Ground SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 151 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-101

NOTE

When DTC P0122 and P0222 are indicated together, it is possible that “RED” wire open circuit.

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 TP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “TP Sensor 2 Volt” displayed on scan tool when accelerator pedal is idle

position and fully depressed.

Is displayed TP sensor value as described voltage in “Scan

To o l D a t a ” ? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

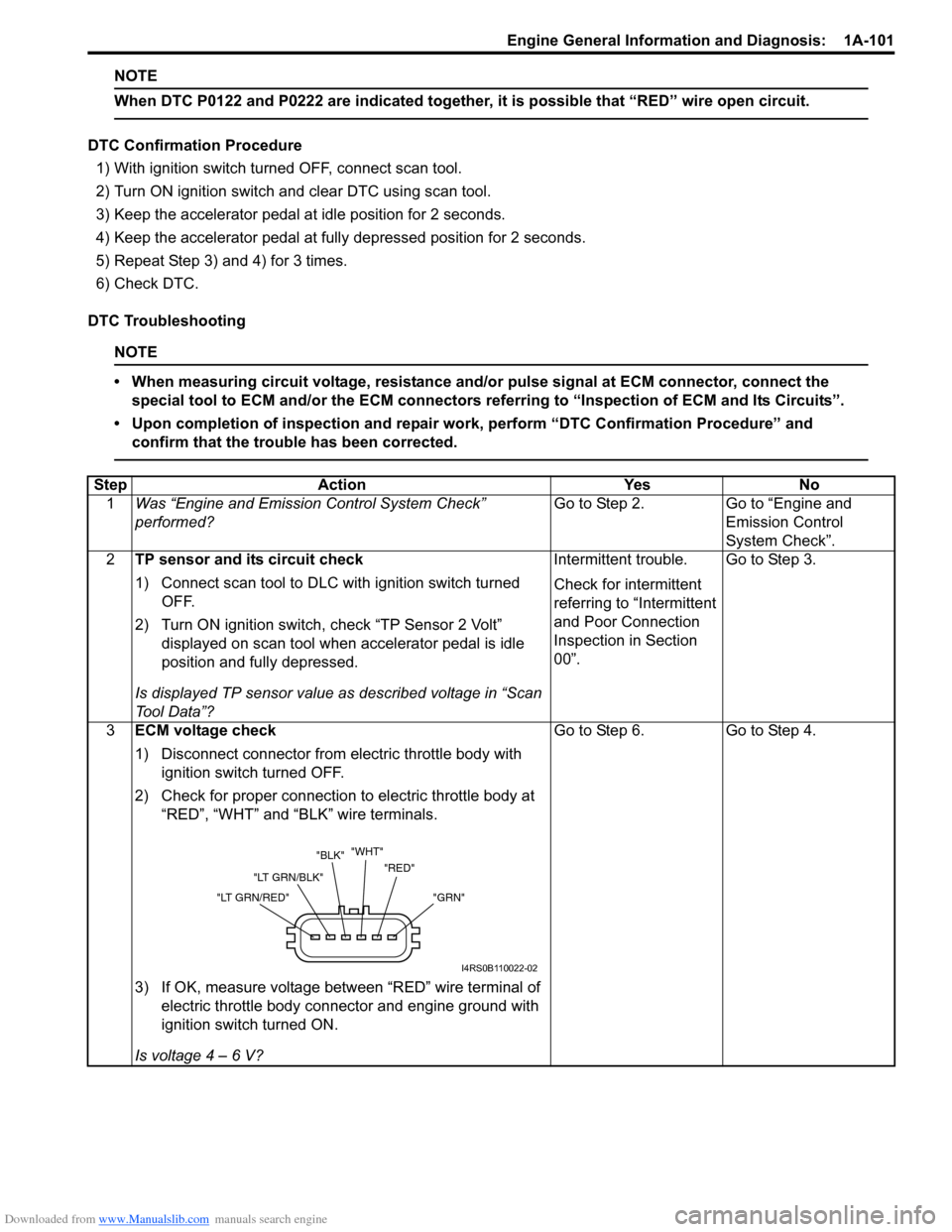

3 ECM voltage check

1) Disconnect connector from electric throttle body with

ignition switch turned OFF.

2) Check for proper connection to electric throttle body at “RED”, “WHT” and “BLK” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of electric throttle body connector and engine ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

"GRN"

"RED"

"WHT"

"BLK"

"LT GRN/BLK"

"LT GRN/RED"

I4RS0B110022-02

Page 152 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-102 Engine General Information and Diagnosis:

DTC P0223: Throttle / Pedal Position Sensor / Switch “B” (Sub) Circuit HighS7RS0B1104038

Wiring Diagram

Refer to “DTC P0222: Throttle / Pedal Position Sensor / Switch “B” (Sub) Circuit Low”.

DTC Detecting Condition and Trouble Area4

ECM voltage check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “C37- 43” terminal.

4) If OK, measure voltage between “C37-43” terminal of ECM connector and engine ground with ignition switch

turned ON.

Is voltage 4 – 6 V? “RED” wire is open or

high resistance circuit.

Go to Step 5.

5 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “C37-43” terminal of ECM connector and engine ground.

Is resistance infinity? Substitute a known-

good ECM and recheck.

“RED” wire is shorted to

ground circuit.

6 Wire harness check

1) Measure voltage between “WHT” wire terminal of

electric throttle body connector and engine ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 9.

Go to Step 7.

7 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “C37- 40” and “C37-42” terminals.

3) If OK, measure resistance between “WHT” and “BLK” wire terminals of electric throttle body connector.

Is resistance infinity? Go to Step 8.

“WHT” wire is shorted to

“BLK” wire.

8 Wire harness check

1) Measure resistance between “WHT” wire terminal of

electric throttle body connector and engine ground with

ignition switch turned OFF.

Is resistance infinity? Substitute a known-

good ECM and recheck.

“WHT” wire is shorted to

ground circuit.

9 Electric throttle body check

1) Check TP sensor referring to “Throttle Position Sensor

Performance Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

Step

Action YesNo

DTC detecting condition Trouble area

Output voltage of throttle position sensor (sub) is more than specified

value for specified time continuously.

(1 driving detection logic) • Throttle position sensor (sub) circuit

• Electric throttle body assembly

•ECM

Page 153 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-103

NOTE

When DTC P0123 and P0223 are indicated together, it is possible that “RED” wire shorted to power

circuit and/or “BLK” wire open.

