fuel injector SUZUKI SX4 2006 1.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 382 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-5 Fuel System:

Repair Instructions

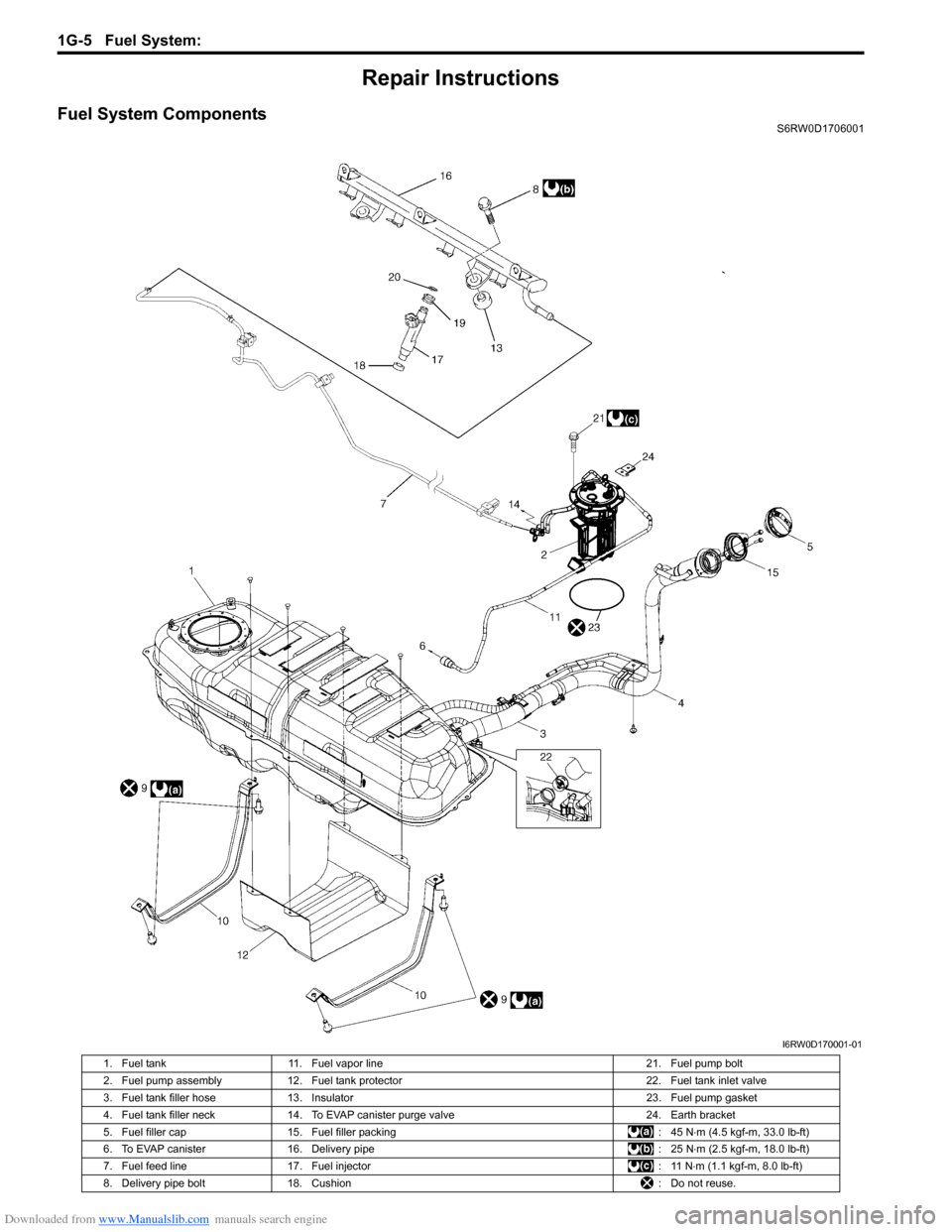

Fuel System ComponentsS6RW0D1706001

I6RW0D170001-01

1. Fuel tank 11. Fuel vapor line 21. Fuel pump bolt

2. Fuel pump assembly 12. Fuel tank protector 22. Fuel tank inlet valve

3. Fuel tank filler hose 13. Insulator 23. Fuel pump gasket

4. Fuel tank filler neck 14. To EVAP canister purge valve 24. Earth bracket

5. Fuel filler cap 15. Fuel filler packing : 45 N⋅m (4.5 kgf-m, 33.0 lb-ft)

6. To EVAP canister 16. Delivery pipe : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

7. Fuel feed line 17. Fuel injector : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

8. Delivery pipe bolt 18. Cushion : Do not reuse.

Page 386 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-9 Fuel System:

