sensor SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 666 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

Step 2. DTC / Freeze Frame Data Check, Record and

Clearance

First, referring to “DTC Check”, check DTC and pending

DTC. If DTC exists, print or write down DTC and freeze

frame data and then clear malfunction DTC(s) by

referring to “DTC Clearance”. Malfunction DTC indicates

malfunction in the system but it is not possible to know

from it whether the malfunction is occurring now or it

occurred in the past and normal condition has been

restored. In order to know that, check symptom in

question according to Step 5 and then recheck DTC

according to Step 6.

Diagnosing a trouble based on the DTC in this step only

or failure to clear the DTC in this step may result in an

faulty diagnosis, trouble diagnosis of a normal circuit or

difficulty in troubleshooting which is otherwise

unnecessary.

Step 3 and 4. Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine and

automatic transaxle referring to “Visual Inspection”.

Step 5. Trouble Symptom Confirmation

Check trouble symptoms based on information obtained

in “Step 1. Customer Complaint Analysis: ” and “Step 2.

DTC / Freeze Frame Data Check, Record and

Clearance: ”.

Also, reconfirm DTC according to “DTC Confirmation

Procedure” described in each DTC flow.

Step 6 and 7. Rechecking and Record of DTC and

Freeze Frame Data

Refer to “DTC Check” for checking procedure.Step 8. A/T Basic Check and A/T Symptom

Diagnosis

Perform basic check of A/T according to “A/T Basic

Check” first. When the end of the flow has been reached,

check the parts of the system suspected as a possible

cause referring to “A/T Symptom Diagnosis” and based

on symptoms appearing on the vehicle (symptoms

obtained through steps of customer complaint analysis,

trouble symptom confirmation and/or A/T basic check)

and repair or replace faulty parts, if any.

Step 9. Troubleshooting for DTC

Based on the DTC indicated in Step 6 / 7 and referring to

“applicable DTC flow”, locate the cause of the trouble,

namely in a sensor, switch, wire harness, connector,

actuator, TCM or other part and repair or replace faulty

parts.

Step 10. Check for Intermittent Problem

Check parts where an intermittent trouble is easy to

occur (e.g. wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11. Final Confirmation Test

Confirm that the problem symptom has gone and the

vehicle is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear

the DTC once and check to ensure that no malfunction

DTC is indicated.

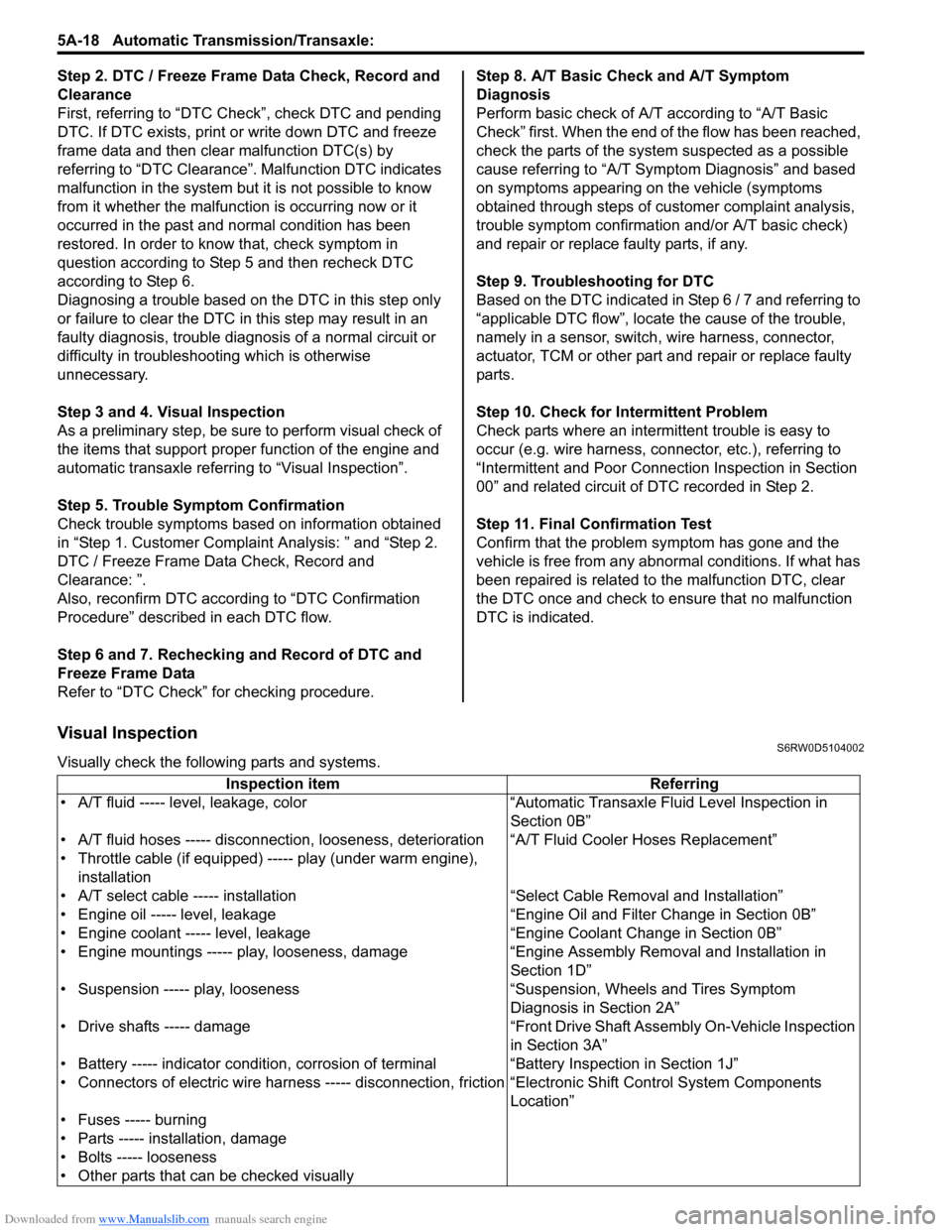

Visual InspectionS6RW0D5104002

Visually check the following parts and systems.

Inspection item Referring

• A/T fluid ----- level, leakage, color “Automatic Transaxle Fluid Level Inspection in

Section 0B”

• A/T fluid hoses ----- disconnection, looseness, deterioration “A/T Fluid Cooler Hoses Replacement”

• Throttle cable (if equipped) ----- play (under warm engine),

installation

• A/T select cable ----- installation “Select Cable Removal and Installation”

• Engine oil ----- level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant ----- level, leakage “Engine Coolant Change in Section 0B”

• Engine mountings ----- play, looseness, damage “Engine Assembly Removal and Installation in

Section 1D”

• Suspension ----- play, looseness “Suspension, Wheels and Tires Symptom

Diagnosis in Section 2A”

• Drive shafts ----- damage “Front Drive Shaft Assembly On-Vehicle Inspection

in Section 3A”

• Battery ----- indicator condition, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ----- disconnection, friction “Electronic Shift Control System Components

Location”

• Fuses ----- burning

• Parts ----- installation, damage

• Bolts ----- looseness

• Other parts that can be checked visually

Page 668 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-20 Automatic Transmission/Transaxle:

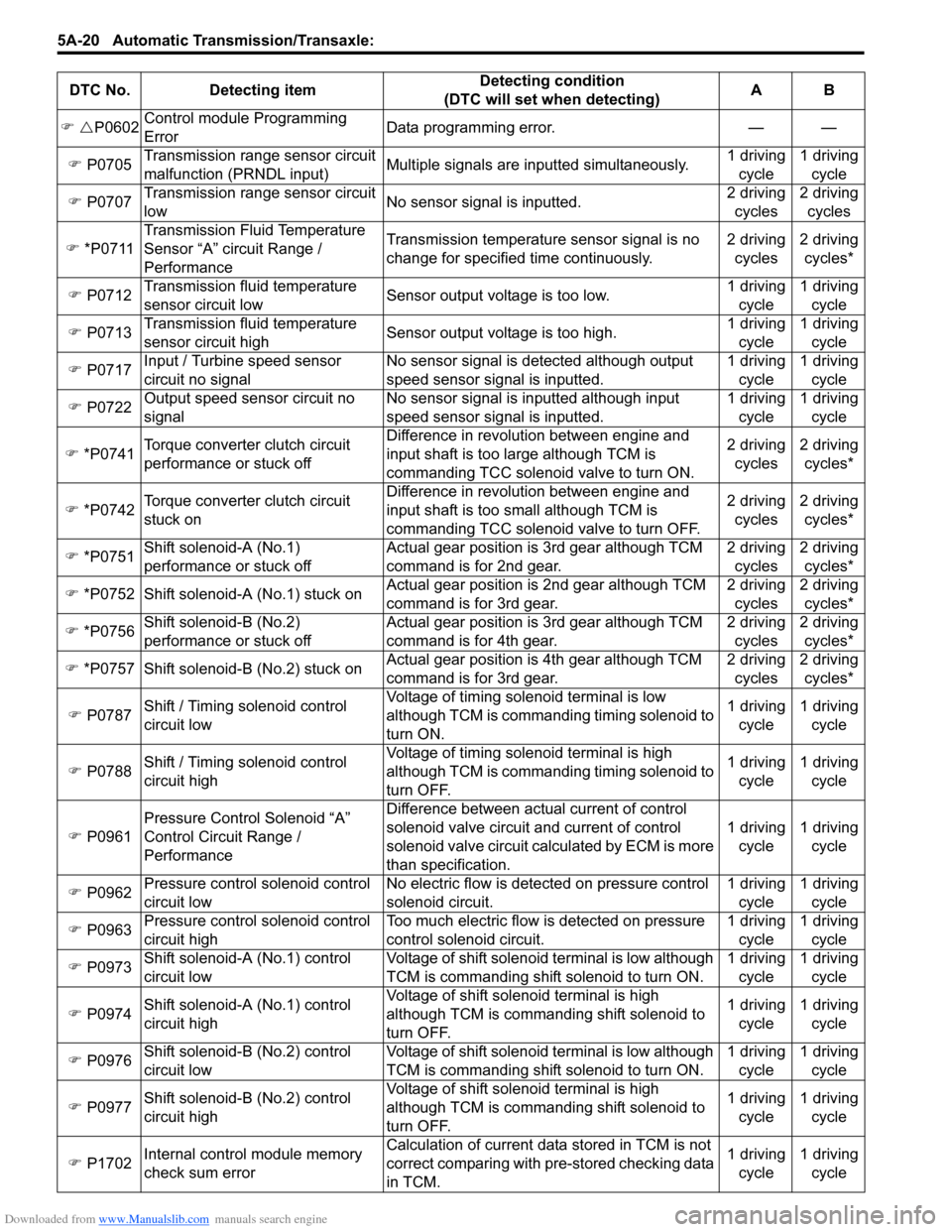

DTC No. Detecting itemDetecting condition

(DTC will set when detecting)AB

�) �UP0602Control module Programming

ErrorData programming error. — —

�) P0705Transmission range sensor circuit

malfunction (PRNDL input)Multiple signals are inputted simultaneously.1 driving

cycle1 driving

cycle

�) P0707Transmission range sensor circuit

lowNo sensor signal is inputted.2 driving

cycles2 driving

cycles

�) *P0711Transmission Fluid Temperature

Sensor “A” circuit Range /

PerformanceTransmission temperature sensor signal is no

change for specified time continuously.2 driving

cycles2 driving

cycles*

�) P0712Transmission fluid temperature

sensor circuit lowSensor output voltage is too low.1 driving

cycle1 driving

cycle

�) P0713Transmission fluid temperature

sensor circuit highSensor output voltage is too high.1 driving

cycle1 driving

cycle

�) P0717Input / Turbine speed sensor

circuit no signalNo sensor signal is detected although output

speed sensor signal is inputted.1 driving

cycle1 driving

cycle

�) P0722Output speed sensor circuit no

signalNo sensor signal is inputted although input

speed sensor signal is inputted.1 driving

cycle1 driving

cycle

�) *P0741Torque converter clutch circuit

performance or stuck offDifference in revolution between engine and

input shaft is too large although TCM is

commanding TCC solenoid valve to turn ON.2 driving

cycles2 driving

cycles*

�) *P0742Torque converter clutch circuit

stuck onDifference in revolution between engine and

input shaft is too small although TCM is

commanding TCC solenoid valve to turn OFF.2 driving

cycles2 driving

cycles*

�) *P0751

Shift solenoid-A (No.1)

performance or stuck offActual gear position is 3rd gear although TCM

command is for 2nd gear.2 driving

cycles2 driving

cycles*

�) *P0752 Shift solenoid-A (No.1) stuck onActual gear position is 2nd gear although TCM

command is for 3rd gear.2 driving

cycles2 driving

cycles*

�) *P0756Shift solenoid-B (No.2)

performance or stuck offActual gear position is 3rd gear although TCM

command is for 4th gear.2 driving

cycles2 driving

cycles*

�) *P0757 Shift solenoid-B (No.2) stuck onActual gear position is 4th gear although TCM

command is for 3rd gear.2 driving

cycles2 driving

cycles*

�) P0787Shift / Timing solenoid control

circuit lowVoltage of timing solenoid terminal is low

although TCM is commanding timing solenoid to

turn ON.1 driving

cycle1 driving

cycle

�) P0788Shift / Timing solenoid control

circuit highVoltage of timing solenoid terminal is high

although TCM is commanding timing solenoid to

turn OFF.1 driving

cycle1 driving

cycle

�) P0961Pressure Control Solenoid “A”

Control Circuit Range /

PerformanceDifference between actual current of control

solenoid valve circuit and current of control

solenoid valve circuit calculated by ECM is more

than specification.1 driving

cycle1 driving

cycle

�) P0962Pressure control solenoid control

circuit lowNo electric flow is detected on pressure control

solenoid circuit.1 driving

cycle1 driving

cycle

�) P0963Pressure control solenoid control

circuit highToo much electric flow is detected on pressure

control solenoid circuit.1 driving

cycle1 driving

cycle

�) P0973Shift solenoid-A (No.1) control

circuit lowVoltage of shift solenoid terminal is low although

TCM is commanding shift solenoid to turn ON.1 driving

cycle1 driving

cycle

�) P0974

Shift solenoid-A (No.1) control

circuit highVoltage of shift solenoid terminal is high

although TCM is commanding shift solenoid to

turn OFF.1 driving

cycle1 driving

cycle

�) P0976Shift solenoid-B (No.2) control

circuit lowVoltage of shift solenoid terminal is low although

TCM is commanding shift solenoid to turn ON.1 driving

cycle1 driving

cycle

�) P0977Shift solenoid-B (No.2) control

circuit highVoltage of shift solenoid terminal is high

although TCM is commanding shift solenoid to

turn OFF.1 driving

cycle1 driving

cycle

�) P1702Internal control module memory

check sum errorCalculation of current data stored in TCM is not

correct comparing with pre-stored checking data

in TCM.1 driving

cycle1 driving

cycle

Page 670 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-22 Automatic Transmission/Transaxle:

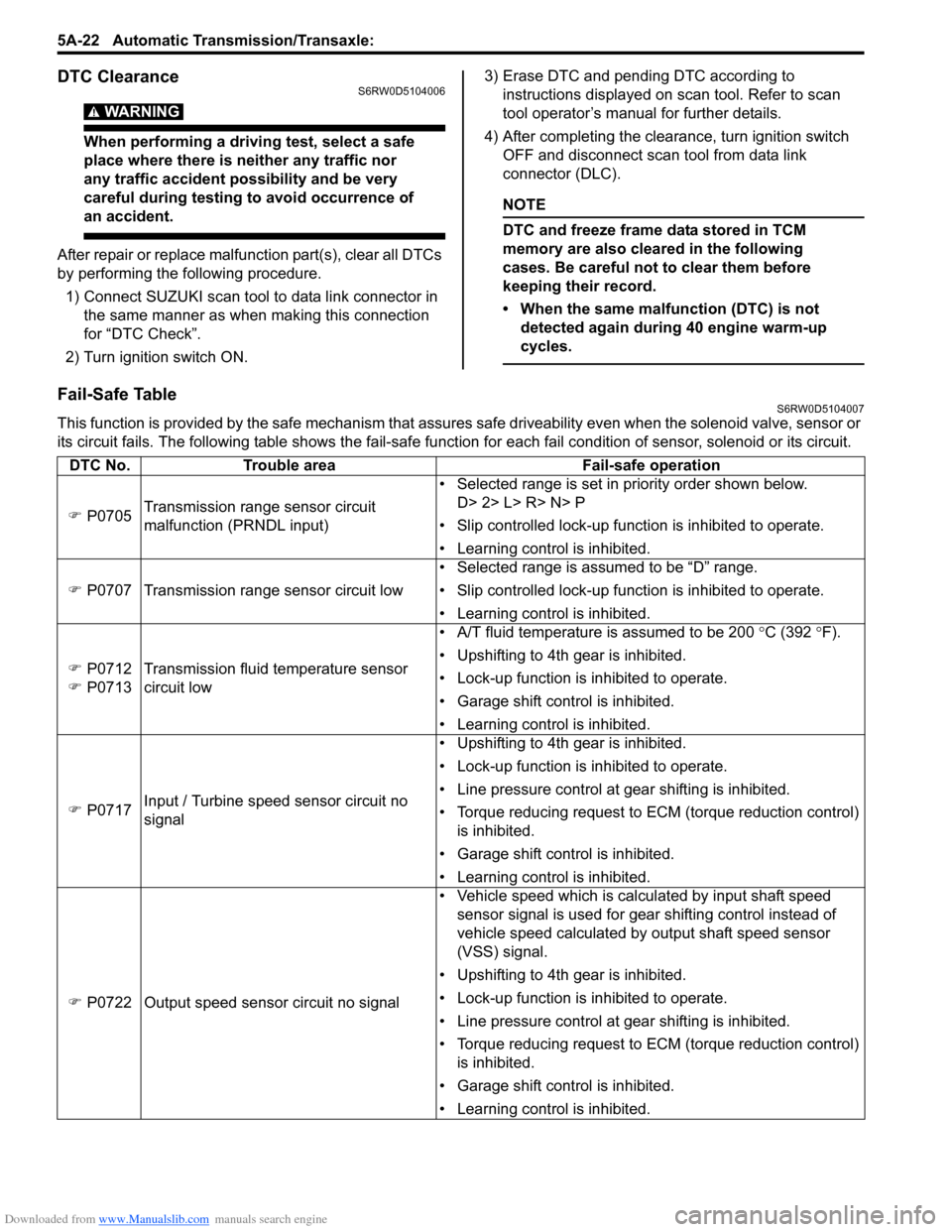

DTC ClearanceS6RW0D5104006

WARNING!

When performing a driving test, select a safe

place where there is neither any traffic nor

any traffic accident possibility and be very

careful during testing to avoid occurrence of

an accident.

After repair or replace malfunction part(s), clear all DTCs

by performing the following procedure.

1) Connect SUZUKI scan tool to data link connector in

the same manner as when making this connection

for “DTC Check”.

2) Turn ignition switch ON.3) Erase DTC and pending DTC according to

instructions displayed on scan tool. Refer to scan

tool operator’s manual for further details.

4) After completing the clearance, turn ignition switch

OFF and disconnect scan tool from data link

connector (DLC).

NOTE

DTC and freeze frame data stored in TCM

memory are also cleared in the following

cases. Be careful not to clear them before

keeping their record.

• When the same malfunction (DTC) is not

detected again during 40 engine warm-up

cycles.

Fail-Safe TableS6RW0D5104007

This function is provided by the safe mechanism that assures safe driveability even when the solenoid valve, sensor or

its circuit fails. The following table shows the fail-safe function for each fail condition of sensor, solenoid or its circuit.

DTC No. Trouble area Fail-safe operation

�) P0705Transmission range sensor circuit

malfunction (PRNDL input)• Selected range is set in priority order shown below.

D> 2> L> R> N> P

• Slip controlled lock-up function is inhibited to operate.

• Learning control is inhibited.

�) P0707 Transmission range sensor circuit low• Selected range is assumed to be “D” range.

• Slip controlled lock-up function is inhibited to operate.

• Learning control is inhibited.

�) P0712

�) P0713Transmission fluid temperature sensor

circuit low• A/T fluid temperature is assumed to be 200 °C (392 °F).

• Upshifting to 4th gear is inhibited.

• Lock-up function is inhibited to operate.

• Garage shift control is inhibited.

• Learning control is inhibited.

�) P0717Input / Turbine speed sensor circuit no

signal• Upshifting to 4th gear is inhibited.

• Lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control)

is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited.

�) P0722 Output speed sensor circuit no signal• Vehicle speed which is calculated by input shaft speed

sensor signal is used for gear shifting control instead of

vehicle speed calculated by output shaft speed sensor

(VSS) signal.

• Upshifting to 4th gear is inhibited.

• Lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control)

is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited.

Page 672 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-24 Automatic Transmission/Transaxle:

