300 SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 160 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-110 Engine General Information and Diagnosis:

DTC P0300 / P0301 / P0302 / P0303 / P0304: Random Misfire Detected / Cylinder 1 / Cylinder 2 /

Cylinder 3 / Cylinder 4 Misfire Detected

S6RW0D1104039

System Description

ECM measures the angle of the crankshaft based on the pulse signal from the CKP sensor and CMP sensor for each

cylinder. If it detects a large change in the angle speed of the crankshaft, it concludes occurrence of a misfire. When

the number of misfire is counted by ECM beyond the DTC detecting condition, it determines the cylinder where the

misfire occurred and output it as DTC.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temp.: –7 °C, 19.4 °F or more

• Engine coolant temp.: –10 °C, 14 °F or more

• Altitude (barometric pressure): 2500 m, 8200 ft or less (560 mmHg, 74.4 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and print Freeze Frame Data or write them down using scan tool.

3) Clear DTC using scan tool.

4) Drive vehicle under freeze frame data condition as noted for 1 min. or more.

5) Stop vehicle and check DTC and pending DTC.DTC detecting condition Trouble area

DTC P0300:

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is detected

at 2 or more cylinders. (MIL flashes as long as this misfire occurs continuously.)

or

• Misfire, which affects exhaust emission adversely during 1000 engine revolution, is

detected at 2 or more cylinders. (2 driving cycle detection logic)• Ignition system

• Fuel injector and its circuit

• Fuel pressure

• EGR system

• Abnormal air drawn in

• Engine compression

• Valve lash adjuster

• Valve timing

• Fuel shortage

• Exhaust system

• Fuel of poor quality DTC P0301, P0302, P0303, P0304:

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is detected

at 1 cylinder. (MIL flashes as long as this misfire occurs continuously.)

or

• Misfire, which affects exhaust emission adversely during 1000 engine revolution, is

detected at 1 cylinder. (2 driving cycle detection logic)

Page 170 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-120 Engine General Information and Diagnosis:

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions are satisfied when using this “DTC confirmation

procedure”.

• Intake air temperature at engine start: –10 °C (14 °F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 70 °C (158 °F) or more

• Altitude (barometric pressure): 2500 m, 8200 ft or less (560 mmHg, 74.4 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up to normal operating temperature.

4) Run engine at idle for 10 min.

5) Drive vehicle and increase engine speed 3000 rpm in 3rd gear or “3” range.

6) Release accelerator pedal and with engine brake applied, keep vehicle coasting for 5 sec. or more. (Keep fuel cut

condition for 5 sec. or more) If fuel cut condition is not kept for 5 sec. or more, coast down a slope in engine speed

1000 – 3000 rpm for 5 sec. or more.

7) Stop vehicle and run engine at idle.

8) For european market model, check whether EGR system readiness/monitoring test has completed or not by using

scan tool.

If evaporative system readiness/monitoring test has not completed, check vehicle conditions (environmental) and

repeat Steps 3) through 7).

9) Check DTC and pending DTC.DTC detecting condition Trouble area

DTC P0401:

Difference in intake manifold absolute pressure between opened EGR valve and closed

EGR valve is smaller than specified value.

(2 driving cycle detection logic, monitoring once / 1 driving)

DTC P0402:

Difference in intake manifold absolute pressure between opened EGR valve and closed

EGR valve is larger than specified value.

(2 driving cycle detection logic, monitoring once / 1 driving)• EGR valve

• EGR passage

• MAP sensor

•ECM

Page 228 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-178 Engine General Information and Diagnosis:

