300 SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 554 of 1556

Downloaded from www.Manualslib.com manuals search engine 3C-7 Transfer:

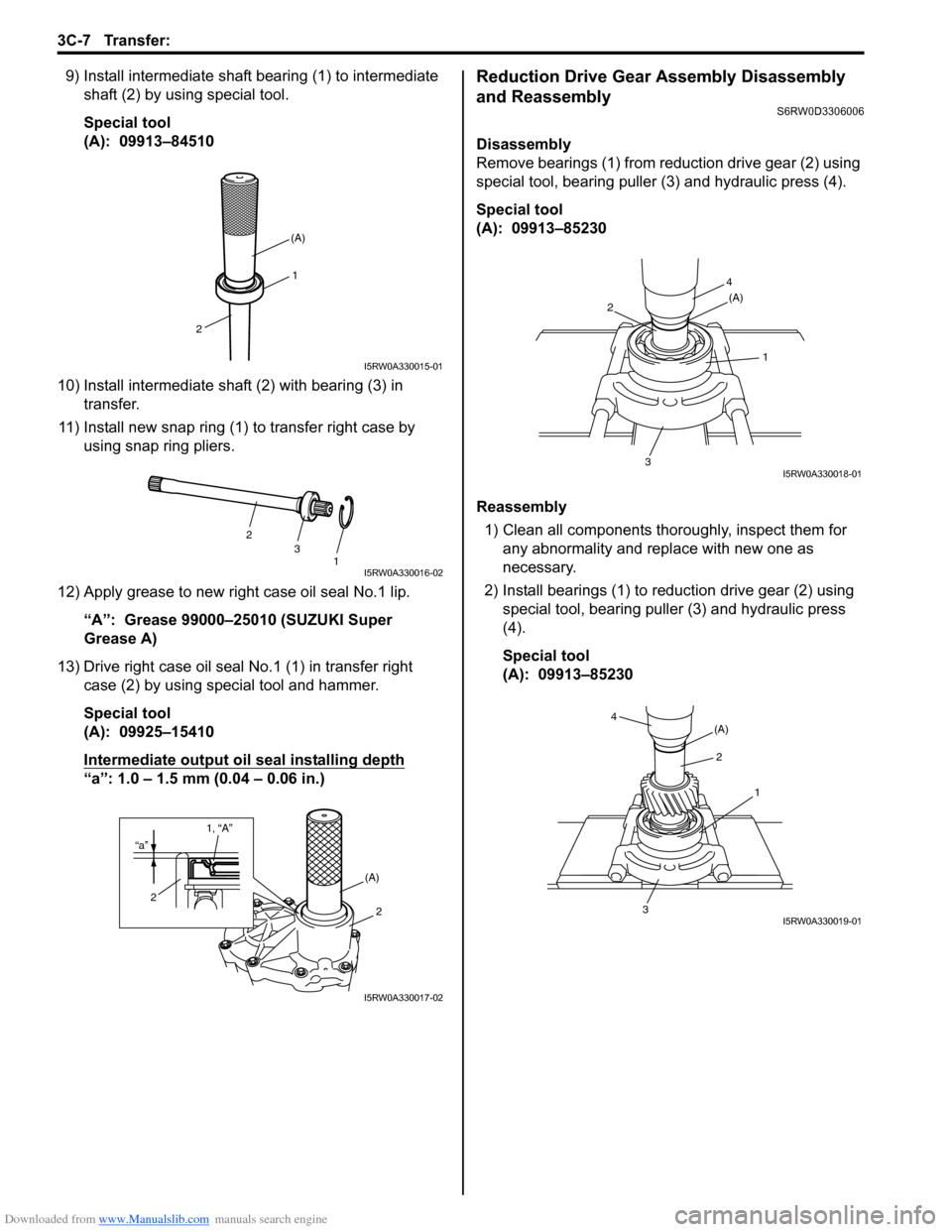

9) Install intermediate shaft bearing (1) to intermediate

shaft (2) by using special tool.

Special tool

(A): 09913–84510

10) Install intermediate shaft (2) with bearing (3) in

transfer.

11) Install new snap ring (1) to transfer right case by

using snap ring pliers.

12) Apply grease to new right case oil seal No.1 lip.

“A”: Grease 99000–25010 (SUZUKI Super

Grease A)

13) Drive right case oil seal No.1 (1) in transfer right

case (2) by using special tool and hammer.

Special tool

(A): 09925–15410

Intermediate output oil seal installing depth

“a”: 1.0 – 1.5 mm (0.04 – 0.06 in.)

