Turning on engine SUZUKI SWIFT 2017 5.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2017, Model line: SWIFT, Model: SUZUKI SWIFT 2017 5.GPages: 336, PDF Size: 6.24 MB

Page 208 of 336

7-17INSPECTION AND MAINTENANCE

74LH0-74E

Pedal to floor carpet minimum dis-

tance “a”: 68 mm (2.7 in.)

With the engine running, measure the dis-

tance between the brake pedal and floor

carpet when the pedal is depressed with

approximately 30 kg (66 lbs) of force. The

minimum distance required is as specified.

Since your vehicle’s brake system is self-

adjusting, there is no need for pedal

adjustment.

If the pedal to floor carpet distance as

measured above is less than the minimum

distance required, have your vehicle

inspected by your MARUTI SUZUKI

dealer.

NOTE:

When measuring the distance between the

brake pedal and floor carpet, be sure not to

include the floor mat or rubber on the floor

carpet in your measurement.

60G104S

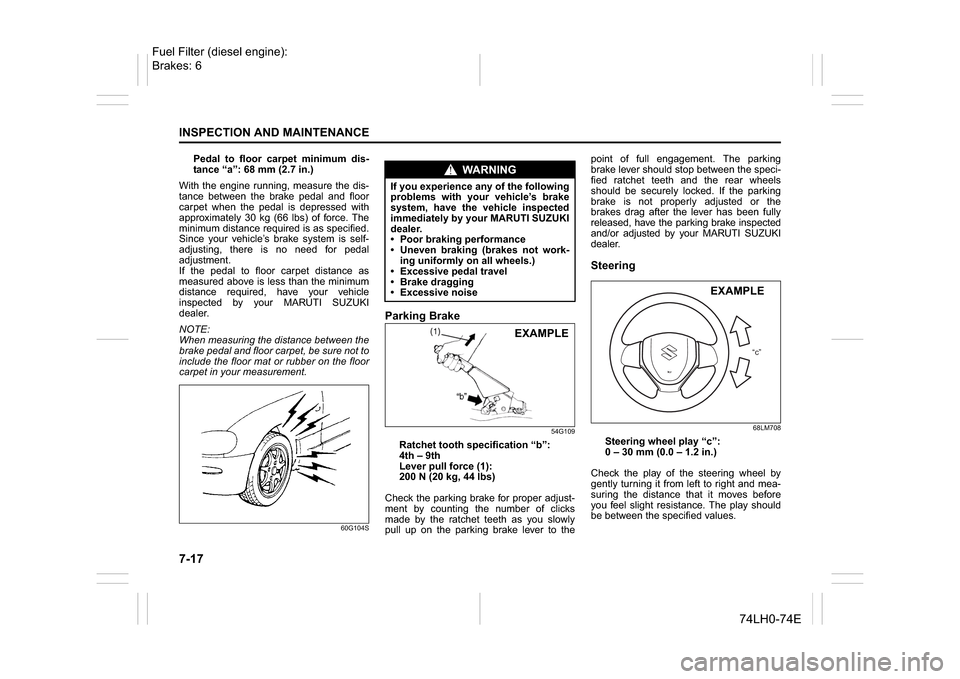

Parking Brake

54G109

Ratchet tooth specification “b”:

4th – 9th

Lever pull force (1):

200 N (20 kg, 44 lbs)

Check the parking brake for proper adjust-

ment by counting the number of clicks

made by the ratchet teeth as you slowly

pull up on the parking brake lever to thepoint of full engagement. The parking

brake lever should stop between the speci-

fied ratchet teeth and the rear wheels

should be securely locked. If the parking

brake is not properly adjusted or the

brakes drag after the lever has been fully

released, have the parking brake inspected

and/or adjusted by your MARUTI SUZUKI

dealer.

Steering

68LM708

Steering wheel play “c”:

0 – 30 mm (0.0 – 1.2 in.)

Check the play of the steering wheel by

gently turning it from left to right and mea-

suring the distance that it moves before

you feel slight resistance. The play should

be between the specified values.

WA R N I N G

If you experience any of the following

problems with your vehicle’s brake

system, have the vehicle inspected

immediately by your MARUTI SUZUKI

dealer.

Poor braking performance

Uneven braking (brakes not work-

ing uniformly on all wheels.)

