sensor SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 684 of 1556

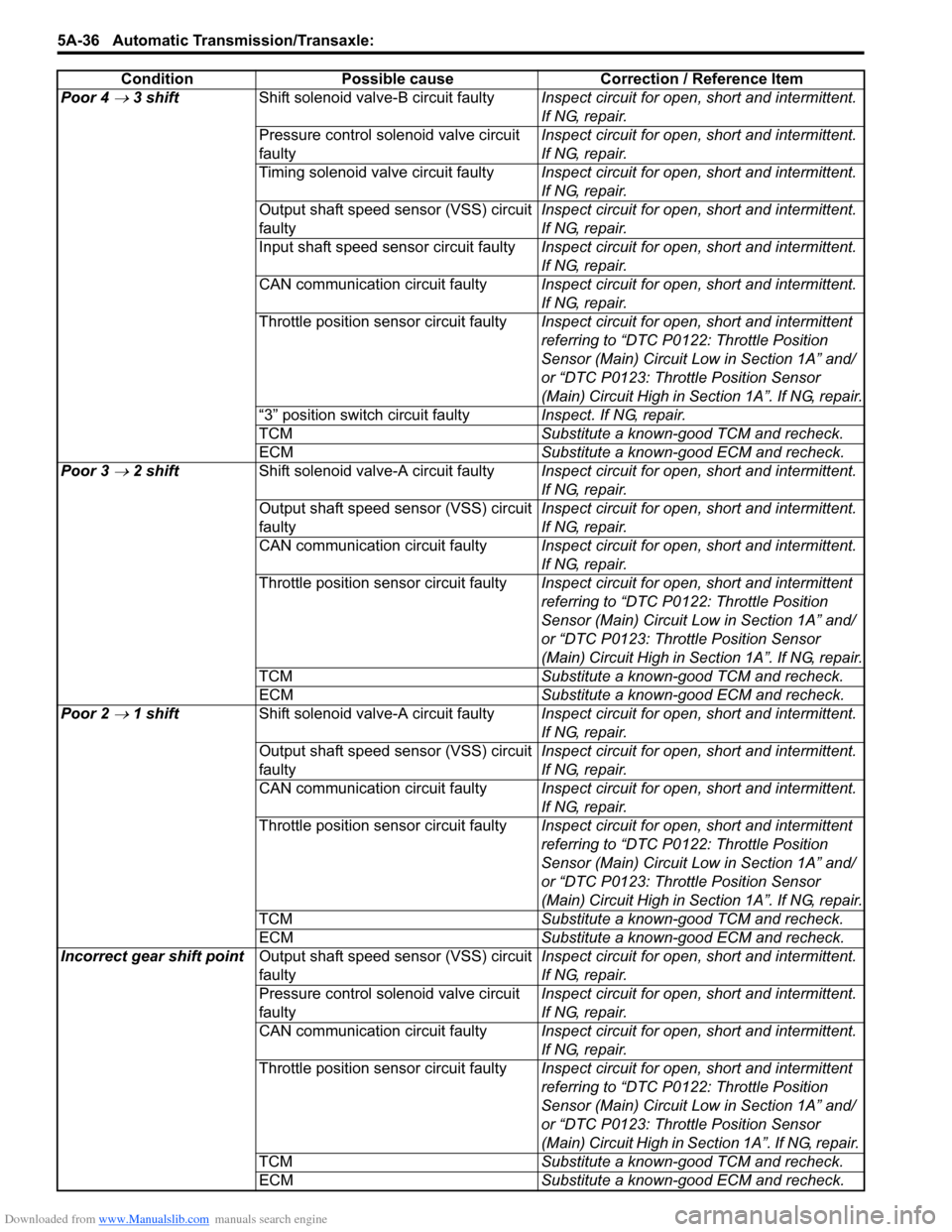

Downloaded from www.Manualslib.com manuals search engine 5A-36 Automatic Transmission/Transaxle:

Poor 4 → 3 shiftShift solenoid valve-B circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

Timing solenoid valve circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor (VSS) circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Input shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0122: Throttle Position

Sensor (Main) Circuit Low in Section 1A” and/

or “DTC P0123: Throttle Position Sensor

(Main) Circuit High in Section 1A”. If NG, repair.

“3” position switch circuit faultyInspect. If NG, repair.

TCMSubstitute a known-good TCM and recheck.

ECMSubstitute a known-good ECM and recheck.

Poor 3

→ 2 shiftShift solenoid valve-A circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor (VSS) circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0122: Throttle Position

Sensor (Main) Circuit Low in Section 1A” and/

or “DTC P0123: Throttle Position Sensor

(Main) Circuit High in Section 1A”. If NG, repair.

TCMSubstitute a known-good TCM and recheck.

ECMSubstitute a known-good ECM and recheck.

Poor 2

→ 1 shiftShift solenoid valve-A circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor (VSS) circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0122: Throttle Position

Sensor (Main) Circuit Low in Section 1A” and/

or “DTC P0123: Throttle Position Sensor

(Main) Circuit High in Section 1A”. If NG, repair.

TCMSubstitute a known-good TCM and recheck.

ECMSubstitute a known-good ECM and recheck.

Incorrect gear shift pointOutput shaft speed sensor (VSS) circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0122: Throttle Position

Sensor (Main) Circuit Low in Section 1A” and/

or “DTC P0123: Throttle Position Sensor

(Main) Circuit High in Section 1A”. If NG, repair.

