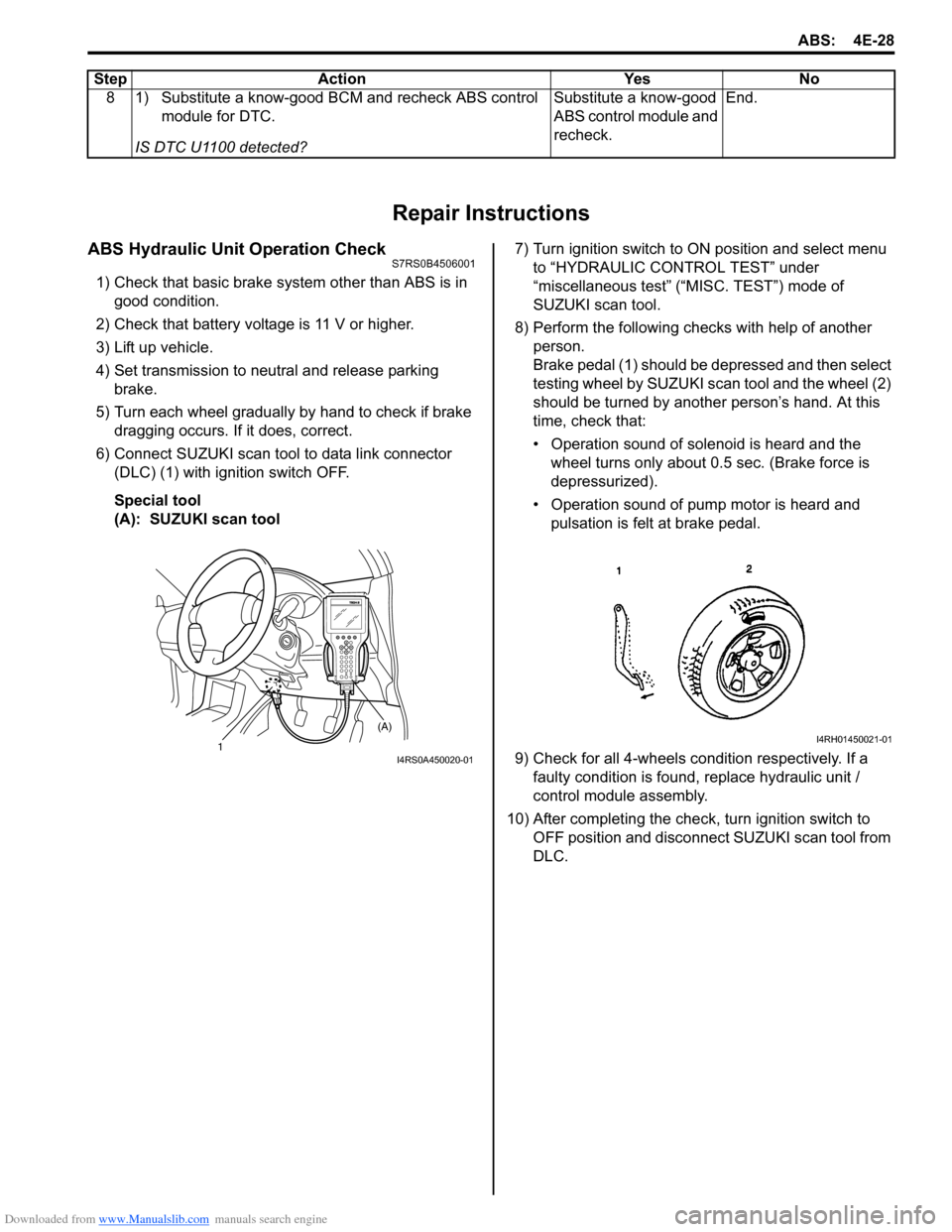

Repair Instructions

ABS Hydraulic Unit Operation CheckS7RS0B4506001

1) Check that basic brake system other than ABS is in good condition.

2) Check that battery voltage is 11 V or higher.

3) Lift up vehicle.

4) Set transmission to neutral and release parking brake.

5) Turn each wheel gradually by hand to check if brake dragging occurs. If it does, correct.

6) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool 7) Turn ignition switch to ON position and select menu

to “HYDRAULIC CONTROL TEST” under

“miscellaneous test” (“MISC. TEST”) mode of

SUZUKI scan tool.

8) Perform the following checks with help of another person.

Brake pedal (1) should be depressed and then select

testing wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check that:

• Operation sound of solenoid is heard and the wheel turns only about 0.5 sec. (Brake force is

depressurized).

• Operation sound of pump motor is heard and pulsation is felt at brake pedal.

