Eps SUZUKI SX4 2006 1.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1353 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-1

Body, Cab and Accessories

Instrumentation / Driver Info. / Horn

Precautions

Precautions in Diagnosing Troubles for Combination MeterS6RW0D9300001

Combination meter uses signals (information) from each control module by CAN communication to control

speedometer, tachometer, fuel meter, engine coolant temp meter, warning light and indicator light (other than air bag

warning light, EPS warning light, headlight leveling warning light (if equipped), rear fog light indicator light (if

equipped), high beam indicator light and turn signal indicator light). Therefor, check that no DTC is detected in each

module before performing combination meter symptom diagnosis. If any DTC is detected, correct trouble indicated by

that DTC troubleshooting first.

General Description

CAN Communication System DescriptionS6RW0D9301001

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

Combination meter communicates control data with each control module as follows.

Combination Meter Transmission Data

BCM

Combination

meterDATA

TransmitCombination meter spec signal

I5RW0A930001-02

Page 1357 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-5

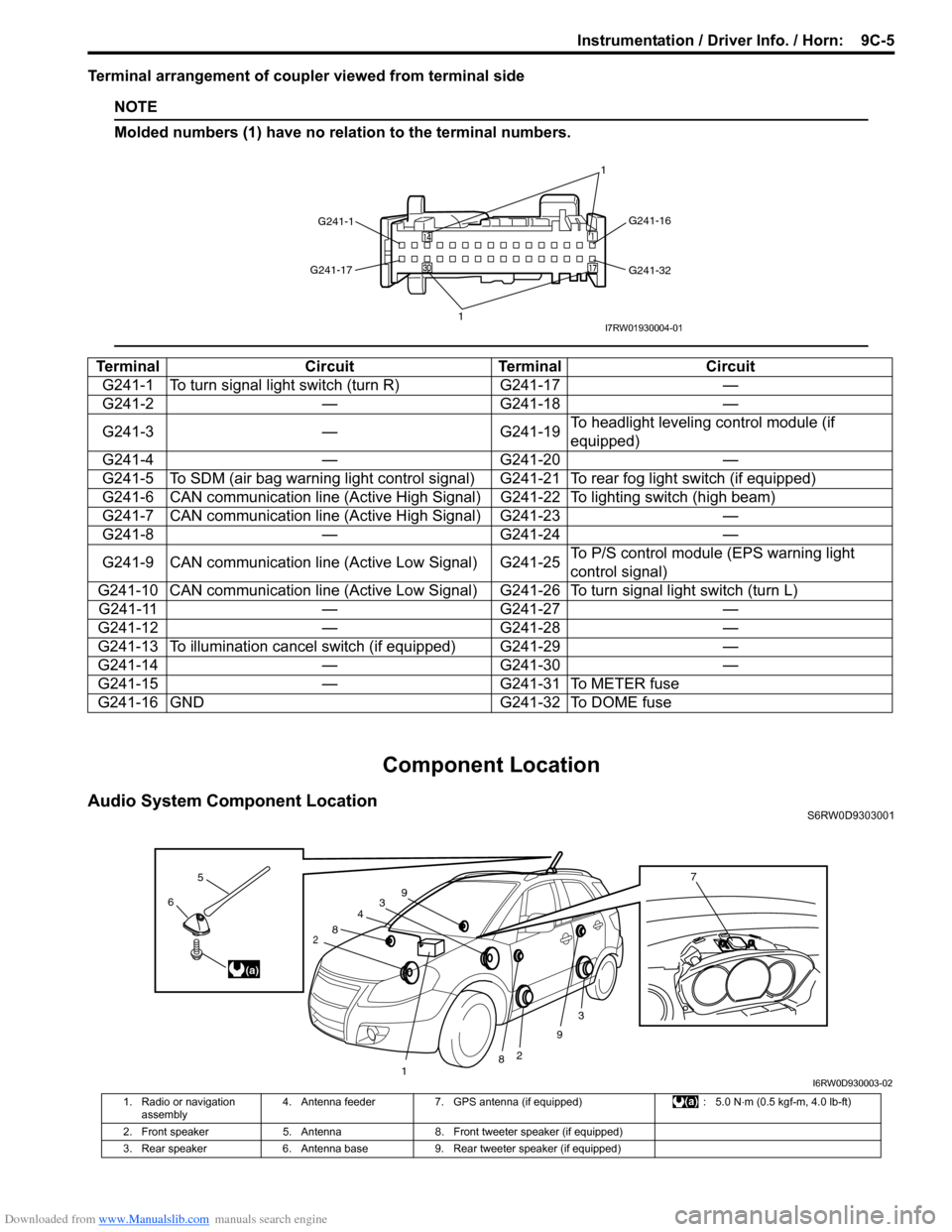

Terminal arrangement of coupler viewed from terminal side

NOTE

Molded numbers (1) have no relation to the terminal numbers.