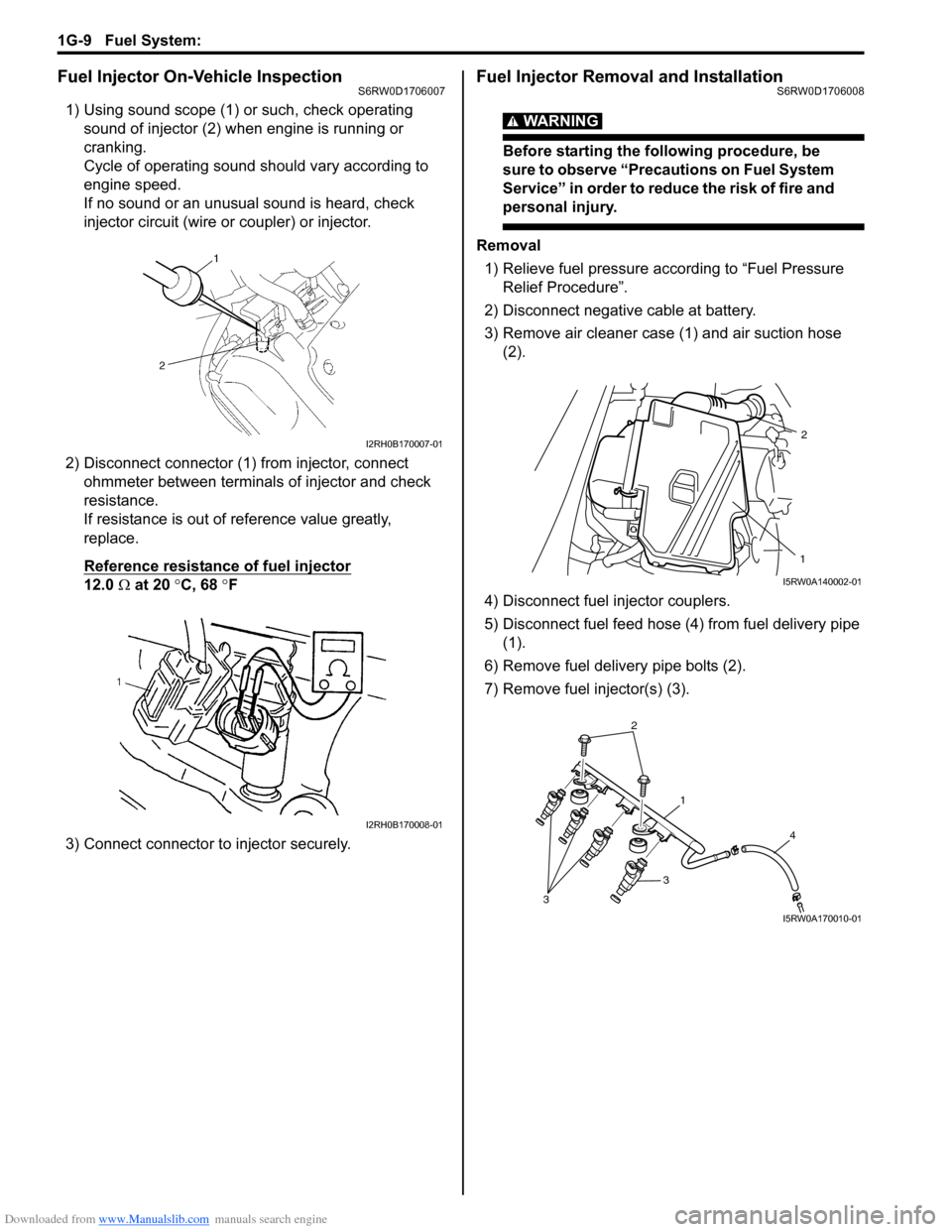

Fuel Injector On-Vehicle InspectionS6RW0D1706007

1) Using sound scope (1) or such, check operating

sound of injector (2) when engine is running or

cranking.

