check engine SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 540 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-43 Differential:

19) Using special tool and plastic hammer, drive oil seal

(2) into differential carrier (1) as shown in figure.

Then apply grease to oil seal lip.

NOTE

Install oil seal horizontally to surface of

differential carrier.

“A”: Grease 99000–25010 (SUZUKI Super

Grease A)

Distance between differential carrier and oil seal

“a”

: 0.5 – 1.5 mm (0.02 – 0.06 in.)

Special tool

(A): 09913–85210

20) Tighten bevel pinion nut (1) gradually with special

tool to specified torque while turning bevel pinion.

Set bearing preload of bevel pinion to specification.

NOTE

• Before taking measurement with torque

wrench, check for smooth rotation with

turning bevel pinion 15 revolutions or

more by hand.

• Be sure to tighten gradually and carefully

till specified pinion bearing preload is

obtained. Turning back overtightened

flange nuts should be avoided.

• Measure pinion bearing preload while

turning bevel pinion about 50 rpm.

• Write down measured value of bevel pinion

bearing preload for differential side

bearing shim adjustment.

Special tool

(A): 09927–27910

Tightening torque

Bevel pinion nut: 230 – 340 N·m (23.0 – 34.0 kgf-

m, 166.5 – 246.0 lb-ft)

Bevel pinion bearing preload (Bevel pinion

rotational torque)

: 1.3 – 2.6 N⋅m (13.0 – 26.0 kgf-cm, 11.3 – 22.6 lb-

in.)

21) Install differential case assembly, bearing outer

races, removed shim and differential cover,

temporarily.

NOTE

• Used left and right outer races are not

interchangeable.

• When measuring bevel pinion bearing

preload, install differential cover with

sealant not applied.

22) Select differential side bearing shim so that bevel

pinion bearing preload may be specified value.

NOTE

Select shims so that thickness of right side

shims and left side shims become almost

even.

Bevel pinion bearing preload

Preload measured in Step 20) + 0.3 – 0.7 N⋅m (3 –

7 kgf-cm, 2.6 – 6.0 lb-in.)

Available shim thickness

0.45, 2.30, 2.35, 2.40, 2.45, 2.50, 2.55, 2.60, 2.65

and 2.70 mm (0.017, 0.090, 0.092, 0.094, 0.096,

0.098, 0.100, 0.102, 0.104 and 0.106 in.)

(A)

11

2, “A”

“a”

I5RW0A320054-02

(A)

1

I5RW0A320055-03

I5RW0A320056-01

Page 541 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-44

23) Remove differential cover.

24) To measure bevel gear backlash, set dial gauge at

right angle to bevel gear tooth, fix drive bevel pinion

and read dial gauge while moving bevel gear.

If bevel gear backlash is out of specification, repeat

Step 22).

NOTE

• Be sure to apply measuring tip of dial

gauge at right angles to convex side of

tooth.

• Measure at least 4 points on drive bevel

gear periphery.

Drive bevel gear back lash

0.1 – 0.2 mm (0.004 – 0.008 in.)Special tool

(A): 09900–20607

(B): 09900–20701

25) As final step, check gear tooth contact as follows.

a) After cleaning 10 drive bevel gear teeth, paint them with gear marking compound evenly by using brush (1) or

sponge etc.

b) Turn gear to bring its painted part in mesh with drive bevel pinion and turn it back and forth by hand to repeat

their contact.

c) Bring painted part up and check contact pattern, referring to the following table. If contact pattern is not normal,

readjust or replace as necessary according to instruction in the table.

NOTE

Be careful not to turn drive bevel gear more than one full revolution, for it will hinder accurate check.

I5RW0A320057-01

A: Paint gear marking compound evenly

1

A

I5JB0A321040-02

Page 542 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-45 Differential:

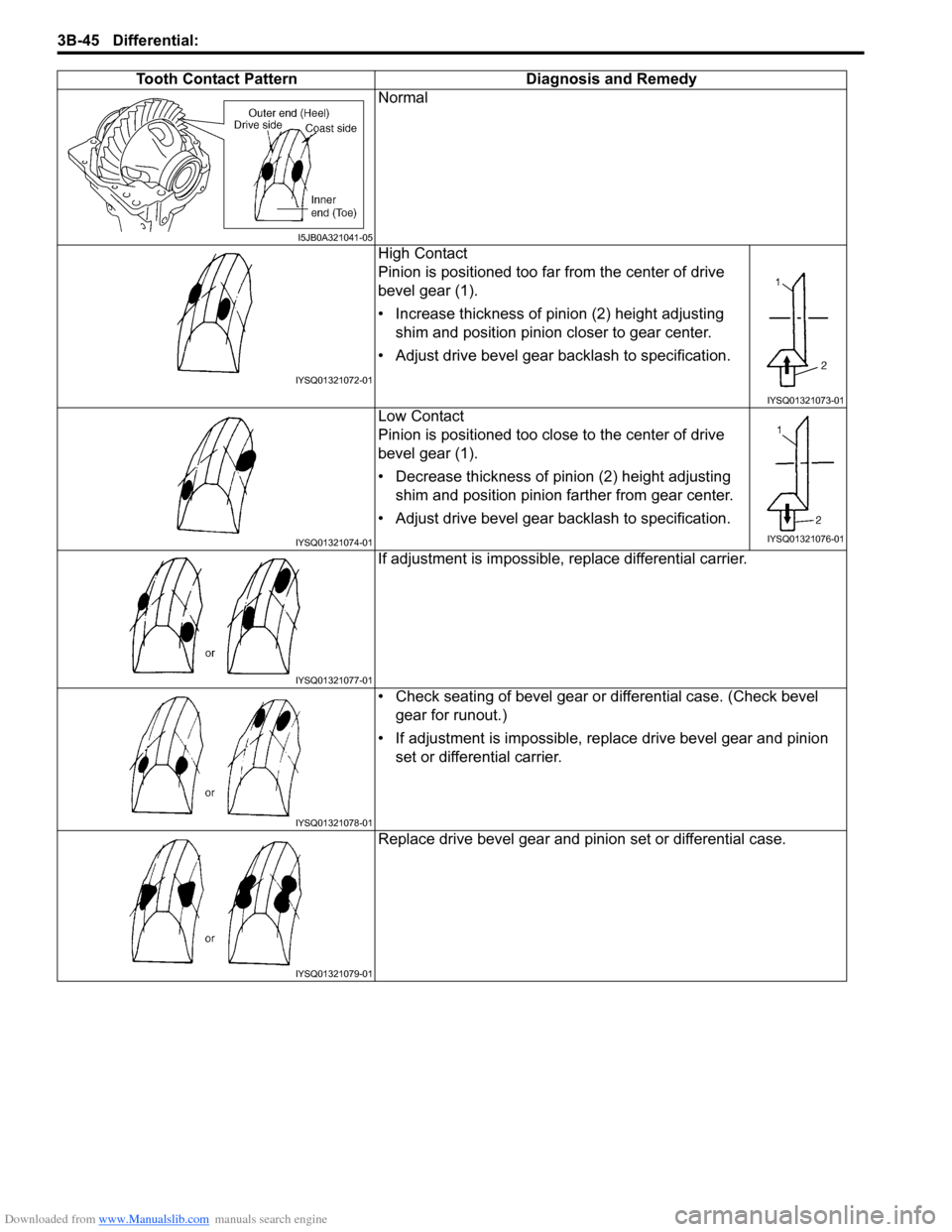

Tooth Contact Pattern Diagnosis and Remedy

Normal

High Contact

Pinion is positioned too far from the center of drive

bevel gear (1).

• Increase thickness of pinion (2) height adjusting

shim and position pinion closer to gear center.

• Adjust drive bevel gear backlash to specification.

Low Contact

Pinion is positioned too close to the center of drive

bevel gear (1).

• Decrease thickness of pinion (2) height adjusting

shim and position pinion farther from gear center.

• Adjust drive bevel gear backlash to specification.

If adjustment is impossible, replace differential carrier.

• Check seating of bevel gear or differential case. (Check bevel

gear for runout.)

• If adjustment is impossible, replace drive bevel gear and pinion

set or differential carrier.

Replace drive bevel gear and pinion set or differential case.

I5JB0A321041-05

IYSQ01321072-01

IYSQ01321073-01

IYSQ01321074-01IYSQ01321076-01

IYSQ01321077-01

IYSQ01321078-01

IYSQ01321079-01

Page 544 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-47 Differential:

31) Clean mating surface of differential carrier (1) and

coupling case (2), apply sealant to carrier as shown

in figure by such amount that its section is 1.5 mm

(0.059 in.) in diameter, mate coupling case with

differential carrier as shown in figure, and then

tighten bolts to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Coupling case bolt (a): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

NOTE

Install coupling pin (3) by fitting it to groove

(4) of coupling case.

