SUZUKI SX4 2006 1.G Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1391 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-6

Windshield Removal and InstallationS6RW0D9506002

Preparation

The windshield is installed by using a special type of

adhesive (that is, one component urethane adhesive

used with primer). For the windshield replacement, it is

important to use an adhesive which provides sufficient

adhesion strength and follow the proper procedure.

CAUTION!

• Described is the glass replacement by

using 3 types of primers and 1 type of

adhesive made by YOKOHAMA (one

component urethane adhesive to be used

with primer in combination). When using

primer and adhesive made by other

manufacturers, be sure to refer to handling

instructions supplied with them.

Negligence in following such procedure or

misuse of the adhesive in any way hinders

its inherent adhesive property. Therefore,

before the work, make sure to read

carefully the instruction and description

given by the maker of the adhesive to be

used and be sure to follow the procedure

and observe each precaution throughout

the work.

• Should coated surface be scratched or

otherwise damaged, be sure to repair

damaged part, or corrosion may start from

there.

Use the specific adhesive which has the following

property.

Glass adhesive shearing strength

40 kg/cm2 (569 lb/in2) or moreAdhesive materials and tools required for removal and

installation.

• One component urethane adhesive and primers used

in combination (For one sheet of windshield).

– Adhesive (470 g (15.7 oz.))

– Primer for glass (30 g (1.0 oz.))

– Primer for body (30 g (1.0 oz.))

– Primer for molding (30 g (1.0 oz.))

• Eyeleteer

•Piano string

• Windshield knife

• Brush for primer application (2 pcs)

•Knife

• Rubber sucker grip

• Sealant gun (for filling adhesive)

• Putty spatula (for correcting adhered parts)

Removal

1) Clean both inside and outside of glass and around it.

2) Remove wiper arms and cowl top garnish.

3) Using tape, cover body surface around glass to

prevent any damage.

4) Remove rear view mirror, sun visor and front pillar

trims (right & left).

5) If necessary, remove instrument panel. Refer to

“Instrument Panel Removal and Installation in

Section 9C”.

6) If necessary, remove head lining. Refer to “Head

Lining Removal and Installation in Section 9H”.

7) Remove (or cut) windshield molding.

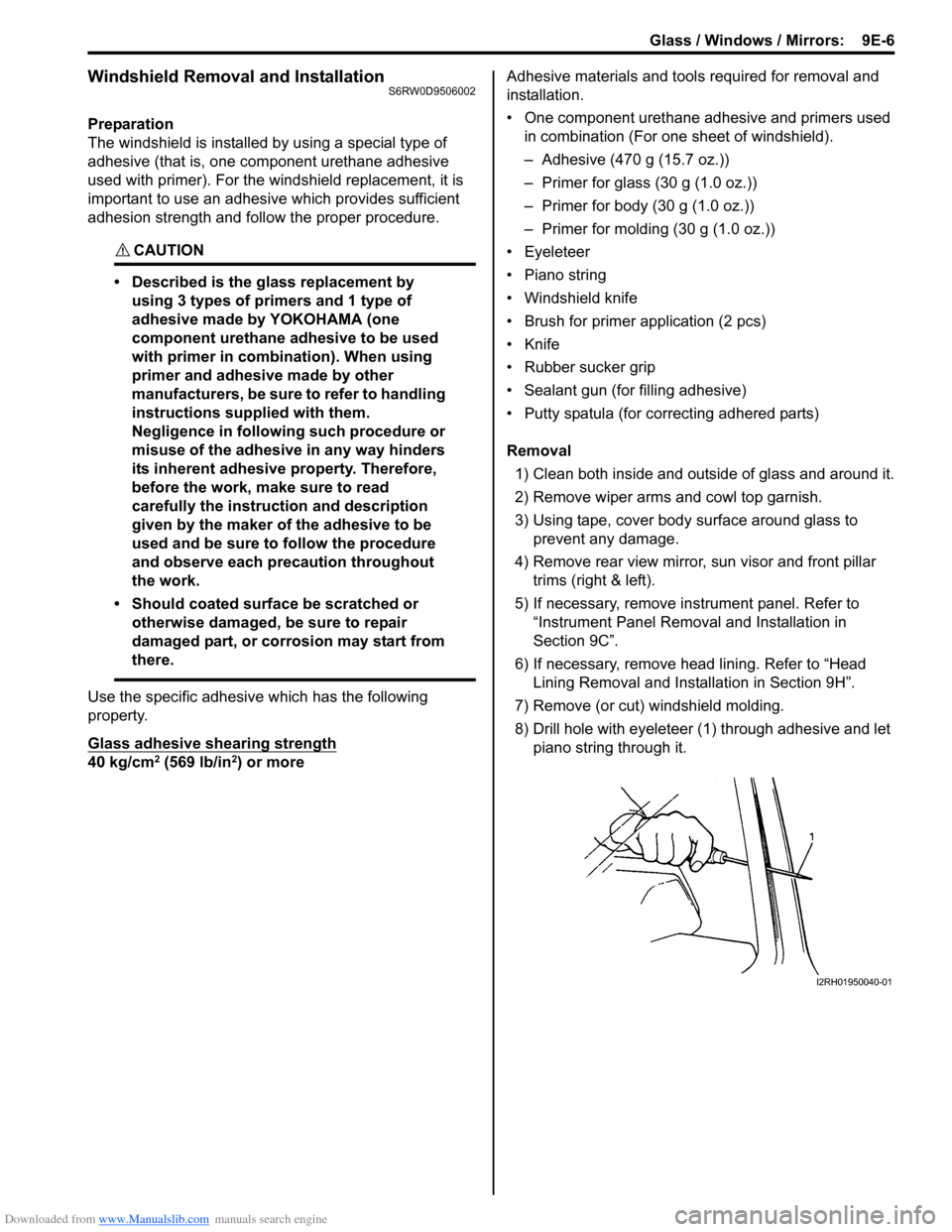

8) Drill hole with eyeleteer (1) through adhesive and let

piano string through it.

