fuel injector SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 13 of 1556

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-6

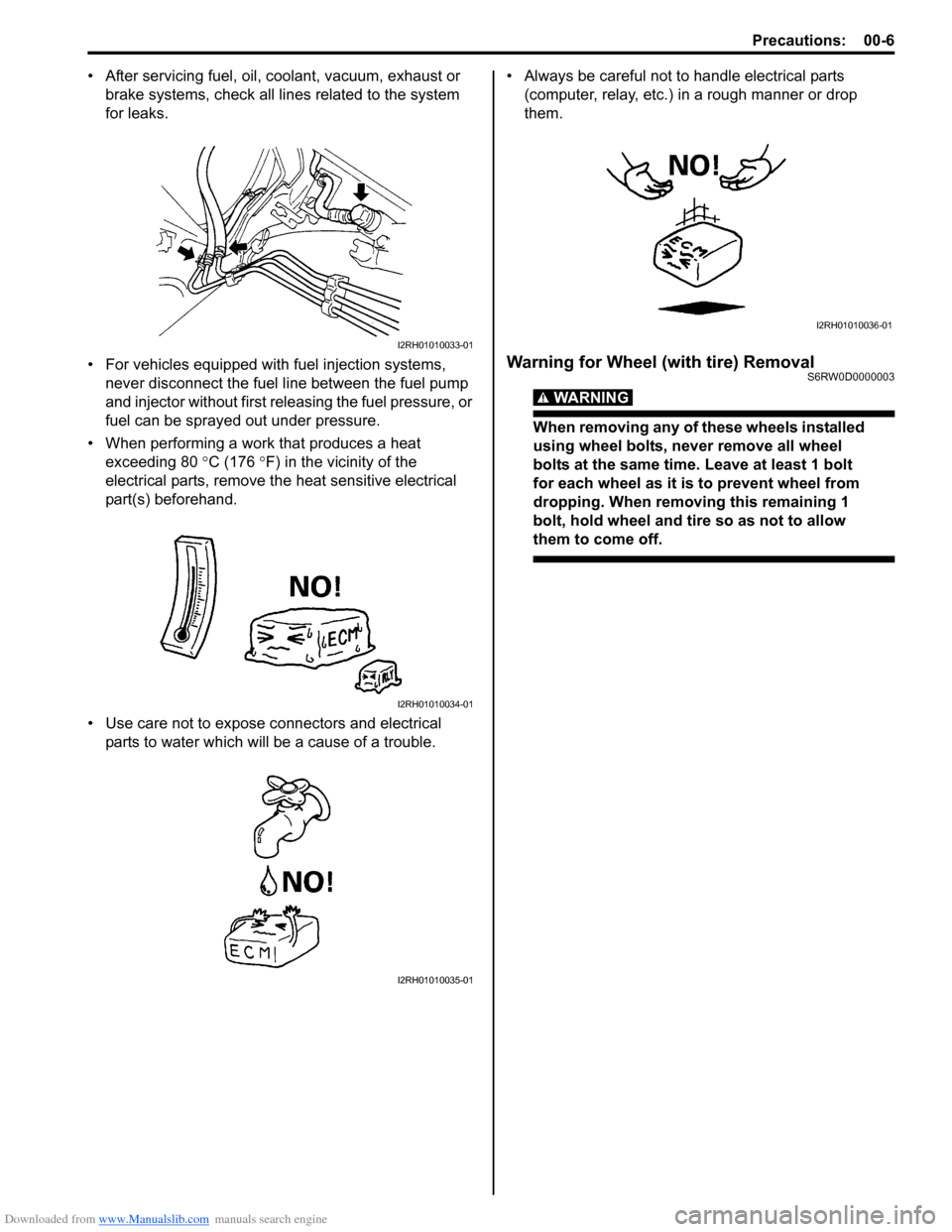

• After servicing fuel, oil, coolant, vacuum, exhaust or

brake systems, check all lines related to the system

for leaks.

• For vehicles equipped with fuel injection systems,

never disconnect the fuel line between the fuel pump

and injector without first releasing the fuel pressure, or

fuel can be sprayed out under pressure.

• When performing a work that produces a heat

exceeding 80 °C (176 °F) in the vicinity of the

electrical parts, remove the heat sensitive electrical

part(s) beforehand.

• Use care not to expose connectors and electrical

parts to water which will be a cause of a trouble.• Always be careful not to handle electrical parts

(computer, relay, etc.) in a rough manner or drop

them.

Warning for Wheel (with tire) RemovalS6RW0D0000003

WARNING!

When removing any of these wheels installed

using wheel bolts, never remove all wheel

bolts at the same time. Leave at least 1 bolt

for each wheel as it is to prevent wheel from

dropping. When removing this remaining 1

bolt, hold wheel and tire so as not to allow

them to come off.

I2RH01010033-01

I2RH01010034-01

I2RH01010035-01

I2RH01010036-01

Page 46 of 1556

Downloaded from www.Manualslib.com manuals search engine 1-ii Table of Contents

DTC P0123: Throttle Position Sensor (Main)

Circuit High ..................................................... 1A-89

DTC P0131 / P0132: O2 Sensor (HO2S)

Circuit Low Voltage / High Voltage (Sensor-

1) ..................................................................... 1A-92

DTC P0133: O2 Sensor (HO2S) Circuit Slow

Response (Sensor-1) ...................................... 1A-95

DTC P0134: O2 Sensor (HO2S) Circuit No

Activity Detected (Sensor-1) ........................... 1A-96

DTC P0137 / P0138: O2 Sensor (HO2S)

Circuit Low Voltage / High Voltage (Sensor-

2) ..................................................................... 1A-98

DTC P0140: O2 Sensor (HO2S) Circuit No

Activity Detected (Sensor-2) ......................... 1A-101

DTC P0171 / P0172: Fuel System Too Lean /

Rich ............................................................... 1A-103

DTC P0222: Throttle Position Sensor (Sub)

Circuit Low .................................................... 1A-105

DTC P0223: Throttle Position Sensor (Sub)

Circuit High ................................................... 1A-107

DTC P0300 / P0301 / P0302 / P0303 / P0304:

Random Misfire Detected / Cylinder 1 /

Cylinder 2 / Cylinder 3 / Cylinder 4 Misfire

Detected ........................................................ 1A-110

DTC P0327 / P0328: Knock Sensor Circuit

Low / High ..................................................... 1A-112

DTC P0335: Crankshaft Position (CKP)

Sensor Circuit ............................................... 1A-114

DTC P0340: Camshaft Position (CMP)

Sensor Circuit ............................................... 1A-116

DTC P0401 / P0402: Exhaust Gas

Recirculation Flow Insufficient Detected /

Excessive Detected ...................................... 1A-119

DTC P0403: Exhaust Gas Recirculation

Control Circuit ............................................... 1A-122

DTC P0420: Catalyst System Efficiency

below Threshold ............................................ 1A-124

DTC P0443: Evaporative Emission System

Purge Control Valve Circuit........................... 1A-126

DTC P0462 / P0463: Fuel Level Sensor

Circuit Low / High .......................................... 1A-128

DTC P0480: Fan 1 (Radiator Cooling Fan)

