TOYOTA CAMRY 1994 XV10 / 4.G Wiring Diagrams Workshop Manual

Manufacturer: TOYOTA, Model Year: 1994, Model line: CAMRY, Model: TOYOTA CAMRY 1994 XV10 / 4.GPages: 307, PDF Size: 5.48 MB

Page 181 of 307

181

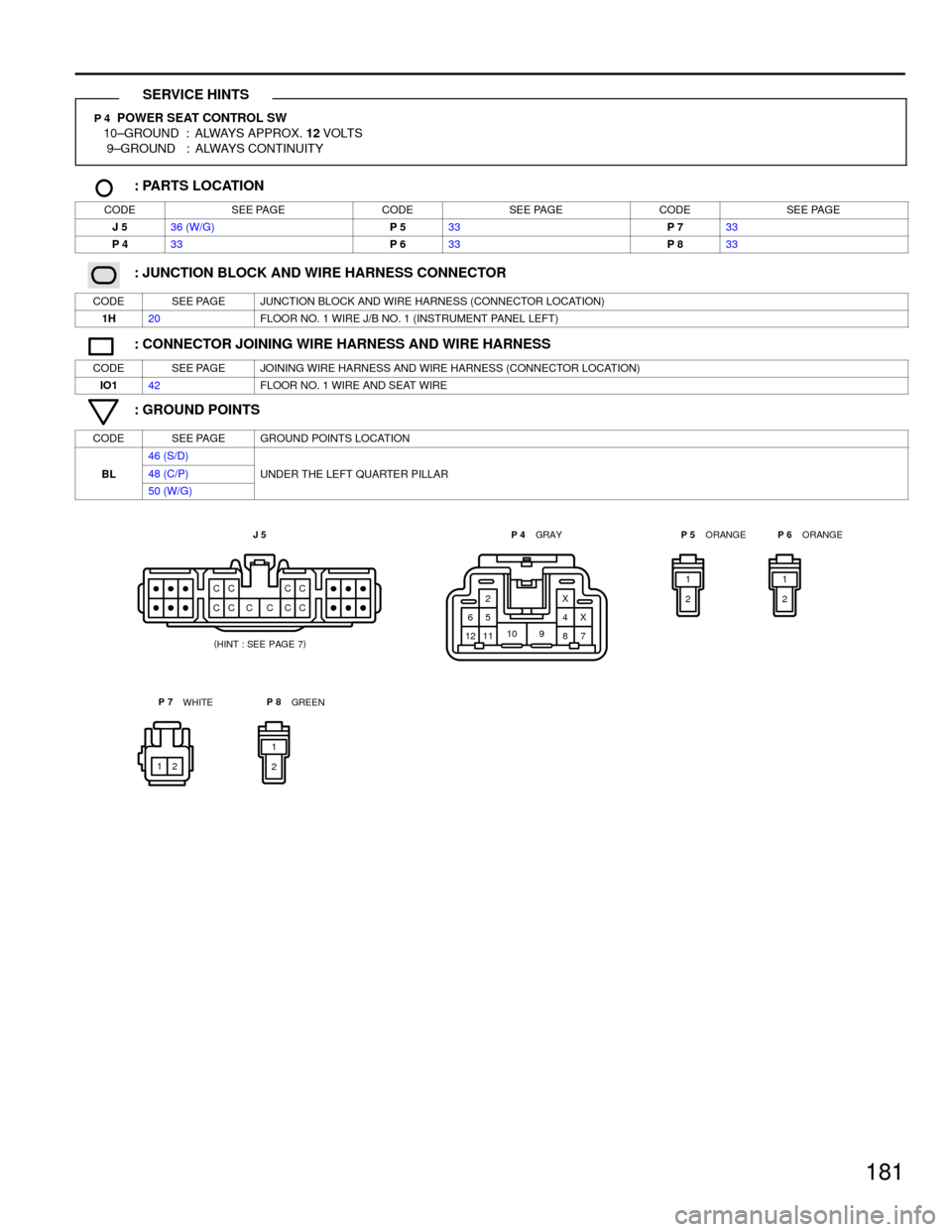

P 4 POWER SEAT CONTROL SW

10±GROUND : ALWAYS APPROX. 12 VOLTS

9±GROUND : ALWAYS CONTINUITY

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

J 536 (W/G)P 533P 733

P 433P 633P 833

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1H20FLOOR NO. 1 WIRE J/B NO. 1 (INSTRUMENT PANEL LEFT)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

IO142FLOOR NO. 1 WIRE AND SEAT WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

46 (S/D)

BL48 (C/P)UNDER THE LEFT QUARTER PILLARBL

50 (W/G)

UNDER THE LEFT QUARTER PILLAR

1

21

2

1

2P4 P5 P6

P7 P8GRAY ORANGE ORANGE

GREEN

12WHITECC CC

CC C C CCJ5

(

HINT : SEE PAGE 7)2X

54

11 89 10

7 X

126

SERVICE HINTS

Page 182 of 307

182

SHIFT LOCK

A

1 2STOP LIGHT

SW

G±R

G±W

G±W G±WL±R

B±RL±R

13 6

KEY INTERLOCK

SOLENOID

L±B W±B

W±B W±B

5 4SHIFT LOCK ECU

SHIFT LOCK

CONTROL SW

SHIFT LOCK

SOLENOID P1

P

P2

SL±

SL+

L±B

2 1 II2 9 II211

B±RL±R

B

BJUNCTION

CONNECTOR

II2 20

G

G±WG±R

L±R

L±R

II1 3

B

B

IEIFJUNCTION

CONNECTOR ()

J3S10

S5

K3J2B 1 A 2

B 2B1NOIS E FILTER

(

FOR STOP LIGHT) N2 ,N3 A

G±W

G±R

1L 91L21M 3 15A

CIG/RADIO15A

ECU±IG15A

STOP

1L 41M 6

FROM POWER SOURCE SYSTEM SEE PAGE 64

Page 183 of 307

BBB

BB B B BBB

BBB J2 J3

B

(

HINT : SEE PAGE 7)(

HINT : SEE PAGE 7)