32) Apply grease to oil seal lip, and then install oil seals

(1) to rear differential (2) using special tool as shown

in figure.

NOTE

Install oil seal horizontally to surface of rear

differential case.

“A”: Grease 99000–25010 (SUZUKI Super

Grease A)

Distance between rear differential and oil seal

“a”

: 1.0 – 2.0 mm (0.04 – 0.08 in.)

Special tool

(A): 09913–75810

33) Install drive shaft flange.

34) Install rear mounting bracket to rear differential

referring to “Front Mounting Arm and/or Rear

Mounting Bracket Assembly Removal and

Installation”.

Rear Differential InspectionS6RW0D3206015

• Check companion flange for wear or damage.

• Check bearings for wear or discoloration.

• Check differential carrier for cracks.

• Check drive bevel pinion and bevel gear for wear or

cracks.

• Check side gears, pinion gears and pinion shaft for

wear or damage.

• Check side gear spline for wear or damage.

1 4

3 2“A”

(a)

I5RW0A320062-04

(A)

2 21, “A”

“a”

I5RW0A320063-02

Page 549 of 1556

Downloaded from www.Manualslib.com manuals search engine Transfer: 3C-2

Repair Instructions

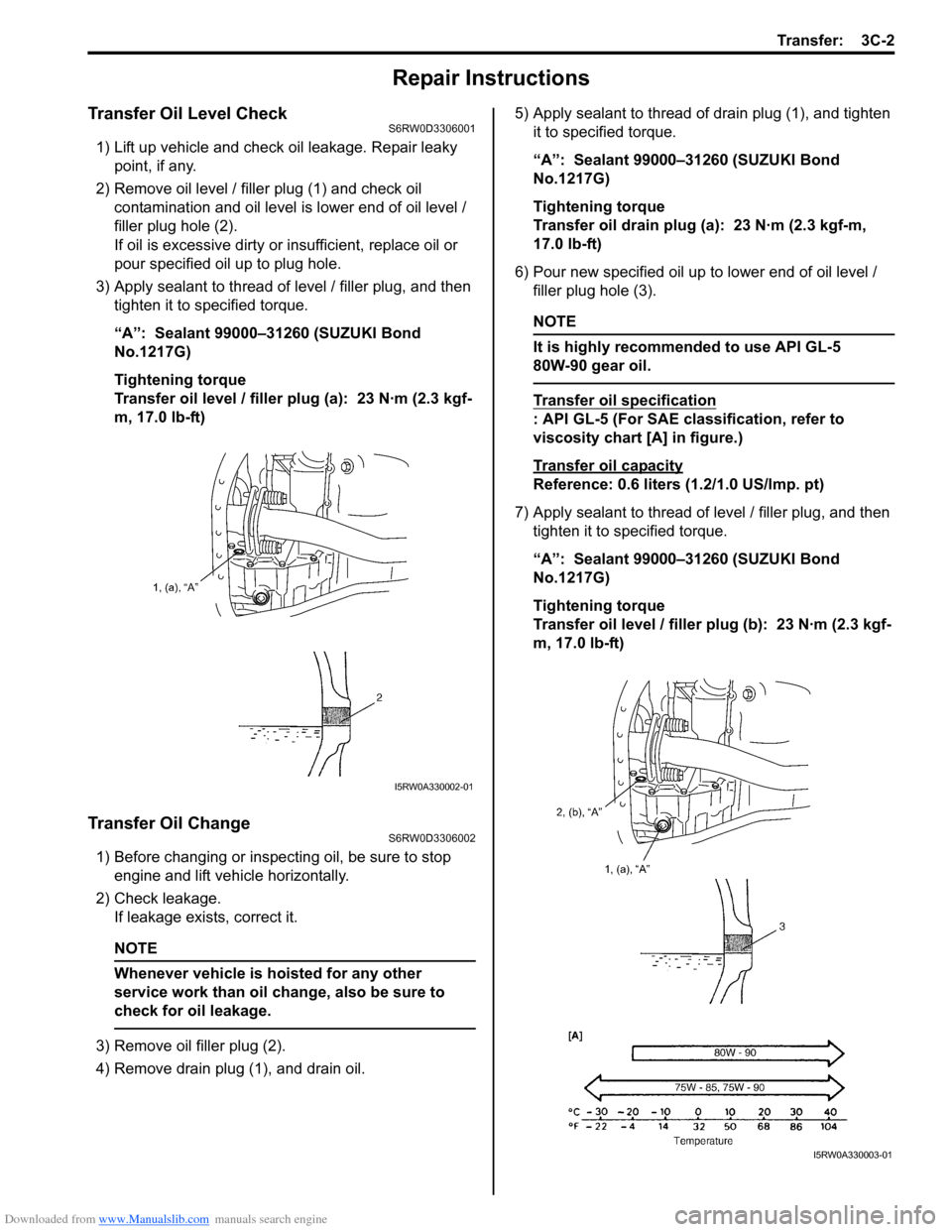

Transfer Oil Level CheckS6RW0D3306001

1) Lift up vehicle and check oil leakage. Repair leaky

point, if any.

2) Remove oil level / filler plug (1) and check oil

contamination and oil level is lower end of oil level /

filler plug hole (2).

If oil is excessive dirty or insufficient, replace oil or

pour specified oil up to plug hole.

3) Apply sealant to thread of level / filler plug, and then

tighten it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transfer oil level / filler plug (a): 23 N·m (2.3 kgf-

m, 17.0 lb-ft)

Transfer Oil ChangeS6RW0D3306002

1) Before changing or inspecting oil, be sure to stop

engine and lift vehicle horizontally.

2) Check leakage.

If leakage exists, correct it.

NOTE

Whenever vehicle is hoisted for any other

service work than oil change, also be sure to

check for oil leakage.

3) Remove oil filler plug (2).

4) Remove drain plug (1), and drain oil.5) Apply sealant to thread of drain plug (1), and tighten

