TOYOTA CAMRY 1994 XV10 / 4.G Wiring Diagrams Workshop Manual

Manufacturer: TOYOTA, Model Year: 1994, Model line: CAMRY, Model: TOYOTA CAMRY 1994 XV10 / 4.GPages: 307, PDF Size: 5.48 MB

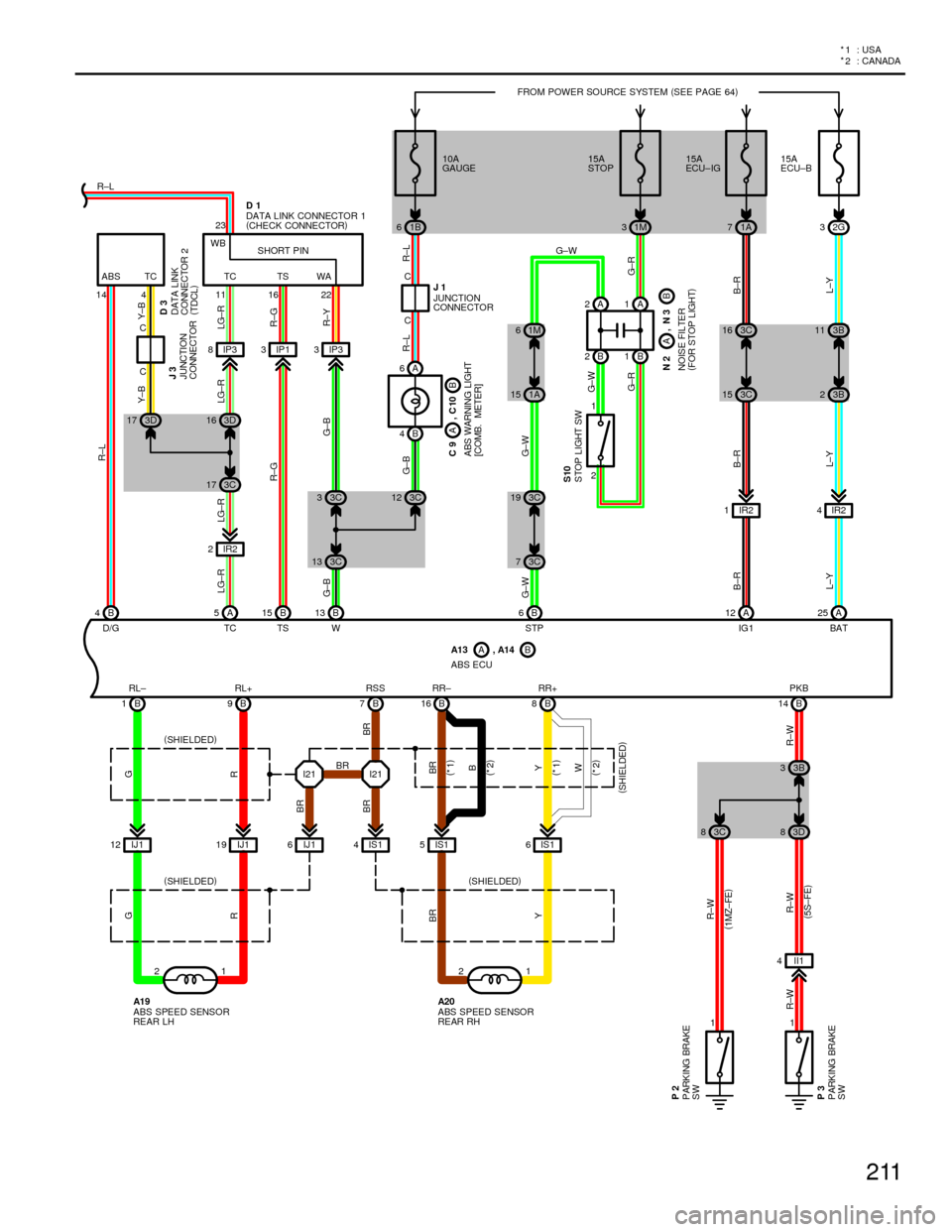

Page 211 of 307

211

*

2 : CANADA *1 : USA

A

A

A

2G

II1 4 IR2 2IR2 1IR24

IS1 6 IS1 5 IS1 4 IJ1 6 IJ1 19 IJ1 12

1 2 1 2I21 I21 B 1B9B7B

16 B8B14A 25 A 12 B 6 B 13 A 5 B 4A 6

B

4

11 IP3 8IP33

B 15

RL± RL+ RSS RR± RR+ PKB

BR ABS TC TC TS WA R±LFROM POWER SOURCE SYSTEM(

SEE PAGE 64)