I2RH01950040-01

Page 1392 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-7 Glass / Windows / Mirrors:

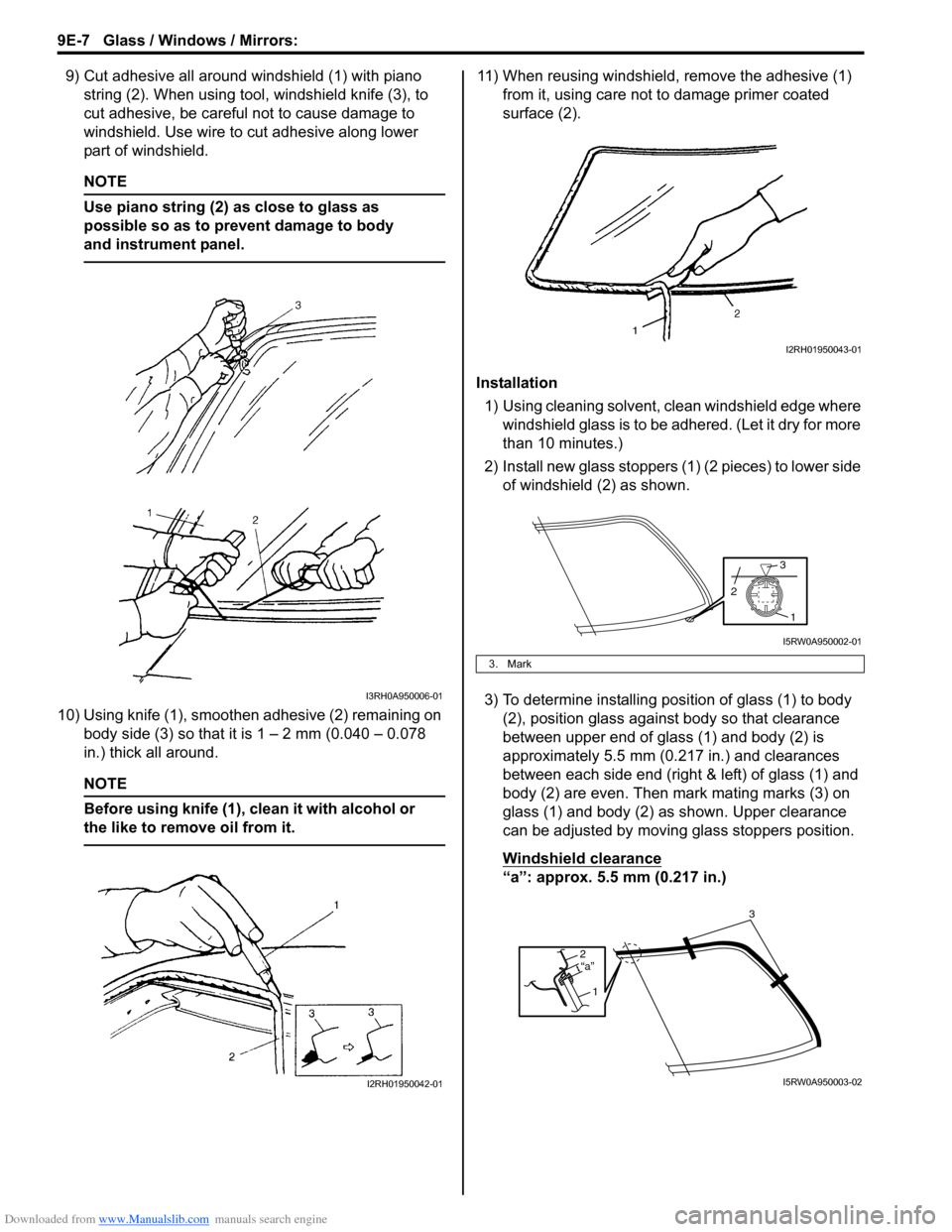

9) Cut adhesive all around windshield (1) with piano

string (2). When using tool, windshield knife (3), to

cut adhesive, be careful not to cause damage to

windshield. Use wire to cut adhesive along lower

part of windshield.

NOTE

Use piano string (2) as close to glass as

possible so as to prevent damage to body

and instrument panel.

10) Using knife (1), smoothen adhesive (2) remaining on

body side (3) so that it is 1 – 2 mm (0.040 – 0.078

in.) thick all around.

NOTE

Before using knife (1), clean it with alcohol or

the like to remove oil from it.

11) When reusing windshield, remove the adhesive (1)

from it, using care not to damage primer coated

surface (2).

Installation

1) Using cleaning solvent, clean windshield edge where

windshield glass is to be adhered. (Let it dry for more

than 10 minutes.)

2) Install new glass stoppers (1) (2 pieces) to lower side

of windshield (2) as shown.

3) To determine installing position of glass (1) to body

(2), position glass against body so that clearance

between upper end of glass (1) and body (2) is

approximately 5.5 mm (0.217 in.) and clearances

between each side end (right & left) of glass (1) and

body (2) are even. Then mark mating marks (3) on

glass (1) and body (2) as shown. Upper clearance

can be adjusted by moving glass stoppers position.

Windshield clearance

“a”: approx. 5.5 mm (0.217 in.)

I3RH0A950006-01

I2RH01950042-01

3. Mark

I2RH01950043-01

1

3

2

I5RW0A950002-01

2

1“a”