9) Check for all 4-wheels co ndition respectively. If a

faulty condition is found, replace hydraulic unit /

control module assembly.

10) After completing the check, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

8 1) Substitute a know-good BCM and recheck ABS control

module for DTC.

IS DTC U1100 detected? Substitute a know-good

ABS control module and

recheck.

End.

Step Action Yes No

1 (A)I4RS0A450020-01

I4RH01450021-01

Page 576 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-2 Electronic Stability Program:

Perform sensor calibration according to “Sensor Calibration”.

Precautions in Speedometer Test or Other TestsS7RS0B4600005

When performing speedometer or other tests using speedometer tester or chassis dynamometer, ESP® function must

be deactivated by ESP ® OFF switch or using SUZUKI scan to ol to complete the tests correctly.

When using SUZUKI scan tool, set to the “MISC. TEST” mode to stop the ESP ® function. Refer to SUZUKI scan tool

operator's manual for further details.

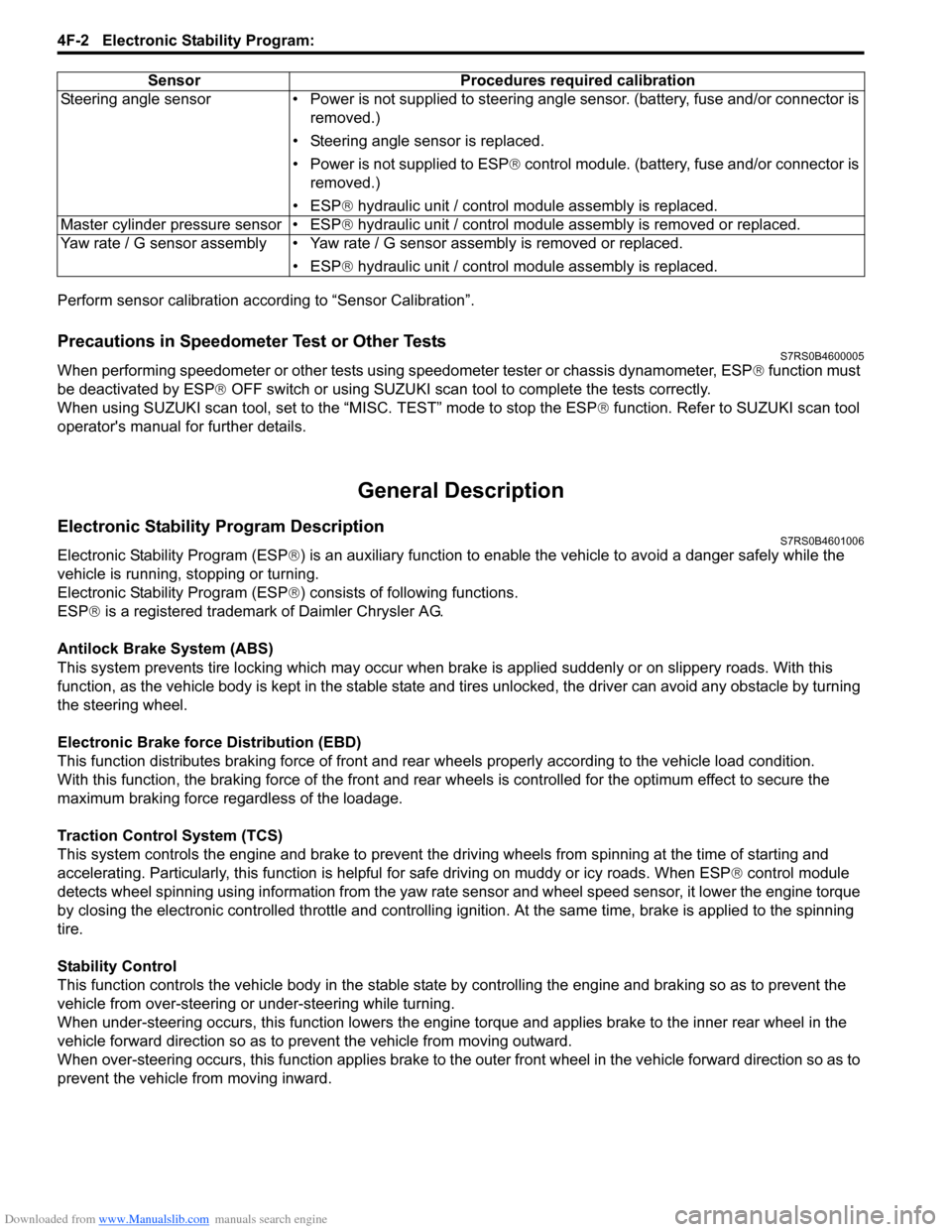

General Description

Electronic Stability Program DescriptionS7RS0B4601006

Electronic Stability Program (ESP ®) is an auxiliary function to enable the vehicle to av oid a danger safely while the

vehicle is running, stopping or turning.