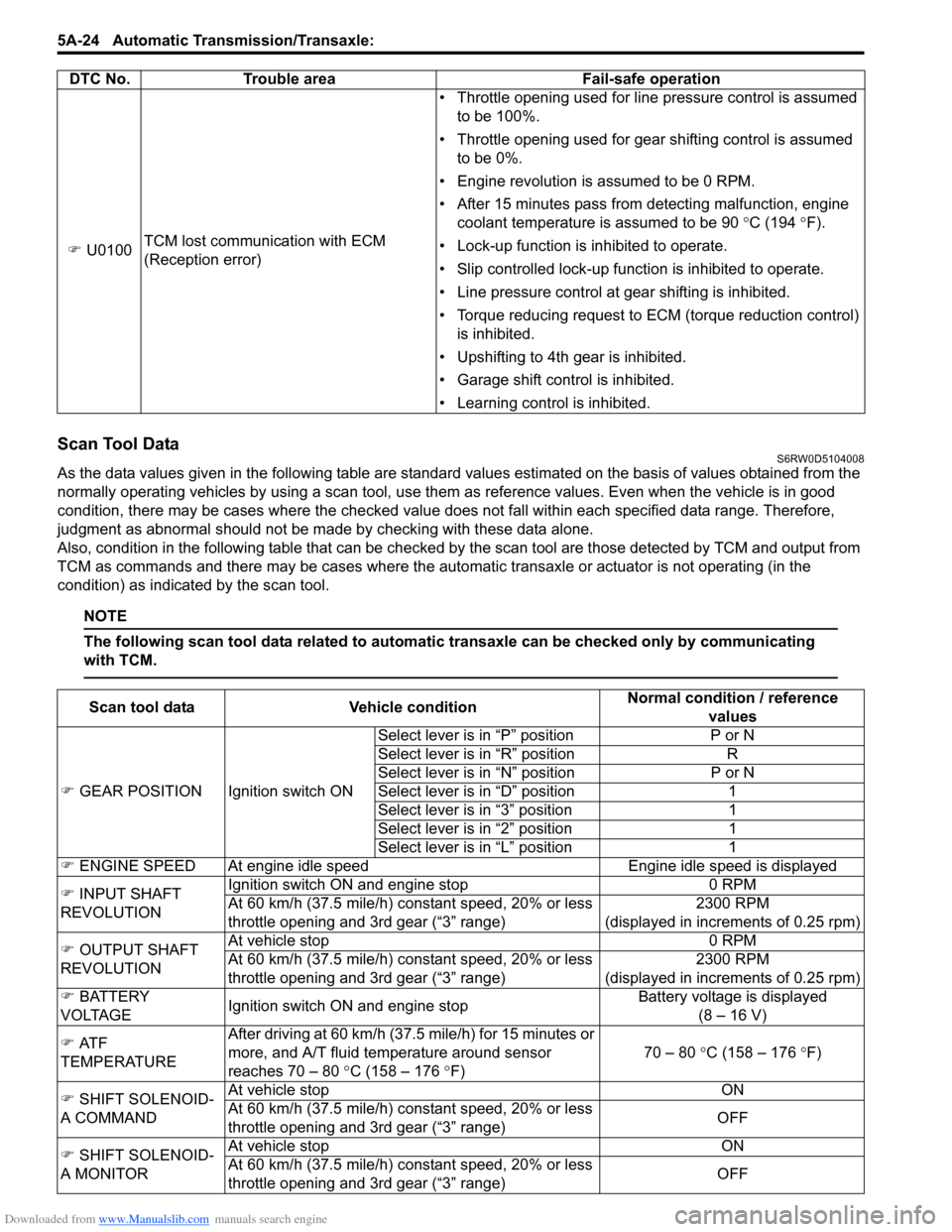

Scan Tool DataS6RW0D5104008

As the data values given in the following table are standard values estimated on the basis of values obtained from the

normally operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good

condition, there may be cases where the checked value does not fall within each specified data range. Therefore,

judgment as abnormal should not be made by checking with these data alone.

Also, condition in the following table that can be checked by the scan tool are those detected by TCM and output from

TCM as commands and there may be cases where the automatic transaxle or actuator is not operating (in the

condition) as indicated by the scan tool.

NOTE

The following scan tool data related to automatic transaxle can be checked only by communicating

with TCM.

�) U0100TCM lost communication with ECM

(Reception error)• Throttle opening used for line pressure control is assumed

to be 100%.

• Throttle opening used for gear shifting control is assumed

to be 0%.

• Engine revolution is assumed to be 0 RPM.

• After 15 minutes pass from detecting malfunction, engine

coolant temperature is assumed to be 90 °C (194 °F).

• Lock-up function is inhibited to operate.

• Slip controlled lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control)

is inhibited.

• Upshifting to 4th gear is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited. DTC No. Trouble area Fail-safe operation

Scan tool data Vehicle conditionNormal condition / reference

values

�) GEAR POSITION Ignition switch ONSelect lever is in “P” position P or N

Select lever is in “R” position R

Select lever is in “N” position P or N

Select lever is in “D” position 1

Select lever is in “3” position 1

Select lever is in “2” position 1

Select lever is in “L” position 1

�) ENGINE SPEED At engine idle speed Engine idle speed is displayed

�) INPUT SHAFT

REVOLUTIONIgnition switch ON and engine stop 0 RPM

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)2300 RPM

(displayed in increments of 0.25 rpm)

�) OUTPUT SHAFT

REVOLUTIONAt vehicle stop 0 RPM

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)2300 RPM

(displayed in increments of 0.25 rpm)

�) BATTERY

VOLTAGEIgnition switch ON and engine stopBattery voltage is displayed

(8 – 16 V)

�) AT F

TEMPERATUREAfter driving at 60 km/h (37.5 mile/h) for 15 minutes or

more, and A/T fluid temperature around sensor

reaches 70 – 80 °C (158 – 176 °F)70 – 80 °C (158 – 176 °F)

�) SHIFT SOLENOID-

A COMMANDAt vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)OFF

�) SHIFT SOLENOID-

A MONITORAt vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)OFF

Page 674 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-26 Automatic Transmission/Transaxle:

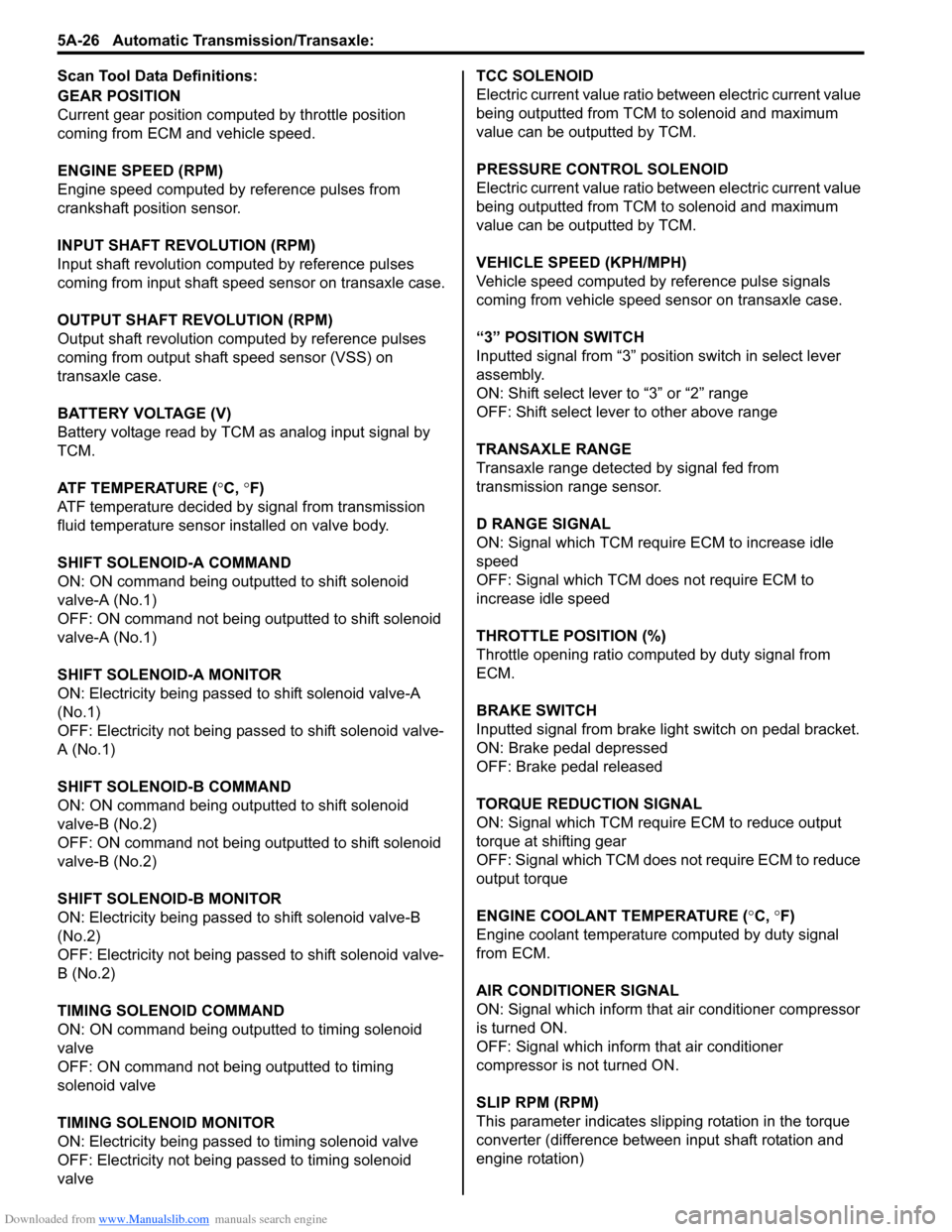

Scan Tool Data Definitions:

GEAR POSITION

Current gear position computed by throttle position

coming from ECM and vehicle speed.

ENGINE SPEED (RPM)

Engine speed computed by reference pulses from

crankshaft position sensor.