Reduction Drive Gear Assembly Disassembly

and Reassembly

S6RW0D3306006

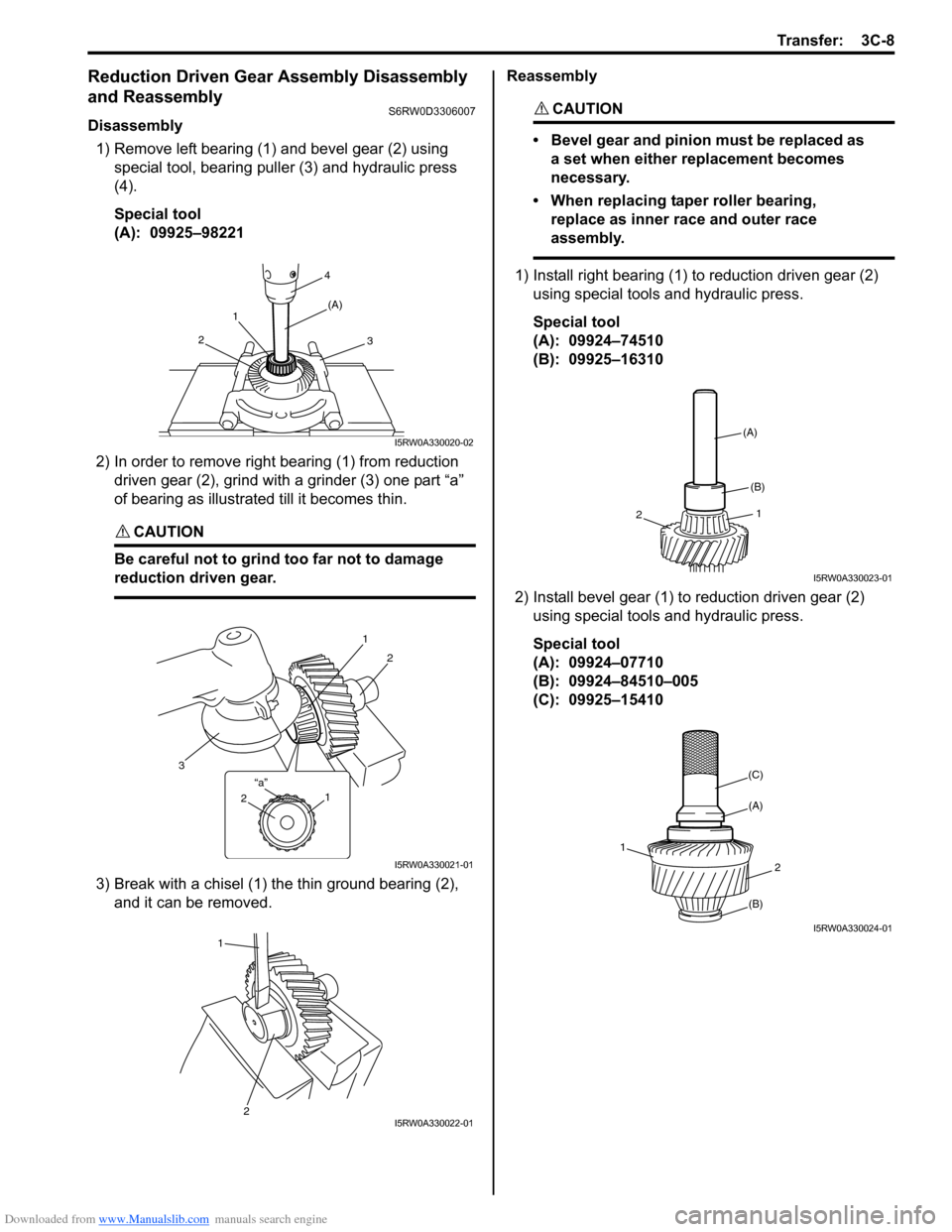

Disassembly

Remove bearings (1) from reduction drive gear (2) using

special tool, bearing puller (3) and hydraulic press (4).

Special tool

(A): 09913–85230

Reassembly

1) Clean all components thoroughly, inspect them for

any abnormality and replace with new one as

necessary.

2) Install bearings (1) to reduction drive gear (2) using

special tool, bearing puller (3) and hydraulic press

(4).

Special tool

(A): 09913–85230

(A)

1

2

I5RW0A330015-01

132

I5RW0A330016-02

(A)

1, “A”

2

2

“a”

I5RW0A330017-02

4

(A)2

1

3I5RW0A330018-01

(A)

2

4

1

3I5RW0A330019-01

Page 555 of 1556

Downloaded from www.Manualslib.com manuals search engine Transfer: 3C-8

Reduction Driven Gear Assembly Disassembly

and Reassembly

S6RW0D3306007

Disassembly

1) Remove left bearing (1) and bevel gear (2) using

special tool, bearing puller (3) and hydraulic press

(4).

Special tool

(A): 09925–98221

2) In order to remove right bearing (1) from reduction

driven gear (2), grind with a grinder (3) one part “a”

of bearing as illustrated till it becomes thin.

CAUTION!

Be careful not to grind too far not to damage

reduction driven gear.

3) Break with a chisel (1) the thin ground bearing (2),

and it can be removed.Reassembly

CAUTION!

• Bevel gear and pinion must be replaced as

a set when either replacement becomes

necessary.

• When replacing taper roller bearing,

replace as inner race and outer race

assembly.

1) Install right bearing (1) to reduction driven gear (2)

using special tools and hydraulic press.

Special tool

(A): 09924–74510

(B): 09925–16310

2) Install bevel gear (1) to reduction driven gear (2)

using special tools and hydraulic press.

Special tool

(A): 09924–07710

(B): 09924–84510–005

(C): 09925–154104

(A)1

23

I5RW0A330020-02

1

2

3

1

2“a”

I5RW0A330021-01

1

2I5RW0A330022-01

(A)

(B)

1

2

I5RW0A330023-01

(C)

(A)

2

1

(B)

I5RW0A330024-01

Page 556 of 1556

Downloaded from www.Manualslib.com manuals search engine 3C-9 Transfer:

3) Install left bearing (1) to reduction driven gear (2)

using special tools and hydraulic press.

