Eps SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 907 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-27

DTC Troubleshooting

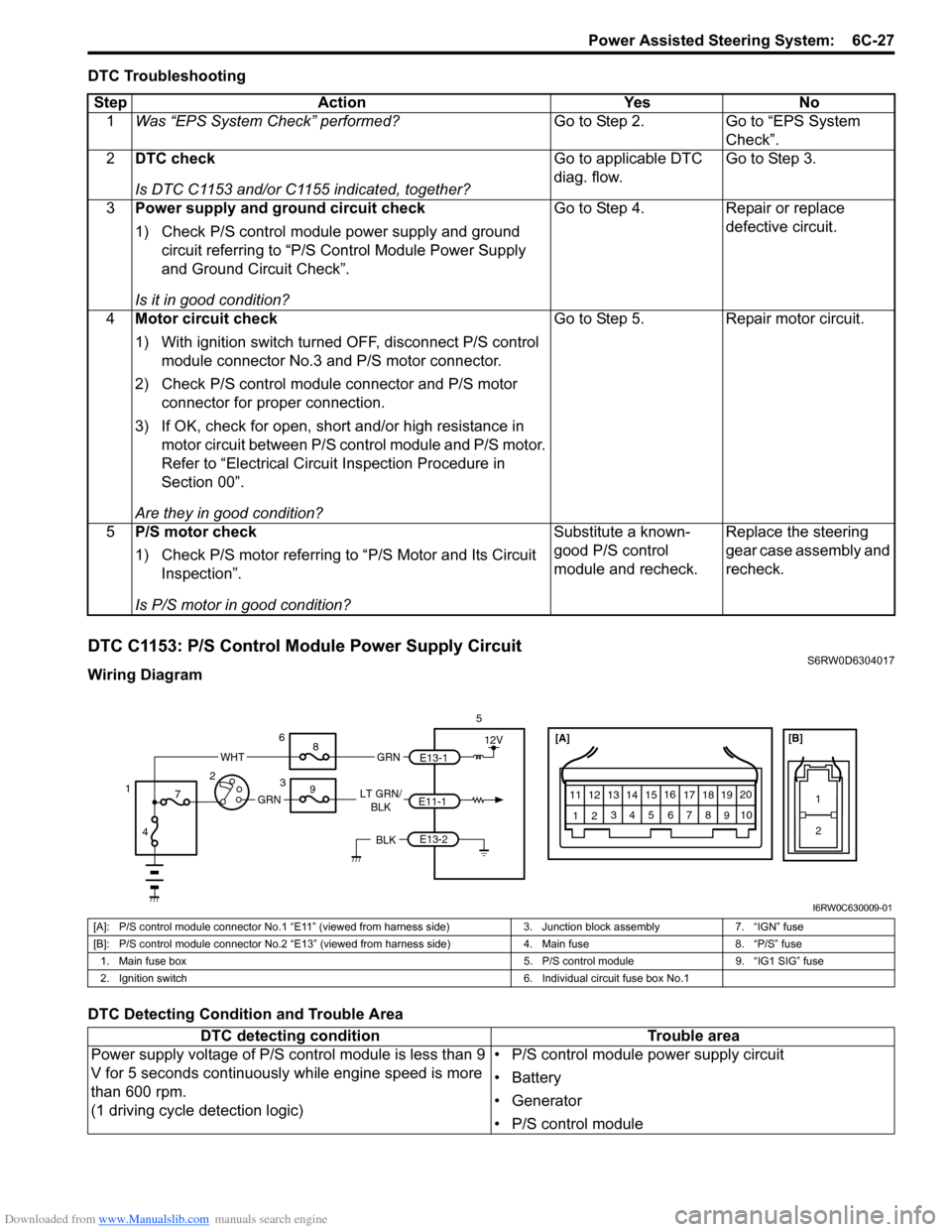

DTC C1153: P/S Control Module Power Supply CircuitS6RW0D6304017

Wiring Diagram

DTC Detecting Condition and Trouble AreaStep Action Yes No

1Was “EPS System Check” performed?Go to Step 2. Go to “EPS System

Check”.

2DTC check

Is DTC C1153 and/or C1155 indicated, together?Go to applicable DTC

diag. flow.Go to Step 3.

3Power supply and ground circuit check

1) Check P/S control module power supply and ground

circuit referring to “P/S Control Module Power Supply

and Ground Circuit Check”.

Is it in good condition?Go to Step 4. Repair or replace

defective circuit.

4Motor circuit check

1) With ignition switch turned OFF, disconnect P/S control

module connector No.3 and P/S motor connector.

2) Check P/S control module connector and P/S motor

connector for proper connection.

3) If OK, check for open, short and/or high resistance in

motor circuit between P/S control module and P/S motor.

Refer to “Electrical Circuit Inspection Procedure in

Section 00”.

Are they in good condition?Go to Step 5. Repair motor circuit.

5P/S motor check

1) Check P/S motor referring to “P/S Motor and Its Circuit

Inspection”.

Is P/S motor in good condition?Substitute a known-

good P/S control

module and recheck.Replace the steering

gear case assembly and

recheck.

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

LT GRN/

BLKE11-1E13-1 GRNGRN

WHT

5

3 6

8

9

7

4 12

12V

E13-2BLK

I6RW0C630009-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 7. “IGN” fuse

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 8. “P/S” fuse

1. Main fuse box 5. P/S control module 9. “IG1 SIG” fuse

2. Ignition switch 6. Individual circuit fuse box No.1

DTC detecting condition Trouble area

Power supply voltage of P/S control module is less than 9

V for 5 seconds continuously while engine speed is more

than 600 rpm.

