check engine SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 520 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-23 Differential:

DTC Confirmation Procedure

1) Clear DTC using scan tool.

2) Start engine and select 2WD/4WD switch to “LOCK” position.

3) Keep engine running at 2000 rpm for 10 seconds. or more.

4) Stop engine and check DTC.

Troubleshooting

Step Action Yes No

1Was “4WD control system check” performed?Go to Step 2. Go to “4WD Control

System Check”.

2Coupling assembly circuit check

1) Disconnect coupling assembly connector “L102” with

ignition switch turned OFF.

2) Check for proper connection to “L102-1” and “L102-4”

terminals of coupling assembly connector.

3) If connection is OK, measure voltage between “L102-1”

terminal of coupling assembly connector and vehicle

body ground.

Is it 10 – 14 V?Go to Step 3. Go to Step 6.

3Coupling assembly ground circuit check

1) Measure resistance between “L102-4” terminal of

coupling assembly connector and vehicle body ground

with ignition switch turned OFF.

Is resistance below 5

Ω?Go to Step 4. Go to Step 5.

4Coupling assembly check

1) Check coupling assembly referring to “Coupling

Assembly Inspection”.

Is it in good condition?Substitute a known-

good 4WD control

module and recheck.Replace coupling

assembly.

5Coupling assembly circuit check

1) Disconnect connector from 4WD control module

connector “G26” with ignition switch turned OFF.

2) Check for proper connection to “G26-2” and “G26-3”

terminals of 4WD control module connector.

3) If connection is OK, measure resistance between “G26-

2” terminal of 4WD control module connector and

vehicle body ground.

Is resistance below 5

Ω?“YEL” wire is open or

high resistance circuit.Substitute a known-

good 4WD control

module and recheck.

6Coupling assembly circuit check

1) Disconnect connector from 4WD control module

connector “G26” with ignition switch turned OFF.

2) Check for proper connection to “G26-3” terminal of 4WD

control module connector.

3) If connection is OK, measure resistance between “G26-

3” terminal of 4WD control module connector and “L102-

1” terminal of coupling assembly connector.

Is resistance below 5

Ω?Substitute a known-

good 4WD control

module and recheck.“GRY” wire is open or

high resistance circuit.

Page 521 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-24

DTC C1253: Coupling Assembly Circuit ShortS6RW0D3204020

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Clear DTC using scan tool.

2) Start engine and select 2WD/4WD switch to “LOCK” position.

3) Keep engine running at 2000 rpm for 10 seconds. or more.

4) Stop engine and check DTC.

Troubleshooting

12V

G26-3

YEL GRY

G26-2

L102-1

L102-4 12

1 2 3

4 5

6 7 8 9 10 11

12

13

14 15 16

17 18 19

20

21 22

23

24 25 26

[A]

21

[B]

I7RW01320007-01

[A]: 4WD control module connector “G26” (viewed from harness side) 1. Coupling assembly

[B]: Coupling assembly connector “L102” (viewed from harness side) 2. 4WD control module

DTC detecting condition Trouble area

2WD/4WD switch is changed of 4WD lock position, and then

vehicle is not changed for more than 5 seconds.• Coupling assembly

• Coupling assembly circuit

• 4WD control module

Step Action Yes No

1Was “4WD control system check” performed?Go to Step 2. Go to “4WD Control

System Check”.

2Coupling assembly circuit check

1) Disconnect coupling assembly connector “L102” with

ignition switch turned OFF.

2) Check for proper connection to “L102-1” and “L102-4”

terminals of coupling assembly connector.

3) If connection is OK, measure voltage between “L102-1”

terminal of coupling assembly connector and vehicle

body ground.

Is it 10 – 14 V?Go to Step 3. Go to Step 6.

3Coupling assembly ground circuit check

1) Measure resistance between “L102-4” terminal of

coupling assembly connector and vehicle body ground

with ignition switch turned OFF.

Is resistance below 5

Ω?Go to Step 4. Go to Step 5.

