check engine SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 620 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-15 ABS:

ABS Warning Light Comes ON SteadyS6RW0D4504009

Wiring Diagram

Refer to “Warning Diagram” under “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

Refer to “Circuit Description” under “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Troubleshooting 3Combination meter power source circuit check

1) Remove combination meter with ignition switch turned

OFF.

2) Check for proper connection to “RED/BLK” and “BLK”

wire of combination meter connector.

3) If OK then turn ON ignition switch and measure voltage

at “RED/BLK” wire of combination meter connector and

vehicle body ground.

Is it 10 - 14 V?Go to Step 4. Repair power source

circuit for combination

meter.

4Combination meter ground circuit check

1) Measure resistance between “BLK” wire of combination

meter connector and vehicle body ground.

Is resistance less than 2

Ω?Substitute a known-

good combination meter

and recheck.“BLK” circuit open or

high resistance. Step Action Yes No

Step Action Yes No

1DTC check

1) Perform diagnostic trouble code check.

Is there any DTC(s)?Go to Step 7 of “ABS

Check”.Go to Step 2.

2ABS hydraulic unit / control module assembly power

and ground circuit check

1) Check that ABS hydraulic unit / control module assembly

power supply circuit and ground circuit is in good

condition referring to “ABS Hydraulic Unit / Control

Module Assembly Power and Ground Circuit Check”.

Are check results OK?Go to Step 3. Repair ABS hydraulic

unit / control module

assembly power or

ground circuit.

3CAN communication line circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check for proper connection to CAN communication line

wire.

4) If OK then check CAN communication line circuit

between control modules for open, short and high

resistance.

Is each CAN communication line circuit in good condition?Substitute a known-

good combination meter

and recheck. If warning

light remains ON,

substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Repair circuit and

recheck.

Page 621 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-16

EBD Warning Light (Brake Warning Light) Comes ON SteadyS6RW0D4504010

Wiring Diagram

Referring to “Wiring Diagram” under “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

EBD warning lamp (brake warning lamp) is controlled by ABS control module and BCM through lamp driver module in

combination meter.

If EBD system is in good condition, ABS control module turns EBD warning lamp ON at the ignition switch ON, keeps

it ON for 2 seconds and then turns it OFF.

EBD warning lamp is turned ON continuously at the following conditions.

• EBD system is an abnormality

• Connector of ABS control module is disconnected

• Parking brake switch is ON

• Brake fluid level is lower than minimum level

The information of parking brake switch and brake fluid level are transmitted from BCM to lamp driver module in

combination meter through CAN communication line.

Troubleshooting

Step Action Yes No

1Parking brake and brake fluid level check

1) Make sure that:

• Parking brake is completely released.

• Brake fluid level is upper than the minimum level.

Are the check results OK?Go to Step 2. Release parking brake

completely and/or

replenish brake fluid.

2ABS warning light operation check

1) Turn ignition switch to ON position.

Does ABS warning light come on steady?Perform “ABS Warning

Light Comes ON

Steady” previously

outlined.Go to Step 3.

3Parking brake switch circuit and brake fluid level switch

circuit check

1) Release parking brake completely, and replenish brake

fluid.

2) Disconnect BCM connectors with ignition switch turned

OFF.

3) Measure resistance between each parking brake switch

circuit, brake fluid level switch circuit and vehicle body

ground.

Are resistance

∞Ω?Go to Step 4. Check each applicable

circuit for short to

vehicle body ground. If

OK then check parking

brake switch and/or

brake fluid level switch.

4DTC check of BCM

1) Connect scan tool to data link connector with ignition

switch turned OFF.

2) Turn ignition switch to ON position and check DTC of

BCM.

Is there DTC U0073?Go to “DTC U0073 (No.

0073): Control Module

Communication Bus Off

in Section 10B”.Go to Step 5.

Page 622 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-17 ABS:

Serial Data Link Circuit CheckS6RW0D4504011

Wiring Diagram5CAN communication line circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check for proper connection to CAN communication line

wire.

4) If OK then check CAN communication line circuit

between control modules for open, short and high

resistance.