R±L

B±R

L±Y B±R

L±Y B±R

L±Y G±W G±WG±BR±G LG±RR±L

LG±R

G±BG±BY±B

LG±R LG±R

R±G

R±YY±B G

R R G

BR

YBR

Y

R±W R±W R±WR±W

11 16 22 4 1423

D/G TC TS W STP IG1 BATWB

DATA LINK

CONNECTOR 2

(

TDCL)

DATA LINK CONNECTOR 1

(

CHECK CONNECTOR)

C C

ABS WARNING LIGHT

[COMB. METER]

ABS SPEED SENSOR

REAR LH(

SHIELDED)

(

SHIELDED)

ABS SPEED SENSOR

REAR RH

PARKING BRAKE

SW

PARKING BRAKE

SW(

1MZ±FE)

ABS ECU

JUNCTION

CONNECTOR

R±LC CJ1

JUNCTION

CONNECTORJ3

C9 ,C10

B

A13 , A14

B

BR BR

BR

A19 A20

P2

P3(

5S±FE)

D1

D3

SHORT PIN

STOP LIGHT SW

G±R

G±W

2 1

S10

B

1 A 2

B 2B1

NOISE FILTER

(

FOR STOP LIGHT) N2 , N3

A

G±W

G±R

IP1 3

(

*1)

(

*

1) B

(

*2)

W

(

*2)

(

SHIELDED)

(

SHIELDED)

