sensor SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1358 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-6 Instrumentation / Driver Info. / Horn:

Diagnostic Information and Procedures

Speedometer and VSS Symptom DiagnosisS6RW0D9304001

Tachometer Symptom DiagnosisS6RW0D9304002

Engine Coolant Temperature (ECT) Meter Symptom DiagnosisS6RW0D9304003

Fuel Meter Symptom DiagnosisS6RW0D9304004

Condition Possible cause Correction / Reference Item

Speedometer shows no

operation or incorrect

operationCircuit fuse blownReplace fuse and check for short circuit.

Front wheel speed sensor or sensor

encoder faulty (M/T model)Check front wheel speed sensor or sensor

encoder referring to “Front and Rear Wheel

Speed Sensor On-Vehicle Inspection in

Section 4E” or “Front Wheel Speed Sensor

Encoder On-Vehicle Inspection in Section 4E”.

Output shaft speed sensor (VSS) faulty

(A/T model)Check output shaft speed sensor (VSS)

referring to “Output Shaft Speed Sensor (VSS)

Inspection in Section 5A”

Wiring or grounding faultyRepair circuit.

Combination meter faulty Replace combination meter.

TCM faulty (A/T model)Check input and output signal of TCM referring

to “Inspection of TCM and Its Circuits in

Section 5A”

ECM faultyReplace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Tachometer shows no

operation or incorrect

operationCircuit fuse blownReplace fuse and check for short circuit.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

ECM faultyReplace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Engine coolant

temperature (ECT) meter

shows no operation or

incorrect operationCircuit fuse blownReplace fuse and check for short circuit.

ECT sensor faultyCheck ECT sensor referring to “Engine

Coolant Temperature (ECT) Sensor Inspection

in Section 1C”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

ECM faultyReplace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Fuel meter shows no

operation or incorrect

operationCircuit fuse blownReplace fuse and check for short circuit.

Fuel level sensor faultyCheck fuel level sensor referring to “Fuel Level

Sensor Inspection”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

ECM faultyReplace after making sure that none of above

parts is faulty.

Page 1359 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-7

Low Fuel Warning Light Symptom DiagnosisS6RW0D9304005

NOTE

• Confirm that fuel meter is in good condition before referring to the following possible causes.

• When fuel level sensor circuit is open or short, fuel level meter indicates empty even if fuel tank

does not empty.

• The low fuel warning light comes ON when fuel level is lower than specification below.

Low fuel warning light operation:

Oil Pressure Warning Light Symptom DiagnosisS6RW0D9304006

Low fuel warning light operation: Fuel amount: Resistance of fuel level sensor:

ON (2WD) Approx. 7.5 liter Approx. 261 Ω

ON (4WD) Approx. 6.8 liter Approx. 261 Ω

Condition Possible cause Correction / Reference Item

Low fuel warning light

does not come ON when

fuel level is lower than

specificationCircuit fuse blownReplace fuse and check for short circuit.

Fuel level sensor faultyCheck fuel level sensor referring to “Fuel Level

Sensor Inspection”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

ECM faultyReplace after making sure that none of above

parts is faulty.

Low fuel warning light

comes ON steadyLow fuelRefill fuel.

Fuel level sensor faultyCheck fuel level sensor referring to “Fuel Level

Sensor Inspection”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

ECM faultyReplace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Oil pressure warning light

does not light up when

ignition switch is turned

to ON position at engine

offCircuit fuse blownReplace fuse and check for short circuit.

Oil pressure switch faultyCheck oil pressure switch referring to “Oil

Pressure Switch Inspection”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

BCM faultyReplace after making sure that none of above

parts is faulty.

Oil pressure warning light

stays ONOil pressure switch faultyCheck oil pressure switch referring to “Oil

Pressure Switch Inspection”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1360 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-8 Instrumentation / Driver Info. / Horn:

Brake and Parking Brake Warning Light Symptom DiagnosisS6RW0D9304007

Seat Belt Reminder Light Symptom DiagnosisS6RW0D9304008

A/T Shift Position Indicator Symptom Diagnosis (A/T Model)S6RW0D9304009

Condition Possible cause Correction / Reference Item

Brake warning light does

not light up when brake

fluid level is low or

parking brake is pulled up

or for 5 seconds after

turning ON ignition switchCircuit fuse blownReplace fuse and check for short circuit.