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 TP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “TP Sensor 2 Volt” displayed on scan tool when accelerator pedal is idle

position and fully depressed.

Is displayed TP sensor value as described voltage in “Scan

To o l D a t a ” ? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

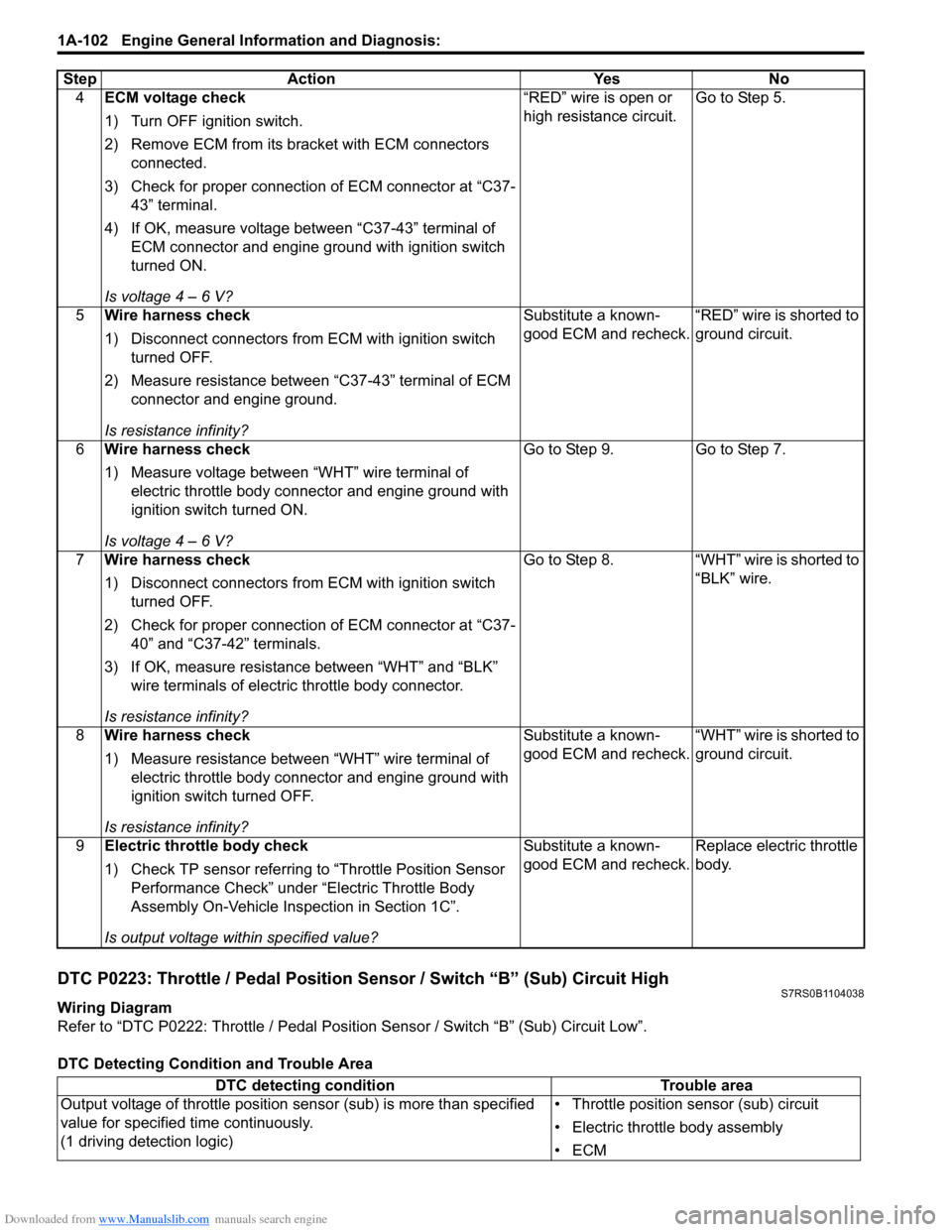

3 ECM voltage check

1) Disconnect connector from electric throttle body with

ignition switch turned OFF.

2) Check for proper connection to electric throttle body at “RED”, “WHT” and “BLK” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of electric throttle body connector and engine ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

"GRN"

"RED"

"WHT"

"BLK"

"LT GRN/BLK"

"LT GRN/RED"

I4RS0B110022-02

Page 154 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-104 Engine General Information and Diagnosis:

4Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “C37- 43” terminal.

3) Measure voltage between “C37-43” terminal of ECM connector and engine ground with ignition switch turned

ON.

Is voltage 0 V? Substitute a known-

good ECM and recheck.

“RED” wire is shorted to

power circuit.

5 Wire harness check

1) Measure voltage between “WHT” wire terminal of

electric throttle body connector and engine ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 9.

Go to Step 6.

6 Wire harness check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “C37- 43” and “C37-40” terminals.

4) If OK, measure voltage between “C37-40” terminal of ECM connector and engine ground with ignition switch

turned ON.

Is voltage 4 – 6 V? “WHT” wire is open or

high resistance circuit.

Go to Step 7.

7 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “WHT” and “RED” wire terminals of electric thrott le body assembly connector.

Is resistance infinity? Go to Step 8.

“WHT” wire is shorted to

“RED” wire.

8 Wire harness check

1) Turn ON ignition switch.

2) Measure voltage between “C37-40” terminal of ECM

connector and engine ground.

Is voltage 0 V? Substitute a known-

good ECM and recheck.

“WHT” wire is shorted to

power circuit.

9 Ground circuit check

1) Turn OFF ignition switch.

2) Measure resistance between “BLK” wire terminal of

electric throttle body connector and engine ground.

Is resistance below 5

Ω? Go to Step 11. Go to Step 10.

10 Ground circuit check

1) Remove ECM from its br acket with ECM connectors

connected.

2) Check for proper connection of ECM connector at “C37- 42” terminal.

3) Measure resistance between “C37-42” terminal of ECM connector and engine ground with ignition switch turned

OFF.

Is resistance below 5

Ω? “BLK” wire is open or

high resistance circuit.

Faulty ECM ground

circuit. If circuit is OK,

substitute a known-

good ECM and recheck.

