relay SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1376 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 9D-2 Wipers / Washers:

Repair Instructions

Wipers and Washers ComponentsS6RW0D9406001

115

6

(b)

(a) 1 1

(b)

2

1314

14[A]

14

1215

(c)

(b)

(a)

3 SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 9D-2 Wipers / Washers:

Repair Instructions

Wipers and Washers ComponentsS6RW0D9406001

115

6

(b)

(a) 1 1

(b)

2

1314

14[A]

14

1215

(c)

(b)

(a)

3](/img/20/7612/w960_7612-1375.png)

Downloaded from www.Manualslib.com manuals search engine 9D-2 Wipers / Washers:

Repair Instructions

Wipers and Washers ComponentsS6RW0D9406001

115

6

(b)

(a) 1 1

(b)

2

1314

14[A]

14

1215

(c)

(b)

(a)

32

4

710

10

10 11118

16

9

16

I7RW01940001-03

1. Windshield wiper blade 8. Washer pump for rear washer 15. Windshield wiper bolt

:Tighten bolts in specified order.

2. Windshield wiper arm 9. Washer tank 16. Washer tank bolt

3. Windshield wiper motor 10. Washer hose[A]: Junction block viewed from relay

side

4. Windshield wiper link 11. Washer nozzle : 18 N⋅m (1.8 kgf-m, 13.0 lb-ft)

Page 1377 of 1556

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-3

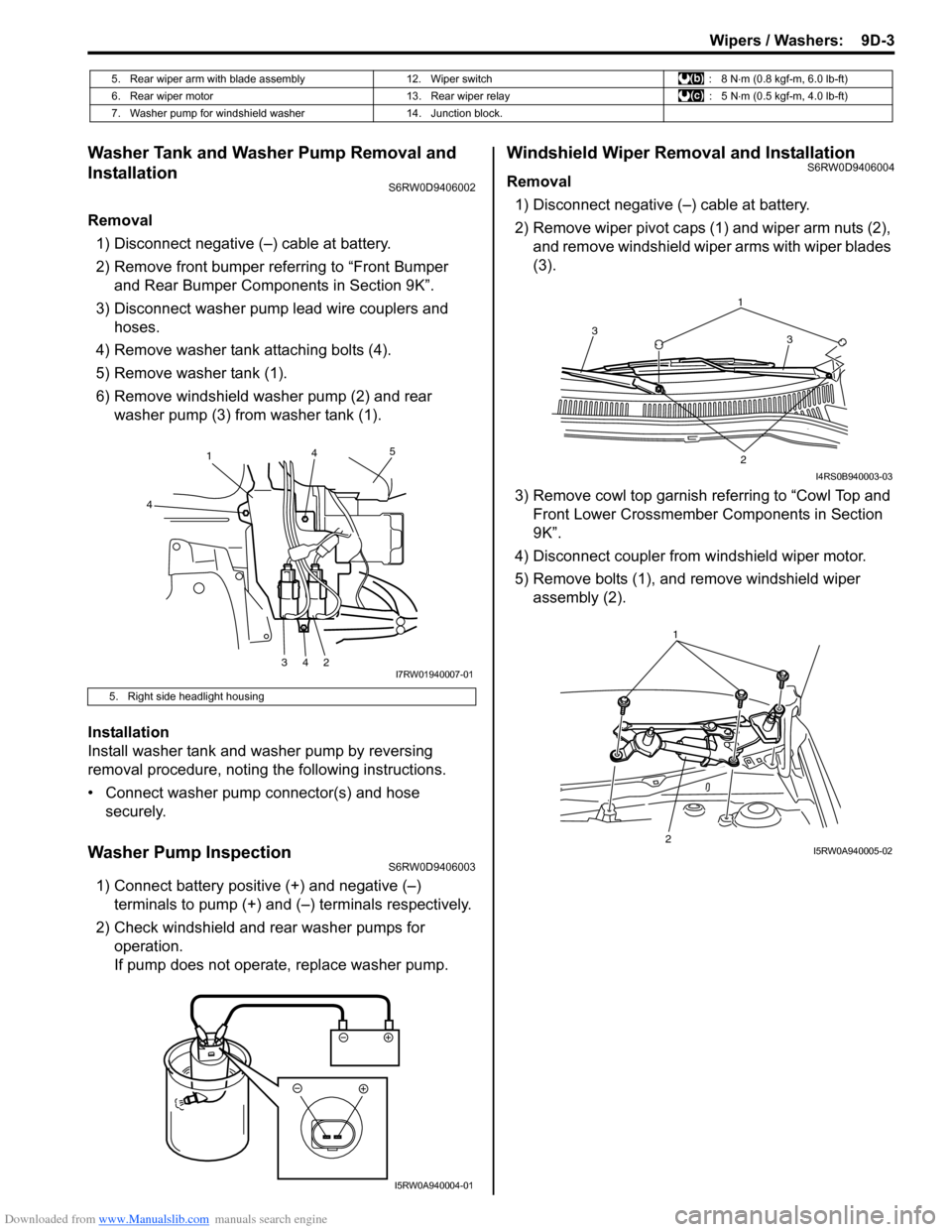

Washer Tank and Washer Pump Removal and

Installation

S6RW0D9406002

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper

and Rear Bumper Components in Section 9K”.