Brake fluid level switch faultyCheck brake fluid level switch referring to

“Brake Fluid Level Switch Inspection”.

Parking brake switch faultyCheck parking brake switch referring to

“Parking Brake Switch Inspection”.

ABS system faultyRefer to “ABS Check in Section 4E”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

BCM faultyReplace after making sure that none of above

parts is faulty.

Brake warning light stays

ONBrake fluid level switch faultyCheck brake fluid level switch referring to

“Brake Fluid Level Switch Inspection”.

Parking brake switch faultyCheck parking brake switch referring to

“Parking Brake Switch Inspection”.

EBD system faultyRefer to “EBD Warning Light (Brake Warning

Light) Check in Section 4E”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

BCM faultyReplace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Seat belt reminder light

does not light upCircuit fuse blownReplace fuse and check for short circuit.

Seat belt switch faultyCheck seat belt switch referring to “Front Seat

Belt Inspection in Section 8A”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

BCM faultyReplace after making sure that none of above

parts is faulty.

Seat belt reminder light

stays ONSeat belt switch faultyCheck seat belt switch referring to “Front Seat

Belt Inspection in Section 8A”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

BCM faultyReplace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

All A/T shift position

indicator does not light upCircuit fuse blownReplace fuse and check for short circuit.

Transmission range sensor (shift switch)

faultyCheck transmission range sensor referring to

“Transmission Range Sensor Inspection and

Adjustment in Section 5A”.

Wiring or ground faultyRepair circuit.

Combination meter faultyReplace combination meter.

TCM faultyReplace after making sure that none of above

parts is faulty.

Page 1362 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-10 Instrumentation / Driver Info. / Horn:

Cigarette Lighter Symptom Diagnosis (If Equipped)S6RW0D9304013

Horn Symptom DiagnosisS6RW0D9304014

Information Display Symptom Diagnosis (If Equipped)S6RW0D9304015

NOTE

This thermometer indicates the ambient temperature in the under side of front bumper member. Under

any one of the following listed conditions, however, even when the ambient temperature goes up, the

thermometer display does not rise so as to correct the rise of the ambient temperature caused by the

radiant heat of the engine. When the ambient temperature drops, the thermometer reading follows the

change in the temperature.

Be sure to bear this in mind when diagnosing trouble.

• The vehicle speed is 30 km/h (18 mph) or lower.

• Vehicle speed signal is faulty.

• The ignition switch is turned on again within 2 hours.

Condition Possible cause Correction / Reference Item

Cigarette lighter shows

no operationCircuit fuse blownReplace fuse and check for short circuit.

Cigarette lighter faultyCheck cigarette lighter.

Ignition switch faultyCheck ignition switch referring to “Ignition

Switch Inspection”.

Wiring or grounding faultyRepair circuit.

Condition Possible cause Correction / Reference Item

Horn does not operateCircuit fuse blownReplace fuse and check for short circuit.

Horn switch faultyCheck horn switch.

Horn relay faultyCheck horn relay referring to “Horn Relay

Inspection”.

Wiring or grounding faultyRepair circuit.

Horn faultyCheck horn referring to “Horn Inspection”.

Condition Possible cause Correction / Reference Item

No displaying of

information displayCircuit fuse BlownReplace fuse and check for short circuit.

Wiring or grounding faultyRepair circuit.

Information display unit faultyReplace unit.

Incorrect thermometer

displayOutside air temperature sensor faultyCheck outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Vehicle speed signal faultyCheck ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring or grounding faultyRepair circuit.