(1 driving cycle detection logic)• P/S control module power supply circuit

• Battery

• Generator

• P/S control module

Page 908 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-28 Power Assisted Steering System:

DTC Troubleshooting

DTC C1155: P/S Control Module Internal FailureS6RW0D6304018

Wiring Diagram

Refer to “DTC C1153: P/S Control Module Power Supply Circuit”.

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1Was “EPS System Check” performed?Go to Step 2. Go to “EPS System

Check”.

2Battery voltage check

1) Check circuit fuse for P/S control module.

2) If OK, measure voltage between positive (+) battery

terminal and vehicle body ground with engine running.

Is voltage 10 V or more?Go to Step 3. Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

3P/S control module power supply circuit check

Check power supply circuit and ground circuit for P/S control

module referring to “P/S Control Module Power Supply and

Ground Circuit Check”.

Is check result in good condition?Substitute a known-

good P/S control

module and recheck.Repair defective circuit.

DTC detecting condition Trouble area

Internal memory (EEPROM) is data error.

(In this case, “EPS” warning light does not light up)

or

Internal circuit is faulty.

or

Power supply voltage of P/S control module exceeded

17.5 V

(1 driving cycle detection logic)• Generator

• P/S control module

Step Action Yes No

1Was “EPS System Check” performed?Go to Step 2. Go to “EPS System

Check”.

2P/S control module power supply and ground circuit

check

Check power supply circuit and ground circuit for P/S control

module referring to “P/S Control Module Power Supply and

Ground Circuit Check”.

Is check result in good condition?Go to Step 3. Repair or replace

defective circuit.

3Battery voltage check

1) Check voltage between positive (+) battery terminal and

vehicle body ground with engine speed at 3000 rpm.

Is voltage 15.5 V or less?Replace P/S control

module.Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

Page 911 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-31

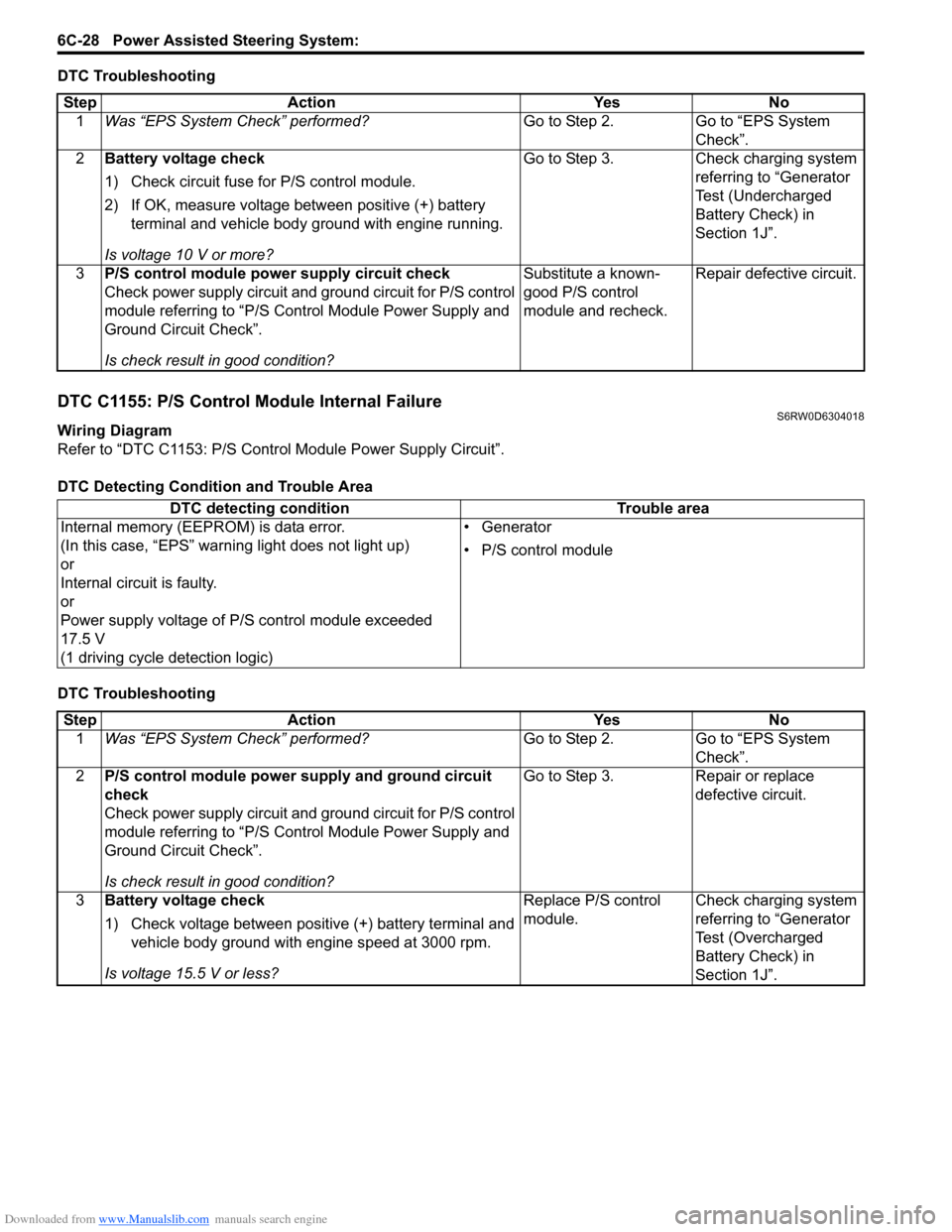

Terminal Wire color Circuit Normal voltage Condition

E11-1 LT GRN/BLKIgnition switch signal for P/S

control module10 – 14 V Ignition switch ON

E11-2 — — — —

E11-3 — — — —

E11-4 PPL Vehicle speed signal*0 – 1 V

↑↓

8 – 14 V

(“Reference

waveform No.7”

under “Inspection

of BCM and Its

Circuits in

Section 10B”)• Ignition switch ON

• Front left tire turned quickly with right

tire locked

E11-5 GRY “EPS” warning light0 V Ignition switch ON

0 – 14 V Engine running

E11-6 — — — —

E11-7 — — — —

E11-8 GRN9 V power supply for torque

sensorAbout 9 V• Ignition switch ON

• Voltage between “E11-8” and “E11-9”

terminals

E11-9 BLK Ground for torque sensors — —

E11-10 WHT Torque sensor signal (Sub)About 2.5 – 4.0 V• Steering wheel with left turn