TCMSubstitute a known-good TCM and recheck.

ECMSubstitute a known-good ECM and recheck. Condition Possible cause Correction / Reference Item

Page 685 of 1556

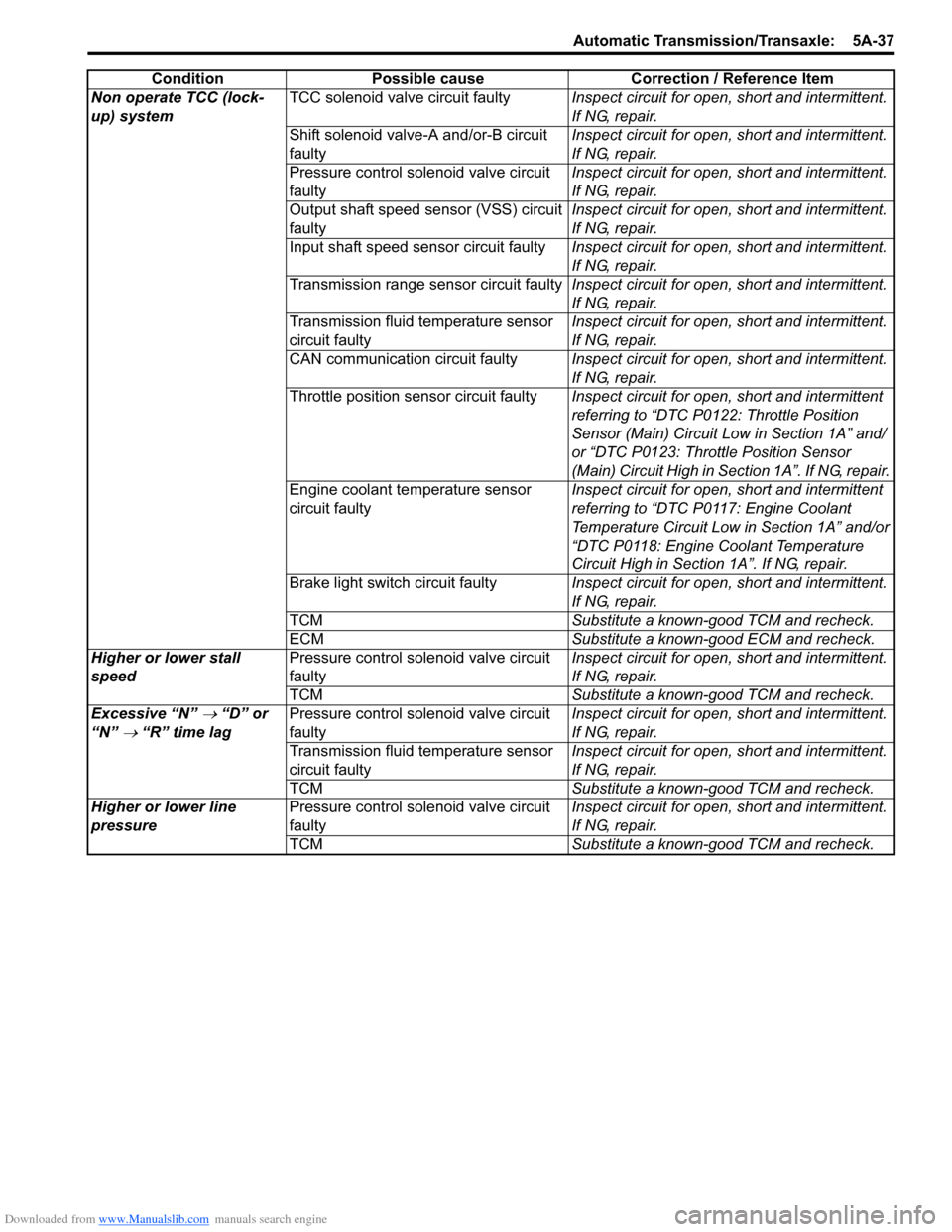

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-37

Non operate TCC (lock-

up) systemTCC solenoid valve circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Shift solenoid valve-A and/or-B circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

Pressure control solenoid valve circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

Output shaft speed sensor (VSS) circuit

faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Input shaft speed sensor circuit faulty Inspect circuit for open, short and intermittent.

If NG, repair.

Transmission range sensor circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

CAN communication circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

Throttle position sensor circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0122: Throttle Position

Sensor (Main) Circuit Low in Section 1A” and/

or “DTC P0123: Throttle Position Sensor

(Main) Circuit High in Section 1A”. If NG, repair.

Engine coolant temperature sensor

circuit faultyInspect circuit for open, short and intermittent

referring to “DTC P0117: Engine Coolant

Temperature Circuit Low in Section 1A” and/or

“DTC P0118: Engine Coolant Temperature

Circuit High in Section 1A”. If NG, repair.

Brake light switch circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

TCMSubstitute a known-good TCM and recheck.

ECMSubstitute a known-good ECM and recheck.

Higher or lower stall

speedPressure control solenoid valve circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

TCMSubstitute a known-good TCM and recheck.

Excessive “N”

→ “D” or

“N”

→ “R” time lagPressure control solenoid valve circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

Transmission fluid temperature sensor

circuit faultyInspect circuit for open, short and intermittent.