12 N3B

13X

45612 S5 S10BLUE12K3

1 2 N2A

183

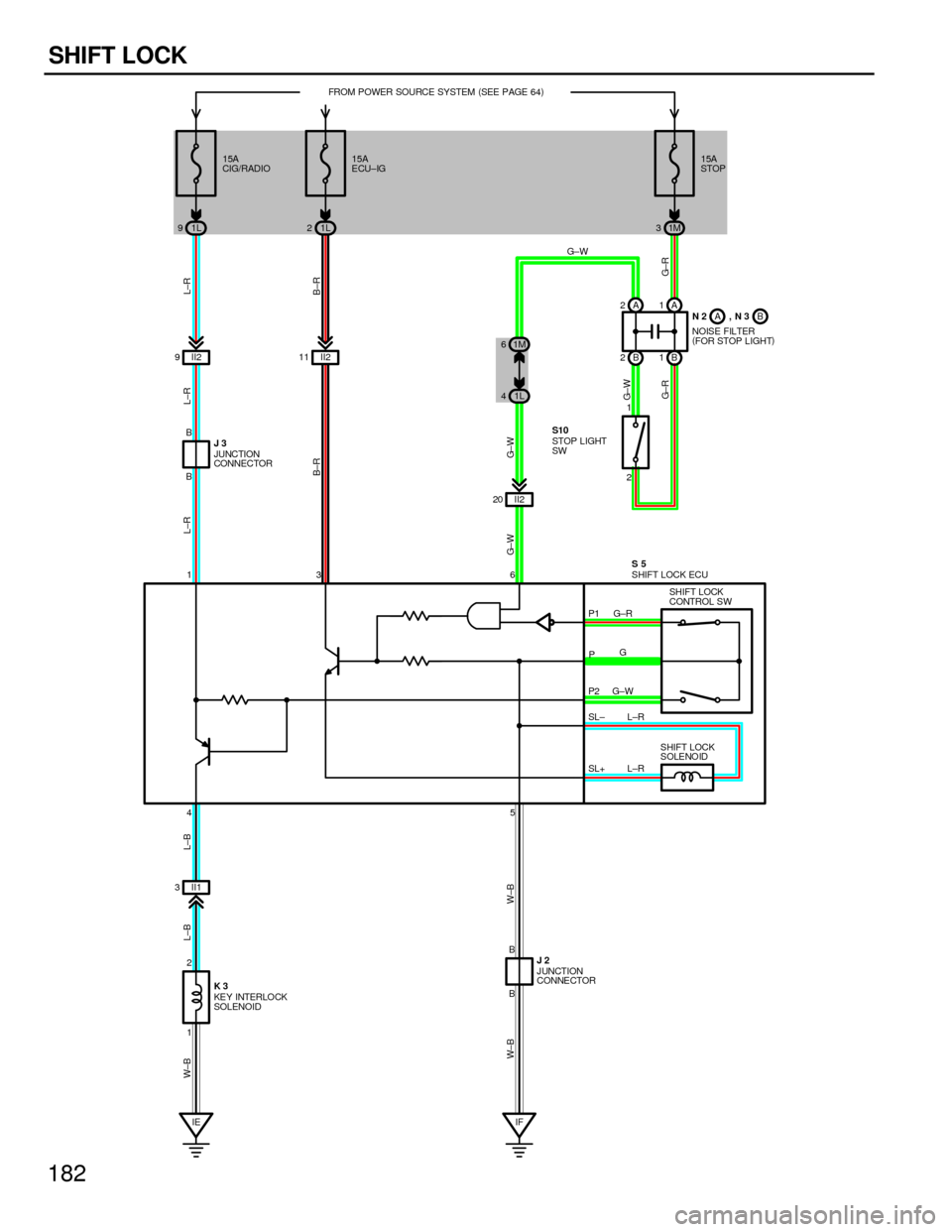

WHEN THE IGNITION SW IS TURNED TO ACC POSITION THE CURRENT FROM THE CIG/RADIO FUSE FLOWS TO TERMINAL 1 OF THE

SHIFT LOCK ECU. WHEN THE IGNITION SW IS TURNED TO ON POSITION THE CURRENT FROM THE ECU±IG FUSE FLOWS TO

TERMINAL 3 OF THE ECU.

1. SHIFT LOCK MECHANISM

WITH THE IGNITION SW ON, WHEN A SIGNAL THAT THE BRAKE PEDAL IS DEPRESSED (STOP LIGHT SW ON) AND A SIGNAL THAT

THE SHIFT LEVER IS PUT IN ªPº POSITION (CONTINUITY BETWEEN P1 AND P OF THE SHIFT LOCK CONTROL SW) IS INPUT TO THE

ECU, THE ECU OPERATES AND CURRENT FLOWS FROM TERMINAL 3 OF THE ECU " TERMINAL SL+ OF THE SHIFT LOCK

SOLENOID " SOLENOID " TERMINAL SL± " TERMINAL 5 OF THE ECU " GROUND. THIS CAUSES THE SHIFT LOCK SOLENOID TO

TURN ON (PLATE STOPPER DISENGAGES) AND THE SHIFT LEVER CAN SHIFT INTO OTHER POSITION THAN THE ªPº POSITION.

2. KEY INTERLOCK MECHANISM

WITH THE IGNITION SW IN ON OR ACC POSITION, WHEN THE SHIFT LEVER IS PUT IN ªPº POSITION (NO CONTINUITY BETWEEN P2

AND P OF SHIFT LOCK CONTROL SW), THE CURRENT FLOWING FROM TERMINAL 4 OF THE ECU " KEYINTERLOCK SOLENOID IS

CUT OFF. THIS CAUSES THE KEYINTERLOCK SOLENOID TO TURN OFF (LOCK LEVER DISENGAGES FROM LOCK POSITION) AND

THE IGNITION KEY CAN BE TURNED FROM ACC TO LOCK POSITION.

S 5 SHIFT LOCK ECU

1±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ACC OR ON POSITION

3±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

5±GROUND : ALWAYS CONTINUITY

6±GROUND : APPROX. 12 VOLTS WITH BRAKE PEDAL DEPRESSED

4±GROUND :0 VOLTS WITH IGNITION SW AT ACC POSITION AND SHIFT LEVER POSITION IN P POSITION

6±12 VOLTS WITH SHIFT LEVER POSITION IN EXCEPT P POSITION

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

J 233N 2A33S1033

J 333N 3B33

K 333S 533

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1L20COWL WIRE AND J/B NO 1 (INSTRUMENT PANEL LEFT)1M20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

II142COWL WIRE AND INSTRUMENT PANEL WIRE

II242INSTRUMENT PANEL WIRE AND COWL WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