Page 522 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-25 Differential:

DTC C1254: 2WD/4WD Switch MalfunctionS6RW0D3204021

Wiring Diagram4Coupling assembly check

1) Check coupling assembly referring to “Coupling

Assembly Inspection”.

Is it in good condition?Substitute a known-

good 4WD control

module and recheck.Replace coupling

assembly.

5Coupling assembly circuit check

1) Disconnect connector from 4WD control module

connector “G26” with ignition switch turned OFF.

2) Check for proper connection to “G26-2” and “G26-3”

terminals of 4WD control module connector.

3) If connection is OK, measure resistance between “G26-

2” terminal of 4WD control module connector and

vehicle body ground.

Is resistance above 1 M

Ω?“YEL” wire is shorted to

ground circuit.Substitute a known-

good 4WD control

module and recheck.

6Coupling assembly circuit check

1) Disconnect connector from 4WD control module

connector “G26” with ignition switch turned OFF.

2) Check for proper connection to “G26-3” terminal of 4WD

control module connector.

3) If connection is OK, measure resistance between “G26-

3” terminal of 4WD control module connector and “L102-

1” terminal of coupling assembly connector.

Is resistance above 1 M

Ω?Substitute a known-

good 4WD control

module and recheck.“GRY” wire is shorted to

ground circuit. Step Action Yes No

G26-13

G26-14GRY/YEL

RED/WHT

12V

1

3

4

L174-1

L174-52L174-4BLK/ORN

1 2 3

4 5

6 7 8 9 10 11

12

13

14 15 16

17 18 19

20

21 22

23

24 25 26

[A]

2

64531

[B]

I7RW01320008-01

[A]: 4WD control module connector “G26” (viewed from harness side) 2. 2WD/4WD switch

[B]: 2WD/4WD switch connector “L174” (viewed from harness side) 3. “4WD” switch

1. 4WD control module 4. “4WD-lock” switch

Page 523 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-26

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Clear DTC using scan tool.

2) Select 2WD/4WD switch to “2WD” position and keep its position for 10 seconds. Similarly select 2WD/4WD switch

to “AUTO” and “LOCK” position.

3) Check DTC.

TroubleshootingDTC detecting condition Trouble area

2WD/4WD switch combination different from specification is

detected for more than 5 seconds.• 2WD/4WD switch

• 2WD/4WD switch circuit

• 4WD control module

Step Action Yes No

1Was “4WD control system check” performed?Go to Step 2. Go to “4WD Control

System Check”.

22WD/4WD switch circuit check

1) Disconnect 2WD/4WD switch connector “L174” with

ignition switch turned OFF.

2) Check for proper connection to “L174-1” and “L174-5”

terminals of 2WD/4WD switch connector.

3) If connection is OK, measure voltage between “L174-1”

terminal or “L174-5” terminal of 2WD/4WD switch

connector and vehicle body ground.

Is it 10 – 14 V?Go to Step 3. Go to Step 5.

32WD/4WD switch ground circuit check

1) Measure resistance between “L174-4” terminal of 2WD/

4WD switch connector and vehicle body ground with

ignition switch turned OFF.

Is resistance below 5

Ω?Go to Step 4. “BLK/ORN” wire is

shorted to ground.

42WD/4WD switch check

1) Check 2WD/4WD switch referring to “2WD/4WD Switch

Inspection”.

Is it in good condition?Substitute a known-

good 4WD control

module and recheck.Replace 2WD/4WD

switch.

52WD/4WD switch circuit check

1) Disconnect connector from 4WD control module

connector “G26” with ignition switch turned OFF.

2) Check for shorted to ground in related circuits.

• Between “G26-13” terminal of 4WD control module

connector and “L174-1” terminal of 2WD/4WD switch

connector.

• Between “G26-14” terminal of 4WD control module

connector and “L174-5” terminal of 2WD/4WD switch

connector.

Are they in good condition?Substitute a known-

good 4WD control

module and recheck.Repair circuit.

