wheel SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 854 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-1 Clutch:

Transmission / Transaxle

Clutch

General Description

Clutch (Hydraulic Type) ConstructionS6RW0D5301001

The clutch is a diaphragm spring clutch of a dry single disc type. The diaphragm spring is of a tapering-finger type,

which is a solid ring in the outer diameter part, with a series of tapered fingers pointing inward.

The disc, carrying four torsional coil springs, is positioned on the transaxle input shaft with an involute spline fit.

The clutch cover is secured to the flywheel, and carries the diaphragm spring in such a way that the peripheral edge

part of the spring pushes on the pressure plate against the flywheel (with the disc in between), when the clutch release

bearing (incorporated in clutch operating cylinder) is held back. This is the engaged condition of the clutch.

Depressing the clutch pedal causes the release bearing (incorporated in clutch operating cylinder) to advance and

pushes on the tips of the tapered fingers of the diaphragm spring. When this happens, the diaphragm spring pulls the

pressure plate away from the flywheel, thereby interrupting the flow of drive from flywheel through clutch disc to

transaxle input shaft. Clutch fluid is supplied from brake fluid reservoir. Clutch fluid level can be checked by brake fluid

level of brake fluid reservoir.

I5RW0A530001-01

1. Crankshaft 4. Pressure plate 7. Operating cylinder assembly

2. Flywheel 5. Clutch cover 8. Input shaft bearing

3. Clutch disc 6. Diaphragm spring 9. Input shaft

Page 855 of 1556

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-2

Diagnostic Information and Procedures

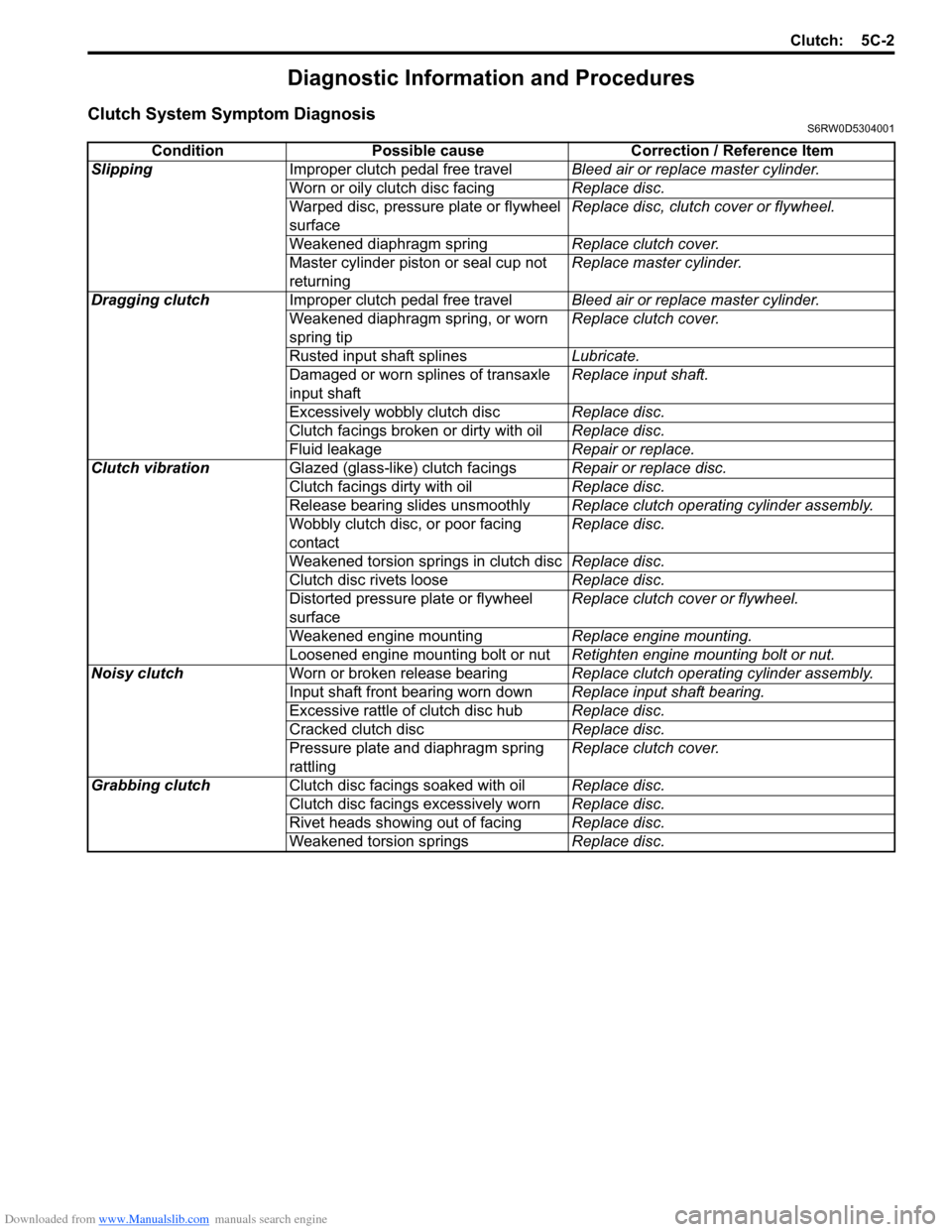

Clutch System Symptom DiagnosisS6RW0D5304001

Condition Possible cause Correction / Reference Item

SlippingImproper clutch pedal free travelBleed air or replace master cylinder.

Worn or oily clutch disc facingReplace disc.

Warped disc, pressure plate or flywheel

surfaceReplace disc, clutch cover or flywheel.

Weakened diaphragm springReplace clutch cover.

Master cylinder piston or seal cup not

returningReplace master cylinder.

Dragging clutchImproper clutch pedal free travelBleed air or replace master cylinder.

Weakened diaphragm spring, or worn

spring tipReplace clutch cover.

Rusted input shaft splinesLubricate.

Damaged or worn splines of transaxle

input shaftReplace input shaft.

Excessively wobbly clutch discReplace disc.

Clutch facings broken or dirty with oilReplace disc.