Information display unit faultyReplace unit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Display of thermometer

does not change at –30

°C

(–22

°F)Outside air temperature is –30 °C (–22

°F) or less—

Outside air temperature sensor faultyCheck outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Information display unit faultyReplace unit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1363 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-11

Clock System Diagnosis (If Equipped)S6RW0D9304016

Display of thermometer

does not change at 50

°C

(122

°F)Outside air temperature is 50 °C (122

°F) or more—

Outside air temperature sensor faultyCheck outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Information display unit faultyReplace unit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Display of thermometer

does not change at “- - -

°C (°F)”Outside air temperature sensor faultyCheck outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Outside air temperature sensor circuit is

open or shortRepair circuit.

Wiring or grounding faultyRepair circuit.

Information display unit faultyReplace unit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Display of fuel

consumption does not

change at “- - - l / 100 km

(km/l, MPG)”Vehicle is not running (instantaneous

fuel consumption mode)—

Fuel consumption was reset (average

fuel consumption mode, if equipped)Vehicle runs for a while.

Vehicle speed signal faultyCheck ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring or grounding faultyRepair circuit.

CAN communication data (information)

can not be received by BCMCheck BCM for DTC referring to “DTC Check

in Section 10B”.

Information display unit faultyReplace unit.

BCM faultyReplace after making sure that none of above

parts is faulty. Condition Possible cause Correction / Reference Item

Condition Possible cause Correction / Reference Item

No displaying of clockCircuit fuse blownReplace fuse and check for short circuit.

Wiring or grounding faultyRepair circuit.

Clock unit faultyReplace unit.

Page 1367 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-15

3) Remove center ventilation louver referring to Step 1)

and 2) of “Information Display (Clock) Removal and

Installation”.

4) Remove combination meter cluster panel (1) pulling

it in arrow direction shown in figure.

5) Remove screws (1) fastening combination meter.

6) Remove combination meter (2) pulling it arrow

direction as shown.

Installation

Reverse removal procedure.