IE42LEFT KICK PANELIF42LEFT KICK PANEL

SYSTEM OUTLINE

SERVICE HINTS

Page 184 of 307

184

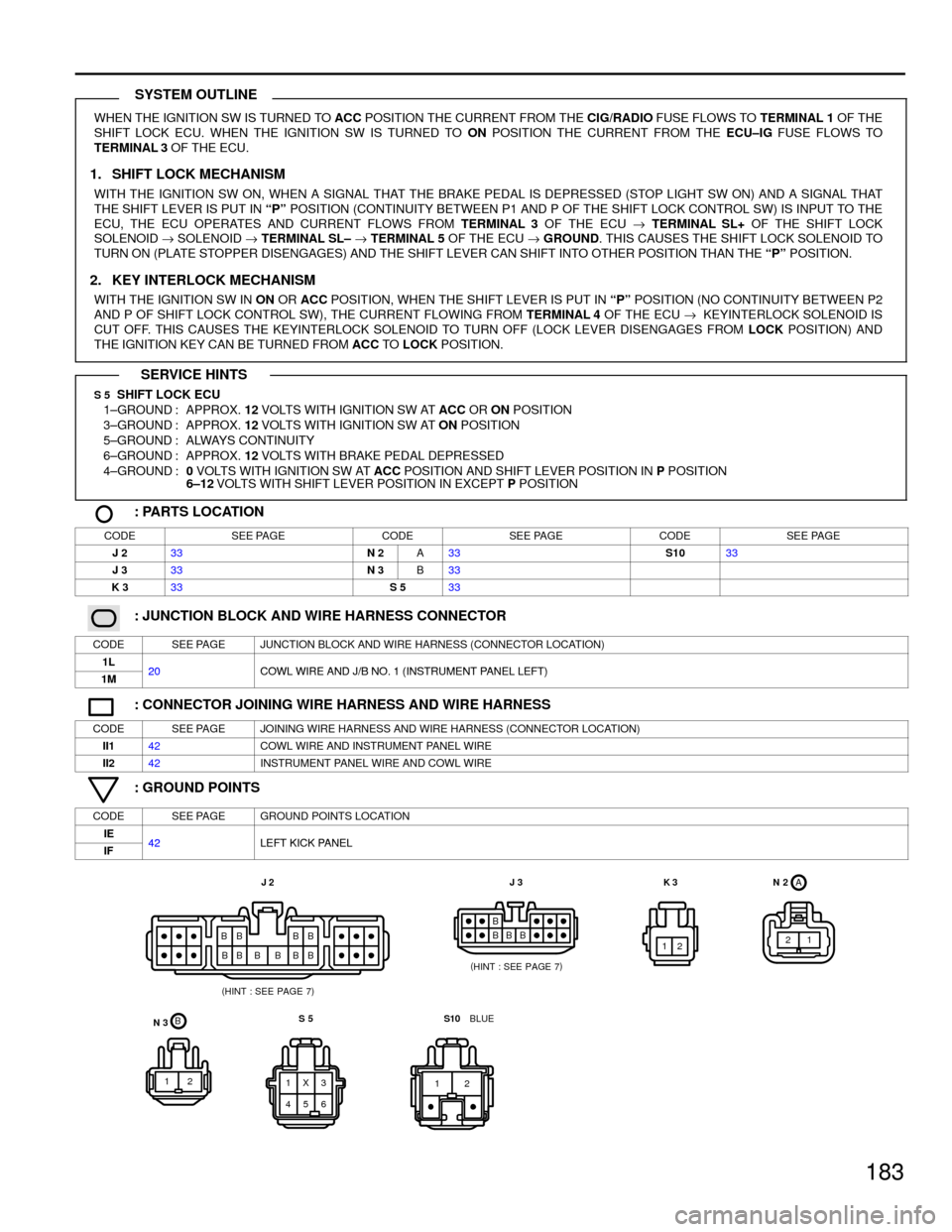

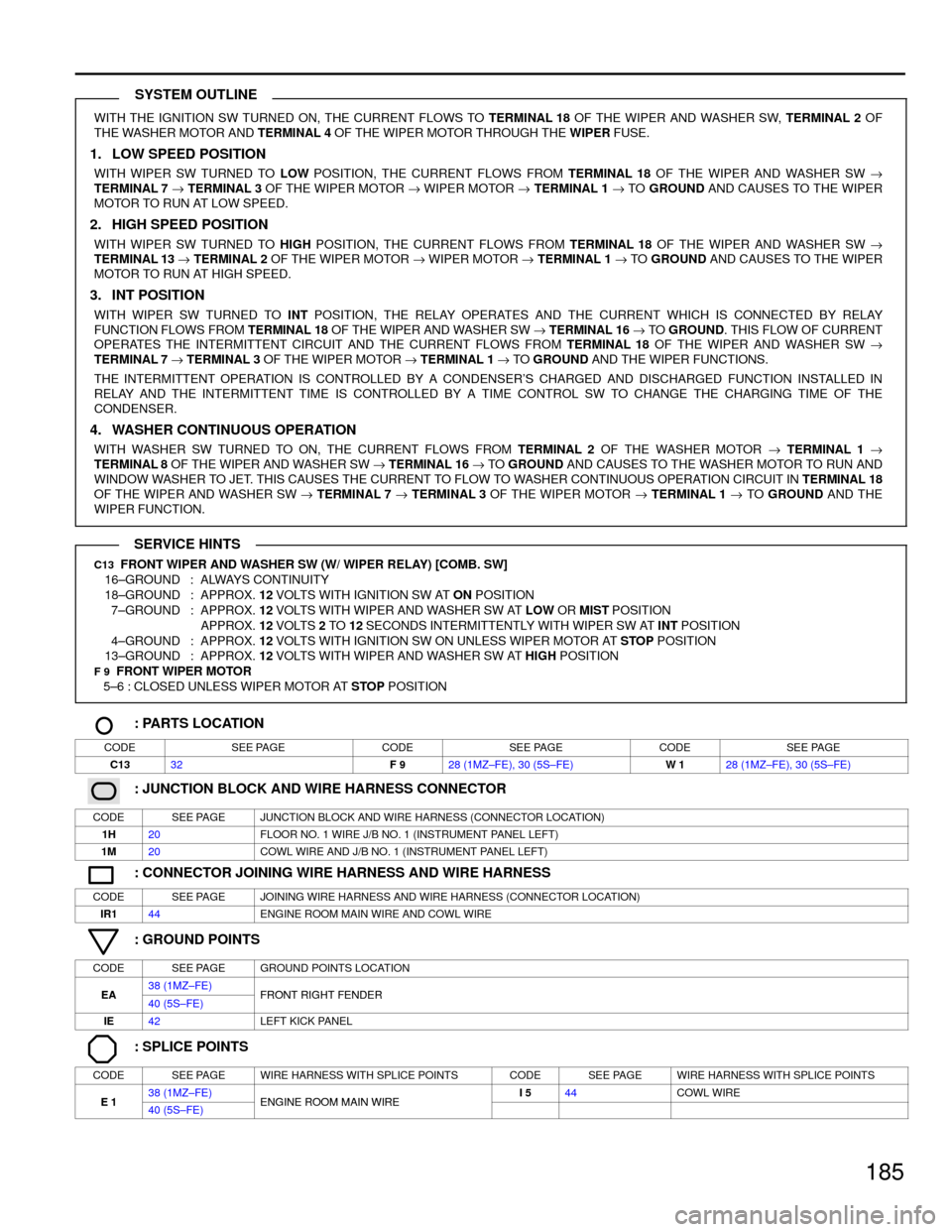

FRONT WIPER AND WASHER

M365 IR1 16 IR115 IR114

IEI5

OFF

MIST

INT

LOW

HIGH

WASHER

L

FROM POWER SOURCE SYSTEM(

SEEPAGE64)

8

4 16

13 7

18

L±O

L±B

L

L±YW±B

L±OL±B

L±Y FRONT WIPER AND WASHER SW(

W/ WIPER RELAY)

[COMB. SW]

FRONT W IP ER MOTOR F9 C13

2IR111

M 12

E1

L L

L

L±W L

WASHER MOTOR W1 L±W

L

12 C13BLACKW1BLACK F9BLACK

IR1 17

EA 1

W±B

X78X

XX

1618 X 4X X

13 X123

6 5 X

1M 220A

WIPER

Page 185 of 307

185

WITH THE IGNITION SW TURNED ON, THE CURRENT FLOWS TO TERMINAL 18 OF THE WIPER AND WASHER SW, TERMINAL 2 OF

THE WASHER MOTOR AND TERMINAL 4 OF THE WIPER MOTOR THROUGH THE WIPER FUSE.