If NG, repair.

TCMSubstitute a known-good TCM and recheck.

Higher or lower line

pressurePressure control solenoid valve circuit

faultyInspect circuit for open, short and intermittent.

If NG, repair.

TCMSubstitute a known-good TCM and recheck. Condition Possible cause Correction / Reference Item

Page 686 of 1556

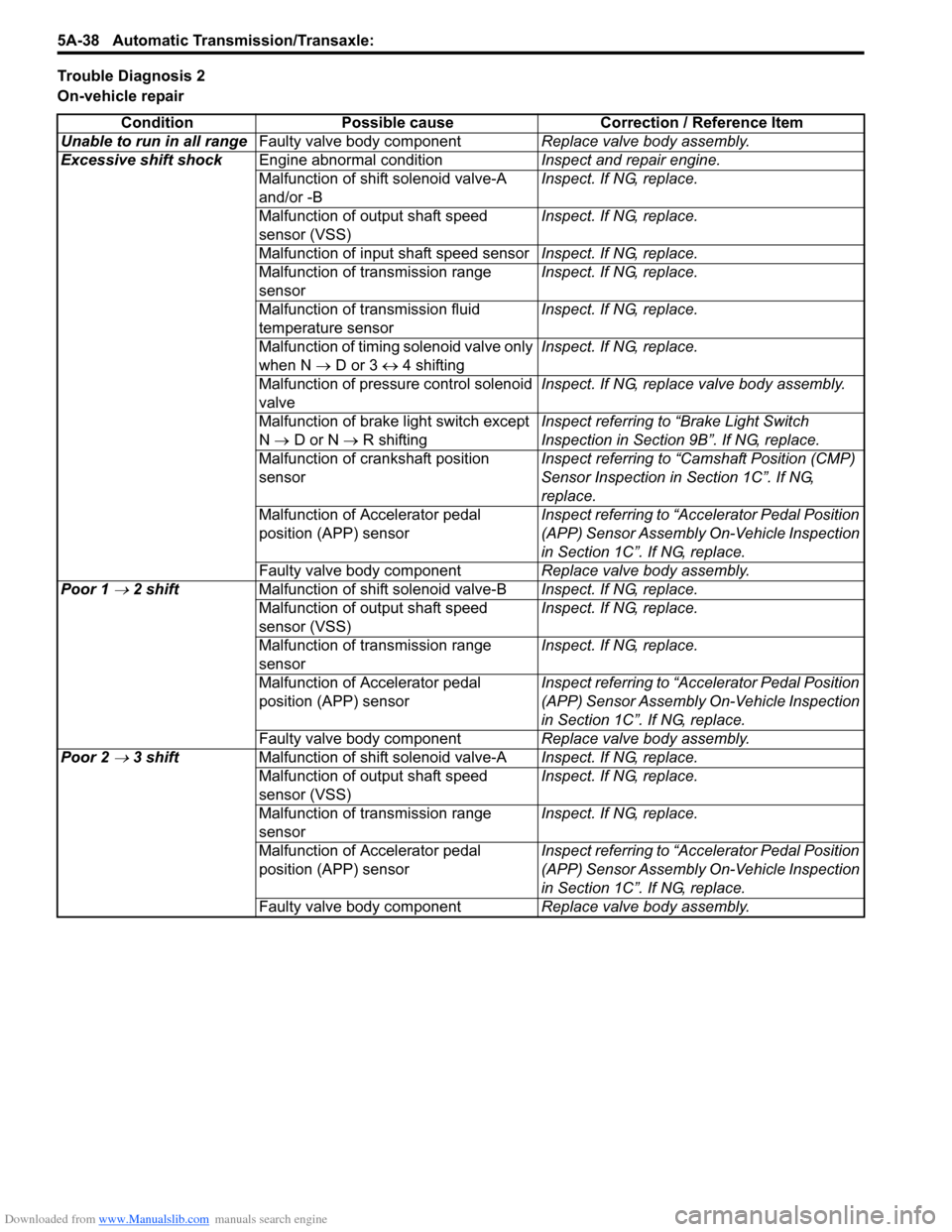

Downloaded from www.Manualslib.com manuals search engine 5A-38 Automatic Transmission/Transaxle:

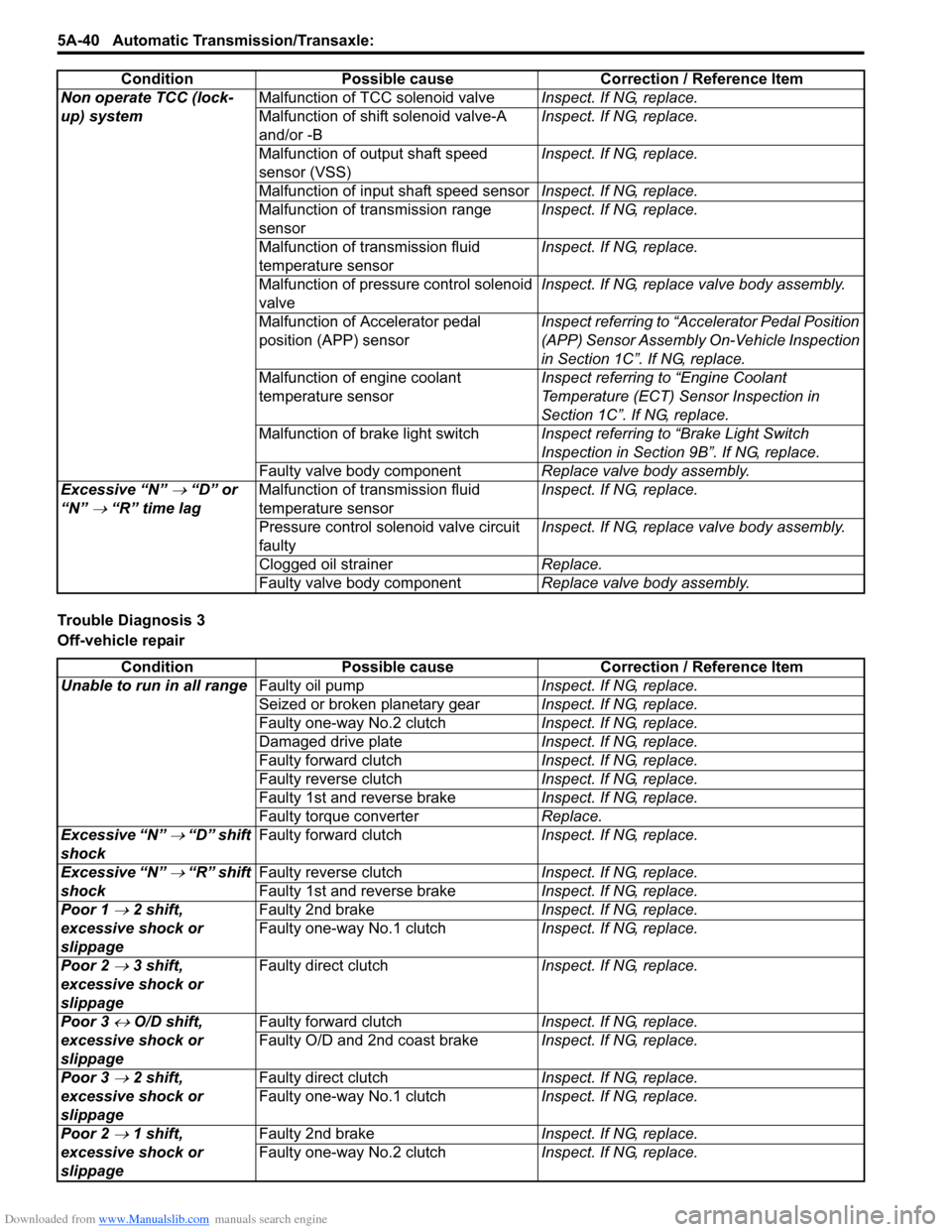

Trouble Diagnosis 2

On-vehicle repair

Condition Possible cause Correction / Reference Item

Unable to run in all rangeFaulty valve body componentReplace valve body assembly.

Excessive shift shockEngine abnormal conditionInspect and repair engine.

Malfunction of shift solenoid valve-A

and/or -BInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of input shaft speed sensorInspect. If NG, replace.

Malfunction of transmission range

sensorInspect. If NG, replace.

Malfunction of transmission fluid

temperature sensorInspect. If NG, replace.

Malfunction of timing solenoid valve only

when N → D or 3 ↔ 4 shiftingInspect. If NG, replace.

Malfunction of pressure control solenoid

valveInspect. If NG, replace valve body assembly.

Malfunction of brake light switch except

N → D or N → R shiftingInspect referring to “Brake Light Switch

Inspection in Section 9B”. If NG, replace.

Malfunction of crankshaft position

sensorInspect referring to “Camshaft Position (CMP)

Sensor Inspection in Section 1C”. If NG,

replace.

Malfunction of Accelerator pedal

position (APP) sensorInspect referring to “Accelerator Pedal Position

(APP) Sensor Assembly On-Vehicle Inspection

in Section 1C”. If NG, replace.

Faulty valve body componentReplace valve body assembly.

Poor 1

→ 2 shiftMalfunction of shift solenoid valve-BInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of transmission range

sensorInspect. If NG, replace.

Malfunction of Accelerator pedal

position (APP) sensorInspect referring to “Accelerator Pedal Position

(APP) Sensor Assembly On-Vehicle Inspection

in Section 1C”. If NG, replace.

Faulty valve body componentReplace valve body assembly.

Poor 2

→ 3 shiftMalfunction of shift solenoid valve-AInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of transmission range

sensorInspect. If NG, replace.

Malfunction of Accelerator pedal

position (APP) sensorInspect referring to “Accelerator Pedal Position

(APP) Sensor Assembly On-Vehicle Inspection

in Section 1C”. If NG, replace.

Faulty valve body componentReplace valve body assembly.