Control Circuit ............................................... 1A-129

DTC P0481: Cooling Fan 2 (A/C Condenser

Fan) Control Circuit ....................................... 1A-131

DTC P0500: Vehicle Speed Sensor (VSS)

Malfunction .................................................... 1A-134

DTC P0532: A/C Refrigerant Pressure

Sensor Circuit Low ........................................ 1A-136

DTC P0533: A/C Refrigerant Pressure

Sensor Circuit High ....................................... 1A-138

DTC P0601 / P0602 / P0607: Internal Control

Module Memory Check Sum Error / Control

Module Programming Error / Control Module

Performance ................................................. 1A-139

DTC P0616: Starter Relay Circuit Low............ 1A-140

DTC P0617: Starter Relay Circuit High ........... 1A-141

DTC P1510: ECM Back-Up Power Supply

Malfunction .................................................... 1A-143DTC P2101: Throttle Actuator Control Motor

Circuit Range / Performance ......................... 1A-144

DTC P2102: Throttle Actuator Control Motor

Circuit Low .................................................... 1A-146

DTC P2103: Throttle Actuator Control Motor

Circuit High.................................................... 1A-147

DTC P2111: Throttle Actuator Control System

- Stuck Open ................................................. 1A-148

DTC P2119: Throttle Actuator Control Throttle

Body Range / Performance ........................... 1A-149

DTC P2122: Pedal Position Sensor (Main)

Circuit Low Input ........................................... 1A-151

DTC P2123: Pedal Position Sensor (Main)

Circuit High Input........................................... 1A-153

DTC P2127: Pedal Position Sensor (Sub)

Circuit Low Input ........................................... 1A-155

DTC P2128: Pedal Position Sensor (Sub)

Circuit High Input........................................... 1A-158

DTC P2135: Throttle Position Sensor (Main /

Sub) Voltage Correlation ............................... 1A-160

DTC P2138: Pedal Position Sensor (Main /

Sub) Voltage Correlation ............................... 1A-163

DTC P2227 / P2228 / P2229: Barometric

Pressure Circuit Malfunction ......................... 1A-165

DTC U0073: Control Module Communication

Bus Off .......................................................... 1A-166

DTC U0101: Lost Communication with TCM .. 1A-166

DTC U0121: Lost Communication with ABS

Control Module .............................................. 1A-166

DTC U0140: Lost Communication with Body

Control Module .............................................. 1A-166

Troubleshooting for CAN-DTC ........................ 1A-167

Inspection of ECM and Its Circuits .................. 1A-172

ECM Power and Ground Circuit Check........... 1A-193

Fuel Injector Circuit Check .............................. 1A-196

Fuel Pump and Its Circuit Check..................... 1A-198

Fuel Pressure Check....................................... 1A-201

A/C Condenser Cooling Fan Control System

Inspection ...................................................... 1A-202

A/C System Circuits Check ............................. 1A-205

Electric Load Signal Circuit Check .................. 1A-209

Radiator Cooling Fan Control System Check . 1A-211

Repair Instructions ..........................................1A-212

Idle Speed and IAC Throttle Valve Opening

Inspection ...................................................... 1A-212

Special Tools and Equipment .........................1A-213

Special Tool .................................................... 1A-213

Aux. Emission Control Devices ............. 1B-1

Diagnostic Information and Procedures ............1B-1

EGR System Inspection (If Equipped) ................ 1B-1

Repair Instructions ..............................................1B-1

EVAP Canister Purge Inspection ........................ 1B-1

EVAP Canister Purge Valve and Its Circuit

Inspection .......................................................... 1B-1

Vacuum Passage Inspection............................... 1B-2

Vacuum Hose Inspection .................................... 1B-3

EVAP Canister Purge Valve Inspection .............. 1B-3

EVAP Canister Inspection ................................... 1B-4

Page 48 of 1556

Downloaded from www.Manualslib.com manuals search engine 1-iv Table of Contents

Crankshaft Inspection .......................................1D-63

Main Bearings Inspection ..................................1D-65

Sensor Plate Inspection ....................................1D-70

Rear Oil Seal Inspection ...................................1D-70

Flywheel Inspection...........................................1D-70

Cylinder Block Inspection ..................................1D-70

Specifications .....................................................1D-71

Tightening Torque Specifications ......................1D-71

Special Tools and Equipment ...........................1D-73

Recommended Service Material .......................1D-73

Special Tool ......................................................1D-73

Engine Lubrication System.....................1E-1

General Description ............................................. 1E-1

Engine Lubrication Description ........................... 1E-1

Diagnostic Information and Procedures ............ 1E-2

Oil Pressure Check ............................................. 1E-2

Repair Instructions .............................................. 1E-3

Oil Pan and Oil Pump Strainer Components....... 1E-3

Oil Pan and Oil Pump Strainer Removal and

Installation ......................................................... 1E-4

Oil Pan and Oil Pump Strainer Cleaning ............. 1E-5

Oil Pump Components ........................................ 1E-6

Oil Pump Removal and Installation ..................... 1E-6

Oil Pump Disassembly and Reassembly ............ 1E-6

Oil Pump Inspection ............................................ 1E-7

Specifications ....................................................... 1E-9

Tightening Torque Specifications ........................ 1E-9

Special Tools and Equipment ............................. 1E-9

Recommended Service Material ......................... 1E-9

Special Tool ........................................................ 1E-9

Engine Cooling System ........................... 1F-1

General Description ............................................. 1F-1

Cooling System Description ................................ 1F-1

Coolant Description ............................................. 1F-1

Schematic and Routing Diagram ........................ 1F-2

Coolant Circulation .............................................. 1F-2

Diagnostic Information and Procedures ............ 1F-3

Engine Cooling Symptom Diagnosis ................... 1F-3

Repair Instructions .............................................. 1F-4

Cooling System Components.............................. 1F-4

Coolant Level Check ........................................... 1F-5

Engine Cooling System Inspection and

Cleaning ............................................................ 1F-5

Cooling System Draining..................................... 1F-5

Cooling System Flush and Refill ......................... 1F-6

Cooling Water Pipes or Hoses Removal and

Installation ......................................................... 1F-6

Thermostat Removal and Installation.................. 1F-7

Thermostat Inspection......................................... 1F-7

Radiator Cooling Fan Assembly On-Vehicle

Inspection .......................................................... 1F-8

Radiator Cooling Fan Relay Inspection............... 1F-8

Radiator Cooling Fan Assembly Removal and

Installation ......................................................... 1F-8

Radiator Cooling Fan Disassembly and

Reassembly ...................................................... 1F-9

Radiator On-Vehicle Inspection and Cleaning .... 1F-9Radiator Removal and Installation ...................... 1F-9