1. LOW SPEED POSITION

WITH WIPER SW TURNED TO LOW POSITION, THE CURRENT FLOWS FROM TERMINAL 18 OF THE WIPER AND WASHER SW "

TERMINAL 7 " TERMINAL 3 OF THE WIPER MOTOR " WIPER MOTOR " TERMINAL 1 " TO GROUND AND CAUSES TO THE WIPER

MOTOR TO RUN AT LOW SPEED.

2. HIGH SPEED POSITION

WITH WIPER SW TURNED TO HIGH POSITION, THE CURRENT FLOWS FROM TERMINAL 18 OF THE WIPER AND WASHER SW "

TERMINAL 13 " TERMINAL 2 OF THE WIPER MOTOR " WIPER MOTOR " TERMINAL 1 " TO GROUND AND CAUSES TO THE WIPER

MOTOR TO RUN AT HIGH SPEED.

3. INT POSITION

WITH WIPER SW TURNED TO INT POSITION, THE RELAY OPERATES AND THE CURRENT WHICH IS CONNECTED BY RELAY

FUNCTION FLOWS FROM TERMINAL 18 OF THE WIPER AND WASHER SW " TERMINAL 16 " TO GROUND. THIS FLOW OF CURRENT

OPERATES THE INTERMITTENT CIRCUIT AND THE CURRENT FLOWS FROM TERMINAL 18 OF THE WIPER AND WASHER SW "

TERMINAL 7 " TERMINAL 3 OF THE WIPER MOTOR " TERMINAL 1 " TO GROUND AND THE WIPER FUNCTIONS.

THE INTERMITTENT OPERATION IS CONTROLLED BY A CONDENSER'S CHARGED AND DISCHARGED FUNCTION INSTALLED IN

RELAY AND THE INTERMITTENT TIME IS CONTROLLED BY A TIME CONTROL SW TO CHANGE THE CHARGING TIME OF THE

CONDENSER.

4. WASHER CONTINUOUS OPERATION

WITH WASHER SW TURNED TO ON, THE CURRENT FLOWS FROM TERMINAL 2 OF THE WASHER MOTOR " TERMINAL 1 "

TERMINAL 8 OF THE WIPER AND WASHER SW " TERMINAL 16 " TO GROUND AND CAUSES TO THE WASHER MOTOR TO RUN AND

WINDOW WASHER TO JET. THIS CAUSES THE CURRENT TO FLOW TO WASHER CONTINUOUS OPERATION CIRCUIT IN TERMINAL 18

OF THE WIPER AND WASHER SW " TERMINAL 7 " TERMINAL 3 OF THE WIPER MOTOR " TERMINAL 1 " TO GROUND AND THE

WIPER FUNCTION.

C13 FRONT WIPER AND WASHER SW (W/ WIPER RELAY) [COMB. SW]

16±GROUND : ALWAYS CONTINUITY

18±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

7±GROUND : APPROX. 12 VOLTS WITH WIPER AND WASHER SW AT LOW OR MIST POSITION

APPROX. 12 VOLTS 2 TO 12 SECONDS INTERMITTENTLY WITH WIPER SW AT INT POSITION

4±GROUND : APPROX. 12 VOLTS WITH IGNITION SW ON UNLESS WIPER MOTOR AT STOP POSITION

13±GROUND : APPROX. 12 VOLTS WITH WIPER AND WASHER SW AT HIGH POSITION

F 9 FRONT WIPER MOTOR

5±6 : CLOSED UNLESS WIPER MOTOR AT STOP POSITION

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C1332F 928 (1MZ±FE), 30 (5S±FE)W 128 (1MZ±FE), 30 (5S±FE)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1H20FLOOR NO. 1 WIRE J/B NO. 1 (INSTRUMENT PANEL LEFT)

1M20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

IR144ENGINE ROOM MAIN WIRE AND COWL WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