3) Disconnect washer pump lead wire couplers and

hoses.

4) Remove washer tank attaching bolts (4).

5) Remove washer tank (1).

6) Remove windshield washer pump (2) and rear

washer pump (3) from washer tank (1).

Installation

Install washer tank and washer pump by reversing

removal procedure, noting the following instructions.

• Connect washer pump connector(s) and hose

securely.

Washer Pump InspectionS6RW0D9406003

1) Connect battery positive (+) and negative (–)

terminals to pump (+) and (–) terminals respectively.

2) Check windshield and rear washer pumps for

operation.

If pump does not operate, replace washer pump.

Windshield Wiper Removal and InstallationS6RW0D9406004

Removal

1) Disconnect negative (–) cable at battery.

2) Remove wiper pivot caps (1) and wiper arm nuts (2),

and remove windshield wiper arms with wiper blades

(3).

3) Remove cowl top garnish referring to “Cowl Top and

Front Lower Crossmember Components in Section

9K”.

4) Disconnect coupler from windshield wiper motor.

5) Remove bolts (1), and remove windshield wiper

assembly (2).

5. Rear wiper arm with blade assembly 12. Wiper switch : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

6. Rear wiper motor 13. Rear wiper relay : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

7. Washer pump for windshield washer 14. Junction block.

5. Right side headlight housing

1

4

34245

I7RW01940007-01

I5RW0A940004-01

1

3 3

2

I4RS0B940003-03

21I5RW0A940005-02

Page 1383 of 1556

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-9

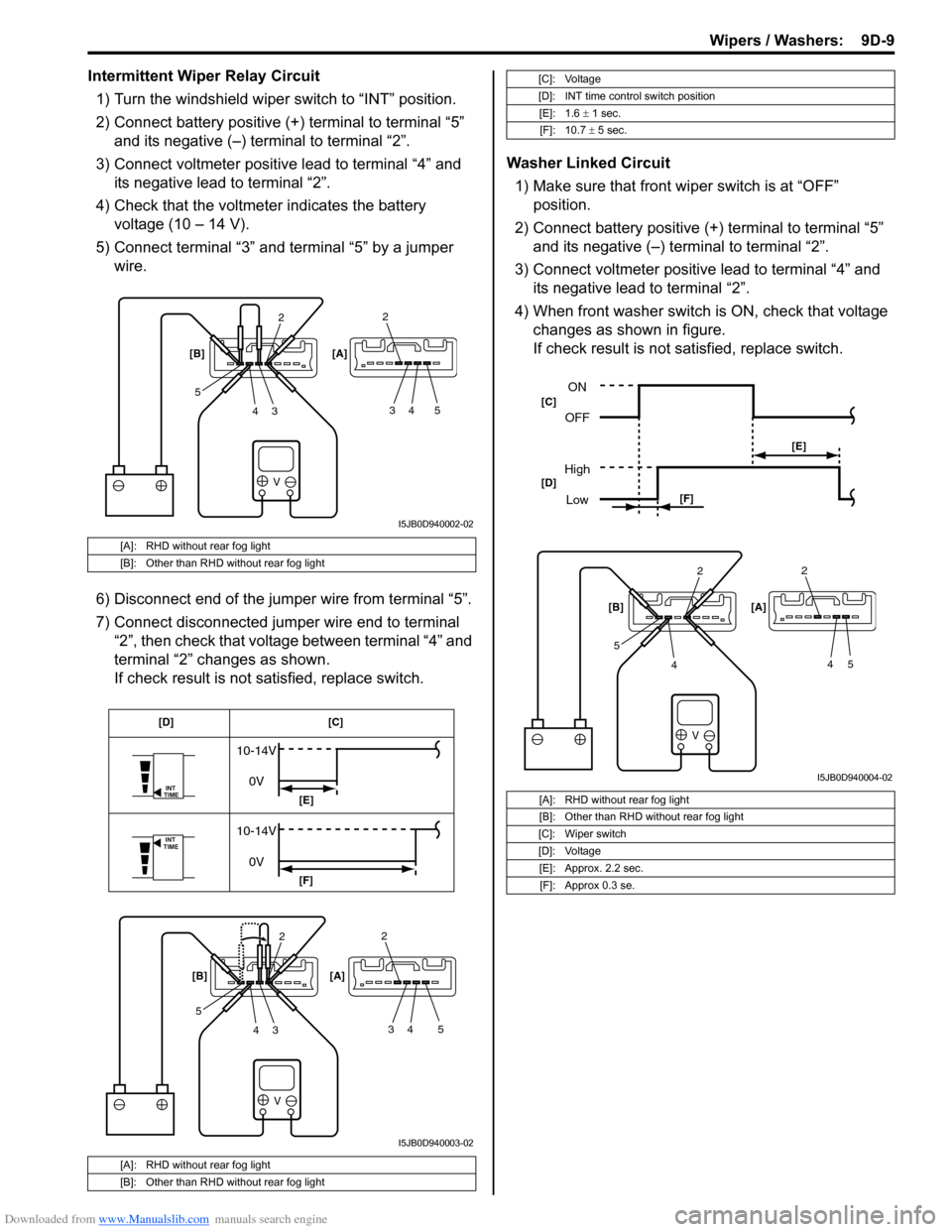

Intermittent Wiper Relay Circuit

1) Turn the windshield wiper switch to “INT” position.