Cycle of operating sound should vary according to

engine speed.

If no sound or an unusual sound is heard, check

injector circuit (wire or coupler) or injector.

2) Disconnect connector (1) from injector, connect

ohmmeter between terminals of injector and check

resistance.

If resistance is out of reference value greatly,

replace.

Reference resistance of fuel injector

12.0 Ω at 20 °C, 68 °F

3) Connect connector to injector securely.

Fuel Injector Removal and InstallationS6RW0D1706008

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk of fire and

personal injury.

Removal

1) Relieve fuel pressure according to “Fuel Pressure

Relief Procedure”.

2) Disconnect negative cable at battery.

3) Remove air cleaner case (1) and air suction hose

(2).

4) Disconnect fuel injector couplers.

5) Disconnect fuel feed hose (4) from fuel delivery pipe

(1).

6) Remove fuel delivery pipe bolts (2).

7) Remove fuel injector(s) (3).

I2RH0B170007-01

I2RH0B170008-01

1

2

I5RW0A140002-01

2

1

4

3

3

I5RW0A170010-01

Page 387 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-10

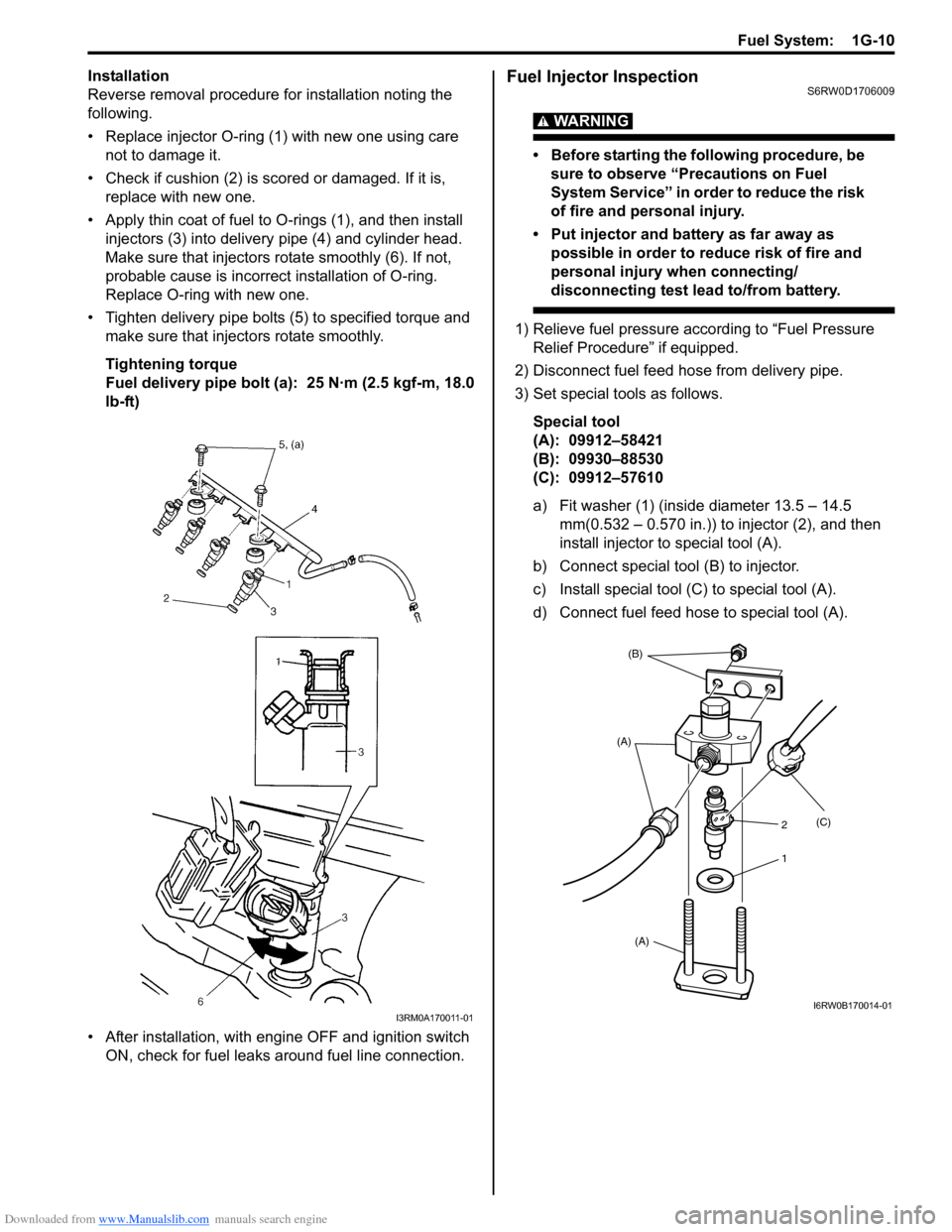

Installation

Reverse removal procedure for installation noting the

following.

• Replace injector O-ring (1) with new one using care

not to damage it.

• Check if cushion (2) is scored or damaged. If it is,

replace with new one.

• Apply thin coat of fuel to O-rings (1), and then install

injectors (3) into delivery pipe (4) and cylinder head.