EA38 (1MZ±FE)FRONT RIGHT FENDEREA40 (5S±FE)FRONT RIGHT FENDER

IE42LEFT KICK PANEL

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

E138 (1MZ±FE)ENGINE ROOM MAIN WIREI 544COWL WIREE 140 (5S±FE)ENGINE ROOM MAIN WIRE

SYSTEM OUTLINE

SERVICE HINTS

Page 186 of 307

186

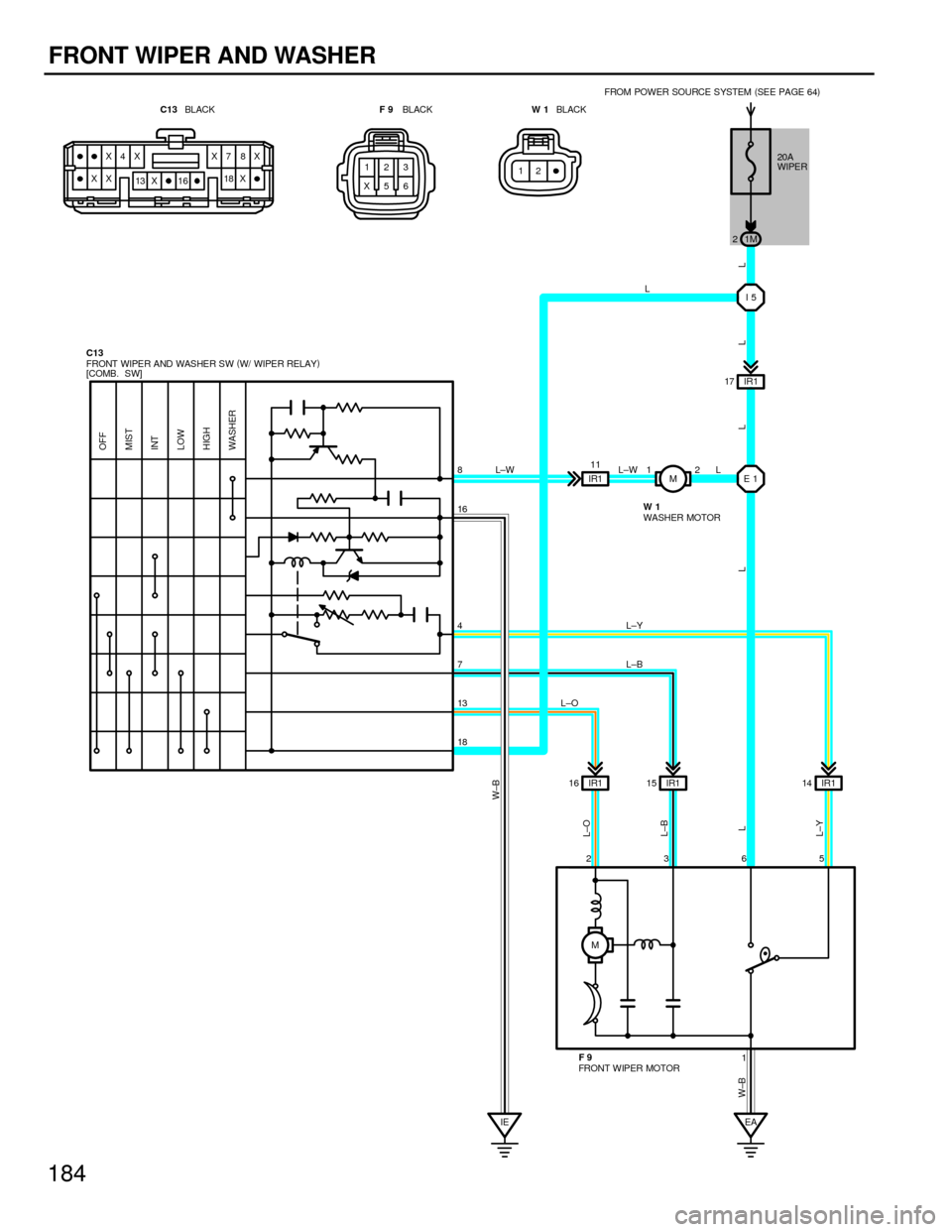

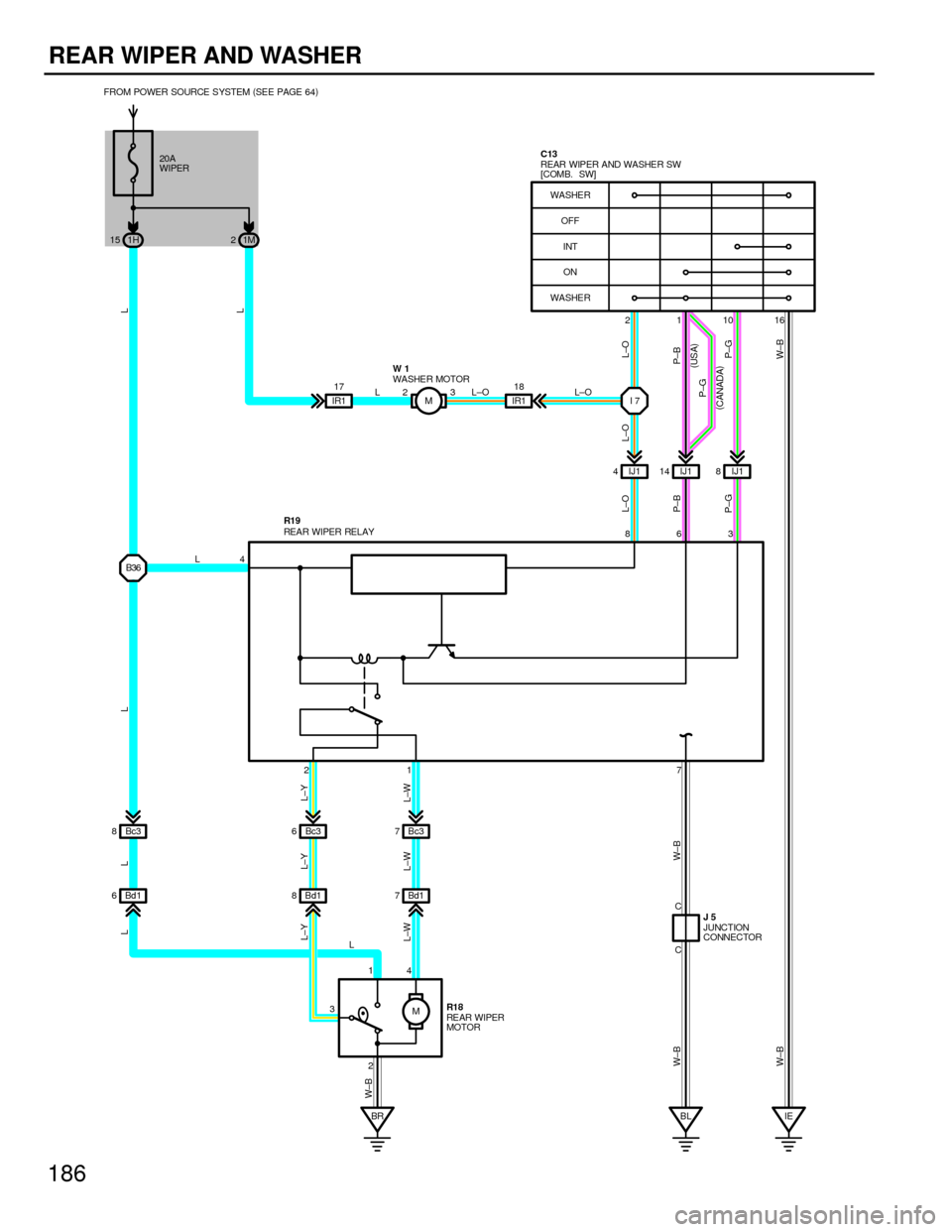

REAR WIPER AND WASHER

IR118

IR117

M 23

IJ1 4IJ114 IJ18

Bc3 8Bc36Bc37

Bd1 6Bd18Bd17I7

B36

M 14

BL IE L L±O L±O

L

L

L

L

L±O

P±B

P±G

W±B L±O L±O

P±B

P±G W±B W±B

W±BL±WL±Y

L±WL±Y

L±WL±YLL L

21 72 1 10 16

3 4

C 863

C FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

JUNCTION

CONNECTOR J5

REAR WIPER

MOTOR R18 REA R WIPER RELAY R19WASHER MOTOR W1REAR WIPER AND WASHER SW

[COMB. SW] C13

OFF

INT

ON

WASHER WASHER

P±G

(

CANADA)

BR 2

W±B

(

US A)