Step Action Yes No

Page 157 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-107

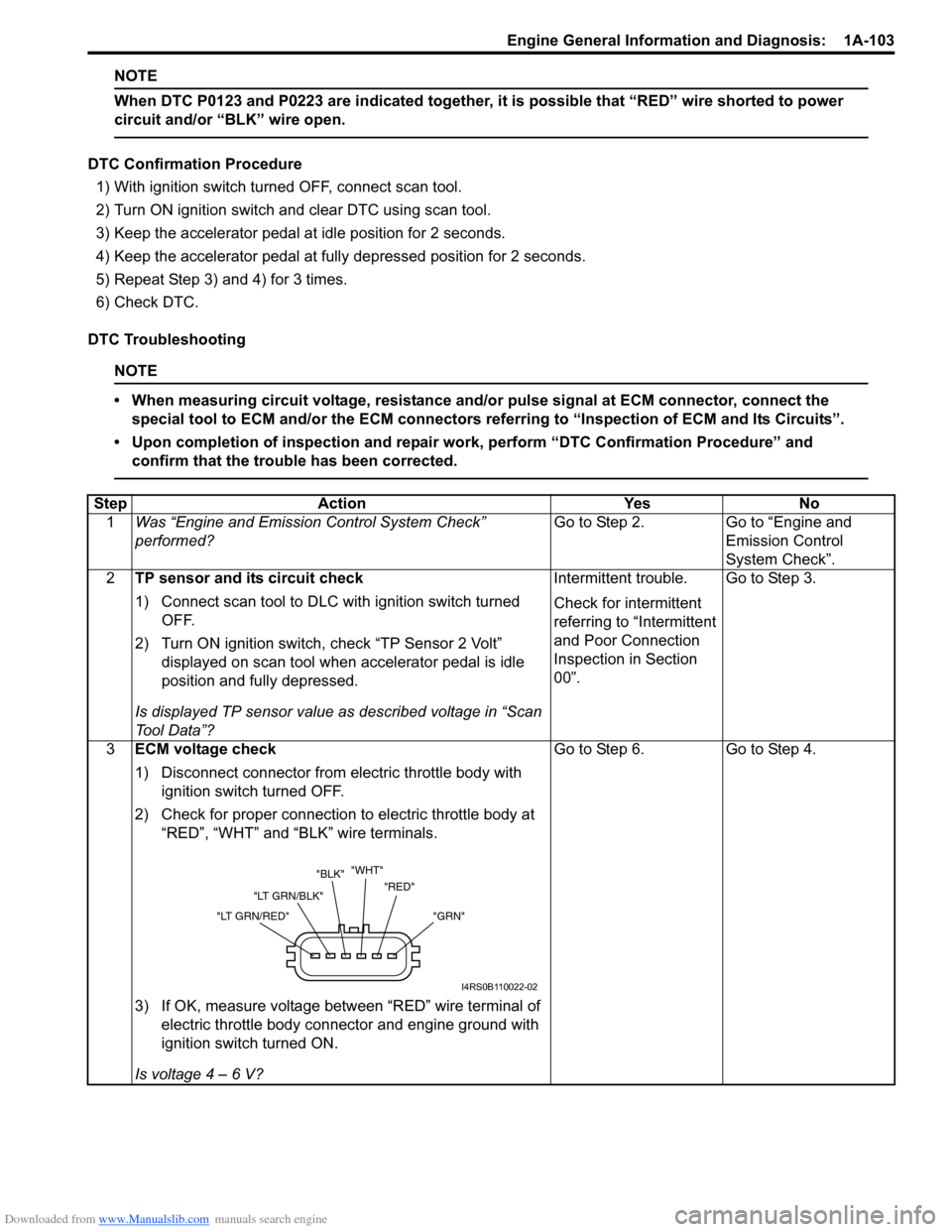

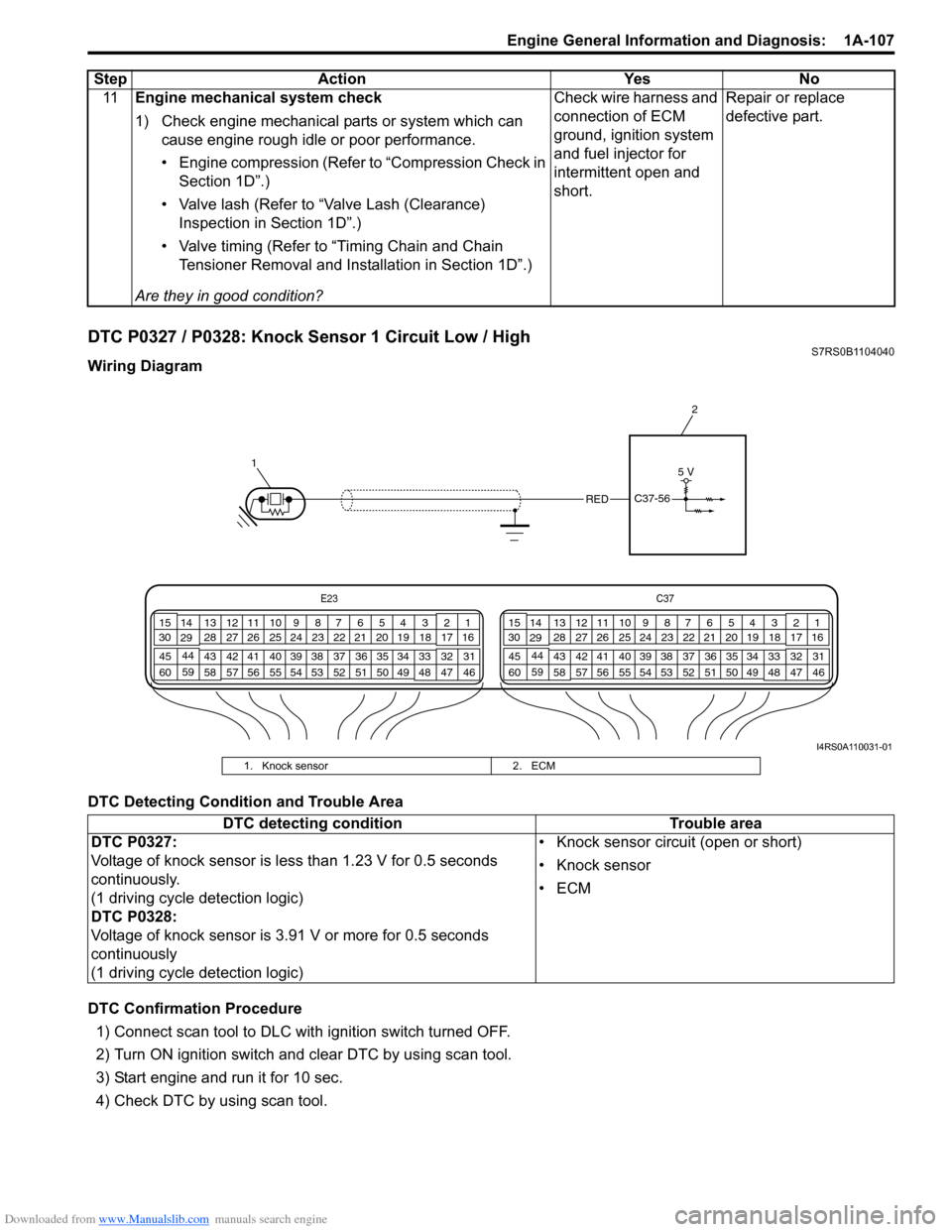

DTC P0327 / P0328: Knock Sensor 1 Circuit Low / HighS7RS0B1104040

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 10 sec.