Is each CAN communication line circuit in good condition?Substitute a known-

good combination meter

and recheck. If EBD

warning light remains

OFF, substitute a

known-good BCM and/

or ABS hydraulic unit /

control module

assembly and recheck.Repair CAN

communication line

circuit. Step Action Yes No

11+BBBG

G1

12V

14BLU

REDWHTE08 [C]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26WHTGRN

3

E08-2

E08-13REDWHT 5

4 12

9

E08-23BLK

67

BLK

REDWHTG241-7G241-10

G241-16

12V

E08-25E08-24

E08-9

WHT/REDWHT/BLU

GRN/ORN

9

2

1

13

G241-31

RED/BLK

8

REDWHTREDWHT

9

10

E08-16 G04-4

G04-2

G04-1

G04-3 E04-1

E04-2

[D]

1 2 3 4 5 6 7 8 9 10 11

12 13 14 15 16 17

18 19 20 21 22G041 2 3 4 5 6 7

8 9 10 11 12 13 14E04

G241 [E]

132 4 5 6 7 8 9 10111213141516

17 1918 20 2122 23 24 25 26 27 28 29 30 31 32 [A]

I6RW0D450008-01

Page 624 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-19 ABS:

Trouble shooting

Step Action Yes No

1Scan tool communication check

Can scan tool communicate with BCM?Go to Step 2. Go to Step 3.

2ABS hydraulic unit / control module assembly power

and ground circuit check

1) Check that ABS hydraulic unit / control module assembly

power supply circuit and ground circuit is in good

condition referring to “ABS Hydraulic Unit / Control

Module Assembly Power and Ground Circuit Check”.

Are check results OK?Go to Step 3. Repair ABS hydraulic

unit / control module

assembly power or

ground circuit.

3Data link connector power source circuit check

1) Disconnect scan tool from data link connector.

2) Check for proper connection to scan tool.

3) If OK then turn ignition switch to ON position, and

measure voltage between terminal B of data link

connector and vehicle body ground.

Is voltage 10 – 12 V?Go to Step 4. Terminal B circuit open

or shorted to ground.

4Data link connector ground circuit check

1) Turn ignition switch to OFF position, and measure

resistance between the following terminals:

• Terminal G of data link connector and vehicle body

ground.

• Terminal G1 of data link connector and vehicle body

ground.

Are resistance less than 2

Ω?Go to Step 5. Terminal G and/or G1

wire circuit open or high

resistance.

5Serial communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by serial data circuit.

3) Check proper connection at serial data circuit terminals.

4) If OK, then check for high resistance, open or short to

power circuit or ground in serial data circuit.

Is check result in good condition?Go to Step 6. Repair serial data circuit

and recheck.

6CAN communication line circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check for proper connection to CAN communication line

wire.

3) If OK then check CAN communication line circuit

between control modules for open, short and high

resistance.

Is each CAN communication line circuit in good condition?Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Repair CAN

communication line

circuit and recheck.