Special tool

(A): 09913–84510

(B): 09924–84510–005

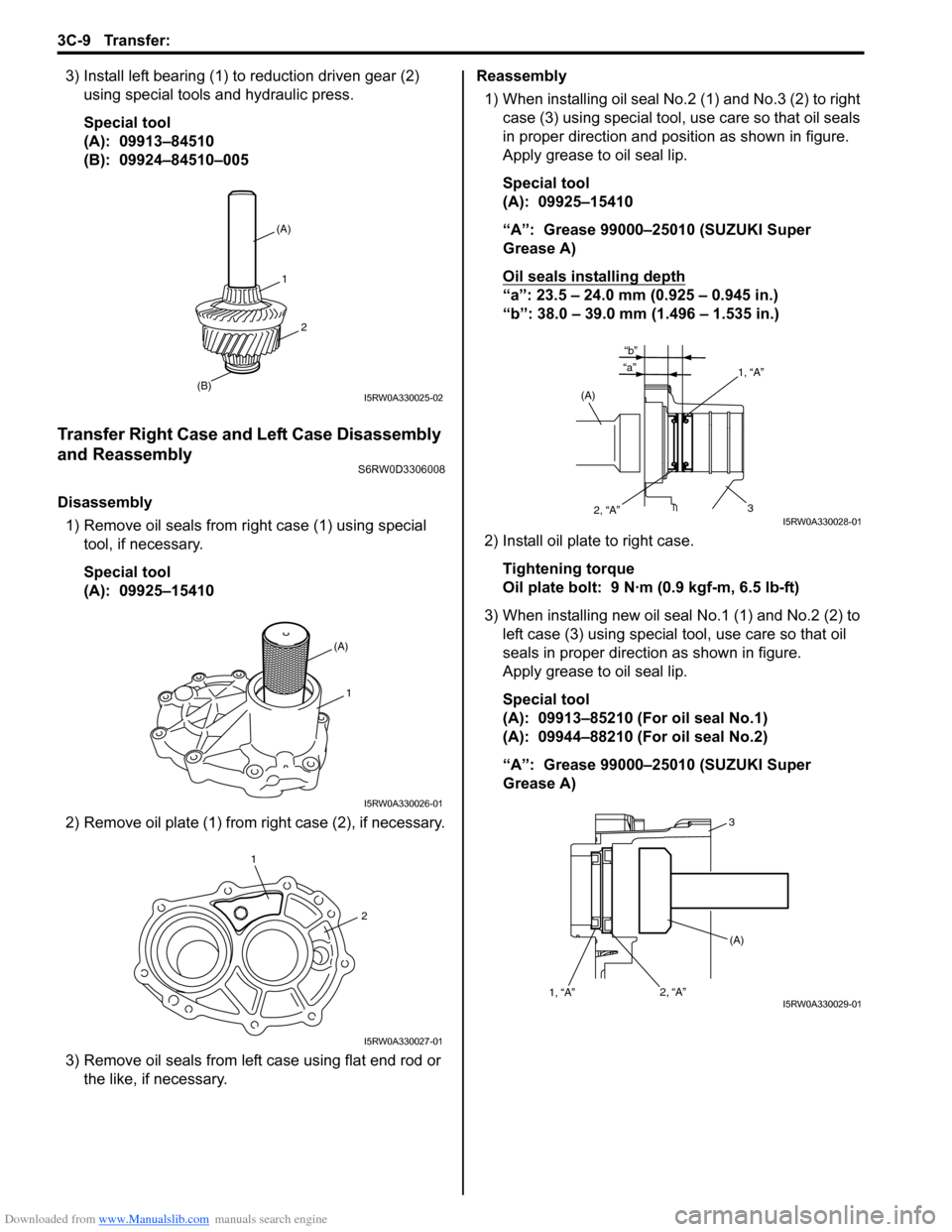

Transfer Right Case and Left Case Disassembly

and Reassembly

S6RW0D3306008

Disassembly

1) Remove oil seals from right case (1) using special

tool, if necessary.

Special tool

(A): 09925–15410

2) Remove oil plate (1) from right case (2), if necessary.

3) Remove oil seals from left case using flat end rod or

the like, if necessary.Reassembly

1) When installing oil seal No.2 (1) and No.3 (2) to right

case (3) using special tool, use care so that oil seals

in proper direction and position as shown in figure.

Apply grease to oil seal lip.

Special tool

(A): 09925–15410

“A”: Grease 99000–25010 (SUZUKI Super

Grease A)

Oil seals installing depth

“a”: 23.5 – 24.0 mm (0.925 – 0.945 in.)

“b”: 38.0 – 39.0 mm (1.496 – 1.535 in.)

2) Install oil plate to right case.

Tightening torque

Oil plate bolt: 9 N·m (0.9 kgf-m, 6.5 lb-ft)

3) When installing new oil seal No.1 (1) and No.2 (2) to

left case (3) using special tool, use care so that oil

seals in proper direction as shown in figure.

Apply grease to oil seal lip.