Electronic Stability Program (ESP ®) consists of following functions.

ESP ® is a registered trademark of Daimler Chrysler AG.

Antilock Brake System (ABS)

This system prevents tire locking which may occur when br ake is applied suddenly or on slippery roads. With this

function, as the vehicle body is kept in the stable state an d tires unlocked, the driver can avoid any obstacle by turning

the steering wheel.

Electronic Brake force Distribution (EBD)

This function distributes braking force of front and rear wheels properly according to the vehicle load condition.

With this function, the braking force of the front and rear wheels is controlled for the optimum effect to secure the

maximum braking force regardless of the loadage.

Traction Control System (TCS)

This system controls the engine and brake to prevent the dr iving wheels from spinning at the time of starting and

accelerating. Particularly, this fu nction is helpful for safe driving on muddy or icy roads. When ESP ® control module

detects wheel spinning using information from the yaw rate sensor and wheel speed sensor, it lower the engine torque

by closing the electronic controlled thro ttle and controlling ignition. At the same time, brake is applied to the spinning

tire.

Stability Control

This function controls the vehicle body in the stable state by controlling the engine and braking so as to prevent the

vehicle from over-steering or under-steering while turning.

When under-steering occurs, this function lowers the engine torque and applies brake to the inner rear wheel in the

vehicle forward direction so as to pr event the vehicle from moving outward.

When over-steering occurs, this function applies brake to the outer front wheel in the vehicle forward direction so as to

prevent the vehicle from moving inward. Sensor Procedures required calibration

Steering angle sensor • Power is not su pplied to steering angle sensor. (battery, fuse and/or connector is

removed.)

• Steering angle sensor is replaced.

• Power is not supplied to ESP ® control module. (battery, fuse and/or connector is

removed.)

• ESP® hydraulic unit / control module assembly is replaced.

Master cylinder pressure sensor • ESP® hydraulic unit / control module assembly is removed or replaced.

Yaw rate / G sensor assembly • Yaw rate / G sensor assembly is removed or replaced.

• ESP® hydraulic unit / control module assembly is replaced.

Page 594 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-20 Electronic Stability Program:

NOTE

•�{: Activated

• X: Deactivated

• *1: If two or more wheel speed sensor are defective, ABS warning lamp, EBD warning lamp and ESP ® warning lamp are lit and all the control functions are deactivated. If one wheel speed sensor is

defective, ABS warning lamp and ESP ® warning lamp are lit and ABS and TCS / stability control are

deactivated.

• *2: ESP ® OFF mode is cancelled and all control functions are activated.

• *3: EBD control function is activated only if po wer supply circuit is little low voltage malfunction.

Scan Tool DataS7RS0B4604024

The parameter data below are values measured with the scan tool when the normally operating vehicle is under the

following conditions. When taking measurements for comparis on by using the scan tool, be sure to check that the

vehicle is under the following conditions.

• Apply parking brake and block wheels.

• Ignition switch ON.

• Turn OFF air conditioning (if equipped).

• Set the wheel in straight-ahead position and hands off steering wheel.

• Turn OFF all electric loads (except ignition).

• Check that there is no DTC.

Scan Tool Data Definition

Battery Volt (V): Battery Voltage is an analog input

signal read by the ESP ® control module. Certain

ESP ® control module functions will be modified if the

battery voltage falls below or rises above

programmed thresholds.

Pump Motor Driver (V): This parameter indicates the

operational condition of the pump motor driver

(transistor).

RF Wheel Speed, LF Wheel Speed, RR Wheel Speed and LR Wheel Speed (km/h, MPH): Wheel speed

is ESP ® control module internal parameter. It is

computed by reference puls es from the wheel speed

sensor. Brake Switch (ON, OFF):

This switch signal informs

the ESP ® control module whether the brake is active

or not.

Master Cyl Press (MPa): Brake fluid pressure from

brake master cylinder.

G Sensor (lateral) (G): Lateral acceleration is

measured by yaw rate / G sensor assembly and

output to ESP ® control module by pulse signal.

Yaw rate sensor (Deg/s): Yaw rate sensor is measured

by yaw rate / G sensor assembly and output to

ESP® control module by pulse signal.

Steering angle Sen ( °): Steering wheel rotation angle

is measured by steering angle sensor and output to

ESP® control module by pulse signal.

