Eps SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 388 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-11 Fuel System:

4) Install suitable vinyl tube onto injector nozzle to

prevent fuel from splashing out when injecting.

5) Put graduated cylinder under injector.

6) Operate fuel pump and apply fuel pressure to

injector as follows:

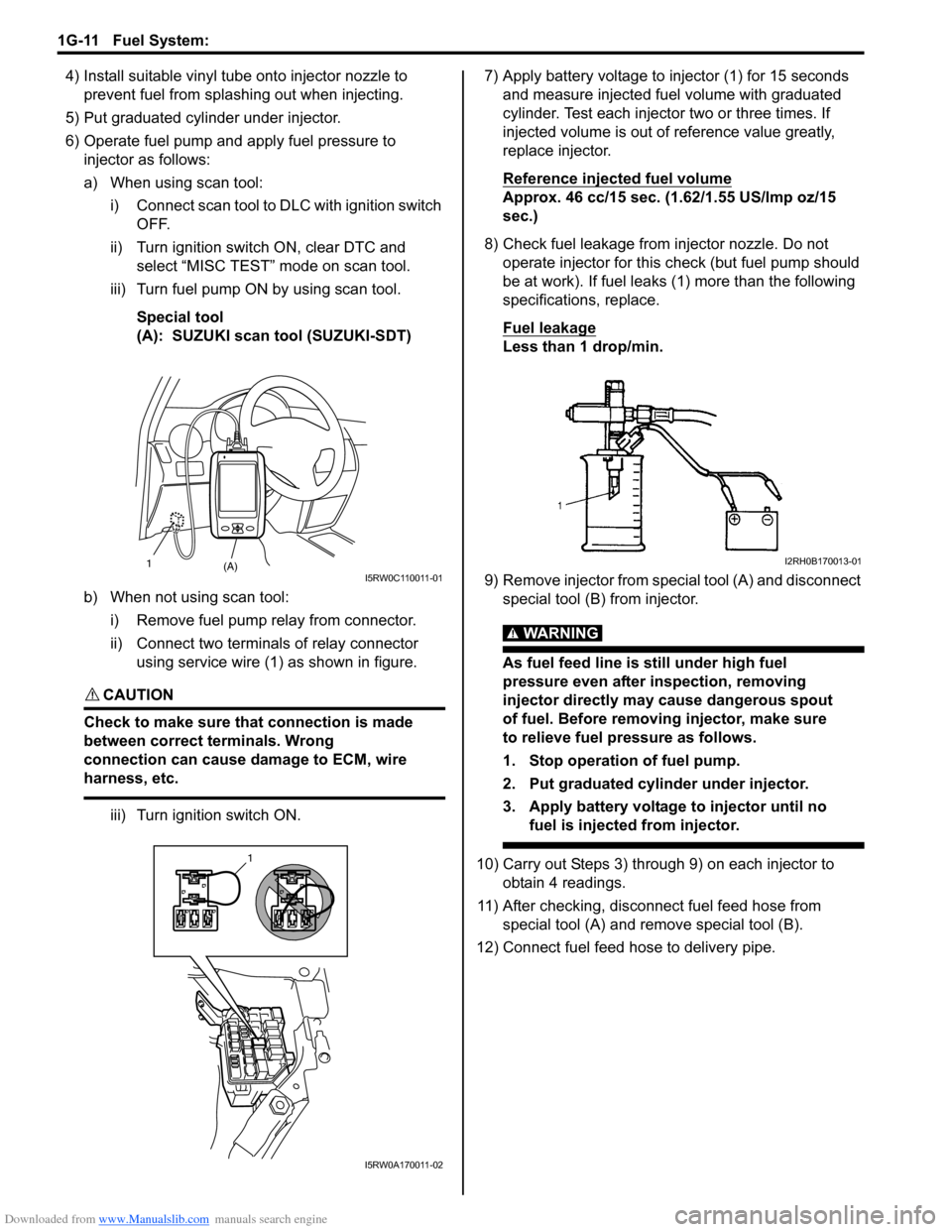

a) When using scan tool:

i) Connect scan tool to DLC with ignition switch

OFF.

ii) Turn ignition switch ON, clear DTC and

select “MISC TEST” mode on scan tool.

iii) Turn fuel pump ON by using scan tool.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)

b) When not using scan tool:

i) Remove fuel pump relay from connector.

ii) Connect two terminals of relay connector

using service wire (1) as shown in figure.

CAUTION!

Check to make sure that connection is made

between correct terminals. Wrong

connection can cause damage to ECM, wire

harness, etc.

iii) Turn ignition switch ON.7) Apply battery voltage to injector (1) for 15 seconds

and measure injected fuel volume with graduated

cylinder. Test each injector two or three times. If

injected volume is out of reference value greatly,

replace injector.

Reference injected fuel volume

Approx. 46 cc/15 sec. (1.62/1.55 US/lmp oz/15

sec.)

8) Check fuel leakage from injector nozzle. Do not

operate injector for this check (but fuel pump should

be at work). If fuel leaks (1) more than the following

specifications, replace.

Fuel leakage

Less than 1 drop/min.

9) Remove injector from special tool (A) and disconnect

special tool (B) from injector.

WARNING!

As fuel feed line is still under high fuel

pressure even after inspection, removing

injector directly may cause dangerous spout

of fuel. Before removing injector, make sure

to relieve fuel pressure as follows.

1. Stop operation of fuel pump.

2. Put graduated cylinder under injector.

3. Apply battery voltage to injector until no

fuel is injected from injector.

10) Carry out Steps 3) through 9) on each injector to

obtain 4 readings.

11) After checking, disconnect fuel feed hose from

special tool (A) and remove special tool (B).

12) Connect fuel feed hose to delivery pipe.

(A) 1I5RW0C110011-01

1

I5RW0A170011-02

I2RH0B170013-01

Page 421 of 1556

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-7

1) Set parking brake and place automatic transaxle in

PARK (NEUTRAL on manual transaxle). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line,

add distilled water.

3) Attach end of one jumper cable to positive terminal

of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to

negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

5) Start engine of vehicle with booster battery and turn

off electrical accessories. Then start engine of the

vehicle with discharged battery.

6) Disconnect jumper cables in the exact reverse order.

With Charging Equipment

CAUTION!

When jump starting engine with charging

equipment, be sure equipment used is 12-

volt and negative ground. Do not use 24-volt

charging equipment. Using such equipment

can cause serious damage to electrical

system or electronic parts.