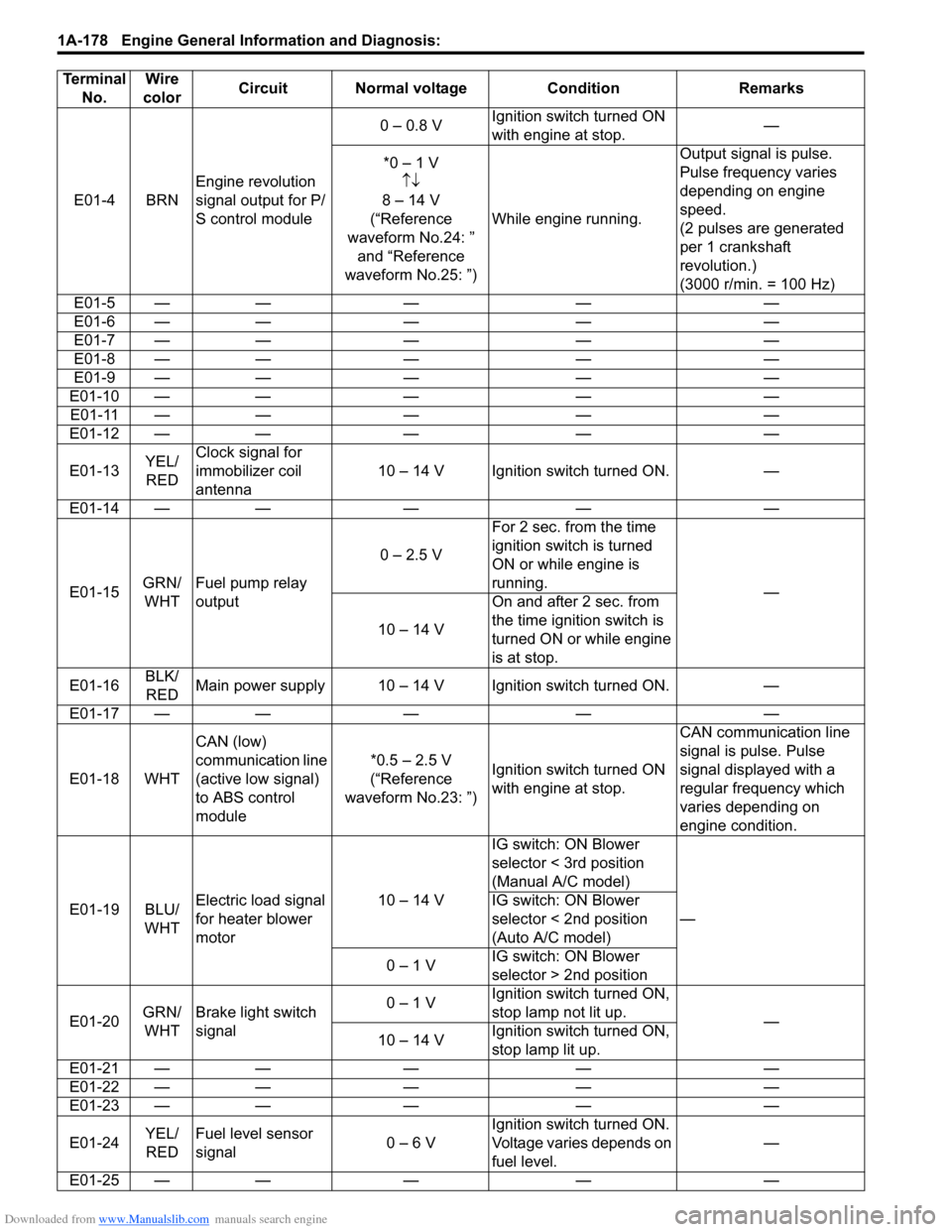

E01-4 BRNEngine revolution

signal output for P/

S control module0 – 0.8 VIgnition switch turned ON

with engine at stop.—

*0 – 1 V

↑↓

8 – 14 V

(“Reference

waveform No.24: ”

and “Reference

waveform No.25: ”)While engine running.Output signal is pulse.

Pulse frequency varies

depending on engine

speed.

(2 pulses are generated

per 1 crankshaft

revolution.)

(3000 r/min. = 100 Hz)

E01-5 — — — — —

E01-6 — — — — —

E01-7 — — — — —

E01-8 — — — — —

E01-9 — — — — —

E01-10 — — — — —

E01-11 — — — — —

E01-12 — — — — —

E01-13YEL/

REDClock signal for

immobilizer coil

antenna10 – 14 V Ignition switch turned ON. —

E01-14 — — — — —

E01-15GRN/

WHTFuel pump relay

output0 – 2.5 VFor 2 sec. from the time

ignition switch is turned

ON or while engine is

running.

—

10 – 14 VOn and after 2 sec. from

the time ignition switch is

turned ON or while engine

is at stop.

E01-16BLK/

REDMain power supply 10 – 14 V Ignition switch turned ON. —

E01-17 — — — — —

E01-18 WHTCAN (low)

communication line

(active low signal)

to ABS control

module*0.5 – 2.5 V

(“Reference

waveform No.23: ”)Ignition switch turned ON

with engine at stop.CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition.

E01-19 BLU/

WHTElectric load signal

for heater blower

motor10 – 14 VIG switch: ON Blower

selector < 3rd position

(Manual A/C model)

— IG switch: ON Blower

selector < 2nd position

(Auto A/C model)

0 – 1 VIG switch: ON Blower

selector > 2nd position

E01-20GRN/

WHTBrake light switch

signal0 – 1 VIgnition switch turned ON,

stop lamp not lit up.

—

10 – 14 VIgnition switch turned ON,

stop lamp lit up.

E01-21 — — — — —

E01-22 — — — — —

E01-23 — — — — —

E01-24YEL/

REDFuel level sensor

signal0 – 6 VIgnition switch turned ON.

Voltage varies depends on

fuel level.—

E01-25 — — — — — Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks

Page 269 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-1

Engine

Engine Electrical Devices

Repair Instructions

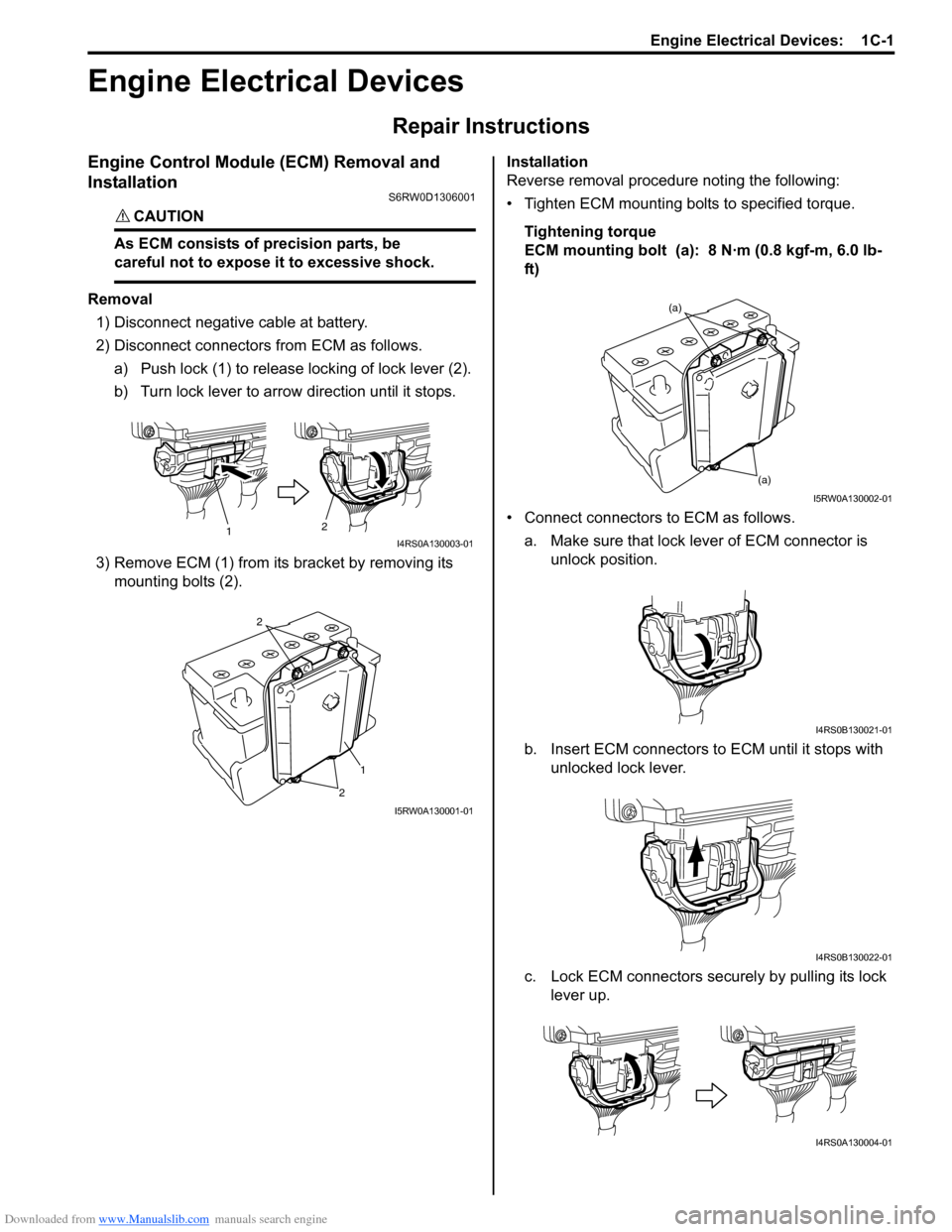

Engine Control Module (ECM) Removal and

Installation

S6RW0D1306001

CAUTION!