Excessive pedal travel

Brake dragging

Excessive noise

EXAMPLE

“c”

EXAMPLE

Fuel Filter (diesel engine):

Brakes: 6

Page 229 of 336

8-6

EMERGENCY SERVICE

74LH0-74E

71LST0802

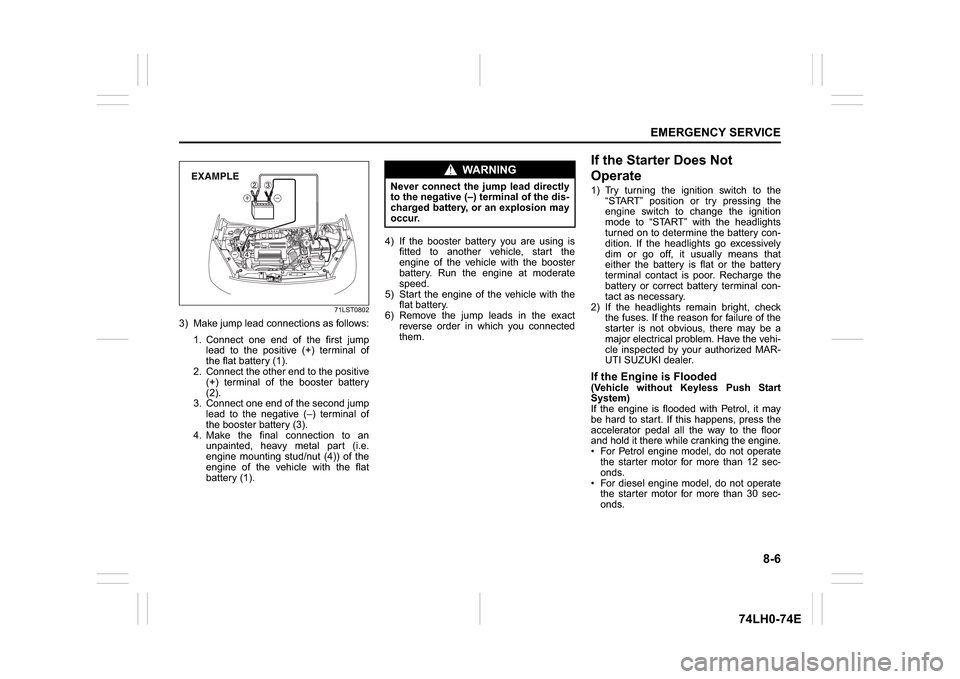

3) Make jump lead connections as follows:

1. Connect one end of the first jump

lead to the positive (+) terminal of

the flat battery (1).

2. Connect the other end to the positive

(+) terminal of the booster battery

(2).

3. Connect one end of the second jump

lead to the negative (–) terminal of

the booster battery (3).

4. Make the final connection to an

unpainted, heavy metal part (i.e.

engine mounting stud/nut (4)) of the

engine of the vehicle with the flat

battery (1).4) If the booster battery you are using is

fitted to another vehicle, start the

engine of the vehicle with the booster

battery. Run the engine at moderate

speed.

5) Start the engine of the vehicle with the

flat battery.

6) Remove the jump leads in the exact

reverse order in which you connected

them.

If the Starter Does Not

Operate1) Try turning the ignition switch to the

“START” position or try pressing the

engine switch to change the ignition

mode to “START” with the headlights

turned on to determine the battery con-

dition. If the headlights go excessively

dim or go off, it usually means that

either the battery is flat or the battery

terminal contact is poor. Recharge the

battery or correct battery terminal con-

tact as necessary.

2) If the headlights remain bright, check

the fuses. If the reason for failure of the

starter is not obvious, there may be a

major electrical problem. Have the vehi-

cle inspected by your authorized MAR-

UTI SUZUKI dealer.If the Engine is Flooded(Vehicle without Keyless Push Start

System)

If the engine is flooded with Petrol, it may

be hard to start. If this happens, press the

accelerator pedal all the way to the floor

and hold it there while cranking the engine.

For Petrol engine model, do not operate

the starter motor for more than 12 sec-

onds.

For diesel engine model, do not operate

the starter motor for more than 30 sec-

onds.

EXAMPLE

WA R N I N G

Never connect the jump lead directly

to the negative (–) terminal of the dis-

charged battery, or an explosion may

occur.