• Out put voltage varies linearly

depending on steering force

About 2.5 V Steering wheel at free

About 1.0 – 2.5 V• Steering wheel with right turn

• Out put voltage varies linearly

depending on steering force

E11-11 BLUSerial communication circuit for

data link connector——

E11-12 BRN Engine speed signal*0 – 1 V

↑↓

8 – 14 V

(“Reference

waveform No.24

and No.25” under

“Inspection of

ECM and Its

Circuits in

Section 1A”)Engine idling

E11-13 — — — —

E11-14 RED/BLU P/S active signal (idle up signal)About 12 V Ignition switch ON

0 – 1 VEngine idling and turned steering wheel

to the right or left until it stops

E11-15 — — — —

E11-16 — — — —

E11-17 — — — —

E11-18 YEL Torque sensor signal (Main)About 1.0 – 2.5 V• Steering wheel with left turn

• Out put voltage varies linearly

depending on steering force

About 2.5 V Steering wheel at free

About 2.5 – 4.0 V• Steering wheel with right turn

• Out put voltage varies linearly

depending on steering force

E11-19 GRY Ground for shield wire — —

Page 917 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-37

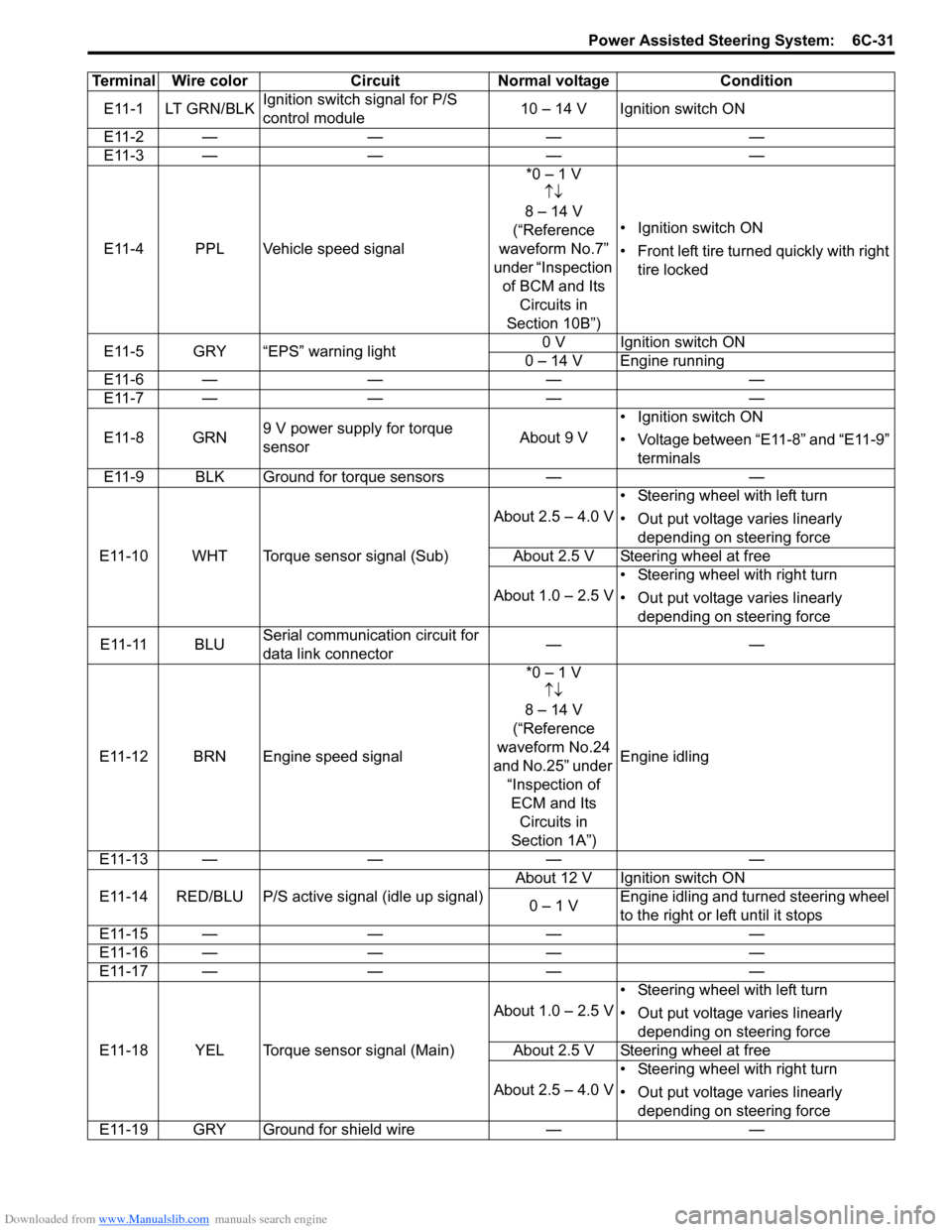

3) Inspect for proper toe referring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

4) After confirming proper toe, tighten tie-rod end lock

nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

5) Tighten wheel bolts to specified torque and lower

hoist.

Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

Tie-Rod End InspectionS6RW0D6306004

• Inspect for play in ball joint.

• Inspect for play in rack end ball joint.

In either case, if found defective, replace.

Steering Shaft Joint On-Vehicle InspectionS6RW0D6306005

Check shaft joint for wear, breakage and any other

damage and replace if any defect exists.

Steering Gear Case Assembly Removal and

Installation

S6RW0D6306006

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps, otherwise, contact coil of air bag

system may get damaged.

1) Remove steering joint cover.

2) Make alignment marks (1) on pinion shaft (2) and

joint of steering lower shaft (3) for a guide during

reinstallation.

3) Loosen joint bolt (steering column side) (4) and

remove joint bolt (pinion shaft side) (5) and

disconnect steering lower shaft (3) from pinion shaft

(2).

4) Disconnect torque sensor connector and P/S motor

connector from steering gear case.

5) Remove front suspension frame referring to “Front

Suspension Frame, Stabilizer Bar and/or Bushing

Removal and Installation in Section 2B”, and then

remove steering gear case.

Installation

1) Install grommet (1) as shown in figure.

I3RM0A630030-01

I4RS0A630043-01

I4RS0B630012-01

2. Protrusion

5

2

1

5

34

3

I4RS0B630013-01

1

2

1

2

I5RW0A630018-02

Page 922 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-42 Power Assisted Steering System:

5) Turn ON ignition switch without engine running and

select scan tool “Data List” mode due to checking

“Sensor (Main) Torque” and “Sensor (Sub) Torque”

displayed on scan tool when steering wheel turned

left and right (if used).

6) Check that characteristic of torque sensor (main and

sub) output voltage or scan tool data and steering

force is as following graph when steering wheel is

turned left and right. If sensor voltage or scan tool

data is out of specified value or does not vary linearly

as the following graph, check EPS control module

and its circuit referring to “Inspection of P/S Control

Module and Its Circuits”.

If they are OK, replace steering gear case assembly.P/S Motor and Its Circuit InspectionS6RW0D6306013

1) Check motor circuit referring to Step 2 to 3 of “DTC

C1141 / C1142 / C1143 / C1145: Motor Circuit

Failure”. If check result is not satisfactory, repair

motor circuit.

2) Disconnect motor connector from steering gear case

assembly with ignition switch turned OFF.

3) Check for resistance between terminals of motor

connector.

If check result is not as specified, check P/S motor

harness for continuity. If it is OK, replace steering

gear case assembly.

Motor circuit resistance

4) Check for insulation between each terminal of motor

connector and body ground.

If check result is not as specified, check P/S motor

harness for insulation. If it is OK, replace steering

gear case assembly.

Motor circuit resistance

5) Hoist vehicle

6) Check that steering wheel turns to left and right

smoothly. If steering wheel does not turn smoothly,

inspect and repair defective steering and suspension

parts.

7) Connect “E12” connector with ignition switch turned

OFF.

[A]: Main sensor

[B]: Sub sensor

[C]: Steering force at left turn

[D]: Steering force at right turn

[E]: Steering wheel at free

[F]: “Sensor (Main) Torque” in “Data List” displayed on scan tool

[G]: “Sensor (Sub) Torque” in “Data List” displayed on scan tool

0

[E][N.m]

MAX

MAX [D] [C]

[E][D] [C]

2.33 - 2.68[V] [F]

[G] [A]

[B]

66

1.65 - 1.9

(1.0 - 1.3)3.0 - 3.4 (3.7 - 4.0)

0 5

2.33 - 2.681.65 - 1.9

(1.0 - 1.3)3.0 - 3.4 (3.7 - 4.0)

0 5

0

[N.m]

MAX

MAX

[V]

6 11.76 11.7611.76 11.766

0 11.5

-12.00 -12.0

11.5

I7RW01632011-02

“E12-1” and “E12-2” (For motor) Approx. 1 Ω

Each terminal and body ground No continuity

[A]: Motor connector “E12” (viewed from harness side)

12

[A]

