wheel SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 943 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-3

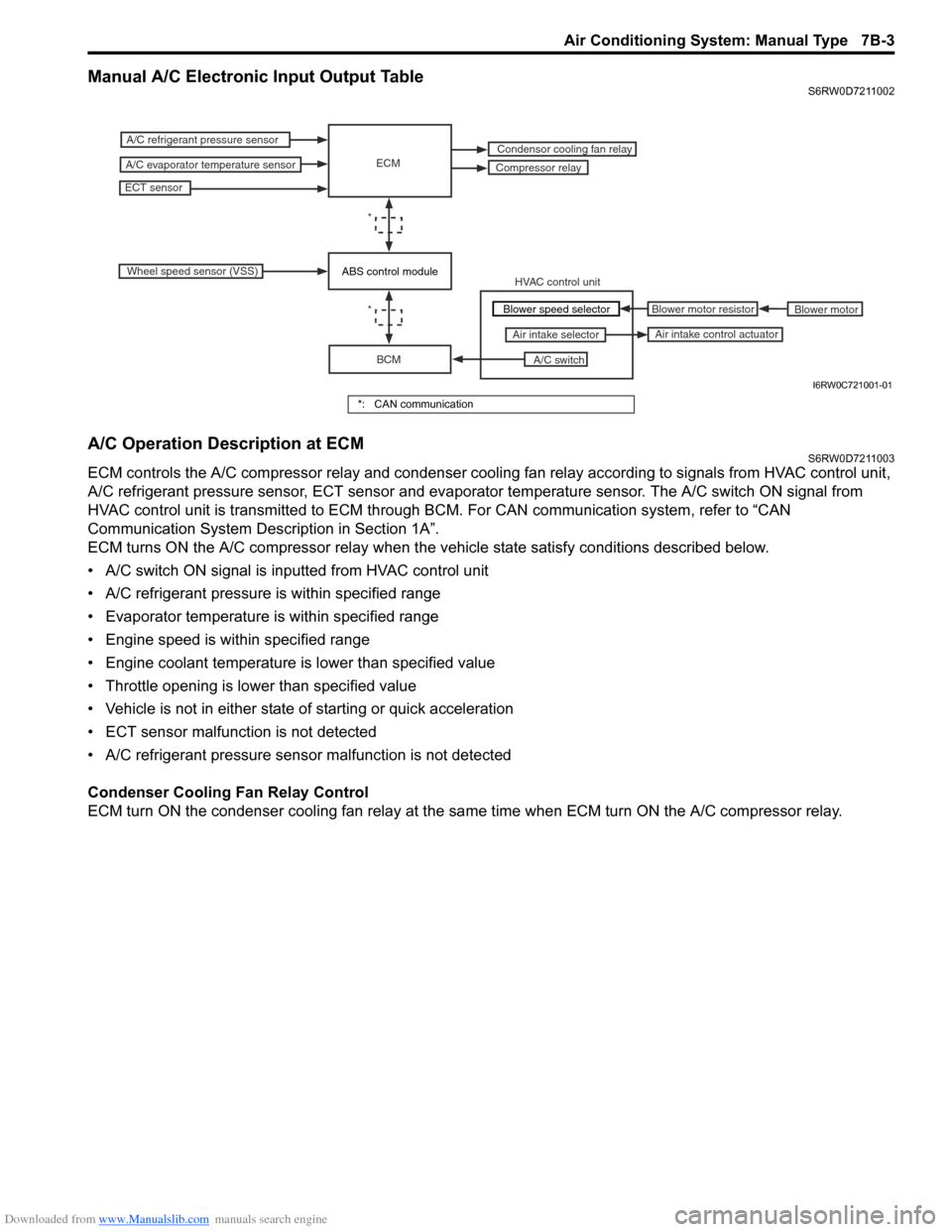

Manual A/C Electronic Input Output TableS6RW0D7211002

A/C Operation Description at ECMS6RW0D7211003

ECM controls the A/C compressor relay and condenser cooling fan relay according to signals from HVAC control unit,

A/C refrigerant pressure sensor, ECT sensor and evaporator temperature sensor. The A/C switch ON signal from

HVAC control unit is transmitted to ECM through BCM. For CAN communication system, refer to “CAN

Communication System Description in Section 1A”.

