fuel injector SUZUKI SX4 2006 1.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 247 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-197

Troubleshooting

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

Step Action Yes No

1Fuel injector check for operating sound

1) Using sound scope, check each injector for operating

sound at engine cranking.

Do all 4 injector make operating sound?Fuel injectors circuit is

in good condition.Go to Step 2.

2Fuel injector resistance check

1) Disconnect connectors from fuel injectors with ignition

switch turned OFF.

2) Check for proper connection to fuel injector at each

terminals.

3) If OK, check all 4 fuel injectors for resistance referring to

“Fuel Injector On-Vehicle Inspection in Section 1G”.

Are all injectors in good condition?Go to Step 3. Faulty fuel injector.

3Fuel injector insulation resistance check

1) Check that there is insulation between each fuel injector

terminal and engine ground.

Is there insulation?Go to Step 4. Faulty fuel injector.

4Fuel injector power supply check

1) Measure voltage between each “BLK/RED” wire terminal

of fuel injector connector and engine ground with ignition

switch turned ON.

Is voltage 10 – 14 V?Go to Step 5. “BLK/RED” wire is open

or shorted to ground

circuit.

If it is in good condition,

go to “ECM Power and

Ground Circuit Check”.

5Wire circuit check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

3) Measure resistance between each “BLU/YEL”, “BLU/

WHT”, “BLU/RED”, “BLU/ORN” wire terminal of fuel

injector connector and vehicle body ground.

Is resistance infinity?Go to Step 6. “BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to ground.

6Wire circuit check

1) Measure voltage between each “BLU/YEL”, “BLU/WHT”,

“BLU/RED”, “BLU/ORN” wire terminal of fuel injector

connector and vehicle body ground with ignition switch

turned ON.

Is voltage 0 V?Go to Step 7. “BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to power supply

circuit.

7Fuel injector drive signal check

1) Connect connectors to each fuel injector and ECM with

ignition switch turned OFF.

2) Turn ON ignition switch.

3) Measure voltage between each “C01-1”, “C01-2”, “C01-

16”, “C01-17” terminal of ECM connector and vehicle

body ground.

Is voltage 10 – 14 V?Check fuel injector

referring to “Fuel

Injector Inspection in

Section 1G”.

If check result is

satisfactory, substitute a

known-good ECM and

recheck.“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

open circuit.

Page 251 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-201

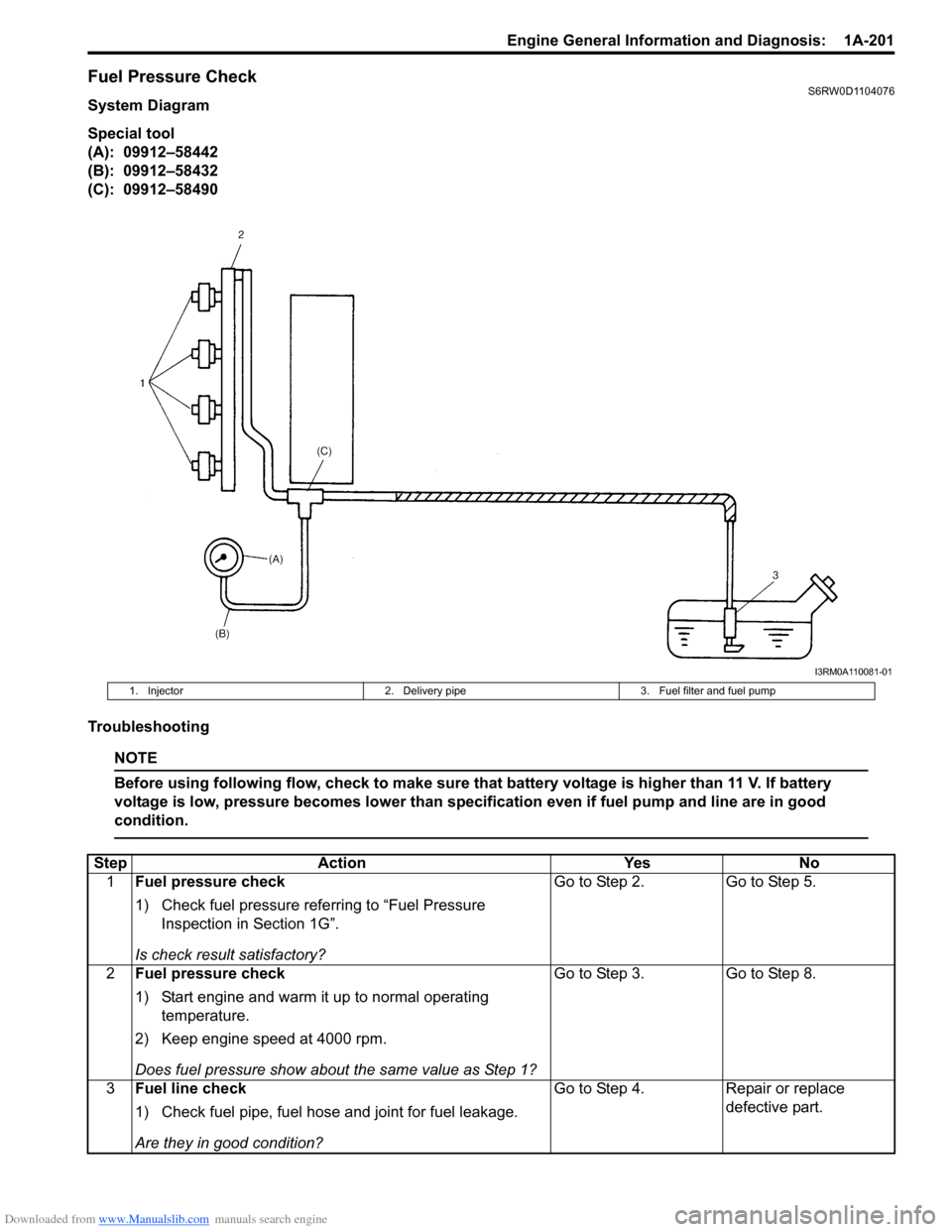

Fuel Pressure CheckS6RW0D1104076

System Diagram

Special tool

(A): 09912–58442

(B): 09912–58432

(C): 09912–58490

Troubleshooting

NOTE

Before using following flow, check to make sure that battery voltage is higher than 11 V. If battery

voltage is low, pressure becomes lower than specification even if fuel pump and line are in good

condition.

