Eps SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1153 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-114

21) Wash your hands with mild soap and water

afterward.

NOTE

Remaining steps are to be followed in the

unlikely event that air bag (inflator) module

did not deploy or seat belt pretensioner did

not activate.

22) Ensure that deployment harness has been

disconnected from 12 volts vehicle battery and that

its two banana plugs have been shorted together by

fully seating one banana plug into the other.

23) Disconnect deployment harness and adapter cable

from air bag (inflator) module or seat belt

pretensioner.

24) Temporarily store undeployed air bag (inflator)

module referring to “Precautions on Service and

Diagnosis of Air Bag System” for details.

25) Contact your local distributor for further assistance.

Deployment / Activation Inside of Vehicle

When the vehicle will be destroyed, or salvaged for

component parts, deploy the air bag modules and/or

activate seat belt pretensioners installed on vehicle.

NOTE

If equipped with the seat belt pretensioners,

activate both side of seat belt pretensioners

at the same time when using special tool (C).

1) Turn ignition switch to LOCK position, remove key

and put on safety glasses.

2) Remove all loose objects from front seats and

instrument panel.

3) Disconnect air bag (inflator) module or seat belt

pretensioner connector as follows.

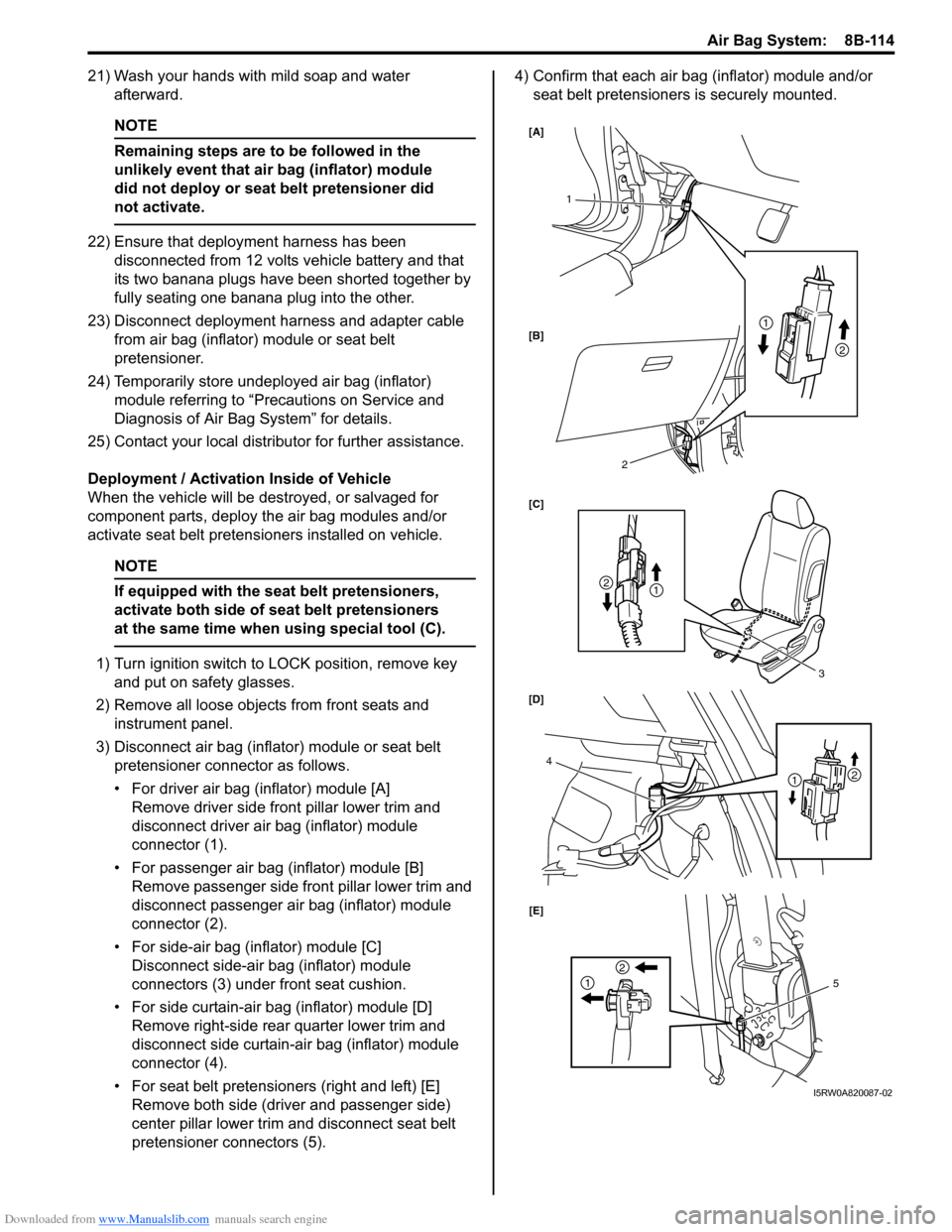

• For driver air bag (inflator) module [A]

Remove driver side front pillar lower trim and

disconnect driver air bag (inflator) module

connector (1).

• For passenger air bag (inflator) module [B]

Remove passenger side front pillar lower trim and

disconnect passenger air bag (inflator) module

connector (2).

• For side-air bag (inflator) module [C]

Disconnect side-air bag (inflator) module

connectors (3) under front seat cushion.

• For side curtain-air bag (inflator) module [D]

Remove right-side rear quarter lower trim and

disconnect side curtain-air bag (inflator) module

connector (4).

• For seat belt pretensioners (right and left) [E]

Remove both side (driver and passenger side)

center pillar lower trim and disconnect seat belt

pretensioner connectors (5).4) Confirm that each air bag (inflator) module and/or

seat belt pretensioners is securely mounted.

