head SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 420 of 1556

Downloaded from www.Manualslib.com manuals search engine 1J-6 Charging System:

3) Ground “F” terminal and start engine, then measure

voltage at “B” terminal as shown in figure.

• Voltage is higher than standard value. It is

considered that generator itself is good but IC

regulator has been damaged, replace IC

regulator.

• Voltage is lower than standard value. It is

considered that generator itself has problem,

check the generator.

Load Check

1) Run engine at 2,000 rpm and turn on head light and

heater motor.

2) Measure current and if it is less than 20 A, repair or

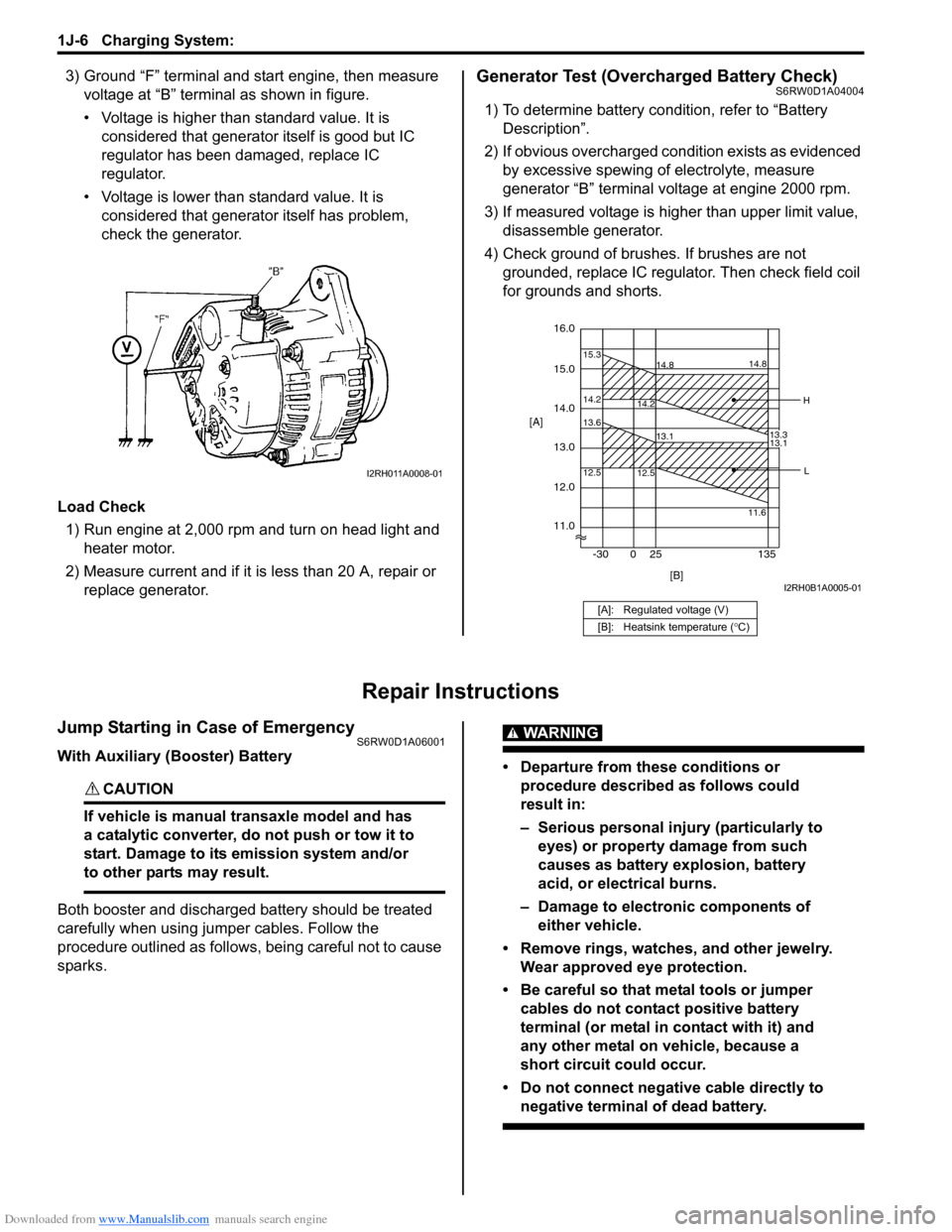

replace generator.Generator Test (Overcharged Battery Check)S6RW0D1A04004

1) To determine battery condition, refer to “Battery

Description”.

2) If obvious overcharged condition exists as evidenced

by excessive spewing of electrolyte, measure

generator “B” terminal voltage at engine 2000 rpm.

3) If measured voltage is higher than upper limit value,

disassemble generator.

4) Check ground of brushes. If brushes are not

grounded, replace IC regulator. Then check field coil

for grounds and shorts.

Repair Instructions

Jump Starting in Case of EmergencyS6RW0D1A06001

With Auxiliary (Booster) Battery

CAUTION!

If vehicle is manual transaxle model and has

a catalytic converter, do not push or tow it to

start. Damage to its emission system and/or

to other parts may result.

Both booster and discharged battery should be treated

carefully when using jumper cables. Follow the

procedure outlined as follows, being careful not to cause

sparks.

WARNING!

• Departure from these conditions or

procedure described as follows could

result in:

– Serious personal injury (particularly to

eyes) or property damage from such

causes as battery explosion, battery

acid, or electrical burns.

– Damage to electronic components of

either vehicle.

• Remove rings, watches, and other jewelry.

Wear approved eye protection.

• Be careful so that metal tools or jumper

cables do not contact positive battery

terminal (or metal in contact with it) and

any other metal on vehicle, because a

short circuit could occur.

• Do not connect negative cable directly to

negative terminal of dead battery.

I2RH011A0008-01

[A]: Regulated voltage (V)

[B]: Heatsink temperature (°C)

16.0

12.0

14.2 15.3

14.8

14.2

13.3 14.8

15.0

11.0 14.0

13.0 [A]

12.5 13.6

13.1

12.5

11.613.1

[B] -30 0 25 135

H

L

I2RH0B1A0005-01

Page 430 of 1556

Downloaded from www.Manualslib.com manuals search engine 1K-3 Exhaust System:

Exhaust Manifold Removal and InstallationS6RW0D1B06002

Removal

WARNING!

