Timing SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 94 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-44 Engine General Information and Diagnosis:

4Check keyless start control system malfunction

1) Check keyless start control system referring to “Keyless

Start System Operation Inspection in Section 10E”.

Is check result satisfactory?Go to Step 5. Keyless start control

system malfunction.

5Is engine cranked?Go to Step 6. Go to “Cranking System

Symptom Diagnosis in

Section 1I”.

6Does engine start?Go to Step 7. Go to Step 9.

7Check idle speed

1) Check engine idle speed referring to “Idle Speed and

IAC Throttle Valve Opening Inspection”.

Is check result as specified?Go to Step 8. Go to “Engine Symptom

Diagnosis”.

8Check ignition timing

1) Check ignition timing referring to “Ignition Timing

Inspection in Section 1H”.

Is check result as specified?Go to “Engine Symptom

Diagnosis”.Check ignition control

related parts referring to

“Ignition Timing

Inspection in Section

1H”.

9Check immobilizer system malfunction

1) Check immobilizer indicator lamp for flashing.

Is it flashing when ignition switch is turned to ON position?Go to “DTC Check in

Section 10C”.Go to Step 10.

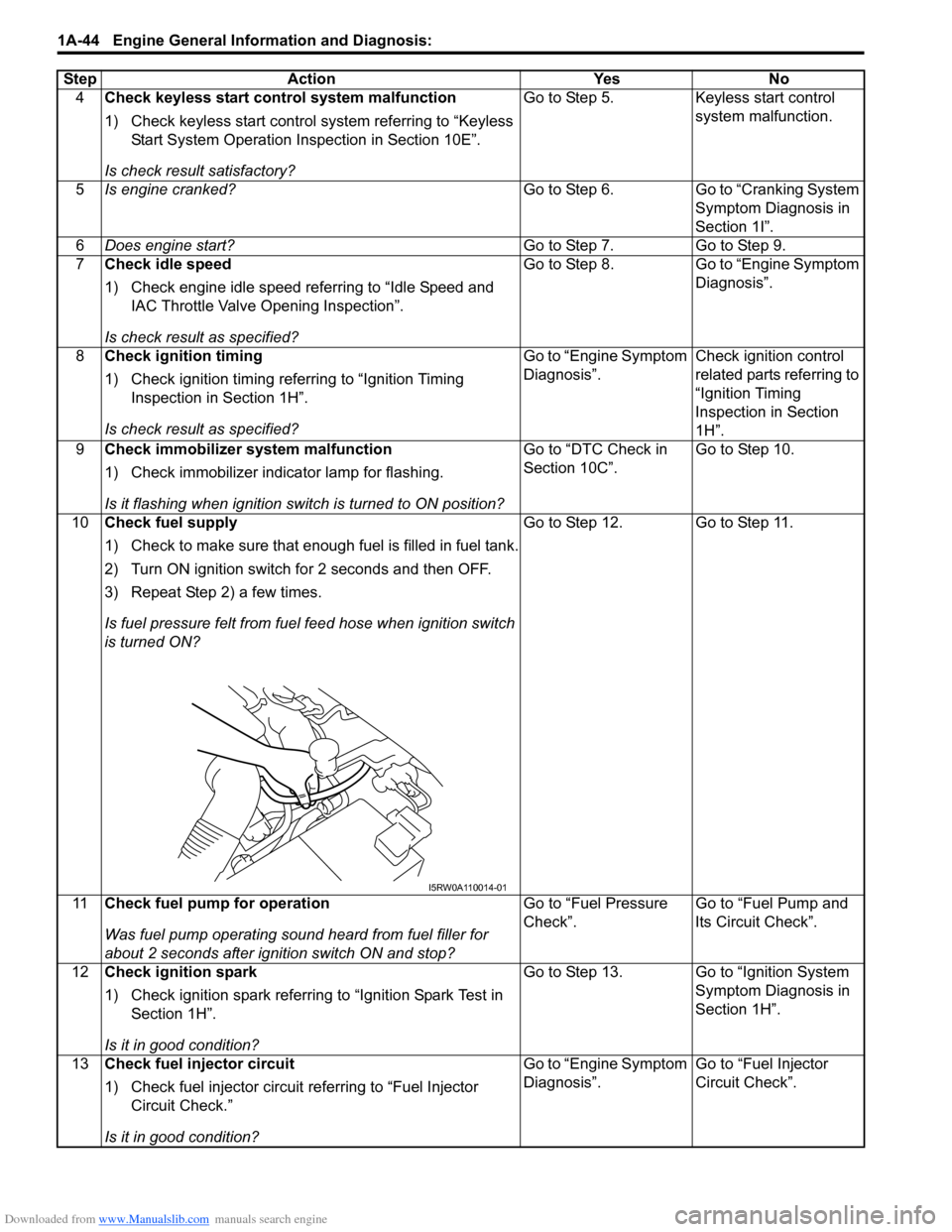

10Check fuel supply

1) Check to make sure that enough fuel is filled in fuel tank.

2) Turn ON ignition switch for 2 seconds and then OFF.

3) Repeat Step 2) a few times.

Is fuel pressure felt from fuel feed hose when ignition switch

is turned ON?Go to Step 12. Go to Step 11.

11Check fuel pump for operation

Was fuel pump operating sound heard from fuel filler for

about 2 seconds after ignition switch ON and stop?Go to “Fuel Pressure

Check”.Go to “Fuel Pump and

Its Circuit Check”.

12Check ignition spark

1) Check ignition spark referring to “Ignition Spark Test in

Section 1H”.

Is it in good condition?Go to Step 13. Go to “Ignition System

Symptom Diagnosis in

Section 1H”.

13Check fuel injector circuit

1) Check fuel injector circuit referring to “Fuel Injector

Circuit Check.”

Is it in good condition?Go to “Engine Symptom

Diagnosis”.Go to “Fuel Injector

Circuit Check”. Step Action Yes No

I5RW0A110014-01

Page 101 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-51

Excessive hydrocarbon

(HC) emission or carbon

monoxide (CO)Faulty spark plug“Spark Plug Inspection in Section 1H”

Leaky or disconnected high-tension cord“High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil with ignitor“Ignition Coil Assembly (Including Ignitor)

Inspection in Section 1H”

Low compression“Compression Check in Section 1D”

Lead contamination of three way

catalytic converterCheck for absence of filler neck restrictor.