Page 687 of 1556

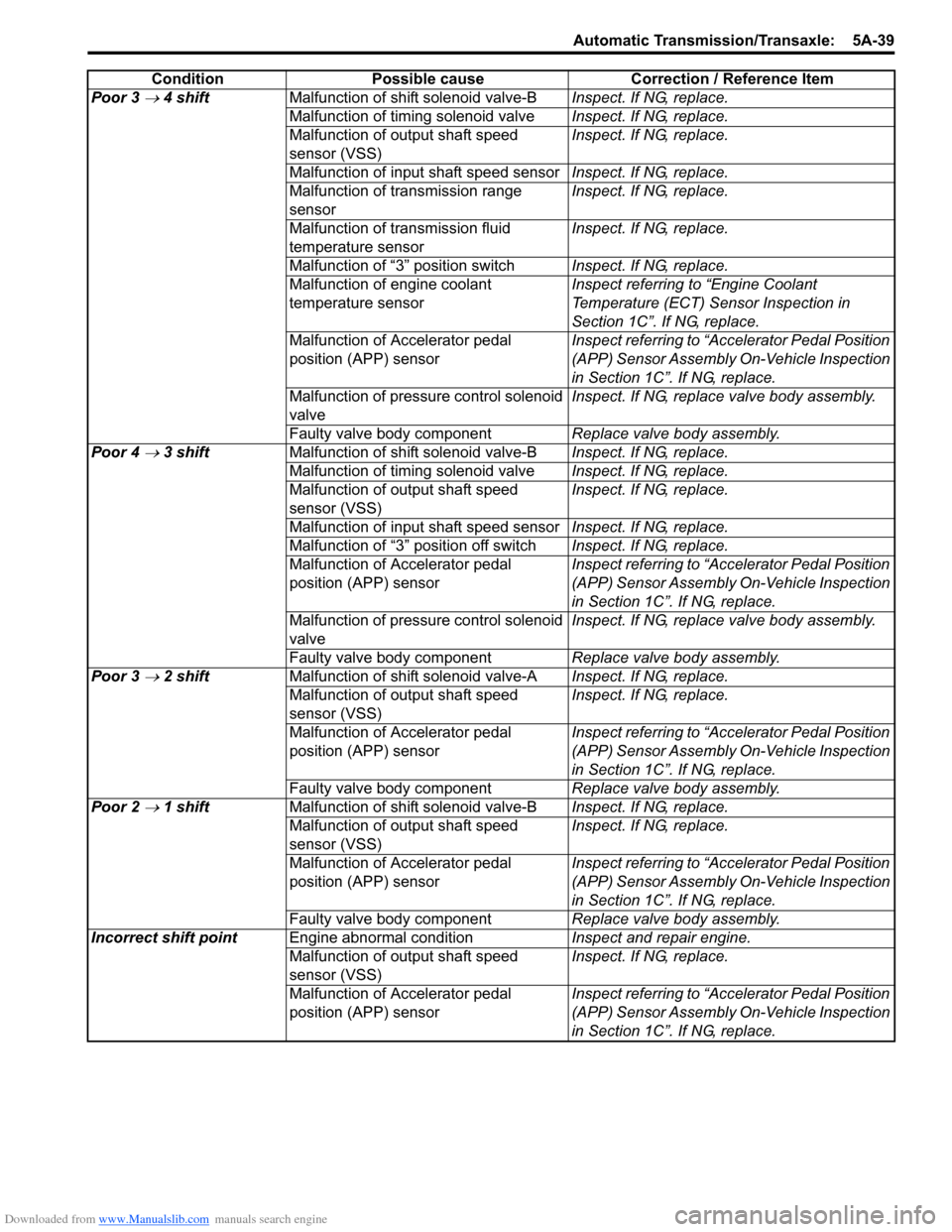

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-39

Poor 3 → 4 shiftMalfunction of shift solenoid valve-BInspect. If NG, replace.

Malfunction of timing solenoid valveInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of input shaft speed sensorInspect. If NG, replace.

Malfunction of transmission range

sensorInspect. If NG, replace.

Malfunction of transmission fluid

temperature sensorInspect. If NG, replace.

Malfunction of “3” position switchInspect. If NG, replace.

Malfunction of engine coolant

temperature sensorInspect referring to “Engine Coolant

Temperature (ECT) Sensor Inspection in

Section 1C”. If NG, replace.

Malfunction of Accelerator pedal

position (APP) sensorInspect referring to “Accelerator Pedal Position

(APP) Sensor Assembly On-Vehicle Inspection

in Section 1C”. If NG, replace.

Malfunction of pressure control solenoid

valveInspect. If NG, replace valve body assembly.

Faulty valve body componentReplace valve body assembly.

Poor 4

→ 3 shiftMalfunction of shift solenoid valve-BInspect. If NG, replace.

Malfunction of timing solenoid valveInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of input shaft speed sensorInspect. If NG, replace.

Malfunction of “3” position off switchInspect. If NG, replace.

Malfunction of Accelerator pedal

position (APP) sensorInspect referring to “Accelerator Pedal Position

(APP) Sensor Assembly On-Vehicle Inspection

in Section 1C”. If NG, replace.

Malfunction of pressure control solenoid

valveInspect. If NG, replace valve body assembly.

Faulty valve body componentReplace valve body assembly.

Poor 3

→ 2 shiftMalfunction of shift solenoid valve-AInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of Accelerator pedal

position (APP) sensorInspect referring to “Accelerator Pedal Position

(APP) Sensor Assembly On-Vehicle Inspection

in Section 1C”. If NG, replace.

Faulty valve body componentReplace valve body assembly.

Poor 2

→ 1 shiftMalfunction of shift solenoid valve-BInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of Accelerator pedal

position (APP) sensorInspect referring to “Accelerator Pedal Position

(APP) Sensor Assembly On-Vehicle Inspection

in Section 1C”. If NG, replace.

Faulty valve body componentReplace valve body assembly.