As ECM consists of precision parts, be

careful not to expose it to excessive shock.

Removal

1) Disconnect negative cable at battery.

2) Disconnect connectors from ECM as follows.

a) Push lock (1) to release locking of lock lever (2).

b) Turn lock lever to arrow direction until it stops.

3) Remove ECM (1) from its bracket by removing its

mounting bolts (2).Installation

Reverse removal procedure noting the following:

• Tighten ECM mounting bolts to specified torque.

Tightening torque

ECM mounting bolt (a): 8 N·m (0.8 kgf-m, 6.0 lb-

ft)

• Connect connectors to ECM as follows.

a. Make sure that lock lever of ECM connector is

unlock position.

b. Insert ECM connectors to ECM until it stops with

unlocked lock lever.

c. Lock ECM connectors securely by pulling its lock

lever up.

12I4RS0A130003-01

1

2 2

I5RW0A130001-01

(a) (a)

I5RW0A130002-01

I4RS0B130021-01

I4RS0B130022-01

I4RS0A130004-01

Page 270 of 1556

Downloaded from www.Manualslib.com manuals search engine 1C-2 Engine Electrical Devices:

Manifold Absolute Pressure (MAP) Sensor

Inspection (If Equipped)

S6RW0D1306002

1) Remove air cleaner assembly.

2) Disconnect connector from MAP sensor.

3) Remove MAP sensor.

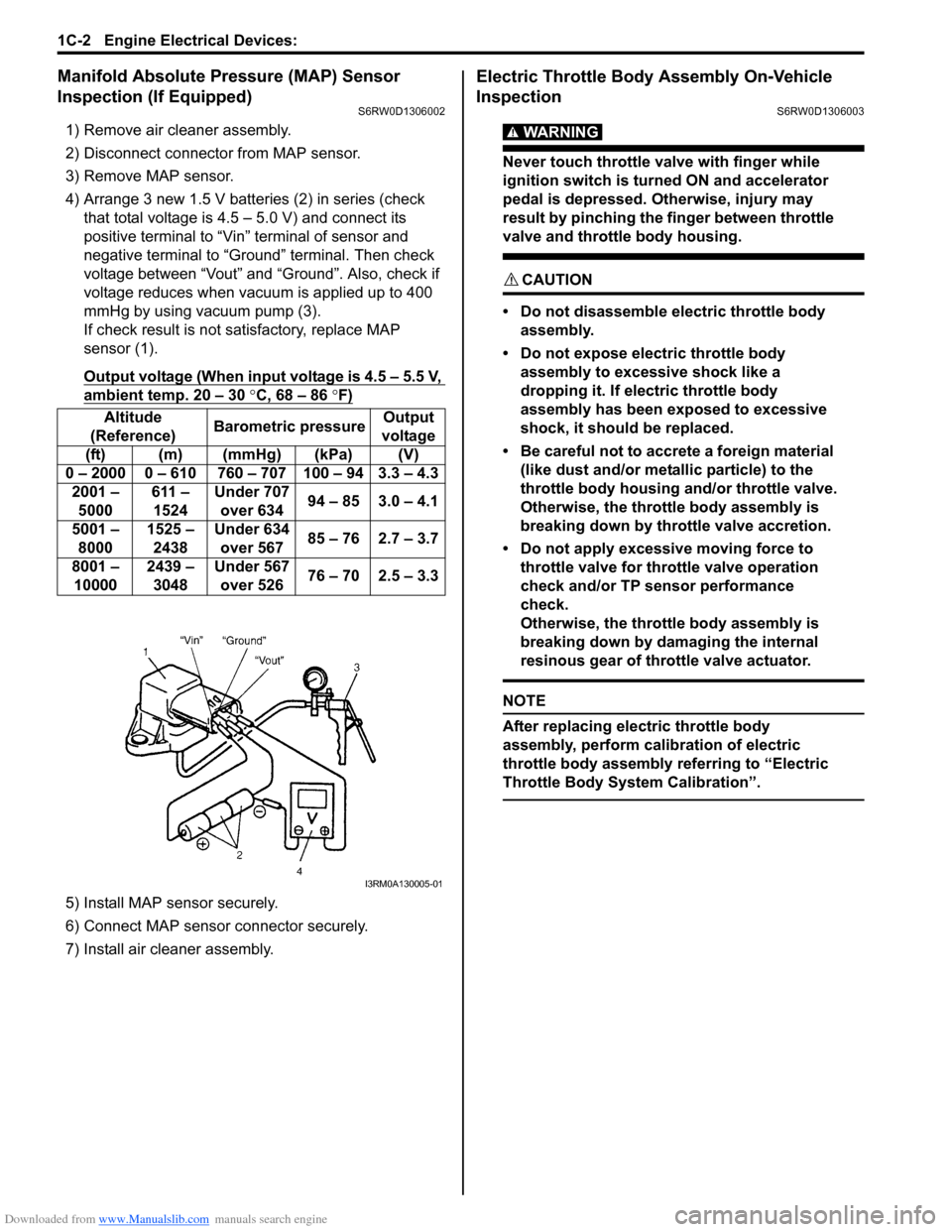

4) Arrange 3 new 1.5 V batteries (2) in series (check

that total voltage is 4.5 – 5.0 V) and connect its

positive terminal to “Vin” terminal of sensor and

negative terminal to “Ground” terminal. Then check

voltage between “Vout” and “Ground”. Also, check if

voltage reduces when vacuum is applied up to 400

mmHg by using vacuum pump (3).