Special tool

(A): 09913–85210 (For oil seal No.1)

(A): 09944–88210 (For oil seal No.2)

“A”: Grease 99000–25010 (SUZUKI Super

Grease A)

(A)

1

2

(B)I5RW0A330025-02

(A)

1

I5RW0A330026-01

1

2

I5RW0A330027-01

1, “A”

2, “A”“a”

(A)

3 “b”

I5RW0A330028-01

3

(A)

2, “A”1, “A”I5RW0A330029-01

Page 557 of 1556

Downloaded from www.Manualslib.com manuals search engine Transfer: 3C-10

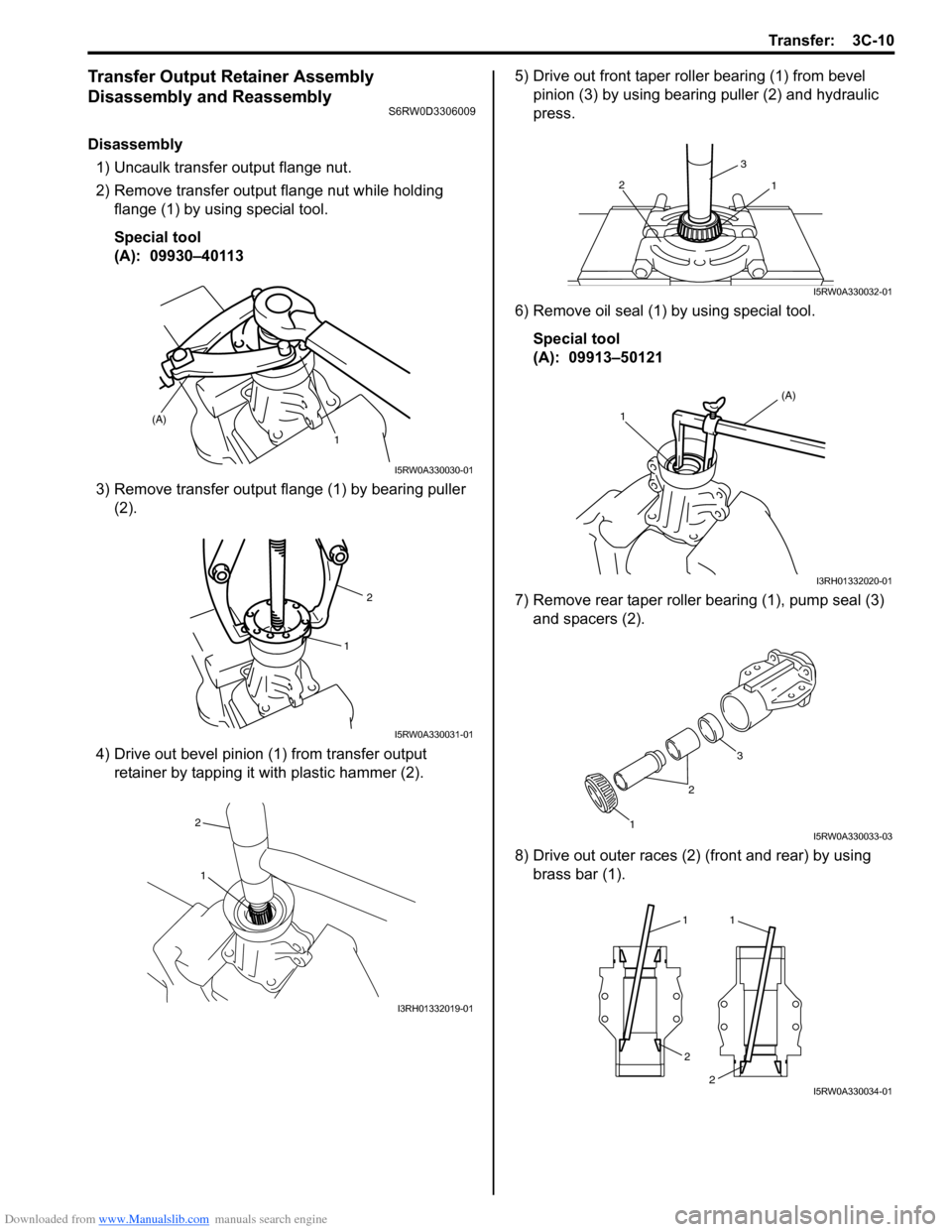

Transfer Output Retainer Assembly

Disassembly and Reassembly

S6RW0D3306009

Disassembly

1) Uncaulk transfer output flange nut.

2) Remove transfer output flange nut while holding

flange (1) by using special tool.

Special tool

(A): 09930–40113

3) Remove transfer output flange (1) by bearing puller

(2).

4) Drive out bevel pinion (1) from transfer output

retainer by tapping it with plastic hammer (2).5) Drive out front taper roller bearing (1) from bevel

pinion (3) by using bearing puller (2) and hydraulic

press.

6) Remove oil seal (1) by using special tool.

Special tool

(A): 09913–50121

7) Remove rear taper roller bearing (1), pump seal (3)

and spacers (2).

8) Drive out outer races (2) (front and rear) by using

brass bar (1).

(A)

1

I5RW0A330030-01

2

1

I5RW0A330031-01

1 2

I3RH01332019-01

3

12

I5RW0A330032-01

1(A)

I3RH01332020-01

1

2

3

I5RW0A330033-03

11

2

2I5RW0A330034-01

Page 558 of 1556

Downloaded from www.Manualslib.com manuals search engine 3C-11 Transfer:

Reassembly

CAUTION!