1

3

4

2

1

21

2

21

2

15 [A]

[B]

[C]

[D]

[E]

I5RW0A820087-02

Page 1155 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-116

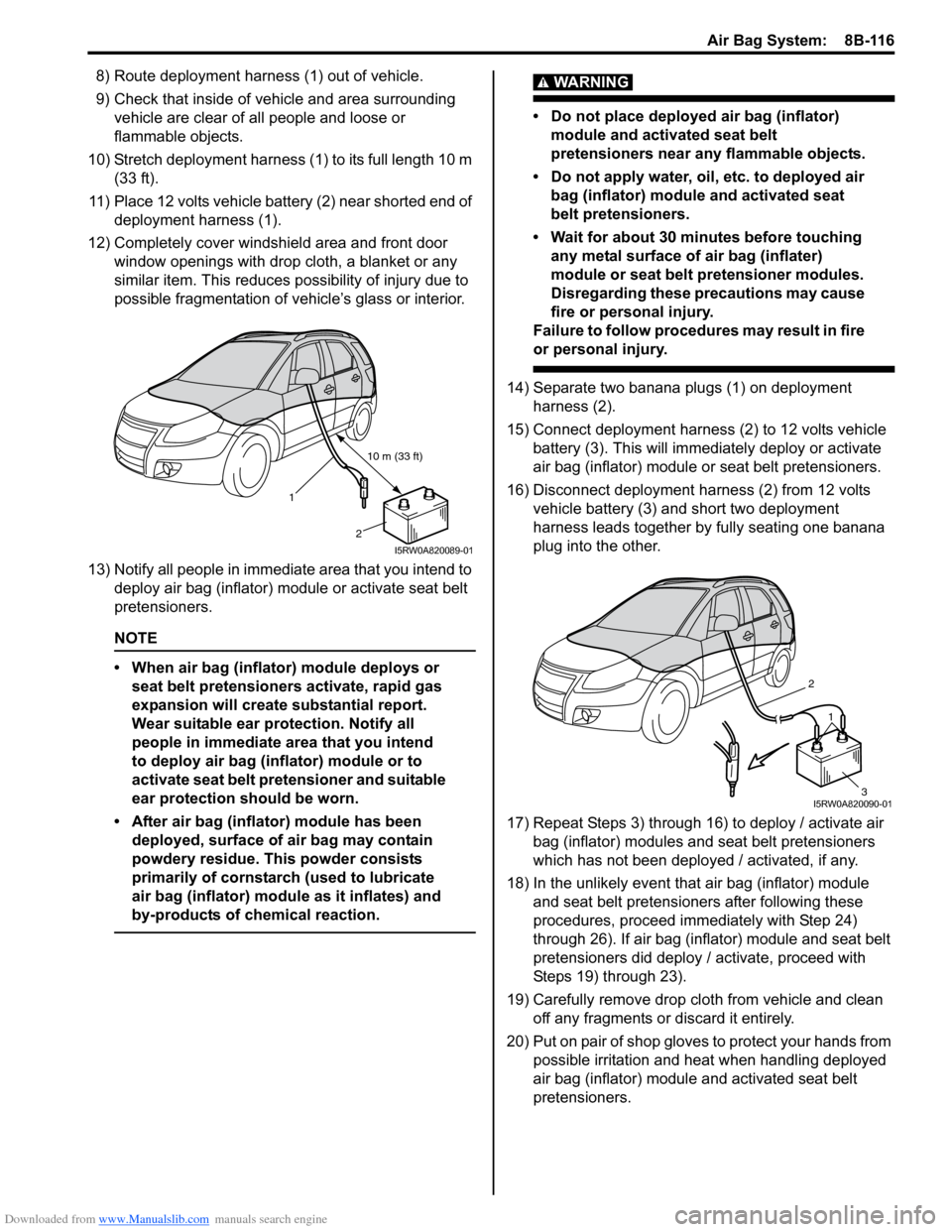

8) Route deployment harness (1) out of vehicle.

9) Check that inside of vehicle and area surrounding

vehicle are clear of all people and loose or

flammable objects.

10) Stretch deployment harness (1) to its full length 10 m

(33 ft).

11) Place 12 volts vehicle battery (2) near shorted end of

deployment harness (1).

12) Completely cover windshield area and front door

window openings with drop cloth, a blanket or any

similar item. This reduces possibility of injury due to

possible fragmentation of vehicle’s glass or interior.

13) Notify all people in immediate area that you intend to

deploy air bag (inflator) module or activate seat belt

pretensioners.

NOTE

• When air bag (inflator) module deploys or

seat belt pretensioners activate, rapid gas

expansion will create substantial report.

Wear suitable ear protection. Notify all

people in immediate area that you intend

to deploy air bag (inflator) module or to

activate seat belt pretensioner and suitable

ear protection should be worn.

• After air bag (inflator) module has been

deployed, surface of air bag may contain

powdery residue. This powder consists

primarily of cornstarch (used to lubricate

air bag (inflator) module as it inflates) and

by-products of chemical reaction.

WARNING!

• Do not place deployed air bag (inflator)

module and activated seat belt

pretensioners near any flammable objects.

• Do not apply water, oil, etc. to deployed air

bag (inflator) module and activated seat

belt pretensioners.

• Wait for about 30 minutes before touching

any metal surface of air bag (inflater)

module or seat belt pretensioner modules.

Disregarding these precautions may cause

fire or personal injury.

Failure to follow procedures may result in fire

or personal injury.

14) Separate two banana plugs (1) on deployment

harness (2).