If check result is not satisfactory, replace MAP

sensor (1).

Output voltage (When input voltage is 4.5 – 5.5 V,

ambient temp. 20 – 30 °C, 68 – 86 °F)

5) Install MAP sensor securely.

6) Connect MAP sensor connector securely.

7) Install air cleaner assembly.

Electric Throttle Body Assembly On-Vehicle

Inspection

S6RW0D1306003

WARNING!

Never touch throttle valve with finger while

ignition switch is turned ON and accelerator

pedal is depressed. Otherwise, injury may

result by pinching the finger between throttle

valve and throttle body housing.

CAUTION!

• Do not disassemble electric throttle body

assembly.

• Do not expose electric throttle body

assembly to excessive shock like a

dropping it. If electric throttle body

assembly has been exposed to excessive

shock, it should be replaced.

• Be careful not to accrete a foreign material

(like dust and/or metallic particle) to the

throttle body housing and/or throttle valve.

Otherwise, the throttle body assembly is

breaking down by throttle valve accretion.

• Do not apply excessive moving force to

throttle valve for throttle valve operation

check and/or TP sensor performance

check.

Otherwise, the throttle body assembly is

breaking down by damaging the internal

resinous gear of throttle valve actuator.

NOTE

After replacing electric throttle body

assembly, perform calibration of electric

throttle body assembly referring to “Electric

Throttle Body System Calibration”.

Altitude

(Reference)Barometric pressureOutput

voltage

(ft) (m) (mmHg) (kPa) (V)

0 – 2000 0 – 610 760 – 707 100 – 94 3.3 – 4.3

2001 –

5000611 –

1524Under 707

over 63494 – 85 3.0 – 4.1

5001 –

80001525 –

2438Under 634

over 56785 – 76 2.7 – 3.7

8001 –

100002439 –

3048Under 567

over 52676 – 70 2.5 – 3.3

I3RM0A130005-01

Page 271 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-3

Throttle Valve Visual Check

1) Remove air cleaner outlet hose.

2) Check that there isn’t any foreign matter caught

between throttle valve and throttle body housing. If

there is, take it out after removing throttle body

referring to “Electric Throttle Body Assembly

Removal and Installation in Section 1D” and clean

inside of throttle body thoroughly.

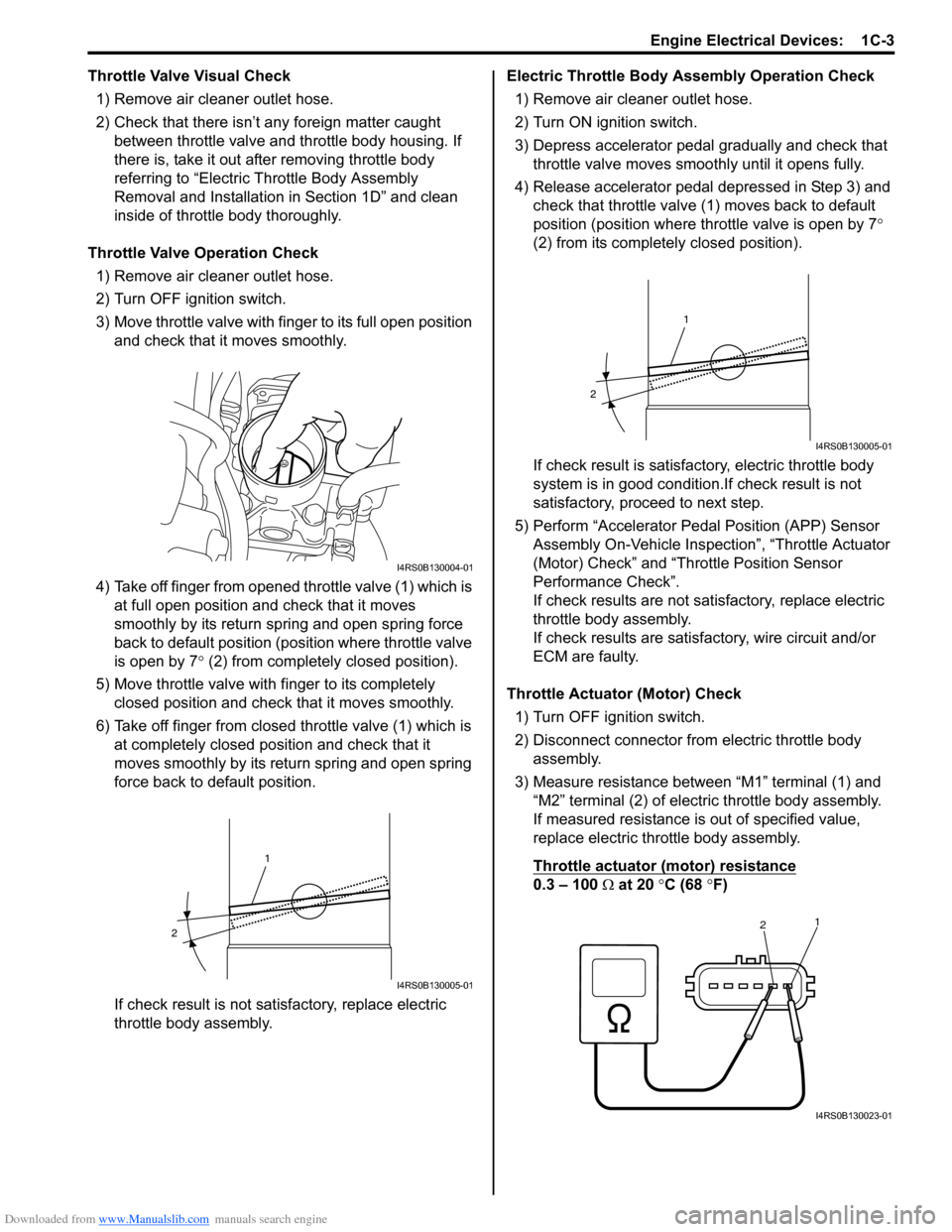

Throttle Valve Operation Check

1) Remove air cleaner outlet hose.

2) Turn OFF ignition switch.