Faulty evaporative emission control

system“EVAP Canister Purge Inspection in Section

1B”

Fuel pressure out of specification“Fuel Pressure Check”

Closed loop system (A/F feedback

compensation) fails (Poor performance

of ECT sensor or MAF sensor)“Engine Coolant Temperature (ECT) Sensor

Inspection in Section 1C” or “Intake Air

Temperature (IAT) Sensor Inspection in

Section 1C”

Faulty electric throttle body assembly“Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly“Accelerator Pedal Position (APP) Sensor

Assembly Inspection in Section 1C”

Faulty injector(s)“Fuel Injector Circuit Check”

Faulty ECM

Engine not at normal operating

temperature

Clogged air cleaner“Air Cleaner Filter Inspection and Cleaning in

Section 1D”

Vacuum leaks“Engine Vacuum Check in Section 1D”

Camshaft position control (VVT) system

out of order (for engine with VVT

system)“Oil Control Valve Inspection (For Engine with

VVT) in Section 1D”

Excessive nitrogen

oxides (NOx) emissionImproper ignition timing“Ignition Timing Inspection in Section 1H”

Lead contamination of catalytic

converterCheck for absence of filler neck restrictor.

Faulty EGR system“EGR System Inspection (If Equipped) in

Section 1B”

Fuel pressure out of specification“Fuel Pressure Check”

Closed loop system (A/F feedback

compensation) fails (Poor performance

of ECT sensor or MAF sensor)“Engine Coolant Temperature (ECT) Sensor

Inspection in Section 1C” or “Intake Air

Temperature (IAT) Sensor Inspection in

Section 1C”

Faulty electric throttle body assembly“Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly“Accelerator Pedal Position (APP) Sensor

Assembly Inspection in Section 1C”

Faulty injector(s)“Fuel Injector Circuit Check”

Faulty ECM

Camshaft position control (VVT) system

out of order (for engine with VVT

system)“Oil Control Valve Inspection (For Engine with

VVT) in Section 1D” Condition Possible cause Correction / Reference Item

Page 105 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-55

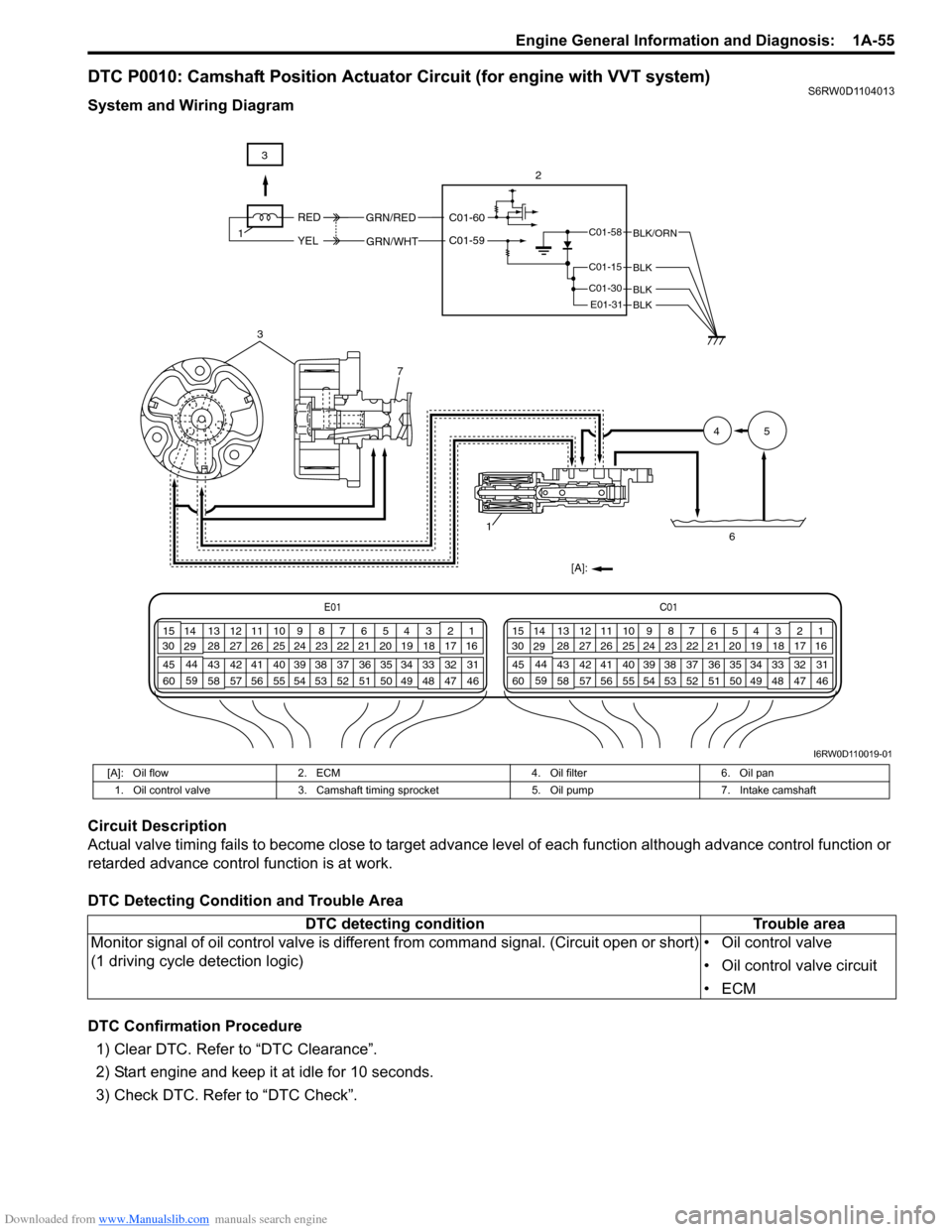

DTC P0010: Camshaft Position Actuator Circuit (for engine with VVT system)S6RW0D1104013

System and Wiring Diagram

Circuit Description

Actual valve timing fails to become close to target advance level of each function although advance control function or

retarded advance control function is at work.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Clear DTC. Refer to “DTC Clearance”.