To avoid danger of being burned, do not

service exhaust system while it is still hot.

Service should be performed after system

cools down.

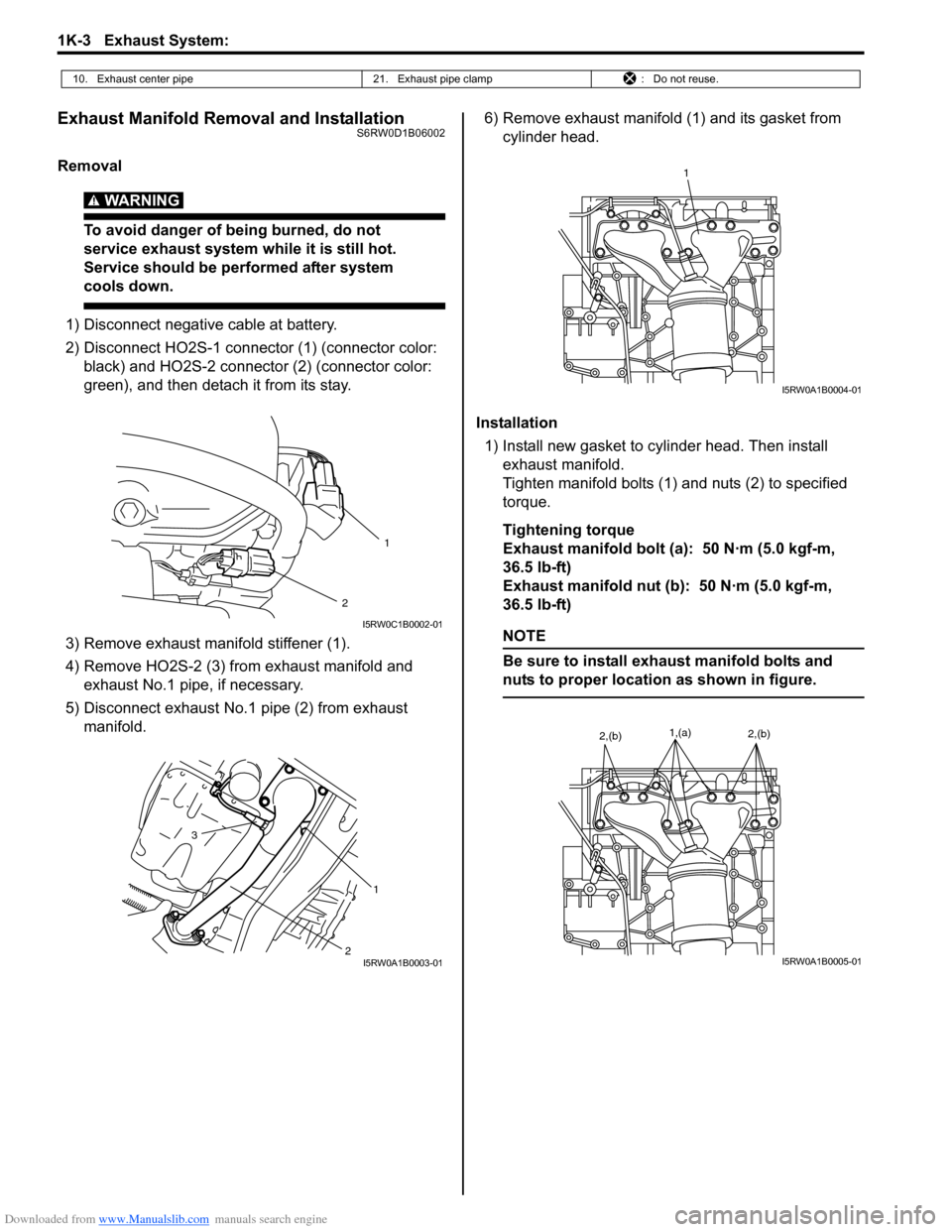

1) Disconnect negative cable at battery.

2) Disconnect HO2S-1 connector (1) (connector color:

black) and HO2S-2 connector (2) (connector color:

green), and then detach it from its stay.

3) Remove exhaust manifold stiffener (1).

4) Remove HO2S-2 (3) from exhaust manifold and

exhaust No.1 pipe, if necessary.

5) Disconnect exhaust No.1 pipe (2) from exhaust

manifold.6) Remove exhaust manifold (1) and its gasket from

cylinder head.

Installation

1) Install new gasket to cylinder head. Then install

exhaust manifold.

Tighten manifold bolts (1) and nuts (2) to specified

torque.

Tightening torque

Exhaust manifold bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

Exhaust manifold nut (b): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

NOTE

Be sure to install exhaust manifold bolts and

nuts to proper location as shown in figure.

10. Exhaust center pipe 21. Exhaust pipe clamp : Do not reuse.

2

1

I5RW0C1B0002-01

2 3

1

I5RW0A1B0003-01

1

I5RW0A1B0004-01

1,(a)2,(b)2,(b)

I5RW0A1B0005-01

Page 733 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-85

Select Lever InspectionS6RW0D5106005

Check select lever for smooth and clear-cut movement

individually. If a malfunction is found, replace select lever

assembly.