Scan Tool Data Standards Condition

Battery Voltage 10.0 – 16.0 V —

Pump Motor Driver 0.0 V —

RF Wheel Speed 0 km/h, 0.0 MPH Veh icle is in stationary condition.

LF Wheel Speed 0 km/h, 0.0 MPH Veh icle is in stationary condition.

RR Wheel Speed 0 km/h, 0.0 MPH Vehic le is in stationary condition.

LR Wheel Speed 0 km/h, 0.0 MPH Veh icle is in stationary condition.

Brake Switch ON Brake pedal is depressed

OFF Brake pedal is released

Master Cyl Press 0 ± 0.8 MPa Brake pedal is released

G Sensor (lateral) 0 ± 0.1 G Vehicle is on the level

Yaw rate sensor 0 ± 4 deg/s Vehicle is on the level

Steering angle Sen 0 ± 3 ° Front wheels are in straight-ahead

position

Stability control INACTIVE Stability control system is not working

TCS control (brake) INACTIVE Brake function by TCS is not working

TCS control (engine) INACTIVE Torque control by TCS is not working

ESP ® off state (cont) ESP®

ON ESP

® OF

F switch is OFF condition

ESP® OFF ESP ® OFF switch is ON condition

Steering angle Sen Neutral Front wheels are in straight-ahead

position

Page 628 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-54 Electronic Stability Program:

Repair Instructions

ESP® Hydraulic Unit Operation CheckS7RS0B4606025

1) Check that basic brake system other than ESP ® is

in good condition.

2) Check that battery voltage is 11 V or higher.

3) Lift up vehicle.

4) Set transmission to neutral and release parking brake.

5) Turn each wheel gradually by hand to check if braked ragging occurs. If it does, correct.

6) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

7) Turn ignition switch to ON position and select menu press / depress in “HYDRAULIC CONTROL TEST”

under “miscellaneous test” (“MISC. TEST”) mode of

SUZUKI scan tool.

Refer to SUZUKI scan tool operator’s manual for

further details.

8) Perform the following checks with help of another person.

• Depressurization checkStep on brake pedal (1) and then select testing

wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check whether the wheel rotates freely due

to brake depressurization. • Pressurization check

Step off brake pedal (1) and then select testing

wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check whether the wheel locks due to brake

pressurization.

NOTE

Pressurization / Depressurization by SUZUKI

scan tool is available for 0.5 second.

9) Check for all 4-wheels condition respectively. If a faulty condition is found, replace hydraulic unit /

control module assembly.

10) After completing the check, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

Sensor CalibrationS7RS0B4606015

CAUTION!

If any DTC(s) other than C1075, C1076 or

C1078 are detected, sensor calibration can

not be completed. Repair the detected DTC

first.

NOTE

Steering angle sensor calibration is needed

when battery, “DOME” fuse or the steering

angle sensor is removed.

This sensor calibration can be done with/

without SUZUKI Scan Tool.

When ESP ® control module and/or yaw rate /

G sensor assembly is removed, sensor

calibration is needed with SUZUKI Scan Tool.

(A)

1

I4RS0B450003-01

I4RH01450021-01

Page 629 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-55

Sensor Calibration (Using SUZUKI Scan Tool)1) Set steering wheel in straight-ahead position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position and confirm that

only any of DTC(s) C1075, C1076 and/or C1077 is

detected. If any other DTC are detected, repair the

detected DTC.

4) Park and level the vehicle with parking brake, stop engine with ignition switch ON, set steering in

straight and without step ping on the brake pedal.

NOTE

Hold the above condition in Step 4) to

calibrate sensor correctly until sensor

calibration is completed.

5) Select menu “SENSOR CALIBRATION” under

“MISC. TEST” mode of SUZUKI scan tool and

calibrate sensor. Refer to scan tool operator's

manual for further derails.

6) After completing the calibra tion, turn ignition switch

to OFF position and disconnect SUZUKI scan tool

from DLC. Steering Angle Sensor Calibration (Not Using

SUZUKI Scan Tool)

1) Set steering wheel in straight-ahead position.

2) Connect battery terminals and/or fuse and start engine.

NOTE

When power is not supplied to the steering

angle sensor by removing battery or fuse,

DTC C1075 is detected and SLIP indicator

lamp (1) flashes.

If DTC other than C1075 is detected, SLIP

indicator lamp flushes and other indicator

illuminate. In that case, repair the detected

DTC first.

3) Drive vehicle straight on level ground at 15 km/h (9.5 mph) or above for few seconds without spinning

wheels. And confirm that SLIP indicator lamp is OFF.

ESP ® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection

S7RS0B4606027

CAUTION!