1A 151M 6

1B 61M31A73 10A

GAUGE15A

ECU±B 15A

ECU±IG 15A

STOP

3C 73C 19

3D 17

3C 173D 16

3C 133C 33C12

3C 15 3B23B 11 3C 16

3B 3

3D 8 3C 8

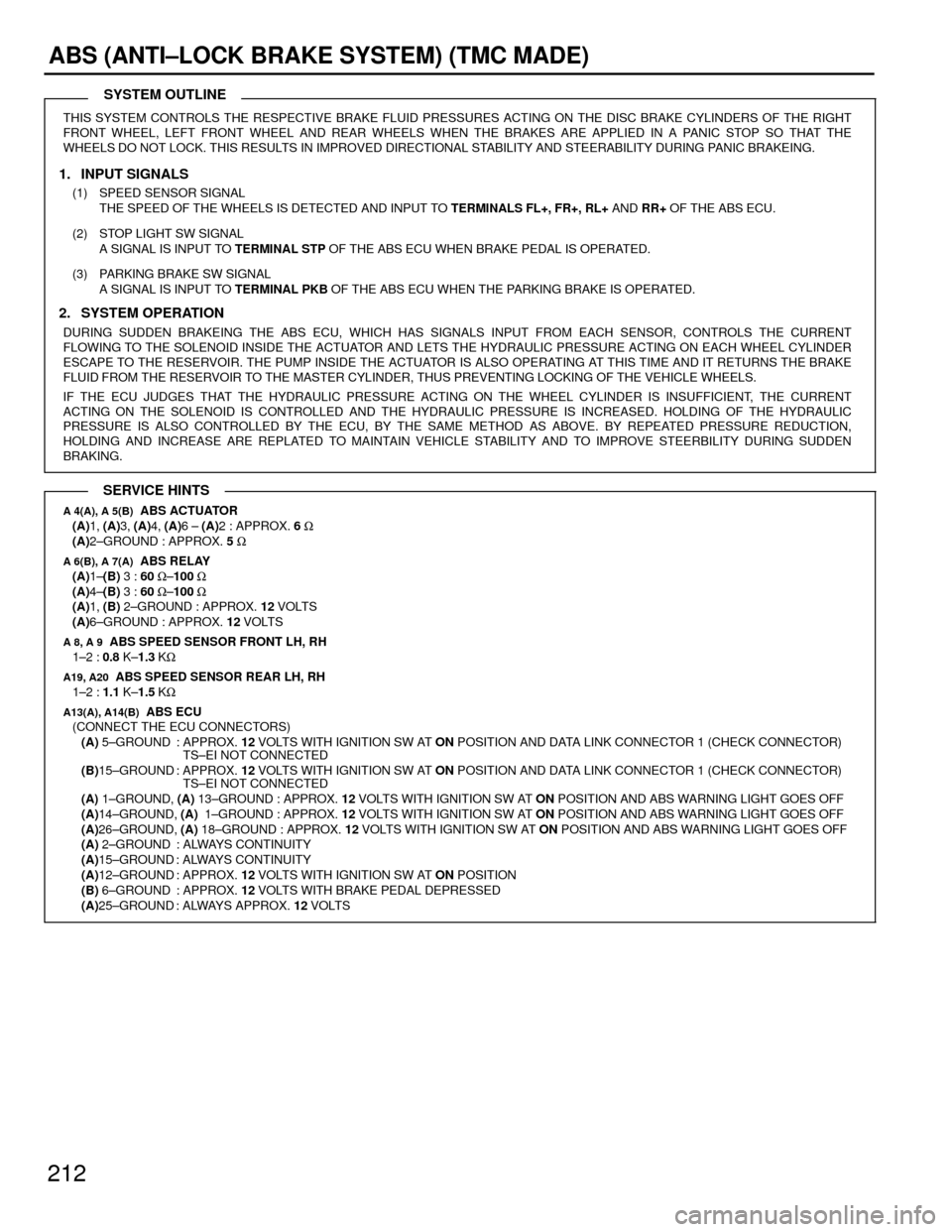

Page 212 of 307

212

ABS (ANTI±LOCK BRAKE SYSTEM) (TMC MADE)

THIS SYSTEM CONTROLS THE RESPECTIVE BRAKE FLUID PRESSURES ACTING ON THE DISC BRAKE CYLINDERS OF THE RIGHT

FRONT WHEEL, LEFT FRONT WHEEL AND REAR WHEELS WHEN THE BRAKES ARE APPLIED IN A PANIC STOP SO THAT THE

WHEELS DO NOT LOCK. THIS RESULTS IN IMPROVED DIRECTIONAL STABILITY AND STEERABILITY DURING PANIC BRAKEING.

1. INPUT SIGNALS

(1) SPEED SENSOR SIGNAL

THE SPEED OF THE WHEELS IS DETECTED AND INPUT TO TERMINALS FL+, FR+, RL+ AND RR+ OF THE ABS ECU.

(2) STOP LIGHT SW SIGNAL

A SIGNAL IS INPUT TO TERMINAL STP OF THE ABS ECU WHEN BRAKE PEDAL IS OPERATED.

(3) PARKING BRAKE SW SIGNAL

A SIGNAL IS INPUT TO TERMINAL PKB OF THE ABS ECU WHEN THE PARKING BRAKE IS OPERATED.

2. SYSTEM OPERATION

DURING SUDDEN BRAKEING THE ABS ECU, WHICH HAS SIGNALS INPUT FROM EACH SENSOR, CONTROLS THE CURRENT

FLOWING TO THE SOLENOID INSIDE THE ACTUATOR AND LETS THE HYDRAULIC PRESSURE ACTING ON EACH WHEEL CYLINDER

ESCAPE TO THE RESERVOIR. THE PUMP INSIDE THE ACTUATOR IS ALSO OPERATING AT THIS TIME AND IT RETURNS THE BRAKE

FLUID FROM THE RESERVOIR TO THE MASTER CYLINDER, THUS PREVENTING LOCKING OF THE VEHICLE WHEELS.

IF THE ECU JUDGES THAT THE HYDRAULIC PRESSURE ACTING ON THE WHEEL CYLINDER IS INSUFFICIENT, THE CURRENT

ACTING ON THE SOLENOID IS CONTROLLED AND THE HYDRAULIC PRESSURE IS INCREASED. HOLDING OF THE HYDRAULIC

PRESSURE IS ALSO CONTROLLED BY THE ECU, BY THE SAME METHOD AS ABOVE. BY REPEATED PRESSURE REDUCTION,

HOLDING AND INCREASE ARE REPLATED TO MAINTAIN VEHICLE STABILITY AND TO IMPROVE STEERBILITY DURING SUDDEN

BRAKING.