Fluid leakageRepair or replace.

Clutch vibrationGlazed (glass-like) clutch facingsRepair or replace disc.

Clutch facings dirty with oilReplace disc.

Release bearing slides unsmoothlyReplace clutch operating cylinder assembly.

Wobbly clutch disc, or poor facing

contactReplace disc.

Weakened torsion springs in clutch discReplace disc.

Clutch disc rivets looseReplace disc.

Distorted pressure plate or flywheel

surfaceReplace clutch cover or flywheel.

Weakened engine mountingReplace engine mounting.

Loosened engine mounting bolt or nutRetighten engine mounting bolt or nut.

Noisy clutchWorn or broken release bearingReplace clutch operating cylinder assembly.

Input shaft front bearing worn downReplace input shaft bearing.

Excessive rattle of clutch disc hubReplace disc.

Cracked clutch discReplace disc.

Pressure plate and diaphragm spring

rattlingReplace clutch cover.

Grabbing clutchClutch disc facings soaked with oilReplace disc.

Clutch disc facings excessively wornReplace disc.

Rivet heads showing out of facingReplace disc.

Weakened torsion springsReplace disc.

Page 856 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-3 Clutch:

Repair Instructions

Clutch Pedal InspectionS6RW0D5306001

Cylinder Push Rod Play “a”

1) Press clutch pedal (1) gradually with finger, stop

when slight increase of resistance is felt and

measure how much pedal has moved (push rod

play) as represented by “a” as shown.

Push rod play

“a”: Max. 3 mm (0.12 in.)

2) If “a” is not within specification, replace master

cylinder (3) or pedal arm (2).

Clutch Pedal Free Travel “b”

1) Depress clutch pedal (1), stop the moment clutch

resistance is felt, and measure how much pedal has

moved (clutch pedal free travel) as represented by

“b” in the figure.

Clutch pedal free travel

“b”

: 2 – 8 mm (0.08 – 0.31 in.)

2) If “b” is not within specification, check pedal arm (2)

and master cylinder (3) and replace defective part.

Clutch Release Margin “c”

1) Pull up parking brake fully and block wheels.

2) Start engine and keep engine at idle with neutral

gear position.

3) Without clutch pedal (1) depressed, slightly push the

shift lever to reverse position until transaxle emits

gear contact noise. Do not shift the lever to reverse

position.

4) With emitting gear contact noise, be slow to depress

clutch pedal (1), and at gear contact noise died

position (release point) stop depressing.

5) Measure distance between release point (4) and full

stroke point (5) on clutch pedal (1) which is shown by

“c” in the figure.