1H 15 1M2 WIPER

20A

Page 187 of 307

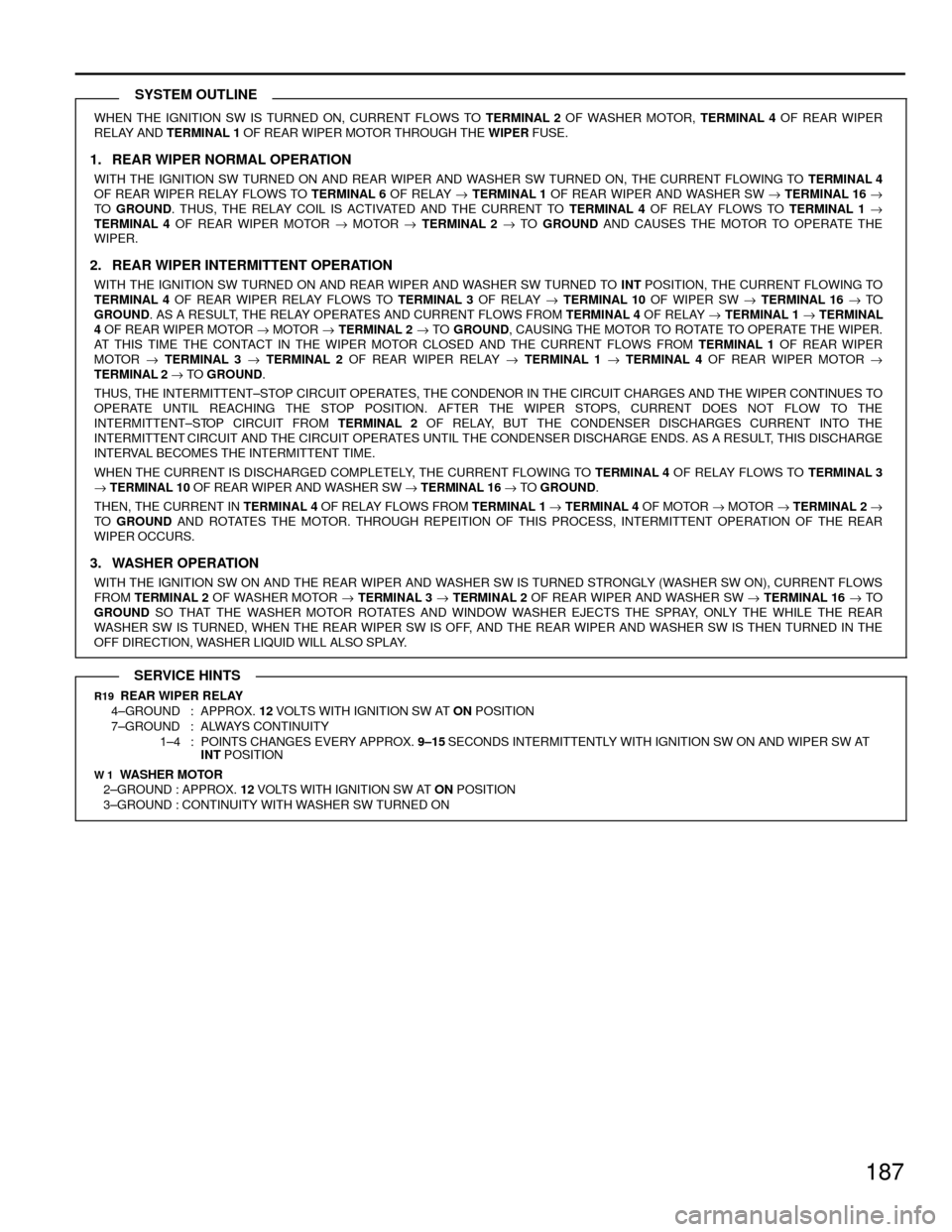

187

WHEN THE IGNITION SW IS TURNED ON, CURRENT FLOWS TO TERMINAL 2 OF WASHER MOTOR, TERMINAL 4 OF REAR WIPER

RELAY AND TERMINAL 1 OF REAR WIPER MOTOR THROUGH THE WIPER FUSE.

1. REAR WIPER NORMAL OPERATION

WITH THE IGNITION SW TURNED ON AND REAR WIPER AND WASHER SW TURNED ON, THE CURRENT FLOWING TO TERMINAL 4

OF REAR WIPER RELAY FLOWS TO TERMINAL 6 OF RELAY " TERMINAL 1 OF REAR WIPER AND WASHER SW " TERMINAL 16 "

TO GROUND. THUS, THE RELAY COIL IS ACTIVATED AND THE CURRENT TO TERMINAL 4 OF RELAY FLOWS TO TERMINAL 1 "

TERMINAL 4 OF REAR WIPER MOTOR " MOTOR " TERMINAL 2 " TO GROUND AND CAUSES THE MOTOR TO OPERATE THE

WIPER.

2. REAR WIPER INTERMITTENT OPERATION

WITH THE IGNITION SW TURNED ON AND REAR WIPER AND WASHER SW TURNED TO INT POSITION, THE CURRENT FLOWING TO

TERMINAL 4 OF REAR WIPER RELAY FLOWS TO TERMINAL 3 OF RELAY " TERMINAL 10 OF WIPER SW " TERMINAL 16 " TO

GROUND. AS A RESULT, THE RELAY OPERATES AND CURRENT FLOWS FROM TERMINAL 4 OF RELAY " TERMINAL 1 " TERMINAL

4 OF REAR WIPER MOTOR " MOTOR " TERMINAL 2 " TO GROUND, CAUSING THE MOTOR TO ROTATE TO OPERATE THE WIPER.

AT THIS TIME THE CONTACT IN THE WIPER MOTOR CLOSED AND THE CURRENT FLOWS FROM TERMINAL 1 OF REAR WIPER

MOTOR " TERMINAL 3 " TERMINAL 2 OF REAR WIPER RELAY " TERMINAL 1 " TERMINAL 4 OF REAR WIPER MOTOR "

TERMINAL 2 " TO GROUND.

THUS, THE INTERMITTENT±STOP CIRCUIT OPERATES, THE CONDENOR IN THE CIRCUIT CHARGES AND THE WIPER CONTINUES TO

OPERATE UNTIL REACHING THE STOP POSITION. AFTER THE WIPER STOPS, CURRENT DOES NOT FLOW TO THE

INTERMITTENT±STOP CIRCUIT FROM TERMINAL 2 OF RELAY, BUT THE CONDENSER DISCHARGES CURRENT INTO THE

INTERMITTENT CIRCUIT AND THE CIRCUIT OPERATES UNTIL THE CONDENSER DISCHARGE ENDS. AS A RESULT, THIS DISCHARGE

INTERVAL BECOMES THE INTERMITTENT TIME.

WHEN THE CURRENT IS DISCHARGED COMPLETELY, THE CURRENT FLOWING TO TERMINAL 4 OF RELAY FLOWS TO TERMINAL 3

" TERMINAL 10 OF REAR WIPER AND WASHER SW " TERMINAL 16 " TO GROUND.

THEN, THE CURRENT IN TERMINAL 4 OF RELAY FLOWS FROM TERMINAL 1 " TERMINAL 4 OF MOTOR " MOTOR " TERMINAL 2 "

TO GROUND AND ROTATES THE MOTOR. THROUGH REPEITION OF THIS PROCESS, INTERMITTENT OPERATION OF THE REAR

WIPER OCCURS.

3. WASHER OPERATION

WITH THE IGNITION SW ON AND THE REAR WIPER AND WASHER SW IS TURNED STRONGLY (WASHER SW ON), CURRENT FLOWS

FROM TERMINAL 2 OF WASHER MOTOR " TERMINAL 3 " TERMINAL 2 OF REAR WIPER AND WASHER SW " TERMINAL 16 " TO

GROUND SO THAT THE WASHER MOTOR ROTATES AND WINDOW WASHER EJECTS THE SPRAY, ONLY THE WHILE THE REAR

WASHER SW IS TURNED, WHEN THE REAR WIPER SW IS OFF, AND THE REAR WIPER AND WASHER SW IS THEN TURNED IN THE

OFF DIRECTION, WASHER LIQUID WILL ALSO SPLAY.