2) Start engine and keep it at idle for 10 seconds.

3) Check DTC. Refer to “DTC Check”.

3

7

1

[A]:45

6

C01-58

C01-15

C01-30

E01-31BLK

BLK

BLK/ORN

RED

YEL

GRN/RED

GRN/WHT

C01-60

C01-59

3

2

1

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

BLK

I6RW0D110019-01

[A]: Oil flow 2. ECM 4. Oil filter 6. Oil pan

1. Oil control valve 3. Camshaft timing sprocket 5. Oil pump 7. Intake camshaft

DTC detecting condition Trouble area

Monitor signal of oil control valve is different from command signal. (Circuit open or short)

(1 driving cycle detection logic)• Oil control valve

• Oil control valve circuit

•ECM

Page 107 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-57

DTC P0011 / P0012: Camshaft Position - Timing Over-Advanced or System Performance / Retarded

(for engine with VVT system)

S6RW0D1104014

System Description

Actual value of advanced valve timing does not reach target value.

Valve timing is advanced although ECM command is most retarding.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and tester, on a level road.

NOTE

Check to make sure that the following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Altitude (barometric pressure): 2500 m, 8200 ft or less (560 mmHg, 74.4 kPa or more)

1) Clear DTC. Refer to “DTC Clearance”.

2) Start engine and drive vehicle under usual driving condition for 5 minutes or longer until engine is warmed up to

normal operating temperature.

3) Stop vehicle.

4) Run engine at idle speed for 1 minute.

5) Start vehicle and increase vehicle speed up to 120 km/h (70 mile/h).

6) Keep vehicle speed at 120 km/h (70 mile/h) for 1 minute or longer at 5th gear position or D range.

7) Decrease vehicle speed gradually.

8) Stop vehicle and turn OFF ignition switch.

9) Repeat Step 4) to 7) one time.

10) Stop vehicle.

11) Check DTC. Refer to “DTC Check”.9Oil control valve check

Check oil control valve referring to “Oil Control Valve

Inspection (For Engine with VVT) in Section 1D”.

Is resistance within specified value?Substitute a known-

good ECM and recheck.Faulty oil control valve. Step Action Yes No

DTC detecting condition Trouble area

Actual value of advanced valve timing does not reach

target value, or valve timing is advanced although ECM

command is most retarding.

(2 driving cycle detection logic)• Oil control valve

• Oil galleries of timing sprocket

• Intake camshaft timing sprocket (Camshaft position

control (VVT) actuator)

• Oil control valve circuit

•ECM

Page 108 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-58 Engine General Information and Diagnosis:

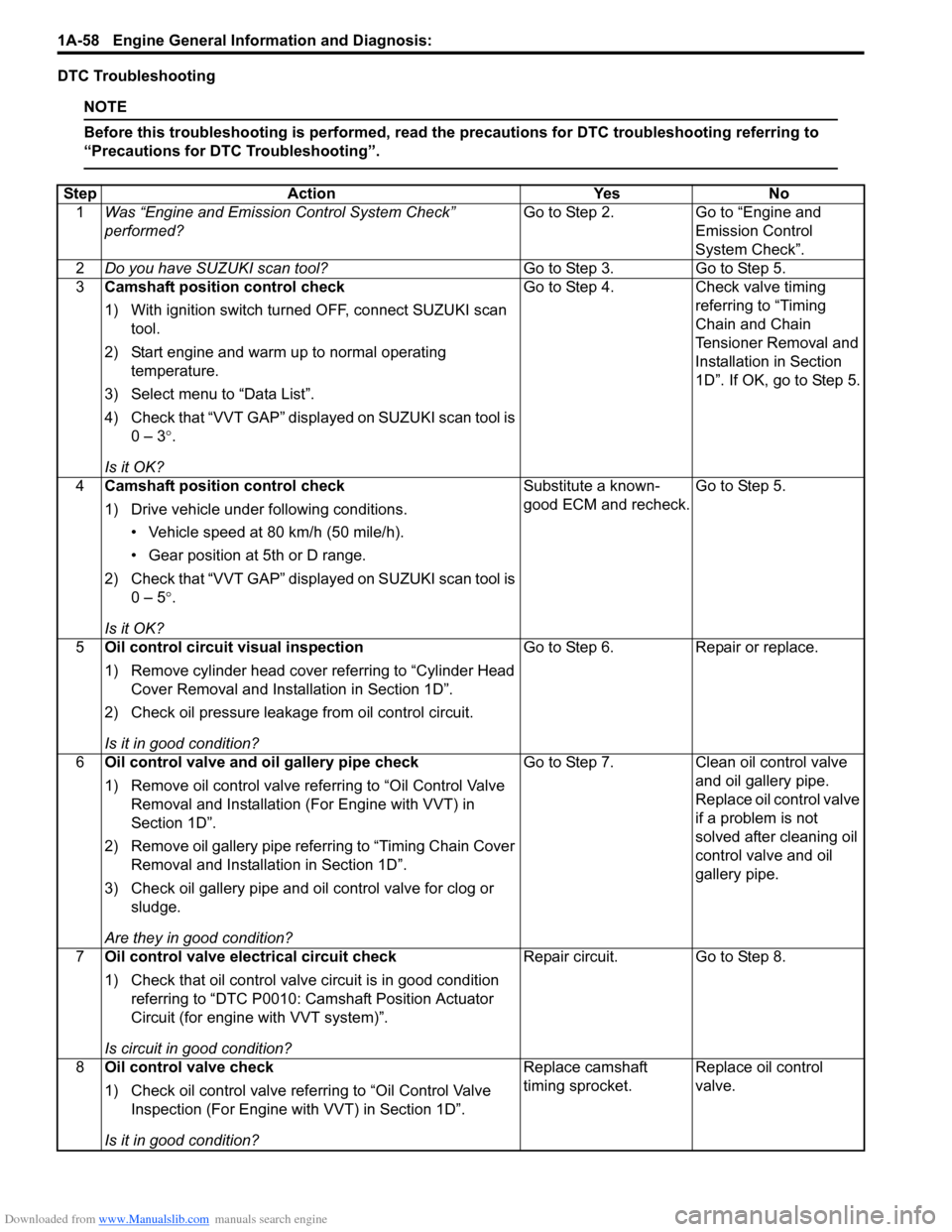

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Do you have SUZUKI scan tool?Go to Step 3. Go to Step 5.

