sensor SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 695 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-47

DTC Troubleshooting

DTC P0712: Transmission Fluid Temperature Sensor Circuit LowS6RW0D5104022

Wiring Diagram

DTC Detecting Condition and Trouble AreaStep Action Yes No

1Was “A/T System Check” performed?Go to Step 2. Go to “A/T System

Check”.

2Inspect transmission fluid temperature sensor

1) Inspect transmission fluid temperature sensor referring

to “Transmission Fluid Temperature Sensor Inspection”.

Is result satisfactory?Go to Step 3 Replace transmission

fluid temperature

sensor.

3Check for transmission fluid temperature sensor circuit

1) Turn ignition switch to OFF position.

2) Disconnect valve body harness connector and TCM

connectors.

3) Check for proper connection to TCM at terminals “C06-

11” and “C06-12”. If connection is OK, check circuit for

open, short and high resistance for the following circuit.

• Between “C06-11” terminal of TCM connector and “LT

GRN” terminal of valve body harness connector.

• Between “C06-12” terminal of TCM connector and

“ORN” terminal of valve body harness connector.

Are they in good condition?Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00”. If OK,

substitute a known-

good TCM and recheck.Repair “LT GRN” and/or

“ORN” circuit.

5V

C06-11

C06-12

LT GRN

ORN

23

12 11

C06C07

[A]

1

I6RW0B510009-03

1. TCM 3. A/T

2. Transmission fluid temperature sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission temperature sensor terminal voltage is less

than specified value for 5 minutes or more after starting

engine.• Transmission fluid temperature sensor or its circuit

malfunction

•TCM

Page 696 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-48 Automatic Transmission/Transaxle:

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory and start engine and keep for 20 minutes or more.

3) Stop vehicle and check DTC.