15) Connect deployment harness (2) to 12 volts vehicle

battery (3). This will immediately deploy or activate

air bag (inflator) module or seat belt pretensioners.

16) Disconnect deployment harness (2) from 12 volts

vehicle battery (3) and short two deployment

harness leads together by fully seating one banana

plug into the other.

17) Repeat Steps 3) through 16) to deploy / activate air

bag (inflator) modules and seat belt pretensioners

which has not been deployed / activated, if any.

18) In the unlikely event that air bag (inflator) module

and seat belt pretensioners after following these

procedures, proceed immediately with Step 24)

through 26). If air bag (inflator) module and seat belt

pretensioners did deploy / activate, proceed with

Steps 19) through 23).

19) Carefully remove drop cloth from vehicle and clean

off any fragments or discard it entirely.

20) Put on pair of shop gloves to protect your hands from

possible irritation and heat when handling deployed

air bag (inflator) module and activated seat belt

pretensioners.

10 m (33 ft)

1

2

I5RW0A820089-01

1

3 2

I5RW0A820090-01

Page 1156 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-117 Air Bag System:

21) Disconnect adapter cable (special tool) from air bag

(inflator) module or seat belt pretensioner as soon as

possible. This will prevent adapter cable (special

tool) from damage due to possible contact with hot

air bag (inflator) module or hot seat belt

pretensioner.

22) Check adapter cable connector as follows.

Adapter cable connector (special tool) is designed to

be reused. However it should be inspected for

damage after deployment and replaced if necessary.

23) With air bag (inflator) modules deployed and seat

belt pretensioners activated, vehicle may be

scrapped in the same manner as non-air bag system

/ seat belt pretensioner equipped vehicle.

NOTE

Remaining steps are to be followed in the

unlikely event that air bag (inflator) module

did not deploy or seat belt pretensioner did

not activate.

24) Remove undeployed air bag (inflator) module(s) and/

or inactivated seat belt pretensioner(s) from vehicle.

For driver air bag (inflator) module, refer to “Driver

Air Bag (Inflator) Module Removal and Installation”.

For passenger air bag (inflator) module, refer to

“Passenger Air Bag (Inflator) Module Removal and

Installation”. For side air bag (inflator) module, refer

to “Side-Air Bag (Inflator) Module Removal and

Installation”. For side curtain-air bag (inflator)

module, refer to “Side Curtain-Air Bag (Inflator)

Module Removal and Installation”. For seat belt

pretensioner, refer to “Front Seat Belt Removal and

Installation in Section 8A”.

25) Temporarily store undeployed air bag (inflator)

module referring to “Precautions on Service and

Diagnosis of Air Bag System” for details.

26) Contact your local distributor for further assistance.

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal

S6RW0D8206019

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which may cause

personal injury. The undeployed air bag

(inflator) module and the inactivated seat belt

pretensioner must not be disposed of

through normal refuse channels.

The undeployed air bag (inflator) module and

the inactivated seat belt pretensioner

contains substances that can cause severe

illness or personal injury if the sealed

container is damaged during disposal.