ECM turns ON the A/C compressor relay when the vehicle state satisfy conditions described below.

• A/C switch ON signal is inputted from HVAC control unit

• A/C refrigerant pressure is within specified range

• Evaporator temperature is within specified range

• Engine speed is within specified range

• Engine coolant temperature is lower than specified value

• Throttle opening is lower than specified value

• Vehicle is not in either state of starting or quick acceleration

• ECT sensor malfunction is not detected

• A/C refrigerant pressure sensor malfunction is not detected

Condenser Cooling Fan Relay Control

ECM turn ON the condenser cooling fan relay at the same time when ECM turn ON the A/C compressor relay.

ECM

BCM

A/C switch Air intake selector

A/C refrigerant pressure sensor

A/C evaporator temperature sensorCompressor relay

ECT sensor

Condensor cooling fan relay

*

Wheel speed sensor (VSS)

HVAC control unit

Blower motor Blower motor resistor

Air intake control actuator

*Blower speed selector

ABS control module

I6RW0C721001-01

*: CAN communication

Page 979 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-39

General Description

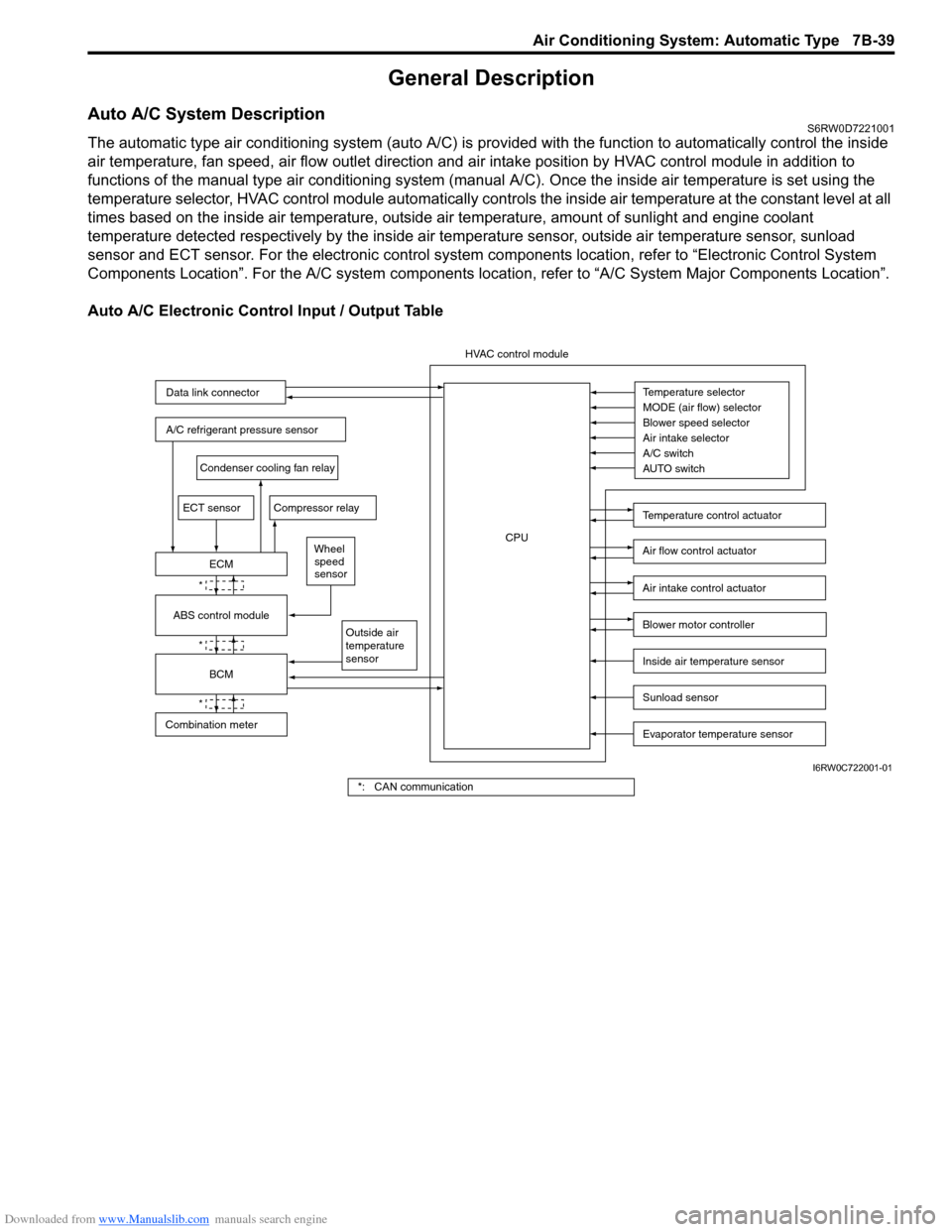

Auto A/C System DescriptionS6RW0D7221001

The automatic type air conditioning system (auto A/C) is provided with the function to automatically control the inside

air temperature, fan speed, air flow outlet direction and air intake position by HVAC control module in addition to

functions of the manual type air conditioning system (manual A/C). Once the inside air temperature is set using the

temperature selector, HVAC control module automatically controls the inside air temperature at the constant level at all

times based on the inside air temperature, outside air temperature, amount of sunlight and engine coolant

temperature detected respectively by the inside air temperature sensor, outside air temperature sensor, sunload

sensor and ECT sensor. For the electronic control system components location, refer to “Electronic Control System

Components Location”. For the A/C system components location, refer to “A/C System Major Components Location”.

Auto A/C Electronic Control Input / Output Table

Temperature selector

MODE (air flow) selector

Blower speed selector

Air intake selector

AUTO switch A/C switch

Outside air

temperature

sensor

A/C refrigerant pressure sensor

Compressor relay

Blower motor controller

Temperature control actuator

Air flow control actuator

Air intake control actuator

BCM

ECM

Data link connector

HVAC control module

CPU

ECT sensor

Sunload sensor