Component Location

Audio System Component LocationS6RW0D9303001

Terminal Circuit Terminal Circuit

G241-1 To turn signal light switch (turn R) G241-17 —

G241-2 — G241-18 —

G241-3 — G241-19To headlight leveling control module (if

equipped)

G241-4 — G241-20 —

G241-5 To SDM (air bag warning light control signal) G241-21 To rear fog light switch (if equipped)

G241-6 CAN communication line (Active High Signal) G241-22 To lighting switch (high beam)

G241-7 CAN communication line (Active High Signal) G241-23 —

G241-8 — G241-24 —

G241-9 CAN communication line (Active Low Signal) G241-25To P/S control module (EPS warning light

control signal)

G241-10 CAN communication line (Active Low Signal) G241-26 To turn signal light switch (turn L)

G241-11 — G241-27 —

G241-12 — G241-28 —

G241-13 To illumination cancel switch (if equipped) G241-29 —

G241-14 — G241-30 —

G241-15 — G241-31 To METER fuse

G241-16 GND G241-32 To DOME fuse

G241-1G241-16

G241-32 G241-17

11I7RW01930004-01

3

2

3

2

1

4

8

8

9

96

5

(a)

7

I6RW0D930003-02

1. Radio or navigation

assembly4. Antenna feeder 7. GPS antenna (if equipped) : 5.0 N⋅m (0.5 kgf-m, 4.0 lb-ft)

2. Front speaker 5. Antenna 8. Front tweeter speaker (if equipped)

3. Rear speaker 6. Antenna base 9. Rear tweeter speaker (if equipped)

Page 1394 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-9 Glass / Windows / Mirrors:

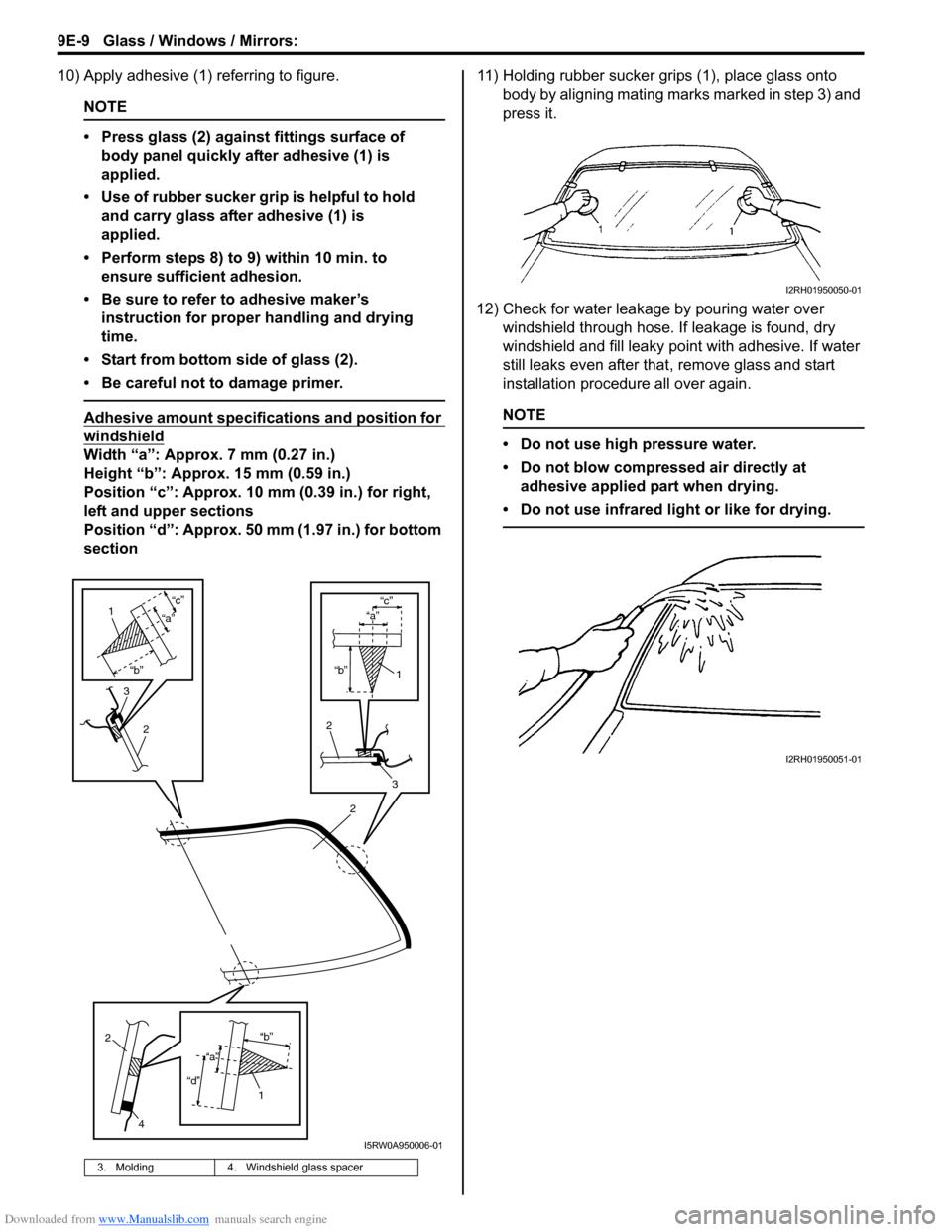

10) Apply adhesive (1) referring to figure.