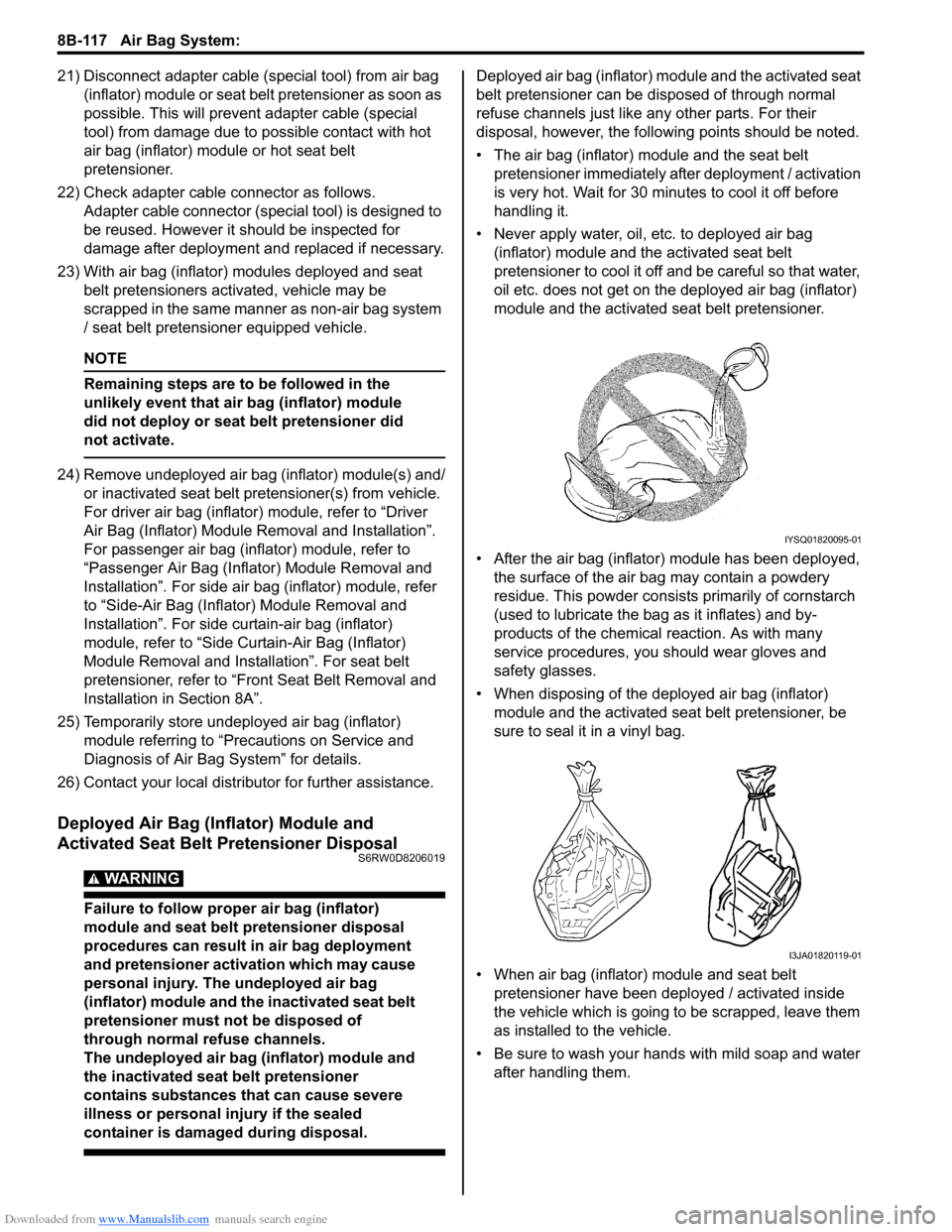

Deployed air bag (inflator) module and the activated seat

belt pretensioner can be disposed of through normal

refuse channels just like any other parts. For their

disposal, however, the following points should be noted.

• The air bag (inflator) module and the seat belt

pretensioner immediately after deployment / activation

is very hot. Wait for 30 minutes to cool it off before

handling it.

• Never apply water, oil, etc. to deployed air bag

(inflator) module and the activated seat belt

pretensioner to cool it off and be careful so that water,

oil etc. does not get on the deployed air bag (inflator)

module and the activated seat belt pretensioner.

• After the air bag (inflator) module has been deployed,

the surface of the air bag may contain a powdery

residue. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-

products of the chemical reaction. As with many

service procedures, you should wear gloves and

safety glasses.

• When disposing of the deployed air bag (inflator)

module and the activated seat belt pretensioner, be

sure to seal it in a vinyl bag.

• When air bag (inflator) module and seat belt

pretensioner have been deployed / activated inside

the vehicle which is going to be scrapped, leave them

as installed to the vehicle.

• Be sure to wash your hands with mild soap and water

after handling them.

IYSQ01820095-01

I3JA01820119-01

Page 1174 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-7 Wiring Systems:

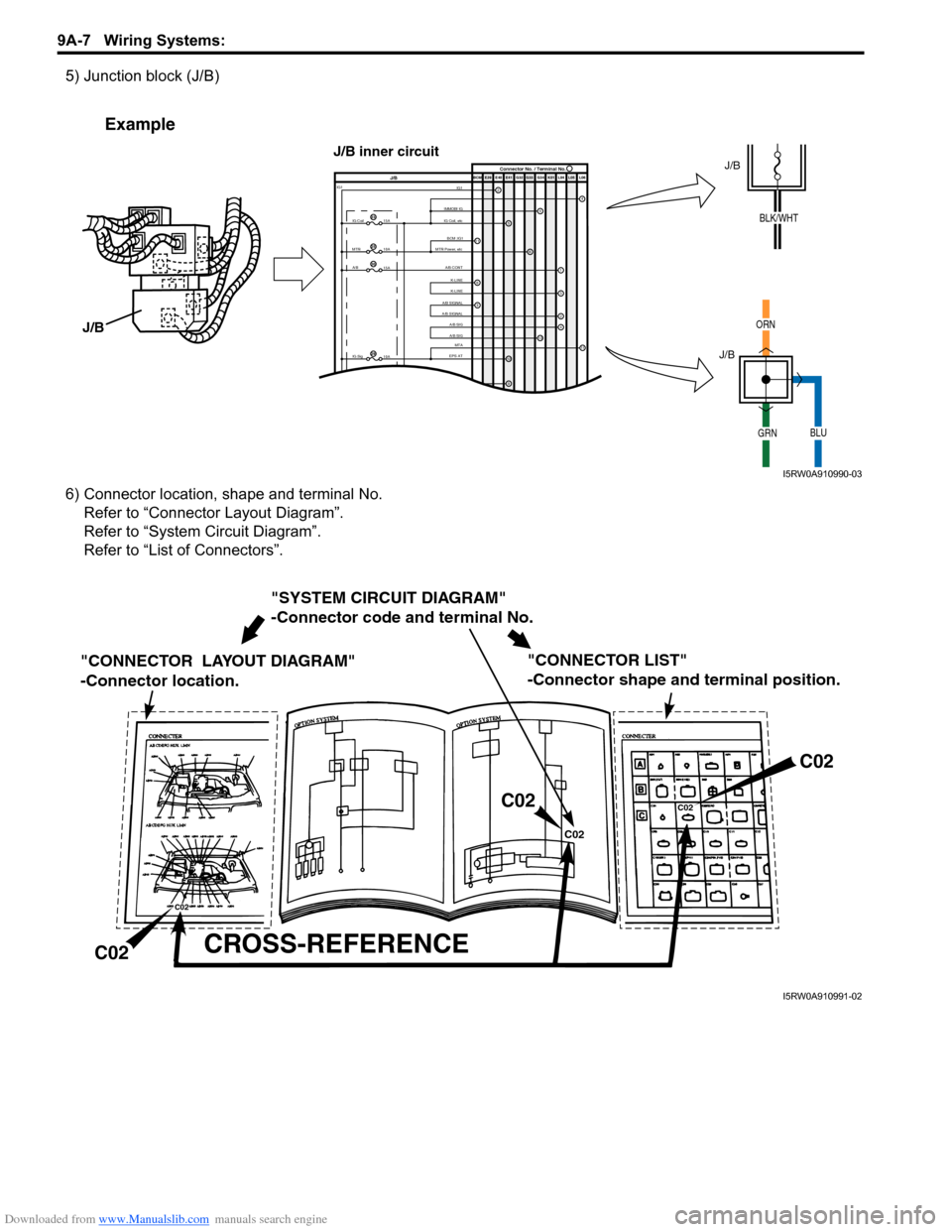

5) Junction block (J/B)

6) Connector location, shape and terminal No.