R19 REAR WIPER RELAY

4±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

7±GROUND : ALWAYS CONTINUITY

1±4 : POINTS CHANGES EVERY APPROX. 9±15 SECONDS INTERMITTENTLY WITH IGNITION SW ON AND WIPER SW AT

INT POSITION

W 1 WASHER MOTOR

2±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

3±GROUND : CONTINUITY WITH WASHER SW TURNED ON

SYSTEM OUTLINE

SERVICE HINTS

Page 188 of 307

188

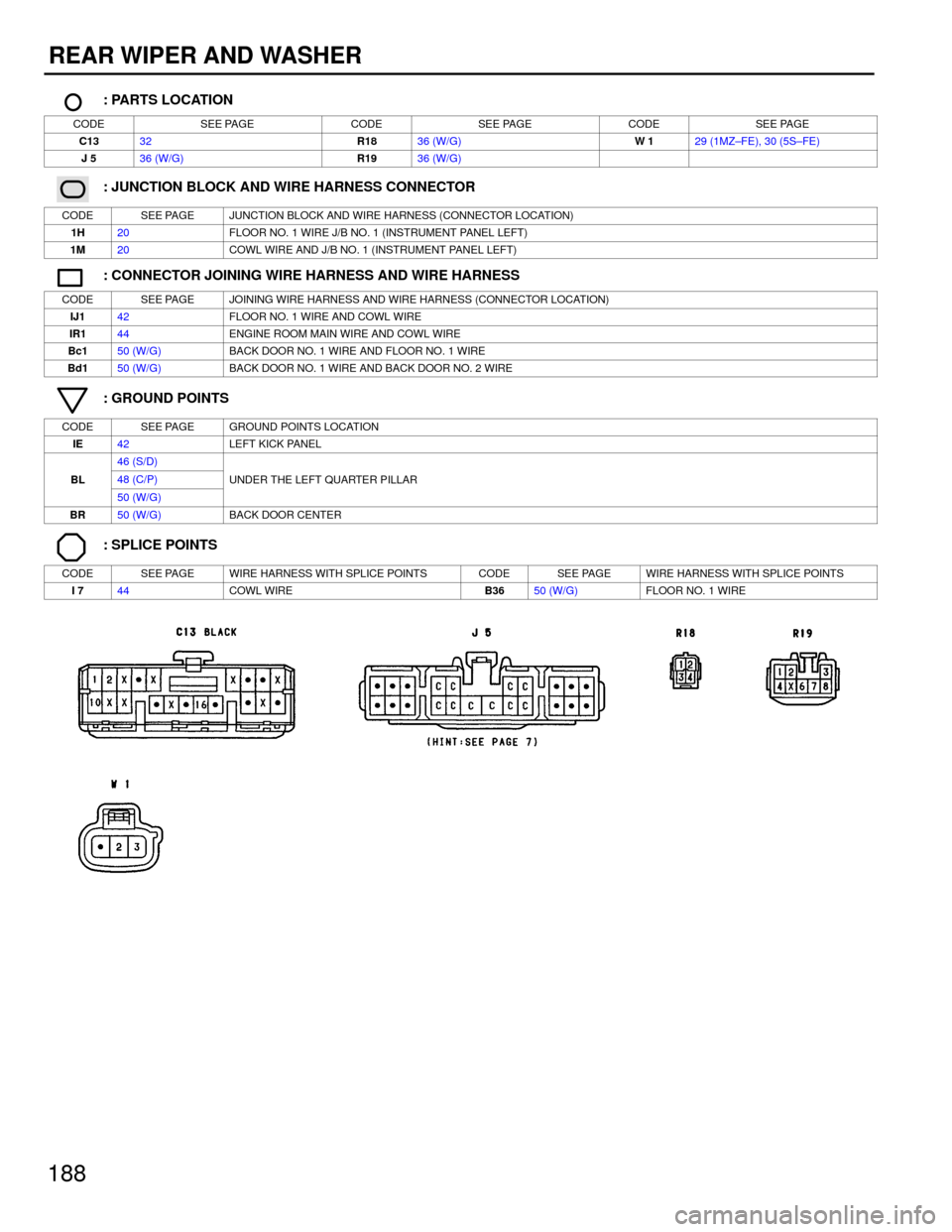

REAR WIPER AND WASHER

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C1332R1836 (W/G)W 129 (1MZ±FE), 30 (5S±FE)

J 536 (W/G)R1936 (W/G)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1H20FLOOR NO. 1 WIRE J/B NO. 1 (INSTRUMENT PANEL LEFT)

1M20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

IJ142FLOOR NO. 1 WIRE AND COWL WIRE

IR144ENGINE ROOM MAIN WIRE AND COWL WIRE

Bc150 (W/G)BACK DOOR NO. 1 WIRE AND FLOOR NO. 1 WIRE

Bd150 (W/G)BACK DOOR NO. 1 WIRE AND BACK DOOR NO. 2 WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

IE42LEFT KICK PANEL

46 (S/D)

BL48 (C/P)UNDER THE LEFT QUARTER PILLARBL

50 (W/G)