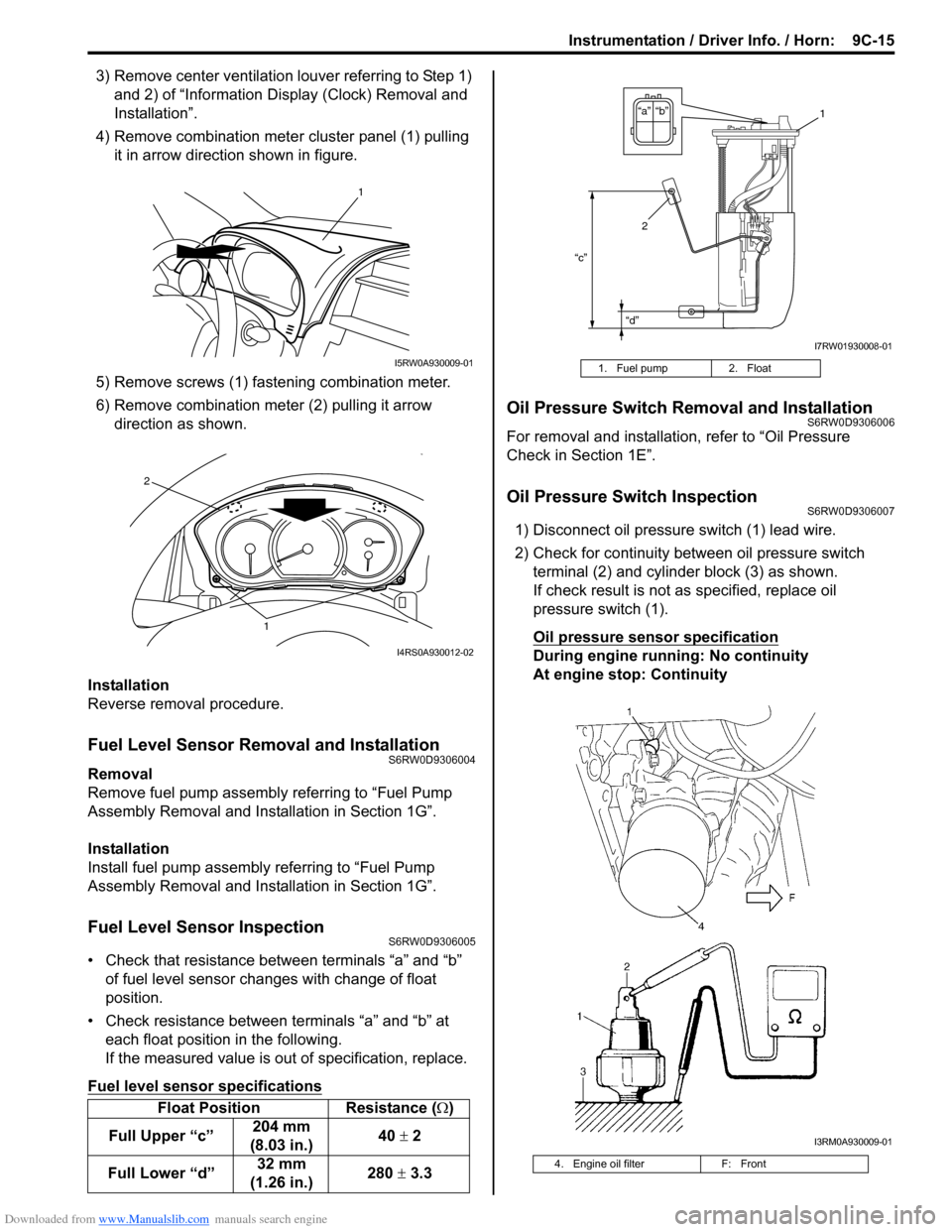

Fuel Level Sensor Removal and InstallationS6RW0D9306004

Removal

Remove fuel pump assembly referring to “Fuel Pump

Assembly Removal and Installation in Section 1G”.

Installation

Install fuel pump assembly referring to “Fuel Pump

Assembly Removal and Installation in Section 1G”.

Fuel Level Sensor InspectionS6RW0D9306005

• Check that resistance between terminals “a” and “b”

of fuel level sensor changes with change of float

position.

• Check resistance between terminals “a” and “b” at

each float position in the following.

If the measured value is out of specification, replace.

Fuel level sensor specifications

Oil Pressure Switch Removal and InstallationS6RW0D9306006

For removal and installation, refer to “Oil Pressure

Check in Section 1E”.

Oil Pressure Switch InspectionS6RW0D9306007

1) Disconnect oil pressure switch (1) lead wire.

2) Check for continuity between oil pressure switch

terminal (2) and cylinder block (3) as shown.

If check result is not as specified, replace oil

pressure switch (1).

Oil pressure sensor specification

During engine running: No continuity

At engine stop: Continuity

Float Position Resistance (Ω)

Full Upper “c”204 mm

(8.03 in.)40 ± 2

Full Lower “d”32 mm

(1.26 in.)280 ± 3.3

1

I5RW0A930009-01

1

2

I4RS0A930012-02

1. Fuel pump 2. Float

4. Engine oil filter F: Front

“c”

“d”

“b” “a”1

2

I7RW01930008-01

I3RM0A930009-01

Page 1368 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-16 Instrumentation / Driver Info. / Horn:

Engine Coolant Temperature (ECT) Sensor

Inspection

S6RW0D9306008

Check engine coolant temperature sensor for resistance,

refer to “Engine Coolant Temperature (ECT) Sensor

Inspection in Section 1C”.

Brake Fluid Level Switch InspectionS6RW0D9306009

Check for continuity between terminals of brake fluid

level switch coupler (1). If found defective, replace

switch.

Brake fluid level switch specification

OFF position (float up): No continuity

ON position (float down): Continuity

Parking Brake Switch InspectionS6RW0D9306010

Check for continuity between parking brake switch

terminal and body ground as shown in figure. If found

defective, replace switch.

Parking brake switch specification

OFF position (parking brake released): No continuity

ON position (parking brake lever pulled up):

Continuity

Door Switch (Front / Rear Door) InspectionS6RW0D9306011

Remove door switch from body and check switch for

continuity. If found defective, replace switch.

Door switch (front / rear door) specification

OFF position (Door closed): No continuity

ON position (Door open): Continuity

Rear End Door Switch InspectionS6RW0D9306012

Check for continuity between terminal “a” and “b” shown

in the following.