it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transfer oil drain plug (a): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

6) Pour new specified oil up to lower end of oil level /

filler plug hole (3).

NOTE

It is highly recommended to use API GL-5

80W-90 gear oil.

Transfer oil specification

: API GL-5 (For SAE classification, refer to

viscosity chart [A] in figure.)

Transfer oil capacity

Reference: 0.6 liters (1.2/1.0 US/lmp. pt)

7) Apply sealant to thread of level / filler plug, and then

tighten it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transfer oil level / filler plug (b): 23 N·m (2.3 kgf-

m, 17.0 lb-ft)

I5RW0A330002-01

I5RW0A330003-01

Page 559 of 1556

Downloaded from www.Manualslib.com manuals search engine Transfer: 3C-12

c) Tighten bevel pinion nut (special tool) so that

specified bearing preload is obtained.

NOTE

Before taking measurement, check for

rotation by hand more than 15 revolutions.

Tightening torque

Rotational torque of bevel pinion (Bearing

preload): 0.50 – 1.30 N·m (0.05 – 0.13 kgf-m,

0.35 – 0.95 lb-ft)

d) Measure height “b” in figure by using vernier

caliper.

Calculate “c” by using measured value.e) Obtain adjusting shim thickness by the following

equation.

f) Select a shim closest to the calculated value

(necessary shim thickness) from among the

available shims or combine shims to become

closest to calculated value.

For example:

Measure distance “b” is 69.95 mm (2.754 in.).

“c” = 69.95 mm (2.754 in.) – 40.0 mm (1.757 in.)

= 29.95 mm (1.179 in.)

“f” = 29.95 mm (1.179 in.) + 74.0 mm (2.913 in.)

– 101.95 mm (4.014 in.) = 2.0 mm (0.079 in.)

Calculated thickness of new shim = 2.0 mm

(0.079 in.)

Available bevel pinion shim thickness

0.30, 1.85, 1.88, 1.91, 1.94, 1.97, 2.00, 2.03,

2.06, 2.09, 2.12 and 2.15 mm (0.012, 0.072,

0.074, 0.075, 0.076, 0.077, 0.078, 0.079, 0.081,

0.082, 0.083 and 0.084 in.) Distance “c” = Height “b” –Height “a” 40 mm

(1.575 in.)

I5RW0A330036-02

“a”

“b”

“c”

I5RW0A330046-01

Necessary

shim

thickness “f”=Distance

“c”+Distance

“d”

–Distance

“e”

74.0 mm

(2.913 in.)101.95 mm

(4.014 in.)

“d”: Pinion shaft mounting distance 74.0 mm (2.913 in.)