Clutch release margin

“c”: 25 – 55 mm (0.98 – 2.17 in.)6) If “c” is not within specification, it is possible that air

is trapped in this system. If suspected so, bleed air

referring to “Air Bleeding of Clutch System”.Upon

completion of above inspection, start engine and

check clutch for proper operation.

Clutch Fluid Level InspectionS6RW0D5306002

Refer to “Brake Fluid Level Inspection in Section 4A”.

Clutch fluid specification

: Refer to the reservoir cap of the brake master

cylinder.

Air Bleeding of Clutch SystemS6RW0D5306003

CAUTION!

When operating the pedal stroke for air

bleeding of clutch system, after releasing the

clutch pedal, be sure to wait 1 second or

more before depressing it again. Otherwise,

the oil seal of operating cylinder will be

damaged, resulting in oil leakage.

Bleed air from clutch system.

Refer to “Air Bleeding of Brake System in Section 4A”.

I5RW0A530002-01

Page 859 of 1556

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-6

Installation

1) Install clutch operating cylinder assembly (2) to

transaxle. Tighten new mounting bolts to specified

torque.

Tightening torque

Clutch operating cylinder assembly mounting

bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

2) Connect clutch fluid pipe (4) to clutch operating

cylinder assembly temporarily.

3) Install clutch pipe joint sleeve (3) to transaxle

securely and then tighten clutch fluid pipe flare nut

(1) to specified torque.

Tightening torque

Clutch fluid pipe flare nut (b): 16 N·m (1.6 kgf-

m, 11.5 lb-ft)4) Remount transaxle assembly referring to “Manual

Transaxle Unit Dismounting and Remounting in

Section 5B”.

5) Bleed air from system and check clutch pedal free

travel. Refer to “Air Bleeding of Clutch System” and

“Clutch Pedal Inspection”.

Clutch Operating Cylinder Assembly InspectionS6RW0D5306013

Check clutch fluid leakage, spring for damage and

bearing for smooth rotation. If malfunction is found,

replace clutch operating cylinder assembly.

Clutch Cover, Clutch Disc and Flywheel ComponentsS6RW0D5306010

3

4

(a)

2

1, (b)

I5RW0A530009-01

I5RW0B530005-03

2

1

3(a)

6

4

5

(b)

I6RW0C530001-01

1. Clutch cover 4. Flywheel : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

2. Clutch disc 5. Input shaft bearing : 70 N⋅m (7.0 kgf-m, 51.0 lb-ft)

3. Clutch cover bolt 6. Flywheel bolt : Do not reuse.

Page 860 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-7 Clutch:

Clutch Cover, Clutch Disc and Flywheel

Removal and Installation

S6RW0D5306011

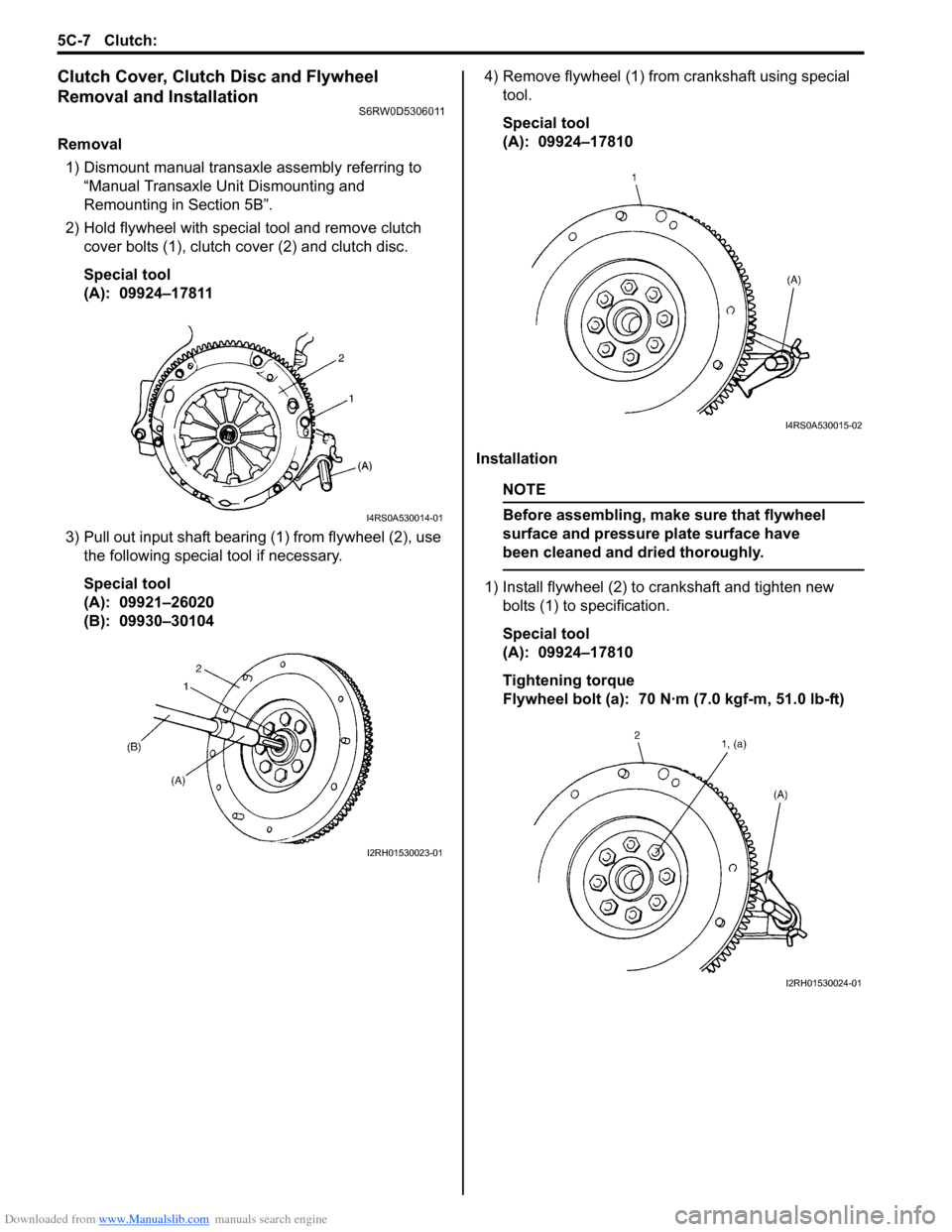

Removal

1) Dismount manual transaxle assembly referring to

“Manual Transaxle Unit Dismounting and

Remounting in Section 5B”.

2) Hold flywheel with special tool and remove clutch

cover bolts (1), clutch cover (2) and clutch disc.

Special tool

(A): 09924–17811

3) Pull out input shaft bearing (1) from flywheel (2), use

the following special tool if necessary.

Special tool

(A): 09921–26020

(B): 09930–301044) Remove flywheel (1) from crankshaft using special

tool.

Special tool

(A): 09924–17810

Installation

NOTE

Before assembling, make sure that flywheel

surface and pressure plate surface have

been cleaned and dried thoroughly.

1) Install flywheel (2) to crankshaft and tighten new

bolts (1) to specification.

Special tool

(A): 09924–17810

Tightening torque

Flywheel bolt (a): 70 N·m (7.0 kgf-m, 51.0 lb-ft)