I3RM0A110081-01

1. Injector 2. Delivery pipe 3. Fuel filter and fuel pump

Step Action Yes No

1Fuel pressure check

1) Check fuel pressure referring to “Fuel Pressure

Inspection in Section 1G”.

Is check result satisfactory?Go to Step 2. Go to Step 5.

2Fuel pressure check

1) Start engine and warm it up to normal operating

temperature.

2) Keep engine speed at 4000 rpm.

Does fuel pressure show about the same value as Step 1?Go to Step 3. Go to Step 8.

3Fuel line check

1) Check fuel pipe, fuel hose and joint for fuel leakage.

Are they in good condition?Go to Step 4. Repair or replace

defective part.

Page 287 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-5

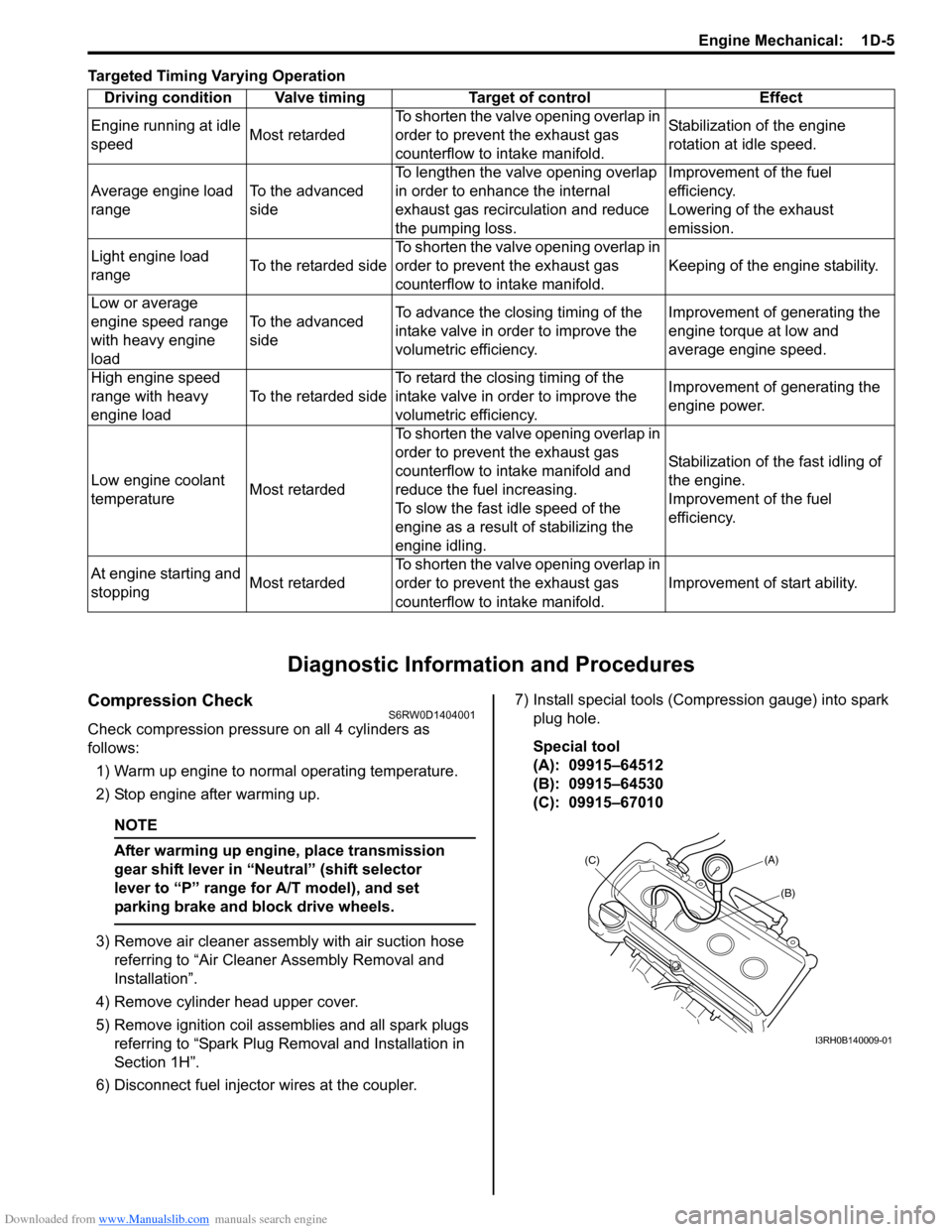

Targeted Timing Varying Operation

Diagnostic Information and Procedures

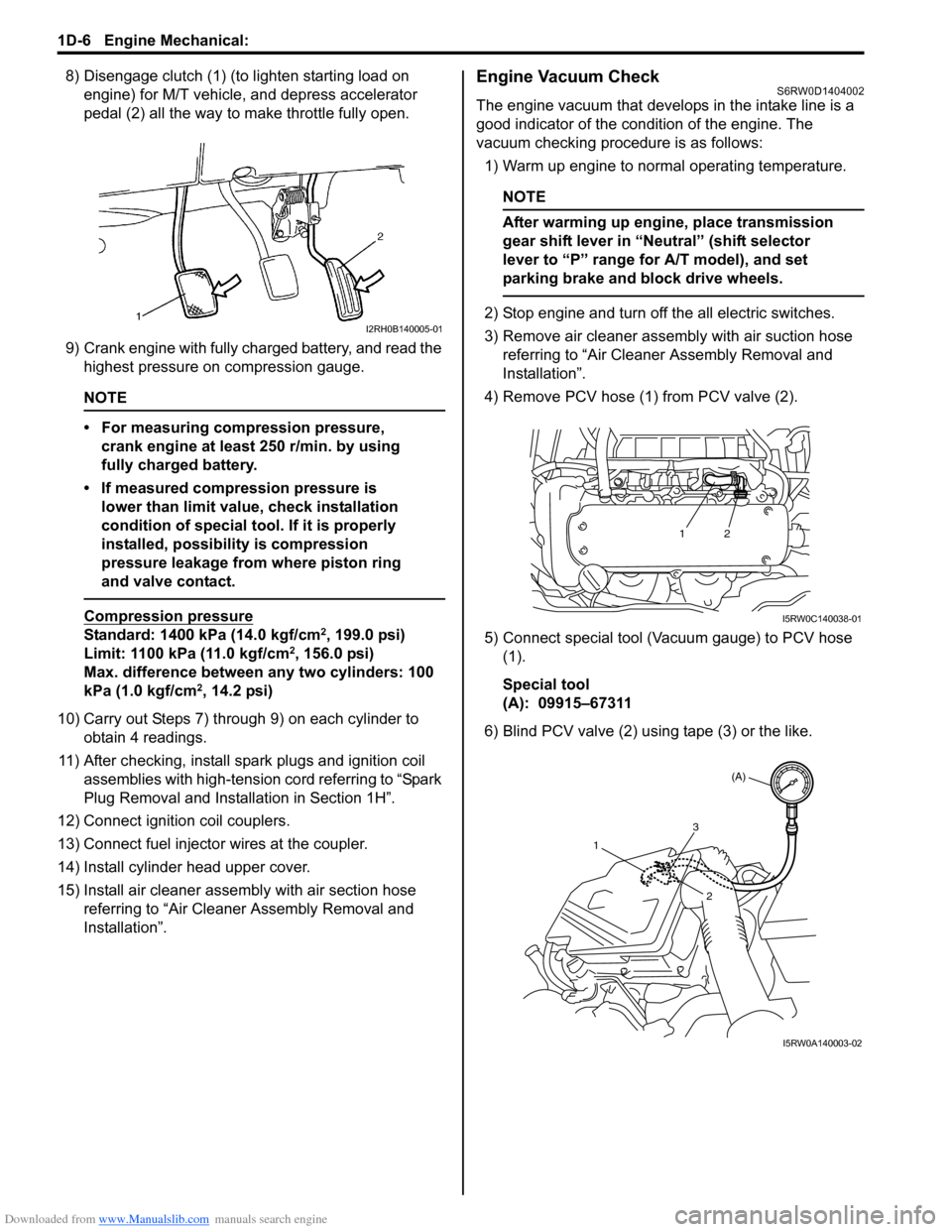

Compression CheckS6RW0D1404001

Check compression pressure on all 4 cylinders as

follows:

1) Warm up engine to normal operating temperature.

2) Stop engine after warming up.

NOTE

After warming up engine, place transmission

gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T model), and set

parking brake and block drive wheels.

3) Remove air cleaner assembly with air suction hose

referring to “Air Cleaner Assembly Removal and

Installation”.

4) Remove cylinder head upper cover.

5) Remove ignition coil assemblies and all spark plugs

referring to “Spark Plug Removal and Installation in

Section 1H”.

6) Disconnect fuel injector wires at the coupler.7) Install special tools (Compression gauge) into spark

plug hole.

Special tool

(A): 09915–64512

(B): 09915–64530

(C): 09915–67010 Driving condition Valve timing Target of control Effect

Engine running at idle

speedMost retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold.Stabilization of the engine

rotation at idle speed.

Average engine load

rangeTo the advanced

sideTo lengthen the valve opening overlap

in order to enhance the internal

exhaust gas recirculation and reduce

the pumping loss.Improvement of the fuel

efficiency.

Lowering of the exhaust

emission.

Light engine load

rangeTo the retarded sideTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold.Keeping of the engine stability.

Low or average

engine speed range

with heavy engine

loadTo the advanced

sideTo advance the closing timing of the

intake valve in order to improve the