3Camshaft position control check

1) With ignition switch turned OFF, connect SUZUKI scan

tool.

2) Start engine and warm up to normal operating

temperature.

3) Select menu to “Data List”.

4) Check that “VVT GAP” displayed on SUZUKI scan tool is

0 – 3°.

Is it OK?Go to Step 4. Check valve timing

referring to “Timing

Chain and Chain

Tensioner Removal and

Installation in Section

1D”. If OK, go to Step 5.

4Camshaft position control check

1) Drive vehicle under following conditions.

• Vehicle speed at 80 km/h (50 mile/h).

• Gear position at 5th or D range.

2) Check that “VVT GAP” displayed on SUZUKI scan tool is

0 – 5°.

Is it OK?Substitute a known-

good ECM and recheck.Go to Step 5.

5Oil control circuit visual inspection

1) Remove cylinder head cover referring to “Cylinder Head

Cover Removal and Installation in Section 1D”.

2) Check oil pressure leakage from oil control circuit.

Is it in good condition?Go to Step 6. Repair or replace.

6Oil control valve and oil gallery pipe check

1) Remove oil control valve referring to “Oil Control Valve

Removal and Installation (For Engine with VVT) in

Section 1D”.

2) Remove oil gallery pipe referring to “Timing Chain Cover

Removal and Installation in Section 1D”.

3) Check oil gallery pipe and oil control valve for clog or

sludge.

Are they in good condition?Go to Step 7. Clean oil control valve

and oil gallery pipe.

Replace oil control valve

if a problem is not

solved after cleaning oil

control valve and oil

gallery pipe.

7Oil control valve electrical circuit check

1) Check that oil control valve circuit is in good condition

referring to “DTC P0010: Camshaft Position Actuator

Circuit (for engine with VVT system)”.

Is circuit in good condition?Repair circuit. Go to Step 8.

8Oil control valve check

1) Check oil control valve referring to “Oil Control Valve

Inspection (For Engine with VVT) in Section 1D”.

Is it in good condition?Replace camshaft

timing sprocket.Replace oil control

valve.

Page 160 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-110 Engine General Information and Diagnosis:

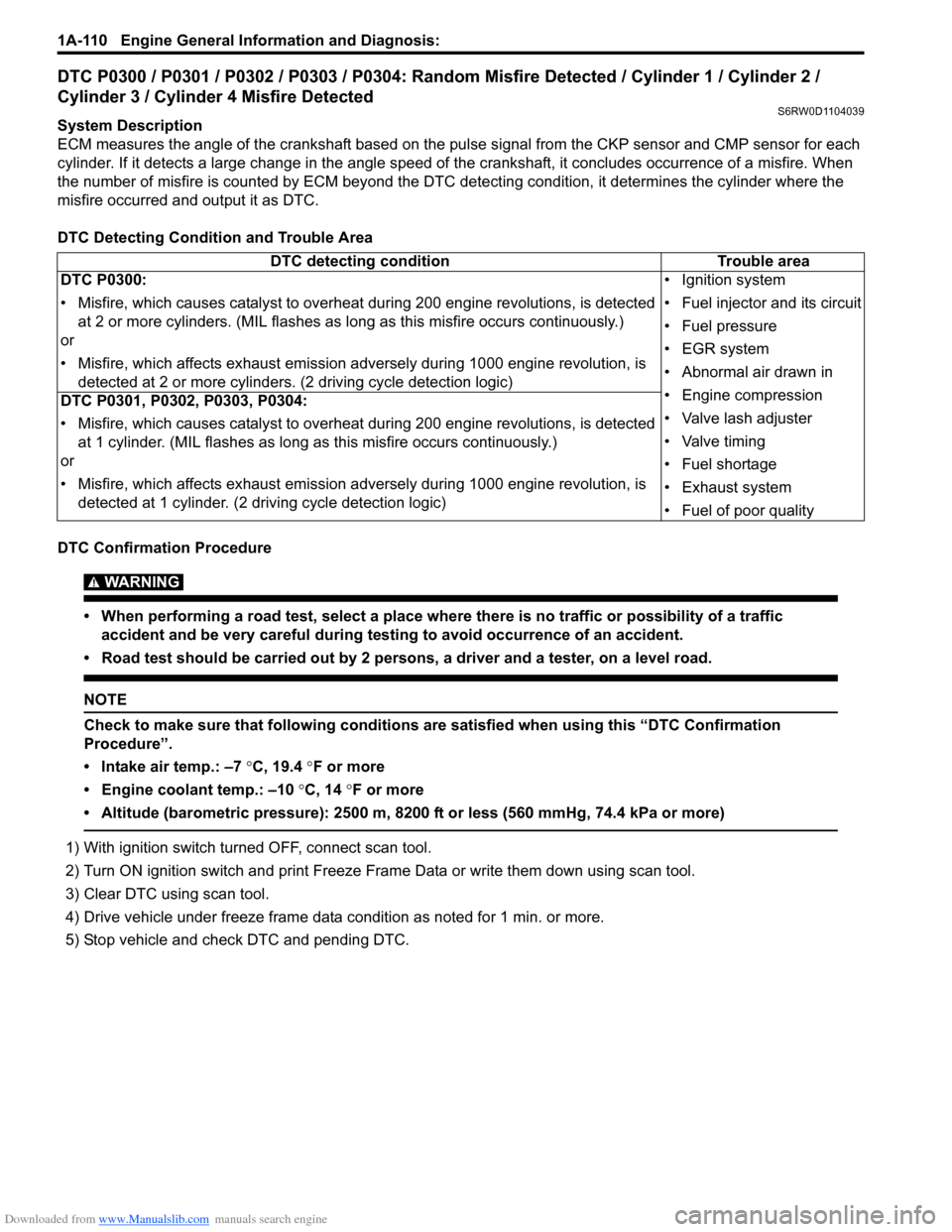

DTC P0300 / P0301 / P0302 / P0303 / P0304: Random Misfire Detected / Cylinder 1 / Cylinder 2 /