Incorrect shift pointEngine abnormal conditionInspect and repair engine.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of Accelerator pedal

position (APP) sensorInspect referring to “Accelerator Pedal Position

(APP) Sensor Assembly On-Vehicle Inspection

in Section 1C”. If NG, replace. Condition Possible cause Correction / Reference Item

Page 688 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-40 Automatic Transmission/Transaxle:

Trouble Diagnosis 3

Off-vehicle repairNon operate TCC (lock-

up) systemMalfunction of TCC solenoid valveInspect. If NG, replace.

Malfunction of shift solenoid valve-A

and/or -BInspect. If NG, replace.

Malfunction of output shaft speed

sensor (VSS)Inspect. If NG, replace.

Malfunction of input shaft speed sensorInspect. If NG, replace.

Malfunction of transmission range

sensorInspect. If NG, replace.

Malfunction of transmission fluid

temperature sensorInspect. If NG, replace.

Malfunction of pressure control solenoid

valveInspect. If NG, replace valve body assembly.

Malfunction of Accelerator pedal

position (APP) sensorInspect referring to “Accelerator Pedal Position

(APP) Sensor Assembly On-Vehicle Inspection

in Section 1C”. If NG, replace.

Malfunction of engine coolant

temperature sensorInspect referring to “Engine Coolant

Temperature (ECT) Sensor Inspection in

Section 1C”. If NG, replace.

Malfunction of brake light switchInspect referring to “Brake Light Switch

Inspection in Section 9B”. If NG, replace.

Faulty valve body componentReplace valve body assembly.

Excessive “N”

→ “D” or

“N”

→ “R” time lagMalfunction of transmission fluid

temperature sensorInspect. If NG, replace.

Pressure control solenoid valve circuit

faultyInspect. If NG, replace valve body assembly.

Clogged oil strainerReplace.

Faulty valve body componentReplace valve body assembly. Condition Possible cause Correction / Reference Item

Condition Possible cause Correction / Reference Item

Unable to run in all rangeFaulty oil pumpInspect. If NG, replace.

Seized or broken planetary gearInspect. If NG, replace.

Faulty one-way No.2 clutchInspect. If NG, replace.

Damaged drive plateInspect. If NG, replace.

Faulty forward clutchInspect. If NG, replace.

Faulty reverse clutchInspect. If NG, replace.

Faulty 1st and reverse brakeInspect. If NG, replace.

Faulty torque converterReplace.

Excessive “N”

→ “D” shift

shockFaulty forward clutchInspect. If NG, replace.

Excessive “N”

→ “R” shift

shockFaulty reverse clutchInspect. If NG, replace.

Faulty 1st and reverse brakeInspect. If NG, replace.

Poor 1

→ 2 shift,

excessive shock or

slippageFaulty 2nd brakeInspect. If NG, replace.

Faulty one-way No.1 clutchInspect. If NG, replace.

Poor 2

→ 3 shift,

excessive shock or

slippageFaulty direct clutchInspect. If NG, replace.

Poor 3

↔ O/D shift,

excessive shock or

slippageFaulty forward clutchInspect. If NG, replace.

Faulty O/D and 2nd coast brakeInspect. If NG, replace.

Poor 3

→ 2 shift,

excessive shock or

slippageFaulty direct clutchInspect. If NG, replace.

Faulty one-way No.1 clutchInspect. If NG, replace.

Poor 2

→ 1 shift,

excessive shock or

slippageFaulty 2nd brakeInspect. If NG, replace.

Faulty one-way No.2 clutchInspect. If NG, replace.

Page 690 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-42 Automatic Transmission/Transaxle:

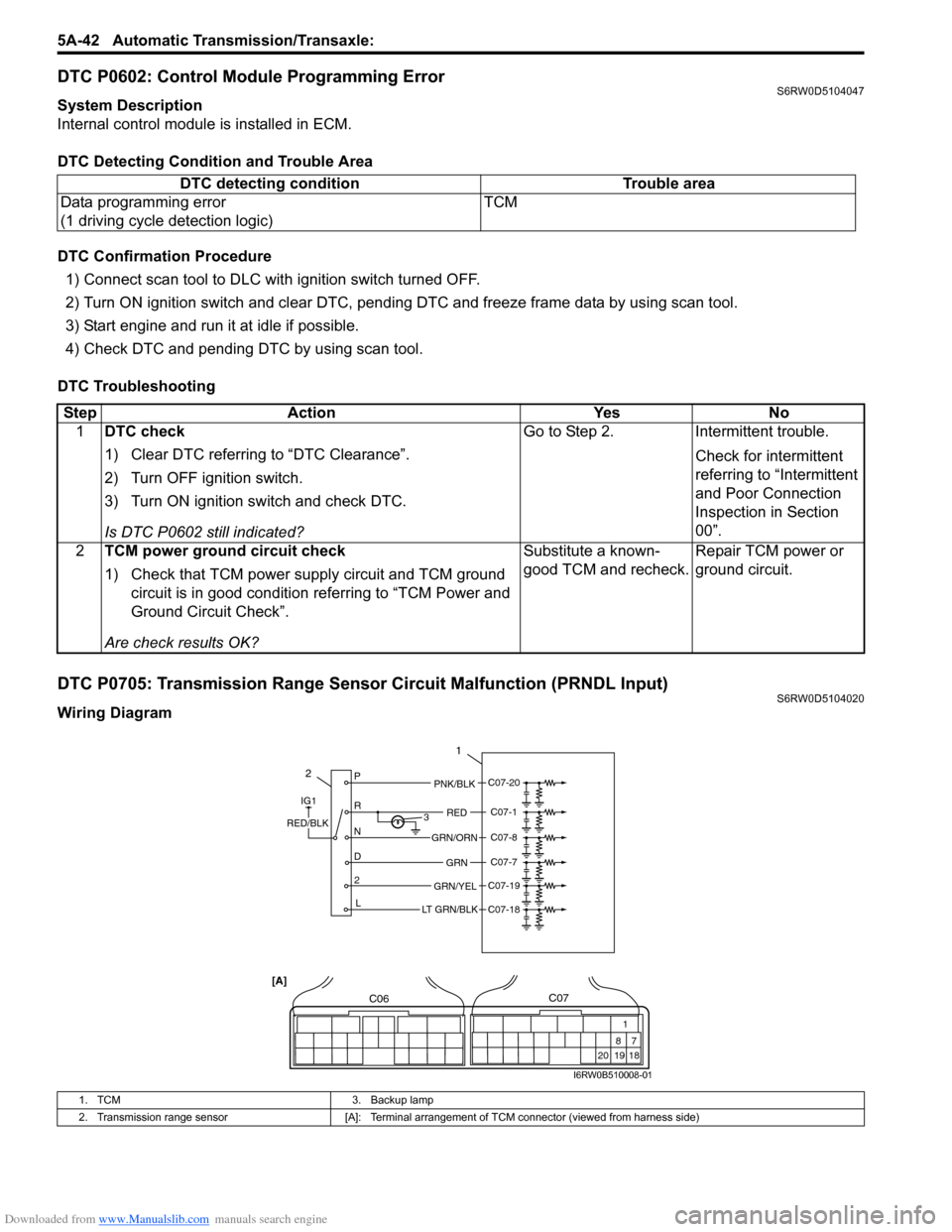

DTC P0602: Control Module Programming ErrorS6RW0D5104047

System Description

Internal control module is installed in ECM.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool.

3) Start engine and run it at idle if possible.

4) Check DTC and pending DTC by using scan tool.

DTC Troubleshooting

DTC P0705: Transmission Range Sensor Circuit Malfunction (PRNDL Input)S6RW0D5104020

Wiring DiagramDTC detecting condition Trouble area

Data programming error

(1 driving cycle detection logic)TCM

Step Action Yes No

1DTC check

1) Clear DTC referring to “DTC Clearance”.

2) Turn OFF ignition switch.

3) Turn ON ignition switch and check DTC.

Is DTC P0602 still indicated?Go to Step 2. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2TCM power ground circuit check

1) Check that TCM power supply circuit and TCM ground

circuit is in good condition referring to “TCM Power and

Ground Circuit Check”.

Are check results OK?Substitute a known-

good TCM and recheck.Repair TCM power or

ground circuit.

2P

R

N

D

2

L3

1

PNK/BLK

RED

GRN

GRN/ORN

GRN/YEL

IG1

RED/BLK

LT GRN/BLK

C07-20

C07-1

C07-8

C07-7

C07-19

C07-18

C06

20 1987

18 1

C07

[A]

I6RW0B510008-01

1. TCM 3. Backup lamp

2. Transmission range sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

Page 691 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-43

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM memory by using scan tool.

3) Start engine and shift select lever to “D” range.

4) Keep engine running at idle speed for 25 seconds or more.

5) Stop vehicle and check DTC.

DTC TroubleshootingDTC detecting condition Trouble area

Multiple or more signals are inputted simultaneously for 10

seconds.• Select cable maladjusted

• Transmission range sensor maladjusted

• Transmission range sensor or its circuit malfunction

•TCM

Step Action Yes No

1Was “A/T System Check” performed?Go to Step 2. Go to “A/T System

Check”.

2Do you have SUZUKI scan tool?Go to Step 3. Go to Step 4.

3Check transmission range sensor circuit for operation

Check by using SUZUKI scan tool:

1) Connect SUZUKI scan tool to DLC with ignition switch

OFF.

2) Turn ignition switch ON and check transmission range

signal (“P”, “R”, “N”, “D”, “2” or “L”) on display when

shifting select lever to each range.

Is applicable range indicated?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 5.

4Check transmission range sensor circuit for operation

Check by not using SUZUKI scan tool:

1) Turn ignition switch ON.

2) Check voltage at terminals “C07-1”, “C07-7”, “C07-8”,

“C07-18”, “C07-19” and “C07-20” respectively with

select lever shifted to each range.

Taking terminal “C07-19” as an example, is battery

voltage indicated only when select lever is shifted to “2”

range and 0 V for other ranges as shown in the following

table.

Check voltage at other terminals likewise, referring to the

following table.

Are check results satisfactory?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 5.

5 1) Check select cable for adjustment referring to “Select

Cable Adjustment”.

Is it adjusted correctly?Go to Step 6. Adjust.

6Check transmission range sensor for installation

position

1) Shift select lever to “N” range.

2) Check that “N” reference line on sensor and needle

direction shaped on lock washer are aligned.

Are they aligned?Go to Step 7. Adjust.