Page 625 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-20

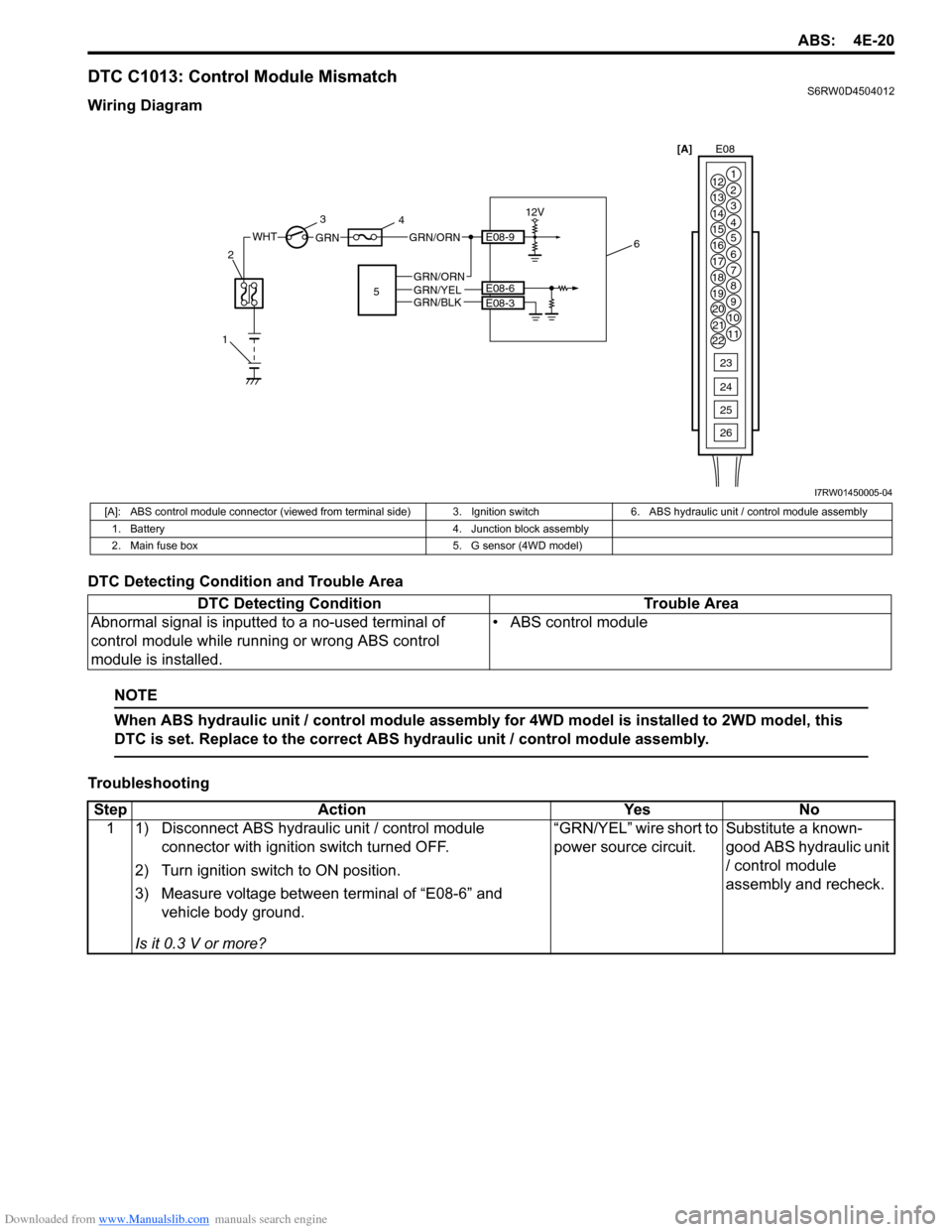

DTC C1013: Control Module MismatchS6RW0D4504012

Wiring Diagram

DTC Detecting Condition and Trouble Area

NOTE

When ABS hydraulic unit / control module assembly for 4WD model is installed to 2WD model, this

DTC is set. Replace to the correct ABS hydraulic unit / control module assembly.

Troubleshooting

WHTGRN

123

4

E08-3 E08-6GRN/BLKGRN/YELGRN/ORN

12V

E08-9GRN/ORN

56[A]E08

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

I7RW01450005-04

[A]: ABS control module connector (viewed from terminal side) 3. Ignition switch 6. ABS hydraulic unit / control module assembly

1. Battery 4. Junction block assembly

2. Main fuse box 5. G sensor (4WD model)

DTC Detecting Condition Trouble Area

Abnormal signal is inputted to a no-used terminal of

control module while running or wrong ABS control

module is installed.• ABS control module

Step Action Yes No

1 1) Disconnect ABS hydraulic unit / control module

connector with ignition switch turned OFF.

2) Turn ignition switch to ON position.

3) Measure voltage between terminal of “E08-6” and

vehicle body ground.

Is it 0.3 V or more?“GRN/YEL” wire short to

power source circuit.Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

Page 626 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-21 ABS:

DTC C1015: G Sensor Circuit (4WD Model)S6RW0D4504013

Wiring Diagram

Refer to “Wiring Diagram” under “DTC C1013: Control Module Mismatch”.

DTC Detecting Condition and Trouble Area

NOTE

When a vehicle is lifted up and its wheel(s) is turned, this DTC is set.

In such case, clear the DTC and check again.

Troubleshooting DTC Detecting Condition Trouble Area

• G sensor signal voltage is out of specified range.

• Vehicle behavior and G sensor signal is disagreed.• G sensor

• G sensor circuit

• ABS control module

Step Action Yes No

1Was “ABS Check” performed?Go to Step 2. Go to “ABS Check”.

2Is G sensor installed its bracket securely?Go to Step 3. Tighten G sensor bolt

and recheck.