Cylinder 3 / Cylinder 4 Misfire Detected

S6RW0D1104039

System Description

ECM measures the angle of the crankshaft based on the pulse signal from the CKP sensor and CMP sensor for each

cylinder. If it detects a large change in the angle speed of the crankshaft, it concludes occurrence of a misfire. When

the number of misfire is counted by ECM beyond the DTC detecting condition, it determines the cylinder where the

misfire occurred and output it as DTC.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temp.: –7 °C, 19.4 °F or more

• Engine coolant temp.: –10 °C, 14 °F or more

• Altitude (barometric pressure): 2500 m, 8200 ft or less (560 mmHg, 74.4 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and print Freeze Frame Data or write them down using scan tool.

3) Clear DTC using scan tool.

4) Drive vehicle under freeze frame data condition as noted for 1 min. or more.

5) Stop vehicle and check DTC and pending DTC.DTC detecting condition Trouble area

DTC P0300:

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is detected

at 2 or more cylinders. (MIL flashes as long as this misfire occurs continuously.)

or

• Misfire, which affects exhaust emission adversely during 1000 engine revolution, is

detected at 2 or more cylinders. (2 driving cycle detection logic)• Ignition system

• Fuel injector and its circuit

• Fuel pressure

• EGR system

• Abnormal air drawn in

• Engine compression

• Valve lash adjuster

• Valve timing

• Fuel shortage

• Exhaust system

• Fuel of poor quality DTC P0301, P0302, P0303, P0304:

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is detected

at 1 cylinder. (MIL flashes as long as this misfire occurs continuously.)

or

• Misfire, which affects exhaust emission adversely during 1000 engine revolution, is

detected at 1 cylinder. (2 driving cycle detection logic)

Page 161 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-111

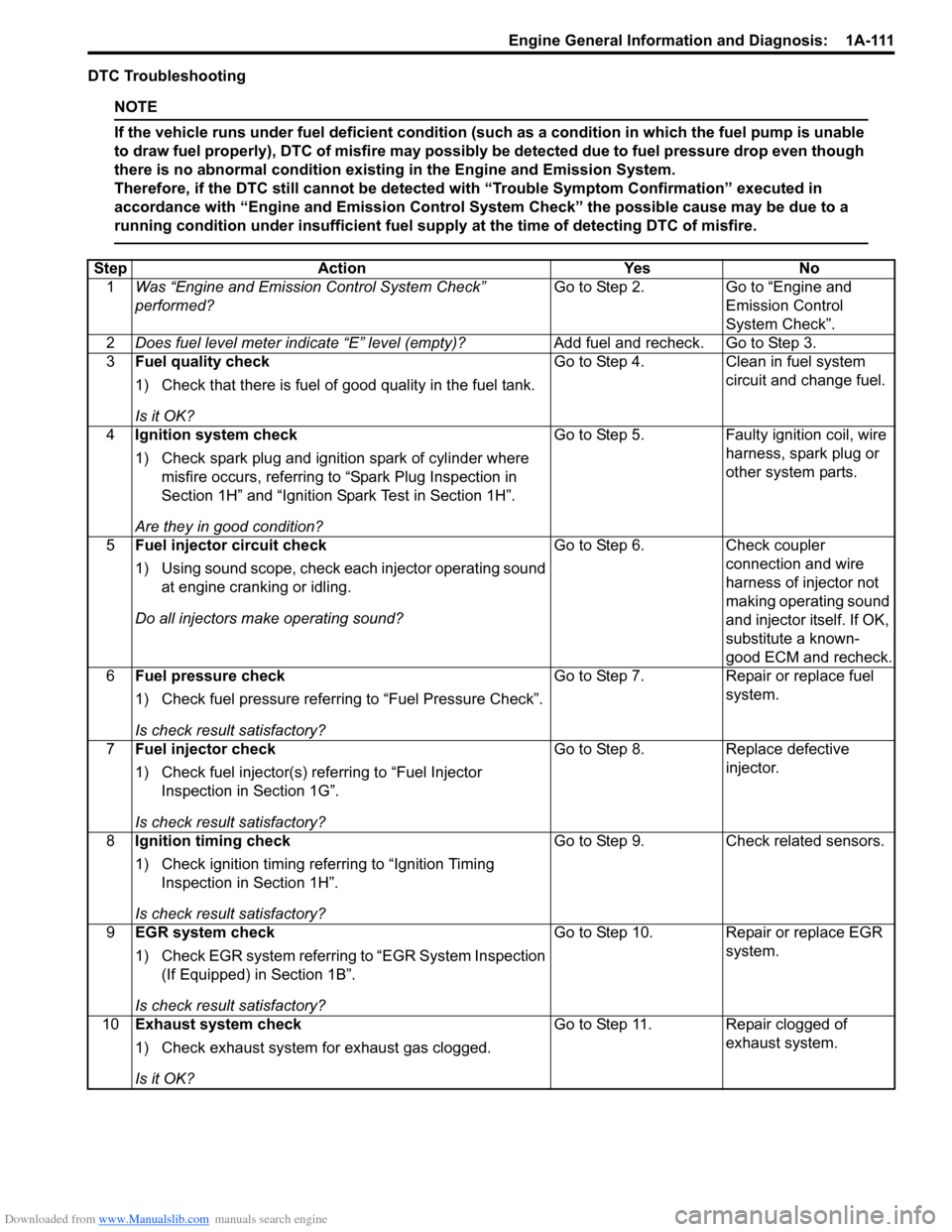

DTC Troubleshooting

NOTE

If the vehicle runs under fuel deficient condition (such as a condition in which the fuel pump is unable

to draw fuel properly), DTC of misfire may possibly be detected due to fuel pressure drop even though

there is no abnormal condition existing in the Engine and Emission System.