Water Pump / Generator Drive Belt Tension

Inspection and Adjustment.............................. 1F-10

Water Pump / Generator Drive Belt Removal

and Installation ................................................ 1F-10

Water Pump Removal and Installation .............. 1F-11

Water Pump Inspection ..................................... 1F-12

Specifications ..................................................... 1F-12

Tightening Torque Specifications ...................... 1F-12

Special Tools and Equipment ........................... 1F-12

Recommended Service Material ....................... 1F-12

Fuel System ............................................. 1G-1

Precautions .......................................................... 1G-1

Precautions on Fuel System Service ................. 1G-1

General Description ............................................ 1G-2

Fuel System Description .................................... 1G-2

Fuel Delivery System Description ...................... 1G-2

Fuel Pump Description ....................................... 1G-2

Schematic and Routing Diagram ....................... 1G-3

Fuel Delivery System Diagram........................... 1G-3

Diagnostic Information and Procedures ........... 1G-3

Fuel Pressure Inspection ................................... 1G-3

Fuel Cut Operation Inspection ........................... 1G-4

Repair Instructions ............................................. 1G-5

Fuel System Components .................................. 1G-5

Fuel Hose Disconnecting and Reconnecting ..... 1G-6

Fuel Pressure Relief Procedure ......................... 1G-7

Fuel Leakage Check Procedure......................... 1G-8

Fuel Lines On-Vehicle Inspection ...................... 1G-8

Fuel Pipe Removal and Installation.................... 1G-8

Fuel Injector On-Vehicle Inspection ................... 1G-9

Fuel Injector Removal and Installation ............... 1G-9

Fuel Injector Inspection .................................... 1G-10

Fuel Filler Cap Inspection ................................ 1G-12

Fuel Tank Inlet Valve Removal and

Installation ...................................................... 1G-12

Fuel Tank Inlet Valve Inspection ...................... 1G-12

Fuel Tank Removal and Installation ................. 1G-13

Fuel Tank Inspection ........................................ 1G-14

Fuel Tank Purging Procedure .......................... 1G-15

Fuel Pump On-Vehicle Inspection.................... 1G-15

Fuel Pump Assembly Removal and

Installation ...................................................... 1G-15

Main Fuel Level Sensor Removal and

Installation ...................................................... 1G-16

Fuel Pump Inspection ...................................... 1G-17

Specifications .................................................... 1G-17

Tightening Torque Specifications ..................... 1G-17

Special Tools and Equipment .......................... 1G-18

Special Tool ..................................................... 1G-18

Ignition System ........................................ 1H-1

General Description .............................................1H-1

Ignition System Construction ..............................1H-1

Schematic and Routing Diagram ........................1H-2

Ignition System Wiring Circuit Diagram...............1H-2

Component Location ...........................................1H-3

Ignition System Components Location................1H-3

Page 63 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-13

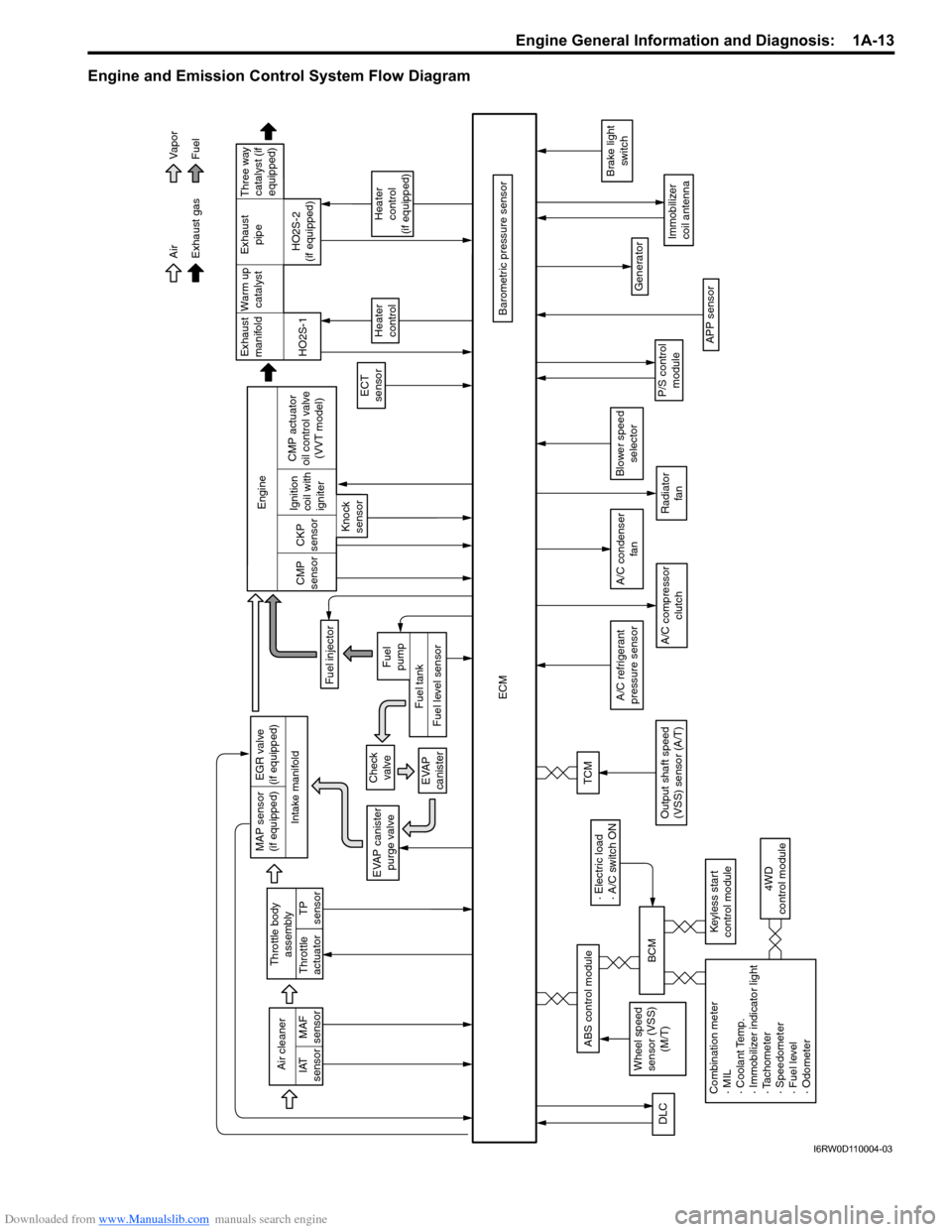

Engine and Emission Control System Flow Diagram

Intake manifoldExhaust

manifold

Exhaust gas Air

Fuel Vapor

War m up

catalystExhaust

pipe

EVAP canister

purge valve

Fuel injector

ECT

sensor

ECM

Heater

control

Heater

control

(if equipped)

Barometric pressure sensor HO2S-1HO2S-2

(if equipped) Engine

CMP

sensorCKP

sensor

Knock

sensorIgnition

coil with

igniter

APP sensor

A/C compressor

clutch

Generator

Immobilizer

coil antenna

P/S control

module

Brake light

switch

Air cleaner

IAT

sensorMAF

sensor

A/C refrigerant

pressure sensor

TP

sensor Throttle body

assembly

Throttle

actuator

A/C condenser

fan

DLC

Radiator

fan

Combination meter

· MIL

· Coolant Temp.