DTC Troubleshooting

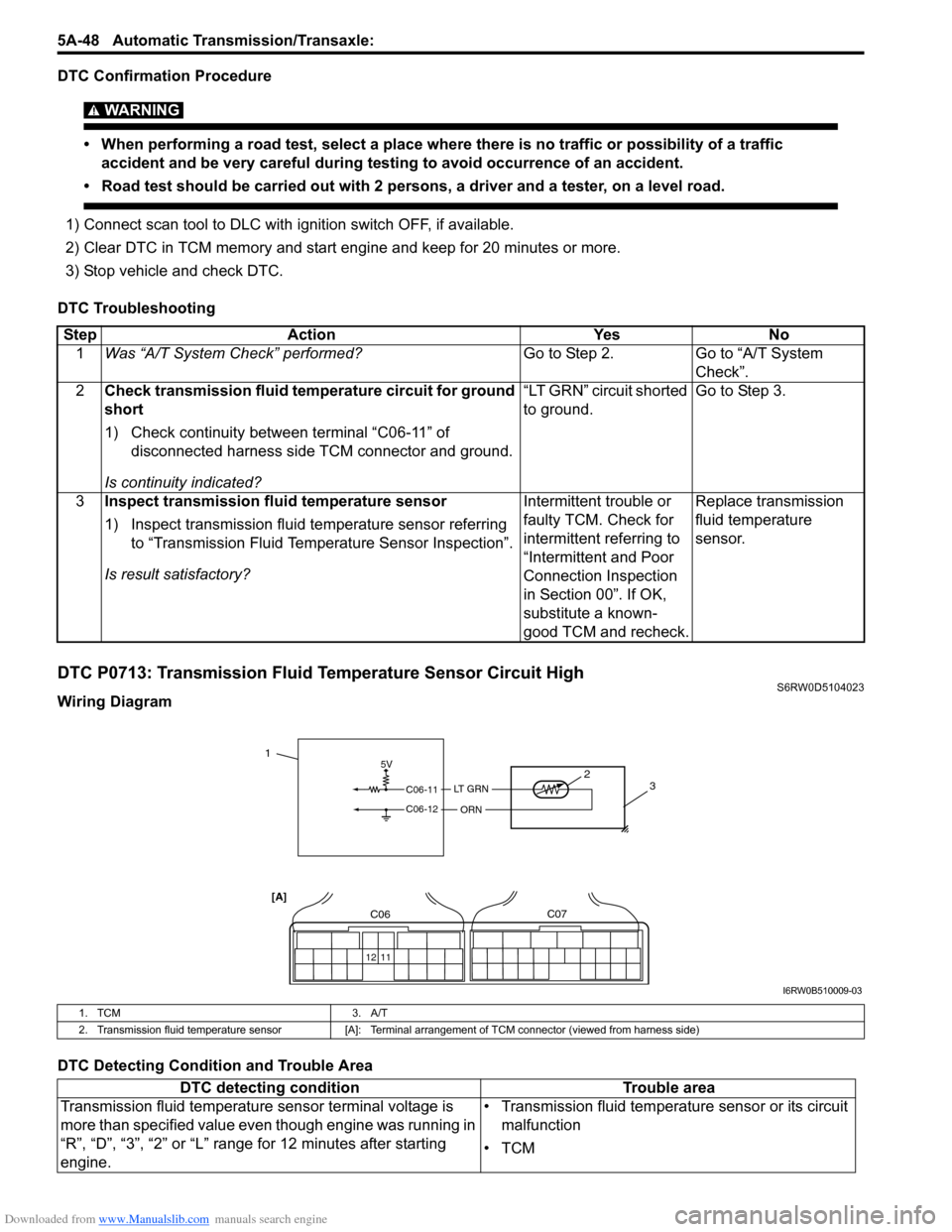

DTC P0713: Transmission Fluid Temperature Sensor Circuit HighS6RW0D5104023

Wiring Diagram

DTC Detecting Condition and Trouble AreaStep Action Yes No

1Was “A/T System Check” performed?Go to Step 2. Go to “A/T System

Check”.

2Check transmission fluid temperature circuit for ground

short

1) Check continuity between terminal “C06-11” of

disconnected harness side TCM connector and ground.

Is continuity indicated?“LT GRN” circuit shorted

to ground.Go to Step 3.

3Inspect transmission fluid temperature sensor

1) Inspect transmission fluid temperature sensor referring

to “Transmission Fluid Temperature Sensor Inspection”.

Is result satisfactory?Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00”. If OK,

substitute a known-

good TCM and recheck.Replace transmission

fluid temperature

sensor.

5V

C06-11

C06-12

LT G R N

ORN

23

12 11

C06C07

[A]

1

I6RW0B510009-03

1. TCM 3. A/T

2. Transmission fluid temperature sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission fluid temperature sensor terminal voltage is

more than specified value even though engine was running in

“R”, “D”, “3”, “2” or “L” range for 12 minutes after starting

engine.• Transmission fluid temperature sensor or its circuit

malfunction

•TCM

Page 697 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-49

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Increase engine coolant temperature to about 50 °C (122 °F) and more.

4) Start vehicle and increase vehicle speed to about 20 km/h (12 mile/h) for 10 minutes or more.

5) Stop vehicle and check DTC.

DTC Troubleshooting

Step Action Yes No

1Was “A/T System Check” performed?Go to Step 2. Go to “A/T System

Check”.

2Check transmission fluid temperature circuit for open

1) Turn ignition switch OFF.

2) Disconnect TCM connectors from TCM.

3) Check for proper connection to transmission fluid

temperature sensor at terminals “C06-11” and “C06-12”.

4) If OK, check continuity between terminals “C06-11” and

“C06-12” of disconnected harness side TCM connector.

Is continuity indicated?Go to Step 3. “LT GRN” or “ORN”

circuit open.

3Check transmission fluid temperature circuit for IG

short

1) Cool down A/T fluid temperature under ambient

temperature.

2) Connect TCM connectors to TCM with ignition switch

OFF.

3) Turn ignition switch ON.

4) Measure voltage between terminal “C06-11” of TCM

connector and ground.

Is it 4.6 V or more?“LT GRN” circuit shorted

to power circuit.

If circuit is OK, go to

St ep 4 .Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.

4Inspect transmission fluid temperature sensor

1) Inspect transmission fluid temperature sensor referring

to “Transmission Fluid Temperature Sensor Inspection”.

Is result satisfactory?Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.Replace transmission

fluid temperature

sensor.