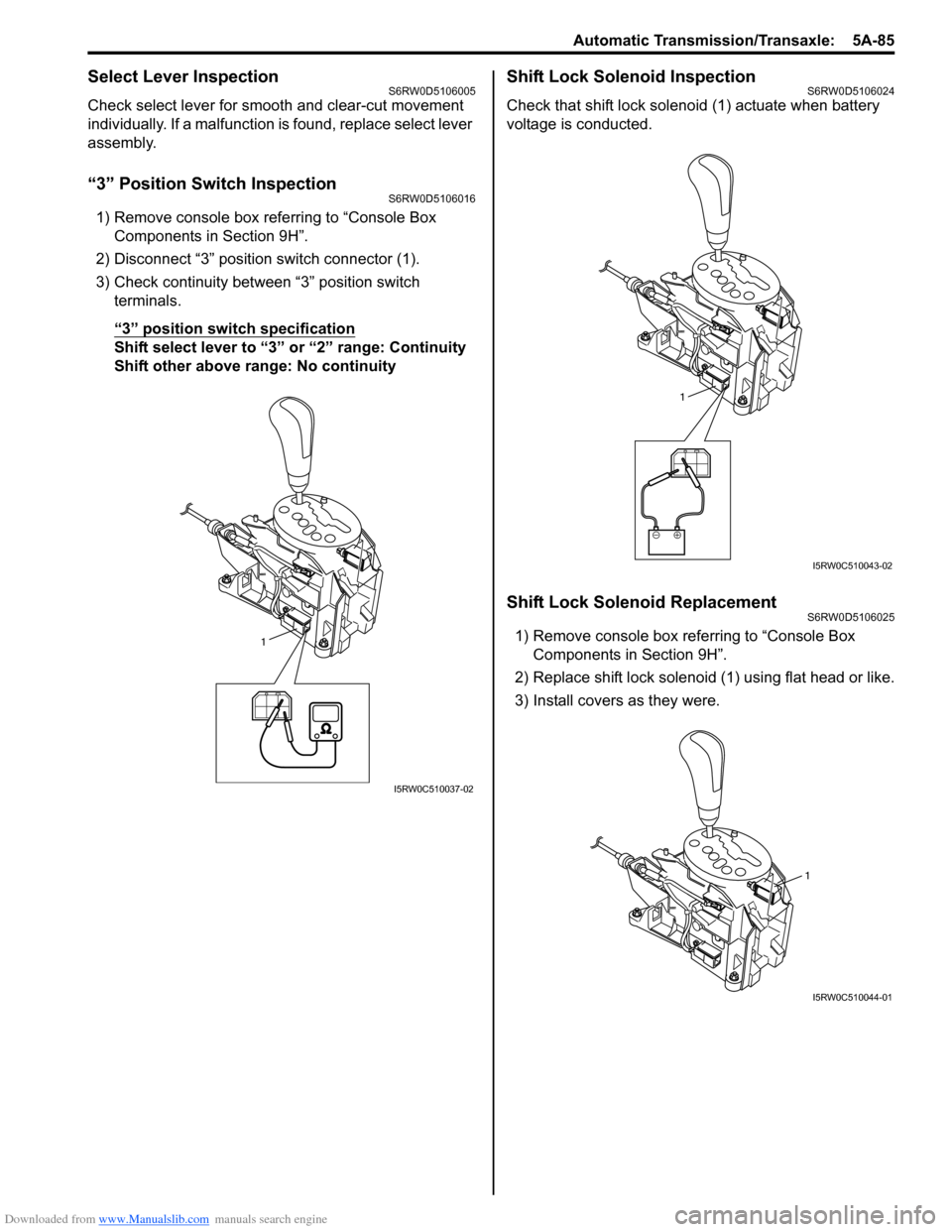

“3” Position Switch InspectionS6RW0D5106016

1) Remove console box referring to “Console Box

Components in Section 9H”.

2) Disconnect “3” position switch connector (1).

3) Check continuity between “3” position switch

terminals.

“3” position switch specification

Shift select lever to “3” or “2” range: Continuity

Shift other above range: No continuity

Shift Lock Solenoid InspectionS6RW0D5106024

Check that shift lock solenoid (1) actuate when battery

voltage is conducted.

Shift Lock Solenoid ReplacementS6RW0D5106025

1) Remove console box referring to “Console Box

Components in Section 9H”.

2) Replace shift lock solenoid (1) using flat head or like.

3) Install covers as they were.1

I5RW0C510037-02

1

I5RW0C510043-02

1

I5RW0C510044-01

Page 748 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-100 Automatic Transmission/Transaxle:

Automatic Transaxle Unit Dismounting and

Remounting

S6RW0D5106029

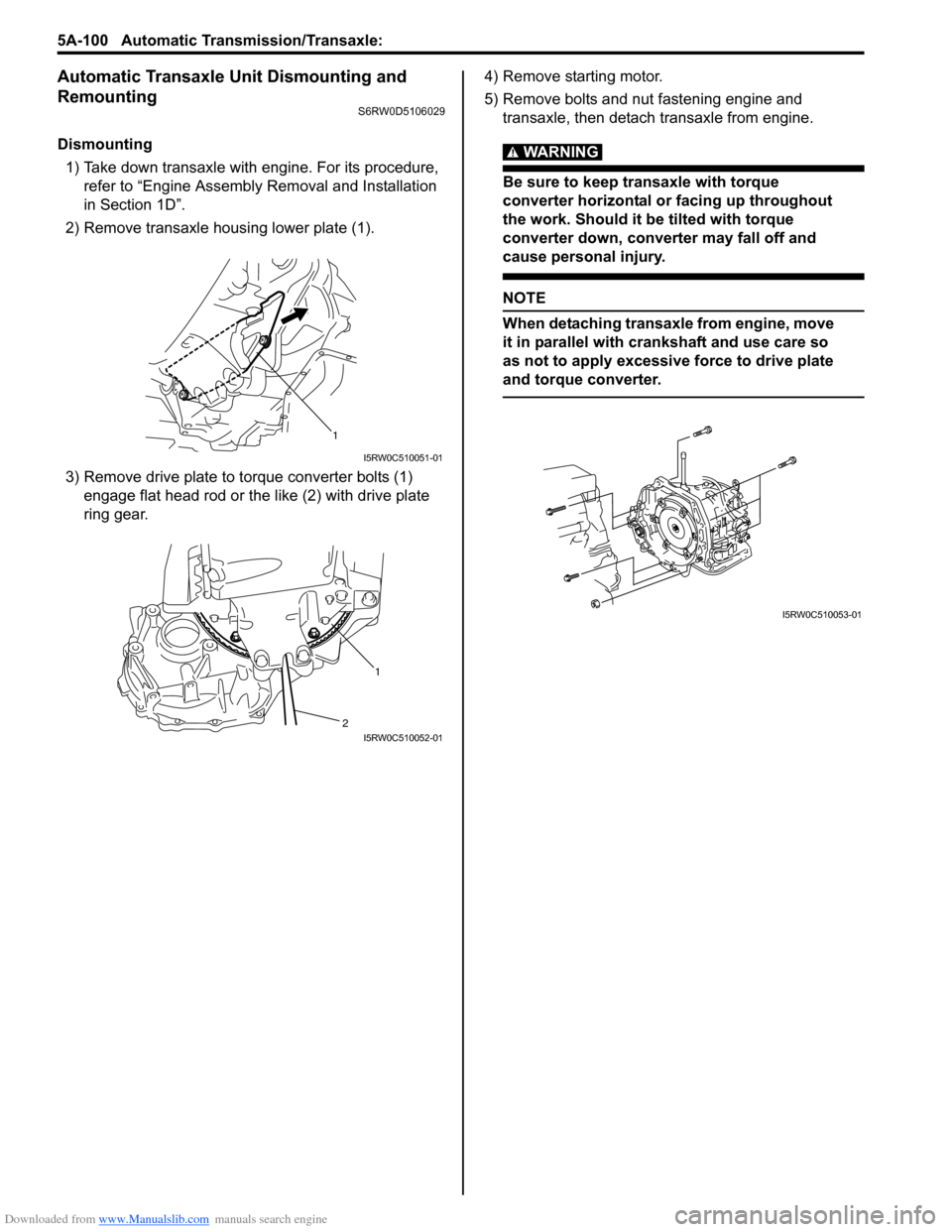

Dismounting

1) Take down transaxle with engine. For its procedure,

refer to “Engine Assembly Removal and Installation

in Section 1D”.

2) Remove transaxle housing lower plate (1).

3) Remove drive plate to torque converter bolts (1)

engage flat head rod or the like (2) with drive plate

ring gear.4) Remove starting motor.

5) Remove bolts and nut fastening engine and

transaxle, then detach transaxle from engine.WARNING!

Be sure to keep transaxle with torque

converter horizontal or facing up throughout

the work. Should it be tilted with torque

converter down, converter may fall off and

cause personal injury.

NOTE

When detaching transaxle from engine, move

it in parallel with crankshaft and use care so

as not to apply excessive force to drive plate

and torque converter.

1

I5RW0C510051-01

1

2I5RW0C510052-01

I5RW0C510053-01

Page 749 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-101

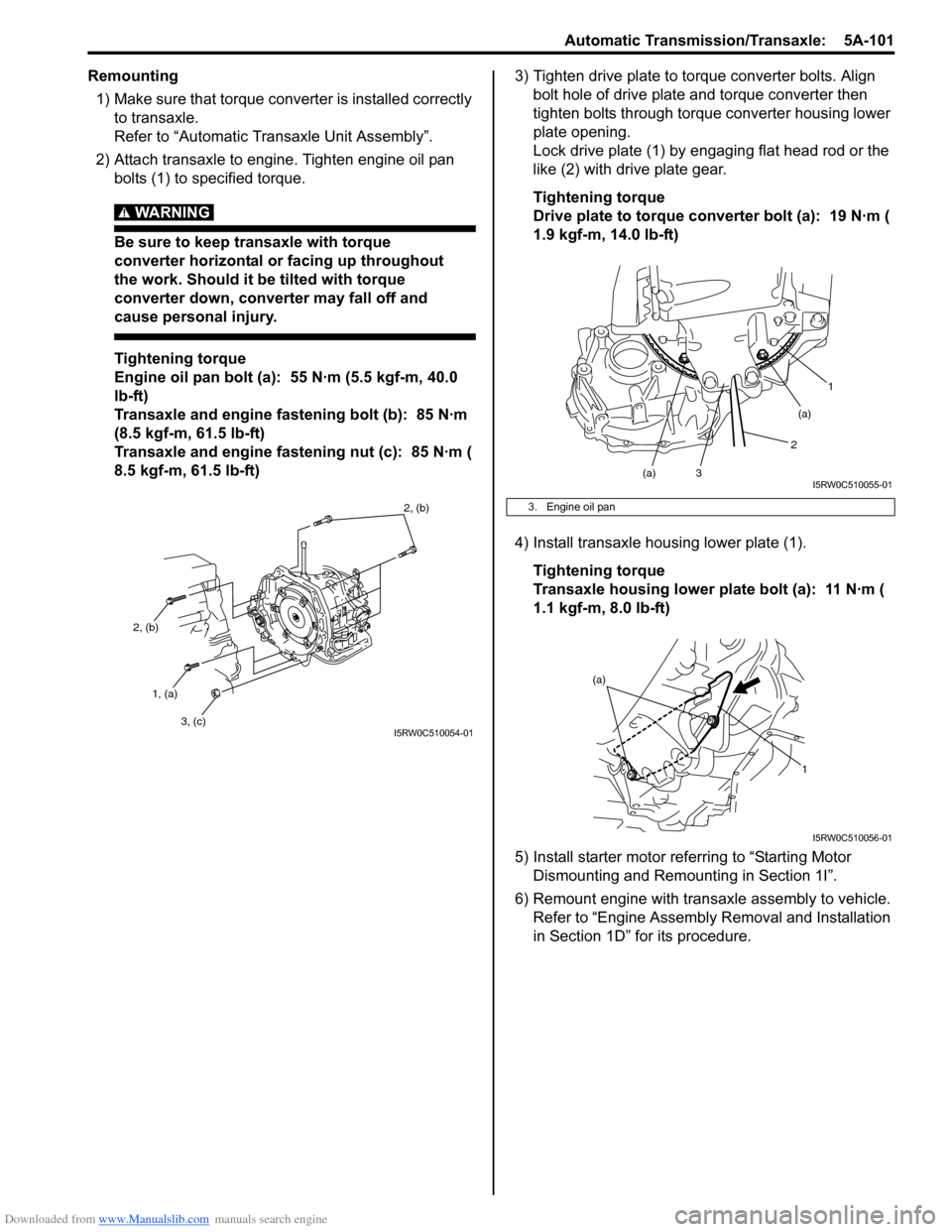

Remounting

1) Make sure that torque converter is installed correctly

to transaxle.

Refer to “Automatic Transaxle Unit Assembly”.

2) Attach transaxle to engine. Tighten engine oil pan

bolts (1) to specified torque.

WARNING!