Refer to “Connector Layout Diagram”.

Refer to “System Circuit Diagram”.

Refer to “List of Connectors”.

IMMOBI IGIG1IG Coil, etcE39 E41E40 BCM G34G33 G32 K01 L04 L05 L06

IG Coil IG1

15A

MTR

10A

A/B

15A

2

65

13

J/BConnector No. / Terminal No.

BCM ;IG1

MTR Power, etc

A/B CONTK-LINE

K-LINE

A/B SIGNAL

A/B SIGNAL

A/B SIG

A/B SIG

IG Sig

10AEPS ATMTA

4

6

1

3

24

8

11

9

12

9

11

23

25

30

29

Example

J/B

J/B

ORN

GRNBLU

J/B

J/B inner circuit

BLK/WHT

I5RW0A910990-03

"SYSTEM CIRCUIT DIAGRAM"

-Connector code and terminal No.

"CONNECTOR LAYOUT DIAGRAM"

-Connector location.

CROSS-REFERENCE

"CONNECTOR LIST"

-Connector shape and terminal position.

C02

C02C02

C02

C02

C02

I5RW0A910991-02

Page 1211 of 1556

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-44

1IG2 SW2

6

LAMP FL

1A/B CONT

A/B SIGNAL

K-LINE

K-LINE

A/B SIGNAL

BCM IG1

D/SL-IN

D/L-IN

D/UL-1

SEQULITY IN

HAZARD

TAIL BCM

D/L (BCM)

RR DEF RLY

BCM (+B)

DOME LP CONT

ACC

R/WIP

GND

SIGNAL GND (BCM)4A/B IND

32

98

2511

2423

206

1412

181

215

107

2217

3

1IG

3LP-L2LP-R

4+B5SW-L

7GND6SW-R

8HAZ

DOME LP (+B)543GND SPARE-1 DOME LP DOOR6HTR4ST1IG25ACC3IG SW (+B)2IG1

18107G271415G2727G27219G2721G27212G2719G27111G2723G2722G2728G272166G2716G2725G271810511G27113G2724G2721G27120G2722G2719G2723G27112G27214G272

10E3235E32512E3259E32514E3251E3258E3252E32511E3253E3256E3235E32316E3257E3254E3232E3239E3233E3237E32310E325 DEF IND RR FOG(+B)

*

*

TAIL(+B)

TAIL SW

TURN SW-L

TURN SW-R

METER (L)

METER (R)

HAZARD SW

HORN SW

H/L LVL SW

*

*

MTR (IG) ANGLE SENSOR

IG COIL

DOME +B

4WD CONT

ACC 2

A/B INDACC 1

F-WIP (RLY)

R-WASHER

*

*

* *

*GND (IP)

SIGNAL GND (IP)

*

*

*

IG COIL

EPS AT

ABS CONT

BACK

STOP SW

EPI

BUL IN

HORN

FR TURN (R)

FR TURN (L)

POSI LP

* *

EPI

STOP SW

F-WIP

HTR FUSE

ST RLY COIL

4

L314

15

L314

16

L314

5

L314

9

L314

212

L314

13

L315

14

L315

7

L315

15

L315

14

L314

11

L314

6

L315

5

L315

8

L314

7

L314

6

L314

18

L314

3

L314

L314

110

L314

9

L315

10

L315

1

L315

3

L315

2

L315

8

L315

11

L315

4

L315 SIGNAL GND (FL)

SEAT HTR

P/W

R-WIP (-)* *ACC 2

ACC 1*

*

DOME (+B)

* * *

*

RR DEF

HTR MIR (L)

HTR MIR (R)

TAIL LP, LICENSEPOWER DR

RR-TURN (L)

RR-TURN (R)

BUL-LD/L-1

D/SL-1 D/UL-1

STOP LP

IG1 ABS

*

*

IG COIL 15A

MTR 10A

A/B 15A

IG1 SIG 10A

ABS 10A

BACK 10A

TAIL 10A

D/L 20A

P/WT 20A

RR DEF 30A

RR FOG 15A

SPARE-2

ACC 15A

ACC 2 15A

WIP 30A

P/W 30A

RR WIP 15A

S/H 15A

IG2 SIG 10A

ST SIG 10A HORN HAZ 15A

STOP 15A4WD 15ARR DEF RLY

SPARE-3

HORN RLY

RR WIP RLY

G272 G272

G271

G272

G271

G272 G271

L314

DOME 15A

To instrument panel harness

(G273)*: Not used To floor harness

(L312)

To instrument panel

harness

(G271 , G272)

To main harness

(E323 , E325)

To floor harness (L314 , L315)To main

harness

(E324)

BCM

To flasher

relayTo floor

harness

(L313)

BLOWER FAN RLY

I6RW0D910904-03

Page 1212 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-45 Wiring Systems:

Junction Block Inner Circuit (Detail (Except Taiwan))S6RW0D910D011

BCM (J/B side connector)

3

4

1

25

15 14 12

13 10

11 9 8 67

17

16182122 19

20

23

1234578 116

12 91034 652 1

G271 G273

G272

10

11 12 13 14 15 16 17 18 19123456789

20

345612L312

23414

3

561214 11

10

157 2 11316 9 8 6

5 4 3

2

1

7

11 10

9 8

15

14 13

1216

L313

L315 E325

2 1

123456789

15 16 17 18 11 10 12 13 14 1

234

5

678 910

E323

L314 E324

IG COIL

IG COILIG1

E323 E325E324 BCM G272G271 G273 L312 L313 L314 L315

IG COIL IG1

15A

MTR

10A

A/B

15A

2

6

5

13

J/BConnector No. / Terminal No.