“e”: Distance from end face of left case to axis of reduction driven gear

101.95 mm (4.014 in.)

“f”: Necessary shim thickness

“d” “e”

“f ”

I5RW0A330037-01

Page 561 of 1556

Downloaded from www.Manualslib.com manuals search engine Transfer: 3C-14

8) Install transfer output flange (1) by tapping with

plastic hammer and tighten transfer output flange nut

gradually so as rotational torque of bevel pinion to be

in specified value.

NOTE

• If rotational torque of bevel pinion exceeds

specification given in the following,

replace pinion shaft spacers and tighten

flange nut.

• Before taking measurement of rotational

torque, rotate pinion over ten rounds in

advance.

Bevel pinion bearing preload

: 0.5 – 1.3 N⋅m (0.05 – 0.13 kgf-m, 0.35 – 0.95 lb-ft)

Special tool

(A): 09930–40113

9) Caulk transfer output flange nut (1).

Transfer Assembly InspectionS6RW0D3306010

• Check each bearing for smooth rotation, wear or

discoloration

If found abnormal, replace.

• Check oil seal for leakage and its lip for excessive

hardness

If either is found, replace.

• Check transfer case for cracks.

• Check bevel pinion and bevel gears for wear or

cracks.

Bevel Gear Tooth Contact InspectionS6RW0D3306011

1) After cleaning tooth surface of bevel gear (1), paint

them with gear marking compound evenly by using

brush or sponge etc.

NOTE

When applying red lead paste to teeth, be

sure to paint tooth surfaces uniformly. The

paste must not be too dry or too fluid.

2) Install transfer output retainer assembly referring to

“Transfer Assembly Disassembly and Reassembly”.

3) Turn transfer output flange clockwise and

counterclockwise repeatedly, and remove transfer

output retainer assembly and bevel gear shims from

transfer assembly.

2. Torque wrench

(A)1

2

I5RW0A330043-01

1

I5RW0A330044-01

I3RH01332043-01

Page 562 of 1556

Downloaded from www.Manualslib.com manuals search engine 3C-15 Transfer:

4) Bring painted part up and check contact pattern referring to the following chart. If contact pattern is not normal,

readjust or replace as necessary according to instruction in chart.

NOTE

• Be careful not to turn bevel gear more than one full revolution, for it will hinder accurate check.

• If bevel gear back lash and bevel pinion shims are adjusted properly, correct tooth contact should

be provided.

If correct tooth contact is not provided even when they are adjusted properly, however, there may be

an abnormal condition in worn tooth, transfer case or retainer. Check each component and replace

as necessary.

Gear tooth contact table

Tooth contact pattern Diagnosis and remedy

Normal

High contact

Pinion is positioned too far from the center of drive bevel

gear.

• Decrease thickness of bevel pinion shim and position

pinion closer to gear center.

• Adjust drive bevel gear backlash to specification.

Low contact

Pinion is positioned too close to the center of drive bevel

gear.

• Increase thickness of bevel pinion shim and position

pinion farther from gear center.

• Adjust drive bevel gear backlash to specification.

These contact patterns indicate that the “offset” of

reduction driven gear is too much or too little. The

remedy is to change the division of the bevel gear

shim(s).

I5RW0A330045-01

I3RH01332045-01

I3RH01332046-01

I3RH01332047-01

Page 567 of 1556

Downloaded from www.Manualslib.com manuals search engine Propeller Shafts: 3D-2

Repair Instructions

Propeller Shaft Joint CheckS6RW0D3406001

If universal joints and ball joint are suspected of

producing chattering or rattling noise, inspect them for

wear. For universal joint, check to see if cross spider

rattles in yokes are worn down and replace defective

propeller shaft assembly with new one.

Noise coming from universal joint and ball joint can be

easily distinguished from other noises because rhythm

of chattering or rattling is in step with cruising speed.

Noise is pronounced particularly on standing start or in

coasting condition (when braking effect of engine is

showing in the drive line).

Propeller Shaft Assembly Removal and

Installation

S6RW0D3406002

Removal

1) Hoist vehicle.

2) Before removing propeller shaft assembly, give

match marks (2) on joint flange and propeller shaft

as shown.

3) Separate propeller shaft assembly (1) from transfer

output flange and rear differential flange.4) Remove propeller shaft by removing center support

nuts (1).

CAUTION!