Therefore, if the DTC still cannot be detected with “Trouble Symptom Confirmation” executed in

accordance with “Engine and Emission Control System Check” the possible cause may be due to a

running condition under insufficient fuel supply at the time of detecting DTC of misfire.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Does fuel level meter indicate “E” level (empty)?Add fuel and recheck. Go to Step 3.

3Fuel quality check

1) Check that there is fuel of good quality in the fuel tank.

Is it OK?Go to Step 4. Clean in fuel system

circuit and change fuel.

4Ignition system check

1) Check spark plug and ignition spark of cylinder where

misfire occurs, referring to “Spark Plug Inspection in

Section 1H” and “Ignition Spark Test in Section 1H”.

Are they in good condition?Go to Step 5. Faulty ignition coil, wire

harness, spark plug or

other system parts.

5Fuel injector circuit check

1) Using sound scope, check each injector operating sound

at engine cranking or idling.

Do all injectors make operating sound?Go to Step 6. Check coupler

connection and wire

harness of injector not

making operating sound

and injector itself. If OK,

substitute a known-

good ECM and recheck.

6Fuel pressure check

1) Check fuel pressure referring to “Fuel Pressure Check”.

Is check result satisfactory?Go to Step 7. Repair or replace fuel

system.

7Fuel injector check

1) Check fuel injector(s) referring to “Fuel Injector

Inspection in Section 1G”.

Is check result satisfactory?Go to Step 8. Replace defective

injector.

8Ignition timing check

1) Check ignition timing referring to “Ignition Timing

Inspection in Section 1H”.

Is check result satisfactory?Go to Step 9. Check related sensors.

9EGR system check

1) Check EGR system referring to “EGR System Inspection

(If Equipped) in Section 1B”.

Is check result satisfactory?Go to Step 10. Repair or replace EGR

system.

10Exhaust system check

1) Check exhaust system for exhaust gas clogged.

Is it OK?Go to Step 11. Repair clogged of

exhaust system.

Page 162 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-112 Engine General Information and Diagnosis:

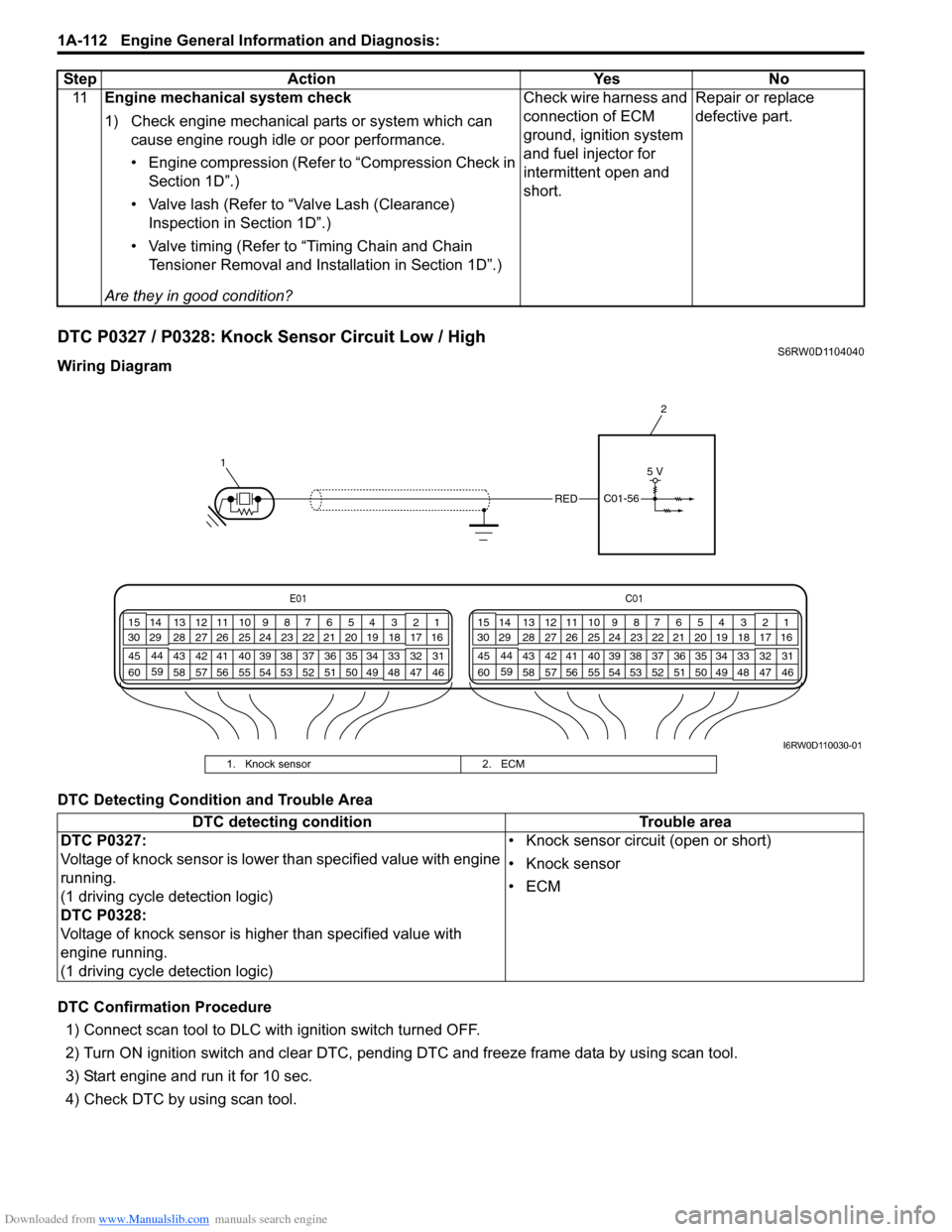

DTC P0327 / P0328: Knock Sensor Circuit Low / HighS6RW0D1104040

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool.

3) Start engine and run it for 10 sec.

4) Check DTC by using scan tool.11Engine mechanical system check

1) Check engine mechanical parts or system which can

cause engine rough idle or poor performance.