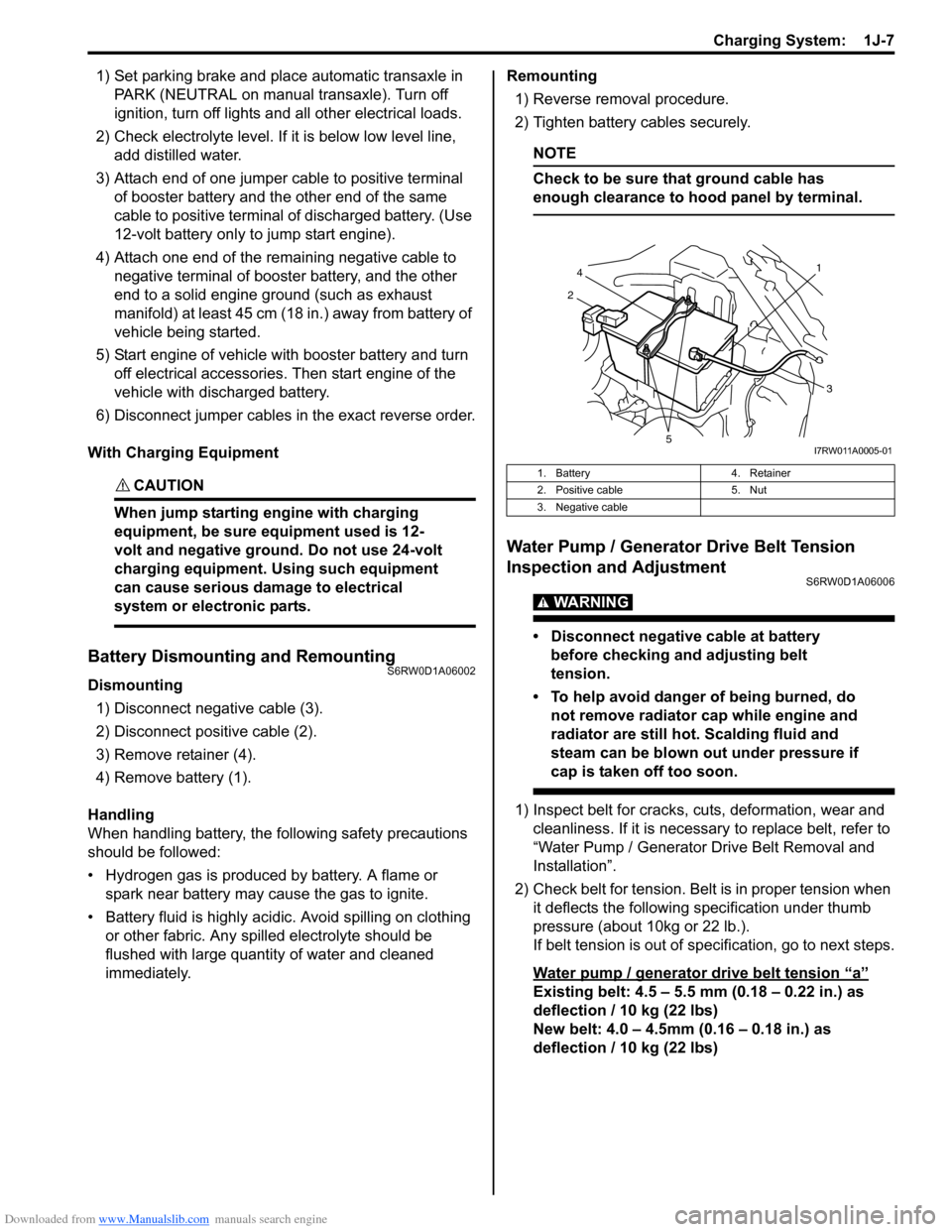

Battery Dismounting and RemountingS6RW0D1A06002

Dismounting

1) Disconnect negative cable (3).

2) Disconnect positive cable (2).

3) Remove retainer (4).

4) Remove battery (1).

Handling

When handling battery, the following safety precautions

should be followed:

• Hydrogen gas is produced by battery. A flame or

spark near battery may cause the gas to ignite.

• Battery fluid is highly acidic. Avoid spilling on clothing

or other fabric. Any spilled electrolyte should be

flushed with large quantity of water and cleaned

immediately.Remounting

1) Reverse removal procedure.

2) Tighten battery cables securely.

NOTE

Check to be sure that ground cable has

enough clearance to hood panel by terminal.

Water Pump / Generator Drive Belt Tension

Inspection and Adjustment

S6RW0D1A06006

WARNING!

• Disconnect negative cable at battery

before checking and adjusting belt

tension.

• To help avoid danger of being burned, do

not remove radiator cap while engine and

radiator are still hot. Scalding fluid and

steam can be blown out under pressure if

cap is taken off too soon.

1) Inspect belt for cracks, cuts, deformation, wear and

cleanliness. If it is necessary to replace belt, refer to

“Water Pump / Generator Drive Belt Removal and

Installation”.

2) Check belt for tension. Belt is in proper tension when

it deflects the following specification under thumb

pressure (about 10kg or 22 lb.).

If belt tension is out of specification, go to next steps.

Water pump / generator drive belt tension

“a”

Existing belt: 4.5 – 5.5 mm (0.18 – 0.22 in.) as

deflection / 10 kg (22 lbs)

New belt: 4.0 – 4.5mm (0.16 – 0.18 in.) as

deflection / 10 kg (22 lbs)