I4RS0A530014-01

I2RH01530023-01

I4RS0A530015-02

I2RH01530024-01

Page 861 of 1556

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-8

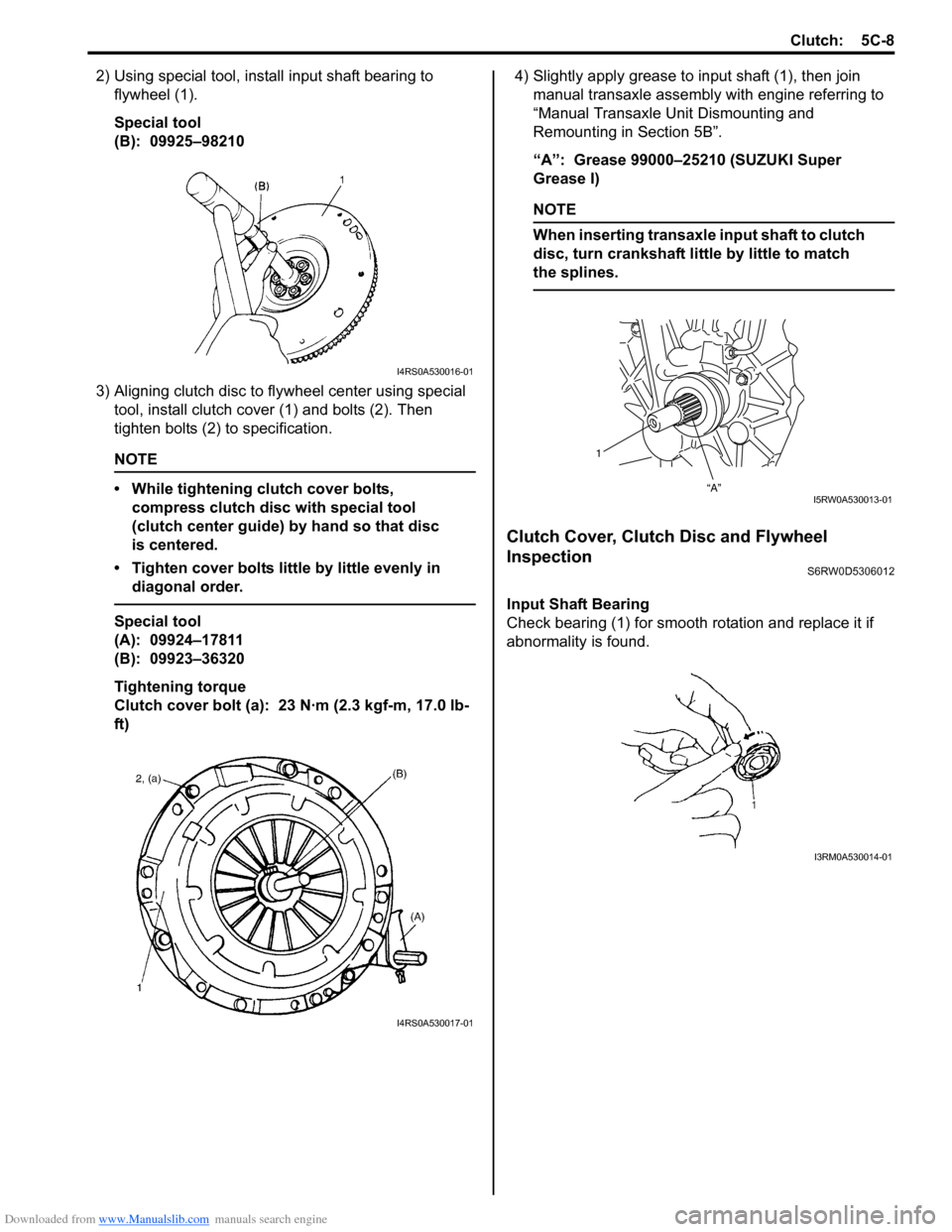

2) Using special tool, install input shaft bearing to

flywheel (1).

Special tool

(B): 09925–98210

3) Aligning clutch disc to flywheel center using special

tool, install clutch cover (1) and bolts (2). Then

tighten bolts (2) to specification.

NOTE

• While tightening clutch cover bolts,

compress clutch disc with special tool

(clutch center guide) by hand so that disc

is centered.

• Tighten cover bolts little by little evenly in

diagonal order.

Special tool

(A): 09924–17811

(B): 09923–36320

Tightening torque

Clutch cover bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-

ft)4) Slightly apply grease to input shaft (1), then join

manual transaxle assembly with engine referring to

“Manual Transaxle Unit Dismounting and

Remounting in Section 5B”.

“A”: Grease 99000–25210 (SUZUKI Super

Grease I)

NOTE

When inserting transaxle input shaft to clutch

disc, turn crankshaft little by little to match

the splines.

Clutch Cover, Clutch Disc and Flywheel

Inspection

S6RW0D5306012

Input Shaft Bearing

Check bearing (1) for smooth rotation and replace it if

abnormality is found.

I4RS0A530016-01

I4RS0A530017-01

1

“A”I5RW0A530013-01

I3RM0A530014-01

Page 862 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-9 Clutch:

Clutch Disc

Measure depth of rivet head depression, i.e. distance

between rivet head and facing surface.

If depression is found to have reached service limit at

any of rivet holes (2), replace clutch disc assembly (1).

Rivet head depth

Standard: 1.65 – 2.25 mm (0.06 – 0.09 in.)

Limit: 0.5 mm (0.02 in.)Clutch Cover

1) Check diaphragm spring (1) for abnormal wear or

damage.

2) Inspect pressure plate (2) for wear or heat spots.

3) If abnormality is found, replace clutch cover.

Do not disassemble it into diaphragm spring and

pressure plate.

Flywheel

Check surface contacting clutch disc for abnormal wear

or heat spots. Replace or repair as required.

Specifications

Tightening Torque SpecificationsS6RW0D5307001

NOTE

The specified tightening torque is also described in the following.