Be sure to keep transaxle with torque

converter horizontal or facing up throughout

the work. Should it be tilted with torque

converter down, converter may fall off and

cause personal injury.

Tightening torque

Engine oil pan bolt (a): 55 N·m (5.5 kgf-m, 40.0

lb-ft)

Transaxle and engine fastening bolt (b): 85 N·m

(8.5 kgf-m, 61.5 lb-ft)

Transaxle and engine fastening nut (c): 85 N·m (

8.5 kgf-m, 61.5 lb-ft)3) Tighten drive plate to torque converter bolts. Align

bolt hole of drive plate and torque converter then

tighten bolts through torque converter housing lower

plate opening.

Lock drive plate (1) by engaging flat head rod or the

like (2) with drive plate gear.

Tightening torque

Drive plate to torque converter bolt (a): 19 N·m (

1.9 kgf-m, 14.0 lb-ft)

4) Install transaxle housing lower plate (1).

Tightening torque

Transaxle housing lower plate bolt (a): 11 N·m (

1.1 kgf-m, 8.0 lb-ft)

5) Install starter motor referring to “Starting Motor

Dismounting and Remounting in Section 1I”.

6) Remount engine with transaxle assembly to vehicle.

Refer to “Engine Assembly Removal and Installation

in Section 1D” for its procedure.

2, (b)

2, (b)

1, (a)

3, (c)I5RW0C510054-01

3. Engine oil pan

1

(a)

(a)3

2

I5RW0C510055-01

1 (a)

I5RW0C510056-01

Page 855 of 1556

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-2

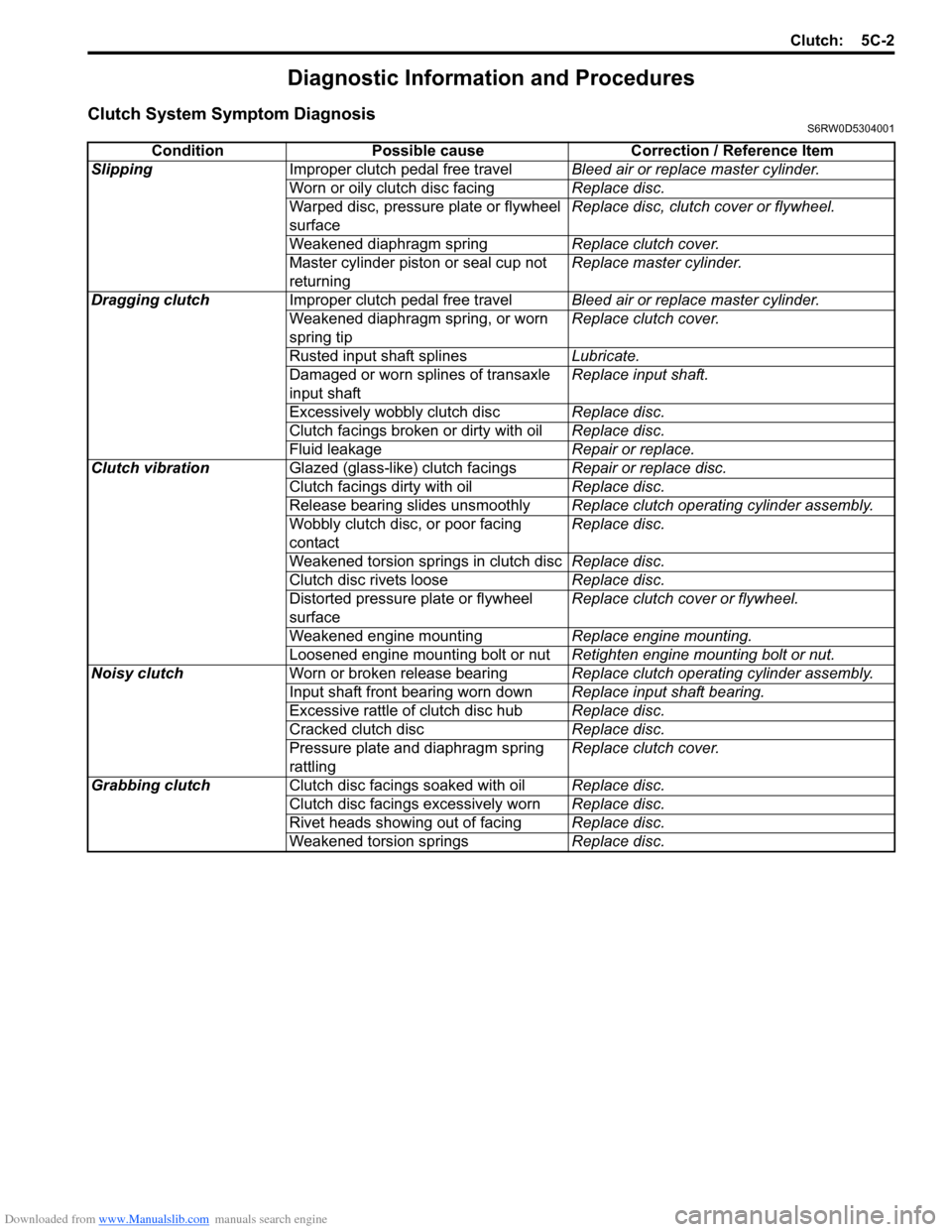

Diagnostic Information and Procedures

Clutch System Symptom DiagnosisS6RW0D5304001

Condition Possible cause Correction / Reference Item

SlippingImproper clutch pedal free travelBleed air or replace master cylinder.

Worn or oily clutch disc facingReplace disc.

Warped disc, pressure plate or flywheel

surfaceReplace disc, clutch cover or flywheel.

Weakened diaphragm springReplace clutch cover.

Master cylinder piston or seal cup not

returningReplace master cylinder.

Dragging clutchImproper clutch pedal free travelBleed air or replace master cylinder.

Weakened diaphragm spring, or worn

spring tipReplace clutch cover.

Rusted input shaft splinesLubricate.

Damaged or worn splines of transaxle

input shaftReplace input shaft.

Excessively wobbly clutch discReplace disc.

Clutch facings broken or dirty with oilReplace disc.

Fluid leakageRepair or replace.