3) Move throttle valve with finger to its full open position

and check that it moves smoothly.

4) Take off finger from opened throttle valve (1) which is

at full open position and check that it moves

smoothly by its return spring and open spring force

back to default position (position where throttle valve

is open by 7° (2) from completely closed position).

5) Move throttle valve with finger to its completely

closed position and check that it moves smoothly.

6) Take off finger from closed throttle valve (1) which is

at completely closed position and check that it

moves smoothly by its return spring and open spring

force back to default position.

If check result is not satisfactory, replace electric

throttle body assembly.Electric Throttle Body Assembly Operation Check

1) Remove air cleaner outlet hose.

2) Turn ON ignition switch.

3) Depress accelerator pedal gradually and check that

throttle valve moves smoothly until it opens fully.

4) Release accelerator pedal depressed in Step 3) and

check that throttle valve (1) moves back to default

position (position where throttle valve is open by 7°

(2) from its completely closed position).

If check result is satisfactory, electric throttle body

system is in good condition.If check result is not

satisfactory, proceed to next step.

5) Perform “Accelerator Pedal Position (APP) Sensor

Assembly On-Vehicle Inspection”, “Throttle Actuator

(Motor) Check” and “Throttle Position Sensor

Performance Check”.

If check results are not satisfactory, replace electric

throttle body assembly.

If check results are satisfactory, wire circuit and/or

ECM are faulty.

Throttle Actuator (Motor) Check

1) Turn OFF ignition switch.

2) Disconnect connector from electric throttle body

assembly.

3) Measure resistance between “M1” terminal (1) and

“M2” terminal (2) of electric throttle body assembly.

If measured resistance is out of specified value,

replace electric throttle body assembly.

Throttle actuator (motor) resistance

0.3 – 100 Ω at 20 °C (68 °F)

I4RS0B130004-01

1

2

I4RS0B130005-01

1

2

I4RS0B130005-01

21

I4RS0B130023-01

Page 272 of 1556

Downloaded from www.Manualslib.com manuals search engine 1C-4 Engine Electrical Devices:

Throttle Position Sensor Performance Check

1) Remove air cleaner outlet hose.

2) Turn OFF ignition switch.

3) Disconnect connector from electric throttle body

assembly.

4) Check throttle position sensor (main and sub) output

voltage as following steps.

a) For throttle position sensor (main), arrange 3

new 1.5 V batteries (1) in series (check that total

voltage is 4.5 – 5.0 V) and connect its positive

terminal to “Vin” terminal (2) and negative

terminal to “Ground” terminal (3) of sensor. Then

using voltmeter, connect positive terminal to

“Vout 1” terminal (4) of sensor and negative

terminal to battery.

b) For throttle position sensor (sub), arrange 3 new

1.5 V batteries (1) in series (check that total

voltage is 4.5 – 5.0 V) and connect its positive

terminal to “Vin” terminal (2) and negative

terminal to “Ground” terminal (3) of sensor. Then

using voltmeter, connect positive terminal to

“Vout 2” terminal (4) of sensor and negative

terminal to battery.

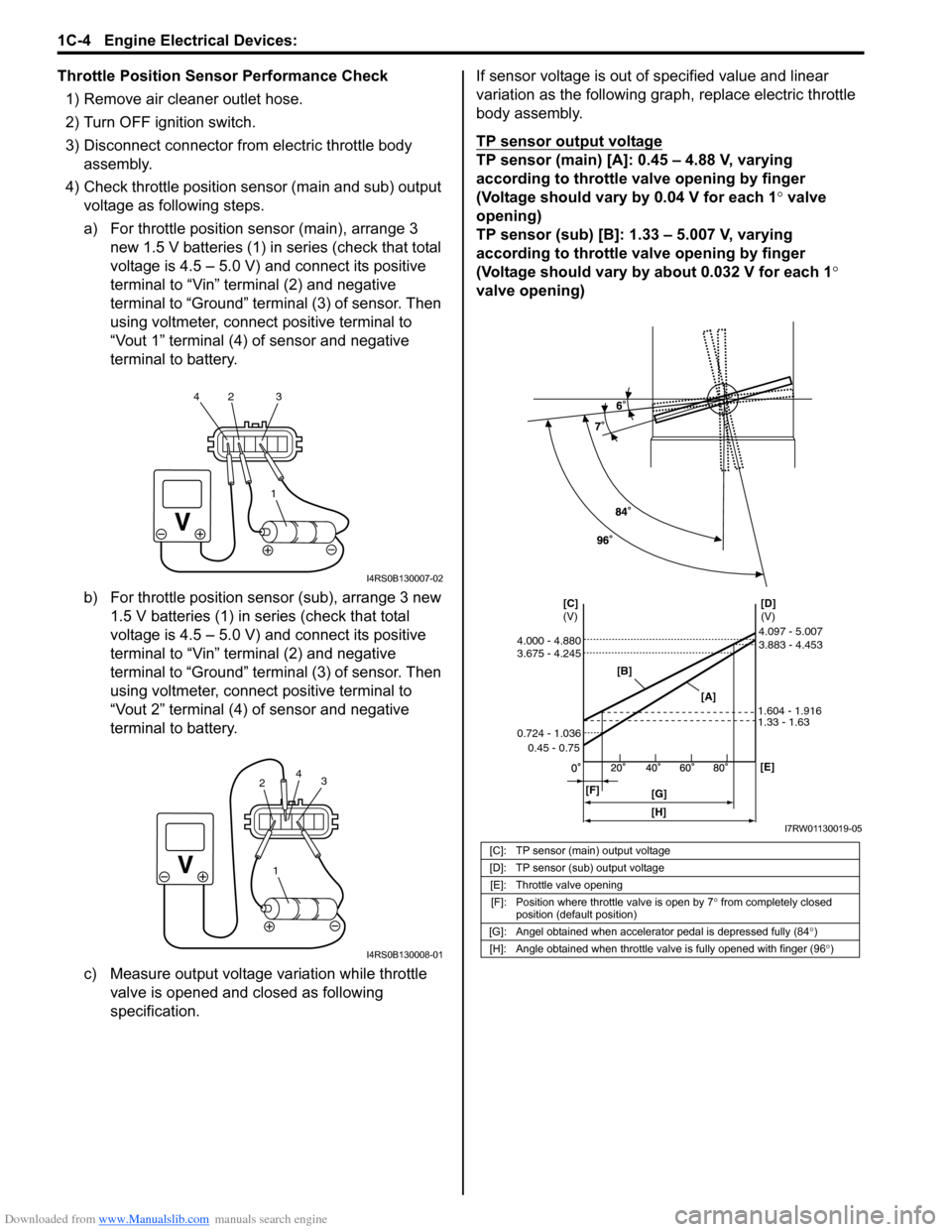

c) Measure output voltage variation while throttle

valve is opened and closed as following

specification.If sensor voltage is out of specified value and linear

variation as the following graph, replace electric throttle

body assembly.