Page 524 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-27 Differential:

DTC U0073: Control Module Communication Bus OffS6RW0D3204022

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U0100: Lost Communication with ECMS6RW0D3204023

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U0121: Lost Communication with ABS / ESP® Control ModuleS6RW0D3204024

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U0155: Lost Communication with Instrument Panel Cluster (IPC) Control ModuleS6RW0D3204025

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

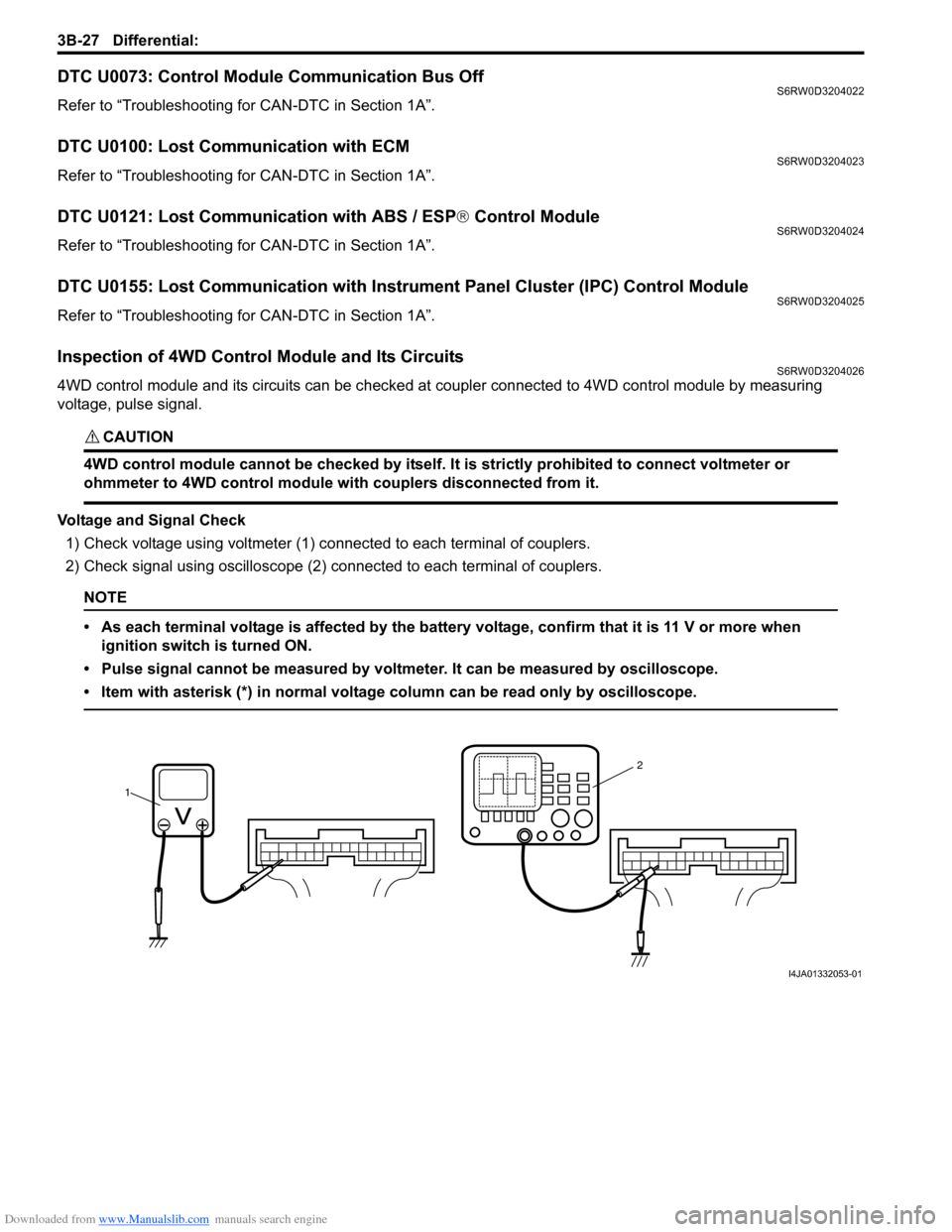

Inspection of 4WD Control Module and Its CircuitsS6RW0D3204026

4WD control module and its circuits can be checked at coupler connected to 4WD control module by measuring

voltage, pulse signal.