Clutch vibrationGlazed (glass-like) clutch facingsRepair or replace disc.

Clutch facings dirty with oilReplace disc.

Release bearing slides unsmoothlyReplace clutch operating cylinder assembly.

Wobbly clutch disc, or poor facing

contactReplace disc.

Weakened torsion springs in clutch discReplace disc.

Clutch disc rivets looseReplace disc.

Distorted pressure plate or flywheel

surfaceReplace clutch cover or flywheel.

Weakened engine mountingReplace engine mounting.

Loosened engine mounting bolt or nutRetighten engine mounting bolt or nut.

Noisy clutchWorn or broken release bearingReplace clutch operating cylinder assembly.

Input shaft front bearing worn downReplace input shaft bearing.

Excessive rattle of clutch disc hubReplace disc.

Cracked clutch discReplace disc.

Pressure plate and diaphragm spring

rattlingReplace clutch cover.

Grabbing clutchClutch disc facings soaked with oilReplace disc.

Clutch disc facings excessively wornReplace disc.

Rivet heads showing out of facingReplace disc.

Weakened torsion springsReplace disc.

Page 862 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-9 Clutch:

Clutch Disc

Measure depth of rivet head depression, i.e. distance

between rivet head and facing surface.

If depression is found to have reached service limit at

any of rivet holes (2), replace clutch disc assembly (1).

Rivet head depth

Standard: 1.65 – 2.25 mm (0.06 – 0.09 in.)

Limit: 0.5 mm (0.02 in.)Clutch Cover

1) Check diaphragm spring (1) for abnormal wear or

damage.

2) Inspect pressure plate (2) for wear or heat spots.

3) If abnormality is found, replace clutch cover.

Do not disassemble it into diaphragm spring and

pressure plate.

Flywheel

Check surface contacting clutch disc for abnormal wear

or heat spots. Replace or repair as required.

Specifications

Tightening Torque SpecificationsS6RW0D5307001

NOTE

The specified tightening torque is also described in the following.

“Clutch Cover, Clutch Disc and Flywheel Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I4RS0A530019-01

I3RM0A530015-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Clutch master cylinder nut 13 1.3 9.5�)

Clutch operating cylinder assembly mounting

bolt10 1.0 7.5�)

Clutch fluid pipe flare nut 16 1.6 11.5�)

Flywheel bolt 70 7.0 51.0�)

Clutch cover bolt 23 2.3 17.0�)

Page 873 of 1556

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-4

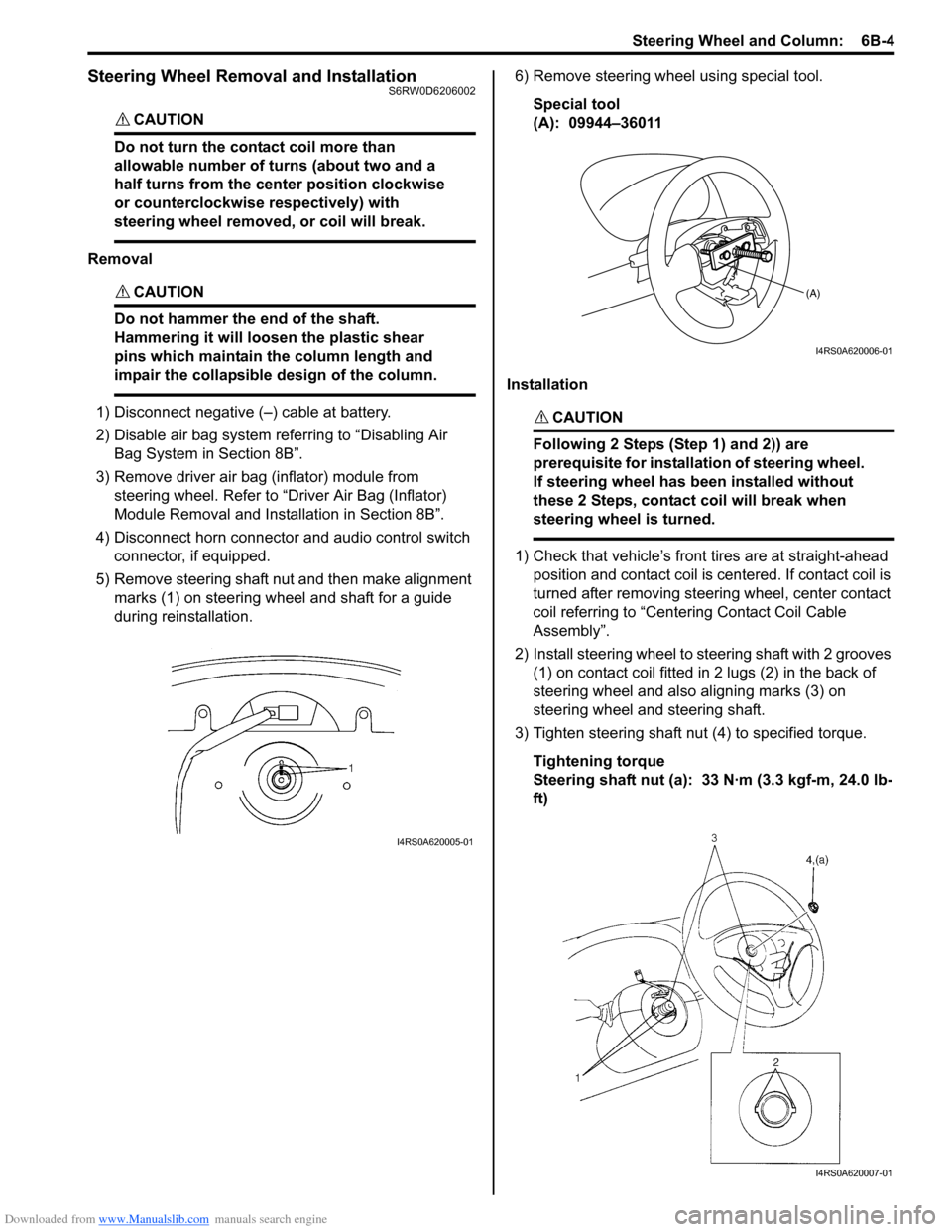

Steering Wheel Removal and InstallationS6RW0D6206002

CAUTION!