• Bevel gear and pinion must be replaced as

a set when either replacement becomes

necessary.

• When replacing taper roller bearing,

replace as inner race and outer race

assembly.

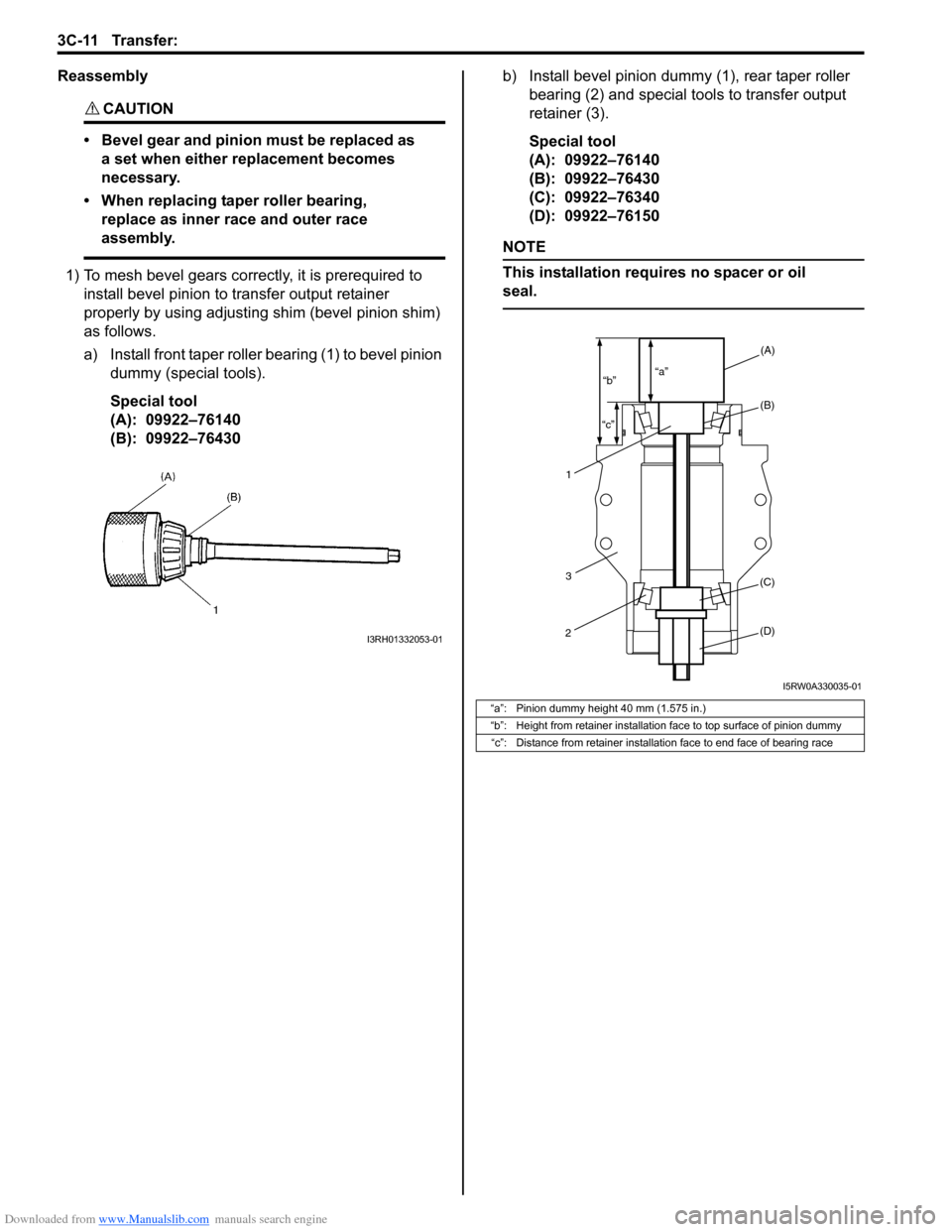

1) To mesh bevel gears correctly, it is prerequired to

install bevel pinion to transfer output retainer

properly by using adjusting shim (bevel pinion shim)

as follows.

a) Install front taper roller bearing (1) to bevel pinion

dummy (special tools).

Special tool

(A): 09922–76140

(B): 09922–76430b) Install bevel pinion dummy (1), rear taper roller

bearing (2) and special tools to transfer output

retainer (3).

Special tool

(A): 09922–76140

(B): 09922–76430

(C): 09922–76340

(D): 09922–76150

NOTE

This installation requires no spacer or oil

seal.

I3RH01332053-01

“a”: Pinion dummy height 40 mm (1.575 in.)

“b”: Height from retainer installation face to top surface of pinion dummy

“c”: Distance from retainer installation face to end face of bearing race

(A)

(B)

1

3

2

(C)

(D)

“a”

“b”

“c”

I5RW0A330035-01

Page 559 of 1556

Downloaded from www.Manualslib.com manuals search engine Transfer: 3C-12

c) Tighten bevel pinion nut (special tool) so that

specified bearing preload is obtained.

NOTE

Before taking measurement, check for

rotation by hand more than 15 revolutions.