volumetric efficiency.Improvement of generating the

engine torque at low and

average engine speed.

High engine speed

range with heavy

engine loadTo the retarded sideTo retard the closing timing of the

intake valve in order to improve the

volumetric efficiency.Improvement of generating the

engine power.

Low engine coolant

temperatureMost retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold and

reduce the fuel increasing.

To slow the fast idle speed of the

engine as a result of stabilizing the

engine idling.Stabilization of the fast idling of

the engine.

Improvement of the fuel

efficiency.

At engine starting and

stoppingMost retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold.Improvement of start ability.

(A)

(C)

(B)

I3RH0B140009-01

Page 288 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-6 Engine Mechanical:

8) Disengage clutch (1) (to lighten starting load on

engine) for M/T vehicle, and depress accelerator

pedal (2) all the way to make throttle fully open.

9) Crank engine with fully charged battery, and read the

highest pressure on compression gauge.

NOTE

• For measuring compression pressure,

crank engine at least 250 r/min. by using

fully charged battery.

• If measured compression pressure is

lower than limit value, check installation

condition of special tool. If it is properly

installed, possibility is compression

pressure leakage from where piston ring

and valve contact.

Compression pressure

Standard: 1400 kPa (14.0 kgf/cm2, 199.0 psi)

Limit: 1100 kPa (11.0 kgf/cm2, 156.0 psi)

Max. difference between any two cylinders: 100

kPa (1.0 kgf/cm

2, 14.2 psi)

10) Carry out Steps 7) through 9) on each cylinder to

obtain 4 readings.

11) After checking, install spark plugs and ignition coil

assemblies with high-tension cord referring to “Spark

Plug Removal and Installation in Section 1H”.

12) Connect ignition coil couplers.

13) Connect fuel injector wires at the coupler.

14) Install cylinder head upper cover.

15) Install air cleaner assembly with air section hose

referring to “Air Cleaner Assembly Removal and

Installation”.

Engine Vacuum CheckS6RW0D1404002

The engine vacuum that develops in the intake line is a

good indicator of the condition of the engine. The

vacuum checking procedure is as follows:

1) Warm up engine to normal operating temperature.