1. Battery 4. Retainer

2. Positive cable 5. Nut

3. Negative cable

21

4

3

5I7RW011A0005-01

Page 603 of 1556

Downloaded from www.Manualslib.com manuals search engine Parking Brake: 4D-2

Repair Instructions

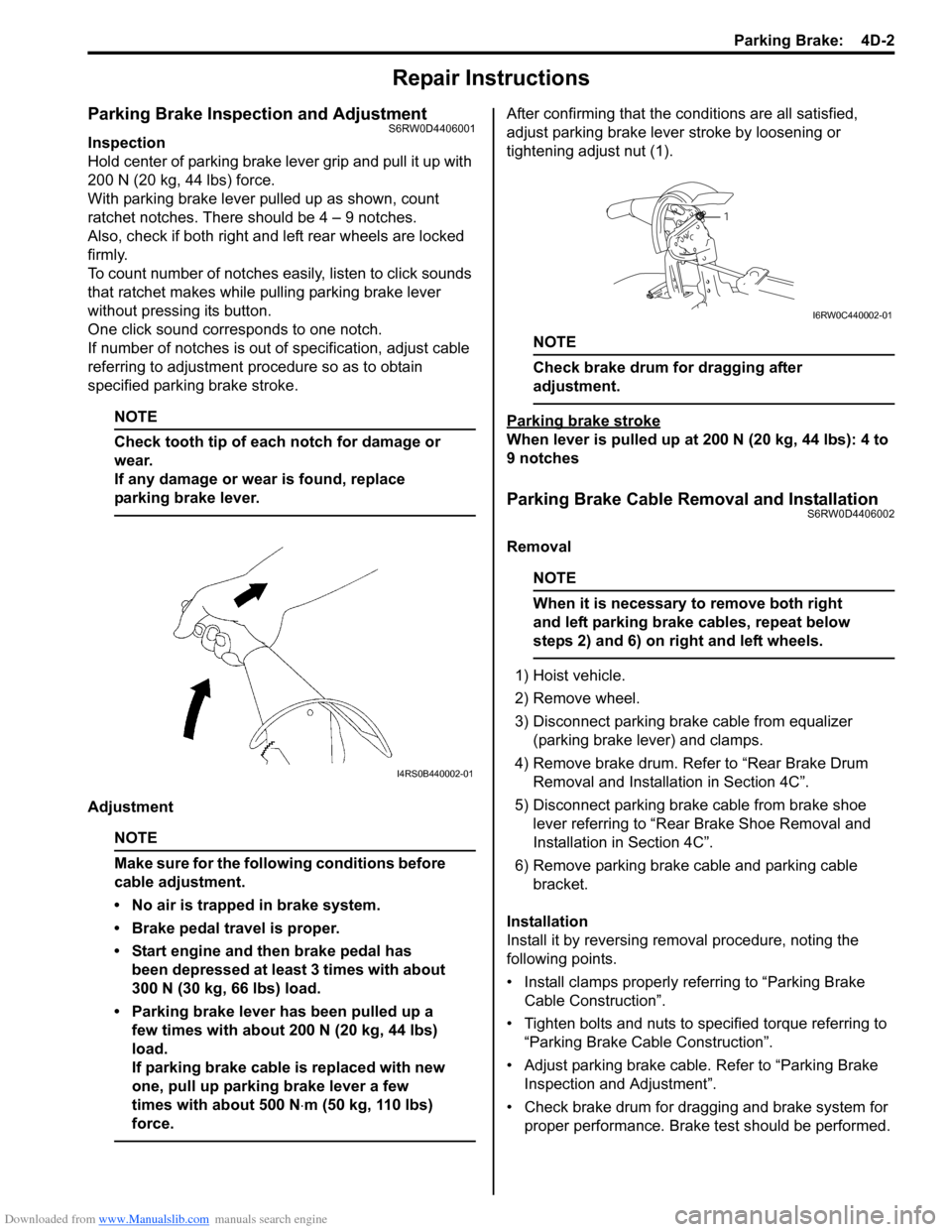

Parking Brake Inspection and AdjustmentS6RW0D4406001

Inspection

Hold center of parking brake lever grip and pull it up with

200 N (20 kg, 44 lbs) force.

With parking brake lever pulled up as shown, count

ratchet notches. There should be 4 – 9 notches.

Also, check if both right and left rear wheels are locked

firmly.

To count number of notches easily, listen to click sounds

that ratchet makes while pulling parking brake lever

without pressing its button.

One click sound corresponds to one notch.

If number of notches is out of specification, adjust cable

referring to adjustment procedure so as to obtain

specified parking brake stroke.

NOTE

Check tooth tip of each notch for damage or

wear.

If any damage or wear is found, replace

parking brake lever.

Adjustment

NOTE

Make sure for the following conditions before

cable adjustment.

• No air is trapped in brake system.

• Brake pedal travel is proper.

• Start engine and then brake pedal has

been depressed at least 3 times with about

300 N (30 kg, 66 lbs) load.

• Parking brake lever has been pulled up a

few times with about 200 N (20 kg, 44 lbs)

load.

If parking brake cable is replaced with new

one, pull up parking brake lever a few

times with about 500 N⋅m (50 kg, 110 lbs)

force.

After confirming that the conditions are all satisfied,

adjust parking brake lever stroke by loosening or

tightening adjust nut (1).

NOTE

Check brake drum for dragging after

adjustment.

Parking brake stroke

When lever is pulled up at 200 N (20 kg, 44 lbs): 4 to

9 notches

Parking Brake Cable Removal and InstallationS6RW0D4406002

Removal

NOTE

When it is necessary to remove both right

and left parking brake cables, repeat below

steps 2) and 6) on right and left wheels.

1) Hoist vehicle.

2) Remove wheel.

3) Disconnect parking brake cable from equalizer

(parking brake lever) and clamps.

4) Remove brake drum. Refer to “Rear Brake Drum

Removal and Installation in Section 4C”.

5) Disconnect parking brake cable from brake shoe

lever referring to “Rear Brake Shoe Removal and

Installation in Section 4C”.

6) Remove parking brake cable and parking cable

bracket.

Installation

Install it by reversing removal procedure, noting the

following points.

• Install clamps properly referring to “Parking Brake

Cable Construction”.

• Tighten bolts and nuts to specified torque referring to

“Parking Brake Cable Construction”.

• Adjust parking brake cable. Refer to “Parking Brake

Inspection and Adjustment”.

• Check brake drum for dragging and brake system for

proper performance. Brake test should be performed.

I4RS0B440002-01

1

I6RW0C440002-01

Page 615 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-10

Problem symptom confirmation

Check if what the customer claimed in “Customer

Questionnaire” is actually found in the vehicle and if that

symptom is found, whether it is identified as a failure.

(This step should be shared with the customer if

possible.) Check warning lights related to brake system

referring to “EBD Warning Light (Brake Warning Light)

Check” and “ABS Warning Light Check”.

DTC check, record and clearance

Perform “DTC Check” procedure, record it and then

clear it referring to “DTC Clearance”.

Recheck DTC referring to “DTC Check”.

When DTC which is recorded at DTC check procedure is

detected again after performing DTC clearance, go to

“Step 4: ABS Check: ” to proceed the diagnosis.

When DTC which is recorded at DTC check procedure is

not indicated anymore after performing DTC clearance,

ABS control module does not perform the system

diagnosis, or temporary abnormality may occur,

therefore go to “Step 2: Driving Test: ” to proceed the

diagnosis.

Step 2: Driving Test

Test drive the vehicle at 40 km/h (25 MPH) for more than

a minute and check if any trouble symptom (such as

abnormal lighting of ABS warning light) exists.

If the malfunction DTC is confirmed again at ignition

switch ON, driving test as described is not necessary.

Proceed to Step 3.

Step 3: DTC Check

Recheck DTC referring to “DTC Check”.

Step 4: ABS Check

According to ABS Check for the DTC confirmation in

Step 3, locate the cause of the trouble, namely in a

sensor, switch, wire harness, connector, actuator

assembly or other part and repair or replace faulty parts.

Step 5: Brakes Diagnosis

Check the parts or system suspected as a possible

cause referring to “Brakes Symptom Diagnosis in

Section 4A” and based on symptoms appearing on the

vehicle (symptom obtained through Steps 1 and 2 and

repair or replace faulty parts, if any).

Step 6: Check for Intermittent Problem

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of trouble code recorded in Step 1

to 3.