2) Connect battery positive (+) terminal to terminal “5”

and its negative (–) terminal to terminal “2”.

3) Connect voltmeter positive lead to terminal “4” and

its negative lead to terminal “2”.

4) Check that the voltmeter indicates the battery

voltage (10 – 14 V).

5) Connect terminal “3” and terminal “5” by a jumper

wire.

6) Disconnect end of the jumper wire from terminal “5”.

7) Connect disconnected jumper wire end to terminal

“2”, then check that voltage between terminal “4” and

terminal “2” changes as shown.

If check result is not satisfied, replace switch.Washer Linked Circuit

1) Make sure that front wiper switch is at “OFF”

position.

2) Connect battery positive (+) terminal to terminal “5”

and its negative (–) terminal to terminal “2”.

3) Connect voltmeter positive lead to terminal “4” and

its negative lead to terminal “2”.

4) When front washer switch is ON, check that voltage

changes as shown in figure.

If check result is not satisfied, replace switch.

[A]: RHD without rear fog light

[B]: Other than RHD without rear fog light

[A]: RHD without rear fog light

[B]: Other than RHD without rear fog light

V

2

3 4 52

34 5 [B] [A]

I5JB0D940002-02

V

INT

TIME

INT

TIME

10-14V

0V

10-14V

0V

2

3 4 52

34 5 [B] [A][C] [D]

[E]

[F]

I5JB0D940003-02

[C]: Voltage

[D]: INT time control switch position

[E]: 1.6 ± 1 sec.

[F]: 10.7 ± 5 sec.

[A]: RHD without rear fog light

[B]: Other than RHD without rear fog light

[C]: Wiper switch

[D]: Voltage

[E]: Approx. 2.2 sec.

[F]: Approx 0.3 se.

V

2

4 52

45 [B] [A]

ON

OFF

High

Low

[E]

[F] [C]

[D]

I5JB0D940004-02

Page 1384 of 1556

Downloaded from www.Manualslib.com manuals search engine 9D-10 Wipers / Washers:

Rear Wiper and Washer Switch Removal and

Installation

S6RW0D9406010

For removal and installation, refer to “Windshield Wiper

and Washer Switch Removal and Installation”.