Use care not to drop it. Otherwise, vibration

may occur during driving.

Installation

Reverse removal procedure to install propeller shaft,

noting the following point.

• When installing propeller shaft, align the match marks

(2). Otherwise, vibration may occur during driving.

• Use the following specification to torque each bolt and

nut.

Tightening torque

Propeller shaft bolt: 23 N·m (2.3 kgf-m, 17.0 lb-ft)

Center support nut: 55 N·m (5.5 kgf-m, 40.0 lb-ft)

Propeller Shaft InspectionS6RW0D3406003

1) Check propeller shaft joints for wear, play and

damage. If any defect is found, replace.

2) Check propeller shaft center support for biting of

foreign matter, crack, abnormal noise and damage. If

any defect is found, replace.

I5JB0A340003-01

2

2

1

1

I5RW0A340002-01

1I5RW0A340003-01

Page 570 of 1556

Downloaded from www.Manualslib.com manuals search engine 4-ii Table of Contents

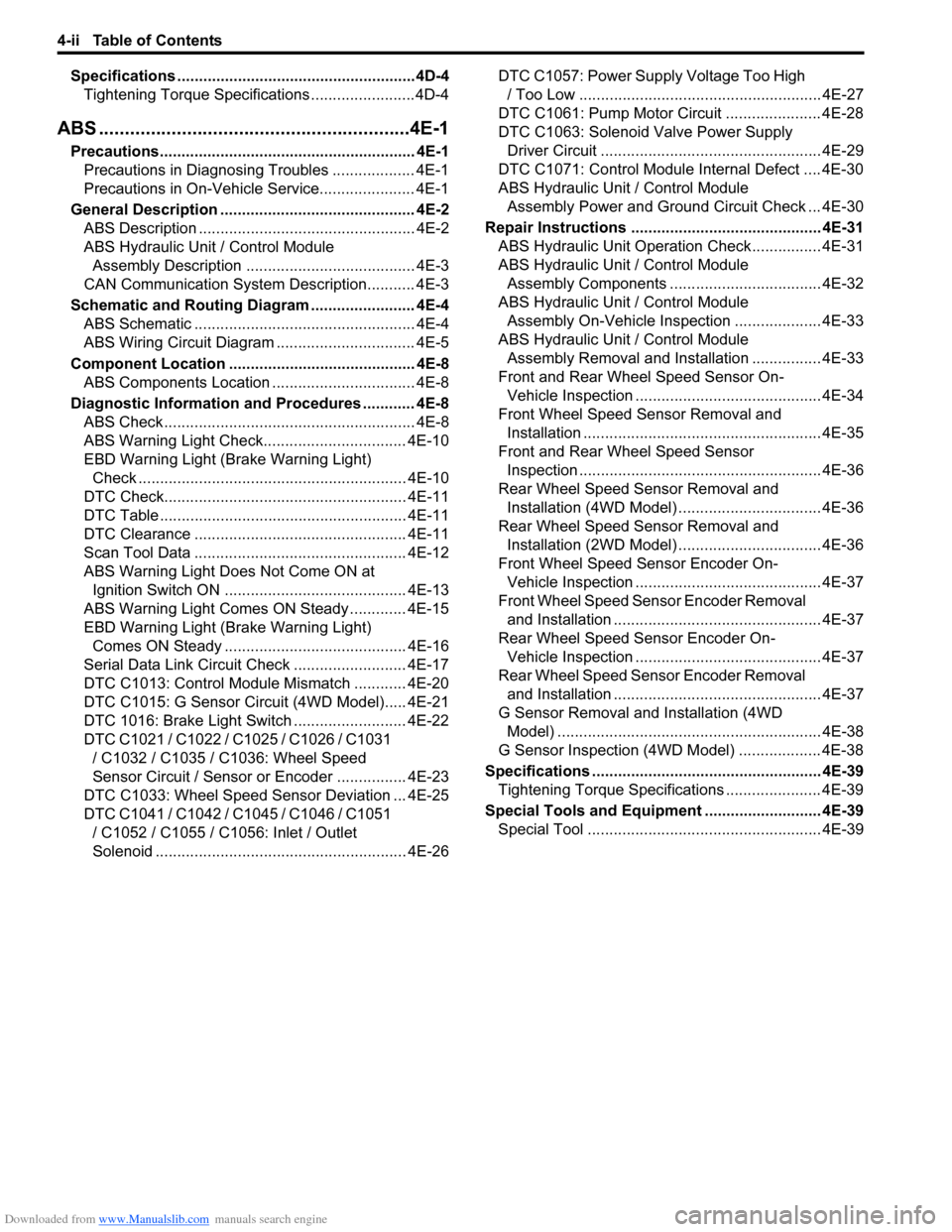

Specifications .......................................................4D-4

Tightening Torque Specifications ........................4D-4

ABS ............................................................4E-1

Precautions........................................................... 4E-1

Precautions in Diagnosing Troubles ................... 4E-1

Precautions in On-Vehicle Service...................... 4E-1

General Description ............................................. 4E-2

ABS Description .................................................. 4E-2

ABS Hydraulic Unit / Control Module

Assembly Description ....................................... 4E-3

CAN Communication System Description........... 4E-3

Schematic and Routing Diagram ........................ 4E-4

ABS Schematic ................................................... 4E-4

ABS Wiring Circuit Diagram ................................ 4E-5

Component Location ........................................... 4E-8

ABS Components Location ................................. 4E-8

Diagnostic Information and Procedures ............ 4E-8

ABS Check .......................................................... 4E-8

ABS Warning Light Check................................. 4E-10

EBD Warning Light (Brake Warning Light)

Check .............................................................. 4E-10

DTC Check........................................................ 4E-11

DTC Table ......................................................... 4E-11

DTC Clearance ................................................. 4E-11

Scan Tool Data ................................................. 4E-12

ABS Warning Light Does Not Come ON at

Ignition Switch ON .......................................... 4E-13

ABS Warning Light Comes ON Steady ............. 4E-15

EBD Warning Light (Brake Warning Light)

Comes ON Steady .......................................... 4E-16