NOTE

• Press glass (2) against fittings surface of

body panel quickly after adhesive (1) is

applied.

• Use of rubber sucker grip is helpful to hold

and carry glass after adhesive (1) is

applied.

• Perform steps 8) to 9) within 10 min. to

ensure sufficient adhesion.

• Be sure to refer to adhesive maker’s

instruction for proper handling and drying

time.

• Start from bottom side of glass (2).

• Be careful not to damage primer.

Adhesive amount specifications and position for

windshield

Width “a”: Approx. 7 mm (0.27 in.)

Height “b”: Approx. 15 mm (0.59 in.)

Position “c”: Approx. 10 mm (0.39 in.) for right,

left and upper sections

Position “d”: Approx. 50 mm (1.97 in.) for bottom

section11) Holding rubber sucker grips (1), place glass onto

body by aligning mating marks marked in step 3) and

press it.

12) Check for water leakage by pouring water over

windshield through hose. If leakage is found, dry

windshield and fill leaky point with adhesive. If water

still leaks even after that, remove glass and start

installation procedure all over again.

NOTE

• Do not use high pressure water.

• Do not blow compressed air directly at

adhesive applied part when drying.

• Do not use infrared light or like for drying.

3. Molding 4. Windshield glass spacer

2

“b”

“c”

2

3

1

“a”

3

2

1

“b”

“c”

“a”

2

4

1“b”

“d”

“a”

I5RW0A950006-01

I2RH01950050-01

I2RH01950051-01

Page 1455 of 1556

Downloaded from www.Manualslib.com manuals search engine Paint / Coatings: 9L-1

Body, Cab and Accessories

Paint / Coatings

General Description

Anti-Corrosion Treatment ConstructionS6RW0D9C01001

WARNING!

Standard shop practices, particularly eye protection, should be followed during the performance of the

following operations to avoid personal injury.

As rust proof treatment, steel sheets are given corrosion resistance on the interior and/or exterior.

These corrosion resistance steel sheet materials are called one of two-side galvanized steel sheets.

It is for the sake of rust protection that these materials are selected and given a variety of treatments as described

blow.

• Steel sheets are treated with cathodic electro primer which is excellent in corrosion resistance.

• Rust proof wax coatings are applied to door and side sill insides where moisture is liable to stay.

• Vinyl coating is applied to body underside and wheel housing inside.

• Sealer is applied to door hem, engine compartment steel sheet-to-steel sheet joint, and the like portions to prevent

water penetration and resulting in rust occurrence.

In panel replacement or collision damage repair, leaving the relevant area untreated as it is in any operation which

does disturb the rust proof treatment will cause corrosion to that area. Therefore, it is the essential function of any

repair operation to correctly recoat the related surfaces of the relevant area.

All the metal panels are coated with metal conditioners and primer coating during vehicle production. Following the

repair and/or replacement parts installation, every accessible bare metal surface should be cleaned and coated with

rust proof primer. Perform this operation prior to the application of sealer and rust proof wax coating.

Sealer is applied to the specific joints of a vehicle during production. The sealer is intended to prevent dust from

entering the vehicle and serves also as an anticorrosion barrier. The sealer is applied to the door and hood hem areas

and between panels. Correct and reseal the originally sealed joints if damaged. Reseal the attaching joints of a new

replacement panel and reseal the hem area of a replacement door or hood.

Use a quality sealer to seal the flanged joints, overlap joints and seams. The sealer must have flexible characteristics

and paint ability after it’s applied to repair areas.

For the sealer to fill open joints, use caulking material. Select a sealer in conformance with the place and purpose of a

specific use. Observe the manufacturer’s label-stand instructions when using the sealer.

In many cases, repaired places require color painting. When this is required, follow the ordinary techniques specified

for the finish preparation, color painting and undercoating build-up.

Rust proof wax, a penetrative compound, is applied to the metal-to-metal surfaces (door and side sill insides) where it

is difficult to use ordinary undercoating material for coating. Therefore, when selecting the rust proof wax, it may be the

penetrative type.

During the undercoating (vinyl coating) application, care should be taken that sealer is not applied to the engine-

related parts and shock absorber mounting or rotating parts. Following the under coating, make sure that body drain

holes are kept open.

The sequence of the application steps of the anti-corrosion materials are as follows:

1) Clean and prepare the metal surface.

2) Apply primer.

3) Apply sealer (all joints sealed originally).

4) Apply color in areas where color is required such as hem flanges, exposed joints and under body components.

5) Apply anticorrosion compound (penetrative wax).

6) Apply undercoating (rust proof material).

Page 1487 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-14

DTC CheckS6RW0DA204005

Using SUZUKI Scan Tool

1) Prepare SUZUKI scan tool.

2) With ignition switch turned OFF, connect it to data link connector (DLC) located on underside of instrument panel

of driver’s side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch ON.