UNDER THE LEFT QUARTER PILLAR

BR50 (W/G)BACK DOOR CENTER

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

I 744COWL WIREB3650 (W/G)FLOOR NO. 1 WIRE

Page 189 of 307

189

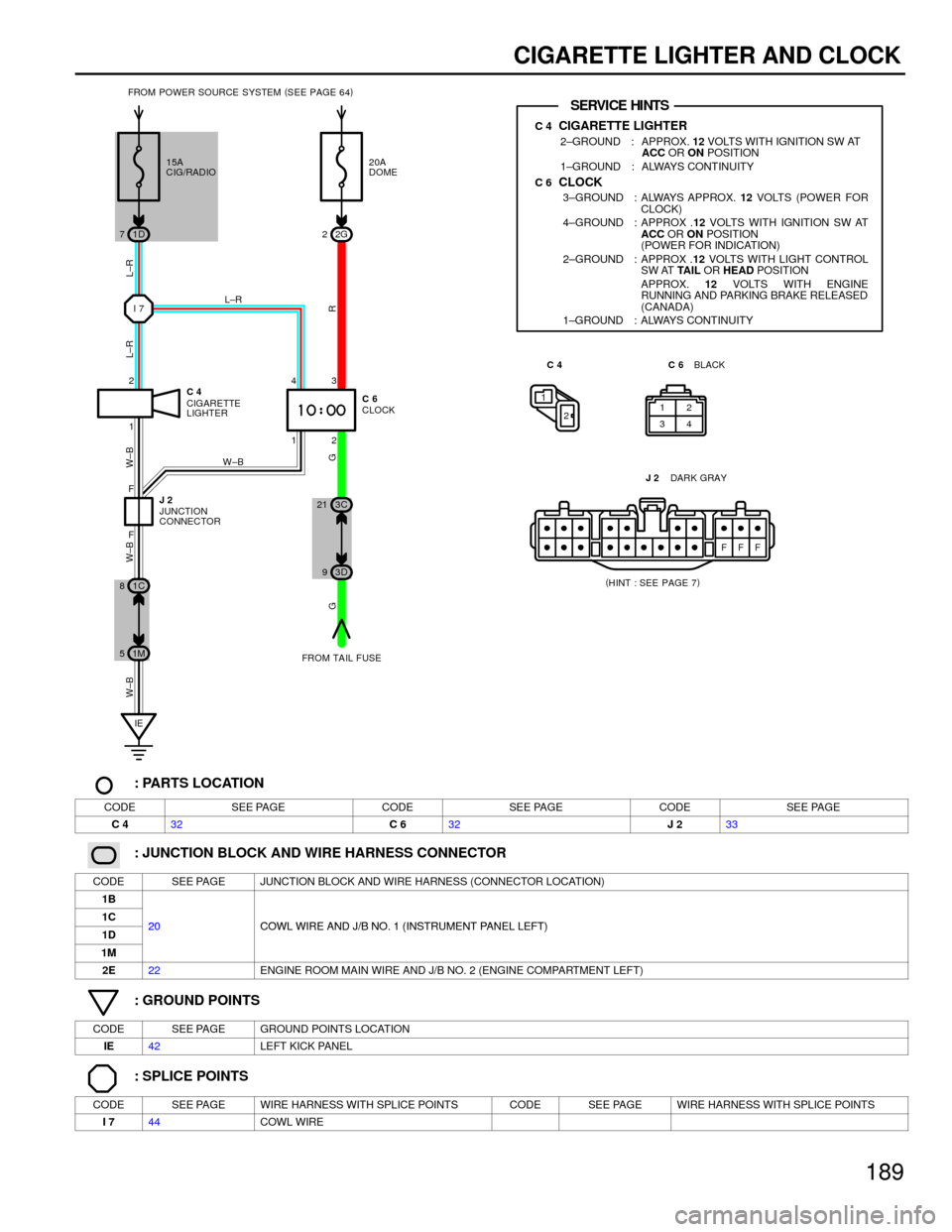

CIGARETTE LIGHTER AND CLOCK

2G 2

I7

IE 1

F12

F243

W±BL±R

L±R

R L±R W±B

G GW±B W±B

FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

20A

DOME

JUNCTION

CONNECTOR

FROM TA IL FUSE CIGARETTE

LIGHTERCLOCK

J2C4

C6SERVI CE HI NTS

F F F C4 C6

J2DARK GRAYBLACK

(

HINT : SEE PAGE 7) 1

212

34

1D 715A

CIG/RADIO

3D 93C 21

1M 51C 8

C 4 CIGARETTE LIGHTER2±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT

ACC OR ON POSITION

1±GROUND : ALWAYS CONTINUITY

C 6

CLOCK3±GROUND : ALWAYS APPROX. 12 VOLTS (POWER FOR

CLOCK)

4±GROUND : APPROX .12 VOLTS WITH IGNITION SW AT

ACC OR ON POSITION

(POWER FOR INDICATION)

2±GROUND : APPROX .12 VOLTS WITH LIGHT CONTROL

SW AT TAIL OR HEAD POSITION

APPROX. 12 VOLTS WITH ENGINE

RUNNING AND PARKING BRAKE RELEASED

(CANADA)

1±GROUND : ALWAYS CONTINUITY

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C 432C 632J 233

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1B

1C20COWL WIRE AND J/B NO 1 (INSTRUMENT PANEL LEFT)1D20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1M

2E22ENGINE ROOM MAIN WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

IE42LEFT KICK PANEL

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

I 744COWL WIRE

Page 190 of 307

190

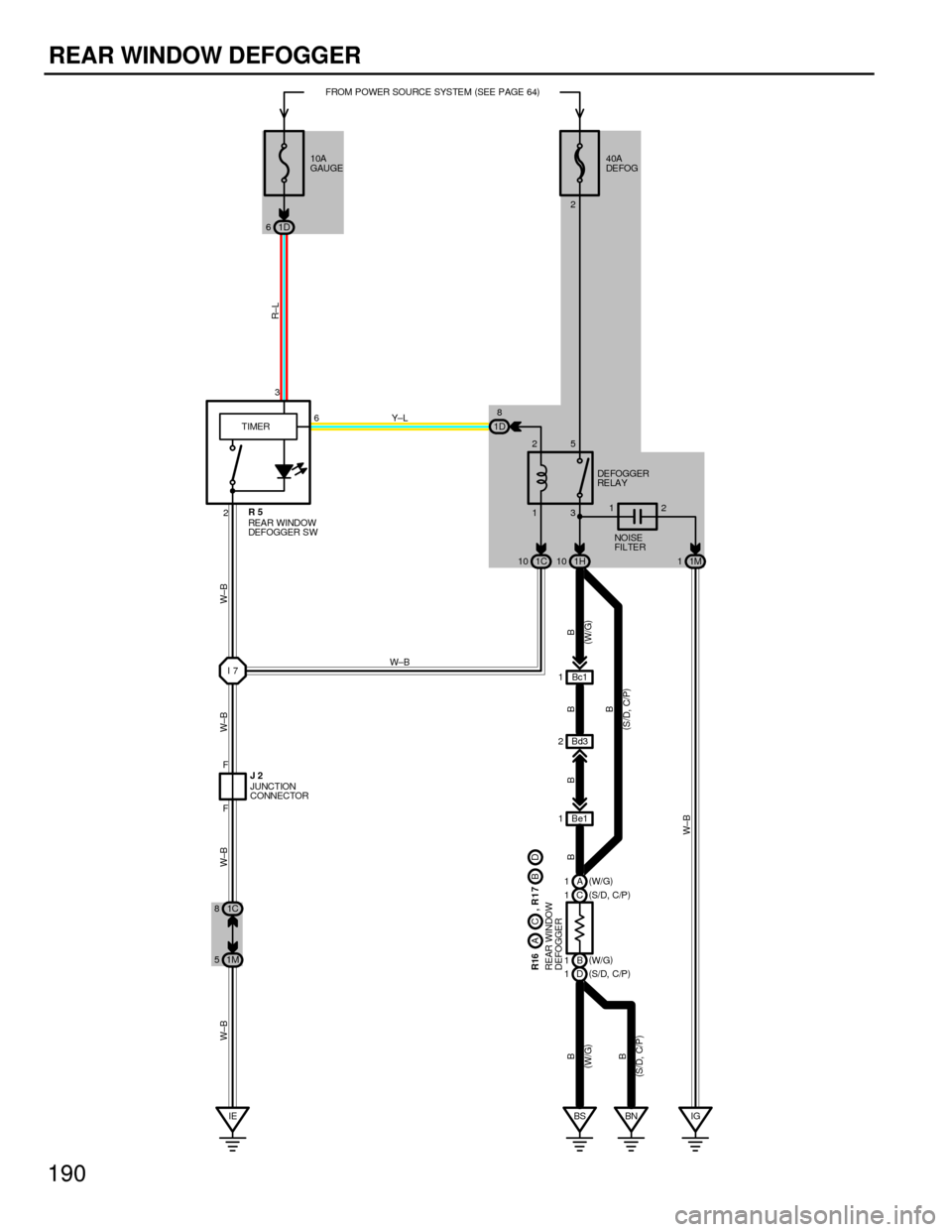

REAR WINDOW DEFOGGER

AC

IEBS 23

6

C 1

B 1 I7

IG F F

JUNCTION

CONNECTOR

REAR WINDOW

DEFOGGER

REA R WINDOW

DEFOGGER SWFROM POWER SOURCE SYSTEM(

SEE PAGE 64)

Y±L

R±L W±B W±B W±B W±B

BB

W±B

R5

J2

R16 , R 1 7B

Bc1 1

Bd3 2

Be1 1

B B B

W±B TIMER

A 1

D 1

BN

B

B(

W/G)

(

S /D, C/P) (

W/G)

(

S/D, C/P)

(

W/G)

(

S/D, C/P)

(

W/G)

(

S/D, C/P)

D

1C 10 1H10 1D8

1M 1 40A

DE FOG

DEFOGGER

RE LA Y

NOISE

FI L TE R 13 25

12 2

1D 6GAUGE

1M 51C 8

10A