3

I5RW0A950003-02

Page 1393 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-8

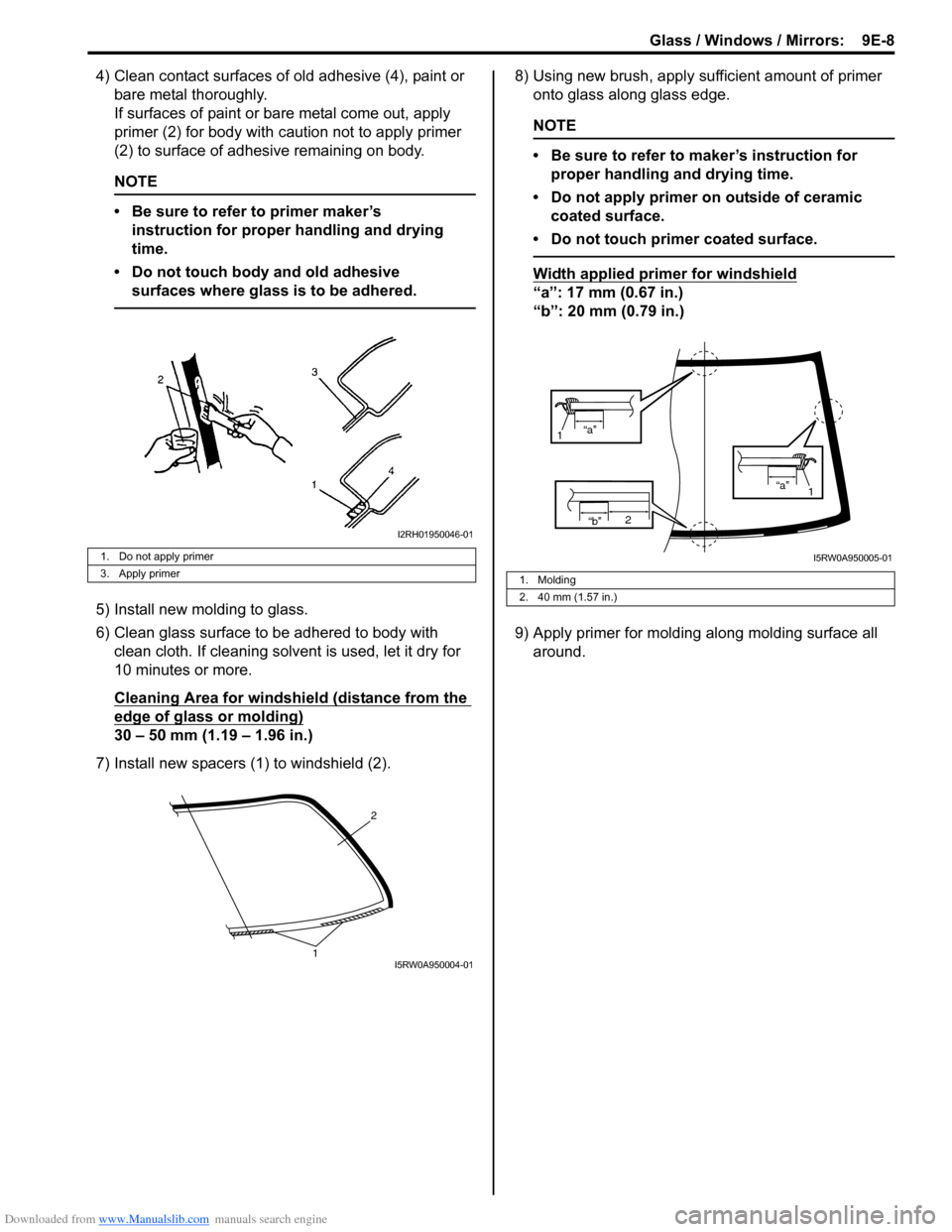

4) Clean contact surfaces of old adhesive (4), paint or

bare metal thoroughly.

If surfaces of paint or bare metal come out, apply

primer (2) for body with caution not to apply primer

(2) to surface of adhesive remaining on body.

NOTE

• Be sure to refer to primer maker’s

instruction for proper handling and drying

time.

• Do not touch body and old adhesive

surfaces where glass is to be adhered.

5) Install new molding to glass.

6) Clean glass surface to be adhered to body with

clean cloth. If cleaning solvent is used, let it dry for

10 minutes or more.

Cleaning Area for windshield (distance from the

edge of glass or molding)

30 – 50 mm (1.19 – 1.96 in.)

7) Install new spacers (1) to windshield (2).8) Using new brush, apply sufficient amount of primer

onto glass along glass edge.

NOTE

• Be sure to refer to maker’s instruction for

proper handling and drying time.

• Do not apply primer on outside of ceramic

coated surface.

• Do not touch primer coated surface.

Width applied primer for windshield

“a”: 17 mm (0.67 in.)

“b”: 20 mm (0.79 in.)

9) Apply primer for molding along molding surface all

around.

1. Do not apply primer

3. Apply primer

I2RH01950046-01

2

1I5RW0A950004-01

1. Molding

2. 40 mm (1.57 in.)

“b”2

“a”

1

“a”

1

I5RW0A950005-01

Page 1394 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-9 Glass / Windows / Mirrors:

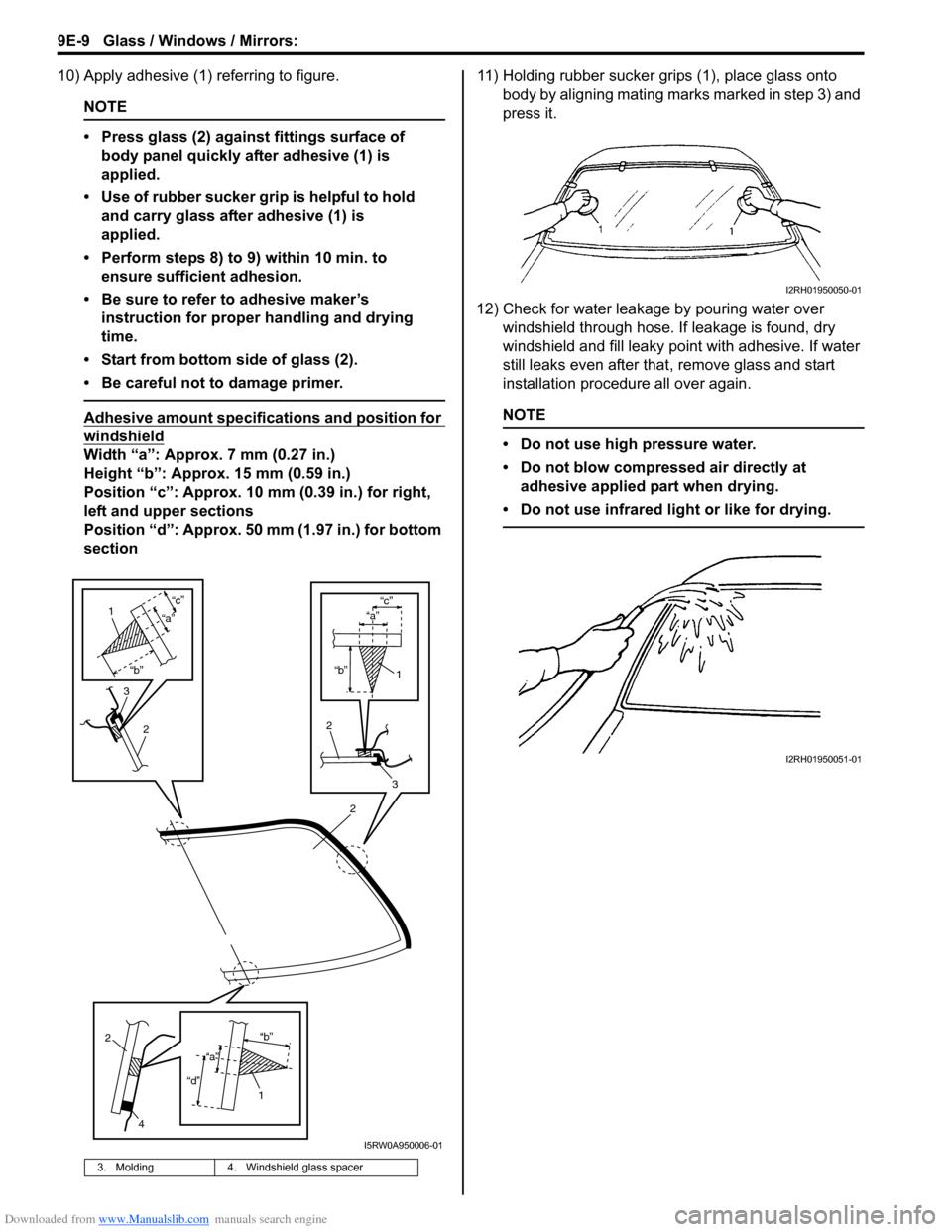

10) Apply adhesive (1) referring to figure.