4) Check DTC by using scan tool. 11

Engine mechanical system check

1) Check engine mechanical parts or system which can

cause engine rough idle or poor performance.

• Engine compression (Refer to “Compression Check in Section 1D”.)

• Valve lash (Refer to “Valve Lash (Clearance) Inspection in Section 1D”.)

• Valve timing (Refer to “Timing Chain and Chain Tensioner Removal and Installation in Section 1D”.)

Are they in good condition? Check wire harness and

connection of ECM

ground, ignition system

and fuel injector for

intermittent open and

short.

Repair or replace

defective part.

Step

Action YesNo

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

1 2

REDC37-56

5 V

I4RS0A110031-01

1. Knock sensor

2. ECM

DTC detecting condition Trouble area

DTC P0327:

Voltage of knock sensor is less than 1.23 V for 0.5 seconds

continuously.

(1 driving cycle detection logic)

DTC P0328:

Voltage of knock sensor is 3.91 V or more for 0.5 seconds

continuously

(1 driving cycle detection logic) • Knock sensor circuit (open or short)

• Knock sensor

•ECM

Page 158 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-108 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Knock sensor circuit check

1) Remove ECM from its br acket with ECM connectors

connected.

2) Measure voltage between “C37-56” terminal of ECM connector and vehicle body ground with engine running.

Is voltage within 1.23 – 3.91 V? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”. If OK, substitute a

known-good ECM and

recheck.Go to Step 3.

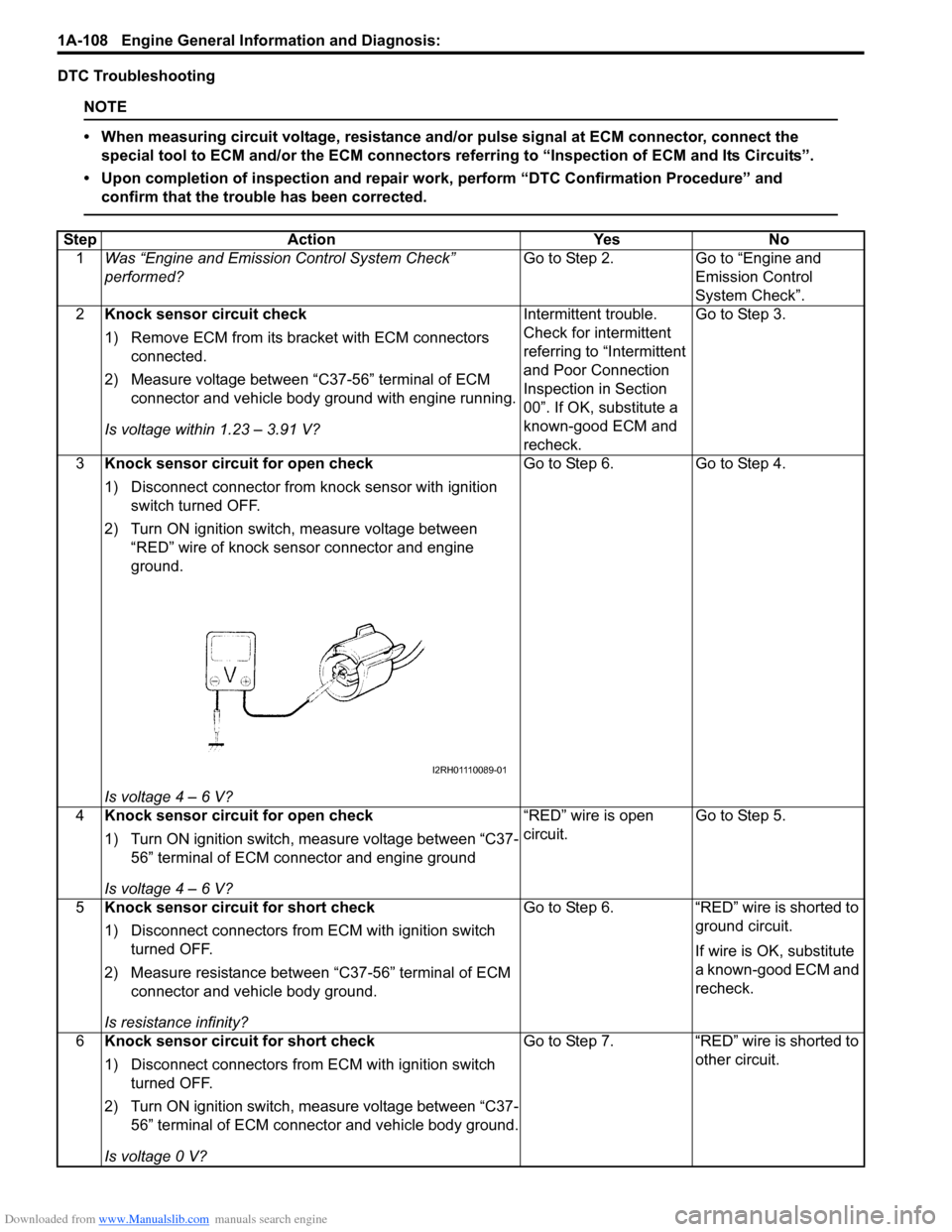

3 Knock sensor circuit for open check

1) Disconnect connector from knock sensor with ignition

switch turned OFF.

2) Turn ON ignition switch, measure voltage between “RED” wire of knock sensor connector and engine

ground.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

4 Knock sensor circuit for open check

1) Turn ON ignition switch, measure voltage between “C37-

56” terminal of ECM connector and engine ground

Is voltage 4 – 6 V? “RED” wire is open

circuit.