4) Read DTC according to instructions displayed on SUZUKI scan tool and print it or write it down.

Refer to SUZUKI scan tool operator’s manual for further details.

If communication between SUZUKI scan tool and BCM is not possible, check if SUZUKI scan tool is

communicable by connecting it to BCM in another vehicle. If communication is possible in this case, SUZUKI scan

tool is in good condition. Then check data link connector and serial data line (circuit) in the vehicle with which

communication was not possible.

5) After completing the check, turn ignition switch off and disconnect SUZUKI scan tool from data link connector.

Without Using SUZUKI Scan Tool

1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds after ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 2 times.

d) Press and release driver side door switch 3 times.

(A)

I5RW0AA20008-02

Page 1488 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-15 Body Electrical Control System:

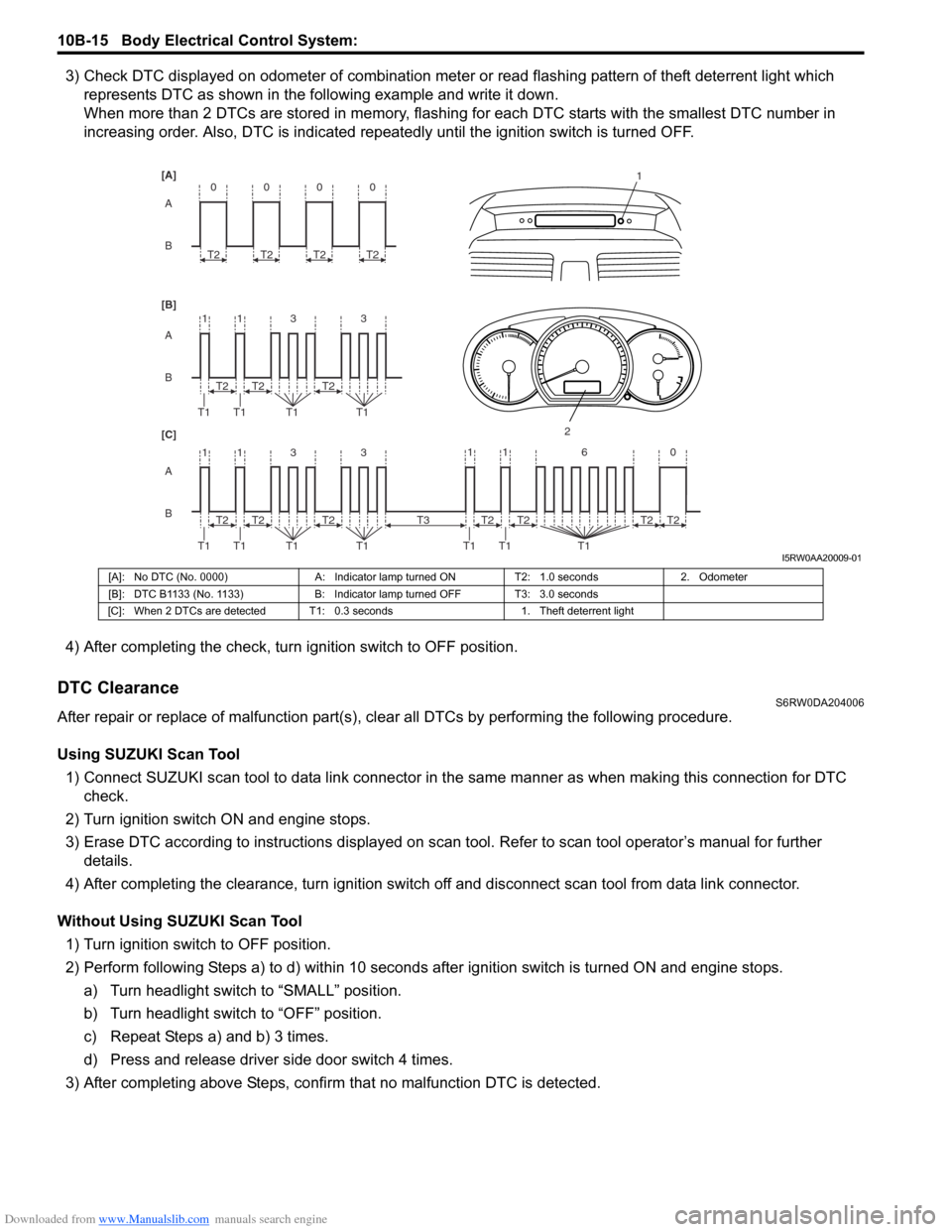

3) Check DTC displayed on odometer of combination meter or read flashing pattern of theft deterrent light which

represents DTC as shown in the following example and write it down.

When more than 2 DTCs are stored in memory, flashing for each DTC starts with the smallest DTC number in

increasing order. Also, DTC is indicated repeatedly until the ignition switch is turned OFF.

4) After completing the check, turn ignition switch to OFF position.

DTC ClearanceS6RW0DA204006

After repair or replace of malfunction part(s), clear all DTCs by performing the following procedure.