Never disassemble ESP ® hydraulic unit /

control module assembly, loosen blind plug

or remove motor. Pe rforming any of these

prohibited services will affect original

performance of ESP ® hydraulic unit / control

module assembly.

Check hydraulic unit for fluid leakage.

If any, repair or replace.

(A)

1

I4RS0B450003-01

1

I6RS0B460028-02

Page 636 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-62 Electronic Stability Program:

4) Turn ignition switch to ON position and select menu “DATA LIST” mode of SUZUKI scan tool. Refer to

scan tool operator's manual for further derails.

5) When brake pedal is released, check “Master Cyl Press” under “DATA LIST” of SUZUKI scan tool.

If pressure is out of specification, replace ESP ®

hydraulic unit / cont rol module assembly.

Master cylinder pressure specification

Brake pedal released: 0 ± 0.8 MPa (0 ± 8 kg/cm2, 0

± 113 psi)

6) Hoist vehicle and remove right-side front wheel.

7) Connect special tool with rubber hose (1) to Front brake caliper bleeder plug (2).

Special tool

(A): 09956–02311

8) When bleeder plug loosen and depress brake pedal to make special tool gauge reading 10 MPa (100 kg/

cm

2, 1422 psi), check “Master Cyl Press” under

“DATA LIST” of SUZUKI scan tool.

If pressure displayed on SUZUKI scan tool is out of

specification, replace ESP ® hydraulic unit / control

module assembly.

Master cylinder pressure specification

Brake pedal depressed 10 MPa (100 kg/cm2, 1422

psi): 10 ± 1.2 MPa (100 ± 12 kg/cm2, 1422 ± 170

psi)

9) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

10) Tighten bleeder plug and bleed air from brake system, referring to “Air Bleeding of Brake System in

Section 4A”.