Tightening torque

Rotational torque of bevel pinion (Bearing

preload): 0.50 – 1.30 N·m (0.05 – 0.13 kgf-m,

0.35 – 0.95 lb-ft)

d) Measure height “b” in figure by using vernier

caliper.

Calculate “c” by using measured value.e) Obtain adjusting shim thickness by the following

equation.

f) Select a shim closest to the calculated value

(necessary shim thickness) from among the

available shims or combine shims to become

closest to calculated value.

For example:

Measure distance “b” is 69.95 mm (2.754 in.).

“c” = 69.95 mm (2.754 in.) – 40.0 mm (1.757 in.)

= 29.95 mm (1.179 in.)

“f” = 29.95 mm (1.179 in.) + 74.0 mm (2.913 in.)

– 101.95 mm (4.014 in.) = 2.0 mm (0.079 in.)

Calculated thickness of new shim = 2.0 mm

(0.079 in.)

Available bevel pinion shim thickness

0.30, 1.85, 1.88, 1.91, 1.94, 1.97, 2.00, 2.03,

2.06, 2.09, 2.12 and 2.15 mm (0.012, 0.072,

0.074, 0.075, 0.076, 0.077, 0.078, 0.079, 0.081,

0.082, 0.083 and 0.084 in.) Distance “c” = Height “b” –Height “a” 40 mm

(1.575 in.)

I5RW0A330036-02

“a”

“b”

“c”

I5RW0A330046-01

Necessary

shim

thickness “f”=Distance

“c”+Distance

“d”

–Distance

“e”

74.0 mm

(2.913 in.)101.95 mm

(4.014 in.)

“d”: Pinion shaft mounting distance 74.0 mm (2.913 in.)

“e”: Distance from end face of left case to axis of reduction driven gear

101.95 mm (4.014 in.)

“f”: Necessary shim thickness

“d” “e”

“f ”

I5RW0A330037-01

Page 560 of 1556

Downloaded from www.Manualslib.com manuals search engine 3C-13 Transfer:

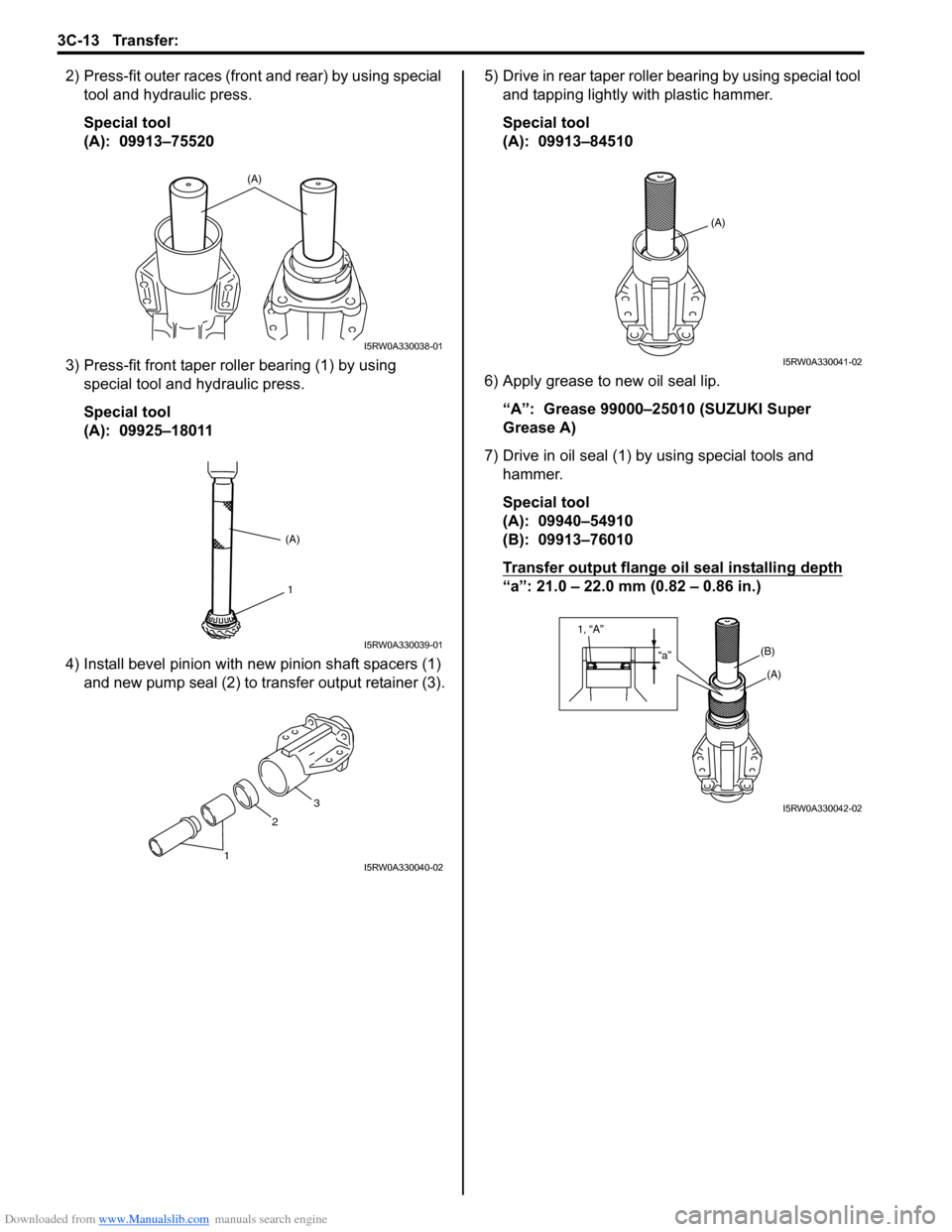

2) Press-fit outer races (front and rear) by using special

tool and hydraulic press.