Step 7: Final Confirmation Test

Confirm that the problem symptom has gone and the

ABS is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear

the DTC once referring to “DTC Clearance” and perform

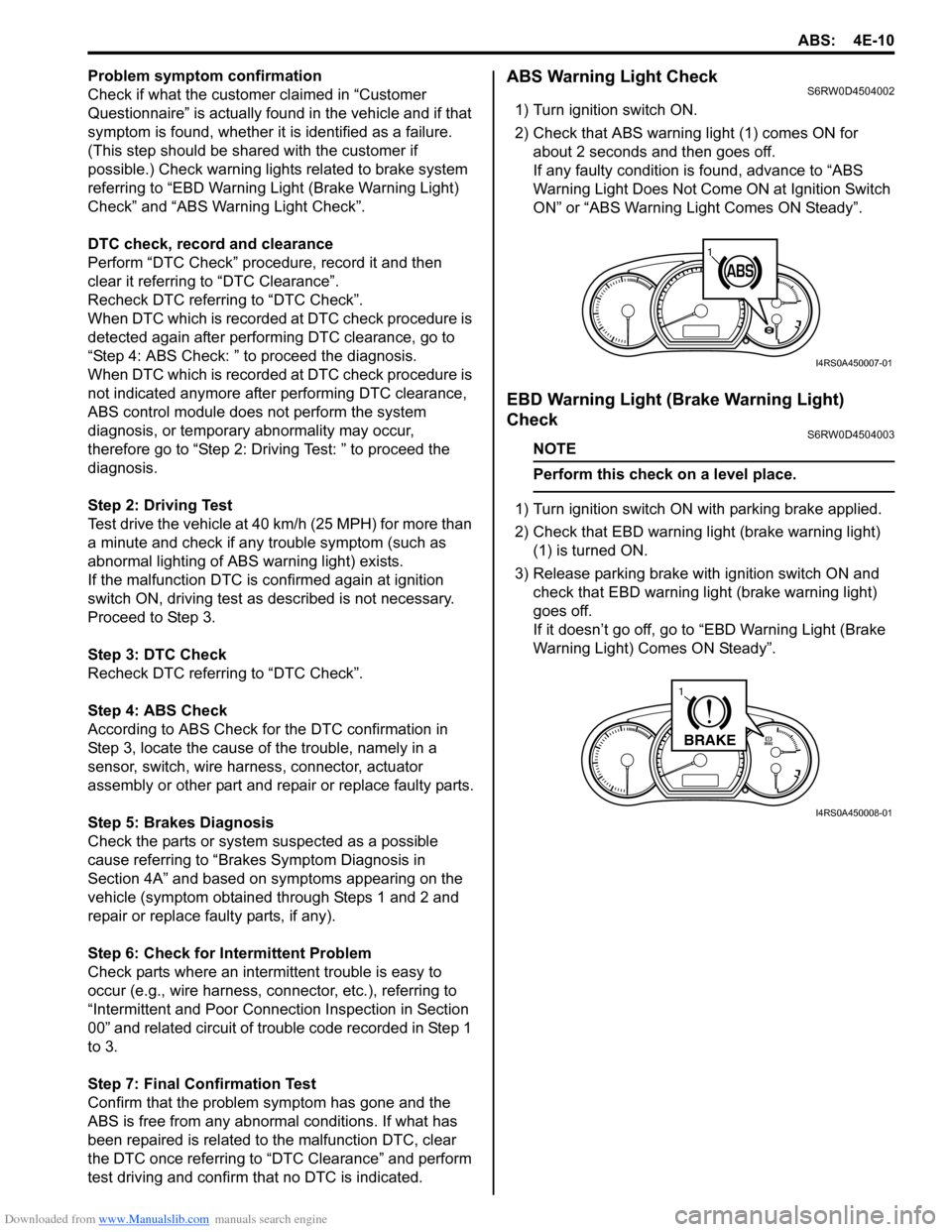

test driving and confirm that no DTC is indicated.ABS Warning Light CheckS6RW0D4504002

1) Turn ignition switch ON.

2) Check that ABS warning light (1) comes ON for

about 2 seconds and then goes off.

If any faulty condition is found, advance to “ABS

Warning Light Does Not Come ON at Ignition Switch

ON” or “ABS Warning Light Comes ON Steady”.

EBD Warning Light (Brake Warning Light)

Check

S6RW0D4504003

NOTE

Perform this check on a level place.

1) Turn ignition switch ON with parking brake applied.

2) Check that EBD warning light (brake warning light)

(1) is turned ON.

3) Release parking brake with ignition switch ON and

check that EBD warning light (brake warning light)

goes off.

If it doesn’t go off, go to “EBD Warning Light (Brake

Warning Light) Comes ON Steady”.