Page 698 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-50 Automatic Transmission/Transaxle:

DTC P0717: Input / Turbine Speed Sensor Circuit MalfunctionS6RW0D5104024

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Shift select lever to “D” range and drive vehicle at 25 km/h (15 mile/h) or more with 3rd gear at least for 1 km (0.6

mile).

4) Stop vehicle and check DTC.

DTC Troubleshooting

C07-6

2.5VWHT

BLKC07-16

1 2

C06

16 6

C07

[A]

I6RW0B510010-01

1. TCM 2. Input shaft speed sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

No input shaft speed sensor signal is detected although

output shaft speed sensor signals are detected.• Input shaft speed sensor or its circuit malfunction

• Improper input shaft speed sensor installation

• Damaged direct clutch drum

• Foreign material attachment to sensor or drum

•TCM

Step Action Yes No

1Was “A/T System Check” performed?Go to Step 2. Go to “A/T System

Check”.

2Check input shaft speed sensor circuit

1) Disconnect TCM connectors with ignition switch OFF.

2) Check for proper connection to input shaft speed sensor

at “C07-6” and “C07-16” terminals.

3) If OK, check resistance of sensor circuit.

Input shaft speed sensor specification

Between terminals “C07-6” and “C07-16”: 560 – 680

Ω at 20 °C (68 °F)

Between terminal “C07-6” / “C07-16” and ground: No

continuity

Are check result satisfactory?Go to Step 4. Go to Step 3.

Page 699 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-51

DTC P0722: Output Speed Sensor (VSS) Circuit No SignalS6RW0D5104025

Wiring Diagram

DTC Detecting Condition and Trouble Area3Inspect input shaft speed sensor

1) Inspect input shaft speed sensor referring to “Input Shaft

Speed Sensor Inspection”.

Is result satisfactory?“WHT” or “BLK” circuit

open or short.Replace input shaft

speed sensor.

4Check visually input shaft speed sensor and direct

clutch drum for the following

• No damage

• No foreign material attached

• Correct installation

Are they in good condition?Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.Clean, repair or replace. Step Action Yes No

I2RH0B510020-01

12 11

C06C07

[A]

112V

IG1

PPLBLK/WHT

BLK/ORNC07-25

23

I6RW0B510011-01

1. TCM 3. To ECM

2. Output shaft speed sensor (VSS) [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

No output shaft speed sensor signal is detected although

input shaft speed sensor signals are detected with “D”, “2” or

“L” range.• Output shaft speed sensor or its circuit malfunction

• Damaged sensor gear (driven gear)

• Damaged output shaft speed sensor (VSS) drive

gear

•TCM

Page 700 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-52 Automatic Transmission/Transaxle:

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Shift select lever to “D” range and drive vehicle at 9 km/h (6 mile/h) or more vehicle speed at least for 1 km (0.6

mile).

4) Stop vehicle and check DTC.

DTC Troubleshooting

Step Action Yes No

1Was “A/T System Check” performed?Go to Step 2. Go to “A/T System

Check”.

2Check output shaft speed sensor (VSS) power circuit

1) Turn ignition switch OFF.

2) Disconnect output shaft speed sensor connector.

3) Turn ignition switch ON.

4) Measure voltage between “BLK/WHT” wire terminal of

disconnected output shaft speed sensor harness side

connector and ground.

Is it 10 – 14 V?Go to Step 3. “BLK/WHT” wire open

or shorted to ground.

3Check output shaft speed sensor (VSS) ground circuit

1) Turn ignition switch OFF.

2) Check continuity between “BLK/ORN” wire terminal of

disconnected output shaft speed sensor harness side

connector and ground.

Is continuity indicated?Go to Step 4. “BLK/ORN” wire open.

4Check output shaft speed sensor (VSS) signal circuit for

short

1) Disconnect TCM connectors.

2) Check continuity between “PPL” wire terminal of

disconnected output shaft speed sensor harness side

connector and ground.

Is continuity indicated?“PPL” wire shorted to

ground.Go to Step 5.

5Check output shaft speed sensor (VSS) signal circuit for

open

1) Check continuity between “PPL” wire terminal of

disconnected output shaft speed sensor harness side

connector and terminal “C07-25” of disconnected

harness side TCM connector.

Is continuity indicated?Go to Step 6. “PPL” wire open.