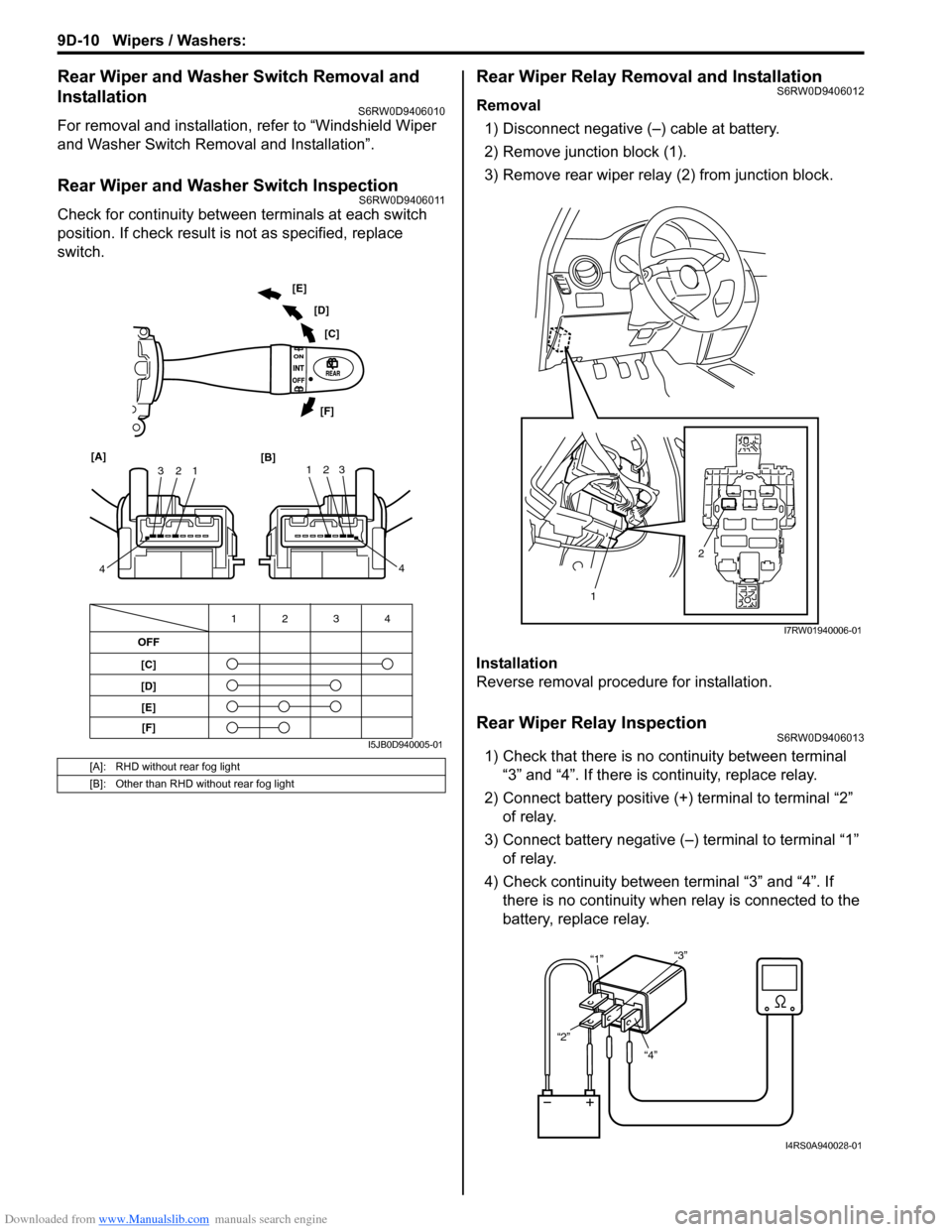

Rear Wiper and Washer Switch InspectionS6RW0D9406011

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Rear Wiper Relay Removal and InstallationS6RW0D9406012

Removal

1) Disconnect negative (–) cable at battery.

2) Remove junction block (1).

3) Remove rear wiper relay (2) from junction block.

Installation

Reverse removal procedure for installation.

Rear Wiper Relay InspectionS6RW0D9406013

1) Check that there is no continuity between terminal

“3” and “4”. If there is continuity, replace relay.

2) Connect battery positive (+) terminal to terminal “2”

of relay.

3) Connect battery negative (–) terminal to terminal “1”

of relay.

4) Check continuity between terminal “3” and “4”. If

there is no continuity when relay is connected to the

battery, replace relay.[A]: RHD without rear fog light

[B]: Other than RHD without rear fog light

OFF

[C]

[D]4 3 12

1 2 3

4 [A]

[B]123

4 [C] [D] [E]

[F]

[E]

[F]

I5JB0D940005-01

2

1

I7RW01940006-01

“4” “2”“1”“3”

I4RS0A940028-01

Page 1388 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-3 Glass / Windows / Mirrors:

Diagnostic Information and Procedures

Rear End door Window Defogger Symptom DiagnosisS6RW0D9504001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Window Control System Symptom DiagnosisS6RW0D9504002

Condition Possible cause Correction / Reference Item

Rear end door window

defogger does not

operateCircuit fuse blownReplace fuse and check for short circuit.

Rear end door window defogger switch

faultyCheck rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faultyCheck rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Defogger wire faultyCheck defogger wire referring to “Rear End

Door Window Defogger Wire Inspection”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

All power windows do not

operateCircuit fuse blownReplace fuse and check for short circuit.

Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Ignition switch faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

Only one power window

does not operatePower window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window sub switch faultyCheck power window sub switch referring to

“Power Window Sub Switch Inspection”.

Wiring and/or coupler faultyCheck wiring and/or coupler.

Power window regulator faultyCheck window regulator.

Power window motor faultyCheck power window motor.

Wiring or grounding faultyRepair circuit.

Driver side door glass

fails to perform auto-up /

auto-down function

(Pinching Prevention

Function Model)Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window motor faultyCheck power window motor referring to “Pulse

Sensor and Its Circuit Inspection (Pinching

Prevention Function Model)”.

Wiring or grounding faultyRepair circuit.

Driver side door glass

fails to lower back even

when a foreign matter is

pinched (Pinching

Prevention Function

Model)Power window main switch has not been

initializedExecute the initial setting of power window

main switch referring to “Power Window Main

Switch Initialization (Pinching Prevention

Function Model)”.

Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window motor faultyCheck power window motor referring to “Pulse

Sensor and Its Circuit Inspection (Pinching

Prevention Function Model)”.

Page 1390 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-5 Glass / Windows / Mirrors:

Door Mirror Heater Symptom Diagnosis (If Equipped)S6RW0D9504004

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Repair Instructions

Windshield ComponentsS6RW0D9506001

Condition Possible cause Correction / Reference Item

All door mirror heaters

does not operateCircuit fuse blownReplace fuse and check for short circuit.

Rear end door window defogger switch

faultyCheck rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faultyCheck rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Only one door mirror

heater does not operateDoor mirror heater faultyCheck door mirror heater refiring to “Door

Mirror Heater Inspection (If Equipped)”.

Wiring or grounding faultyRepair circuit.

3 31

2

44

4

I5RW0A950001-02

1. Windshield glass 3. Windshield glass stopper : Do not reuse.

2. Windshield molding 4. Spacer

Page 1404 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-19 Glass / Windows / Mirrors:

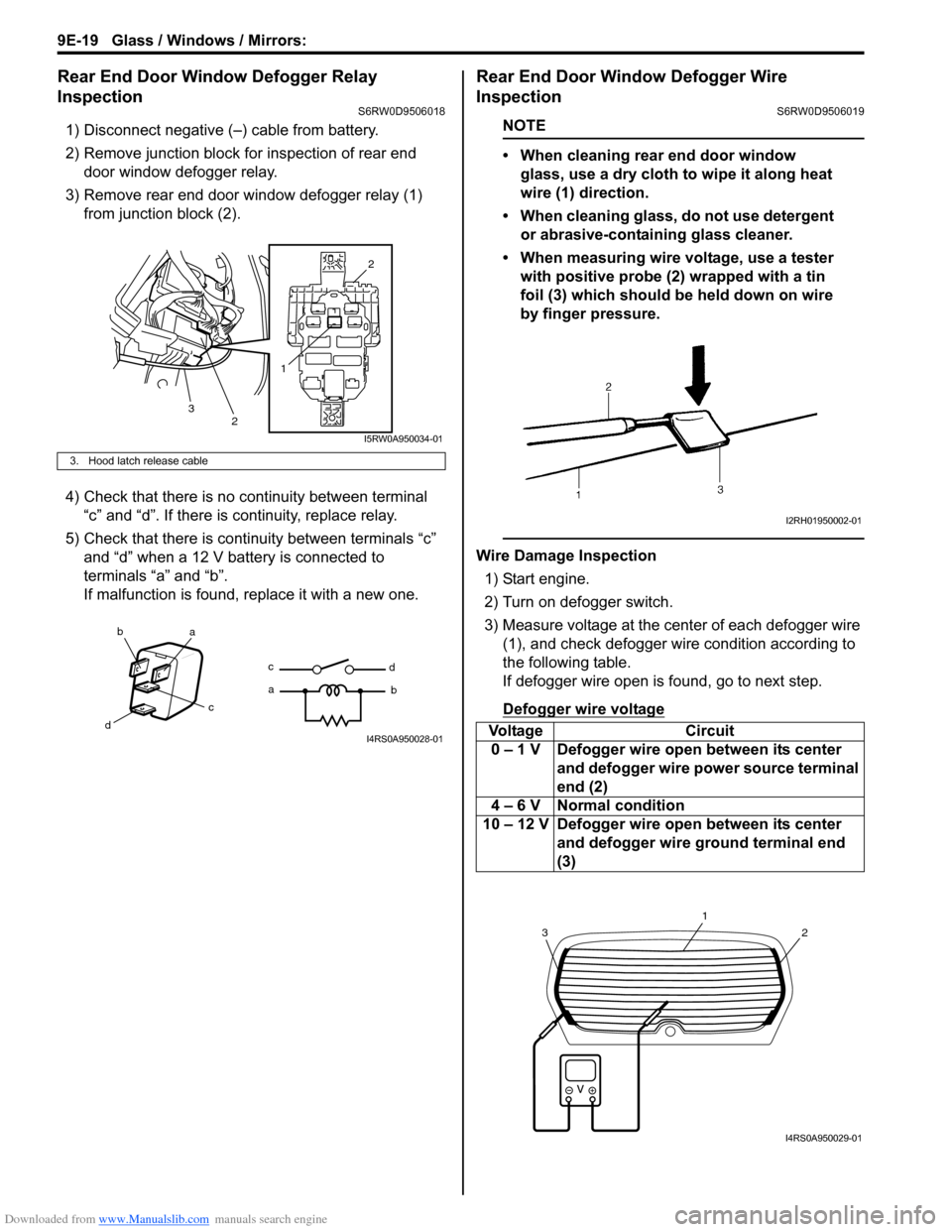

Rear End Door Window Defogger Relay

Inspection

S6RW0D9506018

1) Disconnect negative (–) cable from battery.

2) Remove junction block for inspection of rear end

door window defogger relay.

3) Remove rear end door window defogger relay (1)

from junction block (2).

4) Check that there is no continuity between terminal

“c” and “d”. If there is continuity, replace relay.

5) Check that there is continuity between terminals “c”

and “d” when a 12 V battery is connected to

terminals “a” and “b”.

If malfunction is found, replace it with a new one.

Rear End Door Window Defogger Wire

Inspection

S6RW0D9506019

NOTE

• When cleaning rear end door window

glass, use a dry cloth to wipe it along heat

wire (1) direction.

• When cleaning glass, do not use detergent

or abrasive-containing glass cleaner.

• When measuring wire voltage, use a tester

with positive probe (2) wrapped with a tin

foil (3) which should be held down on wire

by finger pressure.

Wire Damage Inspection

1) Start engine.

2) Turn on defogger switch.

3) Measure voltage at the center of each defogger wire

(1), and check defogger wire condition according to

the following table.

If defogger wire open is found, go to next step.

Defogger wire voltage

3. Hood latch release cable

12

2

3

I5RW0A950034-01

ba

c

dc

ad

bI4RS0A950028-01Voltage Circuit

0 – 1 V Defogger wire open between its center

and defogger wire power source terminal

end (2)

4 – 6 V Normal condition

10 – 12 V Defogger wire open between its center

and defogger wire ground terminal end

(3)

I2RH01950002-01

2

1

3

I4RS0A950029-01

Page 1412 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-1 Security and Locks:

Body, Cab and Accessories

Security and Locks

General Description

Key Coding ConstructionS6RW0D9601001

Key Usage and Identification

Key is used for ignition and door lock cylinders. Key is cut on both edges to make them reversible.

Key identification is obtained from five character key code stamped on key code tag. Using this key code, key code

cutting combination can be determined from a code list (available to owners of key cutting equipment from suppliers).