MTR (IG)

A/B CONT

A/B IND

A/B IND

IG1 SIG

10AEPS AT

ABS CONT

STOP SW

STOP LP

EPI

BUL IN

BUL-LBACK H/L LVL SW

BCM IG111

6

1

4

2

A/B SIGNAL

A/B SIGNAL9

3

K-LINE

K-LINE8

12

9

14

2

3

1

2

11

8

ABS

10A

BACK

10A

ANGLE SENSOR

IG1 ABS16

8

1

(Continued)

Individual circuit fuse box No.2

(In J/B)

20

22

27

26

28

21

I6RW0C910923-01

Page 1218 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-51 Wiring Systems:

1IG2 SW2

6

LAMP FL

1A/B CONT4A/B IND

32

98

2511

2423

206

1412

181

215

107

2217

3

1IG

3LP-L2LP-R

4+B5SW-L

7GND6SW-R

8HAZ

DOME LP (+B)543GND SPARE-16HTR4ST1IG25ACC3IG SW (+B)2IG1

18107G271415G2727G27219G2721G27212G2719G27111G2723G2722G2728G272166G2716G2725G271810511G27113G2724G2721G27120G2722G2719G2723G27112G27214G272

10E3235E32512E3259E32514E3251E3258E3252E32511E3253E3256E3235E32316E3257E3254E3232E3239E3233E3237E32310E325 DEF INDTAIL IND

*

*D/L

TAIL SW

TURN SW-L

TURN SW-R

METER (L)

METER (R)

HAZARD SW

HORN SW

H/L LVL SW

*

*

*

MTR (IG) ANGLE SENSOR

IG COIL

DOME +B

ACC 2

A/B INDACC 1

F-WIP (RLY) R-WIP (CONT)

R-WASHER

TAIL RLY

RR DEF RLY

*GND (IP)

SIGNAL GND (IP)* * * * * * * * * * * * * * *

*

*

*

*

*

*

*

*

IG COIL

EPS AT

ABS CONT

BACK

STOP SW

EPI

BUL IN

HORN

FR TURN (R)

FR TURN (L)

POSI LP

* *

*EPI

STOP SW

F-WIP

HTR FUSE

ST RLY COIL

4

L314

15

L314

16

L314

5

L314

9

L314

212

L314

13

L315

14

L315

7

L315

15

L315

14

L314

11

L314

6

L315

5

L315

8

L314

7

L314

6

L314

18

L314

3

L314

L314

110

L314

9

L315

10

L315

1

L315

3

L315

2

L315

8

L315

11

L315

4

L315 SIGNAL GND (FL)

P/W

R-WIP (-)* * *ACC 2

ACC 1*

*

DOME (+B)

* * *

*

*

*

*

*

RR DEF

HTR MIR (L)

HTR MIR (R)

TAIL LP, LICENSE

RR-TURN (L)

RR-TURN (R)

BUL-L

STOP LP

IG1 ABS

*

*

IG COIL 15A

MTR 10A

A/B 15A

IG1 SIG 10A

ABS 10A

BACK 10A

SPARE-2

D/L 20A

SPARE-3

RR DEF 30A

TAIL 10A

SPARE-4

ACC 15A

ACC 2 15A

WIP 30A

P/W 30A

RR WIP 15A

SPARE-6

IG2 SIG 10A

ST SIG 10A HORN HAZ 15A

STOP 15ASPARE-5RR DEF RLY

TAIL LIGHT RLY

HORN RLY

RR WIP RLY

G272 G272

G271

G272

G271

G272 G271

L314

DOME 15A

To instrument panel harness

(G273)*: Not used To floor harness

(L312)

To instrument panel

harness

(G271 , G272)

To main harness

(E323 , E325)

To floor harness (L314 , L315)To main

harness

(E324)

BCM

To flasher

relayTo floor

harness

(L313)

BLOWER FAN RLY

I6RW0C910928-02

Page 1219 of 1556

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-52

Junction Block Inner Circuit (Detail (Taiwan))S6RW0D910D008

BCM (J/B side connector)

3

4

1

25

15 14 12

13 10

11 9 8 67

17

16182122 19

20

23

1234578 116

12 91034 652 1

G271 G273

G272

10

11 12 13 14 15 16 17 18 19123456789

20

345612L312

23414

3

561214 11

10

157 2 11316 9 8 6

5 4 3

2

1

7

11 10

9 8

15

14 13

1216

L313

L315 E325

2 1

123456789

15 16 17 18 11 10 12 13 14 1

234

5

678 910

E323

L314 E324

IG COIL

IG COILIG1

E323 E325E324 BCM G272G271 G273 L312 L313 L314 L315

IG COIL IG1

15A

MTR

10A

A/B

15A

2

6

5

13

J/BConnector No. / Terminal No.