“Clutch Cover, Clutch Disc and Flywheel Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I4RS0A530019-01

I3RM0A530015-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Clutch master cylinder nut 13 1.3 9.5�)

Clutch operating cylinder assembly mounting

bolt10 1.0 7.5�)

Clutch fluid pipe flare nut 16 1.6 11.5�)

Flywheel bolt 70 7.0 51.0�)

Clutch cover bolt 23 2.3 17.0�)

Page 863 of 1556

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-10

Special Tools and Equipment

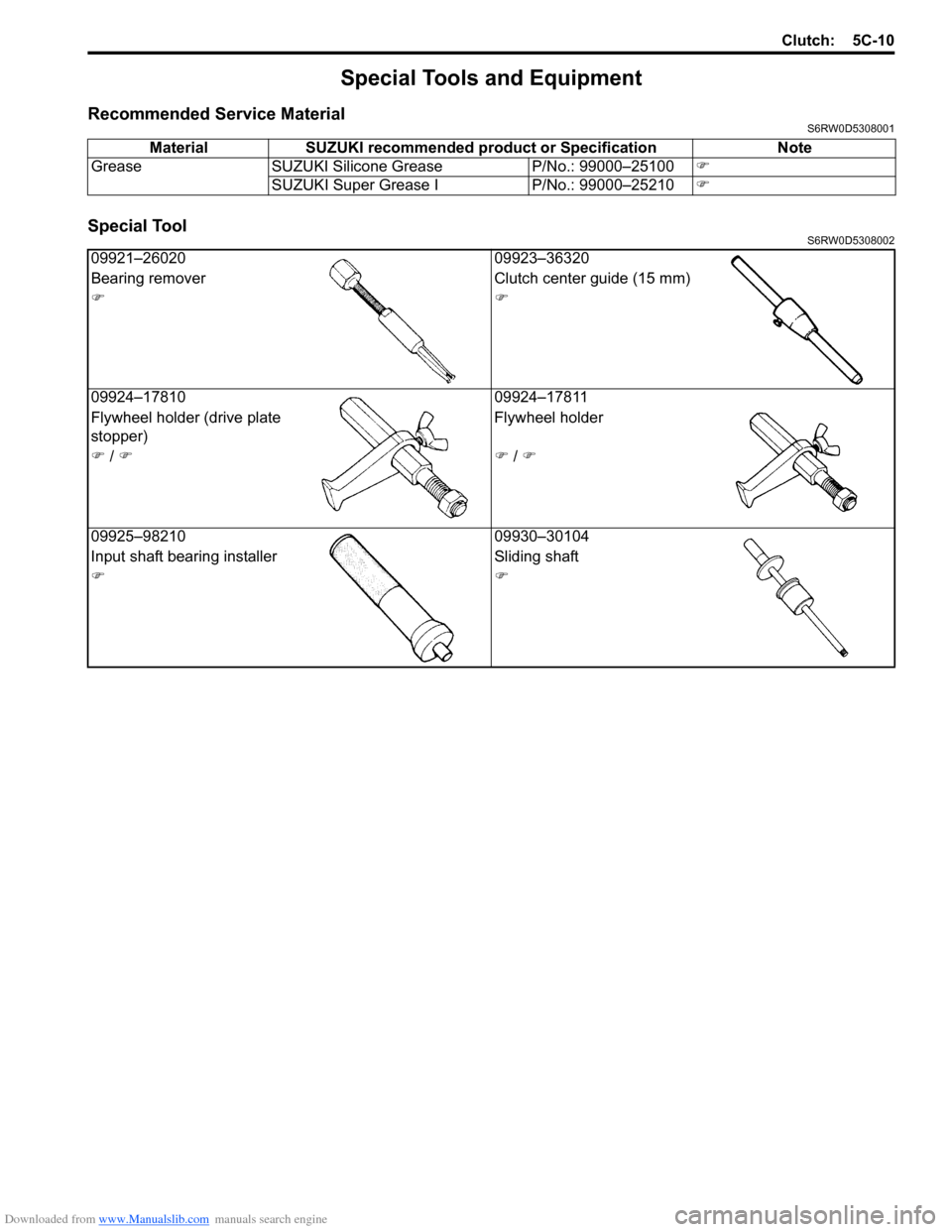

Recommended Service MaterialS6RW0D5308001

Special ToolS6RW0D5308002

Material SUZUKI recommended product or Specification Note

Grease SUZUKI Silicone Grease P/No.: 99000–25100�)