3G sensor check

1) Disconnect G sensor connector and ABS hydraulic unit /

control module connector with ignition switch turned

OFF.

2) Check for proper connection to G sensor connector and

ABS hydraulic unit / control module terminals of “E08-3”

and “E08-6”.

3) If OK then check G sensor referring to “G Sensor

Inspection (4WD Model)”.

Is it in good condition?Go to Step 4. Replace G sensor.

4G sensor power source voltage check

1) Turn ignition switch to ON position and measure voltage

between “GRN/ORN terminal of G sensor connector and

vehicle body ground.

Is it 10 – 14 V?Go to Step 5. “GRN/ORN” circuit

open.

5G sensor signal circuit and ground circuit check

1) Measure resistance between following terminals.

• Between “E08-3” terminal and “GRN/BLK” terminal of

G sensor.

• Between “E08-6” terminal and “GRN/YEL” terminal of

G sensor.

Is each resistance less than 2

Ω?Go to Step 6. “GRN/BLK” and/or

“GRN/YEL” wire circuits

in open or high

resistance.

6G sensor ground circuit check

1) Connect ABS hydraulic unit / control module connector

with ignition switch turned OFF.

2) Turn ignition switch to ON position and measure voltage

between “GRN/BLK” terminal of G sensor connector and

vehicle body ground.

Is it 0 V?Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.“GRN/BLK” circuit to

power circuit.