MTR (IG)

A/B CONT

A/B IND

A/B IND

IG1 SIG

10AEPS AT

ABS CONT

STOP SW

STOP LP

EPI

BUL IN

BUL-LBACK H/L LVL SW

6

1

4

12

9

14

2

3

1

2

11

8

ABS

10A

BACK

10A

ANGLE SENSOR

IG1 ABS16

8

1

(Continued)

Individual circuit fuse box No.2

(In J/B)

20

22

27

26

28

21

I7RW01910916-04

Page 1347 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-28

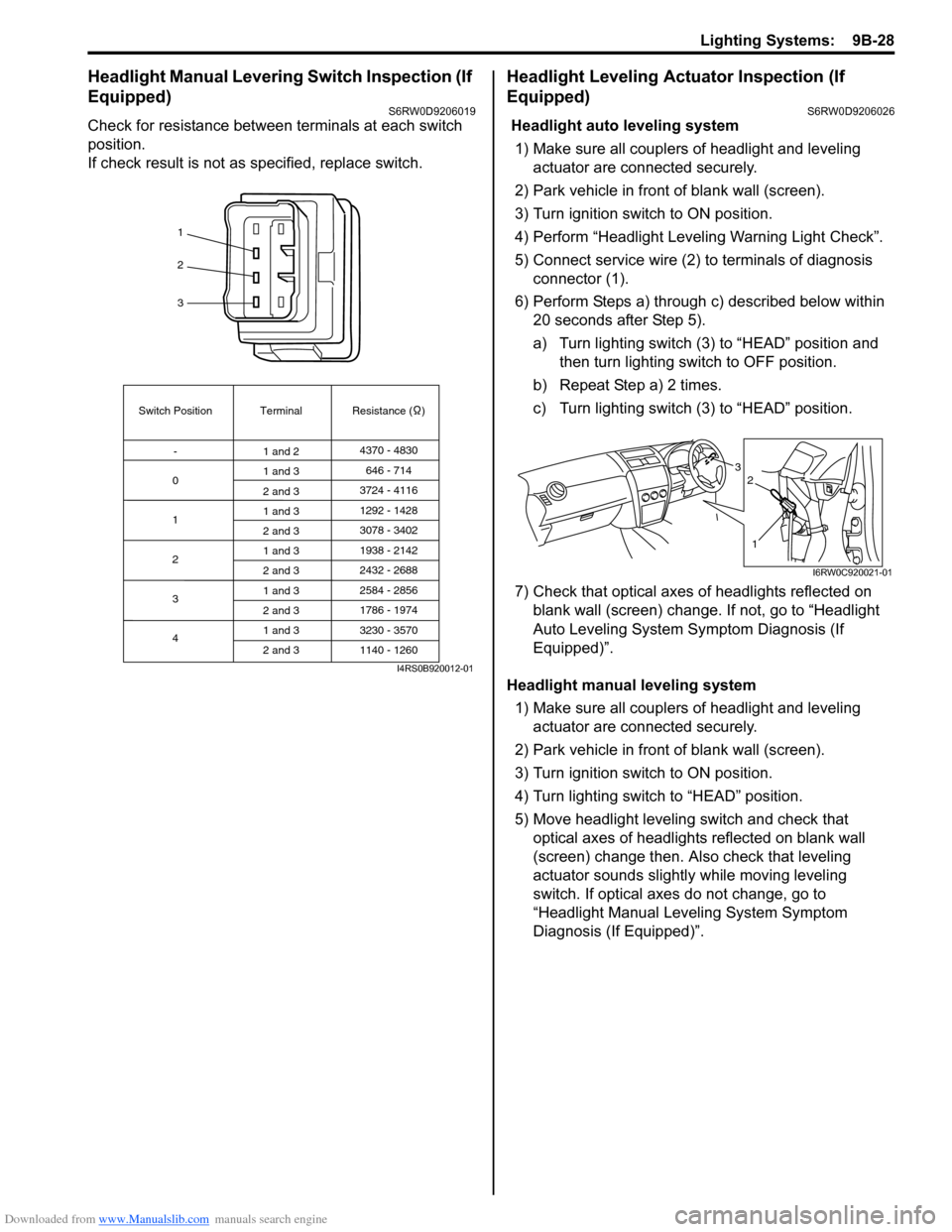

Headlight Manual Levering Switch Inspection (If

Equipped)

S6RW0D9206019

Check for resistance between terminals at each switch

position.

If check result is not as specified, replace switch.

Headlight Leveling Actuator Inspection (If

Equipped)