NOTE

After warming up engine, place transmission

gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T model), and set

parking brake and block drive wheels.

2) Stop engine and turn off the all electric switches.

3) Remove air cleaner assembly with air suction hose

referring to “Air Cleaner Assembly Removal and

Installation”.

4) Remove PCV hose (1) from PCV valve (2).

5) Connect special tool (Vacuum gauge) to PCV hose

(1).

Special tool

(A): 09915–67311

6) Blind PCV valve (2) using tape (3) or the like.I2RH0B140005-01

12

I5RW0C140038-01

(A)

1

2

3

I5RW0A140003-02

Page 299 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-17

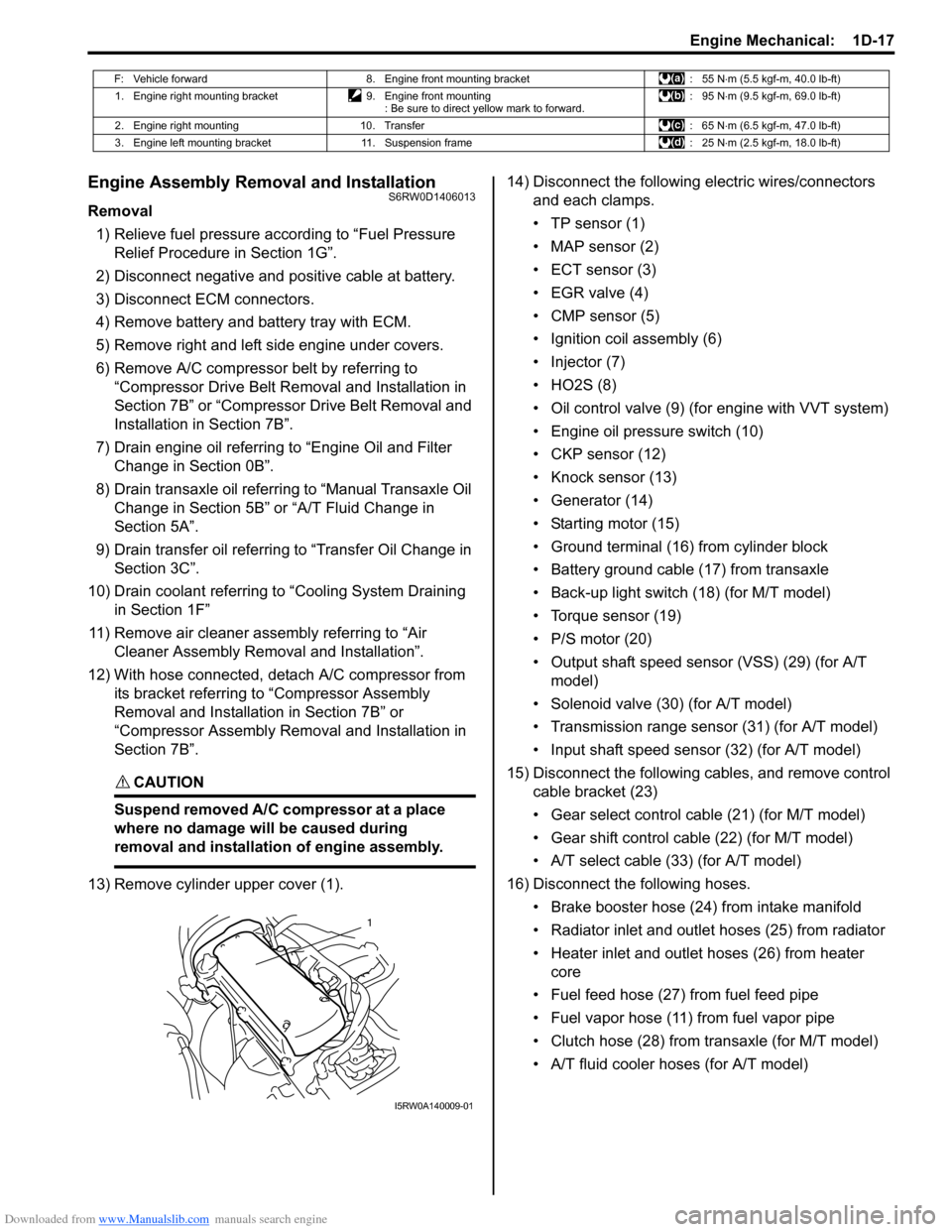

Engine Assembly Removal and InstallationS6RW0D1406013

Removal

1) Relieve fuel pressure according to “Fuel Pressure

Relief Procedure in Section 1G”.

2) Disconnect negative and positive cable at battery.

3) Disconnect ECM connectors.

4) Remove battery and battery tray with ECM.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to

“Compressor Drive Belt Removal and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil referring to “Engine Oil and Filter

Change in Section 0B”.

8) Drain transaxle oil referring to “Manual Transaxle Oil

Change in Section 5B” or “A/T Fluid Change in

Section 5A”.

9) Drain transfer oil referring to “Transfer Oil Change in

Section 3C”.

10) Drain coolant referring to “Cooling System Draining

in Section 1F”

11) Remove air cleaner assembly referring to “Air

Cleaner Assembly Removal and Installation”.

12) With hose connected, detach A/C compressor from

its bracket referring to “Compressor Assembly

Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

13) Remove cylinder upper cover (1).14) Disconnect the following electric wires/connectors

and each clamps.

• TP sensor (1)

• MAP sensor (2)

• ECT sensor (3)

•EGR valve (4)

• CMP sensor (5)

• Ignition coil assembly (6)

• Injector (7)

•HO2S (8)

• Oil control valve (9) (for engine with VVT system)

• Engine oil pressure switch (10)

• CKP sensor (12)

• Knock sensor (13)

• Generator (14)

• Starting motor (15)

• Ground terminal (16) from cylinder block

• Battery ground cable (17) from transaxle

• Back-up light switch (18) (for M/T model)

• Torque sensor (19)

• P/S motor (20)

• Output shaft speed sensor (VSS) (29) (for A/T

model)

• Solenoid valve (30) (for A/T model)

• Transmission range sensor (31) (for A/T model)

• Input shaft speed sensor (32) (for A/T model)

15) Disconnect the following cables, and remove control

cable bracket (23)

• Gear select control cable (21) (for M/T model)

• Gear shift control cable (22) (for M/T model)

• A/T select cable (33) (for A/T model)

16) Disconnect the following hoses.