Go to Step 5.

5 Knock sensor circuit for short check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “C37-56” terminal of ECM connector and vehicle body ground.

Is resistance infinity? Go to Step 6.

“RED” wire is shorted to

ground circuit.

If wire is OK, substitute

a known-good ECM and

recheck.

6 Knock sensor circuit for short check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Turn ON ignition switch, measure voltage between “C37- 56” terminal of ECM connector and vehicle body ground.

Is voltage 0 V? Go to Step 7.

“RED” wire is shorted to

other circuit.

I2RH01110089-01

Page 160 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-110 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

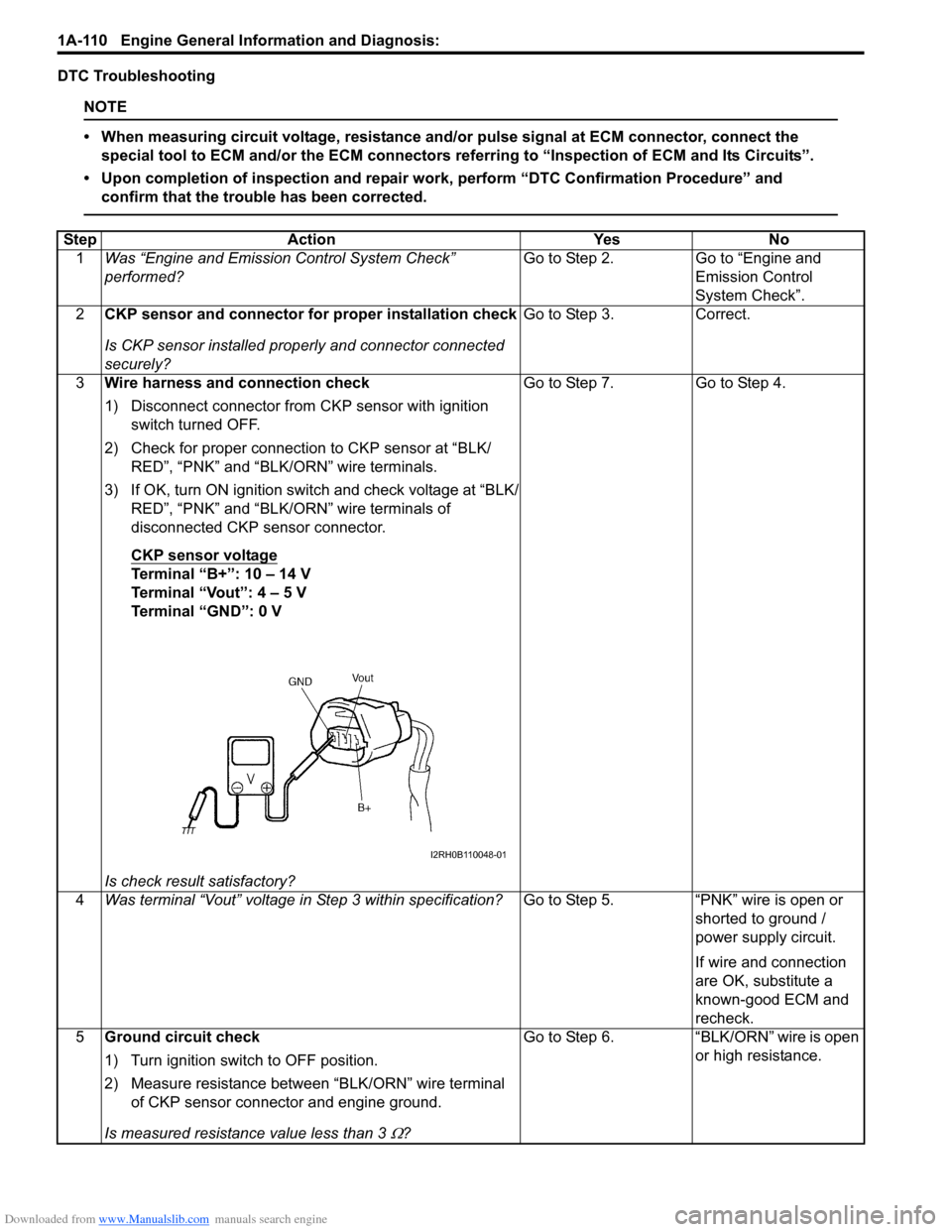

2 CKP sensor and connector for proper installation check

Is CKP sensor installed properly and connector connected

securely? Go to Step 3.

Correct.

3 Wire harness and connection check

1) Disconnect connector from CKP sensor with ignition

switch turned OFF.

2) Check for proper connection to CKP sensor at “BLK/ RED”, “PNK” and “BLK/ORN” wire terminals.

3) If OK, turn ON ignition switch and check voltage at “BLK/ RED”, “PNK” and “BLK/ORN” wire terminals of

disconnected CKP sensor connector.

CKP sensor voltage

Terminal “B+”: 10 – 14 V

Terminal “Vout”: 4 – 5 V

Terminal “GND”: 0 V

Is check result satisfactory? Go to Step 7. Go to Step 4.

4 Was terminal “Vout” voltage in Step 3 within specification? Go to Step 5. “PNK” wire is open or

shorted to ground /

power supply circuit.

If wire and connection

are OK, substitute a

known-good ECM and

recheck.

5 Ground circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK/ORN” wire terminal

of CKP sensor connector and engine ground.

Is measured resistance value less than 3

Ω? Go to Step 6. “BLK/ORN” wire is open

or high resistance.