A 4(A), A 5(B) ABS ACTUATOR

(A)1, (A)3, (A)4, (A)6 ± (A)2 : APPROX. 6 W

(A)2±GROUND : APPROX. 5 W

A 6(B), A 7(A) ABS RELAY

(A)1±(B) 3 : 60 W±100 W

(A)4±(B) 3 : 60 W±100 W

(A)1, (B) 2±GROUND : APPROX. 12 VOLTS

(A)6±GROUND : APPROX. 12 VOLTS

A 8, A 9 ABS SPEED SENSOR FRONT LH, RH

1±2 : 0.8 K±1.3 KW

A19, A20 ABS SPEED SENSOR REAR LH, RH

1±2 : 1.1 K±1.5 KW

A13(A), A14(B) ABS ECU

(CONNECT THE ECU CONNECTORS)

(A) 5±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND DATA LINK CONNECTOR 1 (CHECK CONNECTOR)

TS±EI NOT CONNECTED

(B)15±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND DATA LINK CONNECTOR 1 (CHECK CONNECTOR)

TS±EI NOT CONNECTED

(A) 1±GROUND, (A) 13±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND ABS WARNING LIGHT GOES OFF

(A)14±GROUND, (A) 1±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND ABS WARNING LIGHT GOES OFF

(A)26±GROUND, (A) 18±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND ABS WARNING LIGHT GOES OFF

(A) 2±GROUND : ALWAYS CONTINUITY

(A)15±GROUND : ALWAYS CONTINUITY

(A)12±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

(B) 6±GROUND : APPROX. 12 VOLTS WITH BRAKE PEDAL DEPRESSED

(A)25±GROUND : ALWAYS APPROX. 12 VOLTS

SYSTEM OUTLINE

SERVICE HINTS

Page 213 of 307

213

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

A 4A28 (1MZ±FE), 30 (5S±FE)A1934J 333

A 5B28 (1MZ±FE), 30 (5S±FE)A2034N 2A33

A 6B28 (1MZ±FE), 30 (5S±FE)C 9A32N 3B33

A 7A28 (1MZ±FE), 30 (5S±FE)C10B32P 233

A 828 (1MZ±FE), 30 (5S±FE)D 128 (1MZ±FE), 30 (5S±FE)P 333

A 928 (1MZ±FE), 30 (5S±FE)D 332S1033

A13A32F1028 (1MZ±FE), 30 (5S±FE)

A14B32J 133

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1A

1B20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1M

20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

2G22COWL WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

3B

3C24COWL WIRE AND J/B NO. 3 (BEHIND COMBINATION METER)

3D

24COWL WIRE AND J/B NO. 3 (BEHIND COMBINATION METER)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

EC138 (1MZ±FE)ENGINE WIRE AND ENGINE ROOM MAIN WIREEC140 (5S±FE)ENGINE WIRE AND ENGINE ROOM MAIN WIRE

II142COWL WIRE AND INSTRUMENT PANEL WIRE

IJ142FLOOR NO. 1 WIRE AND COWL WIRE

IP344ENGINE WIRE AND COWL WIRE

IR244ENGINE ROOM MAIN WIRE AND COWL WIRE

IS144FLOOR NO. 2 WIRE AND COWL WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

EA38 (1MZ±FE)FRONT RIGHT FENDEREA40 (5S±FE)FRONT RIGHT FENDER

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

E438 (1MZ±FE)E 640 (5S±FE)ENGINE ROOM MAIN WIREE 440 (5S±FE)ENGINE ROOM MAIN WIREI2144COWL WIRE

E 638 (1MZ±FE)