If check result is not as specified, replace switch.

Rear end door switch specification

Rear end door closed: No continuity

Rear end door opened: Continuity

1. Parking brake switch 2. Parking brake lever

1

I5RW0A930011-01

12

I4RS0A930014-01

I3RH0A930004-01

a

b

I4RS0A930015-01

Page 1369 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-17

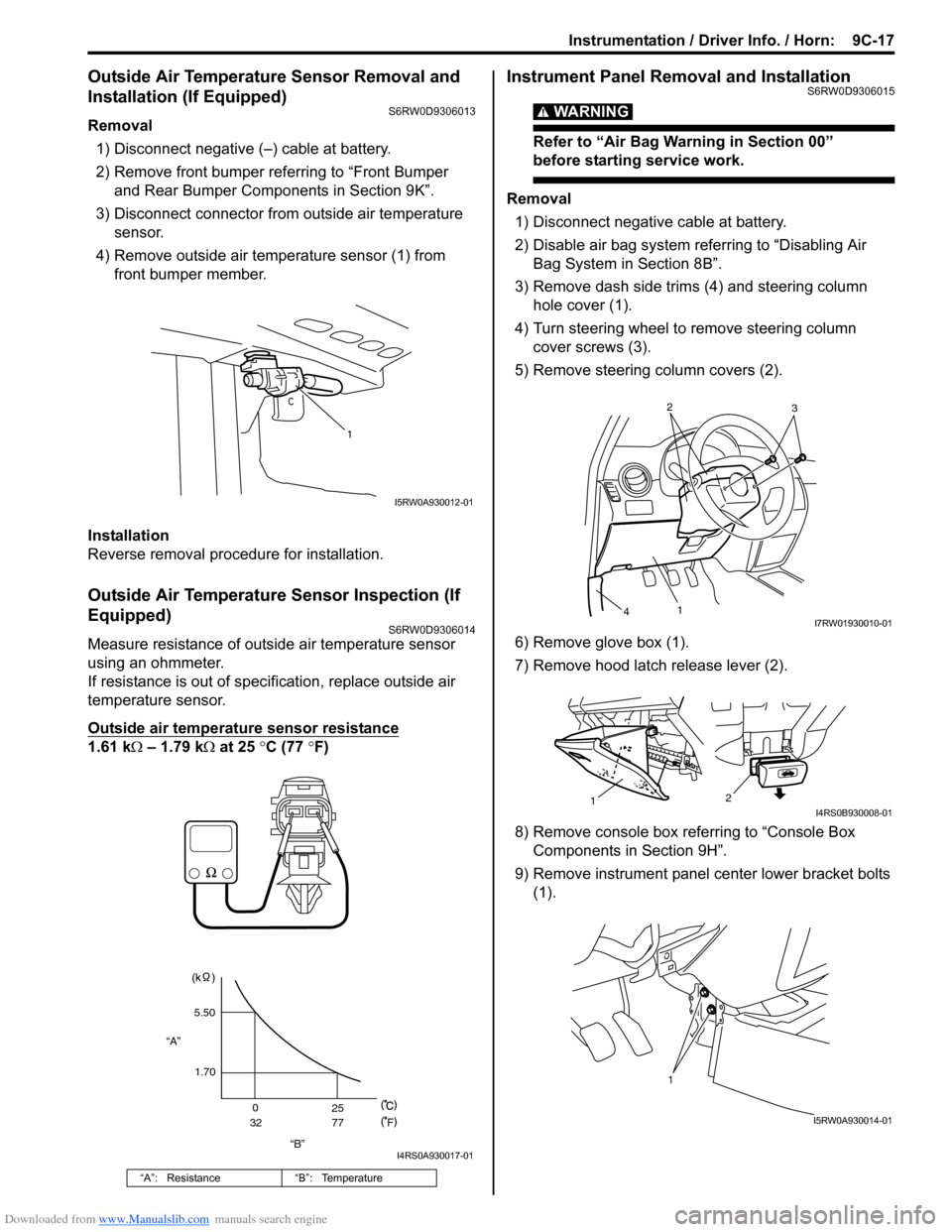

Outside Air Temperature Sensor Removal and

Installation (If Equipped)

S6RW0D9306013

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper

and Rear Bumper Components in Section 9K”.