Inside air temperature sensor

Evaporator temperature sensor

Condenser cooling fan relay

Wheel

speed

sensor

*

*

*

Combination meterABS control module

I6RW0C722001-01

*: CAN communication

Page 1040 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-1 Air Bag System:

Restraint

Air Bag System

Precautions

Precautions on Service and Diagnosis of Air

Bag System

S6RW0D8200004

WARNING!

• If the air bag system and another vehicle

system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel,

dashboard, both front seat or any other on

or around air bag system components.

Modifications can adversely affect air bag

system performance and lead to injury.

• Be sure to follow the procedures described

in this section. Failure to follow

procedures could result in possible air bag

system activation, personal injury or

unneeded air bag system repairs.

• WARNING / CAUTION labels are attached on each

part of air bag system components (SDM, air bag

(inflator) modules and seat belt pretensioners). Be

sure to follow the instructions.

• Many of service procedures require disconnection of

“A/B” fuse and air bag (inflator) module(s) (driver

module, passenger module, side modules and curtain

modules) from initiator circuit to avoid an accidental

deployment.

• Do not apply power to the air bag system unless all

components are connected or a diagnostic flow

requests it, as this will set a DTC.

• The “Air Bag Diagnostic System Check” must be the

starting point of any air bag diagnostics. The “Air Bag

Diagnostic System Check” will verify proper “AIR

BAG” warning light operation and will lead you to the

correct flow to diagnose any air bag malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements.

• Never use air bag component parts from another

vehicle.

• If the vehicle will be exposed to temperatures over 93

°C (200 °F) (for example, during a paint baking

process), remove the air bag system components

beforehand to avoid component damage or

unintended system activation.• When handling the air bag (inflator) modules (driver

module, passenger module, side modules and curtain

modules), seat belt pretensioners (driver module and

passenger module), SDM, forward impact-sensor or

side impact-sensor be careful not to drop it or apply

an impact to it. If an excessive impact was applied

(e.g., SDM, forward impact-sensor are dropped, air

bag (inflator) module is dropped from a height of 90

cm (3 ft) or more, seat belt pretensioner (retractor

assembly) is dropped from a height of 30 cm (1 ft) or

more), never attempt disassembly or repair but

replace it with a new one.