11

I4RS0A450007-01

BRAKE

1

I4RS0A450008-01

Page 619 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-14

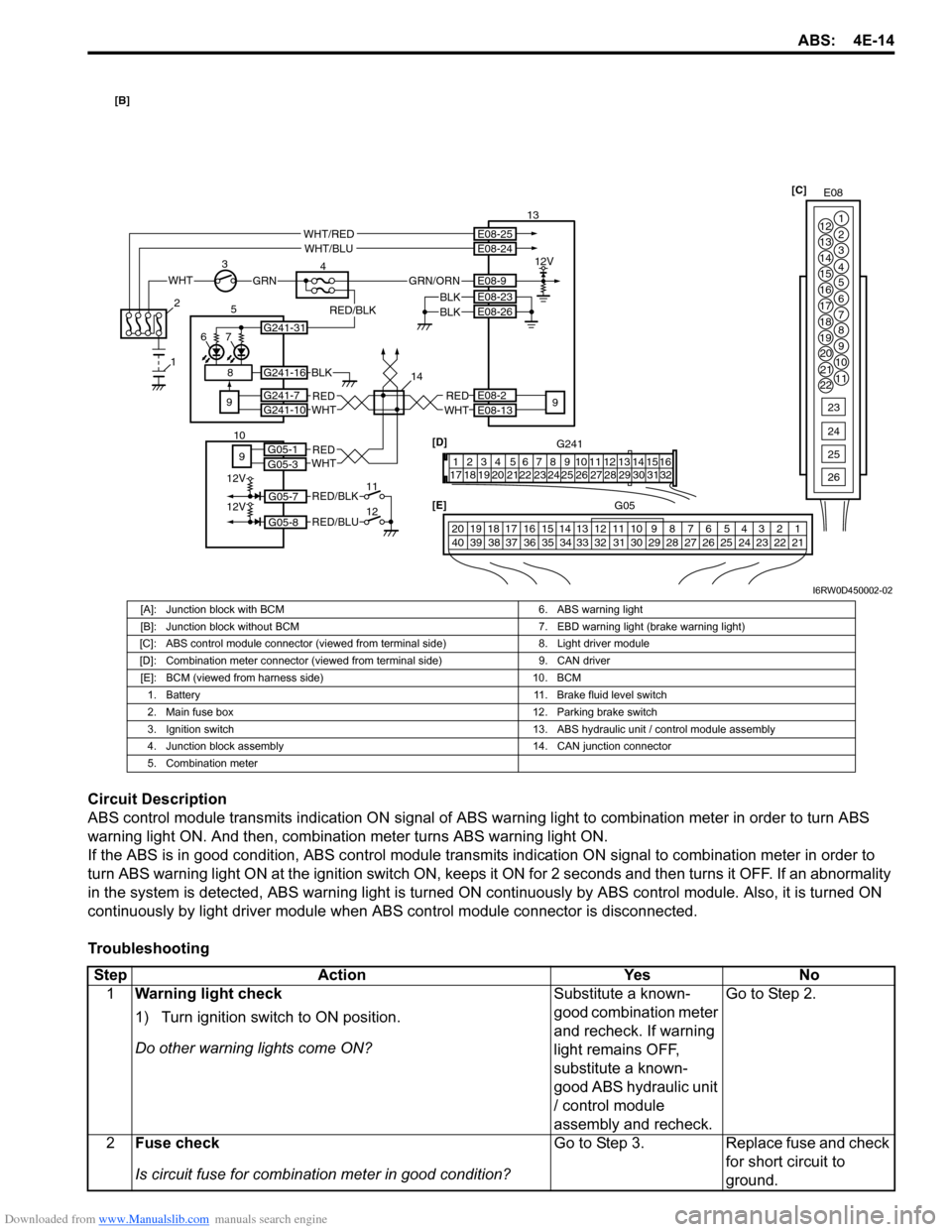

Circuit Description

ABS control module transmits indication ON signal of ABS warning light to combination meter in order to turn ABS

warning light ON. And then, combination meter turns ABS warning light ON.

If the ABS is in good condition, ABS control module transmits indication ON signal to combination meter in order to

turn ABS warning light ON at the ignition switch ON, keeps it ON for 2 seconds and then turns it OFF. If an abnormality

in the system is detected, ABS warning light is turned ON continuously by ABS control module. Also, it is turned ON

continuously by light driver module when ABS control module connector is disconnected.

Troubleshooting

G241 [D]

132 4 5 6 7 8 9 10111213141516

17 1918 20 2122 23 24 25 26 27 28 29 30 31 32E08 [C]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

G05 [E]

1 2 3 4 765 8 9 10 11 14 15 16

36 34 33 32 3135 24 23 2122 28 27 2526 37 39 38 4018 17 13 12 19 20

30 29

WHTGRN

3

E08-2

E08-13REDWHT 5

4 13

9

E08-23

E08-26BLKBLK

67

BLK

REDWHTG241-7G241-10

G241-16

12V

E08-25E08-24

E08-9

WHT/REDWHT/BLU

GRN/ORN

9

2

1

14

G241-31

RED/BLK

8

REDWHT9

12V

12V

11

12G05-7

G05-1G05-3

G05-8

RED/BLK

RED/BLU

10

[B]

I6RW0D450002-02

[A]: Junction block with BCM 6. ABS warning light

[B]: Junction block without BCM 7. EBD warning light (brake warning light)

[C]: ABS control module connector (viewed from terminal side) 8. Light driver module

[D]: Combination meter connector (viewed from terminal side) 9. CAN driver

[E]: BCM (viewed from harness side) 10. BCM

1. Battery 11. Brake fluid level switch

2. Main fuse box 12. Parking brake switch

3. Ignition switch 13. ABS hydraulic unit / control module assembly

4. Junction block assembly 14. CAN junction connector

5. Combination meter

Step Action Yes No

1Warning light check

1) Turn ignition switch to ON position.

Do other warning lights come ON?Substitute a known-

good combination meter

and recheck. If warning

light remains OFF,

substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Go to Step 2.

2Fuse check

Is circuit fuse for combination meter in good condition?Go to Step 3. Replace fuse and check

for short circuit to

ground.

Page 621 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-16

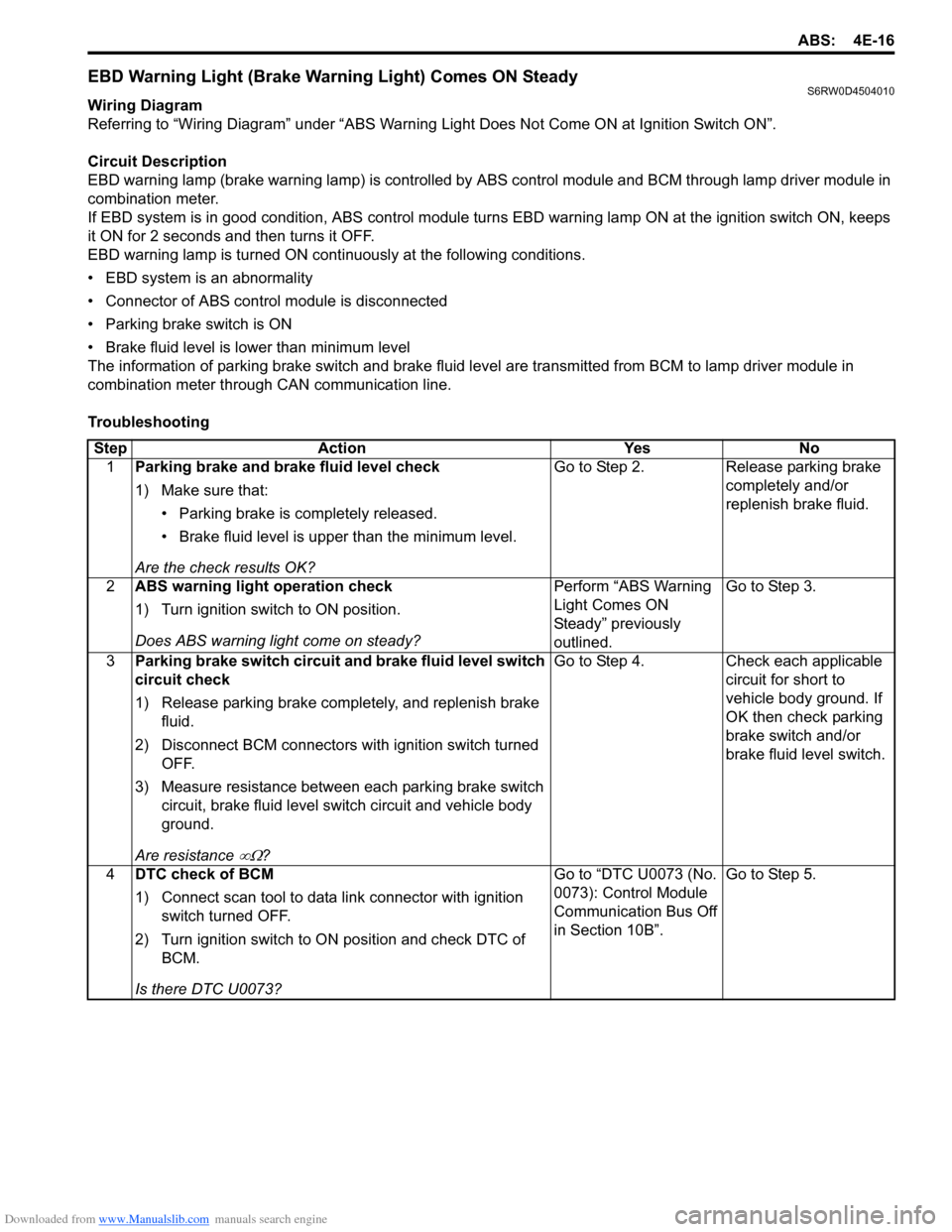

EBD Warning Light (Brake Warning Light) Comes ON SteadyS6RW0D4504010

Wiring Diagram

Referring to “Wiring Diagram” under “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

EBD warning lamp (brake warning lamp) is controlled by ABS control module and BCM through lamp driver module in

combination meter.