CAUTION!

4WD control module cannot be checked by itself. It is strictly prohibited to connect voltmeter or

ohmmeter to 4WD control module with couplers disconnected from it.

Voltage and Signal Check

1) Check voltage using voltmeter (1) connected to each terminal of couplers.

2) Check signal using oscilloscope (2) connected to each terminal of couplers.

NOTE

• As each terminal voltage is affected by the battery voltage, confirm that it is 11 V or more when

ignition switch is turned ON.

• Pulse signal cannot be measured by voltmeter. It can be measured by oscilloscope.

• Item with asterisk (*) in normal voltage column can be read only by oscilloscope.

12

I4JA01332053-01

Page 527 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-30

Repair Instructions

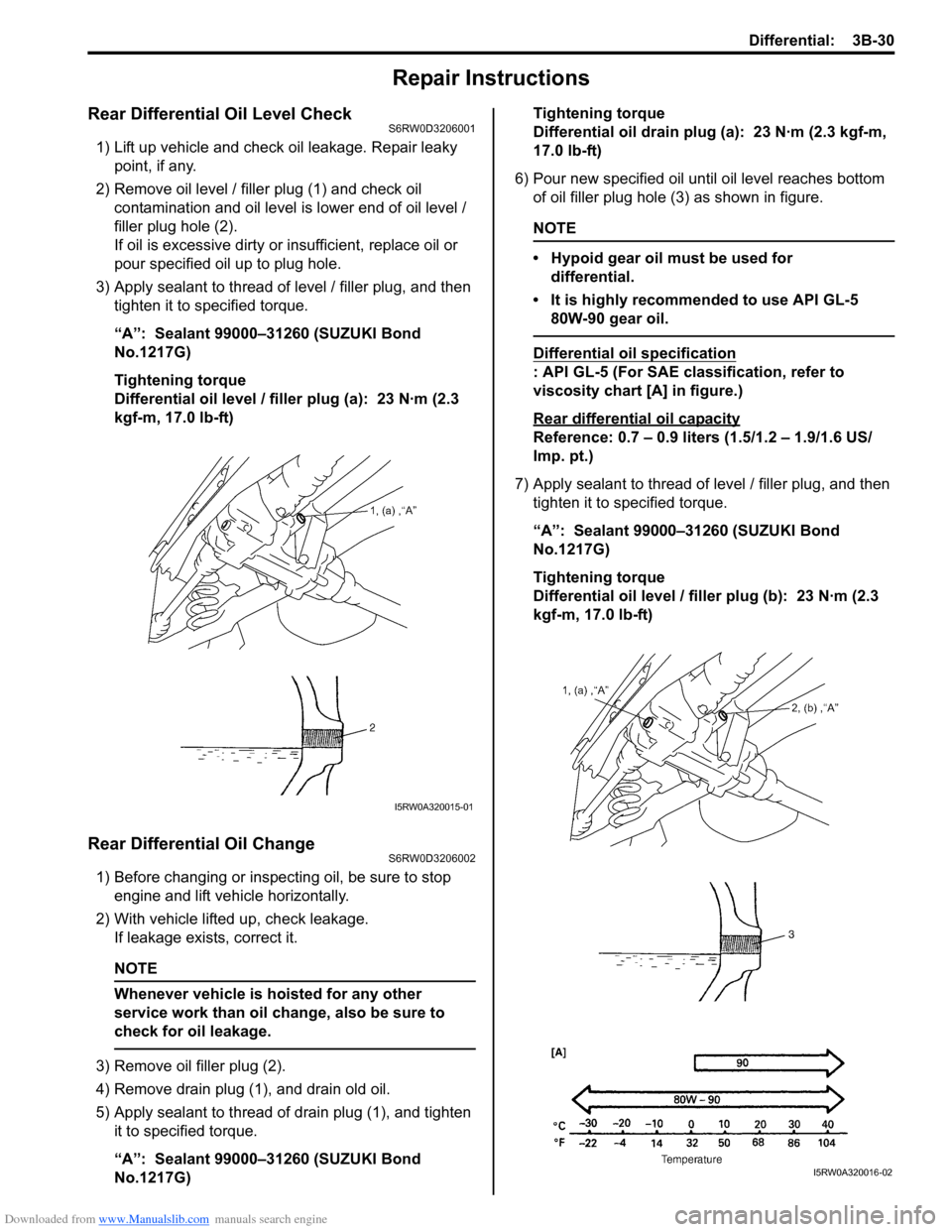

Rear Differential Oil Level CheckS6RW0D3206001

1) Lift up vehicle and check oil leakage. Repair leaky

point, if any.

2) Remove oil level / filler plug (1) and check oil

contamination and oil level is lower end of oil level /

filler plug hole (2).

If oil is excessive dirty or insufficient, replace oil or

pour specified oil up to plug hole.

3) Apply sealant to thread of level / filler plug, and then

tighten it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Differential oil level / filler plug (a): 23 N·m (2.3

kgf-m, 17.0 lb-ft)