Make sure that injectors rotate smoothly (6). If not,

probable cause is incorrect installation of O-ring.

Replace O-ring with new one.

• Tighten delivery pipe bolts (5) to specified torque and

make sure that injectors rotate smoothly.

Tightening torque

Fuel delivery pipe bolt (a): 25 N·m (2.5 kgf-m, 18.0

lb-ft)

• After installation, with engine OFF and ignition switch

ON, check for fuel leaks around fuel line connection.Fuel Injector InspectionS6RW0D1706009

WARNING!

• Before starting the following procedure, be

sure to observe “Precautions on Fuel

System Service” in order to reduce the risk

of fire and personal injury.

• Put injector and battery as far away as

possible in order to reduce risk of fire and

personal injury when connecting/

disconnecting test lead to/from battery.

1) Relieve fuel pressure according to “Fuel Pressure

Relief Procedure” if equipped.

2) Disconnect fuel feed hose from delivery pipe.

3) Set special tools as follows.

Special tool

(A): 09912–58421

(B): 09930–88530

(C): 09912–57610

a) Fit washer (1) (inside diameter 13.5 – 14.5

mm(0.532 – 0.570 in.)) to injector (2), and then

install injector to special tool (A).

b) Connect special tool (B) to injector.

c) Install special tool (C) to special tool (A).

d) Connect fuel feed hose to special tool (A).

I3RM0A170011-01

(B)

(A)

(A)(C)

2

1

I6RW0B170014-01

Page 388 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-11 Fuel System:

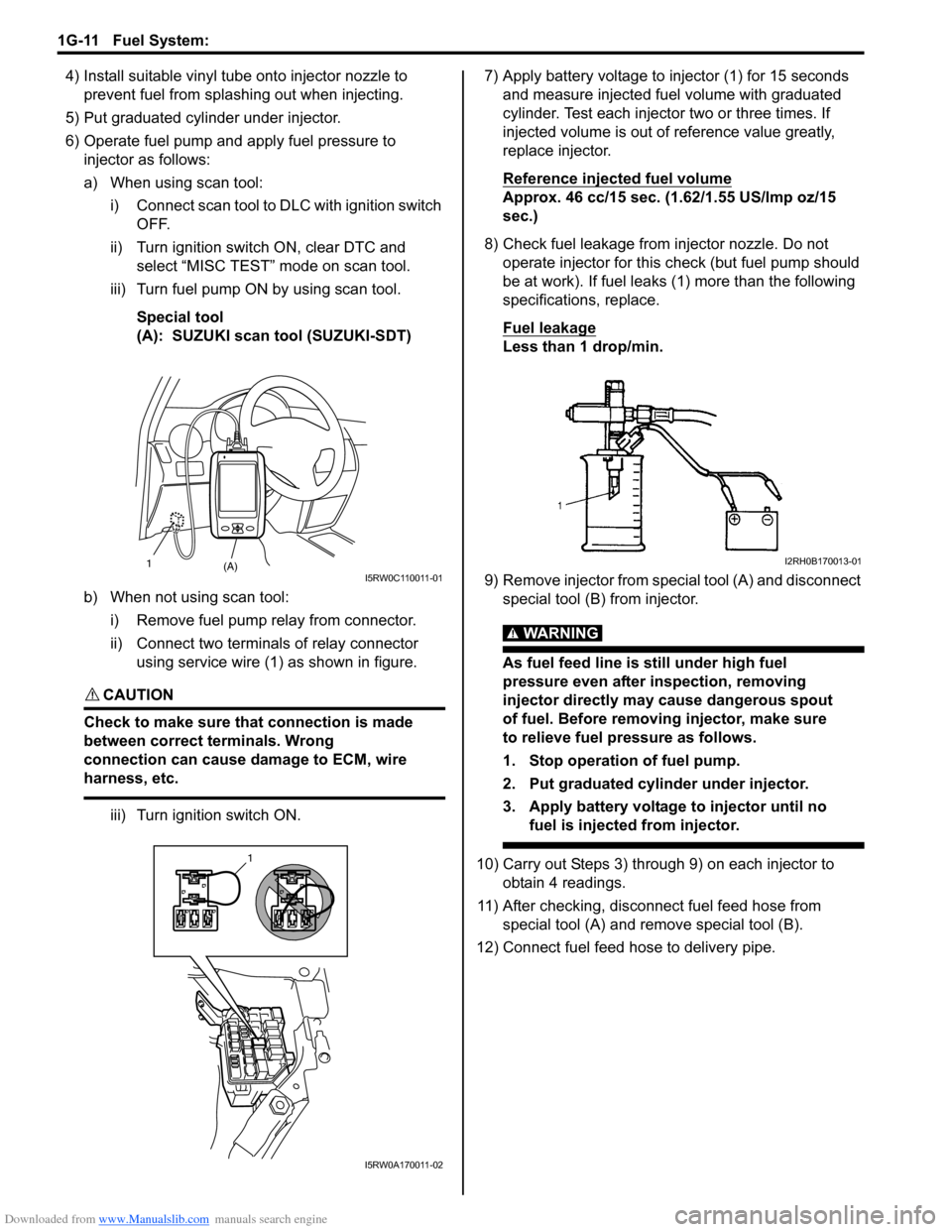

4) Install suitable vinyl tube onto injector nozzle to

prevent fuel from splashing out when injecting.

5) Put graduated cylinder under injector.

6) Operate fuel pump and apply fuel pressure to

injector as follows:

a) When using scan tool:

i) Connect scan tool to DLC with ignition switch

OFF.

ii) Turn ignition switch ON, clear DTC and

select “MISC TEST” mode on scan tool.

iii) Turn fuel pump ON by using scan tool.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)

b) When not using scan tool:

i) Remove fuel pump relay from connector.

ii) Connect two terminals of relay connector

using service wire (1) as shown in figure.

CAUTION!

Check to make sure that connection is made

between correct terminals. Wrong

connection can cause damage to ECM, wire

harness, etc.

iii) Turn ignition switch ON.7) Apply battery voltage to injector (1) for 15 seconds

and measure injected fuel volume with graduated

cylinder. Test each injector two or three times. If

injected volume is out of reference value greatly,

replace injector.

Reference injected fuel volume

Approx. 46 cc/15 sec. (1.62/1.55 US/lmp oz/15

sec.)

8) Check fuel leakage from injector nozzle. Do not

operate injector for this check (but fuel pump should

be at work). If fuel leaks (1) more than the following

specifications, replace.

Fuel leakage

Less than 1 drop/min.

9) Remove injector from special tool (A) and disconnect

special tool (B) from injector.

WARNING!

As fuel feed line is still under high fuel

pressure even after inspection, removing

injector directly may cause dangerous spout

of fuel. Before removing injector, make sure

to relieve fuel pressure as follows.