Page 627 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-22

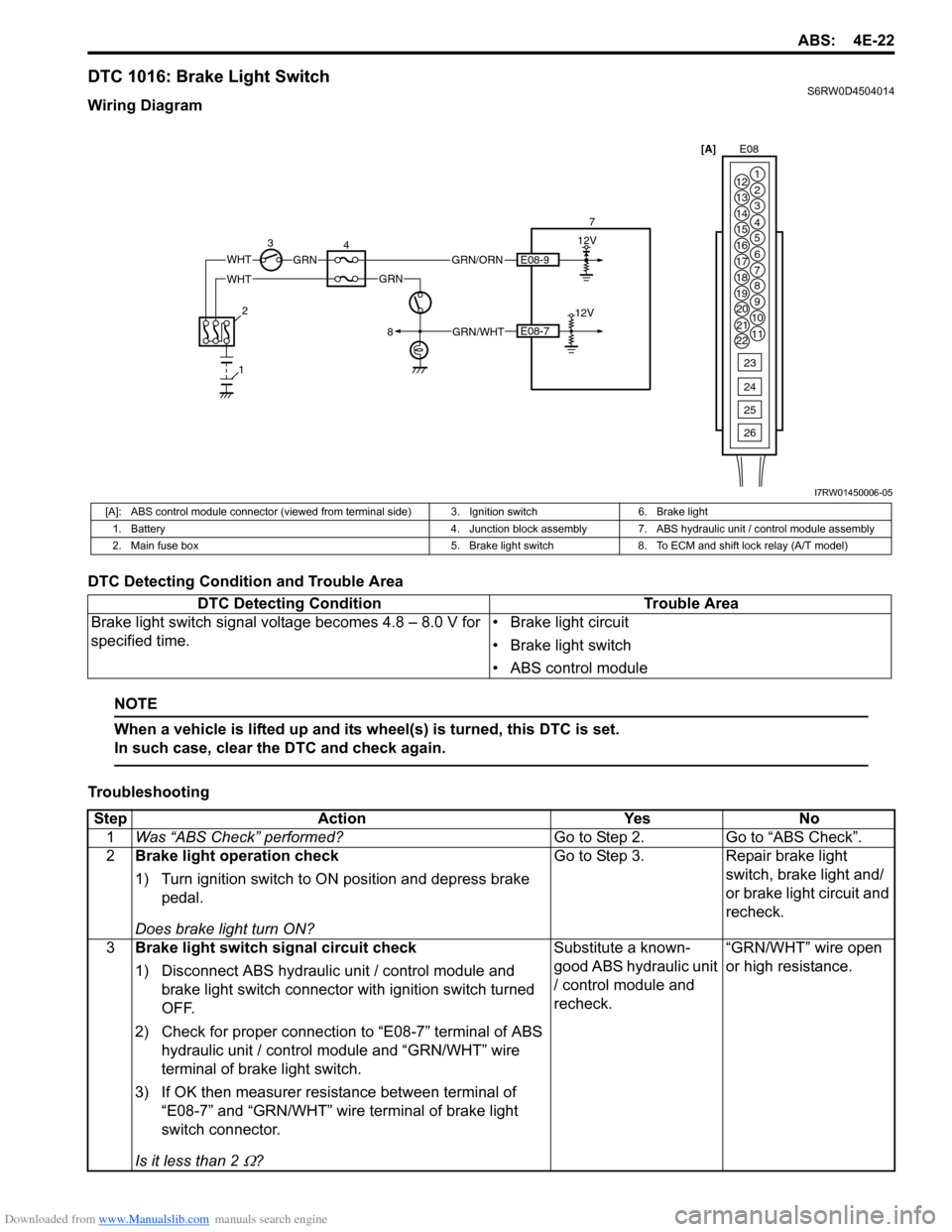

DTC 1016: Brake Light SwitchS6RW0D4504014

Wiring Diagram

DTC Detecting Condition and Trouble Area

NOTE

When a vehicle is lifted up and its wheel(s) is turned, this DTC is set.

In such case, clear the DTC and check again.

Troubleshooting

WHTGRN

34 712V

E08-7

E08-9GRN/ORN

2

8

112V

GRN/WHT

WHTGRN[A]E08

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

I7RW01450006-05

[A]: ABS control module connector (viewed from terminal side) 3. Ignition switch 6. Brake light

1. Battery 4. Junction block assembly 7. ABS hydraulic unit / control module assembly

2. Main fuse box 5. Brake light switch 8. To ECM and shift lock relay (A/T model)

DTC Detecting Condition Trouble Area

Brake light switch signal voltage becomes 4.8 – 8.0 V for

specified time.• Brake light circuit

• Brake light switch

• ABS control module

Step Action Yes No

1Was “ABS Check” performed?Go to Step 2. Go to “ABS Check”.

2Brake light operation check

1) Turn ignition switch to ON position and depress brake

pedal.

Does brake light turn ON?Go to Step 3. Repair brake light

switch, brake light and/

or brake light circuit and

recheck.

3Brake light switch signal circuit check

1) Disconnect ABS hydraulic unit / control module and

brake light switch connector with ignition switch turned

OFF.

2) Check for proper connection to “E08-7” terminal of ABS

hydraulic unit / control module and “GRN/WHT” wire

terminal of brake light switch.

3) If OK then measurer resistance between terminal of

“E08-7” and “GRN/WHT” wire terminal of brake light

switch connector.

Is it less than 2

Ω?Substitute a known-

good ABS hydraulic unit

/ control module and

recheck.“GRN/WHT” wire open

or high resistance.

Page 628 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-23 ABS:

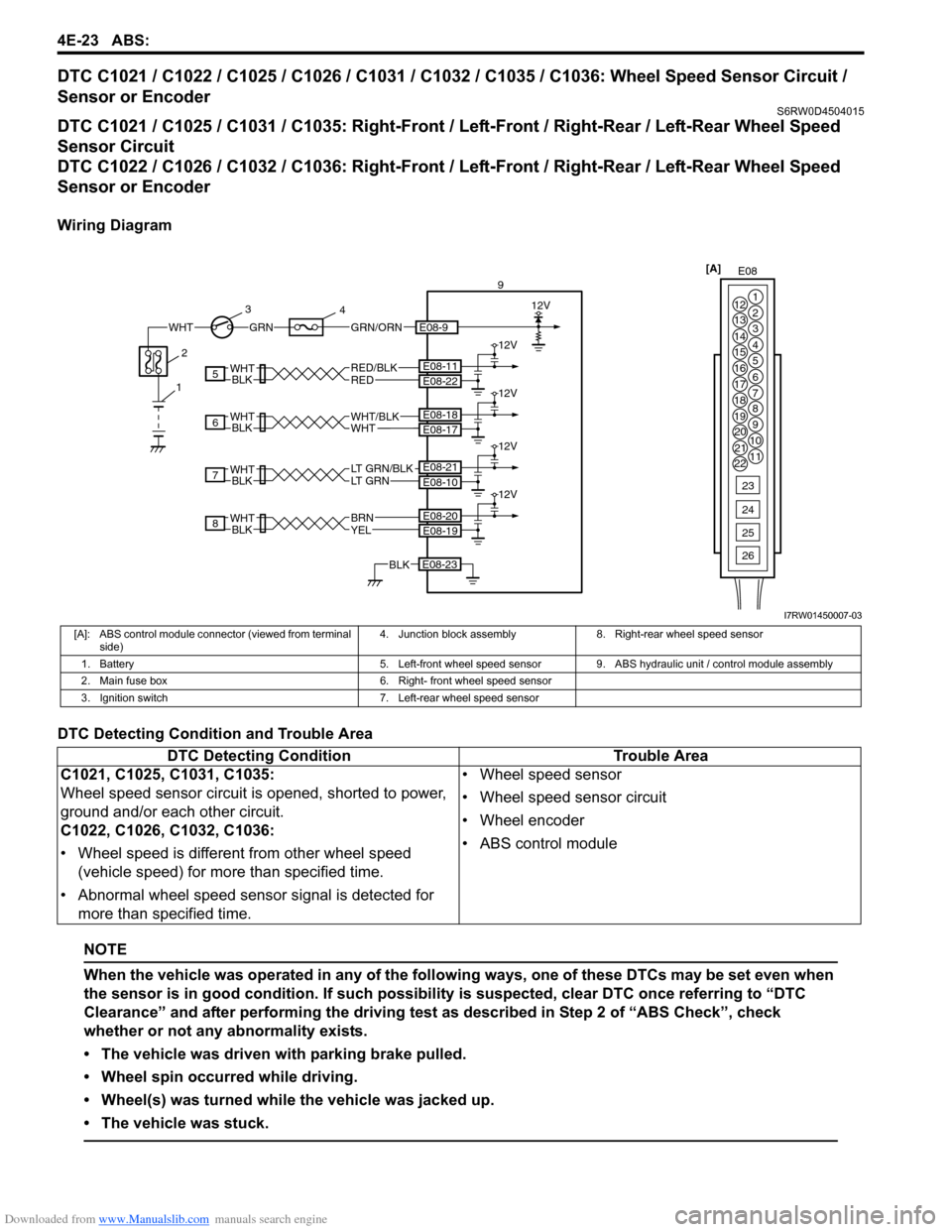

DTC C1021 / C1022 / C1025 / C1026 / C1031 / C1032 / C1035 / C1036: Wheel Speed Sensor Circuit /

Sensor or Encoder

S6RW0D4504015

DTC C1021 / C1025 / C1031 / C1035: Right-Front / Left-Front / Right-Rear / Left-Rear Wheel Speed

Sensor Circuit

DTC C1022 / C1026 / C1032 / C1036: Right-Front / Left-Front / Right-Rear / Left-Rear Wheel Speed

Sensor or Encoder

Wiring Diagram

DTC Detecting Condition and Trouble Area

NOTE

When the vehicle was operated in any of the following ways, one of these DTCs may be set even when

the sensor is in good condition. If such possibility is suspected, clear DTC once referring to “DTC

Clearance” and after performing the driving test as described in Step 2 of “ABS Check”, check

whether or not any abnormality exists.

• The vehicle was driven with parking brake pulled.

• Wheel spin occurred while driving.

• Wheel(s) was turned while the vehicle was jacked up.

• The vehicle was stuck.

E08 [A]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

WHTGRNGRN/ORN

3

4

E08-9

9

12V

8

7

6

5

BLKWHT

BLKWHT

REDRED/BLK

LT GRN/BLKLT GRN

E08-22 E08-11

E08-10 E08-21

E08-23BLK

12V

12V

12V

12V

BLKWHT

BLKWHTWHTWHT/BLK

E08-17 E08-18

YELBRN

E08-19 E08-20

12

I7RW01450007-03

[A]: ABS control module connector (viewed from terminal

side)4. Junction block assembly 8. Right-rear wheel speed sensor

1. Battery 5. Left-front wheel speed sensor 9. ABS hydraulic unit / control module assembly

2. Main fuse box 6. Right- front wheel speed sensor

3. Ignition switch 7. Left-rear wheel speed sensor

DTC Detecting Condition Trouble Area

C1021, C1025, C1031, C1035:

Wheel speed sensor circuit is opened, shorted to power,

ground and/or each other circuit.