6Inspect output shaft speed sensor (VSS)

1) Inspect output shaft speed sensor referring to “Output

Shaft Speed Sensor (VSS) Inspection”.

Is check result satisfactory?Go to Step 7. Replace output shaft

speed sensor (VSS).

Page 701 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-53

DTC P0741 / P0742: TCC Circuit Performance or Stuck OFF / TCC Circuit Stuck ONS6RW0D5104026

DTC Detecting Condition and Trouble Area

DTC P0741

DTC P0742

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine and warm it up to normal operating temperature.

4) Shift select lever to “N” and “D” range for each 10 seconds.

5) Drive vehicle with 3rd or 4th gear in “D” range and lock-up ON for 2 seconds or longer referring to “Automatic Gear

Shift Table”.

6) Shift select lever to “3” range.

7) Drive vehicle with 2nd or 3rd gear in “3” range, 15 – 30% throttle opening and at vehicle speed of 25 – 40 km/h (16

– 25 mile/h) at least for 1 second.

8) Stop vehicle and turn ignition switch OFF.

9) Repeat Step 3) to 7) one time.

10) Stop vehicle and check DTC.7Check output shaft speed sensor (VSS) gears visually

1) Check output shaft speed sensor gears for the

followings.

• No damage in drive gear on differential case

• No damage in driven gear in output shaft speed

sensor

Is result satisfactory?Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.Replace drive gear and/

or driven gear of output

shaft speed sensor. Step Action Yes No

DTC detecting condition Trouble area

When driving vehicle with 3rd or 4th gear in “D” range,

difference in revolution between engine and A/T input (input

shaft speed) is larger than specification although TCM

commanded TCC solenoid valve to turn ON.• Mechanical malfunction of TCC solenoid valve

• Malfunction of valve body assembly

• Fluid passage clogged or leaking

• Torque converter clutch malfunction

DTC detecting condition Trouble area

When driving vehicle with 2nd, 3rd or 4th gear in “D” range,

difference in revolution between engine and A/T input (input

shaft speed) is smaller than specification although TCM

commanded TCC solenoid valve to turn OFF.• Mechanical malfunction of TCC solenoid valve

• Malfunction of valve body assembly

• Fluid passage clogged or leaking

• Torque converter clutch malfunction

Page 725 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-77

Connector “C06”

Terminal Wire color CircuitStandard

voltageCondition

1 BLK Ground 0 – 1 V Ignition switch ON

2LT GRN/

BLKPressure control

solenoid valve (–)0.6 – 1.0 V Ignition switch ON

3 WHT/BLK TCC solenoid valve (–) 0.6 – 1.0 V Ignition switch ON

4GRYPressure control

solenoid valve (+)*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform

No. 1: ”)Engine running at idling.

(Output signal is duty pulse. Duty ratio varies

depending on throttle valve opening.)

5 WHT/BLU TCC solenoid valve (+)*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform

No. 2: ”)Engine running at idling.

(Output signal is duty pulse. Duty ratio varies

depending on torque converter clutch operating

condition.)

6 YEL/BLK Power source 10 – 14 V Ignition switch ON

7WHTCAN communication

line (Low)*2.5 – 3.6 V

↑↓

1.6 – 2.5 V

(“Reference

waveform

No. 3: ”)Engine running at idling with after warming up.

(CAN communication signal is pulse. Pulse signal

frequency varies depending on engine condition.))

8— — — —

9— — — —

10 — — — —

11 LT G R NTransmission fluid

temperature sensor (+)2.9 – 3.1 V Ignition switch ON, fluid temperature is 20 °C (68 °F)

0.3 – 0.5 V Ignition switch ON, fluid temperature is 100 °C (212 °F)

12 ORNTransmission fluid

temperature sensor (–)0 – 1 V Ignition switch ON

13 — — — —

14 BLU/BLK Timing solenoid valve 0 – 1 V Ignition switch ON

15 BLK/YELShift solenoid valve-B

(No.2)9 – 14 V Ignition switch ON, select lever in “P” range

16 BRNShift solenoid valve-A

(No.1)9 – 14 V Ignition switch ON, select lever in “P” range

17 REDCAN communication

line (High)*2.5 – 3.6 V

↑↓

1.6 – 2.5 V

(“Reference

waveform

No. 3: ”)Engine running at idling with after warming up.