I6RW0C630012-02

Page 951 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-11

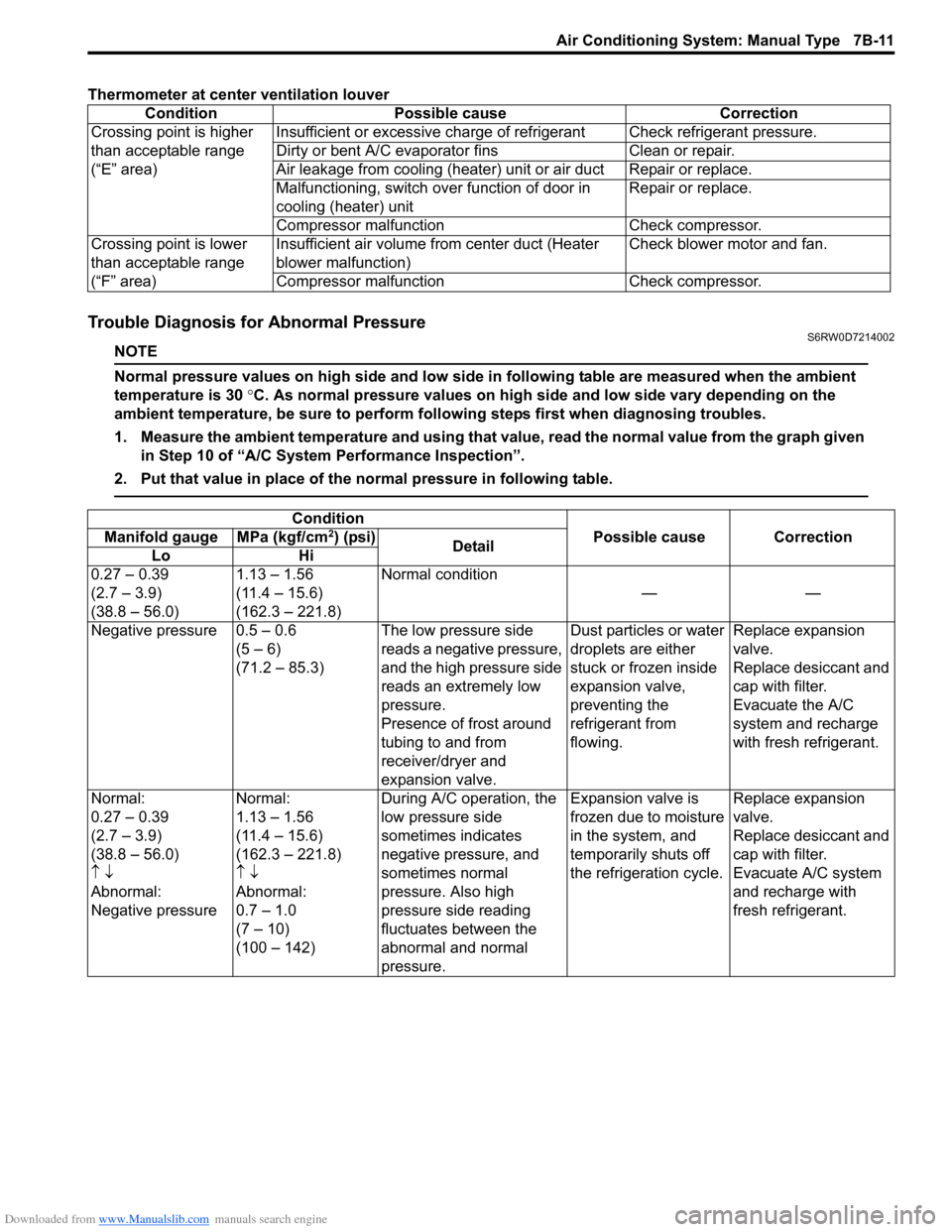

Thermometer at center ventilation louver

Trouble Diagnosis for Abnormal PressureS6RW0D7214002

NOTE

Normal pressure values on high side and low side in following table are measured when the ambient

temperature is 30 °C. As normal pressure values on high side and low side vary depending on the

ambient temperature, be sure to perform following steps first when diagnosing troubles.

1. Measure the ambient temperature and using that value, read the normal value from the graph given

in Step 10 of “A/C System Performance Inspection”.

2. Put that value in place of the normal pressure in following table.

Condition Possible cause Correction

Crossing point is higher

than acceptable range

(“E” area)Insufficient or excessive charge of refrigerant Check refrigerant pressure.

Dirty or bent A/C evaporator fins Clean or repair.

Air leakage from cooling (heater) unit or air duct Repair or replace.

Malfunctioning, switch over function of door in

cooling (heater) unitRepair or replace.

Compressor malfunction Check compressor.

Crossing point is lower

than acceptable range

(“F” area)Insufficient air volume from center duct (Heater

blower malfunction)Check blower motor and fan.

Compressor malfunction Check compressor.

Condition

Possible cause Correction Manifold gauge MPa (kgf/cm2) (psi)

Detail

Lo Hi

0.27 – 0.39

(2.7 – 3.9)

(38.8 – 56.0)1.13 – 1.56

(11.4 – 15.6)

(162.3 – 221.8)Normal condition

——

Negative pressure 0.5 – 0.6

(5 – 6)

(71.2 – 85.3)The low pressure side

reads a negative pressure,

and the high pressure side

reads an extremely low

pressure.

Presence of frost around

tubing to and from

receiver/dryer and

expansion valve.Dust particles or water

droplets are either

stuck or frozen inside

expansion valve,

preventing the

refrigerant from

flowing.Replace expansion

valve.

Replace desiccant and

cap with filter.

Evacuate the A/C

system and recharge

with fresh refrigerant.

Normal:

0.27 – 0.39

(2.7 – 3.9)

(38.8 – 56.0)

↑ ↓

Abnormal:

Negative pressureNormal:

1.13 – 1.56

(11.4 – 15.6)

(162.3 – 221.8)

↑ ↓

Abnormal:

0.7 – 1.0

(7 – 10)

(100 – 142)During A/C operation, the

low pressure side

sometimes indicates

negative pressure, and

sometimes normal

pressure. Also high

pressure side reading

fluctuates between the

abnormal and normal

pressure.Expansion valve is

frozen due to moisture

in the system, and

temporarily shuts off

the refrigeration cycle.Replace expansion

valve.

Replace desiccant and

cap with filter.

Evacuate A/C system

and recharge with

fresh refrigerant.

Page 974 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-34 Air Conditioning System: Manual Type