· Immobilizer indicator light

· Tachometer

· Speedometer

· Fuel level

· Odometer4WD

control module

Wheel speed

sensor (VSS)

(M/T)

· Electric load

· A/C switch ON

BCM

Keyless start

control module

ABS control module

Blower speed

selector

MAP sensor

(if equipped)EGR valve

(if equipped)

Check

valve

EVAP

canister

Fuel level sensorFuel tankFuel

pump

CMP actuator

oil control valve

(VVT model)

TCM

Output shaft speed

(VSS) sensor (A/T)

Three way

catalyst (if

equipped)

I6RW0D110004-03

Page 65 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

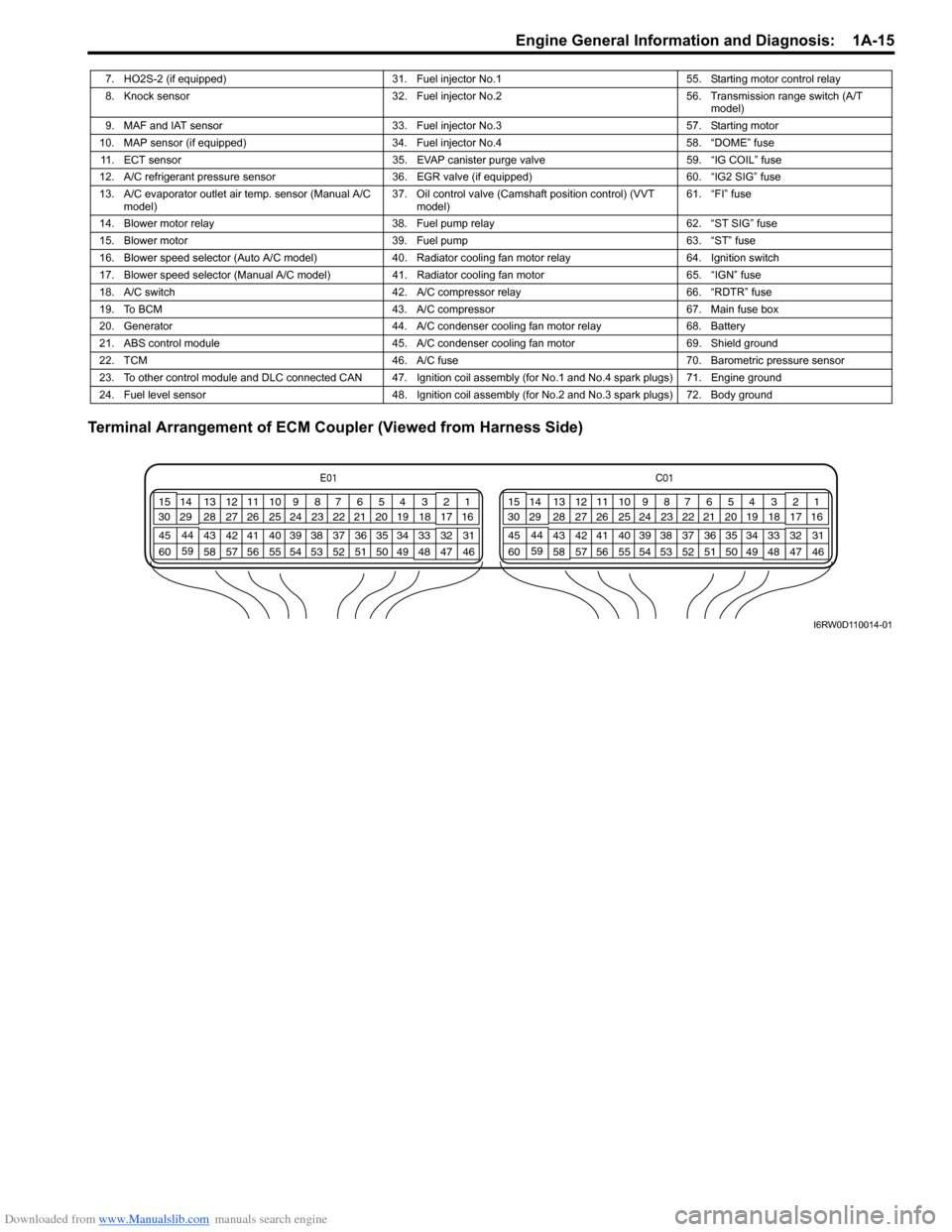

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

7. HO2S-2 (if equipped) 31. Fuel injector No.1 55. Starting motor control relay

8. Knock sensor 32. Fuel injector No.2 56. Transmission range switch (A/T

model)

9. MAF and IAT sensor 33. Fuel injector No.3 57. Starting motor

10. MAP sensor (if equipped) 34. Fuel injector No.4 58. “DOME” fuse

11. ECT sensor 35. EVAP canister purge valve 59. “IG COIL” fuse

12. A/C refrigerant pressure sensor 36. EGR valve (if equipped) 60. “IG2 SIG” fuse

13. A/C evaporator outlet air temp. sensor (Manual A/C

model)37. Oil control valve (Camshaft position control) (VVT

model)61. “FI” fuse

14. Blower motor relay 38. Fuel pump relay 62. “ST SIG” fuse

15. Blower motor 39. Fuel pump 63. “ST” fuse

16. Blower speed selector (Auto A/C model) 40. Radiator cooling fan motor relay 64. Ignition switch

17. Blower speed selector (Manual A/C model) 41. Radiator cooling fan motor 65. “IGN” fuse

18. A/C switch 42. A/C compressor relay 66. “RDTR” fuse

19. To BCM 43. A/C compressor 67. Main fuse box

20. Generator 44. A/C condenser cooling fan motor relay 68. Battery

21. ABS control module 45. A/C condenser cooling fan motor 69. Shield ground

22. TCM 46. A/C fuse 70. Barometric pressure sensor

23. To other control module and DLC connected CAN 47. Ignition coil assembly (for No.1 and No.4 spark plugs) 71. Engine ground

24. Fuel level sensor 48. Ignition coil assembly (for No.2 and No.3 spark plugs) 72. Body ground

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

I6RW0D110014-01

Page 66 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-16 Engine General Information and Diagnosis:

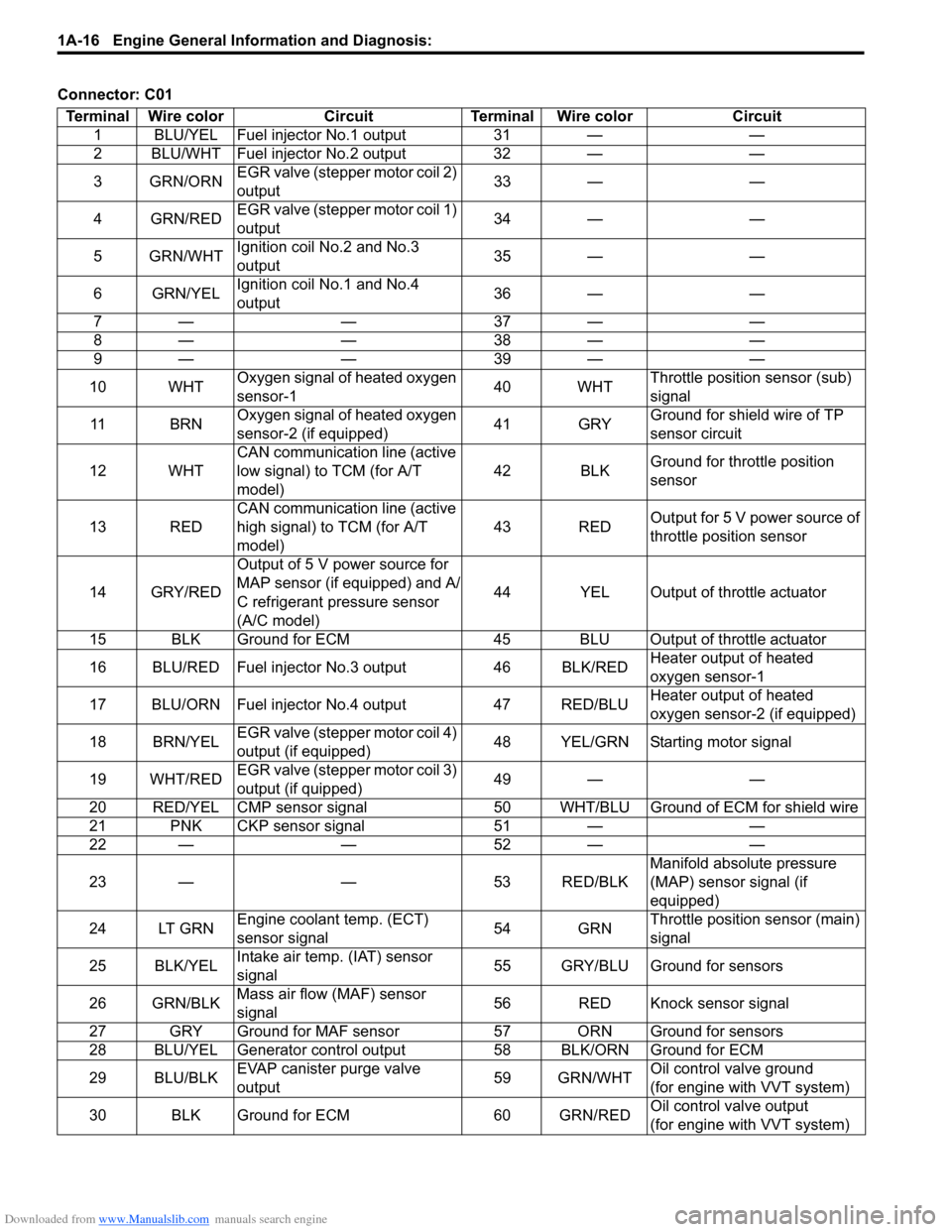

Connector: C01

Terminal Wire color Circuit Terminal Wire color Circuit

1 BLU/YEL Fuel injector No.1 output 31 — —

2 BLU/WHT Fuel injector No.2 output 32 — —

3 GRN/ORNEGR valve (stepper motor coil 2)

output33 — —

4 GRN/REDEGR valve (stepper motor coil 1)

output34 — —

5 GRN/WHTIgnition coil No.2 and No.3

output35 — —

6 GRN/YELIgnition coil No.1 and No.4

output36 — —

7— — 37— —

8— — 38— —

9— — 39— —

10 WHTOxygen signal of heated oxygen

sensor-140 WHTThrottle position sensor (sub)

signal

11 B R NOxygen signal of heated oxygen

sensor-2 (if equipped)41 GRYGround for shield wire of TP

sensor circuit

12 WHTCAN communication line (active

low signal) to TCM (for A/T

model)42 BLKGround for throttle position

sensor

13 REDCAN communication line (active

high signal) to TCM (for A/T

model) 43 REDOutput for 5 V power source of

throttle position sensor

14 GRY/REDOutput of 5 V power source for

MAP sensor (if equipped) and A/

C refrigerant pressure sensor

(A/C model)44 YEL Output of throttle actuator

15 BLK Ground for ECM 45 BLU Output of throttle actuator

16 BLU/RED Fuel injector No.3 output 46 BLK/REDHeater output of heated

oxygen sensor-1

17 BLU/ORN Fuel injector No.4 output 47 RED/BLUHeater output of heated

oxygen sensor-2 (if equipped)

18 BRN/YELEGR valve (stepper motor coil 4)

output (if equipped)48 YEL/GRN Starting motor signal

19 WHT/REDEGR valve (stepper motor coil 3)

output (if quipped)49 — —

20 RED/YEL CMP sensor signal 50 WHT/BLU Ground of ECM for shield wire

21 PNK CKP sensor signal 51 — —

22 — — 52 — —

23 — — 53 RED/BLKManifold absolute pressure

(MAP) sensor signal (if

equipped)

24 LT GRNEngine coolant temp. (ECT)

sensor signal54 GRNThrottle position sensor (main)

signal

25 BLK/YELIntake air temp. (IAT) sensor

signal55 GRY/BLU Ground for sensors

26 GRN/BLKMass air flow (MAF) sensor

signal56 RED Knock sensor signal

27 GRY Ground for MAF sensor 57 ORN Ground for sensors

28 BLU/YEL Generator control output 58 BLK/ORN Ground for ECM

29 BLU/BLKEVAP canister purge valve

output59 GRN/WHTOil control valve ground

(for engine with VVT system)

30 BLK Ground for ECM 60 GRN/REDOil control valve output

(for engine with VVT system)

Page 70 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-20 Engine General Information and Diagnosis:

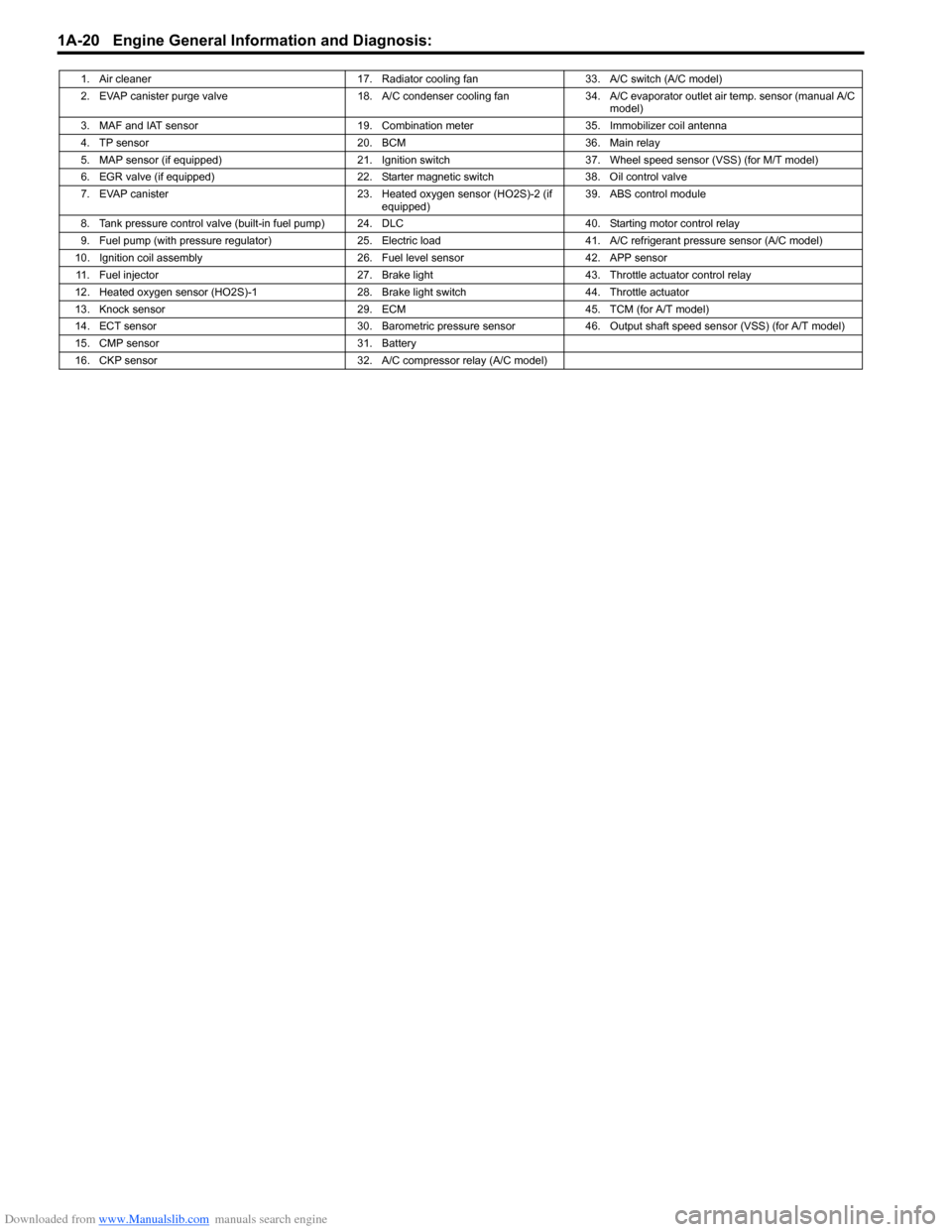

1. Air cleaner 17. Radiator cooling fan 33. A/C switch (A/C model)

2. EVAP canister purge valve 18. A/C condenser cooling fan 34. A/C evaporator outlet air temp. sensor (manual A/C

model)

3. MAF and IAT sensor 19. Combination meter 35. Immobilizer coil antenna

4. TP sensor 20. BCM 36. Main relay

5. MAP sensor (if equipped) 21. Ignition switch37. Wheel speed sensor (VSS) (for M/T model)

6. EGR valve (if equipped) 22. Starter magnetic switch 38. Oil control valve

7. EVAP canister 23. Heated oxygen sensor (HO2S)-2 (if

equipped)39. ABS control module

8. Tank pressure control valve (built-in fuel pump) 24. DLC 40. Starting motor control relay

9. Fuel pump (with pressure regulator) 25. Electric load 41. A/C refrigerant pressure sensor (A/C model)

10. Ignition coil assembly 26. Fuel level sensor 42. APP sensor

11. Fuel injector 27. Brake light 43. Throttle actuator control relay

12. Heated oxygen sensor (HO2S)-1 28. Brake light switch 44. Throttle actuator

13. Knock sensor 29. ECM 45. TCM (for A/T model)

14. ECT sensor 30. Barometric pressure sensor 46. Output shaft speed sensor (VSS) (for A/T model)

15. CMP sensor 31. Battery

16. CKP sensor 32. A/C compressor relay (A/C model)

Page 71 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-21

Component Location

Electronic Control System Components LocationS6RW0D1103001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

H*E*

10

D

G* C

6A

B*

e

3*

12*

a8 13

b

1

5-1

d

2

11

g

4

7

9

i

j

Fh k f

n

c J

5

K*

14

I6RW0D110016-03

Information sensors Control devices Others

1. MAF and IAT sensor a: Fuel injector A: ECM

2. Electric throttle body assembly

(built-in throttle position sensor and throttle

actuator)b: EVAP canister purge valve B: Combination meter

3. Brake light switch c: Fuel pump relay C: EVAP canister

4. ECT sensor d: EGR valve (if equipped) D: A/C evaporator outlet air temp. sensor

(if equipped with A/C)

5. Heated oxygen sensor-1 e: Malfunction indicator lamp E: Data link connector

5-1. Heated oxygen sensor-2 (if equipped) f: Radiator cooling fan relay F: A/C compressor relay (if equipped with A/C)

6. Battery g: Ignition coil assembly (with ignitor) G: BCM (included in junction block assembly)

7. CMP sensor (for engine with VVT system) h: Main relay H: Immobilizer coil antenna

8. MAP sensor (if equipped) i: Oil control valve (for engine with VVT system) J: A/C refrigerant pressure sensor

(if equipped with A/C)

9. CKP sensor j: A/C condenser cooling fan relay K: TCM (for A/T model)

10. Fuel level sensor k: Starting motor control relay

11. Knock sensor m: Immobilizer indicator lamp

12. APP sensor n: Throttle actuator control relay

13. Front wheel speed sensor (RH, LH) (VSS)

14. CMP sensor (for engine without VVT system)

Page 86 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-36 Engine General Information and Diagnosis:

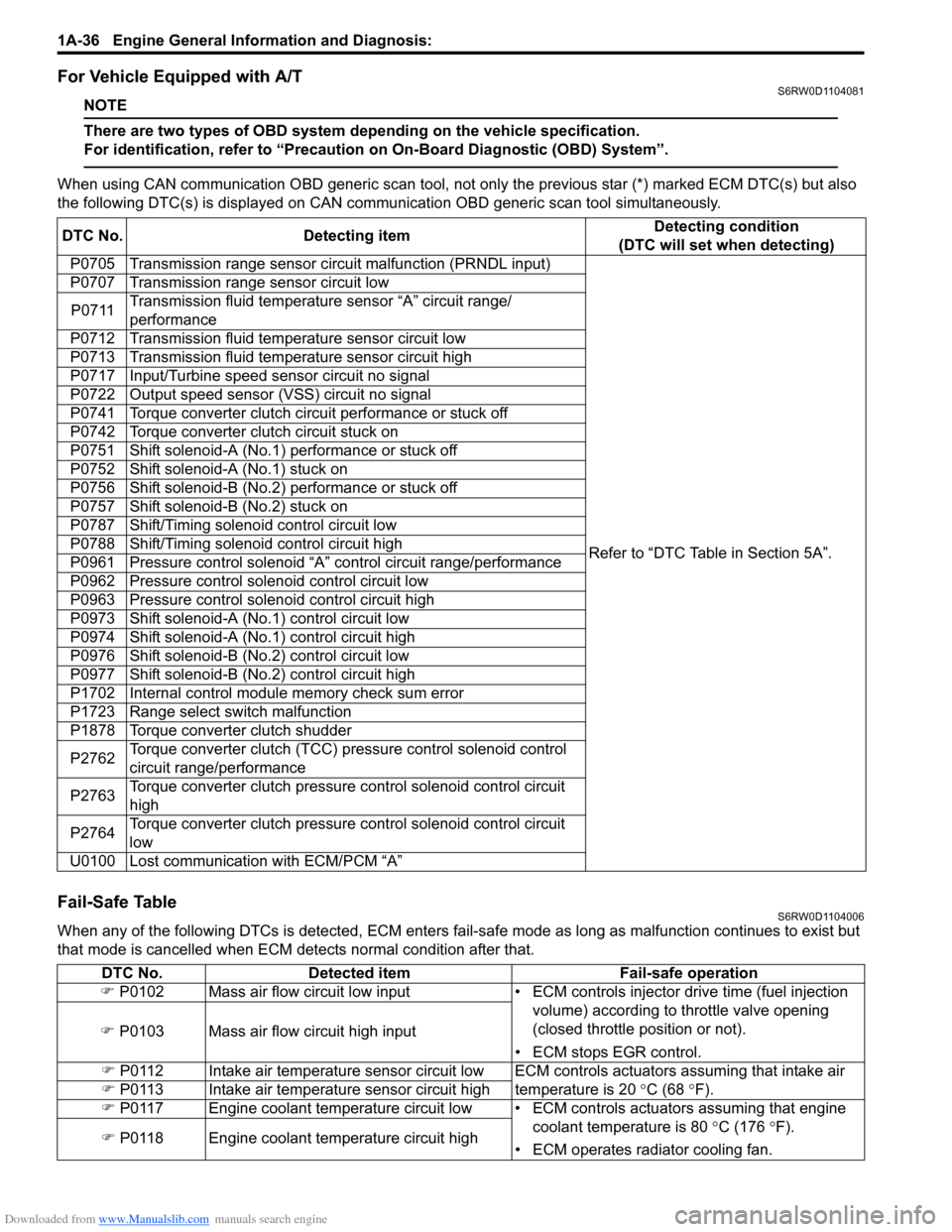

For Vehicle Equipped with A/TS6RW0D1104081

NOTE

There are two types of OBD system depending on the vehicle specification.

For identification, refer to “Precaution on On-Board Diagnostic (OBD) System”.

When using CAN communication OBD generic scan tool, not only the previous star (*) marked ECM DTC(s) but also

the following DTC(s) is displayed on CAN communication OBD generic scan tool simultaneously.

Fail-Safe TableS6RW0D1104006

When any of the following DTCs is detected, ECM enters fail-safe mode as long as malfunction continues to exist but

that mode is cancelled when ECM detects normal condition after that. DTC No. Detecting itemDetecting condition

(DTC will set when detecting)

P0705 Transmission range sensor circuit malfunction (PRNDL input)

Refer to “DTC Table in Section 5A”. P0707 Transmission range sensor circuit low

P0711Transmission fluid temperature sensor “A” circuit range/

performance

P0712 Transmission fluid temperature sensor circuit low

P0713 Transmission fluid temperature sensor circuit high

P0717 Input/Turbine speed sensor circuit no signal

P0722 Output speed sensor (VSS) circuit no signal

P0741 Torque converter clutch circuit performance or stuck off

P0742 Torque converter clutch circuit stuck on

P0751 Shift solenoid-A (No.1) performance or stuck off

P0752 Shift solenoid-A (No.1) stuck on

P0756 Shift solenoid-B (No.2) performance or stuck off

P0757 Shift solenoid-B (No.2) stuck on

P0787 Shift/Timing solenoid control circuit low

P0788 Shift/Timing solenoid control circuit high

P0961 Pressure control solenoid “A” control circuit range/performance

P0962 Pressure control solenoid control circuit low

P0963 Pressure control solenoid control circuit high

P0973 Shift solenoid-A (No.1) control circuit low

P0974 Shift solenoid-A (No.1) control circuit high

P0976 Shift solenoid-B (No.2) control circuit low

P0977 Shift solenoid-B (No.2) control circuit high

P1702 Internal control module memory check sum error

P1723 Range select switch malfunction

P1878 Torque converter clutch shudder

P2762Torque converter clutch (TCC) pressure control solenoid control

circuit range/performance

P2763Torque converter clutch pressure control solenoid control circuit

high

P2764Torque converter clutch pressure control solenoid control circuit

low

U0100 Lost communication with ECM/PCM “A”

DTC No. Detected item Fail-safe operation

�) P0102 Mass air flow circuit low input • ECM controls injector drive time (fuel injection

volume) according to throttle valve opening

(closed throttle position or not).

• ECM stops EGR control. �) P0103 Mass air flow circuit high input

�) P0112 Intake air temperature sensor circuit low ECM controls actuators assuming that intake air

temperature is 20 °C (68 °F). �) P0113 Intake air temperature sensor circuit high

�) P0117 Engine coolant temperature circuit low • ECM controls actuators assuming that engine

coolant temperature is 80 °C (176 °F).

• ECM operates radiator cooling fan. �) P0118 Engine coolant temperature circuit high