(CAN communication signal is pulse. Pulse signal

frequency varies depending on engine condition.)

18 — — — —

19 — — — —

20 — — — —

21 — — — —

22 — — — —

23 BLK Ground 0 – 1 V Ignition switch ON

24 WHT/REDPower source for back-

up10 – 14 V Constantly

Page 726 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-78 Automatic Transmission/Transaxle:

Connector “C07”

Terminal Wire color CircuitStandard

voltageCondition

1REDTransmission range

sensor (“R” range)8 – 14 V Ignition switch ON, select lever at “R” range

0 – 1 V Ignition switch ON, select lever at other than “R” range

2— — — —

3— — — —

4— — — —

5— — — —

6WHTInput shaft speed

sensor (+)2 – 3 V Ignition switch turned ON, engine stops.

*(“Referenc

e waveform

No. 4: ”)While engine running.

(Output signal is waveform. Waveform frequency varies

depending on output shaft speed. (16 pulses are

generated par 1 input shaft revolution.))

7GRNTransmission range

sensor (“D” or “3”

range)8 – 14 V Ignition switch ON, select lever at “D” or “3” range

0 – 1 VIgnition switch ON, select lever at other than “D” or “3”

range

8GRN/ORNTransmission range

sensor (“N” range)8 – 14 V Ignition switch ON, select lever at “N” range

0 – 1 V Ignition switch ON, select lever at other than “N” range

9 YEL “3” position switch8 – 14 VIgnition switch ON, select lever at other than “3” or “2”

range

0 – 1 V Ignition switch ON, select lever at “3” or “2” range

10 — — — —

11 — — — —

12 — — — —

13 — — — —

14 — — — —

15 — — — —

16 BLKInput shaft speed

sensor (–)2 – 3 V Ignition switch ON, engine at stop

17 — — — —

18LT GRN/

BLKTransmission range

sensor (“L” range)8 – 14 V Ignition switch ON, select lever at “L” range

0 – 1 V Ignition switch ON, select lever at other than “L” range

19 GRN/YELTransmission range

sensor (“2” range)8 – 14 V Ignition switch ON, select lever at “2” range

0 – 1 V Ignition switch ON, select lever at other than “2” range

20 PNK/BLKTransmission range

sensor (“P” range)8 – 14 V Ignition switch ON, select lever at “P” range

0 – 1 V Ignition switch ON, select lever at other than “P” range

21 — — — —

22 — — — —

23 BLU Data link connector 8 – 14 V Ignition switch ON

24 — — — —

25 PPLOutput shaft speed

sensor (VSS)8 – 14 V Ignition switch ON

*0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform

No. 5: ”)Vehicle running.

(Sensor signal is pulse. Pulse frequency varies

depending on vehicle speed. (8190 pulses are

generated par 60 km/h, 37.5 mile/h)

26 — — — —

Page 727 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-79

Reference waveform No. 1

Pressure control solenoid valve signal at engine idling.

Reference waveform No. 2

TCC pressure control solenoid valve signal at engine

idling.Reference waveform No. 3

CAN communication line (High & Low) signal at engine

idling.

Reference waveform No. 4

Input shaft speed sensor signal at engine idling. Measurement

terminalCH1: “C06-4” to “C06-1”

Oscilloscope

settingCH1: 5 V/DIV

TIME: 2 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine at specified idle speed

with “P” range.

Measurement

terminalCH1: “C06-5” to “C06-1”

Oscilloscope

settingCH1: 5 V/DIV

Time: 2 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine at specified idle speed

with “P” range

I3RM0B510029-01

I4RS0A510024-01

Measurement

terminalCH1: “C06-7” to “C06-1”

CH2: “C06-17” to “C06-1”

Oscilloscope

settingCH1: 1 V/DIV

TIME: 100 µs/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine at specified idle speed

with “P” range.

Measurement

terminalCH1: “C07-6” to “C06-1”

Oscilloscope

settingCH1: 2 V/DIV

TIME: 10 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine at specified idle speed

with “P” range.

I3RM0B510030-01

I3RM0B510027-01