NOTE

• Press glass (2) against fittings surface of

body panel quickly after adhesive (1) is

applied.

• Use of rubber sucker grip is helpful to hold

and carry glass after adhesive (1) is

applied.

• Perform steps 8) to 9) within 10 min. to

ensure sufficient adhesion.

• Be sure to refer to adhesive maker’s

instruction for proper handling and drying

time.

• Start from bottom side of glass (2).

• Be careful not to damage primer.

Adhesive amount specifications and position for

windshield

Width “a”: Approx. 7 mm (0.27 in.)

Height “b”: Approx. 15 mm (0.59 in.)

Position “c”: Approx. 10 mm (0.39 in.) for right,

left and upper sections

Position “d”: Approx. 50 mm (1.97 in.) for bottom

section11) Holding rubber sucker grips (1), place glass onto

body by aligning mating marks marked in step 3) and

press it.

12) Check for water leakage by pouring water over

windshield through hose. If leakage is found, dry

windshield and fill leaky point with adhesive. If water

still leaks even after that, remove glass and start

installation procedure all over again.

NOTE

• Do not use high pressure water.

• Do not blow compressed air directly at

adhesive applied part when drying.

• Do not use infrared light or like for drying.

3. Molding 4. Windshield glass spacer

2

“b”

“c”

2

3

1

“a”

3

2

1

“b”

“c”

“a”

2

4

1“b”

“d”

“a”

I5RW0A950006-01

I2RH01950050-01

I2RH01950051-01

Page 1395 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-10

CAUTION!

Upon completion of installation, note the

following.

• Sudden closing of door before adhesive is

completely set may cause glass to become

loose or to come off. Therefore, if door is

opened or closed before adhesive is

completely set, make sure to open all door

glasses and use proper care.

• If molding is not securely in place, hold it

down with a tape until adhesive is

completely set.

• Each adhesive has its own setting time.

• Be sure to refer to its maker’s instruction,

check setting time of adhesive to be used

and observe precautions to be taken

before adhesive is set.

• Refrain from driving till adhesive is

completely set so as to ensure proper and

sufficient adhesion.

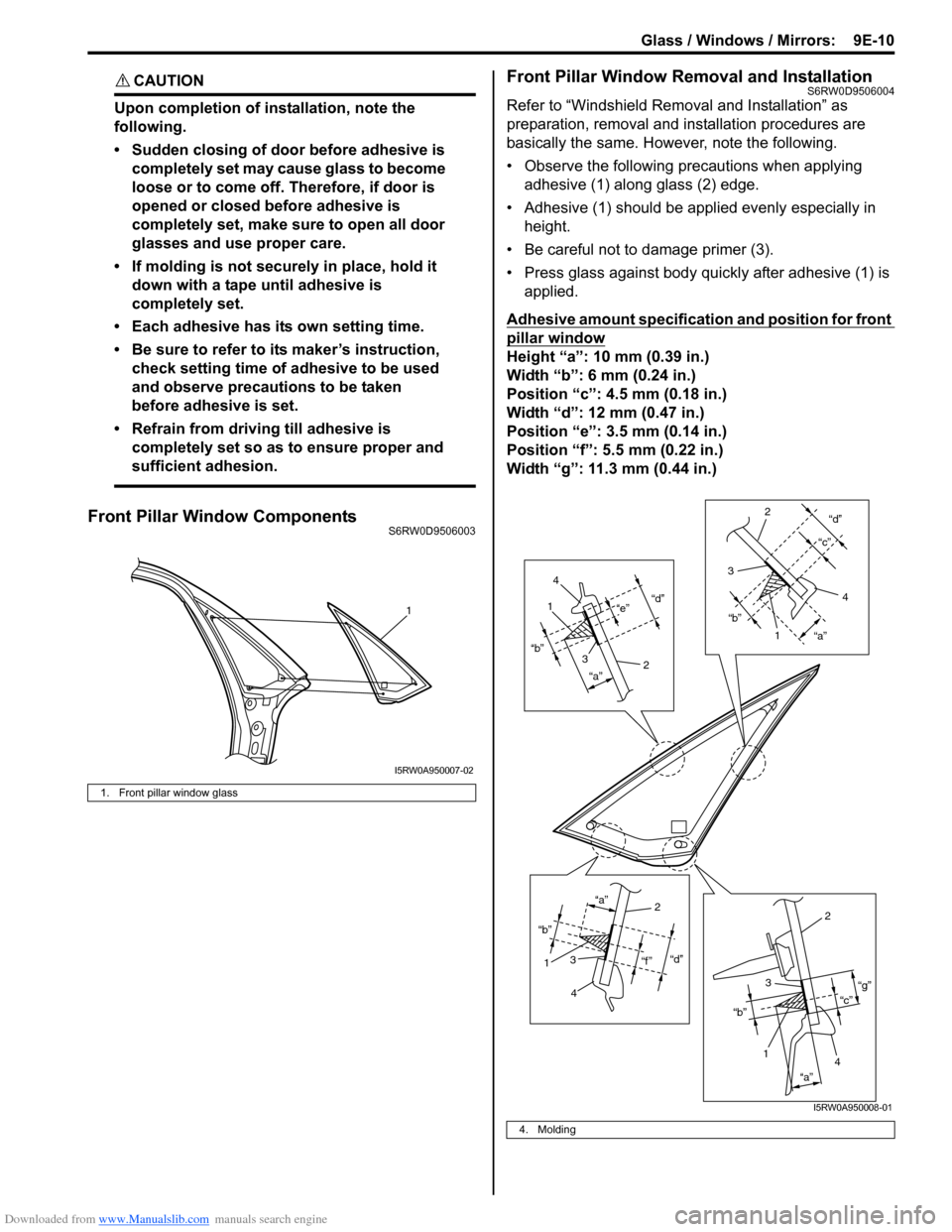

Front Pillar Window ComponentsS6RW0D9506003

Front Pillar Window Removal and InstallationS6RW0D9506004

Refer to “Windshield Removal and Installation” as

preparation, removal and installation procedures are

basically the same. However, note the following.