INPUT SHAFT REVOLUTION (RPM)

Input shaft revolution computed by reference pulses

coming from input shaft speed sensor on transaxle case.

OUTPUT SHAFT REVOLUTION (RPM)

Output shaft revolution computed by reference pulses

coming from output shaft speed sensor (VSS) on

transaxle case.

BATTERY VOLTAGE (V)

Battery voltage read by TCM as analog input signal by

TCM.

ATF TEMPERATURE (°C, °F)

ATF temperature decided by signal from transmission

fluid temperature sensor installed on valve body.

SHIFT SOLENOID-A COMMAND

ON: ON command being outputted to shift solenoid

valve-A (No.1)

OFF: ON command not being outputted to shift solenoid

valve-A (No.1)

SHIFT SOLENOID-A MONITOR

ON: Electricity being passed to shift solenoid valve-A

(No.1)

OFF: Electricity not being passed to shift solenoid valve-

A (No.1)

SHIFT SOLENOID-B COMMAND

ON: ON command being outputted to shift solenoid

valve-B (No.2)

OFF: ON command not being outputted to shift solenoid

valve-B (No.2)

SHIFT SOLENOID-B MONITOR

ON: Electricity being passed to shift solenoid valve-B

(No.2)

OFF: Electricity not being passed to shift solenoid valve-

B (No.2)

TIMING SOLENOID COMMAND

ON: ON command being outputted to timing solenoid

valve

OFF: ON command not being outputted to timing

solenoid valve

TIMING SOLENOID MONITOR

ON: Electricity being passed to timing solenoid valve

OFF: Electricity not being passed to timing solenoid

valveTCC SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

PRESSURE CONTROL SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

VEHICLE SPEED (KPH/MPH)

Vehicle speed computed by reference pulse signals

coming from vehicle speed sensor on transaxle case.

“3” POSITION SWITCH

Inputted signal from “3” position switch in select lever

assembly.

ON: Shift select lever to “3” or “2” range

OFF: Shift select lever to other above range

TRANSAXLE RANGE

Transaxle range detected by signal fed from

transmission range sensor.

D RANGE SIGNAL

ON: Signal which TCM require ECM to increase idle

speed

OFF: Signal which TCM does not require ECM to

increase idle speed

THROTTLE POSITION (%)

Throttle opening ratio computed by duty signal from

ECM.

BRAKE SWITCH

Inputted signal from brake light switch on pedal bracket.

ON: Brake pedal depressed

OFF: Brake pedal released

TORQUE REDUCTION SIGNAL

ON: Signal which TCM require ECM to reduce output

torque at shifting gear

OFF: Signal which TCM does not require ECM to reduce

output torque

ENGINE COOLANT TEMPERATURE (°C, °F)

Engine coolant temperature computed by duty signal

from ECM.

AIR CONDITIONER SIGNAL

ON: Signal which inform that air conditioner compressor

is turned ON.

OFF: Signal which inform that air conditioner

compressor is not turned ON.

SLIP RPM (RPM)

This parameter indicates slipping rotation in the torque

converter (difference between input shaft rotation and

engine rotation)

Page 676 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-28 Automatic Transmission/Transaxle:

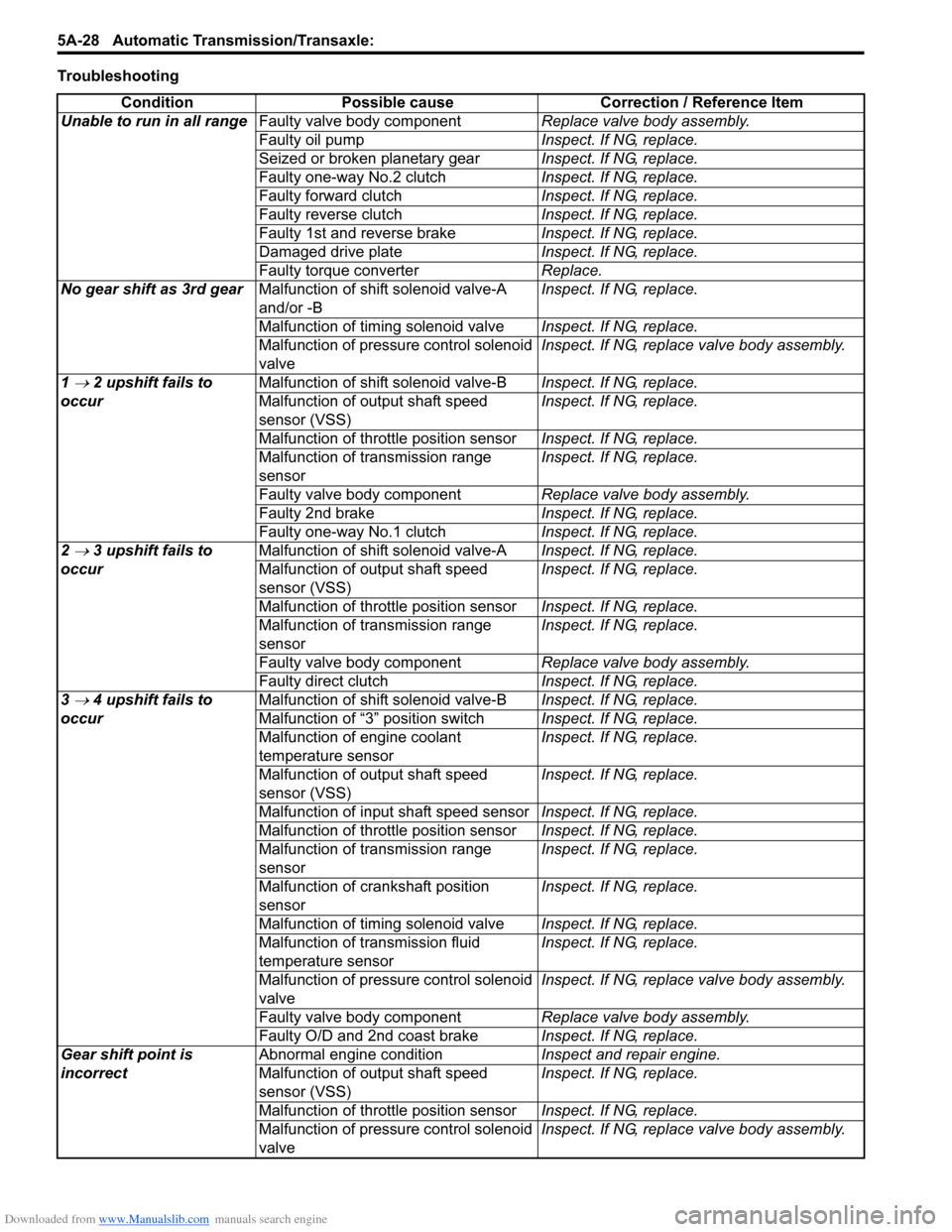

Troubleshooting

Condition Possible cause Correction / Reference Item

Unable to run in all rangeFaulty valve body componentReplace valve body assembly.

Faulty oil pumpInspect. If NG, replace.

Seized or broken planetary gearInspect. If NG, replace.

Faulty one-way No.2 clutchInspect. If NG, replace.

Faulty forward clutchInspect. If NG, replace.

Faulty reverse clutchInspect. If NG, replace.

Faulty 1st and reverse brakeInspect. If NG, replace.

Damaged drive plateInspect. If NG, replace.

Faulty torque converterReplace.

No gear shift as 3rd gearMalfunction of shift solenoid valve-A

and/or -BInspect. If NG, replace.

Malfunction of timing solenoid valveInspect. If NG, replace.

Malfunction of pressure control solenoid

valveInspect. If NG, replace valve body assembly.

1

→ 2 upshift fails to

occurMalfunction of shift solenoid valve-BInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of throttle position sensorInspect. If NG, replace.

Malfunction of transmission range

sensorInspect. If NG, replace.

Faulty valve body componentReplace valve body assembly.