TP sensor output voltage

TP sensor (main) [A]: 0.45 – 4.88 V, varying

according to throttle valve opening by finger

(Voltage should vary by 0.04 V for each 1° valve

opening)

TP sensor (sub) [B]: 1.33 – 5.007 V, varying

according to throttle valve opening by finger

(Voltage should vary by about 0.032 V for each 1°

valve opening)

1 42 3

I4RS0B130007-02

1

3

24

I4RS0B130008-01

[C]: TP sensor (main) output voltage

[D]: TP sensor (sub) output voltage

[E]: Throttle valve opening

[F]: Position where throttle valve is open by 7° from completely closed

position (default position)

[G]: Angel obtained when accelerator pedal is depressed fully (84°)

[H]: Angle obtained when throttle valve is fully opened with finger (96°)

[B]

[A][D]

(V) [C]

(V)

[F]

[G][E] 0.45 - 0.75 0.724 - 1.036 3.675 - 4.245 4.000 - 4.880

1.33 - 1.63 1.604 - 1.9163.883 - 4.453 4.097 - 5.007

[H]

I7RW01130019-05

Page 273 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-5

Electric Throttle Body System CalibrationS6RW0D1306004

NOTE

If the service described under the

“Precautions of Electric Throttle Body

System Calibration in Section 1A” is

performed, calibrate electric throttle body

system as follows.

1) If electric throttle body assembly and/or accelerator

pedal position (APP) sensor assembly are replaced,

perform following steps.

a) Disconnect negative cable at battery for 20

seconds or more for the purpose of clearing

calibration data of closed throttle position from

memory in ECM.

b) Connect negative cable to battery.

2) Keep ignition switch at ON position for 5 seconds or

more without running engine.

Accelerator Pedal Position (APP) Sensor

Assembly On-Vehicle Inspection

S6RW0D1306005

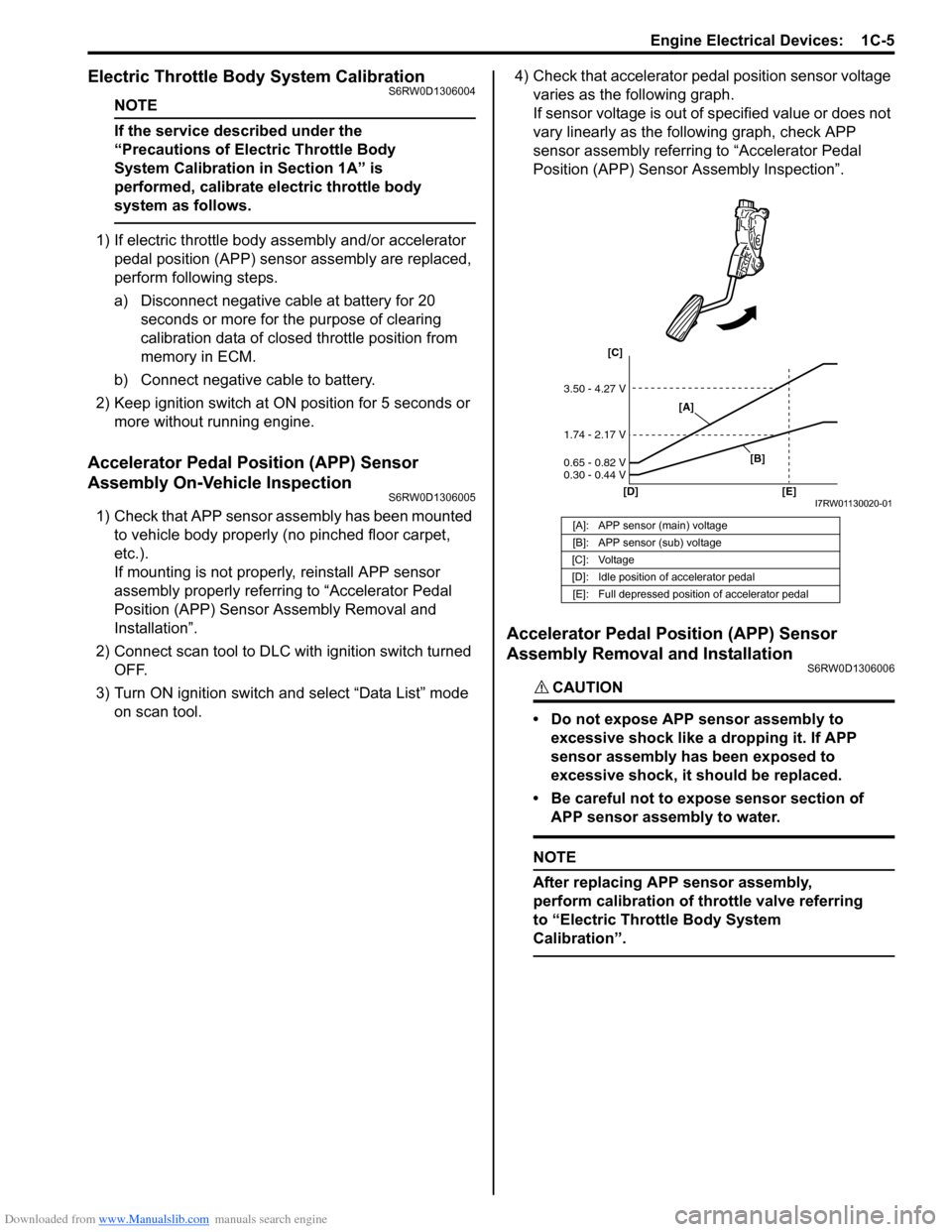

1) Check that APP sensor assembly has been mounted

to vehicle body properly (no pinched floor carpet,

etc.).