• Engine compression (Refer to “Compression Check in

Section 1D”.)

• Valve lash (Refer to “Valve Lash (Clearance)

Inspection in Section 1D”.)

• Valve timing (Refer to “Timing Chain and Chain

Tensioner Removal and Installation in Section 1D”.)

Are they in good condition?Check wire harness and

connection of ECM

ground, ignition system

and fuel injector for

intermittent open and

short.Repair or replace

defective part. Step Action Yes No

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

12

REDC01-56

5 V

I6RW0D110030-01

1. Knock sensor 2. ECM

DTC detecting condition Trouble area

DTC P0327:

Voltage of knock sensor is lower than specified value with engine

running.

(1 driving cycle detection logic)

DTC P0328:

Voltage of knock sensor is higher than specified value with

engine running.

(1 driving cycle detection logic)• Knock sensor circuit (open or short)

• Knock sensor

•ECM

Page 167 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-117

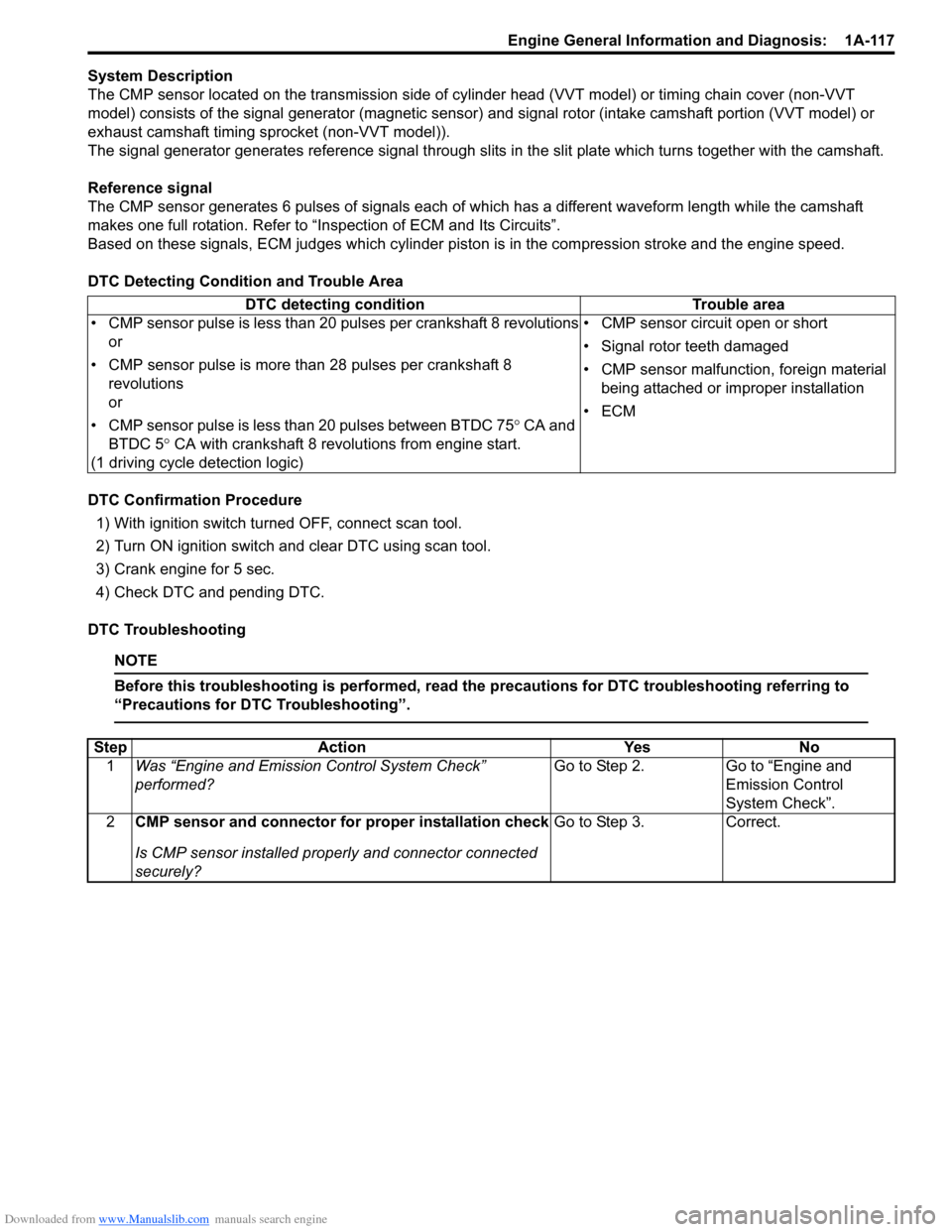

System Description

The CMP sensor located on the transmission side of cylinder head (VVT model) or timing chain cover (non-VVT

model) consists of the signal generator (magnetic sensor) and signal rotor (intake camshaft portion (VVT model) or

exhaust camshaft timing sprocket (non-VVT model)).

The signal generator generates reference signal through slits in the slit plate which turns together with the camshaft.

Reference signal

The CMP sensor generates 6 pulses of signals each of which has a different waveform length while the camshaft

makes one full rotation. Refer to “Inspection of ECM and Its Circuits”.

Based on these signals, ECM judges which cylinder piston is in the compression stroke and the engine speed.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Crank engine for 5 sec.

4) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

DTC detecting condition Trouble area

• CMP sensor pulse is less than 20 pulses per crankshaft 8 revolutions

or

• CMP sensor pulse is more than 28 pulses per crankshaft 8

revolutions

or

• CMP sensor pulse is less than 20 pulses between BTDC 75° CA and

BTDC 5° CA with crankshaft 8 revolutions from engine start.

(1 driving cycle detection logic)• CMP sensor circuit open or short

• Signal rotor teeth damaged

• CMP sensor malfunction, foreign material

being attached or improper installation

•ECM

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2CMP sensor and connector for proper installation check

Is CMP sensor installed properly and connector connected

securely?Go to Step 3. Correct.