Yaw Rate / G Sensor Assembly On-Vehicle

Inspection

S7RS0B4606017

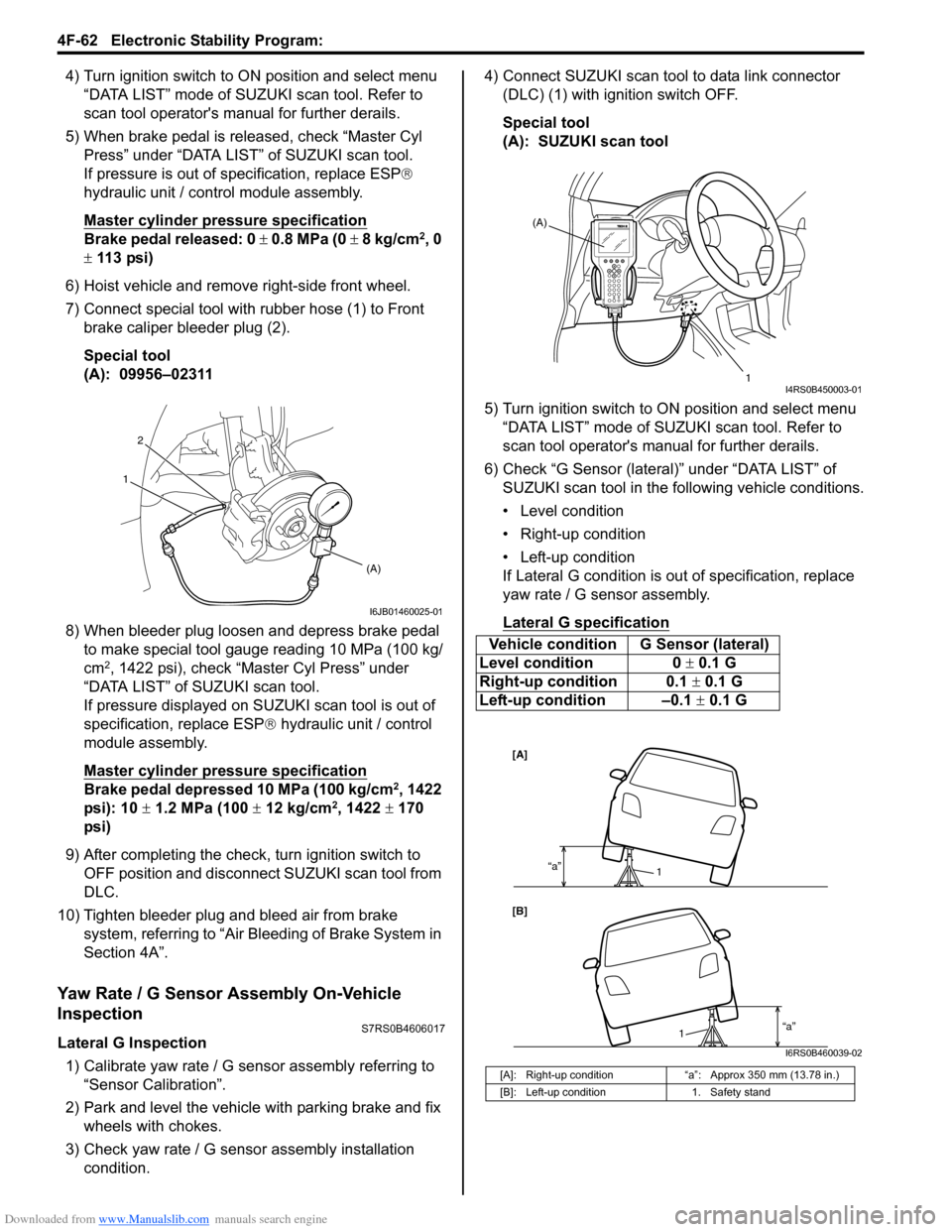

Lateral G Inspection

1) Calibrate yaw rate / G sens or assembly referring to

“Sensor Calibration”.

2) Park and level the vehicle with parking brake and fix wheels with chokes.

3) Check yaw rate / G sensor assembly installation

condition. 4) Connect SUZUKI scan tool to data link connector

(DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

5) Turn ignition switch to ON position and select menu “DATA LIST” mode of SUZUKI scan tool. Refer to

scan tool operator's manual for further derails.

6) Check “G Sensor (lateral)” under “DATA LIST” of SUZUKI scan tool in the following vehicle conditions.

• Level condition

• Right-up condition

• Left-up condition

If Lateral G condition is ou t of specification, replace

yaw rate / G sensor assembly.

Lateral G sp ecification

2

(A)

1

I6JB01460025-01

Vehicle condition G Sensor (lateral)

Level condition 0 ± 0.1 G

Right-up condition 0.1 ± 0.1 G

Left-up condition –0.1 ± 0.1 G

[A]: Right-up condition “a”: Approx 350 mm (13.78 in.)

[B]: Left-up condition 1. Safety stand

(A)

1

I4RS0B450003-01

[A]

[B]“a”

1

“a”1

I6RS0B460039-02

Page 639 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-65

2) Turn ignition switch to ON position and select menu

“DATA LIST” mode of SUZUKI scan tool.

Refer to scan tool operator's manual for further

derails.