ENGINE ROOM MAIN WIRE

I2544ENGINE ROOM MAIN WIRE

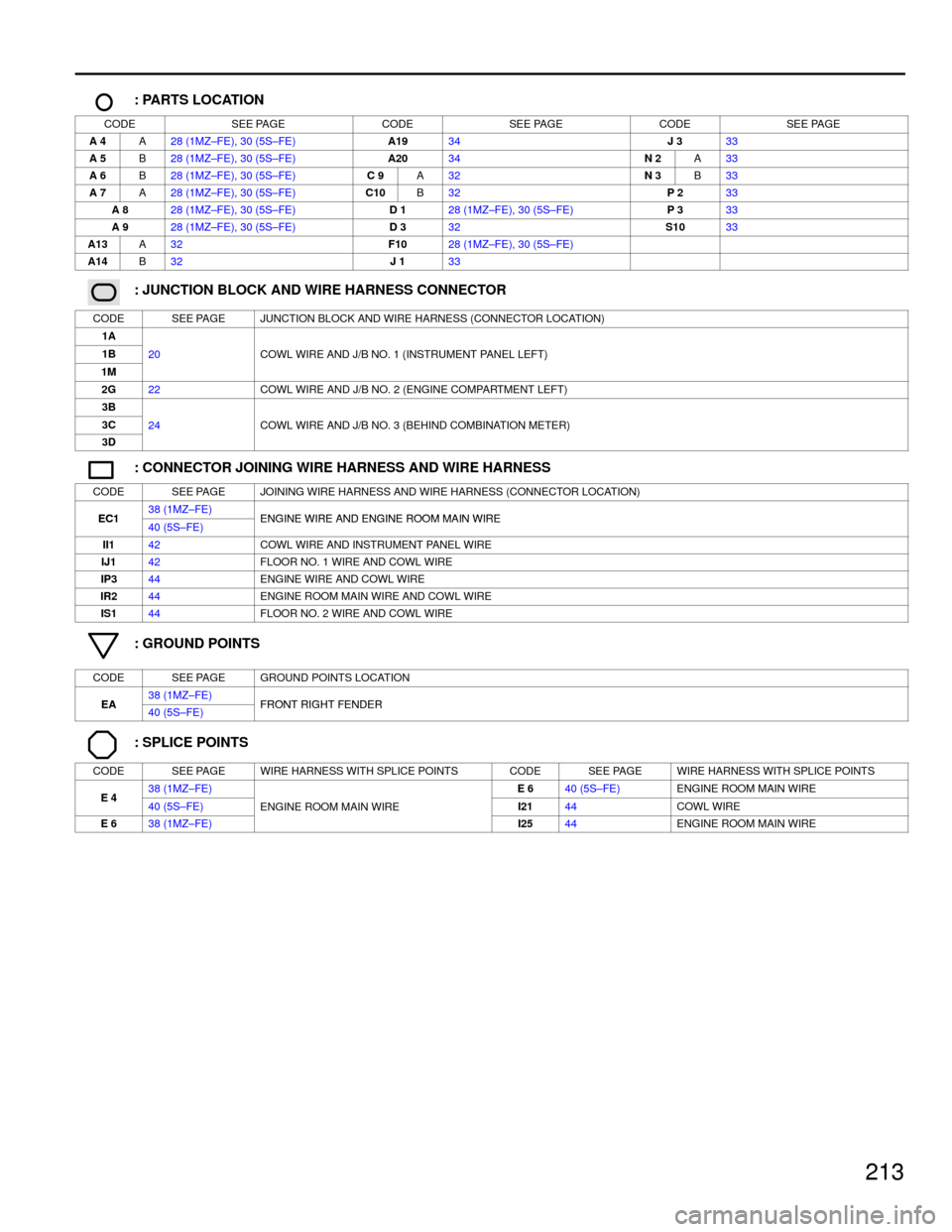

Page 214 of 307

214

ABS (ANTI±LOCK BRAKE SYSTEM) (TMM MADE)

EC1 7

IR2 7IR26IR2 1 IR1 19

B 1A9B 2

A 11 A5A13 A7

IJ1 6IR2 5

I21 I14

1 21 2 B 2B1 A 2A1

2 1

FR+ FR± FL+ FL± +BS STPIG

W

B

R

GR

G

W±B W± B W±BB±R G±WW±L

G±W

G±R

B±R W± L

G±W

G±W

G± R

B±R

G±W

(

SHIELDED) (

SHIELDED)

(

SHIELDED)B A4 ,A5A

ABS ACTUATOR AND ECU FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

B N2 ,N3A

NOISE FILTER

(

FO R STO P L I G HT)