• Brake booster hose (24) from intake manifold

• Radiator inlet and outlet hoses (25) from radiator

• Heater inlet and outlet hoses (26) from heater

core

• Fuel feed hose (27) from fuel feed pipe

• Fuel vapor hose (11) from fuel vapor pipe

• Clutch hose (28) from transaxle (for M/T model)

• A/T fluid cooler hoses (for A/T model)

F: Vehicle forward 8. Engine front mounting bracket : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)

1. Engine right mounting bracket 9. Engine front mounting

: Be sure to direct yellow mark to forward.: 95 N⋅m (9.5 kgf-m, 69.0 lb-ft)

2. Engine right mounting 10. Transfer : 65 N⋅m (6.5 kgf-m, 47.0 lb-ft)

3. Engine left mounting bracket 11. Suspension frame : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

1

I5RW0A140009-01

Page 326 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-44 Engine Mechanical:

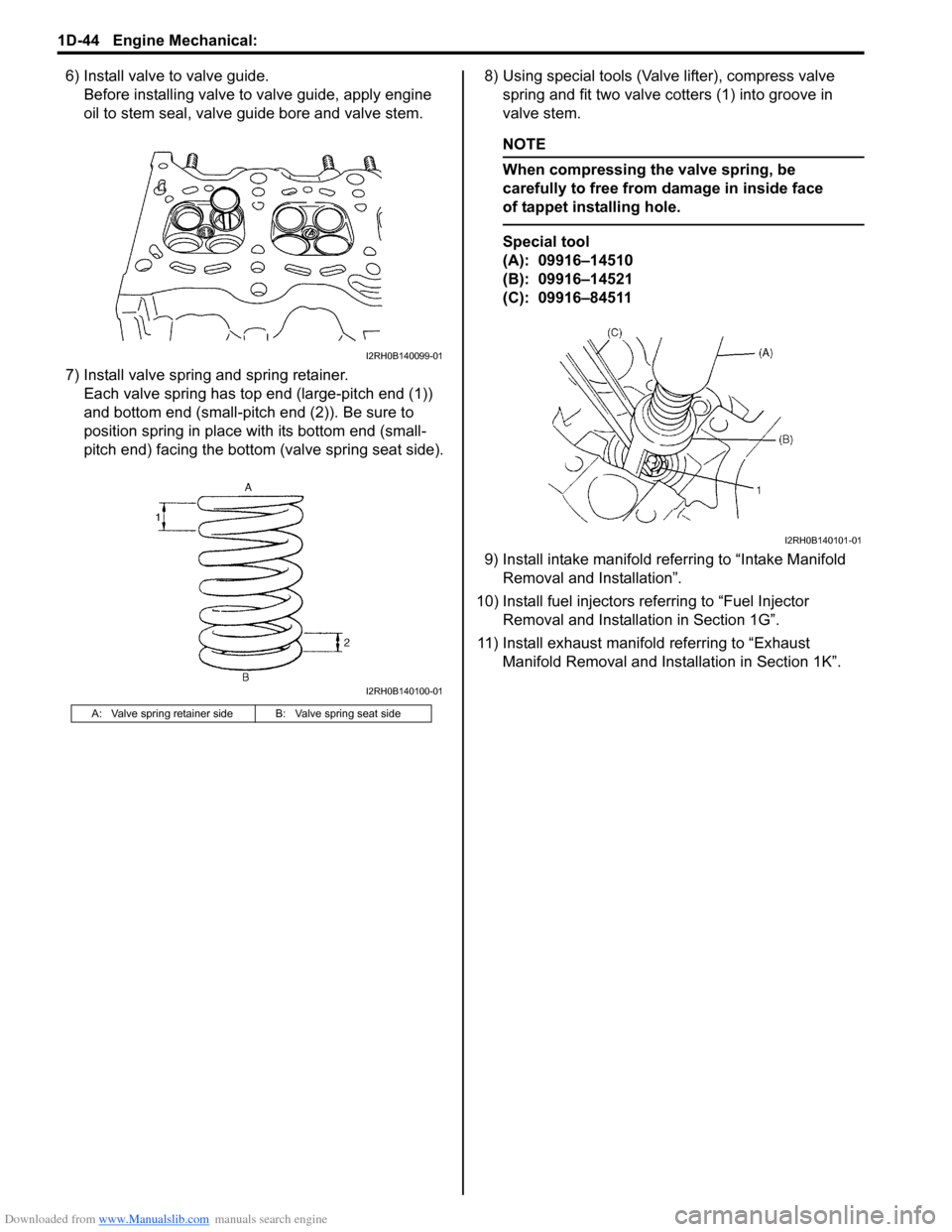

6) Install valve to valve guide.

Before installing valve to valve guide, apply engine

oil to stem seal, valve guide bore and valve stem.

7) Install valve spring and spring retainer.

Each valve spring has top end (large-pitch end (1))

and bottom end (small-pitch end (2)). Be sure to

position spring in place with its bottom end (small-

pitch end) facing the bottom (valve spring seat side).8) Using special tools (Valve lifter), compress valve

spring and fit two valve cotters (1) into groove in

valve stem.

NOTE

When compressing the valve spring, be

carefully to free from damage in inside face

of tappet installing hole.

Special tool

(A): 09916–14510

(B): 09916–14521

(C): 09916–84511

9) Install intake manifold referring to “Intake Manifold

Removal and Installation”.

10) Install fuel injectors referring to “Fuel Injector

Removal and Installation in Section 1G”.

11) Install exhaust manifold referring to “Exhaust

Manifold Removal and Installation in Section 1K”.