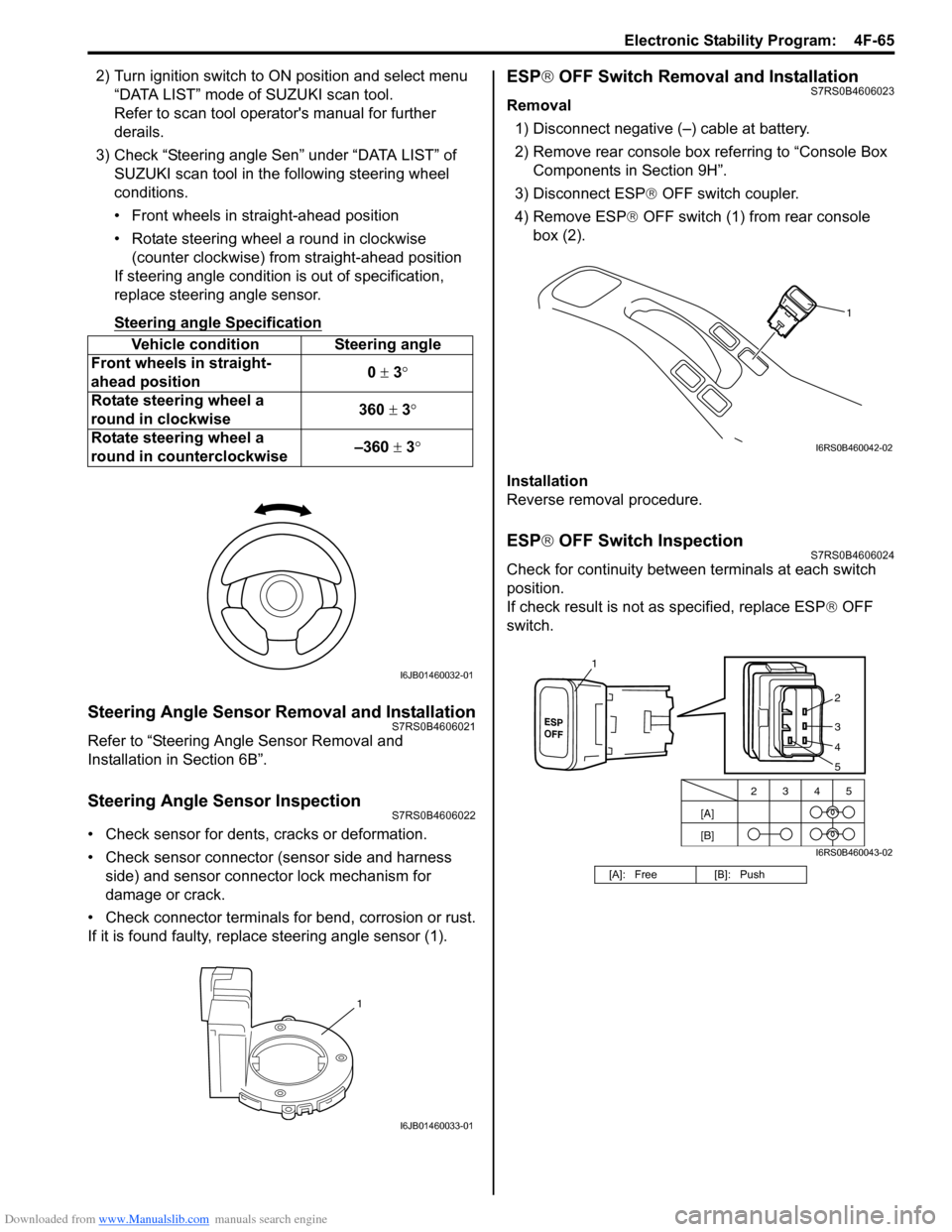

3) Check “Steering angle Sen” under “DATA LIST” of SUZUKI scan tool in th e following steering wheel

conditions.

• Front wheels in straight-ahead position

• Rotate steering wheel a round in clockwise (counter clockwise) from straight-ahead position

If steering angle condition is out of specification,

replace steering angle sensor.

Steering angle Specification

Steering Angle Sensor Removal and InstallationS7RS0B4606021

Refer to “Steering Angle Sensor Removal and

Installation in Section 6B”.

Steering Angle Sensor InspectionS7RS0B4606022

• Check sensor for dents, cracks or deformation.

• Check sensor connector (sensor side and harness

side) and sensor connector lock mechanism for

damage or crack.

• Check connector terminals for bend, corrosion or rust.

If it is found faulty, replace steering angle sensor (1).

ESP ® OFF Switch Removal and InstallationS7RS0B4606023

Removal

1) Disconnect negative (–) cable at battery.

2) Remove rear console box referring to “Console Box Components in Section 9H”.

3) Disconnect ESP ® OFF switch coupler.

4) Remove ESP ® OFF switch (1) from rear console

box (2).

Installation

Reverse removal procedure.

ESP ® OFF Switch InspectionS7RS0B4606024

Check for continuity between terminals at each switch

position.

If check result is not as specified, replace ESP ® OFF

switch.

Vehicle condition Steering angle

Front wheels in straight-

ahead position 0

± 3 °

Rotate steering wheel a

round in clockwise 360

± 3°

Rotate steering wheel a

round in counterclockwise –360

± 3 °

I6JB01460032-01

1

I6JB01460033-01

[A]: Free [B]: Push

1

I6RS0B460042-02

[A]

[B]2345

2

3

4

1

5

I6RS0B460043-02

Page 662 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

Visual InspectionS7RS0B5104002

Visually check the following parts and systems.