I2RH0B110048-01

Page 163 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-113

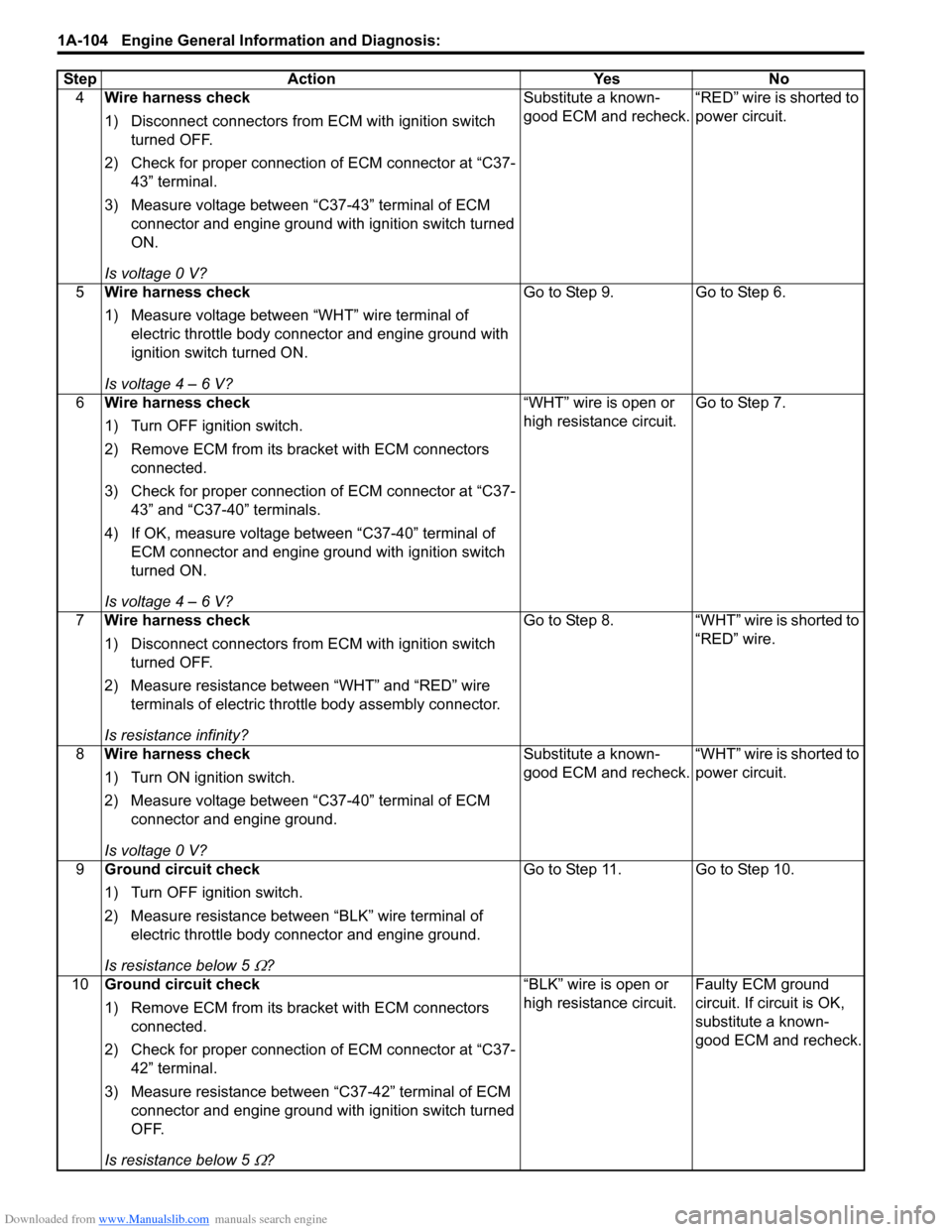

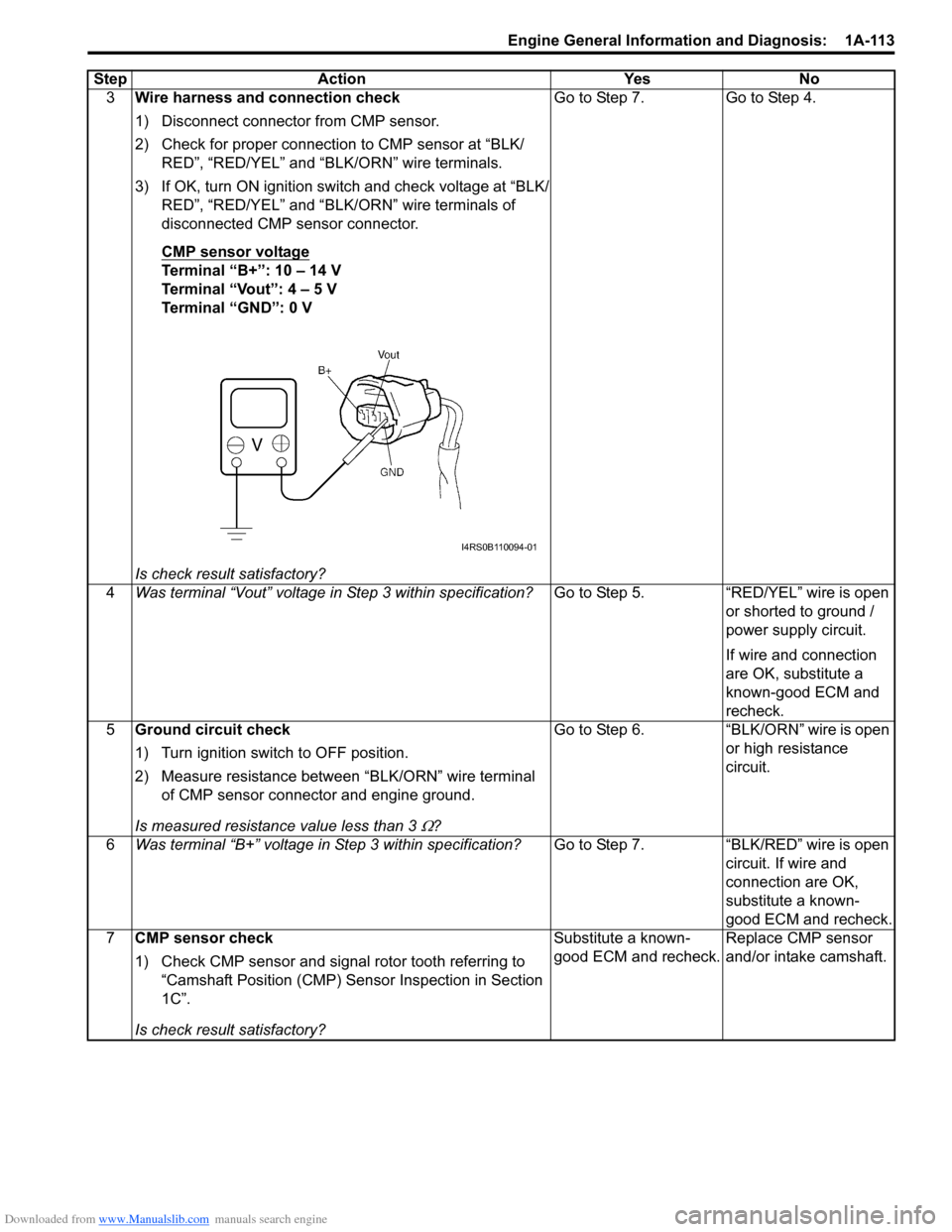

3Wire harness and connection check

1) Disconnect connector from CMP sensor.