Page 91 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-41

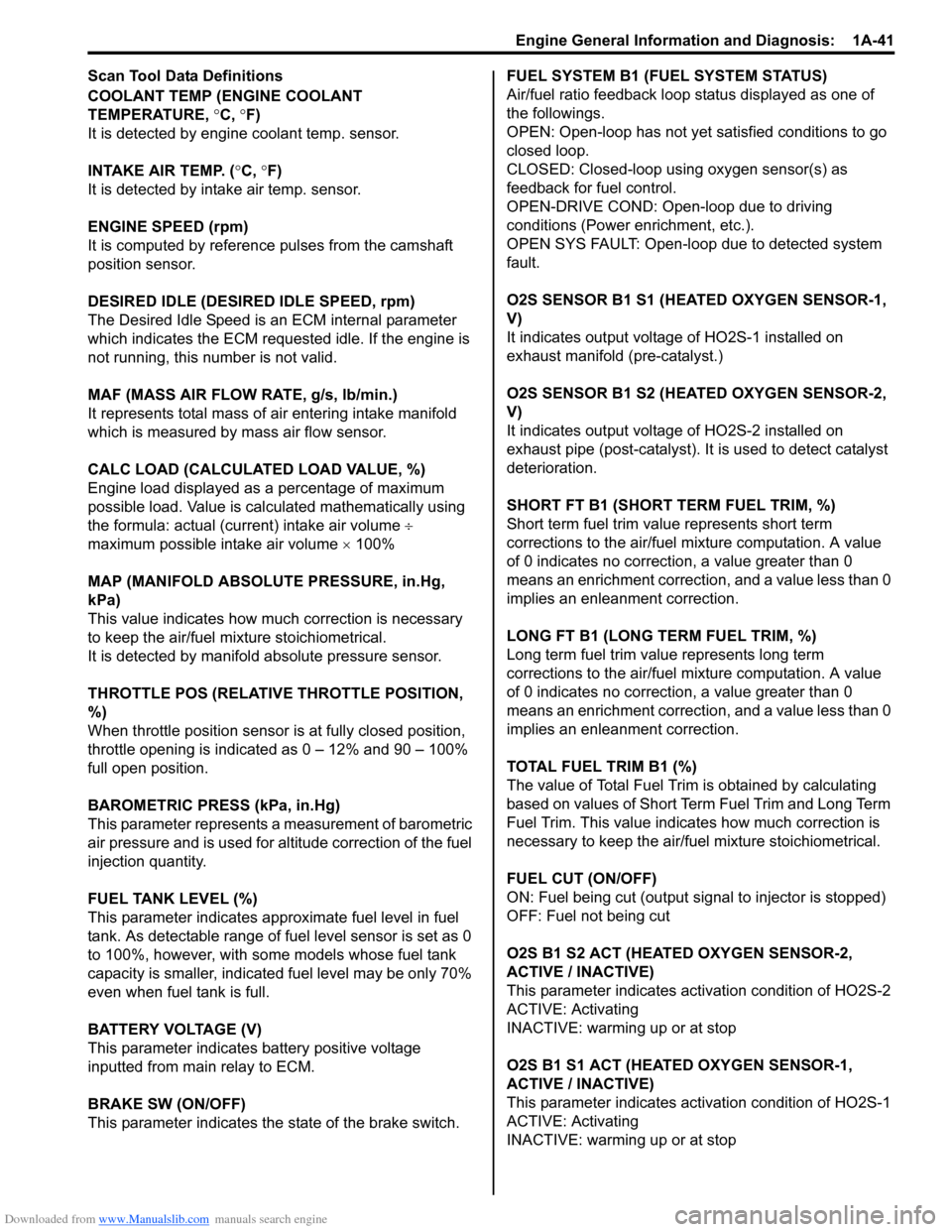

Scan Tool Data Definitions

COOLANT TEMP (ENGINE COOLANT

TEMPERATURE, °C, °F)

It is detected by engine coolant temp. sensor.

INTAKE AIR TEMP. (°C, °F)

It is detected by intake air temp. sensor.

ENGINE SPEED (rpm)

It is computed by reference pulses from the camshaft

position sensor.

DESIRED IDLE (DESIRED IDLE SPEED, rpm)

The Desired Idle Speed is an ECM internal parameter

which indicates the ECM requested idle. If the engine is

not running, this number is not valid.

MAF (MASS AIR FLOW RATE, g/s, lb/min.)

It represents total mass of air entering intake manifold

which is measured by mass air flow sensor.

CALC LOAD (CALCULATED LOAD VALUE, %)

Engine load displayed as a percentage of maximum

possible load. Value is calculated mathematically using

the formula: actual (current) intake air volume ÷

maximum possible intake air volume × 100%

MAP (MANIFOLD ABSOLUTE PRESSURE, in.Hg,

kPa)

This value indicates how much correction is necessary

to keep the air/fuel mixture stoichiometrical.

It is detected by manifold absolute pressure sensor.

THROTTLE POS (RELATIVE THROTTLE POSITION,

%)

When throttle position sensor is at fully closed position,

throttle opening is indicated as 0 – 12% and 90 – 100%

full open position.

BAROMETRIC PRESS (kPa, in.Hg)

This parameter represents a measurement of barometric

air pressure and is used for altitude correction of the fuel

injection quantity.

FUEL TANK LEVEL (%)

This parameter indicates approximate fuel level in fuel

tank. As detectable range of fuel level sensor is set as 0

to 100%, however, with some models whose fuel tank

capacity is smaller, indicated fuel level may be only 70%

even when fuel tank is full.

BATTERY VOLTAGE (V)

This parameter indicates battery positive voltage

inputted from main relay to ECM.

BRAKE SW (ON/OFF)

This parameter indicates the state of the brake switch.FUEL SYSTEM B1 (FUEL SYSTEM STATUS)

Air/fuel ratio feedback loop status displayed as one of

the followings.

OPEN: Open-loop has not yet satisfied conditions to go

closed loop.

CLOSED: Closed-loop using oxygen sensor(s) as

feedback for fuel control.

OPEN-DRIVE COND: Open-loop due to driving

conditions (Power enrichment, etc.).

OPEN SYS FAULT: Open-loop due to detected system

fault.

O2S SENSOR B1 S1 (HEATED OXYGEN SENSOR-1,

V)

It indicates output voltage of HO2S-1 installed on

exhaust manifold (pre-catalyst.)

O2S SENSOR B1 S2 (HEATED OXYGEN SENSOR-2,

V)

It indicates output voltage of HO2S-2 installed on

exhaust pipe (post-catalyst). It is used to detect catalyst

deterioration.

SHORT FT B1 (SHORT TERM FUEL TRIM, %)

Short term fuel trim value represents short term

corrections to the air/fuel mixture computation. A value

of 0 indicates no correction, a value greater than 0

means an enrichment correction, and a value less than 0

implies an enleanment correction.

LONG FT B1 (LONG TERM FUEL TRIM, %)

Long term fuel trim value represents long term

corrections to the air/fuel mixture computation. A value

of 0 indicates no correction, a value greater than 0

means an enrichment correction, and a value less than 0

implies an enleanment correction.

TOTAL FUEL TRIM B1 (%)

The value of Total Fuel Trim is obtained by calculating

based on values of Short Term Fuel Trim and Long Term

Fuel Trim. This value indicates how much correction is

necessary to keep the air/fuel mixture stoichiometrical.

FUEL CUT (ON/OFF)

ON: Fuel being cut (output signal to injector is stopped)

OFF: Fuel not being cut

O2S B1 S2 ACT (HEATED OXYGEN SENSOR-2,

ACTIVE / INACTIVE)

This parameter indicates activation condition of HO2S-2

ACTIVE: Activating

INACTIVE: warming up or at stop

O2S B1 S1 ACT (HEATED OXYGEN SENSOR-1,

ACTIVE / INACTIVE)

This parameter indicates activation condition of HO2S-1

ACTIVE: Activating

INACTIVE: warming up or at stop