If EBD system is in good condition, ABS control module turns EBD warning lamp ON at the ignition switch ON, keeps

it ON for 2 seconds and then turns it OFF.

EBD warning lamp is turned ON continuously at the following conditions.

• EBD system is an abnormality

• Connector of ABS control module is disconnected

• Parking brake switch is ON

• Brake fluid level is lower than minimum level

The information of parking brake switch and brake fluid level are transmitted from BCM to lamp driver module in

combination meter through CAN communication line.

Troubleshooting

Step Action Yes No

1Parking brake and brake fluid level check

1) Make sure that:

• Parking brake is completely released.

• Brake fluid level is upper than the minimum level.

Are the check results OK?Go to Step 2. Release parking brake

completely and/or

replenish brake fluid.

2ABS warning light operation check

1) Turn ignition switch to ON position.

Does ABS warning light come on steady?Perform “ABS Warning

Light Comes ON

Steady” previously

outlined.Go to Step 3.

3Parking brake switch circuit and brake fluid level switch

circuit check

1) Release parking brake completely, and replenish brake

fluid.

2) Disconnect BCM connectors with ignition switch turned

OFF.

3) Measure resistance between each parking brake switch

circuit, brake fluid level switch circuit and vehicle body

ground.

Are resistance

∞Ω?Go to Step 4. Check each applicable

circuit for short to

vehicle body ground. If

OK then check parking

brake switch and/or

brake fluid level switch.

4DTC check of BCM

1) Connect scan tool to data link connector with ignition

switch turned OFF.

2) Turn ignition switch to ON position and check DTC of

BCM.

Is there DTC U0073?Go to “DTC U0073 (No.

0073): Control Module

Communication Bus Off

in Section 10B”.Go to Step 5.

Page 666 of 1556

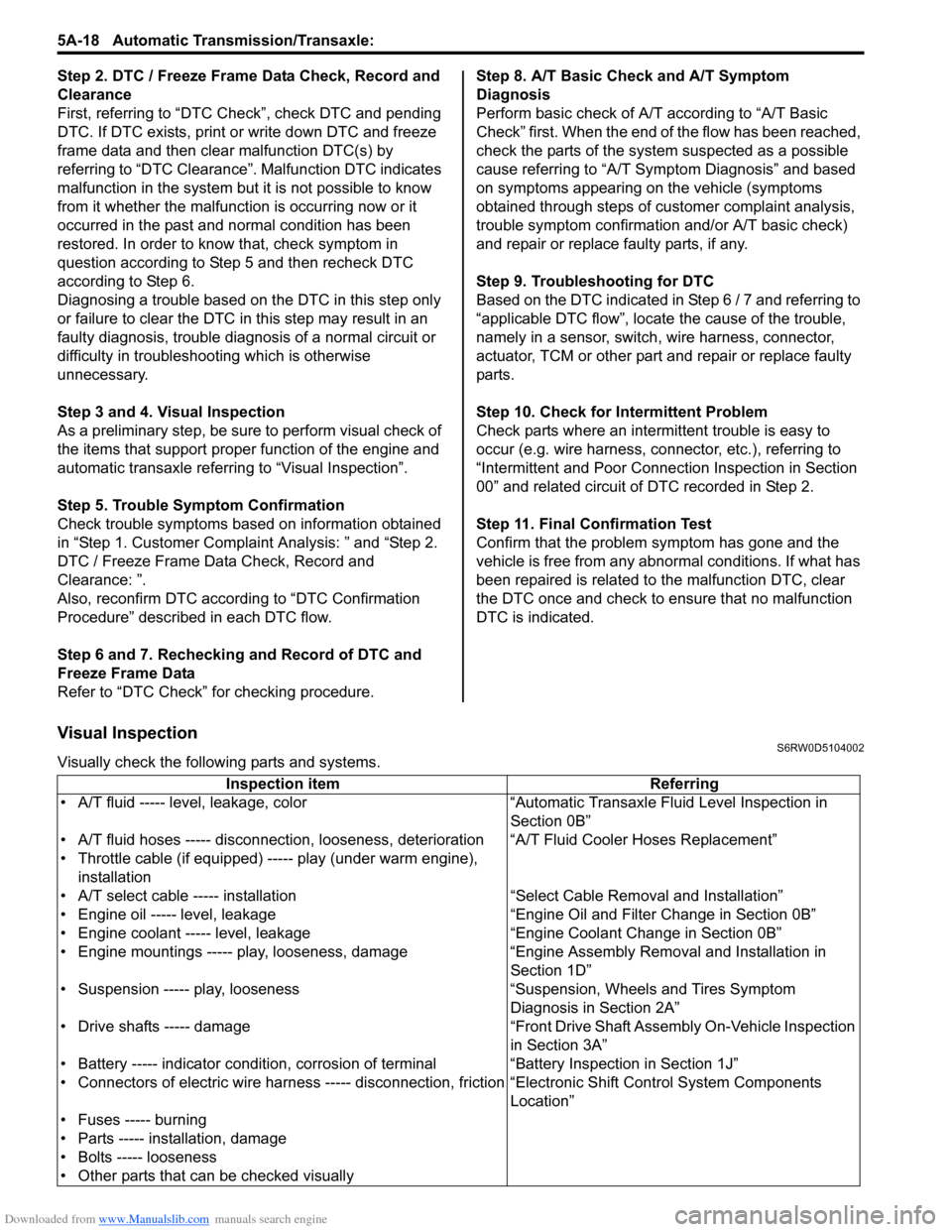

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

Step 2. DTC / Freeze Frame Data Check, Record and

Clearance

First, referring to “DTC Check”, check DTC and pending

DTC. If DTC exists, print or write down DTC and freeze

frame data and then clear malfunction DTC(s) by

referring to “DTC Clearance”. Malfunction DTC indicates

malfunction in the system but it is not possible to know

from it whether the malfunction is occurring now or it

occurred in the past and normal condition has been

restored. In order to know that, check symptom in

question according to Step 5 and then recheck DTC

according to Step 6.