Rear Differential Oil ChangeS6RW0D3206002

1) Before changing or inspecting oil, be sure to stop

engine and lift vehicle horizontally.

2) With vehicle lifted up, check leakage.

If leakage exists, correct it.

NOTE

Whenever vehicle is hoisted for any other

service work than oil change, also be sure to

check for oil leakage.

3) Remove oil filler plug (2).

4) Remove drain plug (1), and drain old oil.

5) Apply sealant to thread of drain plug (1), and tighten

it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)Tightening torque

Differential oil drain plug (a): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

6) Pour new specified oil until oil level reaches bottom

of oil filler plug hole (3) as shown in figure.

NOTE

• Hypoid gear oil must be used for

differential.

• It is highly recommended to use API GL-5

80W-90 gear oil.

Differential oil specification

: API GL-5 (For SAE classification, refer to

viscosity chart [A] in figure.)

Rear differential oil capacity

Reference: 0.7 – 0.9 liters (1.5/1.2 – 1.9/1.6 US/

Imp. pt.)

7) Apply sealant to thread of level / filler plug, and then

tighten it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Differential oil level / filler plug (b): 23 N·m (2.3

kgf-m, 17.0 lb-ft)

I5RW0A320015-01

I5RW0A320016-02

Page 528 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-31 Differential:

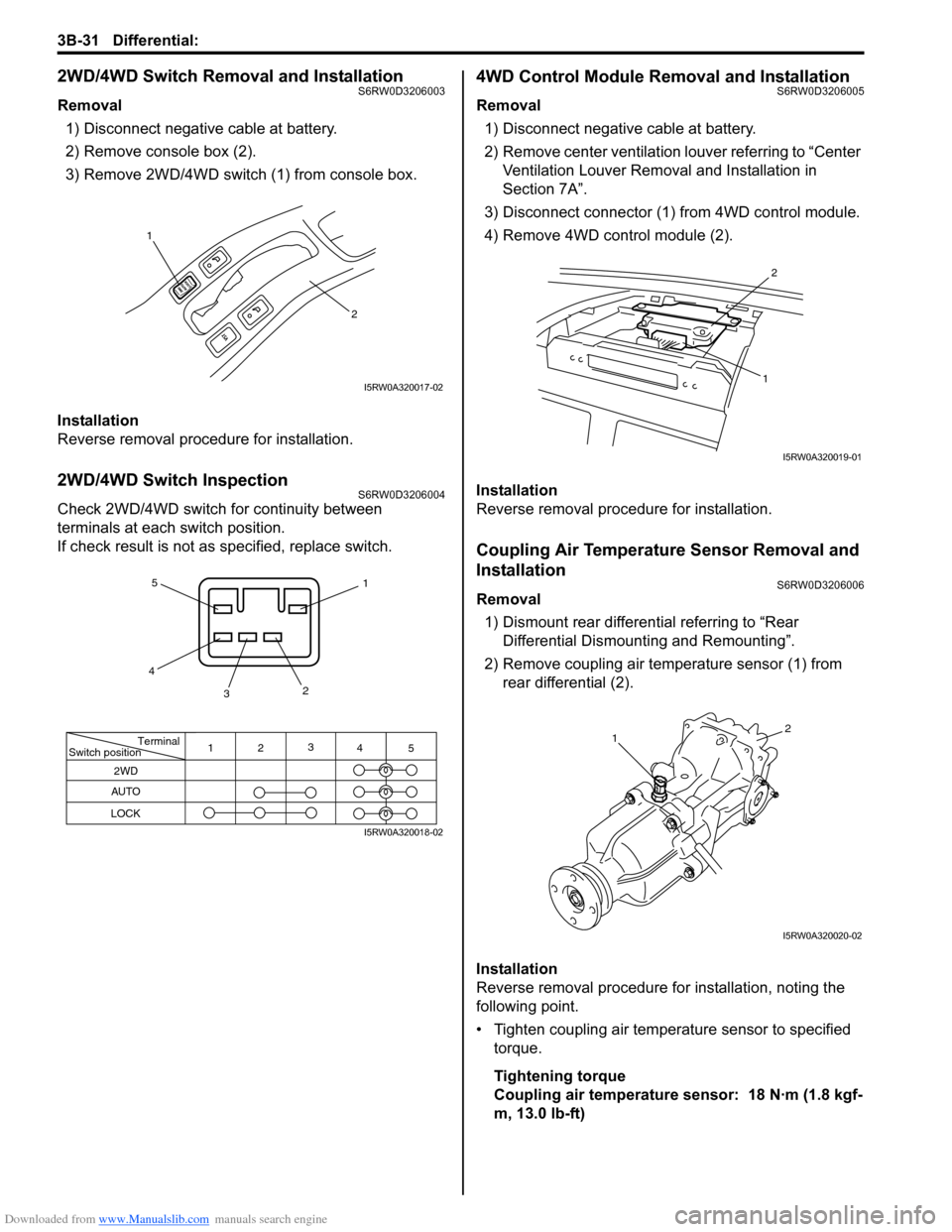

2WD/4WD Switch Removal and InstallationS6RW0D3206003

Removal

1) Disconnect negative cable at battery.

2) Remove console box (2).

3) Remove 2WD/4WD switch (1) from console box.

Installation

Reverse removal procedure for installation.

2WD/4WD Switch InspectionS6RW0D3206004

Check 2WD/4WD switch for continuity between

terminals at each switch position.

If check result is not as specified, replace switch.

4WD Control Module Removal and InstallationS6RW0D3206005

Removal

1) Disconnect negative cable at battery.

2) Remove center ventilation louver referring to “Center

Ventilation Louver Removal and Installation in

Section 7A”.

3) Disconnect connector (1) from 4WD control module.

4) Remove 4WD control module (2).

Installation

Reverse removal procedure for installation.

Coupling Air Temperature Sensor Removal and

Installation

S6RW0D3206006

Removal

1) Dismount rear differential referring to “Rear

Differential Dismounting and Remounting”.

2) Remove coupling air temperature sensor (1) from

rear differential (2).

Installation

Reverse removal procedure for installation, noting the

following point.

• Tighten coupling air temperature sensor to specified

torque.

Tightening torque

Coupling air temperature sensor: 18 N·m (1.8 kgf-

m, 13.0 lb-ft)

1

2

I5RW0A320017-02

Terminal

Switch position

2WD

AUTO

LOCK

11

22

3 3

4 4

5 5

I5RW0A320018-02

2

1

I5RW0A320019-01

12

I5RW0A320020-02

Page 529 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-32

Coupling Air Temperature Sensor InspectionS6RW0D3206007

CAUTION!