• When using electric welding, be sure to disconnect air

bag (inflator) module connectors (driver module,

passenger module, side modules and curtain

modules) and seat belt pretensioner connectors

(driver module and passenger module) respectively.

• When applying paint around the air bag system

related parts, use care so that the harness or

connector will not be exposed to the paint mist.

• Never expose air bag system component parts

directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING!

When performing service on or around air

bag system components or air bag wiring,

follow the procedures listed in “Disabling Air

Bag System” to temporarily disable the air

bag system.

Failure to follow procedures could result in

possible air bag system activation, personal

injury or unneeded air bag system repairs.

Precautions on Handling and Storage of Air Bag

System Components

S6RW0D8200002

SDM

WARNING!

Never power up air bag system when SDM is

not rigidly attached to the vehicle. Otherwise,

personal injury may result.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, SDM must

not be used. Refer to “Air Bag Diagnostic

System Check” when checking SDM.

Page 1051 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-12

Diagnostic Information and Procedures

Air Bag Diagnostic System CheckS6RW0D8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

• The order in which DTCs are diagnosed is

very important. Failure to diagnose the

DTCs in the order specified may result in

extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.

• When measurement of resistance or

voltage is required in the flow, use a tester

along with a correct terminal adapter from

special tool (Connector test adapter kit).

• When a check for proper connection is

required, refer to “Inspection of

Intermittent and Poor Connections”.

• If an open circuit in the air bag wire

harness damaged, connector or terminal is

found, replace the wire harness,

connectors and terminals as an assembly.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.

1) Perform the “Air Bag Diagnostic System Check

Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning light operation through

“AIR BAG” warning light and whether air bag DTCs

exist.)

2) Refer to the proper diagnostic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow”

after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

A: Combination meter 6. Side curtain-air bag (inflator) module (8-

channel system)14. “A/B” fuse in junction block assembly

B: Steering wheel 7. Contact coil assembly 15. Air bag harness in main harness

C: Seat 8. Forward impact-sensor 16. Air bag harness in instrument panel harness

1. “AIR BAG” warning light 9. Apron-side-member (driver side) 17. Air bag harness in floor harness

2. Driver air bag (inflator) module 10. Side impact-sensor (8-channel system) 18. Side-air bag harness (8-channel system)

3. Passenger air bag facing cover 11. Side sill inner panel 19. Side curtain-air bag harness (8-channel

system)

4. Passenger air bag (inflator) module 12. SDM 20. Ground for air bag system

5. Side-air bag (inflator) module (8-channel

system)13. Seat belt pretensioner

Page 1080 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-41 Air Bag System:

DTC Troubleshooting

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2Passenger air bag check

1) Remove passenger air bag (inflator) module referring to

“Passenger Air Bag (Inflator) Module Removal and

Installation”.

2) Check for proper connection to passenger air bag

(inflator) module at terminals in “G259” connector.

3) If OK, then connect special tools (A), (B) and (C) to

“G259” connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM for DTC.

With ignition switch turned ON, is DTC B1041 indicated?Go to Step 3. Replace passenger air

bag (inflator) module

referring to “Passenger

Air Bag (Inflator) Module

Removal and

Installation”.

“G259”

(B) (C)

(A)

STEERING WHEEL

I7RW01821025-02

Page 1082 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-43 Air Bag System:

DTC B1042: Passenger Air Bag Circuit Low ResistanceS6RW0D8204023

Wiring Diagram

Refer to “DTC B1041: Passenger Air Bag Circuit High Resistance”.

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

Passenger air bag circuit is less than 0.9 Ω for more than

4 sec.• Passenger air bag circuit

• Passenger air bag module

•SDM

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2Passenger air bag circuit check

1) Remove passenger air bag (inflator) module referring to

“Passenger Air Bag (Inflator) Module Removal and

Installation”.

2) Check for proper connection to passenger air bag

(inflator) module at terminals in “G259” connector.

3) If OK, then connect special tools (A), (B) and (C) to

“G259” connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM for DTC.