3) Disconnect connector from outside air temperature

sensor.

4) Remove outside air temperature sensor (1) from

front bumper member.

Installation

Reverse removal procedure for installation.

Outside Air Temperature Sensor Inspection (If

Equipped)

S6RW0D9306014

Measure resistance of outside air temperature sensor

using an ohmmeter.

If resistance is out of specification, replace outside air

temperature sensor.

Outside air temperature sensor resistance

1.61 kΩ – 1.79 kΩ at 25 °C (77 °F)

Instrument Panel Removal and InstallationS6RW0D9306015

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal

1) Disconnect negative cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove dash side trims (4) and steering column

hole cover (1).

4) Turn steering wheel to remove steering column

cover screws (3).

5) Remove steering column covers (2).

6) Remove glove box (1).

7) Remove hood latch release lever (2).

8) Remove console box referring to “Console Box

Components in Section 9H”.

9) Remove instrument panel center lower bracket bolts

(1).

“A”: Resistance “B”: Temperature

1

I5RW0A930012-01

“B” “A”5.50

1.70

0

3225

77

F

I4RS0A930017-01

2

3

1

4I7RW01930010-01

2

1I4RS0B930008-01

1

I5RW0A930014-01

Page 1387 of 1556

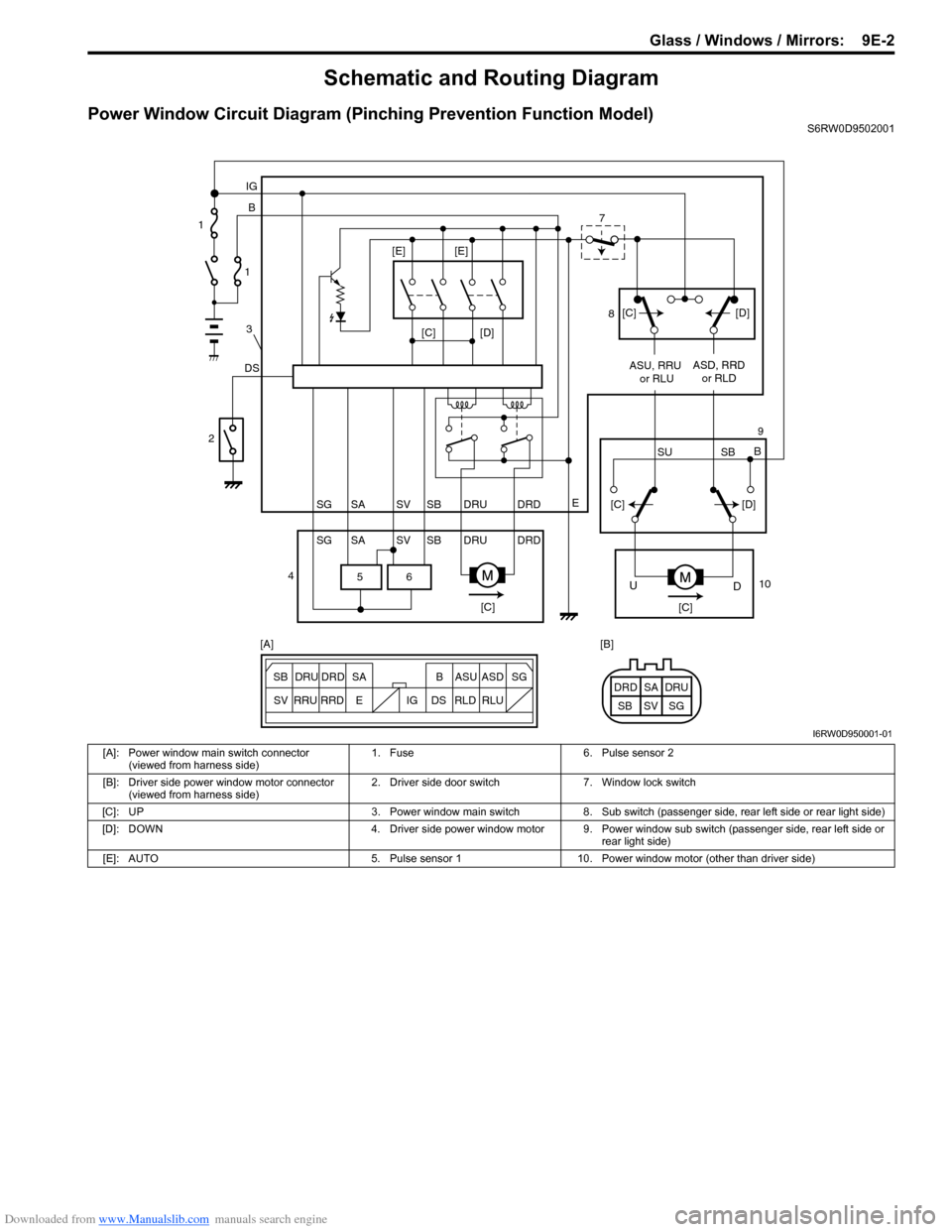

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-2

Schematic and Routing Diagram

Power Window Circuit Diagram (Pinching Prevention Function Model)S6RW0D9502001

6 5

[C][D]

DSB IG

E

SG SV SBSA DRU DRD

SG SV SBSA DRU DRDASU, RRU

or RLUASD, RRD

or RLD

[C][C]

D U

[C][D]

SU SBB [C][D] [E] [E]

ESG

SV SB SADRU DRD B ASU ASD

RRU

RRDDS IG RLD RLUSG SV SBSA DRU DRD [A] [B] 1

1

3

2

47

8

9

10

I6RW0D950001-01

[A]: Power window main switch connector

(viewed from harness side)1. Fuse 6. Pulse sensor 2

[B]: Driver side power window motor connector

(viewed from harness side)2. Driver side door switch 7. Window lock switch

[C]: UP 3. Power window main switch 8. Sub switch (passenger side, rear left side or rear light side)

[D]: DOWN 4. Driver side power window motor 9. Power window sub switch (passenger side, rear left side or

rear light side)

[E]: AUTO 5. Pulse sensor 1 10. Power window motor (other than driver side)