Using SUZUKI Scan Tool

1) Connect SUZUKI scan tool to data link connector in the same manner as when making this connection for DTC

check.

2) Turn ignition switch ON and engine stops.

3) Erase DTC according to instructions displayed on scan tool. Refer to scan tool operator’s manual for further

details.

4) After completing the clearance, turn ignition switch off and disconnect scan tool from data link connector.

Without Using SUZUKI Scan Tool

1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds after ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 3 times.

d) Press and release driver side door switch 4 times.

3) After completing above Steps, confirm that no malfunction DTC is detected.

B A [B] [A]

[C]

B A B A

3 113

3 113 T2

T1 T1 T1T1

1

2

T2T2

T2

T1 T1 T1T1T2T2

0

T2

0

T2

0

T2

0

T2

11 6 0

T1 T1 T1

T2 T3T2T2T2

I5RW0AA20009-01

[A]: No DTC (No. 0000) A: Indicator lamp turned ON T2: 1.0 seconds 2. Odometer

[B]: DTC B1133 (No. 1133) B: Indicator lamp turned OFF T3: 3.0 seconds

[C]: When 2 DTCs are detected T1: 0.3 seconds 1. Theft deterrent light

Page 1493 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-20

DTC B1157 (No. 1157) Air Bag Deployment Signal InputS6RW0DA204011

Wiring Diagram

Refer to “DTC B1150 (No. 1150): Air Bag Communication Circuit Malfunction”.

DTC Detecting Condition and Possible Cause

Flow Test Description

Step 1: Check DTC for SDM.

DTC Troubleshooting

DTC B1170 (No. 1170): EEPROM Access ErrorS6RW0DA204012

DTC Detecting Condition and Possible Cause

DTC Troubleshooting

NOTE

Before performing steps below, be sure to perform “Body Electrical Control System Check”.

1) Ignition switch OFF.

2) Replace BCM.

3) Repeat BCM Check Flow Table.

DTC U0073 (No. 0073): Control Module Communication Bus OffS6RW0DA204013

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U0100 (No. 0100): Lost Communication with ECMS6RW0DA204014

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U0101 (No. 0101): Lost Communication with TCMS6RW0DA204018

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control ModuleS6RW0DA204015

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U1144 (No. 1144): Lost Communication with Keyless Start Control ModuleS6RW0DA204016

Refer to “Troubleshooting for CAN-DTC in Section 1A”. DTC detecting condition Possible cause

Air bag deployment signal is fed from SDM to BCM. • Air bag component parts

• BCM malfunction

Step Action Yes No

1DTC check of SDM

1) Check DTC stored in SDM referring to “DTC Check in

Section 8B”.

Is DTC B1021 detected?Go to “DTC B1021:

Front Air Bag

Deployment Record in

Section 8B”.Substitute a known-

good BCM (included in

junction block) and

recheck.