Faulty 2nd brakeInspect. If NG, replace.

Faulty one-way No.1 clutchInspect. If NG, replace.

2

→ 3 upshift fails to

occurMalfunction of shift solenoid valve-AInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of throttle position sensorInspect. If NG, replace.

Malfunction of transmission range

sensorInspect. If NG, replace.

Faulty valve body componentReplace valve body assembly.

Faulty direct clutchInspect. If NG, replace.

3

→ 4 upshift fails to

occurMalfunction of shift solenoid valve-BInspect. If NG, replace.

Malfunction of “3” position switchInspect. If NG, replace.

Malfunction of engine coolant

temperature sensorInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of input shaft speed sensorInspect. If NG, replace.

Malfunction of throttle position sensorInspect. If NG, replace.

Malfunction of transmission range

sensorInspect. If NG, replace.

Malfunction of crankshaft position

sensorInspect. If NG, replace.

Malfunction of timing solenoid valveInspect. If NG, replace.

Malfunction of transmission fluid

temperature sensorInspect. If NG, replace.

Malfunction of pressure control solenoid

valveInspect. If NG, replace valve body assembly.

Faulty valve body componentReplace valve body assembly.

Faulty O/D and 2nd coast brakeInspect. If NG, replace.

Gear shift point is

incorrectAbnormal engine conditionInspect and repair engine.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of throttle position sensorInspect. If NG, replace.

Malfunction of pressure control solenoid

valveInspect. If NG, replace valve body assembly.

Page 677 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-29

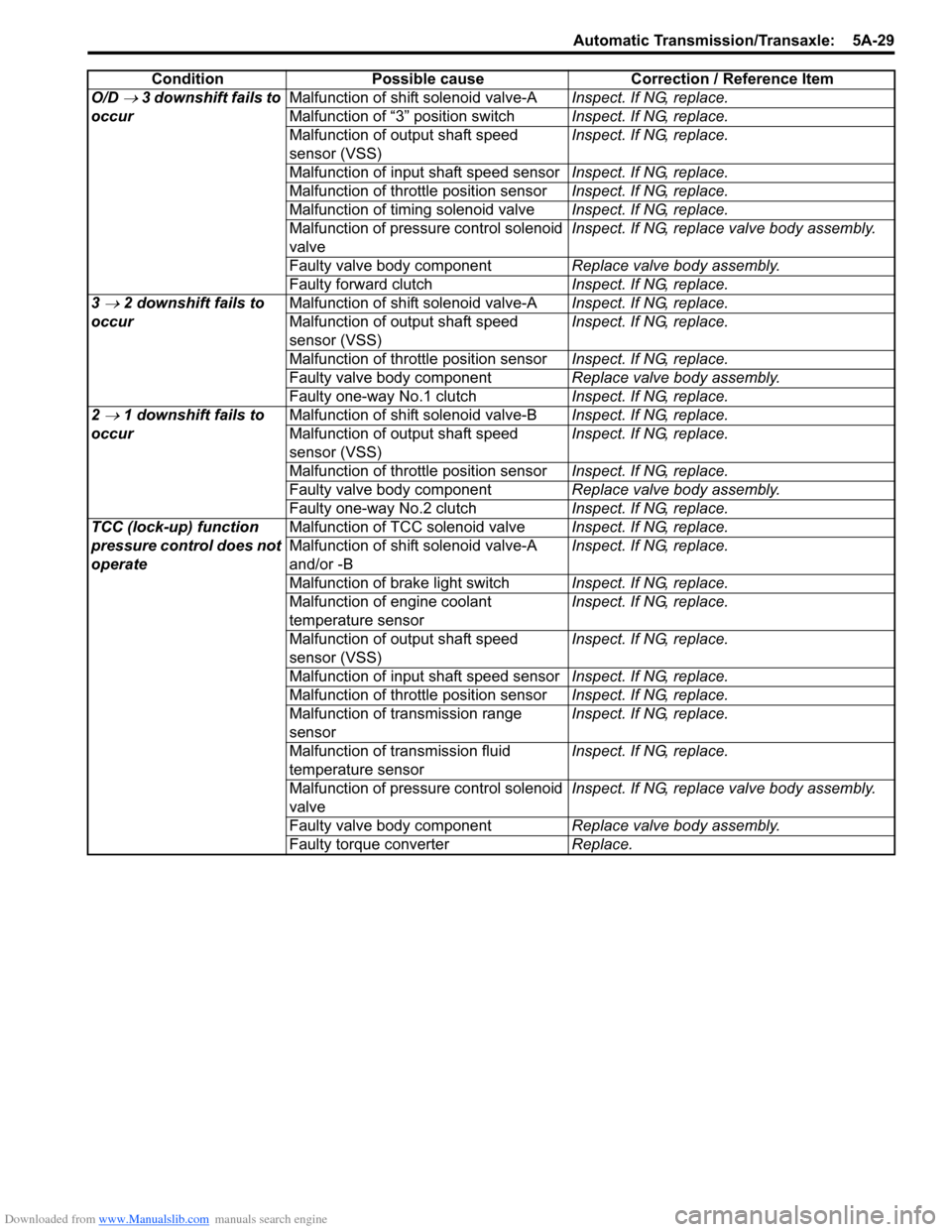

O/D → 3 downshift fails to

occurMalfunction of shift solenoid valve-AInspect. If NG, replace.

Malfunction of “3” position switchInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of input shaft speed sensorInspect. If NG, replace.

Malfunction of throttle position sensorInspect. If NG, replace.

Malfunction of timing solenoid valveInspect. If NG, replace.

Malfunction of pressure control solenoid

valveInspect. If NG, replace valve body assembly.

Faulty valve body componentReplace valve body assembly.

Faulty forward clutchInspect. If NG, replace.

3

→ 2 downshift fails to

occurMalfunction of shift solenoid valve-AInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of throttle position sensorInspect. If NG, replace.

Faulty valve body componentReplace valve body assembly.

Faulty one-way No.1 clutchInspect. If NG, replace.

2

→ 1 downshift fails to

occurMalfunction of shift solenoid valve-BInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of throttle position sensorInspect. If NG, replace.

Faulty valve body componentReplace valve body assembly.

Faulty one-way No.2 clutchInspect. If NG, replace.

TCC (lock-up) function

pressure control does not

operateMalfunction of TCC solenoid valveInspect. If NG, replace.

Malfunction of shift solenoid valve-A

and/or -BInspect. If NG, replace.

Malfunction of brake light switchInspect. If NG, replace.

Malfunction of engine coolant

temperature sensorInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of input shaft speed sensorInspect. If NG, replace.

Malfunction of throttle position sensorInspect. If NG, replace.

Malfunction of transmission range

sensorInspect. If NG, replace.

Malfunction of transmission fluid

temperature sensorInspect. If NG, replace.

Malfunction of pressure control solenoid

valveInspect. If NG, replace valve body assembly.

Faulty valve body componentReplace valve body assembly.