With ignition switch ON, is DTC B1042 indicated?Go to Step 3. Replace passenger air

bag (inflator) module

referring to “Passenger

Air Bag (Inflator) Module

Removal and

Installation”.

“G259”

(B) (C)

(A)

STEERING WHEEL

I7RW01821025-02

Page 1088 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-49 Air Bag System:

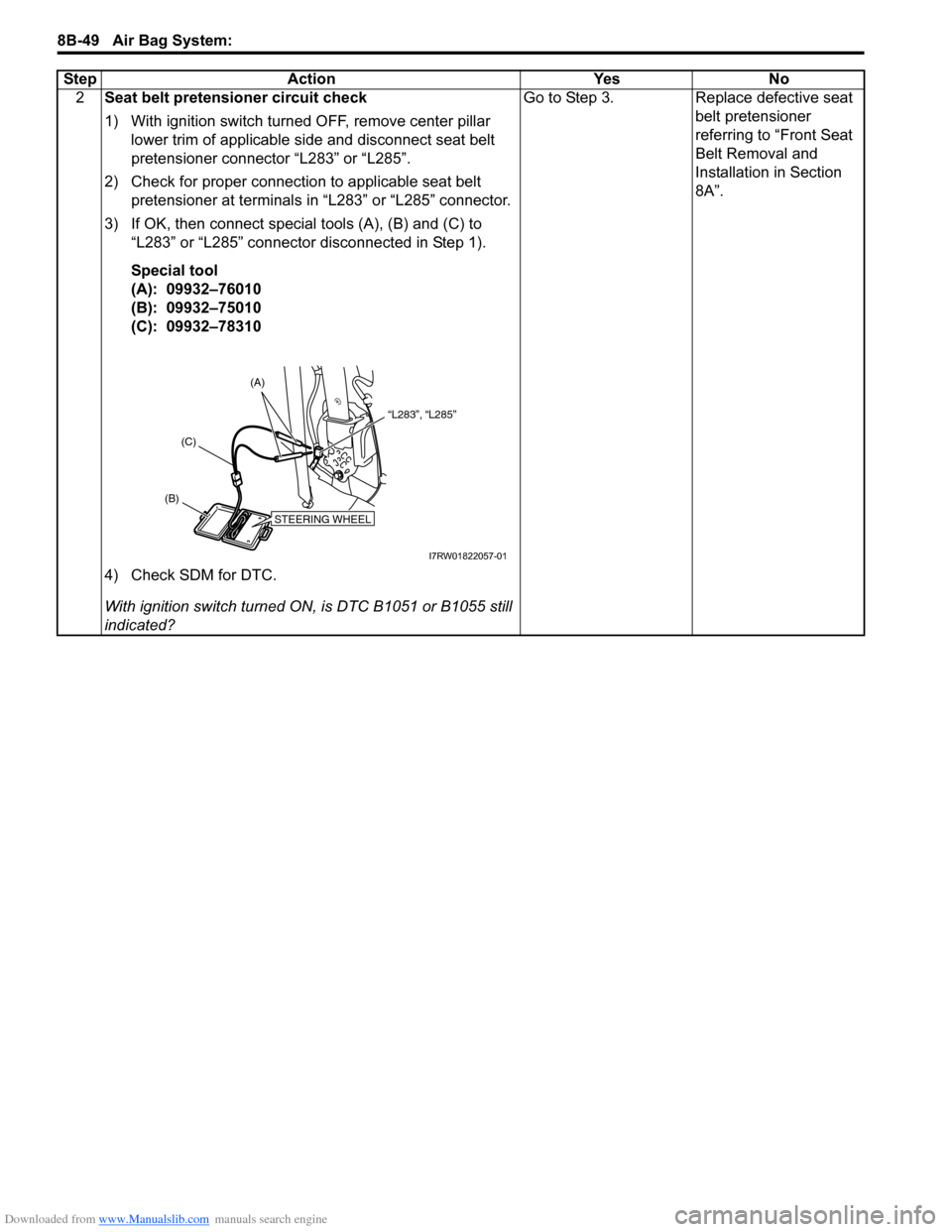

2Seat belt pretensioner circuit check

1) With ignition switch turned OFF, remove center pillar

lower trim of applicable side and disconnect seat belt

pretensioner connector “L283” or “L285”.