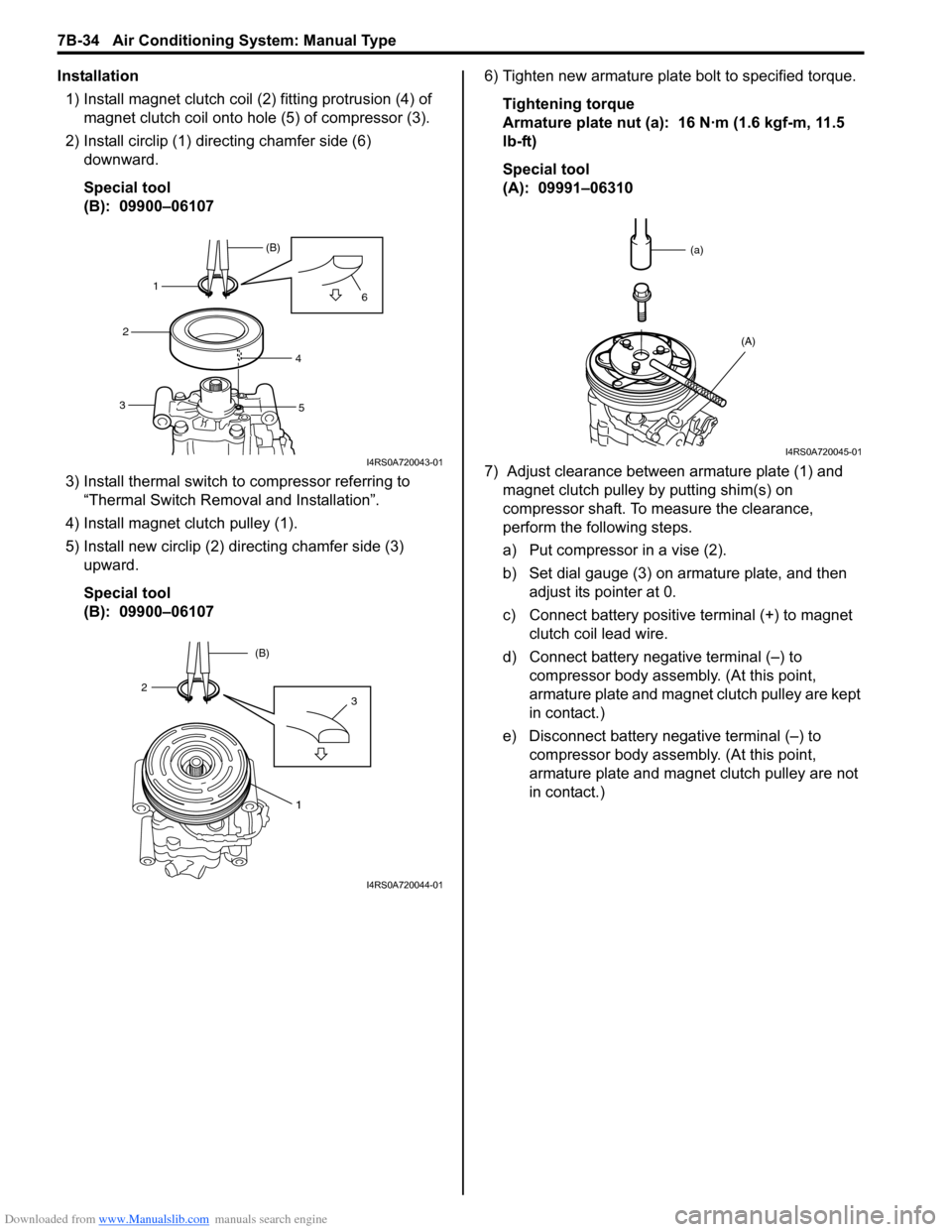

Installation

1) Install magnet clutch coil (2) fitting protrusion (4) of

magnet clutch coil onto hole (5) of compressor (3).

2) Install circlip (1) directing chamfer side (6)

downward.

Special tool

(B): 09900–06107

3) Install thermal switch to compressor referring to

“Thermal Switch Removal and Installation”.

4) Install magnet clutch pulley (1).

5) Install new circlip (2) directing chamfer side (3)

upward.

Special tool

(B): 09900–061076) Tighten new armature plate bolt to specified torque.

Tightening torque

Armature plate nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft)

Special tool

(A): 09991–06310

7) Adjust clearance between armature plate (1) and

magnet clutch pulley by putting shim(s) on

compressor shaft. To measure the clearance,

perform the following steps.

a) Put compressor in a vise (2).

b) Set dial gauge (3) on armature plate, and then

adjust its pointer at 0.

c) Connect battery positive terminal (+) to magnet

clutch coil lead wire.

d) Connect battery negative terminal (–) to

compressor body assembly. (At this point,

armature plate and magnet clutch pulley are kept

in contact.)

e) Disconnect battery negative terminal (–) to

compressor body assembly. (At this point,

armature plate and magnet clutch pulley are not

in contact.)

1(B)

2

34

56

I4RS0A720043-01

1

32(B)

I4RS0A720044-01

(a)

(A)

I4RS0A720045-01

Page 991 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-51

DTC ClearanceS6RW0D7224005

Using SUZUKI Scan tool

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Erase DTC according to instructions displayed on

SUZUKI scan tool.

NOTE

To know how to use SUZUKI scan tool, refer

to operator’s manual for SUZUKI scan tool.

5) After completing the clearance, perform “DTC

Check” and confirm if normal DTC (No code) is

displayed.

6) Turn ignition switch to OFF position, and then

disconnect SUZUKI scan tool from DLC.Not Using SUZUKI Scan Tool

1) Display history DTC by HVAC control module

referring to “Not Using SUZUKI Scan Tool” under

“DTC Check”.

2) Press air intake selector (1) and “A/C” switch (2) at

the same time for 5 seconds or more.

3) After completing above Steps, turn ignition switch to

OFF position.

4) Perform “DTC Check” and confirm if normal DTC is

indicated.