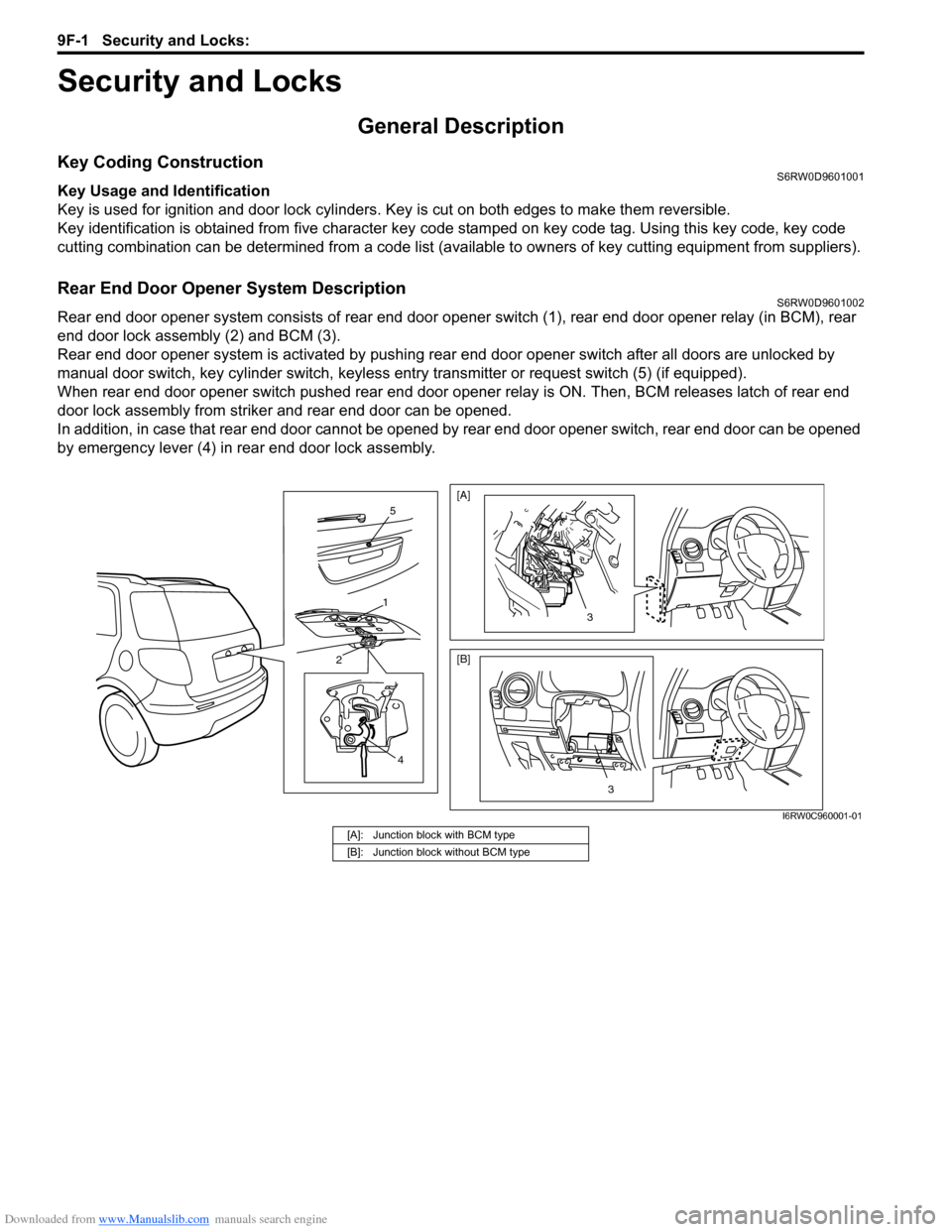

Rear End Door Opener System DescriptionS6RW0D9601002

Rear end door opener system consists of rear end door opener switch (1), rear end door opener relay (in BCM), rear

end door lock assembly (2) and BCM (3).

Rear end door opener system is activated by pushing rear end door opener switch after all doors are unlocked by

manual door switch, key cylinder switch, keyless entry transmitter or request switch (5) (if equipped).

When rear end door opener switch pushed rear end door opener relay is ON. Then, BCM releases latch of rear end

door lock assembly from striker and rear end door can be opened.

In addition, in case that rear end door cannot be opened by rear end door opener switch, rear end door can be opened

by emergency lever (4) in rear end door lock assembly.