Faulty torque converterReplace. Condition Possible cause Correction / Reference Item

Page 680 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-32 Automatic Transmission/Transaxle:

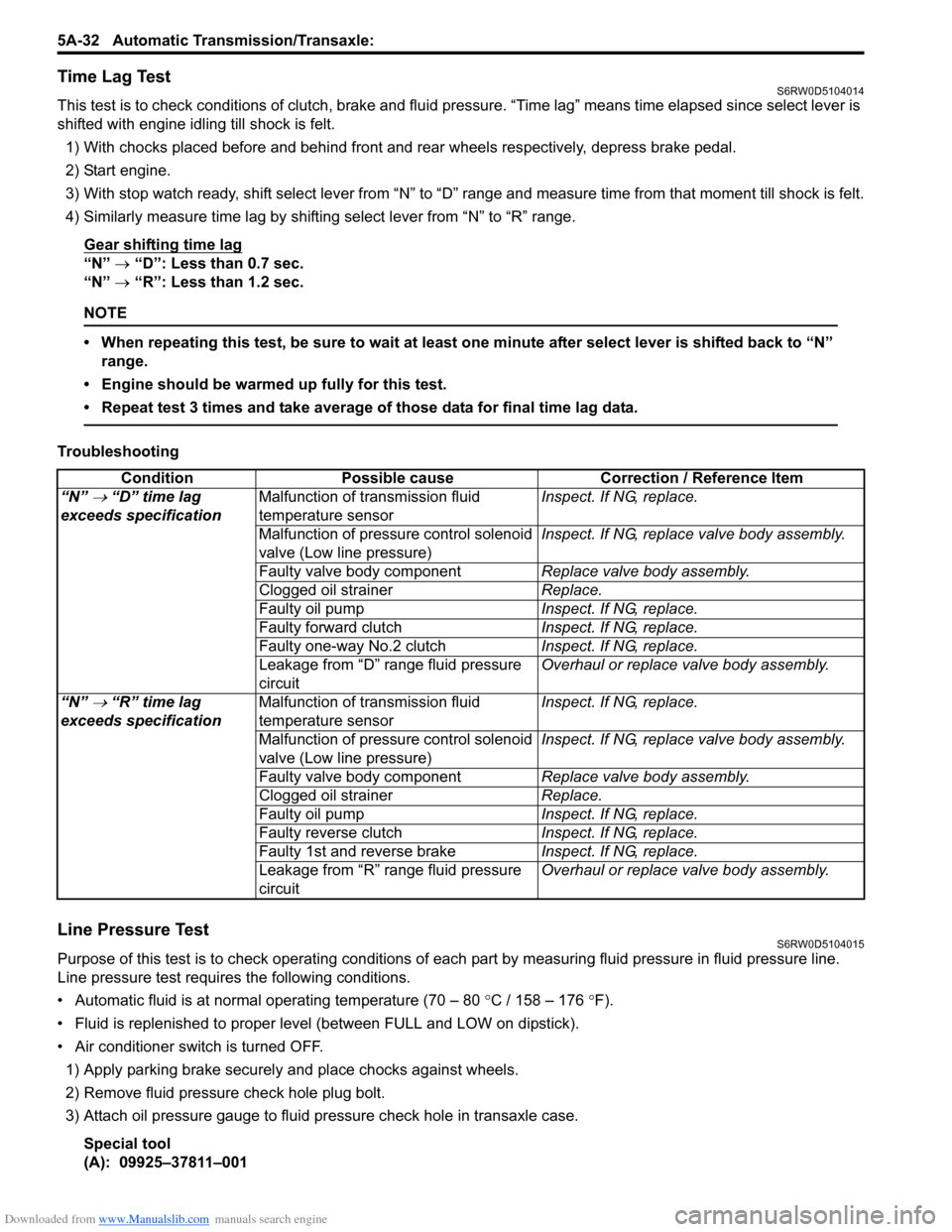

Time Lag TestS6RW0D5104014

This test is to check conditions of clutch, brake and fluid pressure. “Time lag” means time elapsed since select lever is

shifted with engine idling till shock is felt.

1) With chocks placed before and behind front and rear wheels respectively, depress brake pedal.

2) Start engine.

3) With stop watch ready, shift select lever from “N” to “D” range and measure time from that moment till shock is felt.

4) Similarly measure time lag by shifting select lever from “N” to “R” range.

Gear shifting time lag

“N” → “D”: Less than 0.7 sec.

“N” → “R”: Less than 1.2 sec.

NOTE

• When repeating this test, be sure to wait at least one minute after select lever is shifted back to “N”

range.

• Engine should be warmed up fully for this test.

• Repeat test 3 times and take average of those data for final time lag data.

Troubleshooting

Line Pressure TestS6RW0D5104015

Purpose of this test is to check operating conditions of each part by measuring fluid pressure in fluid pressure line.

Line pressure test requires the following conditions.

• Automatic fluid is at normal operating temperature (70 – 80 °C / 158 – 176 °F).

• Fluid is replenished to proper level (between FULL and LOW on dipstick).

• Air conditioner switch is turned OFF.

1) Apply parking brake securely and place chocks against wheels.

2) Remove fluid pressure check hole plug bolt.

3) Attach oil pressure gauge to fluid pressure check hole in transaxle case.

Special tool

(A): 09925–37811–001Condition Possible cause Correction / Reference Item

“N”

→ “D” time lag

exceeds specificationMalfunction of transmission fluid

temperature sensorInspect. If NG, replace.

Malfunction of pressure control solenoid

valve (Low line pressure)Inspect. If NG, replace valve body assembly.

Faulty valve body componentReplace valve body assembly.

Clogged oil strainerReplace.

Faulty oil pumpInspect. If NG, replace.

Faulty forward clutchInspect. If NG, replace.

Faulty one-way No.2 clutchInspect. If NG, replace.

Leakage from “D” range fluid pressure

circuitOverhaul or replace valve body assembly.

“N”

→ “R” time lag

exceeds specificationMalfunction of transmission fluid

temperature sensorInspect. If NG, replace.

Malfunction of pressure control solenoid

valve (Low line pressure)Inspect. If NG, replace valve body assembly.

Faulty valve body componentReplace valve body assembly.

Clogged oil strainerReplace.

Faulty oil pumpInspect. If NG, replace.

Faulty reverse clutchInspect. If NG, replace.

Faulty 1st and reverse brakeInspect. If NG, replace.

Leakage from “R” range fluid pressure

circuitOverhaul or replace valve body assembly.

Page 682 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-34 Automatic Transmission/Transaxle:

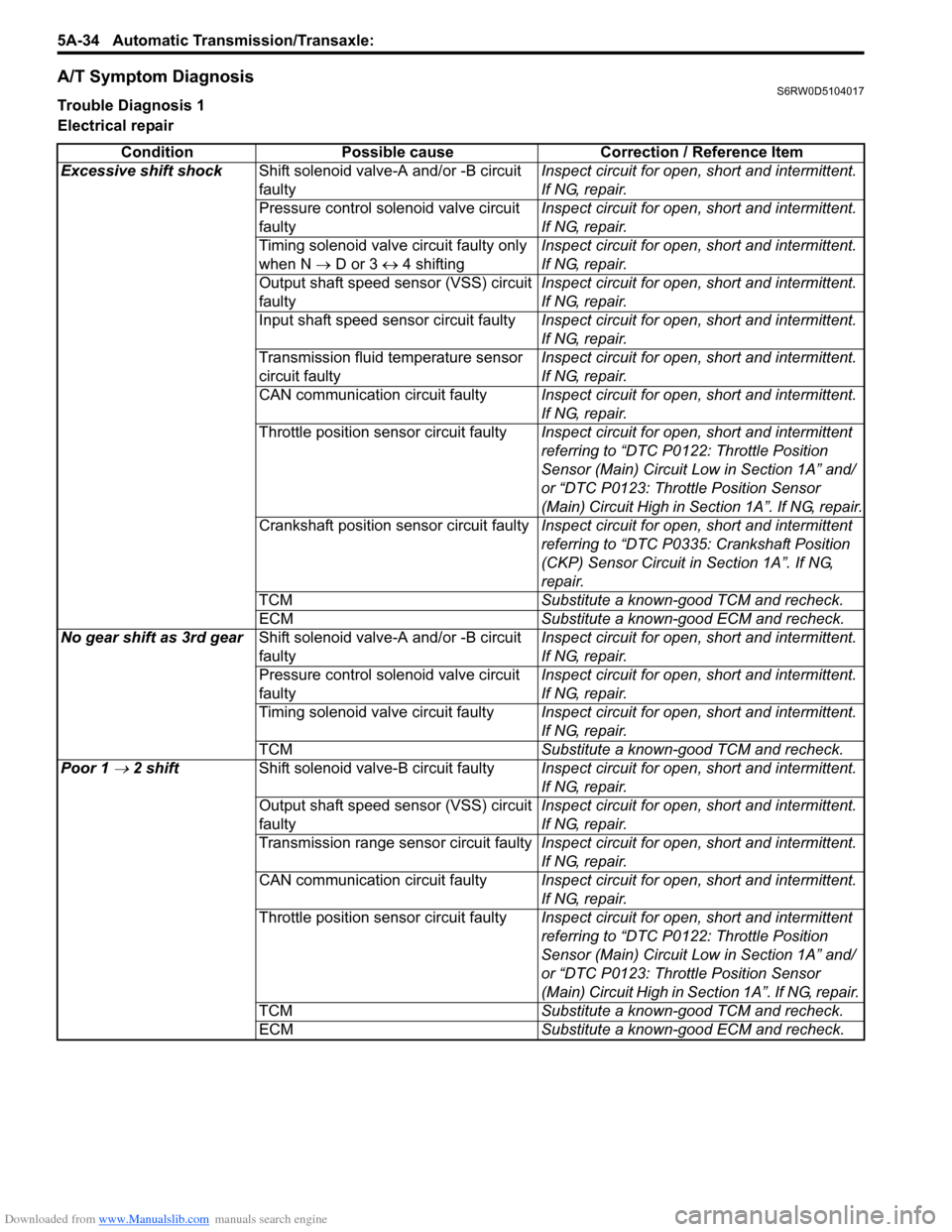

A/T Symptom DiagnosisS6RW0D5104017

Trouble Diagnosis 1

Electrical repair

Condition Possible cause Correction / Reference Item

Excessive shift shockShift solenoid valve-A and/or -B circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

Timing solenoid valve circuit faulty only

when N → D or 3 ↔ 4 shiftingInspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor (VSS) circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

Input shaft speed sensor circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0122: Throttle Position

Sensor (Main) Circuit Low in Section 1A” and/

or “DTC P0123: Throttle Position Sensor

(Main) Circuit High in Section 1A”. If NG, repair.

Crankshaft position sensor circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0335: Crankshaft Position

(CKP) Sensor Circuit in Section 1A”. If NG,

repair.

TCMSubstitute a known-good TCM and recheck.

ECMSubstitute a known-good ECM and recheck.

No gear shift as 3rd gearShift solenoid valve-A and/or -B circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

Timing solenoid valve circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

TCMSubstitute a known-good TCM and recheck.

Poor 1

→ 2 shiftShift solenoid valve-B circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor (VSS) circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0122: Throttle Position

Sensor (Main) Circuit Low in Section 1A” and/

or “DTC P0123: Throttle Position Sensor

(Main) Circuit High in Section 1A”. If NG, repair.

TCMSubstitute a known-good TCM and recheck.

ECMSubstitute a known-good ECM and recheck.

Page 683 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-35

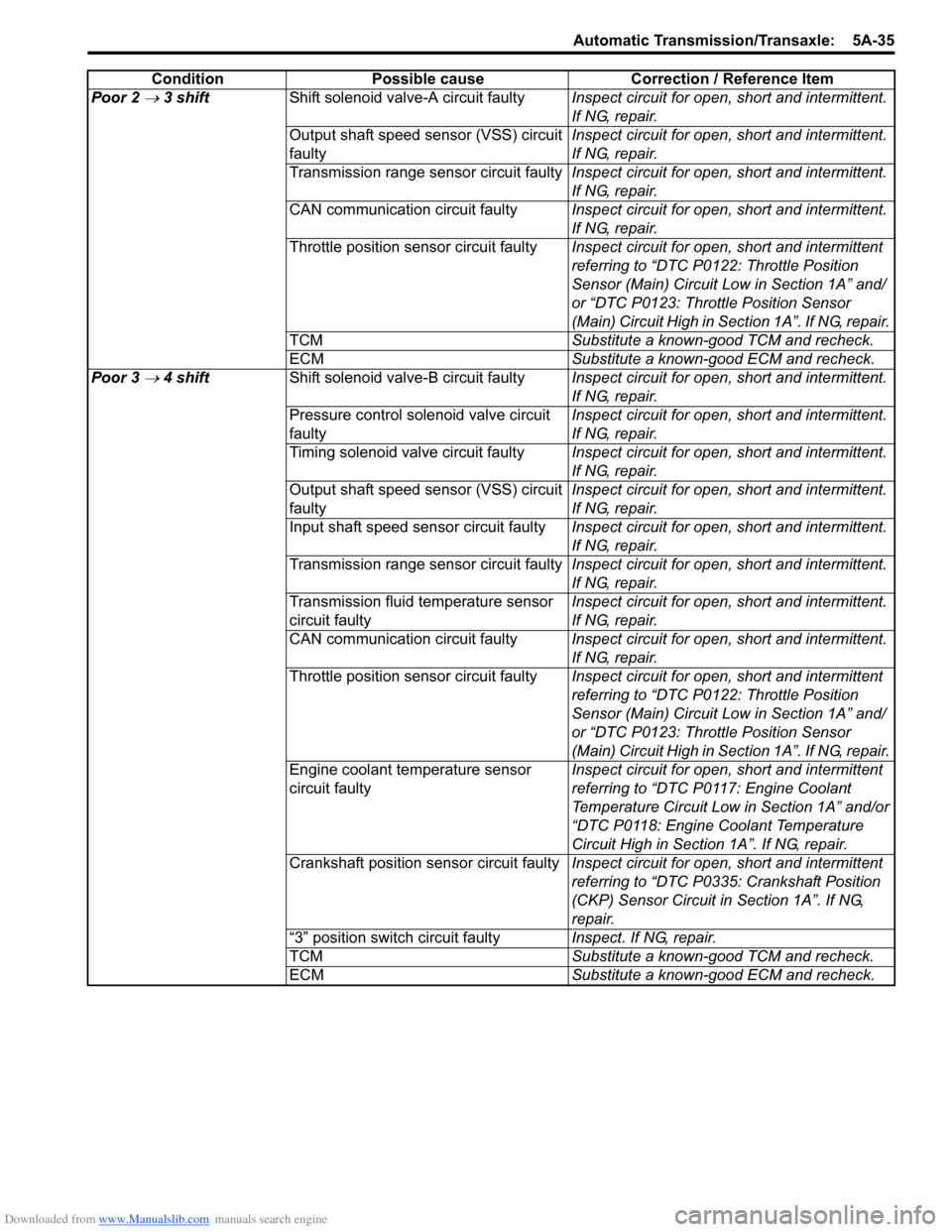

Poor 2 → 3 shiftShift solenoid valve-A circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor (VSS) circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0122: Throttle Position

Sensor (Main) Circuit Low in Section 1A” and/

or “DTC P0123: Throttle Position Sensor

(Main) Circuit High in Section 1A”. If NG, repair.

TCMSubstitute a known-good TCM and recheck.

ECMSubstitute a known-good ECM and recheck.

Poor 3

→ 4 shiftShift solenoid valve-B circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

Timing solenoid valve circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor (VSS) circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Input shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0122: Throttle Position

Sensor (Main) Circuit Low in Section 1A” and/

or “DTC P0123: Throttle Position Sensor

(Main) Circuit High in Section 1A”. If NG, repair.

Engine coolant temperature sensor

circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0117: Engine Coolant

Temperature Circuit Low in Section 1A” and/or

“DTC P0118: Engine Coolant Temperature

Circuit High in Section 1A”. If NG, repair.

Crankshaft position sensor circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0335: Crankshaft Position

(CKP) Sensor Circuit in Section 1A”. If NG,

repair.

“3” position switch circuit faultyInspect. If NG, repair.

TCMSubstitute a known-good TCM and recheck.

ECMSubstitute a known-good ECM and recheck. Condition Possible cause Correction / Reference Item