SUZUKI Super Grease I P/No.: 99000–25210�)

09921–26020 09923–36320

Bearing remover Clutch center guide (15 mm)

�)�)

09924–17810 09924–17811

Flywheel holder (drive plate

stopper)Flywheel holder

�) / �)�) / �)

09925–98210 09930–30104

Input shaft bearing installer Sliding shaft

�)�)

Page 865 of 1556

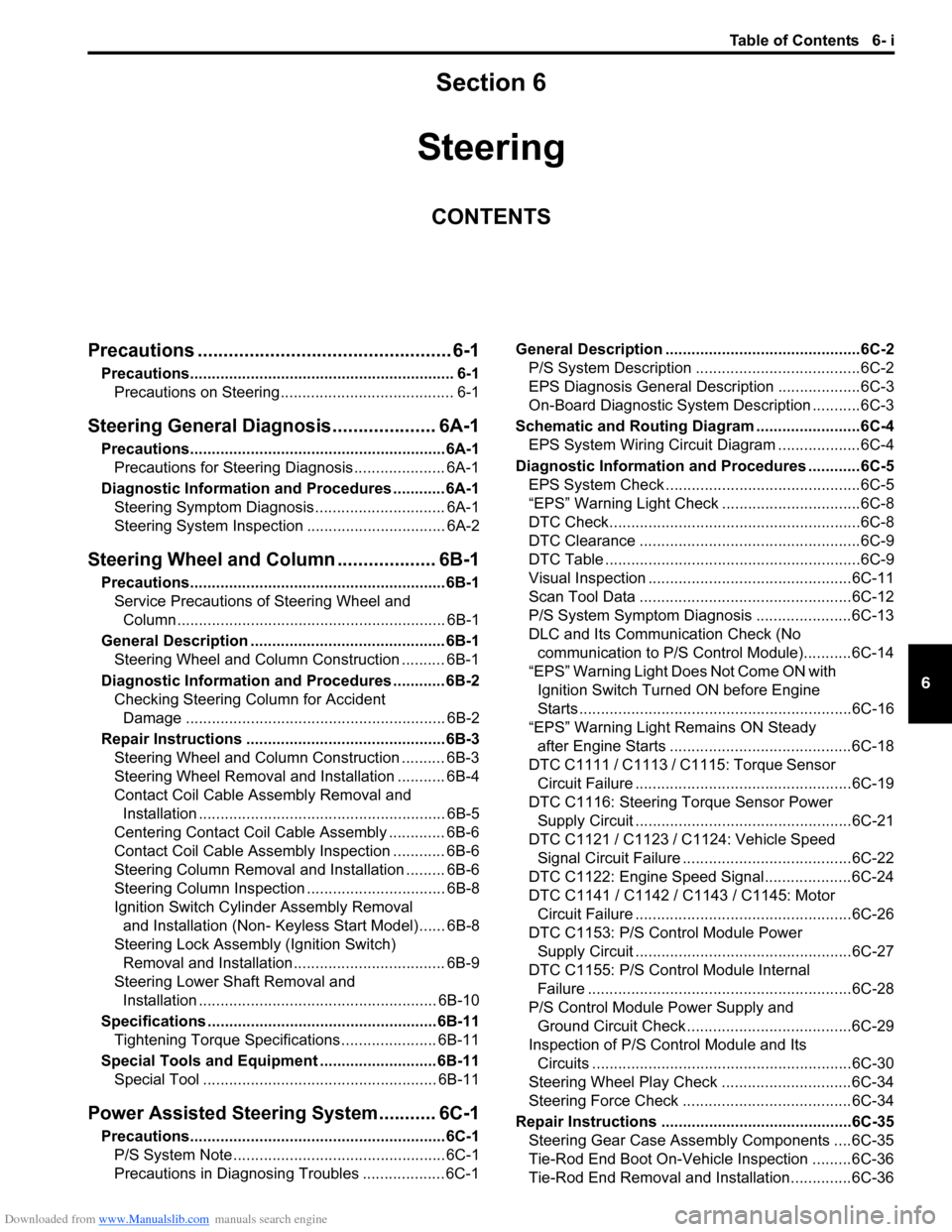

Downloaded from www.Manualslib.com manuals search engine Table of Contents 6- i

6

Section 6

CONTENTS

Steering

Precautions ................................................. 6-1

Precautions............................................................. 6-1

Precautions on Steering........................................ 6-1

Steering General Diagnosis.................... 6A-1

Precautions........................................................... 6A-1

Precautions for Steering Diagnosis ..................... 6A-1

Diagnostic Information and Procedures ............ 6A-1

Steering Symptom Diagnosis .............................. 6A-1

Steering System Inspection ................................ 6A-2

Steering Wheel and Column................... 6B-1

Precautions........................................................... 6B-1

Service Precautions of Steering Wheel and

Column.............................................................. 6B-1

General Description ............................................. 6B-1

Steering Wheel and Column Construction .......... 6B-1

Diagnostic Information and Procedures ............ 6B-2

Checking Steering Column for Accident

Damage ............................................................ 6B-2

Repair Instructions .............................................. 6B-3

Steering Wheel and Column Construction .......... 6B-3

Steering Wheel Removal and Installation ........... 6B-4

Contact Coil Cable Assembly Removal and

Installation ......................................................... 6B-5

Centering Contact Coil Cable Assembly ............. 6B-6

Contact Coil Cable Assembly Inspection ............ 6B-6

Steering Column Removal and Installation ......... 6B-6

Steering Column Inspection ................................ 6B-8

Ignition Switch Cylinder Assembly Removal

and Installation (Non- Keyless Start Model)...... 6B-8

Steering Lock Assembly (Ignition Switch)

Removal and Installation................................... 6B-9

Steering Lower Shaft Removal and

Installation ....................................................... 6B-10

Specifications..................................................... 6B-11

Tightening Torque Specifications ...................... 6B-11

Special Tools and Equipment ........................... 6B-11

Special Tool ...................................................... 6B-11

Power Assisted Steering System........... 6C-1

Precautions........................................................... 6C-1

P/S System Note ................................................. 6C-1

Precautions in Diagnosing Troubles ................... 6C-1General Description .............................................6C-2