If mounting is not properly, reinstall APP sensor

assembly properly referring to “Accelerator Pedal

Position (APP) Sensor Assembly Removal and

Installation”.

2) Connect scan tool to DLC with ignition switch turned

OFF.

3) Turn ON ignition switch and select “Data List” mode

on scan tool.4) Check that accelerator pedal position sensor voltage

varies as the following graph.

If sensor voltage is out of specified value or does not

vary linearly as the following graph, check APP

sensor assembly referring to “Accelerator Pedal

Position (APP) Sensor Assembly Inspection”.

Accelerator Pedal Position (APP) Sensor

Assembly Removal and Installation

S6RW0D1306006

CAUTION!

• Do not expose APP sensor assembly to

excessive shock like a dropping it. If APP

sensor assembly has been exposed to

excessive shock, it should be replaced.

• Be careful not to expose sensor section of

APP sensor assembly to water.

NOTE

After replacing APP sensor assembly,

perform calibration of throttle valve referring

to “Electric Throttle Body System

Calibration”.

[A]: APP sensor (main) voltage

[B]: APP sensor (sub) voltage

[C]: Voltage

[D]: Idle position of accelerator pedal

[E]: Full depressed position of accelerator pedal

[C]

[D] [E]

3.50 - 4.27 V

1.74 - 2.17 V

0.65 - 0.82 V

0.30 - 0.44 V

[A]

[B]

I7RW01130020-01

Page 274 of 1556

Downloaded from www.Manualslib.com manuals search engine 1C-6 Engine Electrical Devices:

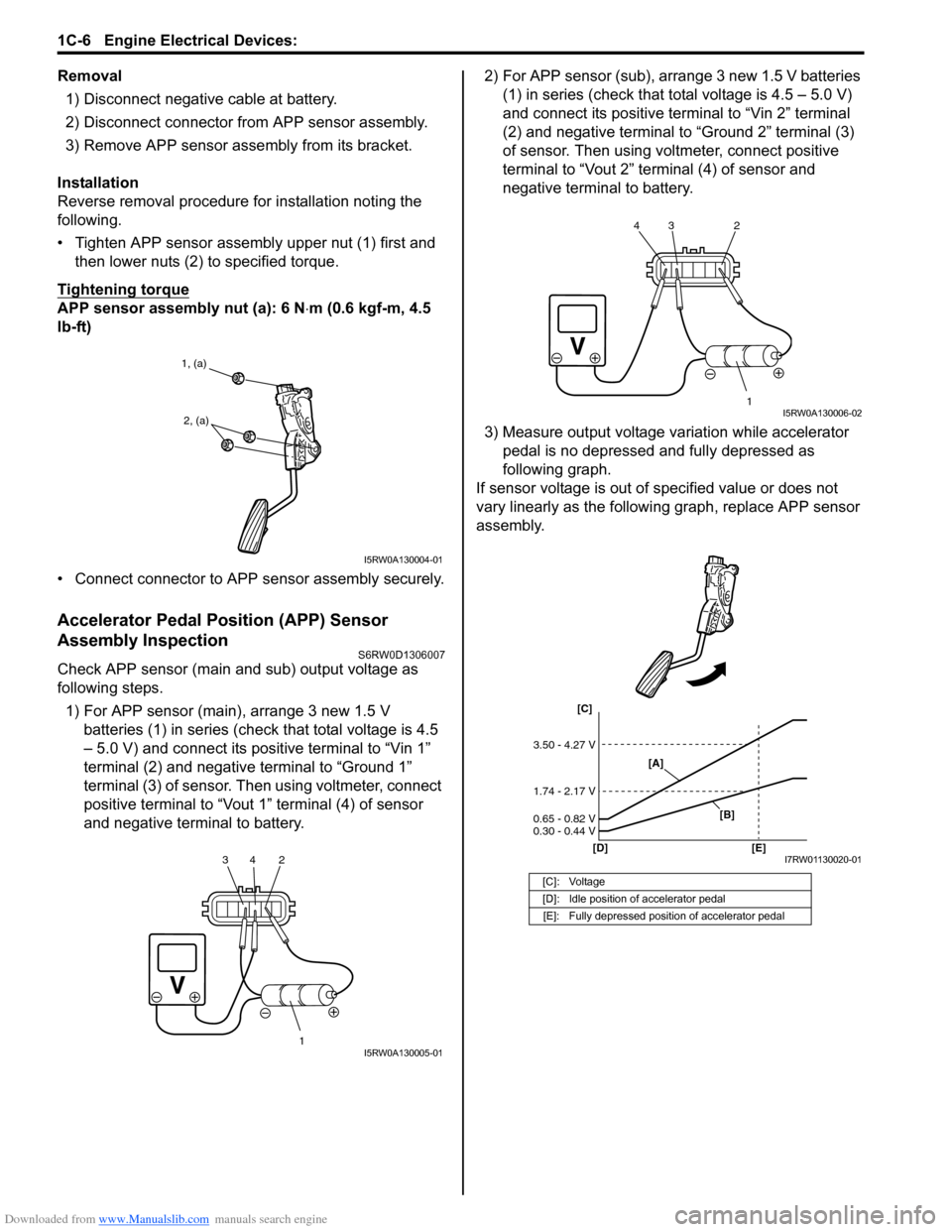

Removal

1) Disconnect negative cable at battery.

2) Disconnect connector from APP sensor assembly.

3) Remove APP sensor assembly from its bracket.

Installation

Reverse removal procedure for installation noting the

following.

• Tighten APP sensor assembly upper nut (1) first and

then lower nuts (2) to specified torque.

Tightening torque

APP sensor assembly nut (a): 6 N⋅m (0.6 kgf-m, 4.5

lb-ft)

• Connect connector to APP sensor assembly securely.

Accelerator Pedal Position (APP) Sensor

Assembly Inspection

S6RW0D1306007

Check APP sensor (main and sub) output voltage as

following steps.