• Observe the following precautions when applying

adhesive (1) along glass (2) edge.

• Adhesive (1) should be applied evenly especially in

height.

• Be careful not to damage primer (3).

• Press glass against body quickly after adhesive (1) is

applied.

Adhesive amount specification and position for front

pillar window

Height “a”: 10 mm (0.39 in.)

Width “b”: 6 mm (0.24 in.)

Position “c”: 4.5 mm (0.18 in.)

Width “d”: 12 mm (0.47 in.)

Position “e”: 3.5 mm (0.14 in.)

Position “f”: 5.5 mm (0.22 in.)

Width “g”: 11.3 mm (0.44 in.)

1. Front pillar window glass

1

I5RW0A950007-02

4. Molding

“d”

“a” “b”“e”1

2 3

4

“d”

“a” “b”“c”

1 2

3

4

“d”

“f ” “a”

“b”12

3

4

“c”“g”

“a” “b”

12

3

4

I5RW0A950008-01

Page 1396 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-11 Glass / Windows / Mirrors:

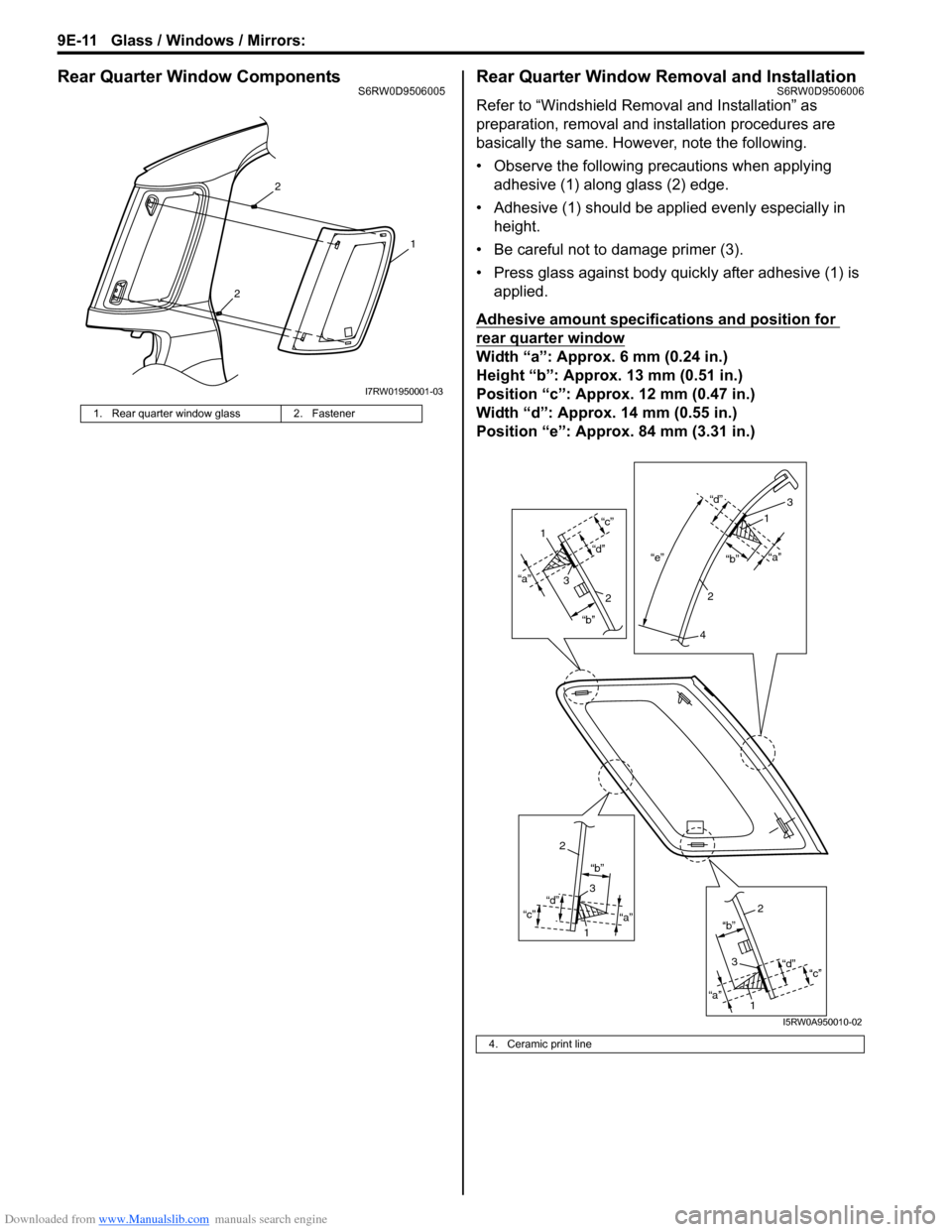

Rear Quarter Window ComponentsS6RW0D9506005Rear Quarter Window Removal and InstallationS6RW0D9506006

Refer to “Windshield Removal and Installation” as

preparation, removal and installation procedures are

basically the same. However, note the following.

• Observe the following precautions when applying

adhesive (1) along glass (2) edge.

• Adhesive (1) should be applied evenly especially in

height.

• Be careful not to damage primer (3).

• Press glass against body quickly after adhesive (1) is

applied.

Adhesive amount specifications and position for

rear quarter window

Width “a”: Approx. 6 mm (0.24 in.)

Height “b”: Approx. 13 mm (0.51 in.)

Position “c”: Approx. 12 mm (0.47 in.)

Width “d”: Approx. 14 mm (0.55 in.)

Position “e”: Approx. 84 mm (3.31 in.)