A: Valve spring retainer side B: Valve spring seat side

I2RH0B140099-01

I2RH0B140100-01

I2RH0B140101-01

Page 378 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-1 Fuel System:

Engine

Fuel System

Precautions

Precautions on Fuel System ServiceS6RW0D1700001

WARNING!

Before attempting service of any type on fuel system, the following should be always observed in

order to reduce the risk of fire and personal injury.

• Disconnect negative cable at battery.

• Do not smoke, and place no smoking signs near work area.

• Be sure to have CO

2 fire extinguisher handy.

• Be sure to perform work in a well-ventilated area and away from any open flames (such as gas hot

heater).

• Wear safety glasses.

• To relieve fuel vapor pressure in fuel tank, remove fuel filler cap from fuel filler neck and then

reinstall it.

• As fuel feed line is still under high fuel pressure even after stopping engine, loosening or

disconnecting fuel feed line directly may cause dangerous spout of fuel. Before loosening or

disconnecting fuel feed line, make sure to relieve fuel pressure referring to “Fuel Pressure Relief

Procedure”.

• A small amount of fuel may be released when the fuel line is disconnected. In order to reduce the

risk of personal injury, cover a shop cloth to the fitting to be disconnected. Be sure to put that cloth

in an approved container after disconnecting.

• Never run engine with fuel pump relay disconnected when engine and exhaust system are hot.

• Note that fuel hose connection varies with each type of pipe. Be sure to connect and clamp each

hose correctly referring to “Fuel Hose Disconnecting and Reconnecting”.

After connecting, make sure that it has no twist or kink.

• When installing injector or fuel feed pipe, lubricate its O-ring with gasoline.

• When servicing the fuel tank, it should be treated with respect, with no contact with sharp edges or

hot surfaces. In addition, the fuel tank should not be dropped since fuel tank, fuel pump and other

components can be damaged by the impact. If dropped, all components should be replaced because

there is a risk of damage.

• The fuel tank is made of resin.

Be sure not to allow solvent (chemical article such as grease and sealant) to attach to the fuel tank

as some chemical reaction may occur, causing the fuel tank to be swollen, hardened or distorted

leakage and resulting in fuel leakage from the fuel tank.

Page 379 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-2

General Description

Fuel System DescriptionS6RW0D1701001

CAUTION!

This engine requires the unleaded fuel only.

The leaded and/or low lead fuel can result in

engine damage and reduce the effectiveness

of the emission control system.

The main components of the fuel system are fuel tank,

fuel pump assembly (with fuel filter, fuel level gauge, fuel

pressure regulator), fuel feed line and fuel vapor line.

For the details of fuel flow, refer to “Fuel Delivery System

Diagram”.

Fuel Delivery System DescriptionS6RW0D1701002

The fuel delivery system consists of the fuel tank, fuel

pump assembly (with built-in fuel filter and fuel pressure

regulator), delivery pipe, injectors and fuel feed line.

The fuel in the fuel tank is pumped up by the fuel pump,

sent into delivery pipe and injected by the injectors.

As the fuel pump assembly is equipped with built-in fuel

filter and fuel pressure regulator, the fuel is filtered and

its pressure is regulated before being sent to the feed

pipe.

The excess fuel at fuel pressure regulation process is

returned back into the fuel tank.

Also, fuel vapor generated in fuel tank is led through the

fuel vapor line into the EVAP canister.

For system diagram, refer to “Fuel Delivery System

Diagram”.