2) Check for proper connection to applicable seat belt

pretensioner at terminals in “L283” or “L285” connector.

3) If OK, then connect special tools (A), (B) and (C) to

“L283” or “L285” connector disconnected in Step 1).

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM for DTC.

With ignition switch turned ON, is DTC B1051 or B1055 still

indicated?Go to Step 3. Replace defective seat

belt pretensioner

referring to “Front Seat

Belt Removal and

Installation in Section

8A”. Step Action Yes No

STEERING WHEEL

(B)(C)(A)

“L283”, “L285”

I7RW01822057-01

Page 1090 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-51 Air Bag System:

DTC B1052 / B1056: Seat Belt Pretensioner Circuit Low ResistanceS6RW0D8204027

DTC B1052: Driver Seat Belt Pretensioner Circuit Low Resistance

DTC B1056: Passenger Seat Belt Pretensioner Circuit Low Resistance

Wiring Diagram

Refer to “DTC B1051 / B1055: Seat Belt Pretensioner Circuit High Resistance”.

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

DTC B1052:

Driver seat belt pretensioner circuit is less than 0.9 Ω for

more than 4 sec.

DTC B1056:

Passenger seat belt pretensioner circuit is less than 0.9 Ω

for more than 4 sec.• Driver / passenger seat belt pretensioner circuit

• Driver / passenger seat belt pretensioner

•SDM

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

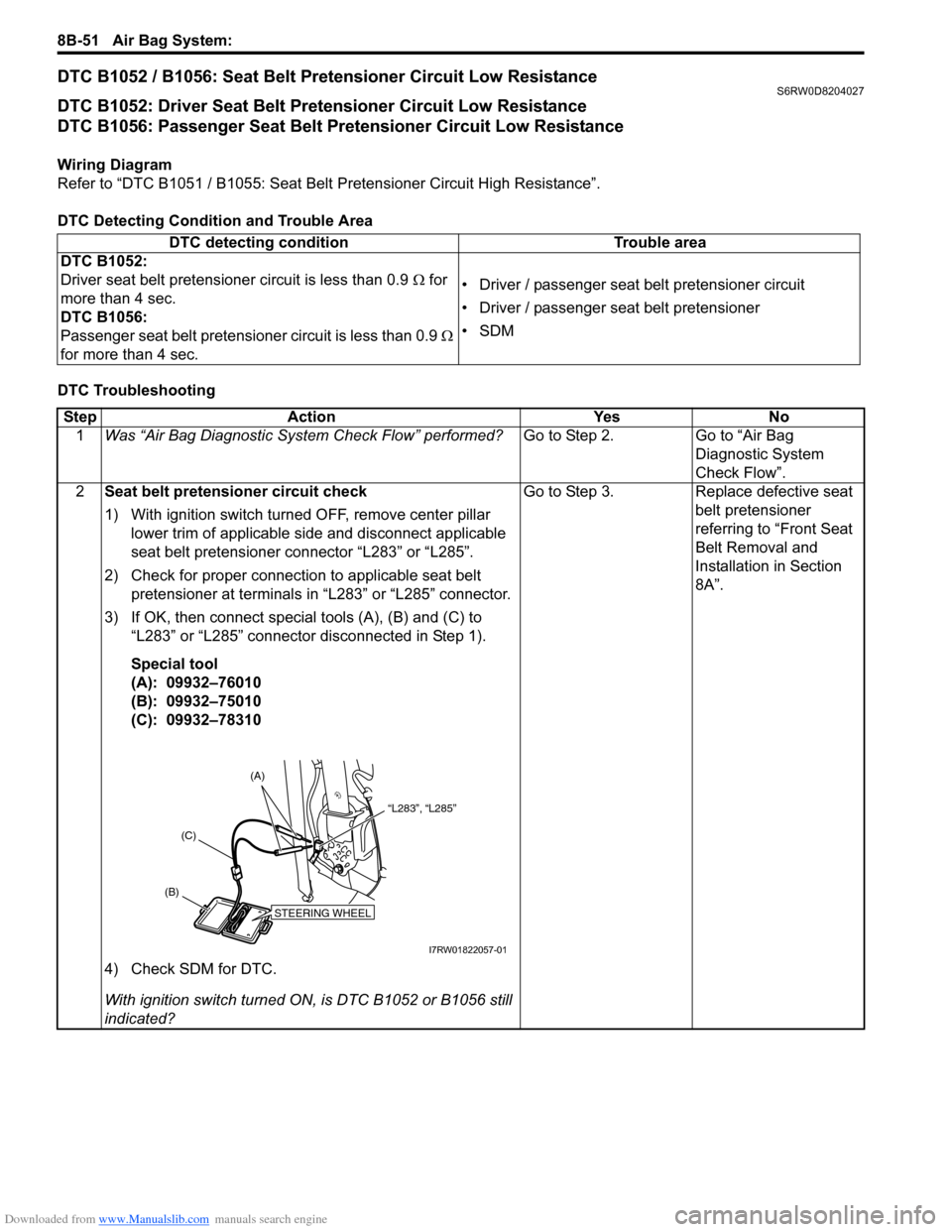

2Seat belt pretensioner circuit check

1) With ignition switch turned OFF, remove center pillar

lower trim of applicable side and disconnect applicable

seat belt pretensioner connector “L283” or “L285”.

2) Check for proper connection to applicable seat belt

pretensioner at terminals in “L283” or “L285” connector.

3) If OK, then connect special tools (A), (B) and (C) to

“L283” or “L285” connector disconnected in Step 1).

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM for DTC.

With ignition switch turned ON, is DTC B1052 or B1056 still

indicated?Go to Step 3. Replace defective seat

belt pretensioner

referring to “Front Seat

Belt Removal and

Installation in Section

8A”.

STEERING WHEEL

(B)(C)(A)

“L283”, “L285”

I7RW01822057-01

Page 1095 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-56

DTC Troubleshooting