1. Rear quarter window glass 2. Fastener

2

2

1

I7RW01950001-03

4. Ceramic print line

“a”

“b”

“d”“c”“e”“a”

“b” “d”

“a” “b”

“d”

“c”

“a”“b”

“d”

“c”

1

3

2

3

1

2

4

2

3

1

2

3

1

I5RW0A950010-02

Page 1397 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-12

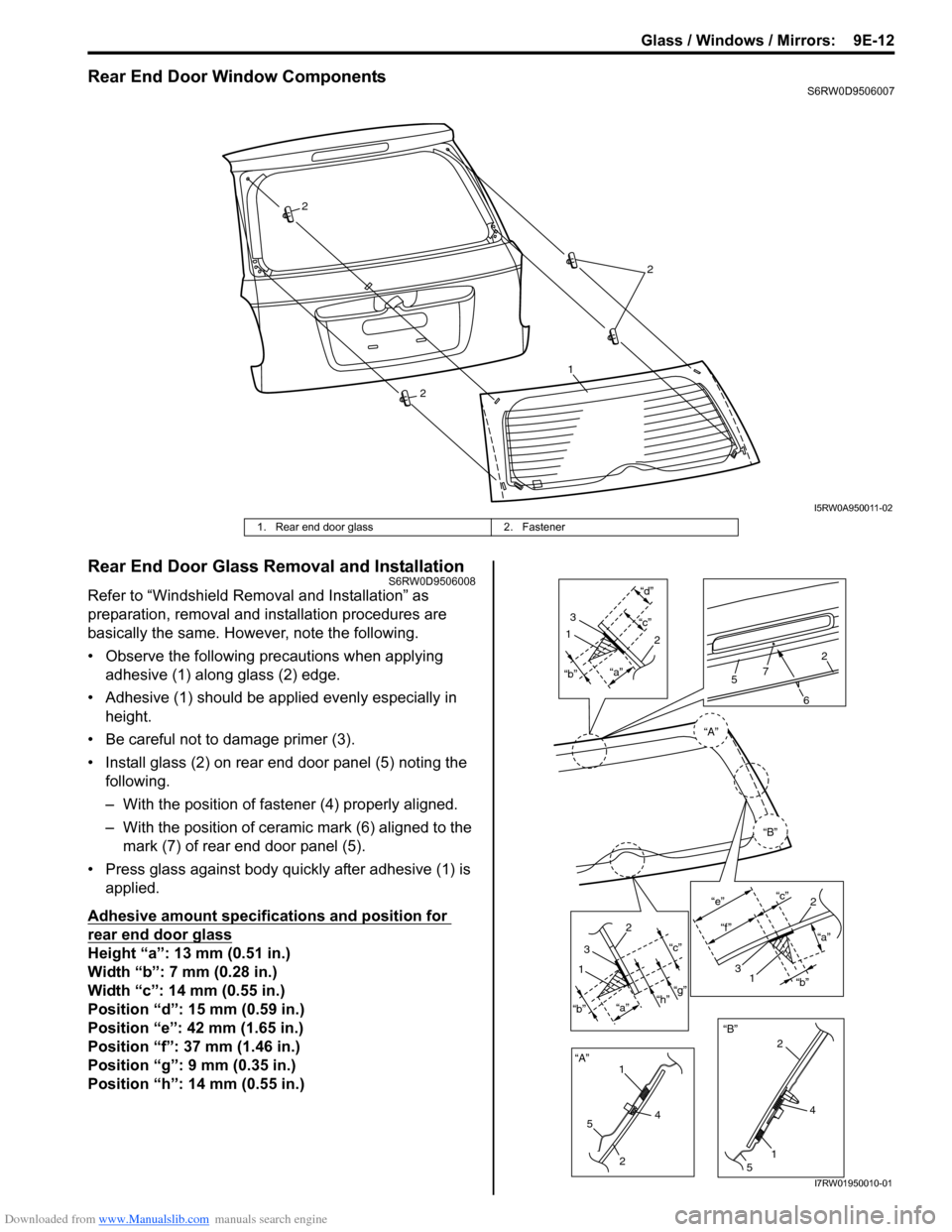

Rear End Door Window ComponentsS6RW0D9506007

Rear End Door Glass Removal and InstallationS6RW0D9506008

Refer to “Windshield Removal and Installation” as

preparation, removal and installation procedures are

basically the same. However, note the following.

• Observe the following precautions when applying

adhesive (1) along glass (2) edge.

• Adhesive (1) should be applied evenly especially in

height.

• Be careful not to damage primer (3).

• Install glass (2) on rear end door panel (5) noting the

following.

– With the position of fastener (4) properly aligned.

– With the position of ceramic mark (6) aligned to the

mark (7) of rear end door panel (5).

• Press glass against body quickly after adhesive (1) is

applied.

Adhesive amount specifications and position for

rear end door glass

Height “a”: 13 mm (0.51 in.)

Width “b”: 7 mm (0.28 in.)

Width “c”: 14 mm (0.55 in.)

Position “d”: 15 mm (0.59 in.)

Position “e”: 42 mm (1.65 in.)

Position “f”: 37 mm (1.46 in.)

Position “g”: 9 mm (0.35 in.)

Position “h”: 14 mm (0.55 in.)

2

2

1

2

I5RW0A950011-02

1. Rear end door glass 2. Fastener

“A”“a”“c”“d”1

3

12

“a”

“b”“c”

“g”

“h”

1

2

3

“A”

“B”“B” “b”

5

24

15

4 2

6

572

“a” “c”

“e”

“f ”

2

31“b”

I7RW01950010-01

Page 1398 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-13 Glass / Windows / Mirrors:

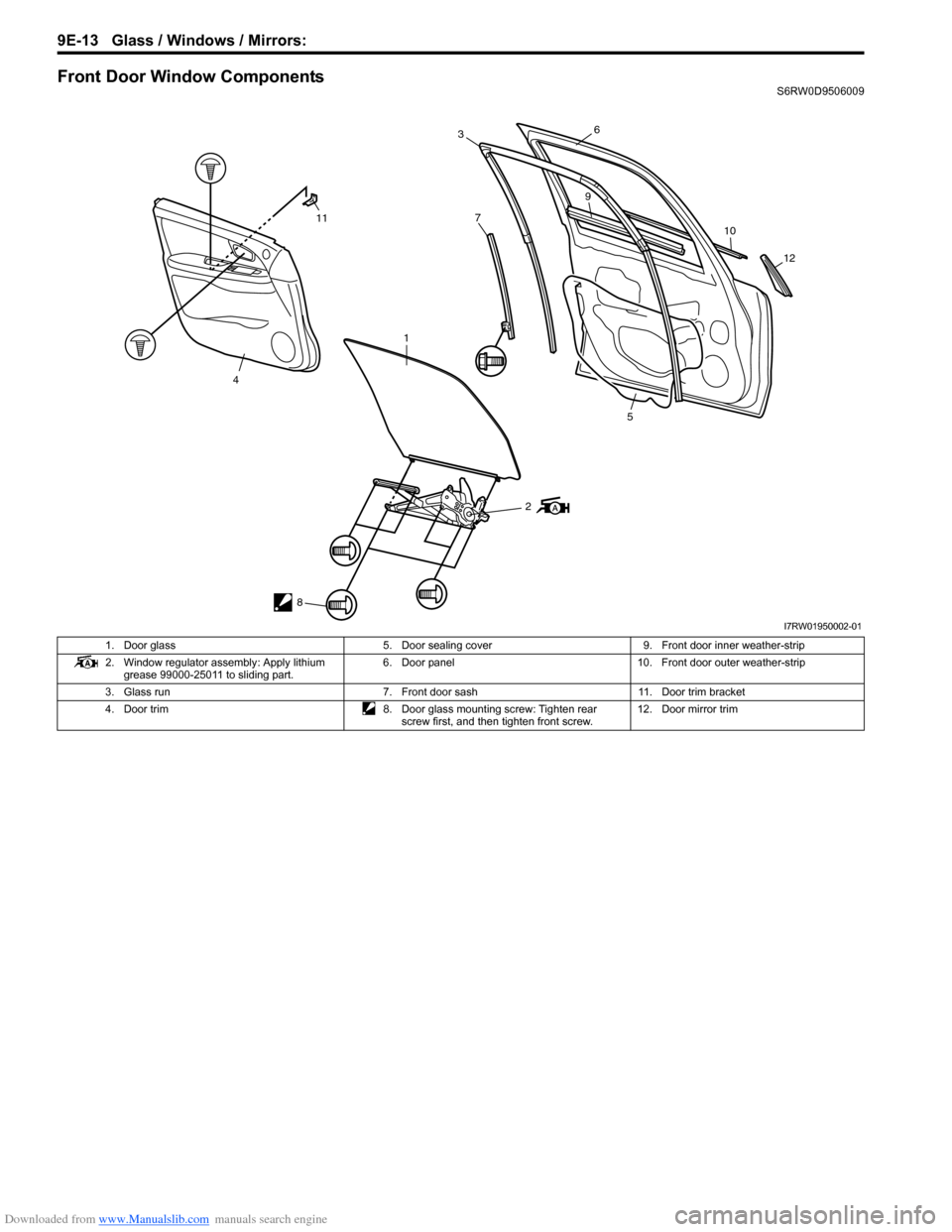

Front Door Window ComponentsS6RW0D9506009

2

8

11

4

1

7

36

9

10

12

5

I7RW01950002-01

1. Door glass 5. Door sealing cover 9. Front door inner weather-strip

2. Window regulator assembly: Apply lithium

grease 99000-25011 to sliding part.6. Door panel 10. Front door outer weather-strip

3. Glass run 7. Front door sash 11. Door trim bracket

4. Door trim 8. Door glass mounting screw: Tighten rear

screw first, and then tighten front screw.12. Door mirror trim

Page 1399 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-14

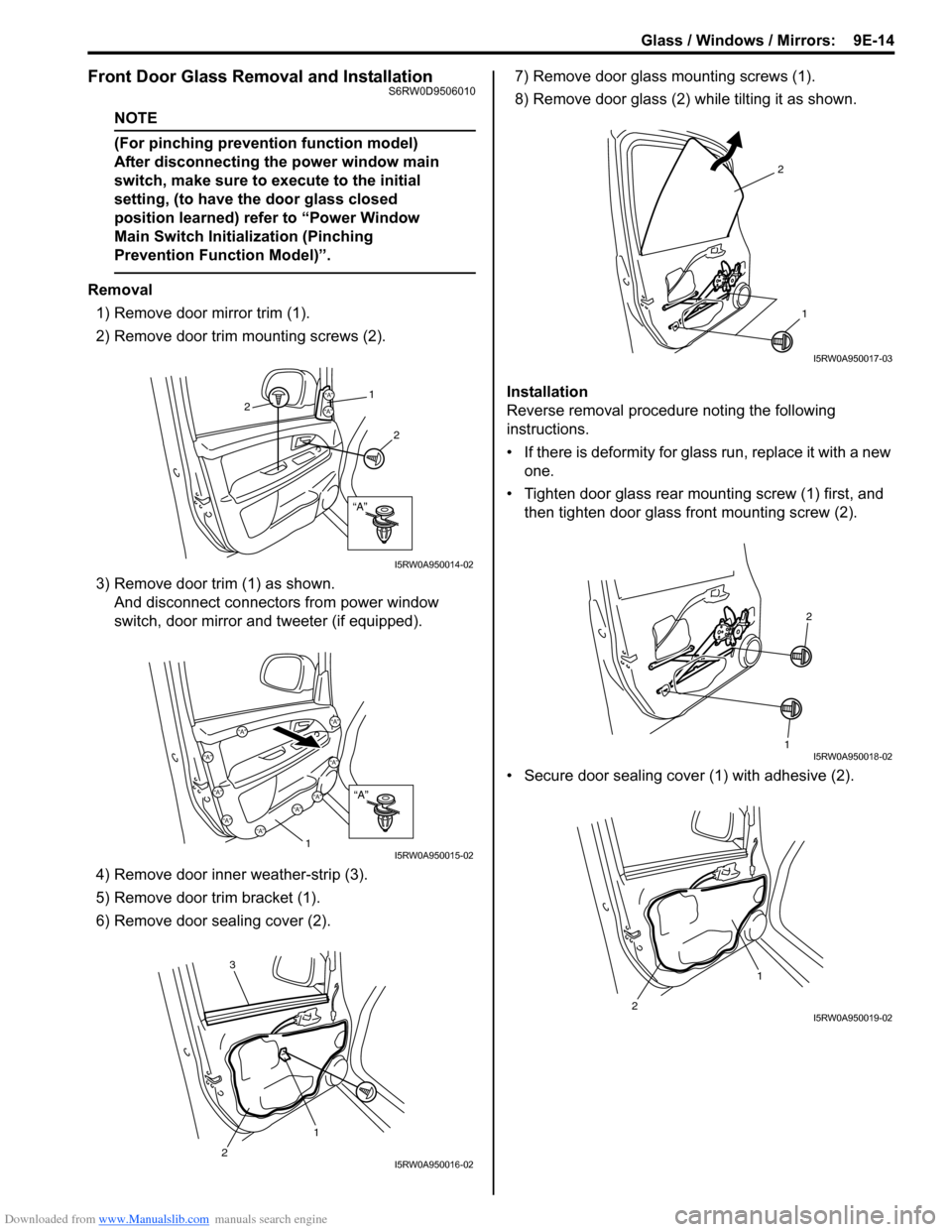

Front Door Glass Removal and InstallationS6RW0D9506010

NOTE

(For pinching prevention function model)

After disconnecting the power window main

switch, make sure to execute to the initial

setting, (to have the door glass closed

position learned) refer to “Power Window

Main Switch Initialization (Pinching

Prevention Function Model)”.