S6RW0D9206026

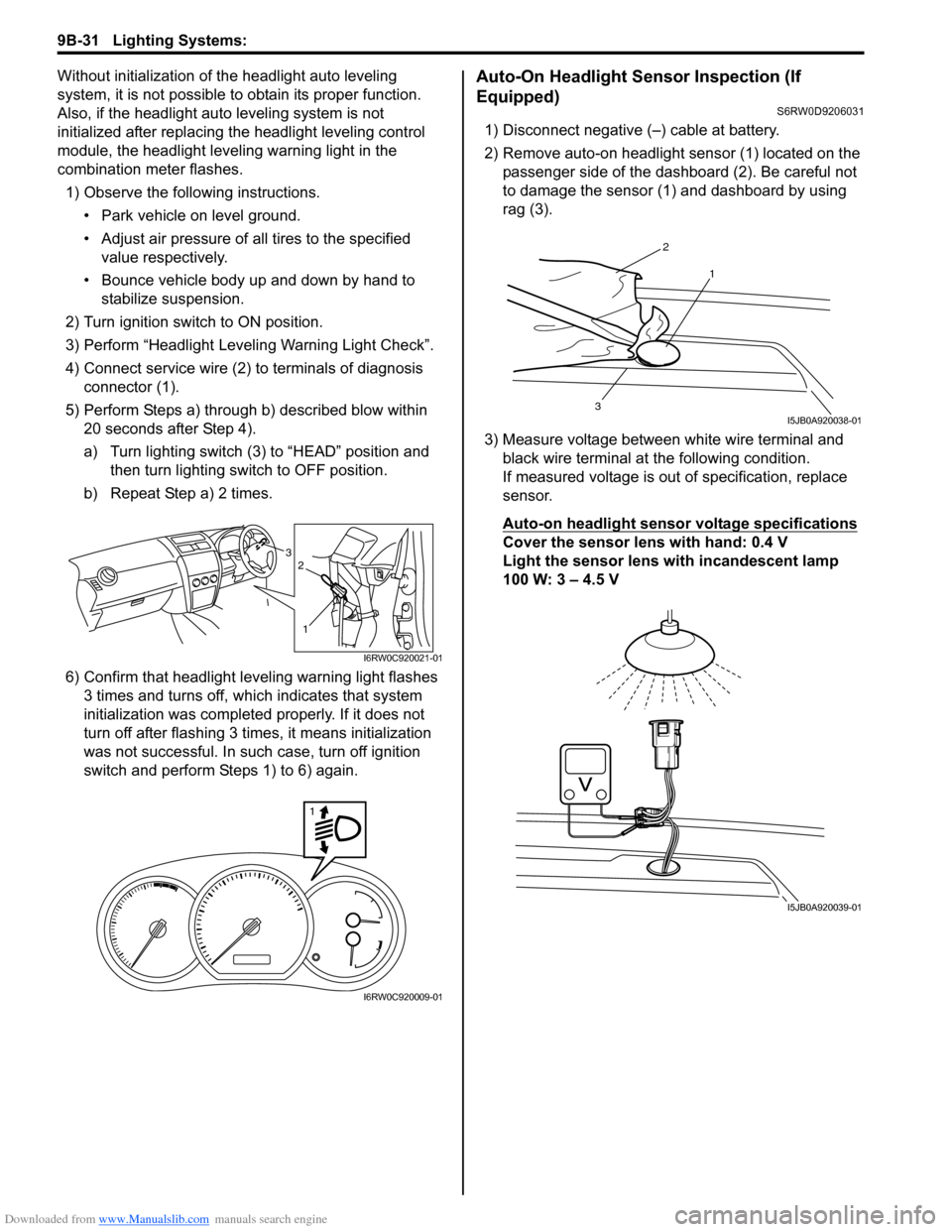

Headlight auto leveling system

1) Make sure all couplers of headlight and leveling

actuator are connected securely.

2) Park vehicle in front of blank wall (screen).

3) Turn ignition switch to ON position.

4) Perform “Headlight Leveling Warning Light Check”.

5) Connect service wire (2) to terminals of diagnosis

connector (1).

6) Perform Steps a) through c) described below within

20 seconds after Step 5).

a) Turn lighting switch (3) to “HEAD” position and

then turn lighting switch to OFF position.

b) Repeat Step a) 2 times.

c) Turn lighting switch (3) to “HEAD” position.

7) Check that optical axes of headlights reflected on

blank wall (screen) change. If not, go to “Headlight

Auto Leveling System Symptom Diagnosis (If

Equipped)”.

Headlight manual leveling system

1) Make sure all couplers of headlight and leveling

actuator are connected securely.

2) Park vehicle in front of blank wall (screen).

3) Turn ignition switch to ON position.

4) Turn lighting switch to “HEAD” position.

5) Move headlight leveling switch and check that

optical axes of headlights reflected on blank wall

(screen) change then. Also check that leveling

actuator sounds slightly while moving leveling

switch. If optical axes do not change, go to

“Headlight Manual Leveling System Symptom

Diagnosis (If Equipped)”.

1

2

3

Switch Position

0Terminal Resistance ( )

-

1

2

3

41 and 24370 - 4830

1 and 3

2 and 3

1 and 3

2 and 3

1 and 3

2 and 3

1 and 3

2 and 3

1 and 3

2 and 3646 - 714

3724 - 4116

3078 - 3402 1292 - 1428

1938 - 2142

2584 - 2856

3230 - 3570 2432 - 2688

1786 - 1974

1140 - 1260

I4RS0B920012-01

3

1

2

I6RW0C920021-01

Page 1350 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-31 Lighting Systems:

Without initialization of the headlight auto leveling

system, it is not possible to obtain its proper function.

Also, if the headlight auto leveling system is not

initialized after replacing the headlight leveling control

module, the headlight leveling warning light in the

combination meter flashes.

1) Observe the following instructions.

• Park vehicle on level ground.

• Adjust air pressure of all tires to the specified

value respectively.

• Bounce vehicle body up and down by hand to

stabilize suspension.

2) Turn ignition switch to ON position.

3) Perform “Headlight Leveling Warning Light Check”.

4) Connect service wire (2) to terminals of diagnosis

connector (1).

5) Perform Steps a) through b) described blow within

20 seconds after Step 4).

a) Turn lighting switch (3) to “HEAD” position and

then turn lighting switch to OFF position.

b) Repeat Step a) 2 times.

6) Confirm that headlight leveling warning light flashes

3 times and turns off, which indicates that system

initialization was completed properly. If it does not

turn off after flashing 3 times, it means initialization

was not successful. In such case, turn off ignition

switch and perform Steps 1) to 6) again.Auto-On Headlight Sensor Inspection (If

Equipped)

S6RW0D9206031

1) Disconnect negative (–) cable at battery.

2) Remove auto-on headlight sensor (1) located on the

passenger side of the dashboard (2). Be careful not

to damage the sensor (1) and dashboard by using

rag (3).

3) Measure voltage between white wire terminal and

black wire terminal at the following condition.

If measured voltage is out of specification, replace

sensor.

Auto-on headlight sensor voltage specifications

Cover the sensor lens with hand: 0.4 V

Light the sensor lens with incandescent lamp

100 W: 3 – 4.5 V3

1

2

I6RW0C920021-01

1

I6RW0C920009-01

2

1

3I5JB0A920038-01

I5JB0A920039-01