Diagnosing a trouble based on the DTC in this step only

or failure to clear the DTC in this step may result in an

faulty diagnosis, trouble diagnosis of a normal circuit or

difficulty in troubleshooting which is otherwise

unnecessary.

Step 3 and 4. Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine and

automatic transaxle referring to “Visual Inspection”.

Step 5. Trouble Symptom Confirmation

Check trouble symptoms based on information obtained

in “Step 1. Customer Complaint Analysis: ” and “Step 2.

DTC / Freeze Frame Data Check, Record and

Clearance: ”.

Also, reconfirm DTC according to “DTC Confirmation

Procedure” described in each DTC flow.

Step 6 and 7. Rechecking and Record of DTC and

Freeze Frame Data

Refer to “DTC Check” for checking procedure.Step 8. A/T Basic Check and A/T Symptom

Diagnosis

Perform basic check of A/T according to “A/T Basic

Check” first. When the end of the flow has been reached,

check the parts of the system suspected as a possible

cause referring to “A/T Symptom Diagnosis” and based

on symptoms appearing on the vehicle (symptoms

obtained through steps of customer complaint analysis,

trouble symptom confirmation and/or A/T basic check)

and repair or replace faulty parts, if any.

Step 9. Troubleshooting for DTC

Based on the DTC indicated in Step 6 / 7 and referring to

“applicable DTC flow”, locate the cause of the trouble,

namely in a sensor, switch, wire harness, connector,

actuator, TCM or other part and repair or replace faulty

parts.

Step 10. Check for Intermittent Problem

Check parts where an intermittent trouble is easy to

occur (e.g. wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11. Final Confirmation Test

Confirm that the problem symptom has gone and the

vehicle is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear

the DTC once and check to ensure that no malfunction

DTC is indicated.

Visual InspectionS6RW0D5104002

Visually check the following parts and systems.

Inspection item Referring

• A/T fluid ----- level, leakage, color “Automatic Transaxle Fluid Level Inspection in

Section 0B”

• A/T fluid hoses ----- disconnection, looseness, deterioration “A/T Fluid Cooler Hoses Replacement”

• Throttle cable (if equipped) ----- play (under warm engine),

installation

• A/T select cable ----- installation “Select Cable Removal and Installation”

• Engine oil ----- level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant ----- level, leakage “Engine Coolant Change in Section 0B”

• Engine mountings ----- play, looseness, damage “Engine Assembly Removal and Installation in

Section 1D”

• Suspension ----- play, looseness “Suspension, Wheels and Tires Symptom

Diagnosis in Section 2A”

• Drive shafts ----- damage “Front Drive Shaft Assembly On-Vehicle Inspection

in Section 3A”

• Battery ----- indicator condition, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ----- disconnection, friction “Electronic Shift Control System Components

Location”

• Fuses ----- burning

• Parts ----- installation, damage

• Bolts ----- looseness

• Other parts that can be checked visually

Page 734 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-86 Automatic Transmission/Transaxle:

Select Cable ComponentsS6RW0D5106006

Select Cable Removal and InstallationS6RW0D5106007

Removal

1) Remove console box referring to “Console Box

Components in Section 9H”.

2) Disconnect select cable from select lever and then

detach from bracket.

3) Remove clip and disconnect select cable from

manual select lever.

4) Remove select cable retainer from dash panel.

Installation

Install select cable by reversing removal procedure.

The important steps in installation are as follows.

• Apply grease to pin and cable joint.

• Tighten bolts to specified torque referring to “Select

Cable Components”.• Adjusting procedure is as follows. Refer to “Select

Cable Adjustment”.Select Cable AdjustmentS6RW0D5106008

1) Shift manual shift lever to “N” range (transmission

range sensor “N” range).

(a)

(b)

(c)

6

7A

112

[B]

[B] [A]

[A]

34

5

9

8

101

A

I5RW0C510031-01

[A]: View [A] 5. Clip 11. Radiator inlet hose

[B]: View [B] 6. Manual select lever pin

: Apply lithium grease 99000-25011 to all around pin (0.15 g):23 N⋅m (2.0 kgf-m, 17.0 lb-ft)

1. Select lever assembly 7. Select lever pin

: Apply lithium grease 99000-25011 to all around pin (0.15 g):6.5 N⋅m (0.65 kgf-m, 5.0 lb-ft)

2. Select cable 8. Adjuster case : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

3. Cable bracket 9. Lock

4. Manual select lever 10. P/S control module

“P”“R”“N”

“D”

“2”

“L”

I2RH0B510040-01

Page 736 of 1556

![SUZUKI SX4 2006 1.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 5A-88 Automatic Transmission/Transaxle:

Installation

1) Lay interlock cable to its original cabling route.

C

1 2

3

4

5

61

9 [C] [A]

7

12

3

4

5 SUZUKI SX4 2006 1.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 5A-88 Automatic Transmission/Transaxle:

Installation

1) Lay interlock cable to its original cabling route.

C

1 2

3

4

5

61

9 [C] [A]

7

12

3

4

5](/img/20/7612/w960_7612-735.png)

Downloaded from www.Manualslib.com manuals search engine 5A-88 Automatic Transmission/Transaxle:

Installation

1) Lay interlock cable to its original cabling route.

C

1 2

3

4

5

61

9 [C] [A]

7

12

3

4

567

8

2 [B]

I5RW0C510073-01

[A]: LH steering vehicle 2. Clamp 6. EPS control module

[B]: RH steering vehicle 3. Steering lock assembly / Steering lock unit (if equipped with Keyless