Page 692 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-44 Automatic Transmission/Transaxle:

Table for Step 4

DTC P0707: Transmission Range Sensor Circuit LowS6RW0D5104021

Wiring Diagram

DTC Detecting Condition and Trouble Area7 1) Check transmission range sensor referring to

“Transmission Range Sensor Inspection and

Adjustment”.

Are check results satisfactory?“RED/BLK”, “PNK/BLK”,

“RED”, “GRN/ORN”,

“GRN”, “GRN/YEL” or

“LT GRN/BLK” circuit

shorted to power circuit

or shorted each other. If

wires and connections

are OK, substitute a

know-good TCM and

recheck.Replace transmission

range sensor. Step Action Yes No

Te r m i n a l

C07-20 C07-1 C07-8 C07-7 C07-19 C07-18

Select lever

positionP 8 – 14 V 0 V 0 V 0 V 0 V 0 V

R0 V8 – 14 V0 V0 V0 V0 V

N 0 V 0 V 8 – 14 V 0 V 0 V 0 V

D or 3 0 V 0 V 0 V 8 – 14 V 0 V 0 V

20 V0 V0 V0 V8 – 14 V0 V

L0 V0 V0 V0 V0 V8 – 14 V

2P

R

N

D

2

L3

1

PNK/BLK

RED

GRN

GRN/ORN

GRN/YEL

IG1

RED/BLK

LT GRN/BLK

C07-20

C07-1

C07-8

C07-7

C07-19

C07-18

C06

20 1987

18 1

C07

[A]

I6RW0B510008-01

1. TCM 3. Backup lamp

2. Transmission range sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission range switch signal (P, R, N, D, 2, or L) is not

inputted for more than 28 seconds when vehicle speed is

faster than 30 km/h (19 mile/h) and engine speed is faster

than 1500 rpm.• Select cable maladjusted

• Transmission range sensor maladjusted

• Transmission range sensor or its circuit malfunction

•TCM

Page 693 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-45

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM memory by using scan tool.

3) Start engine and shift select lever to “D” range.

4) Start vehicle and increase vehicle speed to 40 km/h (25 mile/h) or more for 1 minutes.

5) Stop vehicle and turn ignition switch OFF.

6) Repeat Step 3) to 4) one time.

7) Stop vehicle and check DTC.

DTC Troubleshooting

Step Action Yes No

1Was “A/T System Check” performed?Go to Step 2. Go to “A/T System

Check”.

2Do you have SUZUKI scan tool?Go to Step 3. Go to Step 4.

3Check transmission range sensor circuit for operation

Check by using SUZUKI scan tool:

1) Connect SUZUKI scan tool to DLC with ignition switch

OFF.

2) Turn ignition switch ON and check transmission range

signal (P, R, N, D, 2 or L) on display when shifting select

lever to each range.

Is applicable range indicated?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 5.

4Check transmission range sensor circuit for operation

Check by not using SUZUKI scan tool:

1) Turn ignition switch ON.

2) Check voltage at terminals “C07-1”, “C07-7”, “C07-8”,

“C07-18”, “C07-19” and “C07-20” respectively with

select lever shifted to each range.

Taking terminal “C07-19” as an example, is battery

voltage indicated only when select lever is shifted to “2”

range and 0 V for other ranges as shown in the following

table.

Check voltage at other terminals likewise, referring to the

following table.

Are check results satisfactory?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 5.

5 1) Check select cable for adjustment referring to “Select

Cable Adjustment”.

Is it adjusted correctly?Go to Step 6. Adjust.

6Check transmission range sensor for installation

position

1) Shift select lever to “N” range.

2) Check that “N” reference line on sensor and needle

direction shaped on lock washer are aligned.

Are they aligned?Go to Step 7. Adjust.

Page 694 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-46 Automatic Transmission/Transaxle:

Table for Step 4

DTC P0711: Transmission Fluid Temperature Sensor “A” Control Range / PerformanceS6RW0D5104048

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Start vehicle and increase vehicle speed to 40 km/h (25 mile/h) for 10 minutes or more.

5) Stop vehicle and check DTC.7 1) Check transmission range sensor referring to

“Transmission Range Sensor Inspection and

Adjustment”.

Are check results satisfactory?“RED/BLK”, “PNK/BLK”,

“RED”, “GRN/ORN”,

“GRN”, “GRN/YEL” or

“LT GRN/BLK” circuit

open or short to ground.

If wires and connections

are OK, substitute a

know-good TCM and

recheck.Replace transmission

range sensor. Step Action Yes No

Te r m i n a l

C07-20 C07-1 C07-8 C07-7 C07-19 C07-18

Select lever

positionP 8 – 14 V 0 V 0 V 0 V 0 V 0 V

R0 V8 – 14 V0 V0 V0 V0 V

N 0 V 0 V 8 – 14 V 0 V 0 V 0 V

D or 3 0 V 0 V 0 V 8 – 14 V 0 V 0 V

20 V0 V0 V0 V8 – 14 V0 V

L0 V0 V0 V0 V0 V8 – 14 V

5V

C06-11

C06-12

LT G R N

ORN

23

12 11

C06C07

[A]

1

I6RW0B510009-03

1. TCM 3. A/T

2. Transmission fluid temperature sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission temperature sensor signal is no change and

less than 20 °C (68 °F) while vehicle is running at 40 km/h

(25 mile/h) or more in vehicle speed for 10 minutes or more.• Transmission fluid temperature sensor or its circuit

malfunction

•TCM