C1022, C1026, C1032, C1036:

• Wheel speed is different from other wheel speed

(vehicle speed) for more than specified time.

• Abnormal wheel speed sensor signal is detected for

more than specified time.• Wheel speed sensor

• Wheel speed sensor circuit

• Wheel encoder

• ABS control module

Page 629 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-24

DTC Troubleshooting

Step Action Yes No

1Was “ABS Check” performed?Go to Step 2. Go to “ABS Check”.

2Check tire condition

1) Check that tire pressure is specifications.

Are they in good condition?Go to Step 3. Replace tire or adjust

tire pressure and

recheck.

3Wheel speed sensor circuit check

1) Disconnect ABS hydraulic unit / control module

connector and applicable wheel speed sensor connector

with ignition switch turned OFF.

2) Check for proper connection to ABS hydraulic unit /

control module connector at applicable terminals and

terminals of applicable wheel speed sensor.

3) If OK then check applicable wheel speed sensor circuit

for open, short and high resistance.

Is each applicable wheel speed sensor circuit in good

condition?Go to Step 4. Repair circuit and

recheck

4Wheel speed sensor check

1) Inspection applicable wheel speed sensor referring to

“Front and Rear Wheel Speed Sensor Inspection”.

Is it in good condition?Go to Step 5. Clean or replace.

5Wheel speed sensor encoder check

1) Inspection applicable wheel speed sensor encoder

referring to “Front Wheel Speed Sensor Encoder On-

Vehicle Inspection” and/or “Rear Wheel Speed Sensor

Encoder On-Vehicle Inspection”.

Is it in good condition?Go to Step 6. Clean or replace wheel

hub assembly.

6Wheel speed sensor signal check

1) Inspection applicable wheel speed sensor referring to

“Front and Rear Wheel Speed Sensor On-Vehicle

Inspection”.

Is it in good condition?Substitute a known-

good wheel hub

assembly and recheck.

If DTC detected,

substitute a known-

good ABS hydraulic unit

/ control module and

recheck.Replace wheel speed

sensor and recheck.

Page 630 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-25 ABS:

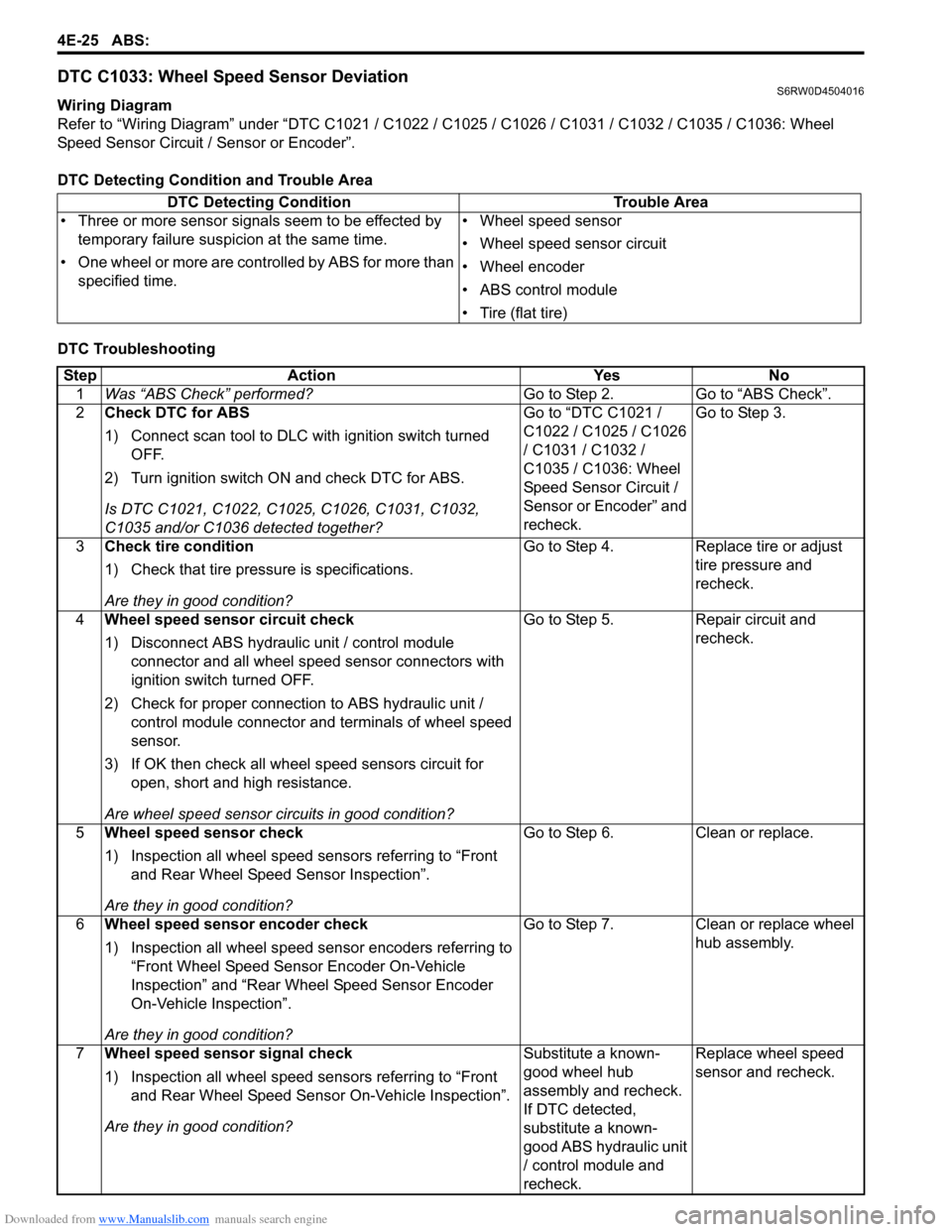

DTC C1033: Wheel Speed Sensor DeviationS6RW0D4504016

Wiring Diagram

Refer to “Wiring Diagram” under “DTC C1021 / C1022 / C1025 / C1026 / C1031 / C1032 / C1035 / C1036: Wheel

Speed Sensor Circuit / Sensor or Encoder”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting DTC Detecting Condition Trouble Area

• Three or more sensor signals seem to be effected by

temporary failure suspicion at the same time.

• One wheel or more are controlled by ABS for more than

specified time.• Wheel speed sensor

• Wheel speed sensor circuit

• Wheel encoder

• ABS control module

• Tire (flat tire)

Step Action Yes No

1Was “ABS Check” performed?Go to Step 2. Go to “ABS Check”.

2Check DTC for ABS

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC for ABS.

Is DTC C1021, C1022, C1025, C1026, C1031, C1032,

C1035 and/or C1036 detected together?Go to “DTC C1021 /

C1022 / C1025 / C1026

/ C1031 / C1032 /

C1035 / C1036: Wheel

Speed Sensor Circuit /

Sensor or Encoder” and

recheck.Go to Step 3.

3Check tire condition

1) Check that tire pressure is specifications.

Are they in good condition?Go to Step 4. Replace tire or adjust

tire pressure and

recheck.

4Wheel speed sensor circuit check

1) Disconnect ABS hydraulic unit / control module

connector and all wheel speed sensor connectors with

ignition switch turned OFF.

2) Check for proper connection to ABS hydraulic unit /

control module connector and terminals of wheel speed

sensor.

3) If OK then check all wheel speed sensors circuit for

open, short and high resistance.

Are wheel speed sensor circuits in good condition?Go to Step 5. Repair circuit and

recheck.

5Wheel speed sensor check

1) Inspection all wheel speed sensors referring to “Front

and Rear Wheel Speed Sensor Inspection”.

Are they in good condition?Go to Step 6. Clean or replace.

6Wheel speed sensor encoder check

1) Inspection all wheel speed sensor encoders referring to

“Front Wheel Speed Sensor Encoder On-Vehicle

Inspection” and “Rear Wheel Speed Sensor Encoder

On-Vehicle Inspection”.

Are they in good condition?Go to Step 7. Clean or replace wheel

hub assembly.

7Wheel speed sensor signal check

1) Inspection all wheel speed sensors referring to “Front

and Rear Wheel Speed Sensor On-Vehicle Inspection”.

Are they in good condition?Substitute a known-

good wheel hub

assembly and recheck.

If DTC detected,

substitute a known-

good ABS hydraulic unit

/ control module and

recheck.Replace wheel speed

sensor and recheck.