Page 262 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-212 Engine General Information and Diagnosis:

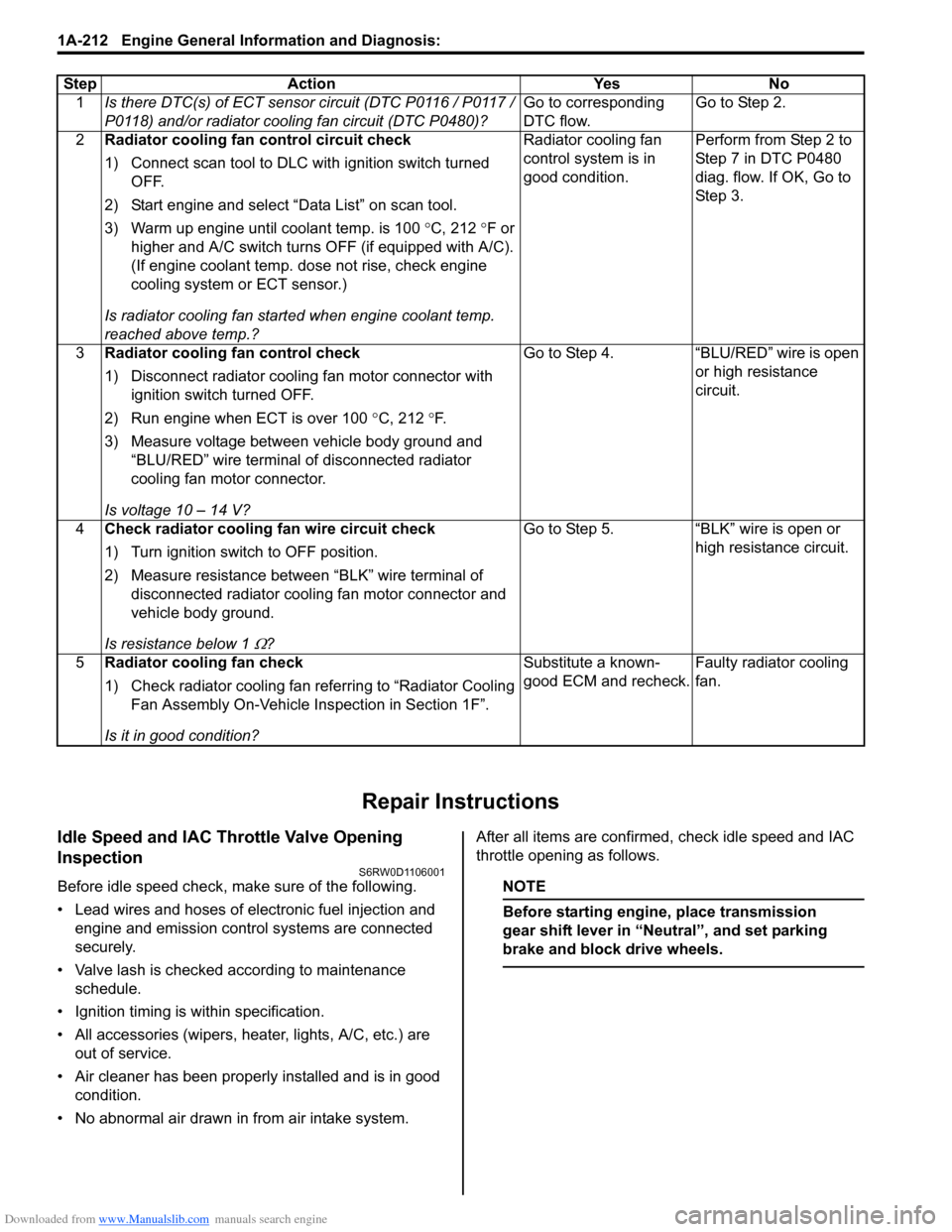

Repair Instructions

Idle Speed and IAC Throttle Valve Opening

Inspection

S6RW0D1106001

Before idle speed check, make sure of the following.

• Lead wires and hoses of electronic fuel injection and

engine and emission control systems are connected

securely.

• Valve lash is checked according to maintenance

schedule.

• Ignition timing is within specification.

• All accessories (wipers, heater, lights, A/C, etc.) are

out of service.

• Air cleaner has been properly installed and is in good

condition.

• No abnormal air drawn in from air intake system.After all items are confirmed, check idle speed and IAC

throttle opening as follows.NOTE

Before starting engine, place transmission

gear shift lever in “Neutral”, and set parking

brake and block drive wheels.

Step Action Yes No

1Is there DTC(s) of ECT sensor circuit (DTC P0116 / P0117 /

P0118) and/or radiator cooling fan circuit (DTC P0480)?Go to corresponding

DTC flow.Go to Step 2.

2Radiator cooling fan control circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “Data List” on scan tool.

3) Warm up engine until coolant temp. is 100 °C, 212 °F or

higher and A/C switch turns OFF (if equipped with A/C).

(If engine coolant temp. dose not rise, check engine

cooling system or ECT sensor.)

Is radiator cooling fan started when engine coolant temp.

reached above temp.?Radiator cooling fan

control system is in

good condition.Perform from Step 2 to

Step 7 in DTC P0480

diag. flow. If OK, Go to

Ste p 3.

3Radiator cooling fan control check

1) Disconnect radiator cooling fan motor connector with

ignition switch turned OFF.

2) Run engine when ECT is over 100 °C, 212 °F.

3) Measure voltage between vehicle body ground and

“BLU/RED” wire terminal of disconnected radiator

cooling fan motor connector.

Is voltage 10 – 14 V?Go to Step 4. “BLU/RED” wire is open

or high resistance

circuit.

4Check radiator cooling fan wire circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK” wire terminal of

disconnected radiator cooling fan motor connector and

vehicle body ground.

Is resistance below 1

Ω?Go to Step 5. “BLK” wire is open or

high resistance circuit.

5Radiator cooling fan check

1) Check radiator cooling fan referring to “Radiator Cooling

Fan Assembly On-Vehicle Inspection in Section 1F”.

Is it in good condition?Substitute a known-

good ECM and recheck.Faulty radiator cooling

fan.