1. Stop operation of fuel pump.

2. Put graduated cylinder under injector.

3. Apply battery voltage to injector until no

fuel is injected from injector.

10) Carry out Steps 3) through 9) on each injector to

obtain 4 readings.

11) After checking, disconnect fuel feed hose from

special tool (A) and remove special tool (B).

12) Connect fuel feed hose to delivery pipe.

(A) 1I5RW0C110011-01

1

I5RW0A170011-02

I2RH0B170013-01

Page 395 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-18

Special Tools and Equipment

Special ToolS6RW0D1708001

09912–57610 09912–58421

Injector checking tool plate Checking tool set

�)This kit includes the

following items. 1. Tool body

and washer, 2. Body plug, 3.

Body attachment-1, 4.

Holder, 5. Return hose and

clamp, 6. Body attachment-2

and washer, 7. Hose

attachment-1, 8. Hose

attachment-2 �)

09912–58432 09912–58442

Fuel pressure gauge hose Fuel pressure gauge

This tool is included in fuel

pressure gauge set (09912-

58413). �)This tool is included in fuel

pressure gauge set (09912-

58413). �)

09912–58490 09919–47020

3-way joint & hose Quick joint remover

�)�)

09930–88530 SUZUKI scan tool (SUZUKI-

SDT)

Injector test lead —

�)This kit includes following

items. 1. SUZUKI-SDT 2.

DLC3 cable 3. USB cable 4.

AC/DC power supply 5.

Voltage meter probe 6.

Storage case �)

1

2

34

56

Page 1170 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-3 Wiring Systems:

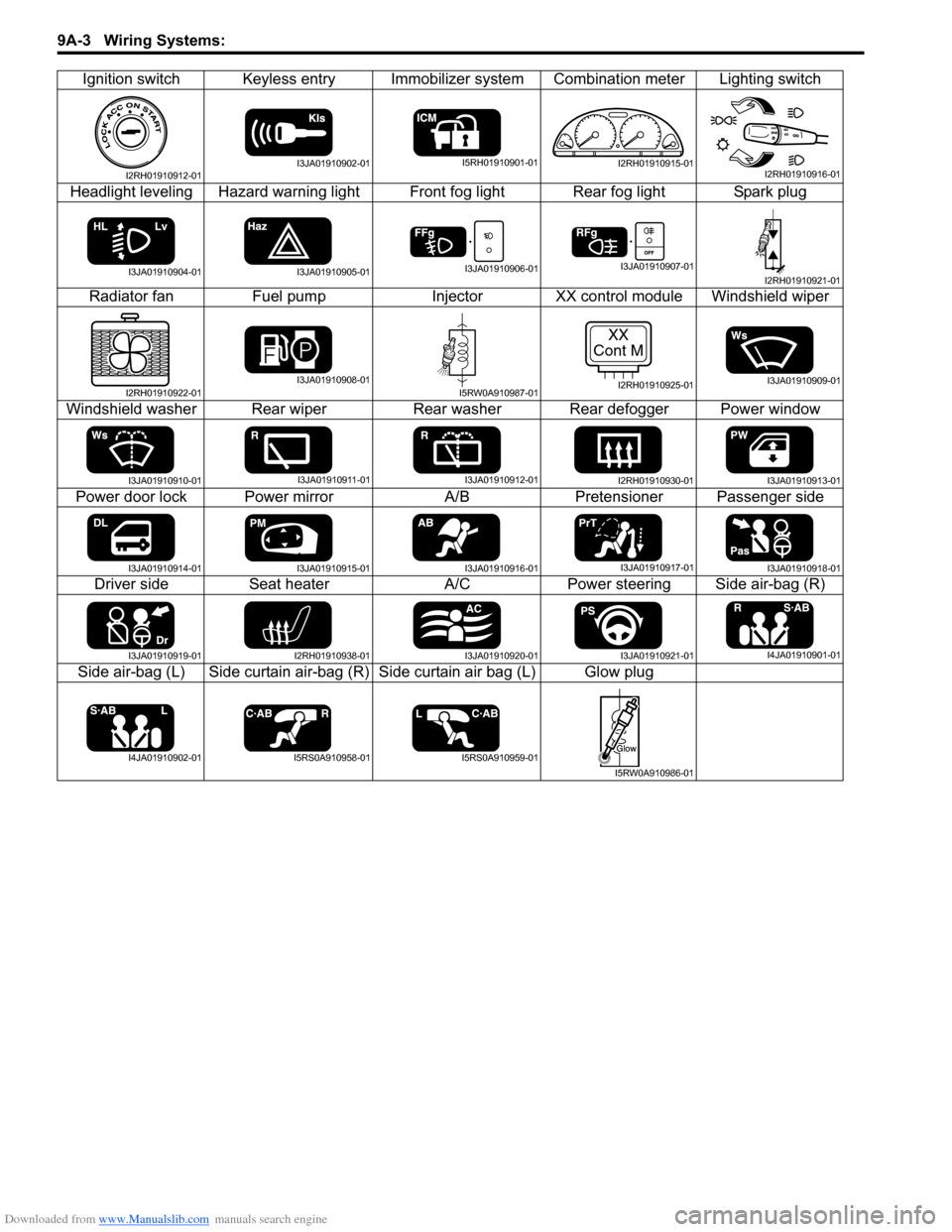

Ignition switch Keyless entry Immobilizer system Combination meter Lighting switch

Headlight leveling Hazard warning light Front fog light Rear fog light Spark plug

Radiator fan Fuel pump Injector XX control module Windshield wiper

Windshield washer Rear wiper Rear washer Rear defogger Power window

Power door lock Power mirror A/B Pretensioner Passenger side

Driver side Seat heater A/C Power steering Side air-bag (R)

Side air-bag (L) Side curtain air-bag (R) Side curtain air bag (L) Glow plug

I2RH01910912-01I3JA01910902-01I5RH01910901-01I2RH01910915-01I2RH01910916-01

I3JA01910904-01I3JA01910905-01I3JA01910906-01I3JA01910907-01I2RH01910921-01

I2RH01910922-01I3JA01910908-01I5RW0A910987-01

XX

Cont M

I2RH01910925-01I3JA01910909-01

I3JA01910910-01I3JA01910911-01I3JA01910912-01I2RH01910930-01I3JA01910913-01

I3JA01910914-01I3JA01910915-01I3JA01910916-01I3JA01910917-01I3JA01910918-01

I3JA01910919-01I2RH01910938-01I3JA01910920-01I3JA01910921-01I4JA01910901-01

I4JA01910902-01I5RS0A910958-01I5RS0A910959-01

I5RW0A910986-01

Page 1171 of 1556

![SUZUKI SX4 2006 1.G Service Service Manual Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-4

How to Read Connector Layout DiagramS6RW0D9101004

[A-1]: Harness symbol and corresponding harness name

A: Battery harness SUZUKI SX4 2006 1.G Service Service Manual Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-4

How to Read Connector Layout DiagramS6RW0D9101004

[A-1]: Harness symbol and corresponding harness name

A: Battery harness](/img/20/7612/w960_7612-1170.png)

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-4

How to Read Connector Layout DiagramS6RW0D9101004

[A-1]: Harness symbol and corresponding harness name

A: Battery harness

B: A/C harness

C: Engine harness

D: Injector harness

E: Main harness, Oil pressure switch wire, Console wire

G: Instrument panel harness

J: Side door wire (Power window)

K: Interior light harness, Rear speaker wire, Roof wire

L: Floor harness, G sensor wire (Fuel pump harness)

M: Rear bumper harness

O: Rear end door harness

Q: Air bag/Pretensioner harness

R: (Fuel pump wire)

[A-2]: Connector Number

[B]: Ground point No.

12

11

[B][B]

Connector code

[A-1] [A-2]L 36

L13L15

R01 L14L12L11L10 L09 L36

R02 L24 L25 L33

L28 L20 L26 (TO O01)

{

L05

L16

L32 L19 L01 (TO G01)

L02 (TO E04)

L03 (TO E05) L42

R05 R04

L07 (TO K02)

I2RH01910901-01