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2Side-air bag circuit check

1) Remove applicable driver / passenger side-air bag

(inflator) module from seat back referring to “Side-Air

Bag (Inflator) Module Removal and Installation”.

2) Check for proper connection to applicable side-air bag

(inflator) module at terminal in connector “Q104” or

“Q105”.

3) If OK, then connect special tools (A), (B) and (C) to

applicable side-air bag (inflator) connector “Q104” or

“Q105”.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM for DTC.

With ignition switch turned ON, is DTC B1061 or B1065 still

indicated?Go to Step 3. Replace side-air bag

(inflator) module

referring to “Side-Air

Bag (Inflator) Module

Removal and

Installation”.

“Q104”, “Q105”

STEERING WHEEL(B) (C)

(A)

I7RW01822077-01

Page 1098 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-59 Air Bag System:

DTC B1062 / B1066: Side-Air Bag Circuit Low ResistanceS6RW0D8204054

DTC B1062: Driver Side-Air Bag Circuit Low Resistance

DTC B1066: Passenger Side-Air Bag Circuit Low Resistance

Wiring Diagram

Refer to “DTC B1061 / B1065: Side-Air Bag Circuit High Resistance”.

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

DTC B1062:

Driver side-air bag circuit is less than 1.0 Ω for more than

4 sec.

DTC B1066:

Passenger side-air bag circuit is less than 1.0 Ω for more

than 4 sec.• Driver / passenger side-air bag circuit

• Driver / passenger side-air bag module

•SDM

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2Side-air bag circuit check

1) Remove applicable driver / passenger side-air bag

(inflator) module from seat back referring to “Side-Air

Bag (Inflator) Module Removal and Installation”.

2) Check for proper connection to applicable side-air bag

(inflator) module at terminal in connector “Q104” or

“Q105”.

3) If OK, then connect special tools (A), (B) and (C) to

applicable side-air bag (inflator) connector “Q104” or

“Q105”.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM for DTC.

With ignition switch turned ON, is DTC B1062 or B1066 still

indicated?Go to Step 3. Replace side-air bag

(inflator) module

referring to “Side-Air

Bag (Inflator) Module

Removal and

Installation”.

“Q104”, “Q105”

STEERING WHEEL(B) (C)

(A)

I7RW01822077-01