Do not turn the contact coil more than

allowable number of turns (about two and a

half turns from the center position clockwise

or counterclockwise respectively) with

steering wheel removed, or coil will break.

Removal

CAUTION!

Do not hammer the end of the shaft.

Hammering it will loosen the plastic shear

pins which maintain the column length and

impair the collapsible design of the column.

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove driver air bag (inflator) module from

steering wheel. Refer to “Driver Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Disconnect horn connector and audio control switch

connector, if equipped.

5) Remove steering shaft nut and then make alignment

marks (1) on steering wheel and shaft for a guide

during reinstallation.6) Remove steering wheel using special tool.

Special tool

(A): 09944–36011

InstallationCAUTION!

Following 2 Steps (Step 1) and 2)) are

prerequisite for installation of steering wheel.

If steering wheel has been installed without

these 2 Steps, contact coil will break when

steering wheel is turned.

1) Check that vehicle’s front tires are at straight-ahead

position and contact coil is centered. If contact coil is

turned after removing steering wheel, center contact

coil referring to “Centering Contact Coil Cable

Assembly”.

2) Install steering wheel to steering shaft with 2 grooves

(1) on contact coil fitted in 2 lugs (2) in the back of

steering wheel and also aligning marks (3) on

steering wheel and steering shaft.

3) Tighten steering shaft nut (4) to specified torque.

Tightening torque

Steering shaft nut (a): 33 N·m (3.3 kgf-m, 24.0 lb-

ft)

I4RS0A620005-01

(A)

I4RS0A620006-01

I4RS0A620007-01

Page 874 of 1556

Downloaded from www.Manualslib.com manuals search engine 6B-5 Steering Wheel and Column:

4) Connect horn connector and audio control switch

connector, if necessary.

5) Install driver air bag (inflator) module to steering

wheel. Refer to “Driver Air Bag (Inflator) Module

Removal and Installation in Section 8B”.

6) Connect negative (–) cable to battery.

7) Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

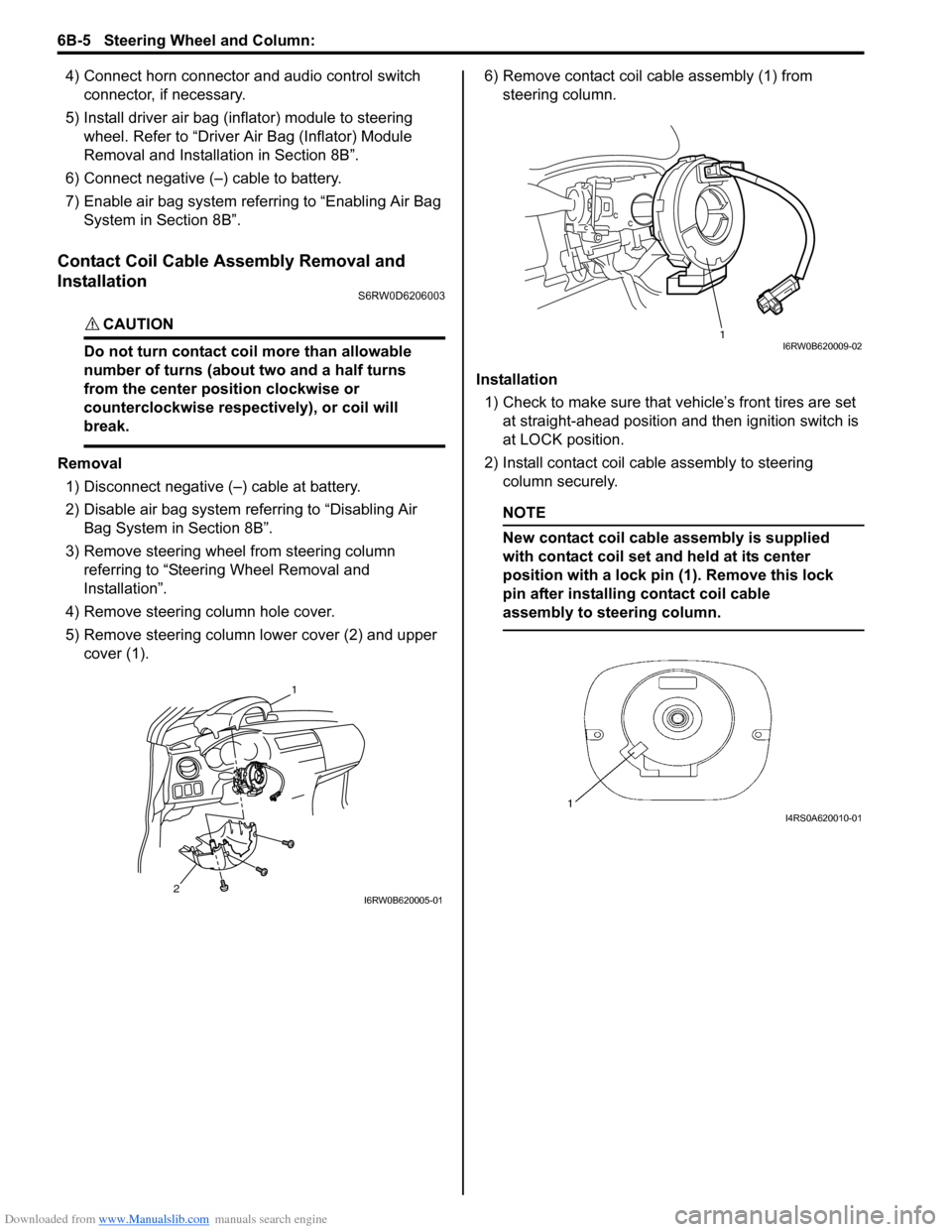

Contact Coil Cable Assembly Removal and

Installation

S6RW0D6206003

CAUTION!

Do not turn contact coil more than allowable

number of turns (about two and a half turns

from the center position clockwise or

counterclockwise respectively), or coil will

break.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove steering wheel from steering column

referring to “Steering Wheel Removal and

Installation”.

4) Remove steering column hole cover.

5) Remove steering column lower cover (2) and upper

cover (1).6) Remove contact coil cable assembly (1) from

steering column.