P/S System Description ......................................6C-2

EPS Diagnosis General Description ...................6C-3

On-Board Diagnostic System Description ...........6C-3

Schematic and Routing Diagram ........................6C-4

EPS System Wiring Circuit Diagram ...................6C-4

Diagnostic Information and Procedures ............6C-5

EPS System Check .............................................6C-5

“EPS” Warning Light Check ................................6C-8

DTC Check..........................................................6C-8

DTC Clearance ...................................................6C-9

DTC Table ...........................................................6C-9

Visual Inspection ...............................................6C-11

Scan Tool Data .................................................6C-12

P/S System Symptom Diagnosis ......................6C-13

DLC and Its Communication Check (No

communication to P/S Control Module)...........6C-14

“EPS” Warning Light Does Not Come ON with

Ignition Switch Turned ON before Engine

Starts ...............................................................6C-16

“EPS” Warning Light Remains ON Steady

after Engine Starts ..........................................6C-18

DTC C1111 / C1113 / C1115: Torque Sensor

Circuit Failure ..................................................6C-19

DTC C1116: Steering Torque Sensor Power

Supply Circuit ..................................................6C-21

DTC C1121 / C1123 / C1124: Vehicle Speed

Signal Circuit Failure .......................................6C-22

DTC C1122: Engine Speed Signal....................6C-24

DTC C1141 / C1142 / C1143 / C1145: Motor

Circuit Failure ..................................................6C-26

DTC C1153: P/S Control Module Power

Supply Circuit ..................................................6C-27

DTC C1155: P/S Control Module Internal

Failure .............................................................6C-28

P/S Control Module Power Supply and

Ground Circuit Check ......................................6C-29

Inspection of P/S Control Module and Its

Circuits ............................................................6C-30

Steering Wheel Play Check ..............................6C-34

Steering Force Check .......................................6C-34

Repair Instructions ............................................6C-35

Steering Gear Case Assembly Components ....6C-35

Tie-Rod End Boot On-Vehicle Inspection .........6C-36

Tie-Rod End Removal and Installation..............6C-36

Page 867 of 1556

Downloaded from www.Manualslib.com manuals search engine Precautions: 6-1

Ste eri ng

Precautions

Precautions

Precautions on SteeringS6RW0D6000001

Air Bag Warning

Refer to “Air Bag System Service Warning in Section 00”.

Precautions for Steering Diagnosis

Refer to “Precautions for Steering Diagnosis in Section 6A”.

Service Precautions of Steering Wheel and Column

Refer to “Service Precautions of Steering Wheel and Column in Section 6B”.

P/S System Note

Refer to “P/S System Note in Section 6C”.