Page 1388 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-3 Glass / Windows / Mirrors:

Diagnostic Information and Procedures

Rear End door Window Defogger Symptom DiagnosisS6RW0D9504001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Window Control System Symptom DiagnosisS6RW0D9504002

Condition Possible cause Correction / Reference Item

Rear end door window

defogger does not

operateCircuit fuse blownReplace fuse and check for short circuit.

Rear end door window defogger switch

faultyCheck rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faultyCheck rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Defogger wire faultyCheck defogger wire referring to “Rear End

Door Window Defogger Wire Inspection”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

All power windows do not

operateCircuit fuse blownReplace fuse and check for short circuit.

Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Ignition switch faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

Only one power window

does not operatePower window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window sub switch faultyCheck power window sub switch referring to

“Power Window Sub Switch Inspection”.

Wiring and/or coupler faultyCheck wiring and/or coupler.

Power window regulator faultyCheck window regulator.

Power window motor faultyCheck power window motor.

Wiring or grounding faultyRepair circuit.

Driver side door glass

fails to perform auto-up /

auto-down function

(Pinching Prevention

Function Model)Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window motor faultyCheck power window motor referring to “Pulse

Sensor and Its Circuit Inspection (Pinching

Prevention Function Model)”.

Wiring or grounding faultyRepair circuit.

Driver side door glass

fails to lower back even

when a foreign matter is

pinched (Pinching

Prevention Function

Model)Power window main switch has not been

initializedExecute the initial setting of power window

main switch referring to “Power Window Main

Switch Initialization (Pinching Prevention

Function Model)”.

Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window motor faultyCheck power window motor referring to “Pulse

Sensor and Its Circuit Inspection (Pinching

Prevention Function Model)”.