Installation

1) Check to make sure that vehicle’s front tires are set

at straight-ahead position and then ignition switch is

at LOCK position.

2) Install contact coil cable assembly to steering

column securely.

NOTE

New contact coil cable assembly is supplied

with contact coil set and held at its center

position with a lock pin (1). Remove this lock

pin after installing contact coil cable

assembly to steering column.

2

1

I6RW0B620005-01

1I6RW0B620009-02

I4RS0A620010-01

Page 875 of 1556

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-6

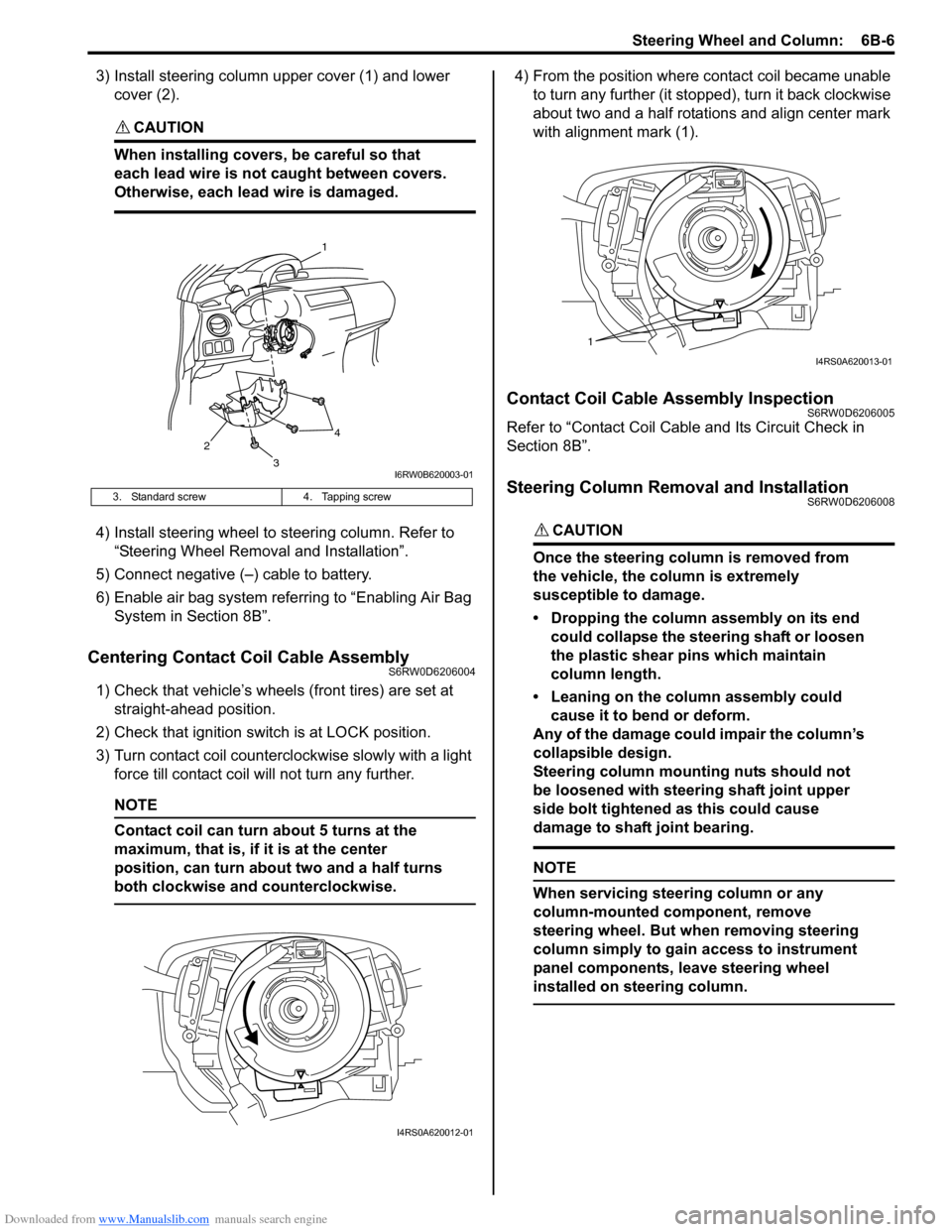

3) Install steering column upper cover (1) and lower

cover (2).

CAUTION!

When installing covers, be careful so that

each lead wire is not caught between covers.

Otherwise, each lead wire is damaged.

4) Install steering wheel to steering column. Refer to

“Steering Wheel Removal and Installation”.

5) Connect negative (–) cable to battery.

6) Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Centering Contact Coil Cable AssemblyS6RW0D6206004

1) Check that vehicle’s wheels (front tires) are set at

straight-ahead position.

2) Check that ignition switch is at LOCK position.

3) Turn contact coil counterclockwise slowly with a light

force till contact coil will not turn any further.

NOTE

Contact coil can turn about 5 turns at the

maximum, that is, if it is at the center

position, can turn about two and a half turns

both clockwise and counterclockwise.

4) From the position where contact coil became unable

to turn any further (it stopped), turn it back clockwise

about two and a half rotations and align center mark

with alignment mark (1).

Contact Coil Cable Assembly InspectionS6RW0D6206005

Refer to “Contact Coil Cable and Its Circuit Check in

Section 8B”.

Steering Column Removal and InstallationS6RW0D6206008

CAUTION!

Once the steering column is removed from

the vehicle, the column is extremely

susceptible to damage.

• Dropping the column assembly on its end

could collapse the steering shaft or loosen

the plastic shear pins which maintain

column length.

• Leaning on the column assembly could

cause it to bend or deform.

Any of the damage could impair the column’s

collapsible design.

Steering column mounting nuts should not

be loosened with steering shaft joint upper

side bolt tightened as this could cause

damage to shaft joint bearing.

NOTE

When servicing steering column or any

column-mounted component, remove

steering wheel. But when removing steering

column simply to gain access to instrument

panel components, leave steering wheel

installed on steering column.

3. Standard screw 4. Tapping screw

2

1

3

4

I6RW0B620003-01

I4RS0A620012-01

1

I4RS0A620013-01