4

2

1

5

3

[A]

[B]

3

I6RW0C960001-01

[A]: Junction block with BCM type

[B]: Junction block without BCM type

Page 1415 of 1556

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-4

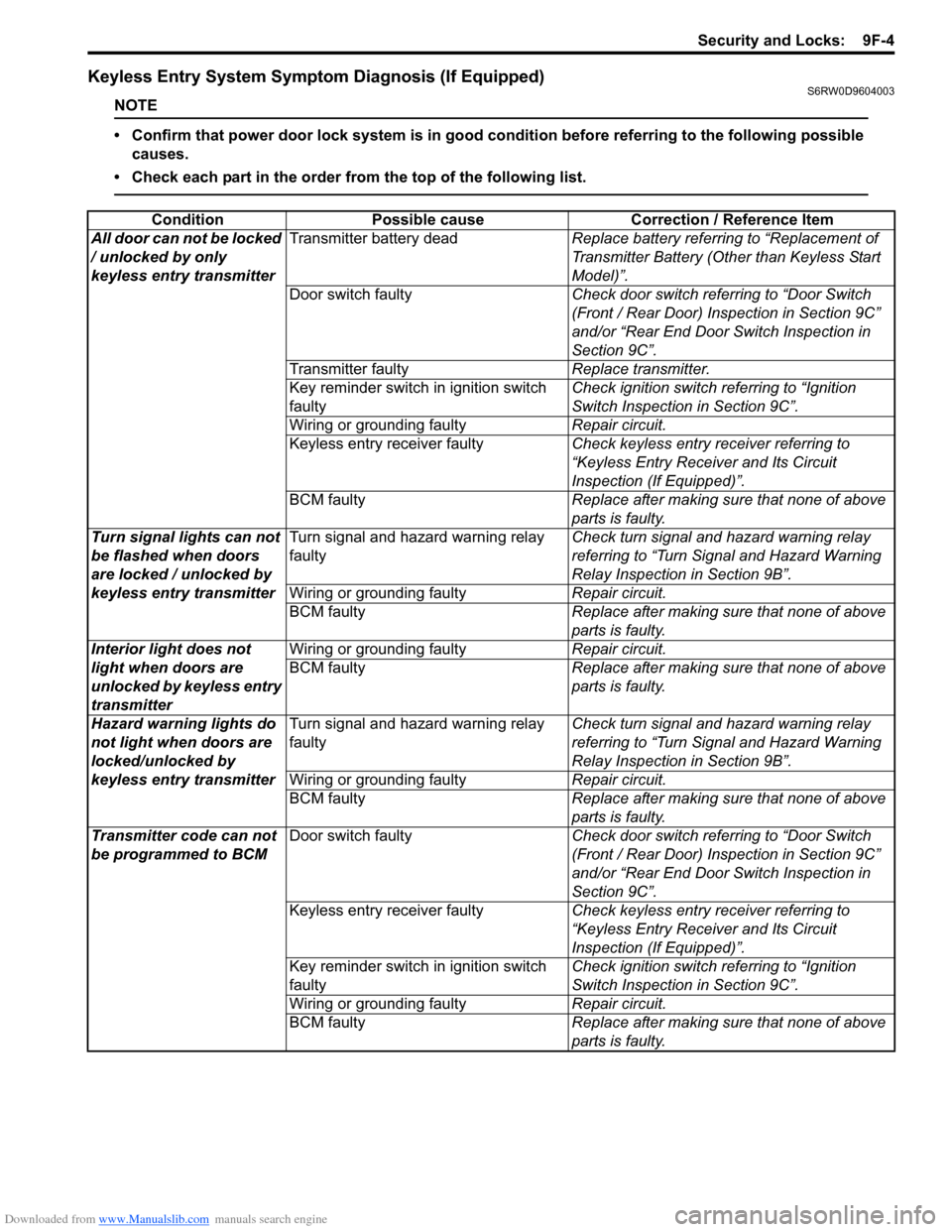

Keyless Entry System Symptom Diagnosis (If Equipped)S6RW0D9604003

NOTE

• Confirm that power door lock system is in good condition before referring to the following possible

causes.

• Check each part in the order from the top of the following list.

Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by only

keyless entry transmitterTransmitter battery deadReplace battery referring to “Replacement of

Transmitter Battery (Other than Keyless Start

Model)”.

Door switch faultyCheck door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Transmitter faultyReplace transmitter.

Key reminder switch in ignition switch

faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

Keyless entry receiver faultyCheck keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection (If Equipped)”.

BCM faultyReplace after making sure that none of above

parts is faulty.

Turn signal lights can not

be flashed when doors

are locked / unlocked by

keyless entry transmitterTurn signal and hazard warning relay

faultyCheck turn signal and hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection in Section 9B”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Interior light does not

light when doors are

unlocked by keyless entry

transmitterWiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Hazard warning lights do

not light when doors are

locked/unlocked by

keyless entry transmitterTurn signal and hazard warning relay

faultyCheck turn signal and hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection in Section 9B”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Transmitter code can not

be programmed to BCMDoor switch faultyCheck door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Keyless entry receiver faultyCheck keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection (If Equipped)”.

Key reminder switch in ignition switch

faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1474 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-1 Body Electrical Control System:

Control Systems

Body Electrical Control System

Precautions

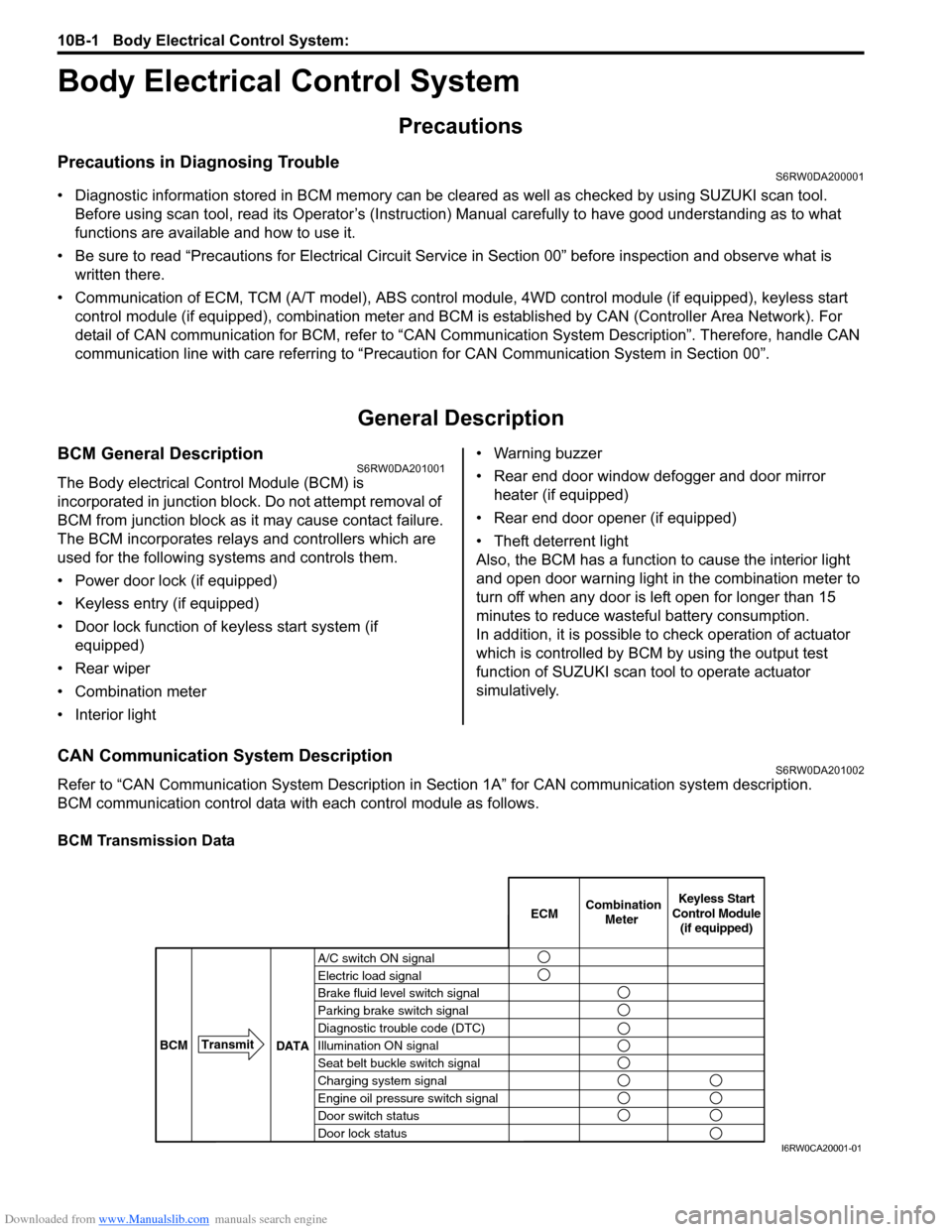

Precautions in Diagnosing TroubleS6RW0DA200001

• Diagnostic information stored in BCM memory can be cleared as well as checked by using SUZUKI scan tool.

Before using scan tool, read its Operator’s (Instruction) Manual carefully to have good understanding as to what

functions are available and how to use it.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection and observe what is

written there.

• Communication of ECM, TCM (A/T model), ABS control module, 4WD control module (if equipped), keyless start

control module (if equipped), combination meter and BCM is established by CAN (Controller Area Network). For

detail of CAN communication for BCM, refer to “CAN Communication System Description”. Therefore, handle CAN

communication line with care referring to “Precaution for CAN Communication System in Section 00”.

General Description

BCM General DescriptionS6RW0DA201001

The Body electrical Control Module (BCM) is

incorporated in junction block. Do not attempt removal of

BCM from junction block as it may cause contact failure.

The BCM incorporates relays and controllers which are

used for the following systems and controls them.

• Power door lock (if equipped)

• Keyless entry (if equipped)

• Door lock function of keyless start system (if

equipped)

• Rear wiper

• Combination meter

• Interior light• Warning buzzer

• Rear end door window defogger and door mirror

heater (if equipped)

• Rear end door opener (if equipped)

• Theft deterrent light

Also, the BCM has a function to cause the interior light

and open door warning light in the combination meter to

turn off when any door is left open for longer than 15

minutes to reduce wasteful battery consumption.

In addition, it is possible to check operation of actuator

which is controlled by BCM by using the output test

function of SUZUKI scan tool to operate actuator

simulatively.

CAN Communication System DescriptionS6RW0DA201002

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

BCM communication control data with each control module as follows.

BCM Transmission Data

A/C switch ON signal

Electric load signal

Brake fluid level switch signal

Parking brake switch signal

Diagnostic trouble code (DTC)

Illumination ON signal

Seat belt buckle switch signal

Charging system signal

Engine oil pressure switch signal

Door switch status

Door lock statusECMKeyless Start

Control Module

(if equipped) Combination

Meter

BCMTransmit

DATA

I6RW0CA20001-01