(A)

1I5RW0A722004-01

21

I5RW0A722007-01

Page 1036 of 1556

Downloaded from www.Manualslib.com manuals search engine 8A-5 Seat Belts:

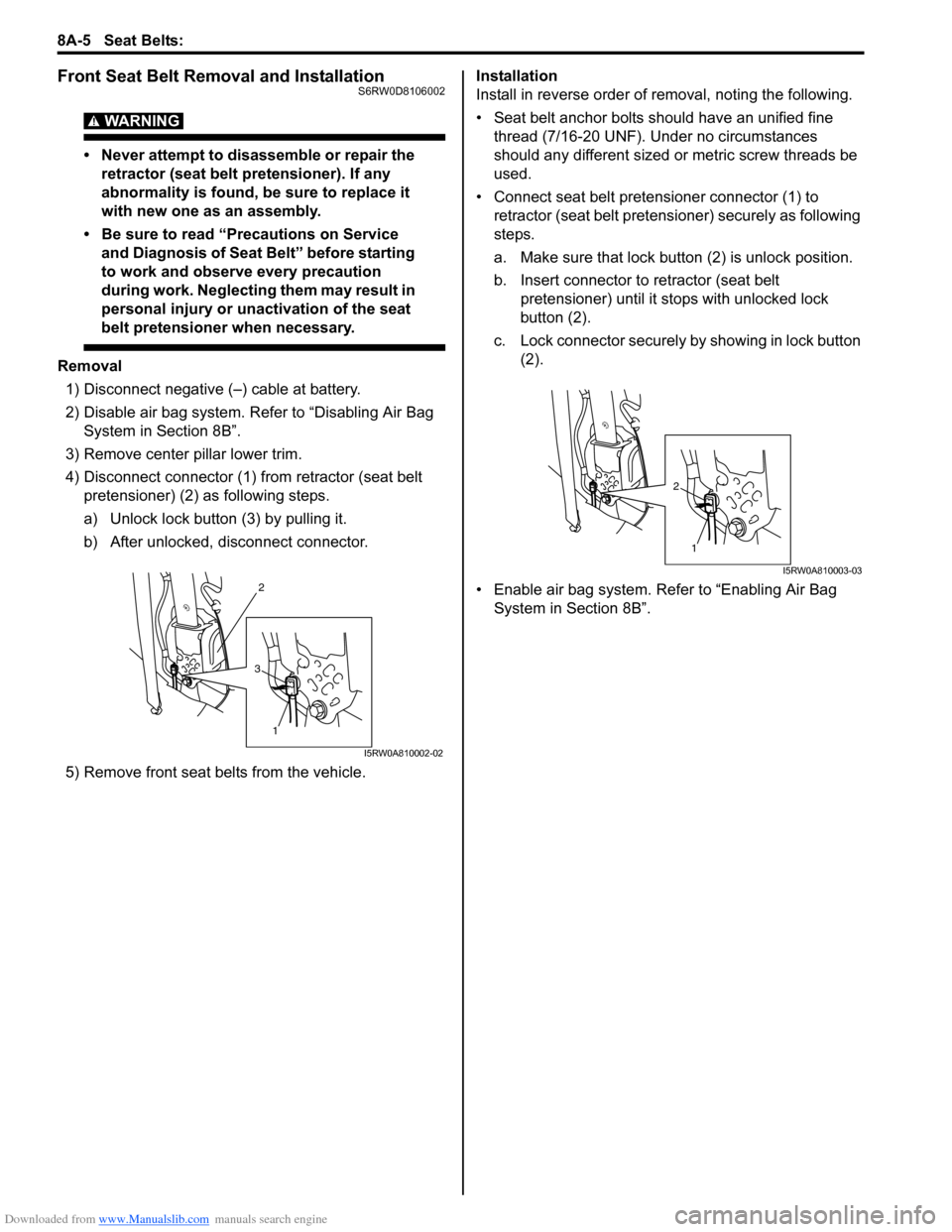

Front Seat Belt Removal and InstallationS6RW0D8106002

WARNING!

• Never attempt to disassemble or repair the

retractor (seat belt pretensioner). If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Seat Belt” before starting

to work and observe every precaution

during work. Neglecting them may result in

personal injury or unactivation of the seat

belt pretensioner when necessary.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Remove center pillar lower trim.

4) Disconnect connector (1) from retractor (seat belt

pretensioner) (2) as following steps.

a) Unlock lock button (3) by pulling it.

b) After unlocked, disconnect connector.

5) Remove front seat belts from the vehicle.Installation

Install in reverse order of removal, noting the following.

• Seat belt anchor bolts should have an unified fine

thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.

• Connect seat belt pretensioner connector (1) to

retractor (seat belt pretensioner) securely as following

steps.

a. Make sure that lock button (2) is unlock position.

b. Insert connector to retractor (seat belt

pretensioner) until it stops with unlocked lock

button (2).

c. Lock connector securely by showing in lock button

(2).

• Enable air bag system. Refer to “Enabling Air Bag

System in Section 8B”.

2

1

3

I5RW0A810002-02

1

2

I5RW0A810003-03

Page 1152 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-113 Air Bag System:

12) Notify all people in immediate area that you intend to

deploy / activate air bag (inflator) module or seat belt

pretensioner.

NOTE

• When air bag (inflator) module deploys and

seat belt pretensioner activates, rapid gas

expansion will create substantial report.

Wear suitable ear protection. Notify all

people in immediate area that you intend

to deploy air bag (inflator) module or

activate seat belt pretensioner and suitable

ear protection should be worn.

• When driver air bag (inflator) module

deploys, driver air bag (inflator) module

may jump about 30 cm (1 ft) vertically. This

is normal reaction to force of rapid gas

expansion inside of drive air bag (inflator)

module.

• After air bag (inflator) module has been

deployed, surface of air bag (inflator) may

contain powdery residue. This powder

consists primarily of cornstarch (used to

lubricate bag (inflator) as it inflates) and by

products of chemical reaction.

WARNING!

• Do not place deployed air bag (inflator)

module and activated seat belt

pretensioner near any flammable objects.

• Do not apply water, oil, etc. to deployed air

bag (inflator) module and activated seat

belt pretensioner.