2) Check for proper connection to CMP sensor at “BLK/

RED”, “RED/YEL” and “B LK/ORN” wire terminals.

3) If OK, turn ON ignition switch and check voltage at “BLK/ RED”, “RED/YEL” and “BLK/ORN” wire terminals of

disconnected CMP sensor connector.

CMP sensor voltage

Terminal “B+”: 10 – 14 V

Terminal “Vout”: 4 – 5 V

Terminal “GND”: 0 V

Is check result satisfactory? Go to Step 7. Go to Step 4.

4 Was terminal “Vout” voltage in Step 3 within specification? Go to Step 5. “RED/YEL” wire is open

or shorted to ground /

power supply circuit.

If wire and connection

are OK, substitute a

known-good ECM and

recheck.

5 Ground circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK/ORN” wire terminal

of CMP sensor connector and engine ground.

Is measured resistance value less than 3

Ω? Go to Step 6. “BLK/ORN” wire is open

or high resistance

circuit.

6 Was terminal “B+” voltage in Step 3 within specification? Go to Step 7. “BLK/RED” wire is open

circuit. If wire and

connection are OK,

substitute a known-

good ECM and recheck.

7 CMP sensor check

1) Check CMP sensor and signal rotor tooth referring to

“Camshaft Position (CMP) Sensor Inspection in Section

1C”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

Replace CMP sensor

and/or intake camshaft.

Step Action Yes No

I4RS0B110094-01

Page 165 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-115

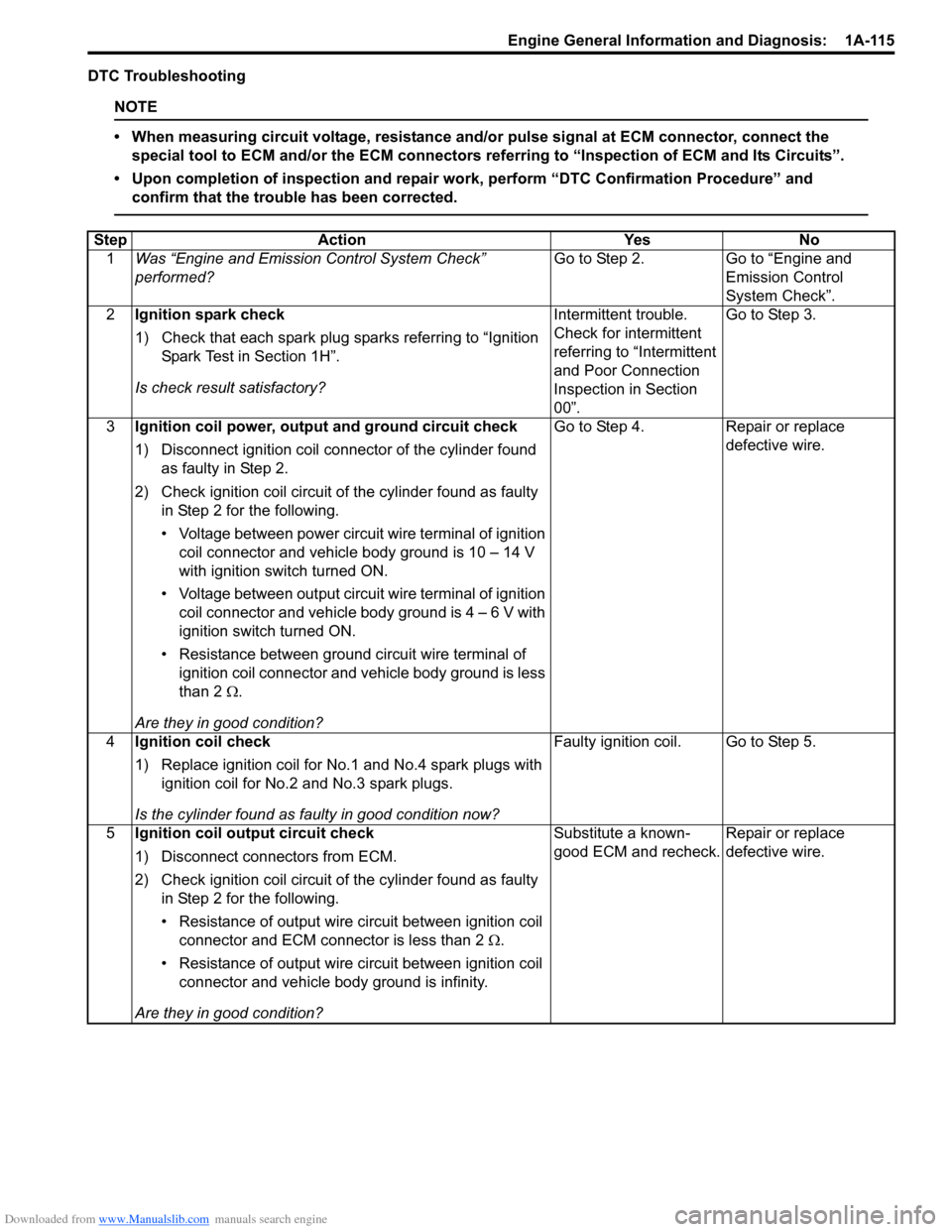

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Ignition spark check

1) Check that each spark plug sparks referring to “Ignition

Spark Test in Section 1H”.

Is check result satisfactory? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 3.

3 Ignition coil power, output and ground circuit check

1) Disconnect ignition coil connector of the cylinder found

as faulty in Step 2.

2) Check ignition coil circuit of the cylinder found as faulty in Step 2 for the following.

• Voltage between power circuit wire terminal of ignition coil connector and vehicle body ground is 10 – 14 V

with ignition switch turned ON.

• Voltage between output circuit wire terminal of ignition coil connector and vehicle body ground is 4 – 6 V with

ignition switch turned ON.

• Resistance between ground circuit wire terminal of ignition coil connector and vehicle body ground is less

than 2 Ω.

Are they in good condition? Go to Step 4.

Repair or replace

defective wire.

4 Ignition coil check

1) Replace ignition coil for No.1 and No.4 spark plugs with

ignition coil for No.2 and No.3 spark plugs.

Is the cylinder found as faulty in good condition now? Faulty ignition coil. Go to Step 5.