Do not heat up coupling air temperature

sensor more than 100 °C (212 °F). Otherwise,

coupling air temperature sensor will be

damaged.

• Blow hot air to temperature sensing part (2) of

coupling air temperature sensor (3) using hot air drier

(4) and measure resistance between sensor terminals

while heating air gradually.

If measured resistance does not show such

characteristic as shown, replace air temperature

sensor.

Coupling Assembly InspectionS6RW0D3206008

• Check coupling assembly for oil leakage. If leakage

exists, replace it.

• Measure resistance between “a” terminal and “b”

terminal of coupling connector (1).

If measured resistance is out of specification, check

harness for open or short.

If OK, replace coupling assembly.

Coupling assembly resistance

: 2 – 3 Ω

[A]: Lower limit [D]: Resistance

[B]: Normal [E]: Temperature

[C]: Upper limit 1. Temperature gauge

020

32 68 17680 (6.00)

(0.34) (2.56)

1

4

23

[D]

[C]

[B]

[A]

[E]

I5RW0A320021-01

1

“a” “b”I5RW0A320064-01

Page 535 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-38

14) Using a hammer and brass bar (1), drive out front

bearing outer race (2).

15) Using a hammer and brass bar (1), drive out rear

bearing outer race (2).

Reassembly

Judging from faulty conditions noted before disassembly

and what is found through visual check of bearing and

gear tooth etc. after disassembly, prepare replacing

parts and proceed to reassembly according to

procedures as described in the following.

CAUTION!

• Bevel gear and pinion must be replaced as

a set when either replacement becomes

necessary.

• When replacing taper roller bearing,

replace as inner race & outer race

assembly.

1) Press-fit bevel pinion bearing outer races to

differential carrier (1) by using special tools and

hydraulic press as shown in the figure.

Special tool

(A): 09913–85210

(B): 09913–75510

2) After applying differential oil to differential gears (4),

pinions (5), pinion shaft (3), side washers (1), spring

washers (7) and pinion washers (2), install them in

differential case (6).

For correct installing direction of side washers and

spring washers, refer to figure.

NOTE

Used left and right differential side washers

are not interchangeable.

3) Check pinion gear (1) for smooth rotation.

1

2

I5RW0A320038-01

1

2

I5RW0A320039-01

(B)(A)

1

I5RW0A320040-02

7 6

4

5

3

21

I5RW0A320041-01

I3RH01322031-01

Page 538 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-41 Differential:

9) Set special tools and make drive bevel pinion

mounting dummy.

Special tool

(A): 09922–76120

(B): 09922–76250

10) Install dial gauge (1) to mounting dummy as shown

in figure.

Special tool set distance

“a”: 38.0 mm (1.496 in.)

“b”: 0 mm (0.000 in.)

11) Set special tools and make drive bevel pinion

dummy.

Special tool

(A): 09922–76140

(B): 09922–76420

(C): 09922–76330

(D): 09922–7634012) Apply gear oil to drive bevel pinion bearings, install

special tools with bearings to differential carrier as

shown in figure.

Special tool

(A): 09922–76140

(B): 09922–76420

(C): 09922–76330

(D): 09922–76340

(E): 09922–76150

(F): 09922–76530

NOTE

This installation requires no spacer or oil

seal.

13) Tighten bevel pinion nut (special tool) (1) so that

specified bearing preload is obtained.

NOTE

Before taking measurement, check for

rotation by hand more than 15 revolutions.

Pinion bearing preload (at 50 r/min)

: 1.3 – 2.6 N⋅m (13.0 – 26.0 kgf-cm, 11.3 – 22.6 lb-

in.)

I5RW0A320047-01

(C)

(D)

(A)

(A)(B)I5RW0A320048-01

(E) (D) (C)(B) (A) (F)I5RW0A320049-01

1

I5RW0A320050-01