• Wait for about 30 minutes before touching

any metal surface of air bag (inflater)

module or seat belt pretensioner module.

Disregarding these precautions may cause

fire or personal injury.

Failure to follow procedures may result in fire

or personal injury.

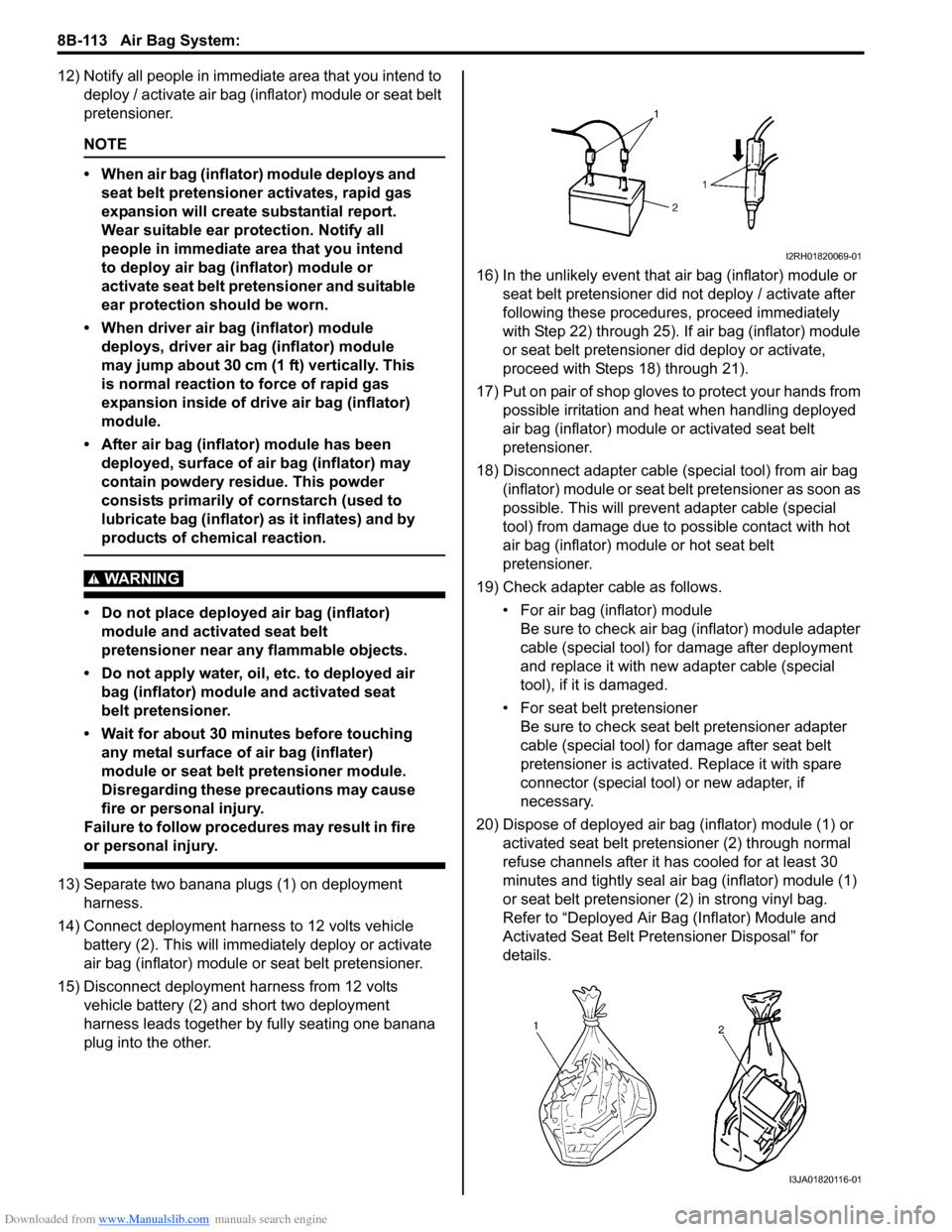

13) Separate two banana plugs (1) on deployment

harness.

14) Connect deployment harness to 12 volts vehicle

battery (2). This will immediately deploy or activate

air bag (inflator) module or seat belt pretensioner.

15) Disconnect deployment harness from 12 volts

vehicle battery (2) and short two deployment

harness leads together by fully seating one banana

plug into the other.16) In the unlikely event that air bag (inflator) module or

seat belt pretensioner did not deploy / activate after

following these procedures, proceed immediately

with Step 22) through 25). If air bag (inflator) module

or seat belt pretensioner did deploy or activate,

proceed with Steps 18) through 21).

17) Put on pair of shop gloves to protect your hands from

possible irritation and heat when handling deployed

air bag (inflator) module or activated seat belt

pretensioner.

18) Disconnect adapter cable (special tool) from air bag

(inflator) module or seat belt pretensioner as soon as

possible. This will prevent adapter cable (special

tool) from damage due to possible contact with hot

air bag (inflator) module or hot seat belt

pretensioner.

19) Check adapter cable as follows.

• For air bag (inflator) module

Be sure to check air bag (inflator) module adapter

cable (special tool) for damage after deployment

and replace it with new adapter cable (special

tool), if it is damaged.

• For seat belt pretensioner

Be sure to check seat belt pretensioner adapter

cable (special tool) for damage after seat belt

pretensioner is activated. Replace it with spare

connector (special tool) or new adapter, if

necessary.

20) Dispose of deployed air bag (inflator) module (1) or

activated seat belt pretensioner (2) through normal

refuse channels after it has cooled for at least 30

minutes and tightly seal air bag (inflator) module (1)

or seat belt pretensioner (2) in strong vinyl bag.

Refer to “Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal” for

details.

I2RH01820069-01

I3JA01820116-01