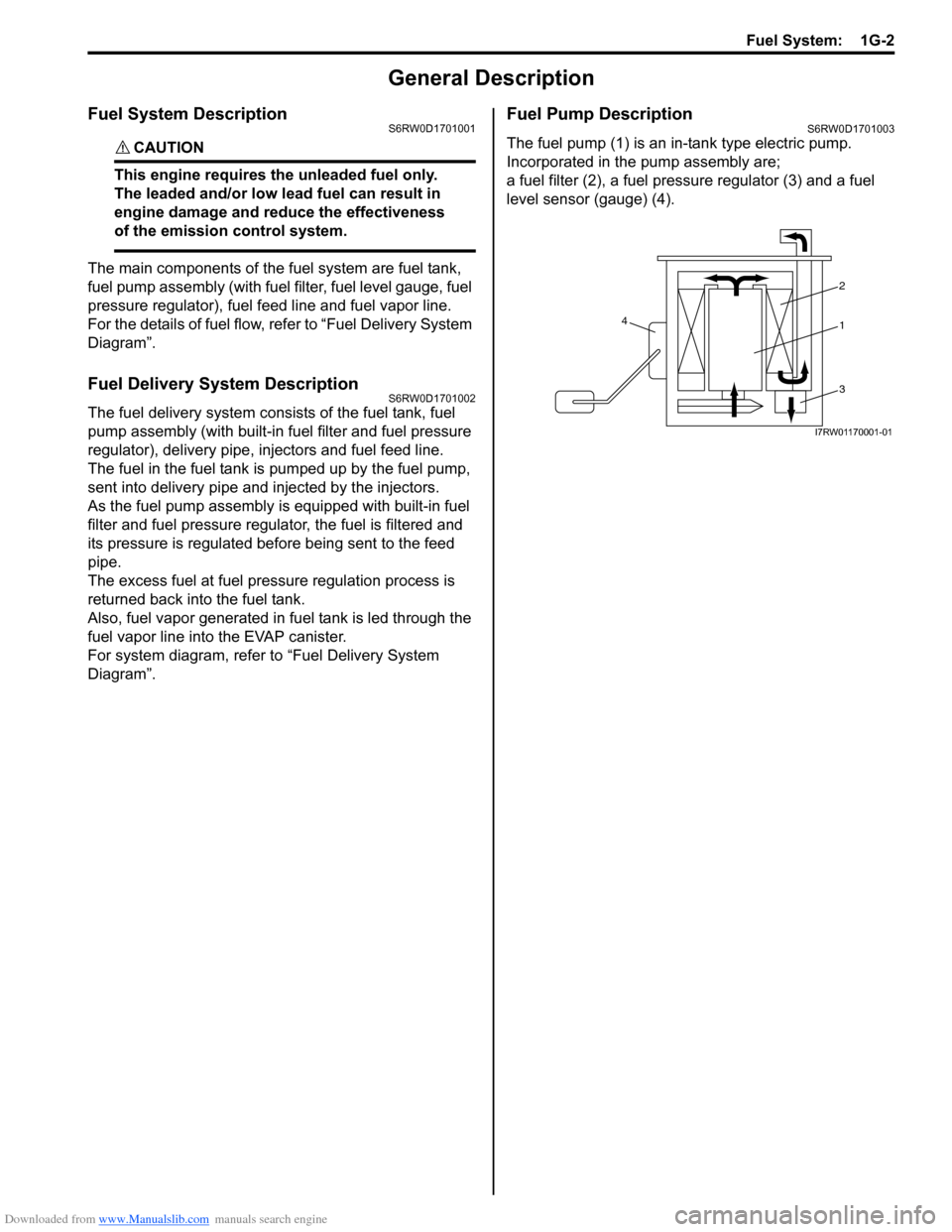

Fuel Pump DescriptionS6RW0D1701003

The fuel pump (1) is an in-tank type electric pump.

Incorporated in the pump assembly are;

a fuel filter (2), a fuel pressure regulator (3) and a fuel

level sensor (gauge) (4).

2

41

3

I7RW01170001-01

Page 380 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-3 Fuel System:

Schematic and Routing Diagram

Fuel Delivery System DiagramS6RW0D1702001

Diagnostic Information and Procedures

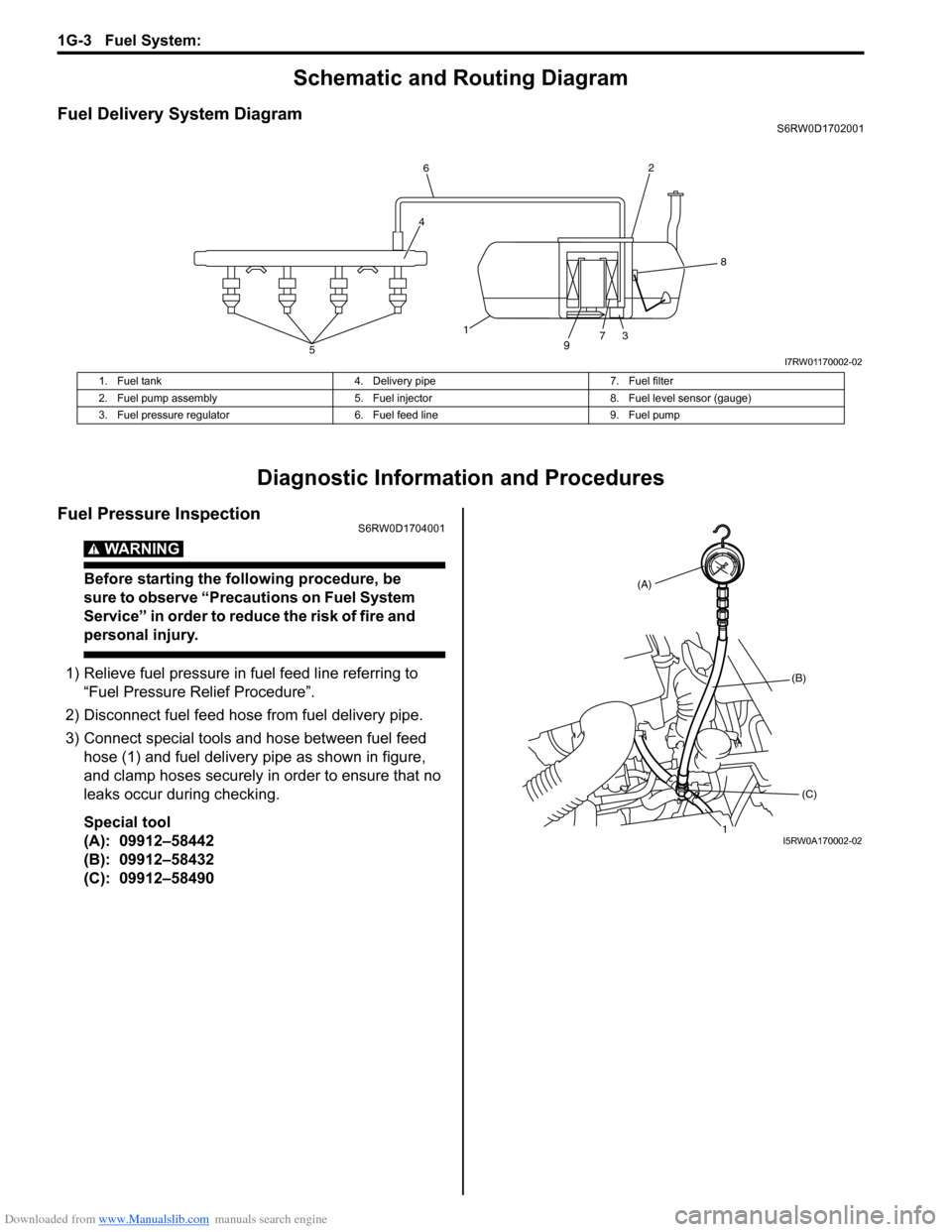

Fuel Pressure InspectionS6RW0D1704001

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk of fire and

personal injury.

1) Relieve fuel pressure in fuel feed line referring to

“Fuel Pressure Relief Procedure”.

2) Disconnect fuel feed hose from fuel delivery pipe.

3) Connect special tools and hose between fuel feed

hose (1) and fuel delivery pipe as shown in figure,

and clamp hoses securely in order to ensure that no

leaks occur during checking.

Special tool

(A): 09912–58442

(B): 09912–58432

(C): 09912–58490

73 6

1 4

5

8

9

2

I7RW01170002-02

1. Fuel tank 4. Delivery pipe 7. Fuel filter

2. Fuel pump assembly 5. Fuel injector 8. Fuel level sensor (gauge)

3. Fuel pressure regulator 6. Fuel feed line 9. Fuel pump

(C) (B)

(A)

1I5RW0A170002-02

Page 381 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-4

4) Check that battery voltage is 11 V or more.