STOP LIGHT SW S10

W± B

A9 A8

ABS SPEED SENSOR

FRONT RHABS SPEED SENSOR

FRONT LH FUS E BO X F18

60A ABS

11M 31A7 15A

STOP15A

ECU±IG

1A 151M 6

3C 19

3C 7

3C 153C 16

Page 215 of 307

215

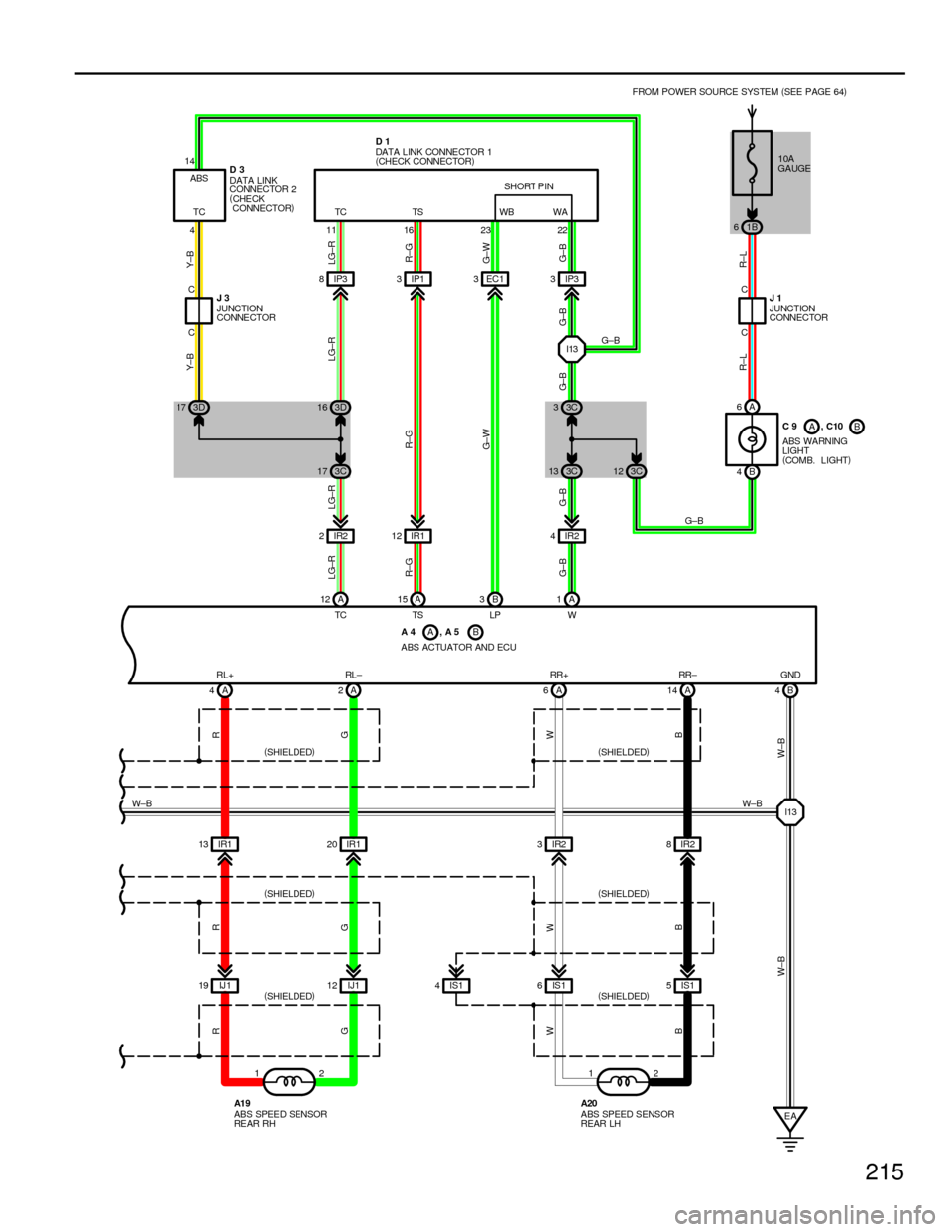

C C IP3 8IP13EC13IP33

IR1 20 IR23IR28

IJ 1 19 IJ112 IS14IS16IS15 IR1 13A 12 A15 B3A1

A 4A2A6A14 B4 I13

B 4A 6

2 12 1

EA C C

RL+ RL± RR+ RR± GNDTC TS TC ABS

IR2 2IR112 IR24 11 16 23 22WA WB

I13 G±B G±B

TC TS LP W

R

G

W

B R

G R

G

W

BW

B

W±B W±B

W±BW±B

LG±R

R±G

G±B G±BLG±R

R±G

G±WLG±R

G±B G± B

R±L R±LY±B Y±B

R±G

G±W

G±B LG±R

4 14

A1 9A20 J3D3

J1 DATA LINK

CONNECTOR 2

(

CHE CK

CONNECTOR)