Removal

1) Remove door mirror trim (1).

2) Remove door trim mounting screws (2).

3) Remove door trim (1) as shown.

And disconnect connectors from power window

switch, door mirror and tweeter (if equipped).

4) Remove door inner weather-strip (3).

5) Remove door trim bracket (1).

6) Remove door sealing cover (2).7) Remove door glass mounting screws (1).

8) Remove door glass (2) while tilting it as shown.

Installation

Reverse removal procedure noting the following

instructions.

• If there is deformity for glass run, replace it with a new

one.

• Tighten door glass rear mounting screw (1) first, and

then tighten door glass front mounting screw (2).

• Secure door sealing cover (1) with adhesive (2).

“A”

“A”

“A”21

2

I5RW0A950014-02

“A”

“A”

“A”

“A”“A”

“A”“A”

“A”

“A”

“A”

1I5RW0A950015-02

3

1

2I5RW0A950016-02

2

1

I5RW0A950017-03

2

1

I5RW0A950018-02

2

1

I5RW0A950019-02

Page 1400 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-15 Glass / Windows / Mirrors:

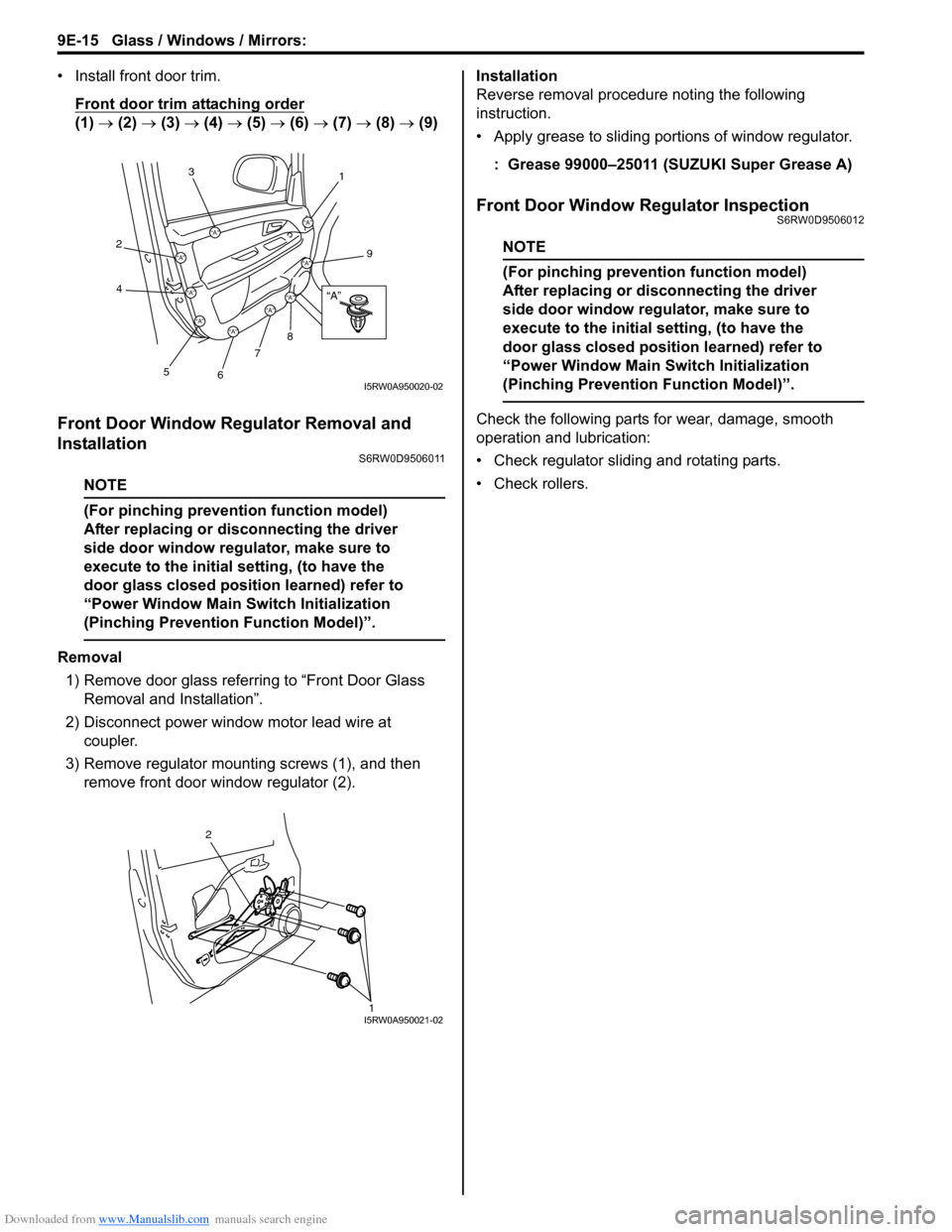

• Install front door trim.

Front door trim attaching order

(1) → (2) → (3) → (4) → (5) → (6) → (7) → (8) → (9)

Front Door Window Regulator Removal and

Installation

S6RW0D9506011

NOTE

(For pinching prevention function model)

After replacing or disconnecting the driver

side door window regulator, make sure to

execute to the initial setting, (to have the

door glass closed position learned) refer to

“Power Window Main Switch Initialization

(Pinching Prevention Function Model)”.

Removal

1) Remove door glass referring to “Front Door Glass

Removal and Installation”.

2) Disconnect power window motor lead wire at

coupler.

3) Remove regulator mounting screws (1), and then

remove front door window regulator (2).Installation

Reverse removal procedure noting the following

instruction.

• Apply grease to sliding portions of window regulator.

: Grease 99000–25011 (SUZUKI Super Grease A)

Front Door Window Regulator InspectionS6RW0D9506012

NOTE

(For pinching prevention function model)

After replacing or disconnecting the driver

side door window regulator, make sure to

execute to the initial setting, (to have the

door glass closed position learned) refer to

“Power Window Main Switch Initialization

(Pinching Prevention Function Model)”.

Check the following parts for wear, damage, smooth

operation and lubrication:

• Check regulator sliding and rotating parts.

• Check rollers.

“A”

“A”

“A”

“A”“A”

“A”“A”

“A”

“A”

“A”

3

2

4

5

6

7

8

9

1

I5RW0A950020-02

2

1I5RW0A950021-02