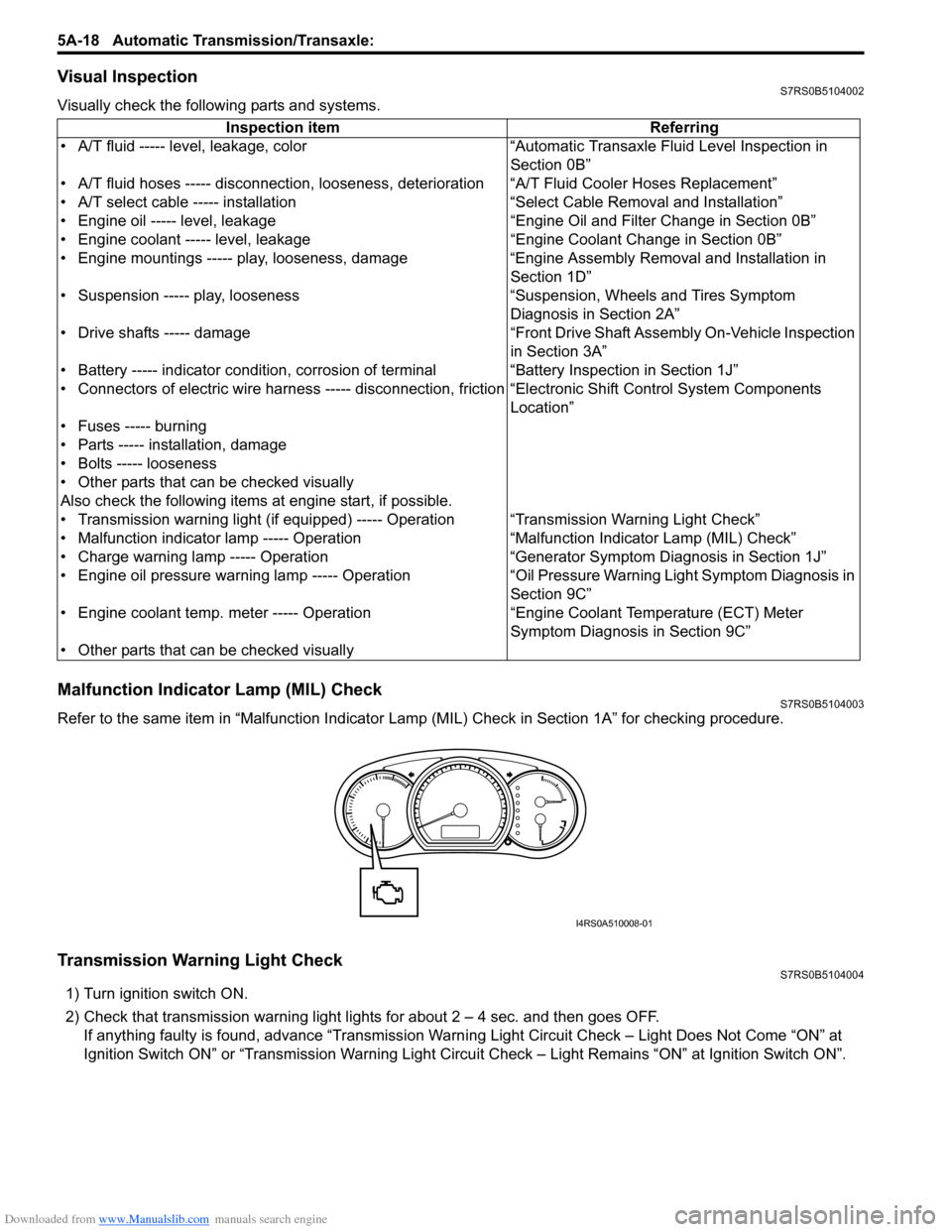

Malfunction Indicator Lamp (MIL) CheckS7RS0B5104003

Refer to the same item in “Malfunction Indicator Lam p (MIL) Check in Section 1A” for checking procedure.

Transmission Warning Light CheckS7RS0B5104004

1) Turn ignition switch ON.

2) Check that transmission warning light lights for about 2 – 4 sec. and then goes OFF.

If anything faulty is found, advance “Transmission Warn ing Light Circuit Check – Light Does Not Come “ON” at

Ignition Switch ON” or “Transmission Warning Light Circu it Check – Light Remains “ON” at Ignition Switch ON”.

Inspection item Referring

• A/T fluid ----- level, leakage, color “Automatic Transaxle Fluid Level Inspection in Section 0B”

• A/T fluid hoses ----- disconnection, looseness, deterioration “A/T Fluid Cooler Hoses Replacement”

• A/T select cable ----- installation “S elect Cable Removal and Installation”

• Engine oil ----- level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant ----- level, leakage “Engine Coolant Change in Section 0B”

• Engine mountings ----- play, looseness, damage “Engine Assembly Removal and Installation in Section 1D”

• Suspension ----- play, looseness “Suspension, Wheels and Tires Symptom Diagnosis in Section 2A”

• Drive shafts ----- damage “Front Drive Shaft Assembly On-Vehicle Inspection in Section 3A”

• Battery ----- indicator condition, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ----- disconnection, friction “Electronic Shift Control System Components

Location”

• Fuses ----- burning

• Parts ----- installation, damage

• Bolts ----- looseness

• Other parts that can be checked visually

Also check the following items at engine start, if possible.

• Transmission warning light (if equipped) ----- Operation “Transmission Warning Light Check”

• Malfunction indicator lamp ----- Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp ----- Operation “Generator Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp ----- Operation “Oil Pressure Warning Ligh t Symptom Diagnosis in

Section 9C”

• Engine coolant temp. meter ----- Operation “Engine Coolant Temperature (ECT) Meter

Symptom Diagnosis in Section 9C”

• Other parts that can be checked visually

I4RS0A510008-01