Special tool

(A): 09913–75520

3) Press-fit front taper roller bearing (1) by using

special tool and hydraulic press.

Special tool

(A): 09925–18011

4) Install bevel pinion with new pinion shaft spacers (1)

and new pump seal (2) to transfer output retainer (3).5) Drive in rear taper roller bearing by using special tool

and tapping lightly with plastic hammer.

Special tool

(A): 09913–84510

6) Apply grease to new oil seal lip.

“A”: Grease 99000–25010 (SUZUKI Super

Grease A)

7) Drive in oil seal (1) by using special tools and

hammer.

Special tool

(A): 09940–54910

(B): 09913–76010

Transfer output flange oil seal installing depth

“a”: 21.0 – 22.0 mm (0.82 – 0.86 in.)

(A)

I5RW0A330038-01

(A)

1

I5RW0A330039-01

1

2

3

I5RW0A330040-02

(A)

I5RW0A330041-02

(B)

(A)

1, “A”

“a”

I5RW0A330042-02

Page 561 of 1556

Downloaded from www.Manualslib.com manuals search engine Transfer: 3C-14

8) Install transfer output flange (1) by tapping with

plastic hammer and tighten transfer output flange nut

gradually so as rotational torque of bevel pinion to be

in specified value.

NOTE

• If rotational torque of bevel pinion exceeds

specification given in the following,

replace pinion shaft spacers and tighten

flange nut.

• Before taking measurement of rotational

torque, rotate pinion over ten rounds in

advance.

Bevel pinion bearing preload

: 0.5 – 1.3 N⋅m (0.05 – 0.13 kgf-m, 0.35 – 0.95 lb-ft)

Special tool

(A): 09930–40113

9) Caulk transfer output flange nut (1).

Transfer Assembly InspectionS6RW0D3306010

• Check each bearing for smooth rotation, wear or

discoloration

If found abnormal, replace.

• Check oil seal for leakage and its lip for excessive

hardness

If either is found, replace.

• Check transfer case for cracks.

• Check bevel pinion and bevel gears for wear or

cracks.

Bevel Gear Tooth Contact InspectionS6RW0D3306011

1) After cleaning tooth surface of bevel gear (1), paint

them with gear marking compound evenly by using

brush or sponge etc.

NOTE

When applying red lead paste to teeth, be

sure to paint tooth surfaces uniformly. The

paste must not be too dry or too fluid.

2) Install transfer output retainer assembly referring to

“Transfer Assembly Disassembly and Reassembly”.

3) Turn transfer output flange clockwise and

counterclockwise repeatedly, and remove transfer

output retainer assembly and bevel gear shims from

transfer assembly.

2. Torque wrench

(A)1

2

I5RW0A330043-01

1

I5RW0A330044-01

I3RH01332043-01

Page 562 of 1556

Downloaded from www.Manualslib.com manuals search engine 3C-15 Transfer:

4) Bring painted part up and check contact pattern referring to the following chart. If contact pattern is not normal,

readjust or replace as necessary according to instruction in chart.

NOTE

• Be careful not to turn bevel gear more than one full revolution, for it will hinder accurate check.

• If bevel gear back lash and bevel pinion shims are adjusted properly, correct tooth contact should

be provided.

If correct tooth contact is not provided even when they are adjusted properly, however, there may be

an abnormal condition in worn tooth, transfer case or retainer. Check each component and replace

as necessary.

Gear tooth contact table

Tooth contact pattern Diagnosis and remedy

Normal

High contact

Pinion is positioned too far from the center of drive bevel

gear.

• Decrease thickness of bevel pinion shim and position

pinion closer to gear center.

• Adjust drive bevel gear backlash to specification.

Low contact

Pinion is positioned too close to the center of drive bevel

gear.

• Increase thickness of bevel pinion shim and position

pinion farther from gear center.

• Adjust drive bevel gear backlash to specification.

These contact patterns indicate that the “offset” of

reduction driven gear is too much or too little. The

remedy is to change the division of the bevel gear

shim(s).

I5RW0A330045-01

I3RH01332045-01

I3RH01332046-01

I3RH01332047-01

Page 578 of 1556

Downloaded from www.Manualslib.com manuals search engine 4A-7 Brake Control System and Diagnosis:

Repair Instructions

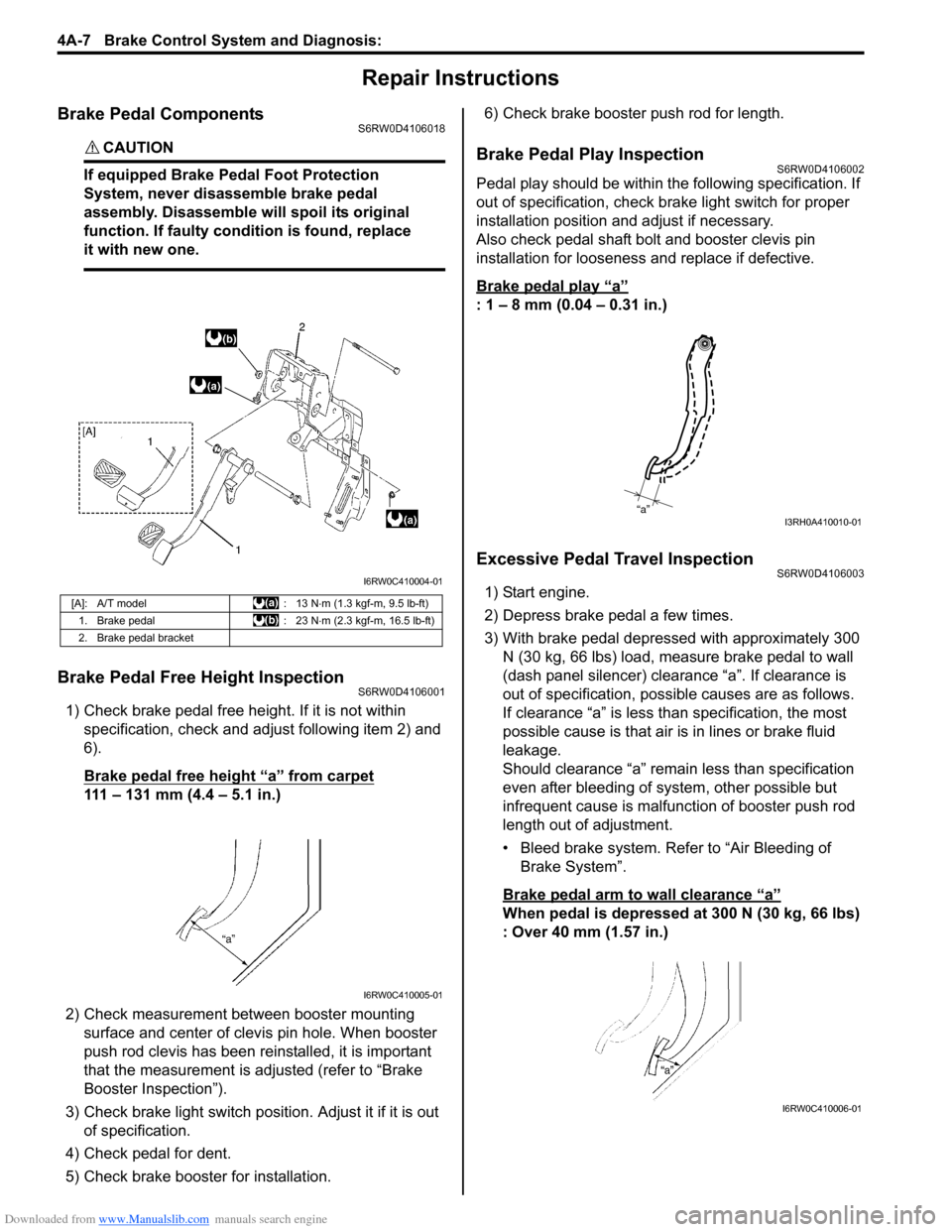

Brake Pedal ComponentsS6RW0D4106018

CAUTION!

If equipped Brake Pedal Foot Protection

System, never disassemble brake pedal

assembly. Disassemble will spoil its original

function. If faulty condition is found, replace

it with new one.

Brake Pedal Free Height InspectionS6RW0D4106001

1) Check brake pedal free height. If it is not within

specification, check and adjust following item 2) and

6).

Brake pedal free height “a” from carpet

111 – 131 mm (4.4 – 5.1 in.)

2) Check measurement between booster mounting

surface and center of clevis pin hole. When booster

push rod clevis has been reinstalled, it is important

that the measurement is adjusted (refer to “Brake

Booster Inspection”).

3) Check brake light switch position. Adjust it if it is out

of specification.

4) Check pedal for dent.

5) Check brake booster for installation.6) Check brake booster push rod for length.

Brake Pedal Play InspectionS6RW0D4106002

Pedal play should be within the following specification. If

out of specification, check brake light switch for proper

installation position and adjust if necessary.

Also check pedal shaft bolt and booster clevis pin

installation for looseness and replace if defective.

Brake pedal play

“a”

: 1 – 8 mm (0.04 – 0.31 in.)

Excessive Pedal Travel InspectionS6RW0D4106003

1) Start engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximately 300

N (30 kg, 66 lbs) load, measure brake pedal to wall

(dash panel silencer) clearance “a”. If clearance is

out of specification, possible causes are as follows.

If clearance “a” is less than specification, the most

possible cause is that air is in lines or brake fluid

leakage.

Should clearance “a” remain less than specification

even after bleeding of system, other possible but

infrequent cause is malfunction of booster push rod

length out of adjustment.

• Bleed brake system. Refer to “Air Bleeding of

Brake System”.

Brake pedal arm to wall clearance

“a”

When pedal is depressed at 300 N (30 kg, 66 lbs)

: Over 40 mm (1.57 in.)

[A]: A/T model : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

1. Brake pedal : 23 N⋅m (2.3 kgf-m, 16.5 lb-ft)

2. Brake pedal bracket

I6RW0C410004-01

I6RW0C410005-01

“a”I3RH0A410010-01

I6RW0C410006-01