Serial Data Link Circuit Check .......................... 4E-17

DTC C1013: Control Module Mismatch ............ 4E-20

DTC C1015: G Sensor Circuit (4WD Model)..... 4E-21

DTC 1016: Brake Light Switch .......................... 4E-22

DTC C1021 / C1022 / C1025 / C1026 / C1031

/ C1032 / C1035 / C1036: Wheel Speed

Sensor Circuit / Sensor or Encoder ................ 4E-23

DTC C1033: Wheel Speed Sensor Deviation ... 4E-25

DTC C1041 / C1042 / C1045 / C1046 / C1051

/ C1052 / C1055 / C1056: Inlet / Outlet

Solenoid .......................................................... 4E-26DTC C1057: Power Supply Voltage Too High

/ Too Low ........................................................ 4E-27

DTC C1061: Pump Motor Circuit ...................... 4E-28

DTC C1063: Solenoid Valve Power Supply

Driver Circuit ................................................... 4E-29

DTC C1071: Control Module Internal Defect .... 4E-30

ABS Hydraulic Unit / Control Module

Assembly Power and Ground Circuit Check ... 4E-30

Repair Instructions ............................................ 4E-31

ABS Hydraulic Unit Operation Check................ 4E-31

ABS Hydraulic Unit / Control Module

Assembly Components ................................... 4E-32

ABS Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4E-33

ABS Hydraulic Unit / Control Module

Assembly Removal and Installation ................ 4E-33

Front and Rear Wheel Speed Sensor On-

Vehicle Inspection ........................................... 4E-34

Front Wheel Speed Sensor Removal and

Installation ....................................................... 4E-35

Front and Rear Wheel Speed Sensor

Inspection ........................................................ 4E-36

Rear Wheel Speed Sensor Removal and

Installation (4WD Model) ................................. 4E-36

Rear Wheel Speed Sensor Removal and

Installation (2WD Model) ................................. 4E-36

Front Wheel Speed Sensor Encoder On-

Vehicle Inspection ........................................... 4E-37

Front Wheel Speed Sensor Encoder Removal

and Installation ................................................ 4E-37

Rear Wheel Speed Sensor Encoder On-

Vehicle Inspection ........................................... 4E-37

Rear Wheel Speed Sensor Encoder Removal

and Installation ................................................ 4E-37

G Sensor Removal and Installation (4WD

Model) ............................................................. 4E-38

G Sensor Inspection (4WD Model) ................... 4E-38

Specifications ..................................................... 4E-39

Tightening Torque Specifications ...................... 4E-39

Special Tools and Equipment ........................... 4E-39

Special Tool ...................................................... 4E-39