start system)7. Brake switch bracket

[C]: View C 4. Key cylinder cover 8. Wiring harness

1. Key interlock cable 5. Select lever assembly 9. Marking

Page 865 of 1556

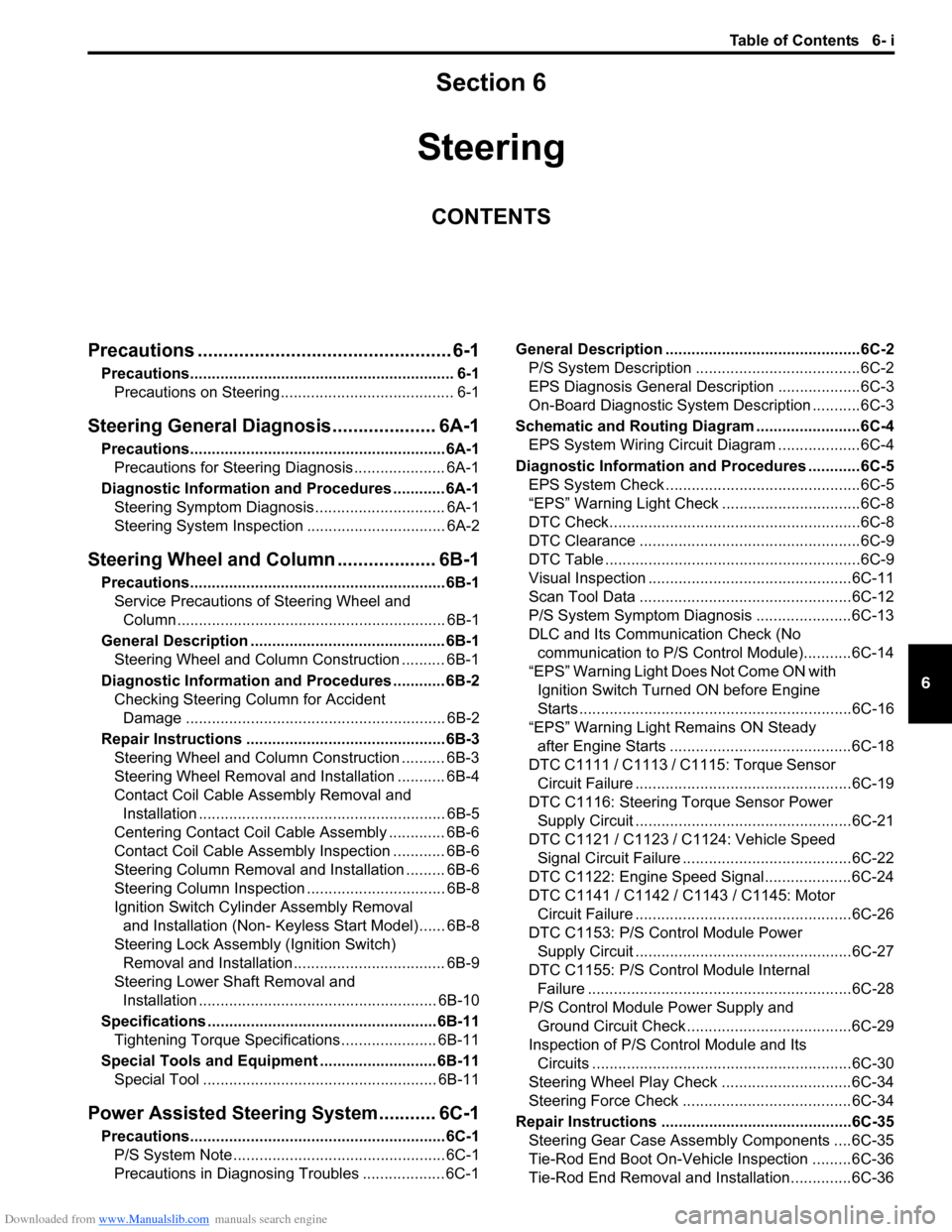

Downloaded from www.Manualslib.com manuals search engine Table of Contents 6- i

6

Section 6

CONTENTS

Steering

Precautions ................................................. 6-1

Precautions............................................................. 6-1

Precautions on Steering........................................ 6-1

Steering General Diagnosis.................... 6A-1

Precautions........................................................... 6A-1

Precautions for Steering Diagnosis ..................... 6A-1

Diagnostic Information and Procedures ............ 6A-1

Steering Symptom Diagnosis .............................. 6A-1

Steering System Inspection ................................ 6A-2

Steering Wheel and Column................... 6B-1

Precautions........................................................... 6B-1

Service Precautions of Steering Wheel and

Column.............................................................. 6B-1

General Description ............................................. 6B-1

Steering Wheel and Column Construction .......... 6B-1

Diagnostic Information and Procedures ............ 6B-2

Checking Steering Column for Accident

Damage ............................................................ 6B-2

Repair Instructions .............................................. 6B-3

Steering Wheel and Column Construction .......... 6B-3

Steering Wheel Removal and Installation ........... 6B-4

Contact Coil Cable Assembly Removal and

Installation ......................................................... 6B-5

Centering Contact Coil Cable Assembly ............. 6B-6

Contact Coil Cable Assembly Inspection ............ 6B-6

Steering Column Removal and Installation ......... 6B-6

Steering Column Inspection ................................ 6B-8

Ignition Switch Cylinder Assembly Removal

and Installation (Non- Keyless Start Model)...... 6B-8

Steering Lock Assembly (Ignition Switch)

Removal and Installation................................... 6B-9

Steering Lower Shaft Removal and

Installation ....................................................... 6B-10

Specifications..................................................... 6B-11

Tightening Torque Specifications ...................... 6B-11

Special Tools and Equipment ........................... 6B-11

Special Tool ...................................................... 6B-11

Power Assisted Steering System........... 6C-1

Precautions........................................................... 6C-1

P/S System Note ................................................. 6C-1

Precautions in Diagnosing Troubles ................... 6C-1General Description .............................................6C-2

P/S System Description ......................................6C-2

EPS Diagnosis General Description ...................6C-3

On-Board Diagnostic System Description ...........6C-3

Schematic and Routing Diagram ........................6C-4

EPS System Wiring Circuit Diagram ...................6C-4

Diagnostic Information and Procedures ............6C-5

EPS System Check .............................................6C-5

“EPS” Warning Light Check ................................6C-8

DTC Check..........................................................6C-8

DTC Clearance ...................................................6C-9

DTC Table ...........................................................6C-9

Visual Inspection ...............................................6C-11

Scan Tool Data .................................................6C-12

P/S System Symptom Diagnosis ......................6C-13

DLC and Its Communication Check (No

communication to P/S Control Module)...........6C-14

“EPS” Warning Light Does Not Come ON with

Ignition Switch Turned ON before Engine

Starts ...............................................................6C-16

“EPS” Warning Light Remains ON Steady

after Engine Starts ..........................................6C-18

DTC C1111 / C1113 / C1115: Torque Sensor

Circuit Failure ..................................................6C-19

DTC C1116: Steering Torque Sensor Power

Supply Circuit ..................................................6C-21

DTC C1121 / C1123 / C1124: Vehicle Speed

Signal Circuit Failure .......................................6C-22

DTC C1122: Engine Speed Signal....................6C-24

DTC C1141 / C1142 / C1143 / C1145: Motor

Circuit Failure ..................................................6C-26

DTC C1153: P/S Control Module Power

Supply Circuit ..................................................6C-27

DTC C1155: P/S Control Module Internal

Failure .............................................................6C-28

P/S Control Module Power Supply and

Ground Circuit Check ......................................6C-29

Inspection of P/S Control Module and Its

Circuits ............................................................6C-30

Steering Wheel Play Check ..............................6C-34

Steering Force Check .......................................6C-34

Repair Instructions ............................................6C-35

Steering Gear Case Assembly Components ....6C-35

Tie-Rod End Boot On-Vehicle Inspection .........6C-36

Tie-Rod End Removal and Installation..............6C-36