DTC detecting condition Possible cause

Data write error or check sum error. BCM malfunction

Page 1533 of 1556

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-11

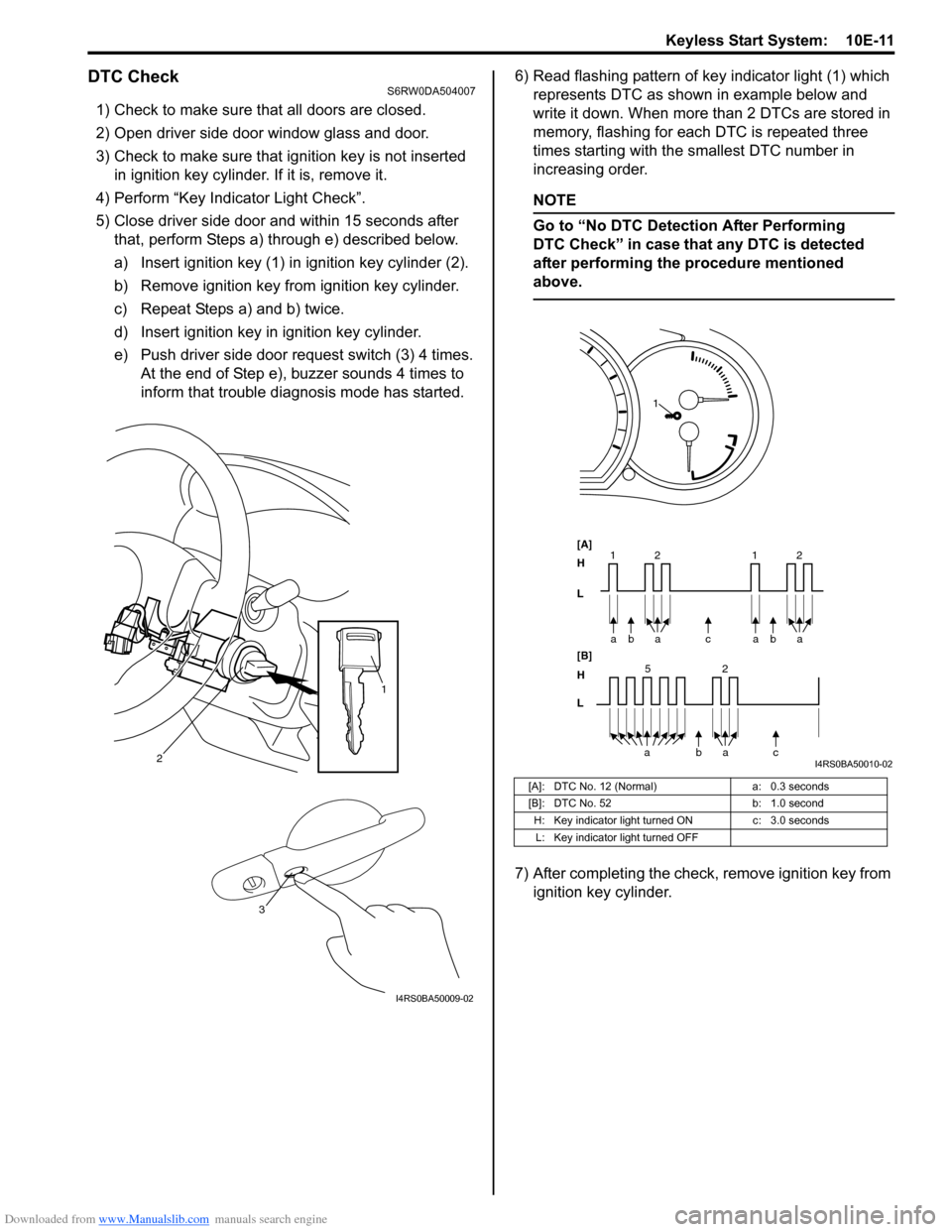

DTC CheckS6RW0DA504007

1) Check to make sure that all doors are closed.

2) Open driver side door window glass and door.

3) Check to make sure that ignition key is not inserted

in ignition key cylinder. If it is, remove it.

4) Perform “Key Indicator Light Check”.

5) Close driver side door and within 15 seconds after

that, perform Steps a) through e) described below.

a) Insert ignition key (1) in ignition key cylinder (2).

b) Remove ignition key from ignition key cylinder.

c) Repeat Steps a) and b) twice.

d) Insert ignition key in ignition key cylinder.

e) Push driver side door request switch (3) 4 times.

At the end of Step e), buzzer sounds 4 times to

inform that trouble diagnosis mode has started.6) Read flashing pattern of key indicator light (1) which

represents DTC as shown in example below and

write it down. When more than 2 DTCs are stored in

memory, flashing for each DTC is repeated three

times starting with the smallest DTC number in

increasing order.

NOTE

Go to “No DTC Detection After Performing

DTC Check” in case that any DTC is detected

after performing the procedure mentioned

above.

7) After completing the check, remove ignition key from

ignition key cylinder.

2

1

3

I4RS0BA50009-02

[A]: DTC No. 12 (Normal) a: 0.3 seconds

[B]: DTC No. 52 b: 1.0 second

H: Key indicator light turned ON c: 3.0 seconds

L: Key indicator light turned OFF

bc a a

[A]

H

L

H

L [B]

52

bac a 2 11baa2

1

I4RS0BA50010-02

Page 1534 of 1556

Downloaded from www.Manualslib.com manuals search engine 10E-12 Keyless Start System:

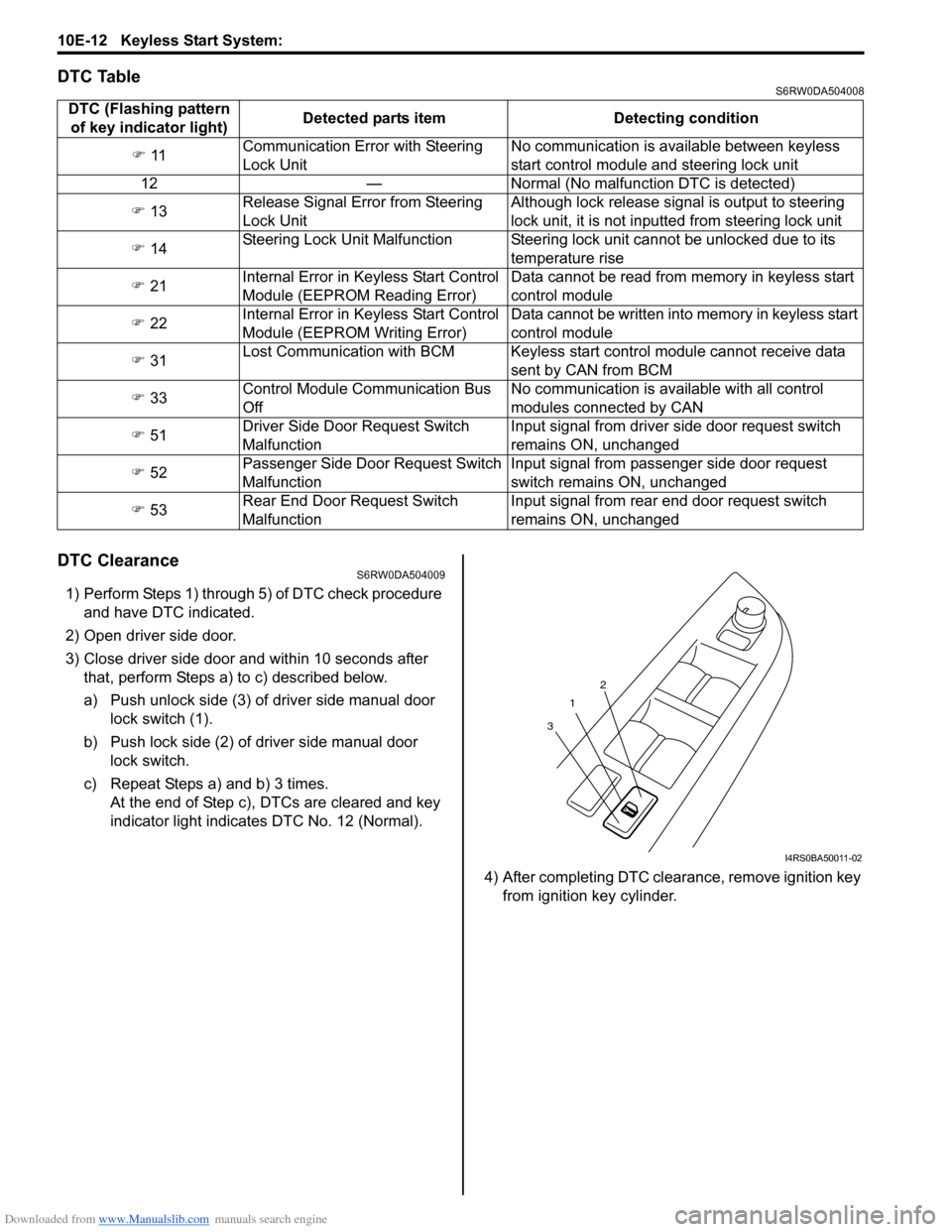

DTC TableS6RW0DA504008

DTC ClearanceS6RW0DA504009

1) Perform Steps 1) through 5) of DTC check procedure

and have DTC indicated.

2) Open driver side door.

3) Close driver side door and within 10 seconds after

that, perform Steps a) to c) described below.

a) Push unlock side (3) of driver side manual door

lock switch (1).

b) Push lock side (2) of driver side manual door

lock switch.

c) Repeat Steps a) and b) 3 times.

At the end of Step c), DTCs are cleared and key

indicator light indicates DTC No. 12 (Normal).

4) After completing DTC clearance, remove ignition key

from ignition key cylinder. DTC (Flashing pattern

of key indicator light)Detected parts item Detecting condition

�) 11Communication Error with Steering

Lock UnitNo communication is available between keyless

start control module and steering lock unit

12 — Normal (No malfunction DTC is detected)

�) 13Release Signal Error from Steering

Lock UnitAlthough lock release signal is output to steering

lock unit, it is not inputted from steering lock unit

�) 14Steering Lock Unit Malfunction Steering lock unit cannot be unlocked due to its

temperature rise

�) 21Internal Error in Keyless Start Control

Module (EEPROM Reading Error)Data cannot be read from memory in keyless start

control module

�) 22Internal Error in Keyless Start Control

Module (EEPROM Writing Error)Data cannot be written into memory in keyless start

control module

�) 31Lost Communication with BCM Keyless start control module cannot receive data