5 Ignition coil output circuit check

1) Disconnect connectors from ECM.

2) Check ignition coil circuit of the cylinder found as faulty

in Step 2 for the following.

• Resistance of output wire circuit between ignition coil

connector and ECM connector is less than 2 Ω.

• Resistance of output wire circuit between ignition coil connector and vehicle b ody ground is infinity.

Are they in good condition? Substitute a known-

good ECM and recheck.

Repair or replace

defective wire.

Page 169 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-119

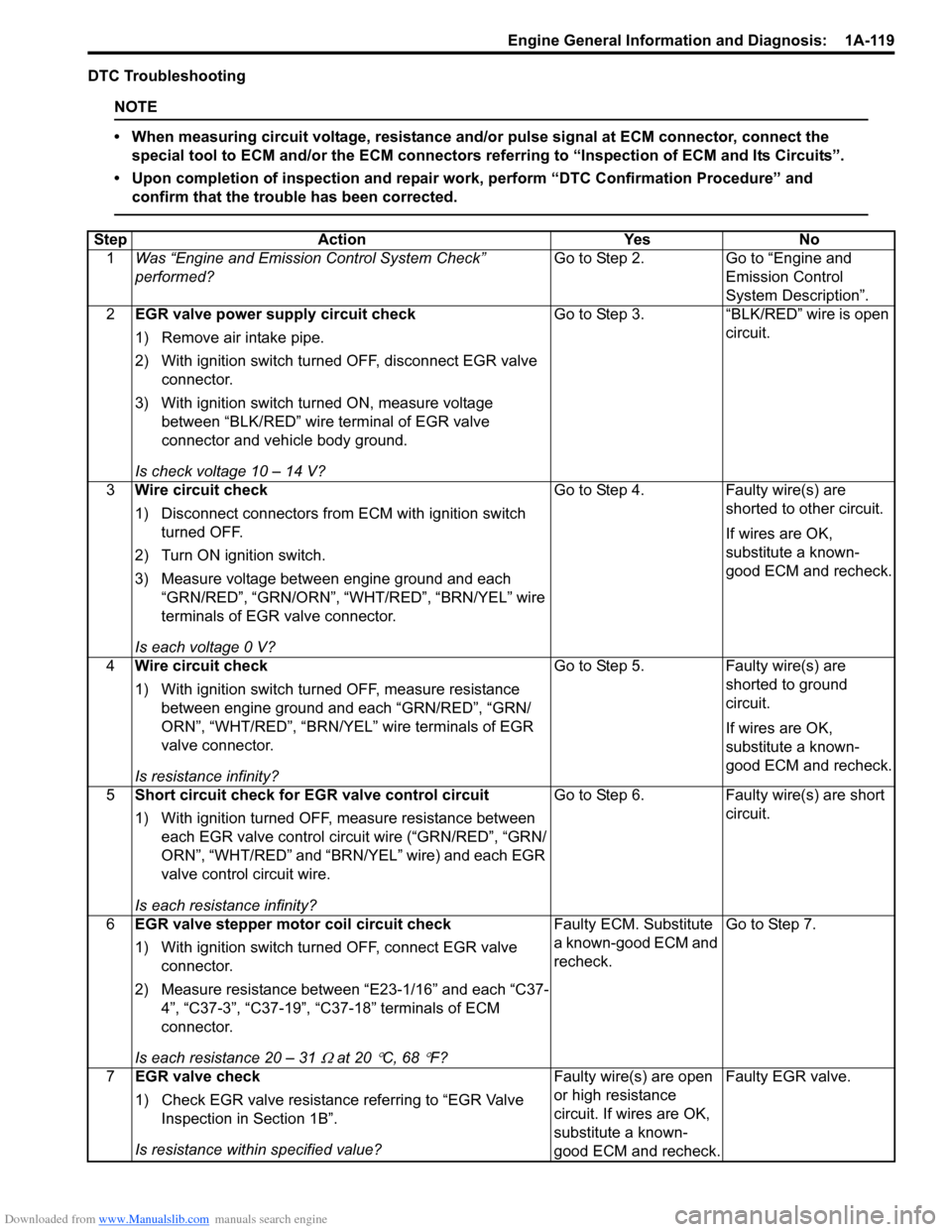

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Description”.

2 EGR valve power supply circuit check

1) Remove air intake pipe.

2) With ignition switch turned OFF, disconnect EGR valve

connector.

3) With ignition switch turned ON, measure voltage between “BLK/RED” wire terminal of EGR valve

connector and vehicle body ground.

Is check voltage 10 – 14 V? Go to Step 3.

“BLK/RED” wire is open

circuit.

3 Wire circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Turn ON ignition switch.

3) Measure voltage between engine ground and each “GRN/RED”, “GRN/ORN”, “W HT/RED”, “BRN/YEL” wire

terminals of EGR valve connector.

Is each voltage 0 V? Go to Step 4.

Faulty wire(s) are

shorted to other circuit.

If wires are OK,

substitute a known-

good ECM and recheck.

4 Wire circuit check

1) With ignition switch turned OFF, measure resistance

between engine ground and each “GRN/RED”, “GRN/

ORN”, “WHT/RED”, “BRN/YEL” wire terminals of EGR

valve connector.

Is resistance infinity? Go to Step 5.

Faulty wire(s) are

shorted to ground

circuit.

If wires are OK,

substitute a known-

good ECM and recheck.

5 Short circuit check for EGR valve control circuit

1) With ignition turned OFF, measure resistance between

each EGR valve control circ uit wire (“GRN/RED”, “GRN/

ORN”, “WHT/RED” and “BRN/ YEL” wire) and each EGR

valve control circuit wire.

Is each resistance infinity? Go to Step 6.

Faulty wire(s) are short

circuit.

6 EGR valve stepper motor coil circuit check

1) With ignition switch turned OFF, connect EGR valve

connector.

2) Measure resistance between “E23-1/16” and each “C37- 4”, “C37-3”, “C37-19”, “C37-18” terminals of ECM

connector.

Is each resistance 20 – 31

Ω at 20 °C, 68 °F? Faulty ECM. Substitute

a known-good ECM and

recheck.

Go to Step 7.

7 EGR valve check

1) Check EGR valve resistance referring to “EGR Valve

Inspection in Section 1B”.

Is resistance within specified value? Faulty wire(s) are open

or high resistance

circuit. If wires are OK,

substitute a known-

good ECM and recheck.Faulty EGR valve.