5) Measure fuel pressure at each condition.

If measured pressure is out of specification, refer to

“Fuel Pressure Check in Section 1A” and check each

possibly defective part. Replace if found defective.

a) Turn ignition switch ON to operate fuel pump and

after 2 seconds turn it OFF. Repeat this 3 or 4

times and then check fuel pressure.

Fuel pressure specification

With fuel pump operating and engine

stopped: 360 – 400 kPa (3.6 – 4.0 kgf/cm2,

51.2 – 56.9 psi)

b) Start engine and warm it up to normal operating

temperature, and measure fuel pressure at

idling.

Fuel pressure specification

At specified idle speed: 360 – 400 kPa (3.6 –

4.0 kgf/cm2, 51.2 – 56.9 psi)

c) Stop engine, and measure fuel pressure at one

minute after stopping.

Fuel pressure specification

With 1 min. after engine (fuel pump) stop

(Pressure reduces as time passes): Over 250

kPa (2.5 kgf/cm

2, 35.6 psi)

6) After checking fuel pressure, remove fuel pressure

gauge.

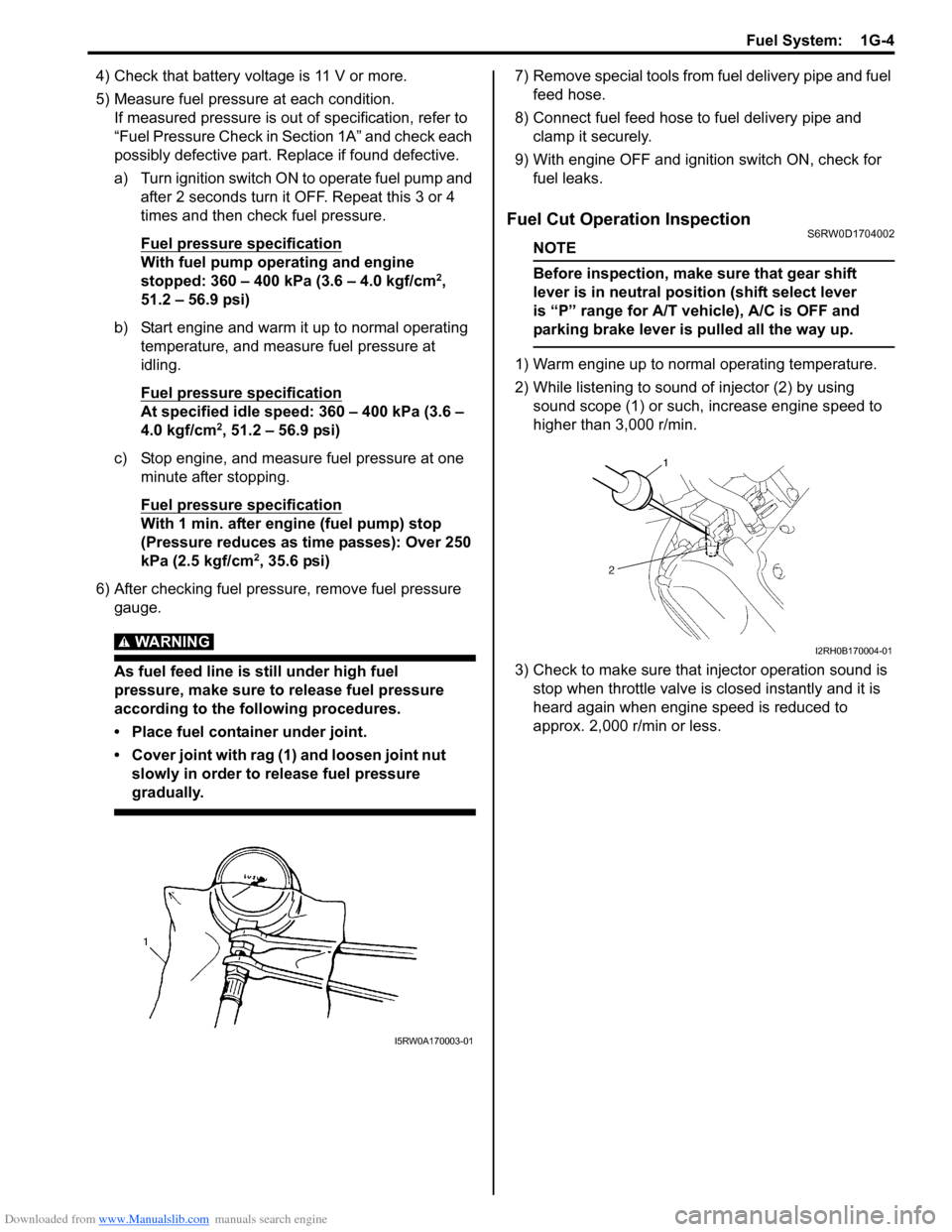

WARNING!

As fuel feed line is still under high fuel

pressure, make sure to release fuel pressure

according to the following procedures.

• Place fuel container under joint.

• Cover joint with rag (1) and loosen joint nut

slowly in order to release fuel pressure

gradually.

7) Remove special tools from fuel delivery pipe and fuel

feed hose.

8) Connect fuel feed hose to fuel delivery pipe and

clamp it securely.

9) With engine OFF and ignition switch ON, check for

fuel leaks.

Fuel Cut Operation InspectionS6RW0D1704002

NOTE

Before inspection, make sure that gear shift

lever is in neutral position (shift select lever

is “P” range for A/T vehicle), A/C is OFF and

parking brake lever is pulled all the way up.

1) Warm engine up to normal operating temperature.

2) While listening to sound of injector (2) by using

sound scope (1) or such, increase engine speed to

higher than 3,000 r/min.

3) Check to make sure that injector operation sound is

stop when throttle valve is closed instantly and it is

heard again when engine speed is reduced to

approx. 2,000 r/min or less.

I5RW0A170003-01

I2RH0B170004-01