1) For APP sensor (main), arrange 3 new 1.5 V

batteries (1) in series (check that total voltage is 4.5

– 5.0 V) and connect its positive terminal to “Vin 1”

terminal (2) and negative terminal to “Ground 1”

terminal (3) of sensor. Then using voltmeter, connect

positive terminal to “Vout 1” terminal (4) of sensor

and negative terminal to battery.2) For APP sensor (sub), arrange 3 new 1.5 V batteries

(1) in series (check that total voltage is 4.5 – 5.0 V)

and connect its positive terminal to “Vin 2” terminal

(2) and negative terminal to “Ground 2” terminal (3)

of sensor. Then using voltmeter, connect positive

terminal to “Vout 2” terminal (4) of sensor and

negative terminal to battery.

3) Measure output voltage variation while accelerator

pedal is no depressed and fully depressed as

following graph.

If sensor voltage is out of specified value or does not

vary linearly as the following graph, replace APP sensor

assembly.

1, (a)

2, (a)

I5RW0A130004-01

1 2 34I5RW0A130005-01

[C]: Voltage

[D]: Idle position of accelerator pedal

[E]: Fully depressed position of accelerator pedal

1 2 3 4I5RW0A130006-02

[C]

[D] [E]

3.50 - 4.27 V

1.74 - 2.17 V

0.65 - 0.82 V

0.30 - 0.44 V

[A]

[B]

I7RW01130020-01

Page 275 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-7

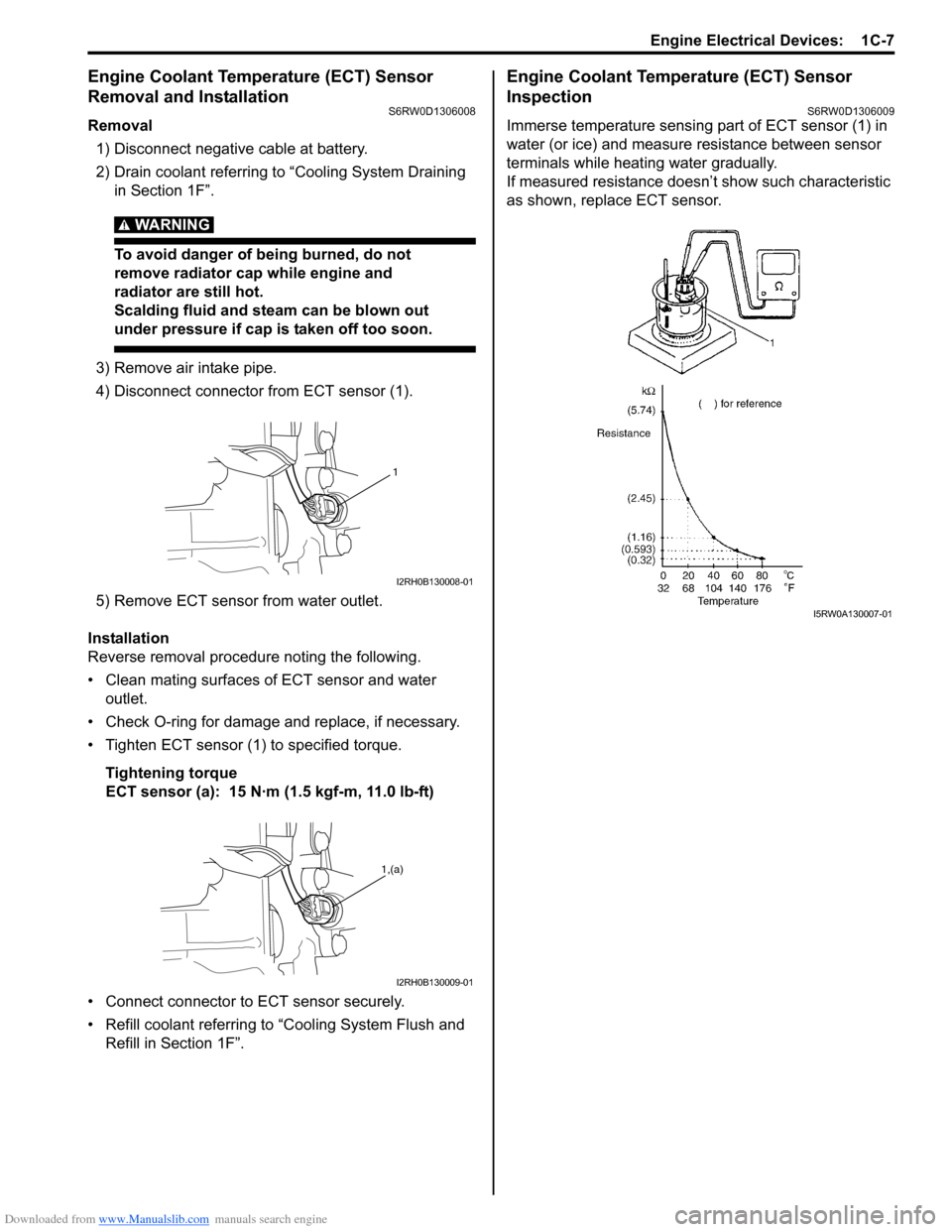

Engine Coolant Temperature (ECT) Sensor

Removal and Installation

S6RW0D1306008

Removal

1) Disconnect negative cable at battery.

2) Drain coolant referring to “Cooling System Draining

in Section 1F”.

WARNING!

To avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot.

Scalding fluid and steam can be blown out

under pressure if cap is taken off too soon.

3) Remove air intake pipe.

4) Disconnect connector from ECT sensor (1).

5) Remove ECT sensor from water outlet.

Installation

Reverse removal procedure noting the following.

• Clean mating surfaces of ECT sensor and water

outlet.

• Check O-ring for damage and replace, if necessary.

• Tighten ECT sensor (1) to specified torque.

Tightening torque

ECT sensor (a): 15 N·m (1.5 kgf-m, 11.0 lb-ft)

• Connect connector to ECT sensor securely.

• Refill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

Engine Coolant Temperature (ECT) Sensor

Inspection

S6RW0D1306009

Immerse temperature sensing part of ECT sensor (1) in

water (or ice) and measure resistance between sensor

terminals while heating water gradually.

If measured resistance doesn’t show such characteristic

as shown, replace ECT sensor.

1

I2RH0B130008-01

1,(a)

I2RH0B130009-01

I5RW0A130007-01