sent by CAN from BCM

�) 33Control Module Communication Bus

OffNo communication is available with all control

modules connected by CAN

�) 51Driver Side Door Request Switch

MalfunctionInput signal from driver side door request switch

remains ON, unchanged

�) 52Passenger Side Door Request Switch

MalfunctionInput signal from passenger side door request

switch remains ON, unchanged

�) 53Rear End Door Request Switch

MalfunctionInput signal from rear end door request switch

remains ON, unchanged

1

32

I4RS0BA50011-02

Page 1553 of 1556

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-31

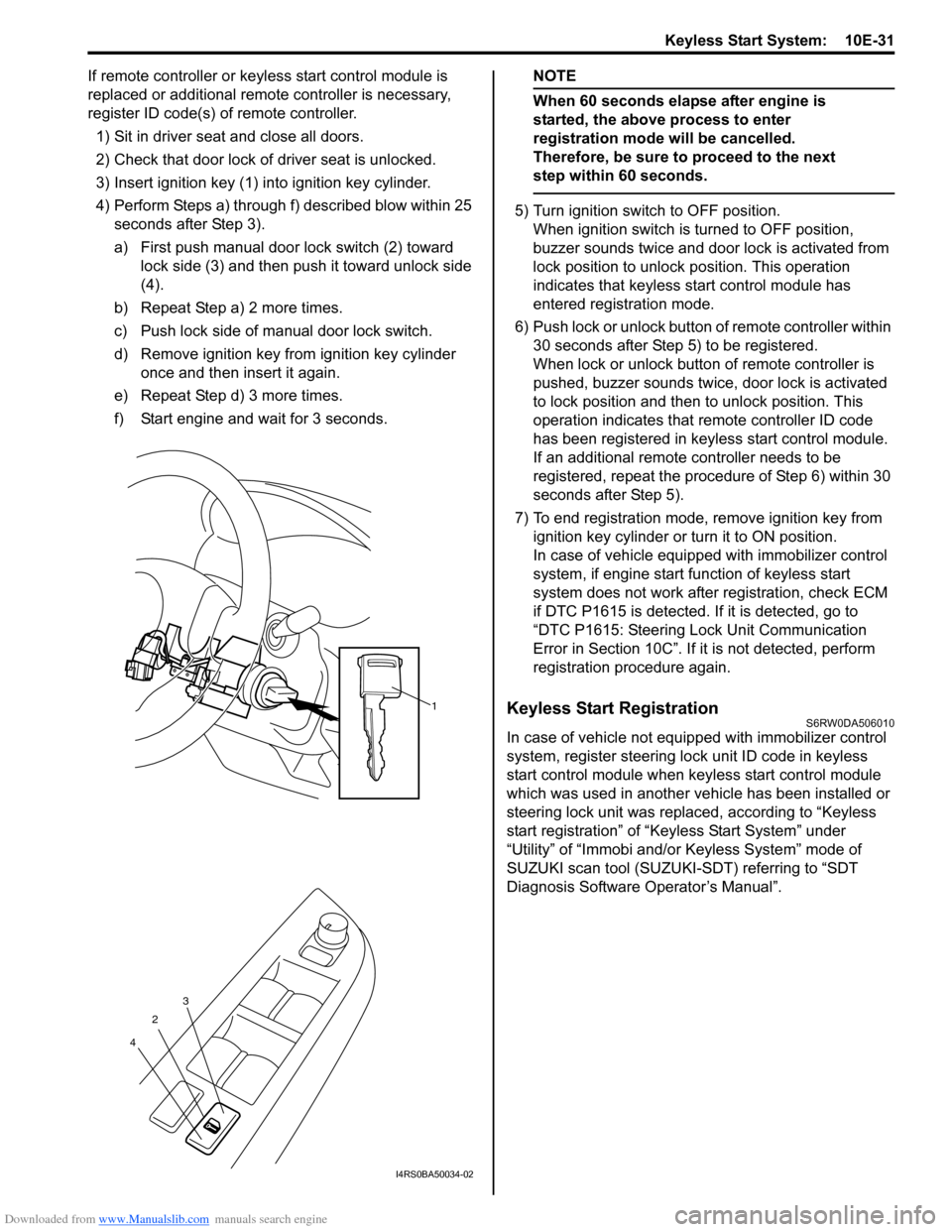

If remote controller or keyless start control module is

replaced or additional remote controller is necessary,

register ID code(s) of remote controller.

1) Sit in driver seat and close all doors.

2) Check that door lock of driver seat is unlocked.

3) Insert ignition key (1) into ignition key cylinder.

4) Perform Steps a) through f) described blow within 25

seconds after Step 3).

a) First push manual door lock switch (2) toward

lock side (3) and then push it toward unlock side

(4).

b) Repeat Step a) 2 more times.

c) Push lock side of manual door lock switch.

d) Remove ignition key from ignition key cylinder

once and then insert it again.

e) Repeat Step d) 3 more times.

f) Start engine and wait for 3 seconds.NOTE

When 60 seconds elapse after engine is

started, the above process to enter

registration mode will be cancelled.

Therefore, be sure to proceed to the next

step within 60 seconds.

5) Turn ignition switch to OFF position.

When ignition switch is turned to OFF position,

buzzer sounds twice and door lock is activated from

lock position to unlock position. This operation

indicates that keyless start control module has

entered registration mode.

6) Push lock or unlock button of remote controller within

30 seconds after Step 5) to be registered.

When lock or unlock button of remote controller is

pushed, buzzer sounds twice, door lock is activated

to lock position and then to unlock position. This

operation indicates that remote controller ID code

has been registered in keyless start control module.

If an additional remote controller needs to be

registered, repeat the procedure of Step 6) within 30

seconds after Step 5).

7) To end registration mode, remove ignition key from

ignition key cylinder or turn it to ON position.

In case of vehicle equipped with immobilizer control

system, if engine start function of keyless start

system does not work after registration, check ECM

if DTC P1615 is detected. If it is detected, go to

“DTC P1615: Steering Lock Unit Communication

Error in Section 10C”. If it is not detected, perform

registration procedure again.

Keyless Start RegistrationS6RW0DA506010

In case of vehicle not equipped with immobilizer control

system, register steering lock unit ID code in keyless

start control module when keyless start control module

which was used in another vehicle has been installed or

steering lock unit was replaced, according to “Keyless

start registration” of “Keyless Start System” under

“Utility” of “Immobi and/or Keyless System” mode of

SUZUKI scan tool (SUZUKI-SDT) referring to “SDT

Diagnosis Software Operator’s Manual”.

1

2

43

I4RS0BA50034-02