JUNCTION

CONNE CTORJUNCTION

CONNECTOR SHORT PIN

ABS SPEED SENSOR

RE AR RHABS SPEED SENSOR

REAR LH DATA LINK CONNE CTOR 1

(

CHECK CONNECTOR) D1

(

SHIELDED) (

SHIELDED) (

SHIELDED)(

SHIELDED)

(

SHIELDED)

(

SHIELDED)B C9 ,C10

A

B A4 ,A5AABS WARNING

LIGHT

(

COMB. LIGHT)

ABS ACTUATOR AND ECUFROM POWER SOURCE SYSTEM(

SEE PAGE 64)

3C 17 3D 17 3D163C 13 3C12 3C 3

10A

GAUGE

1B 6

Page 216 of 307

216

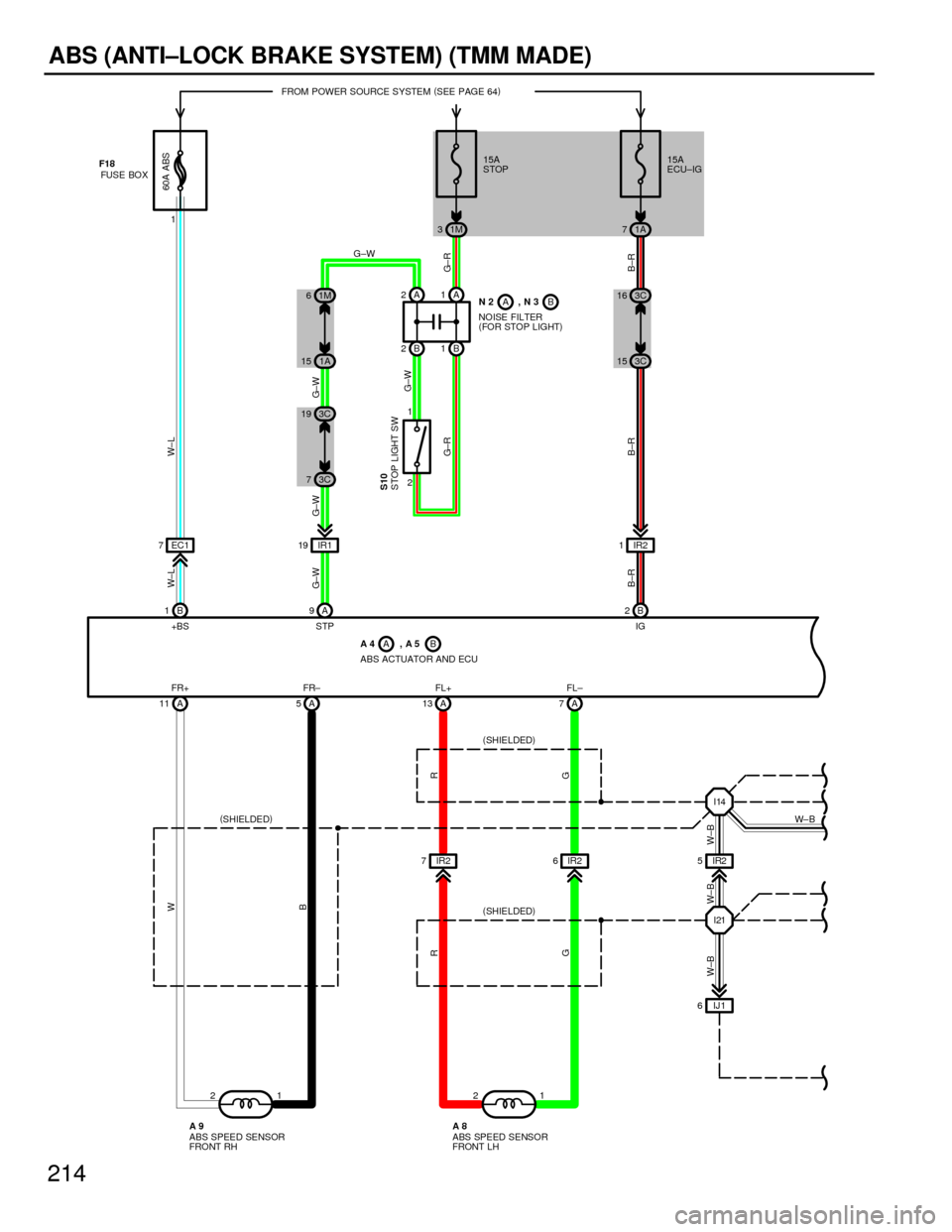

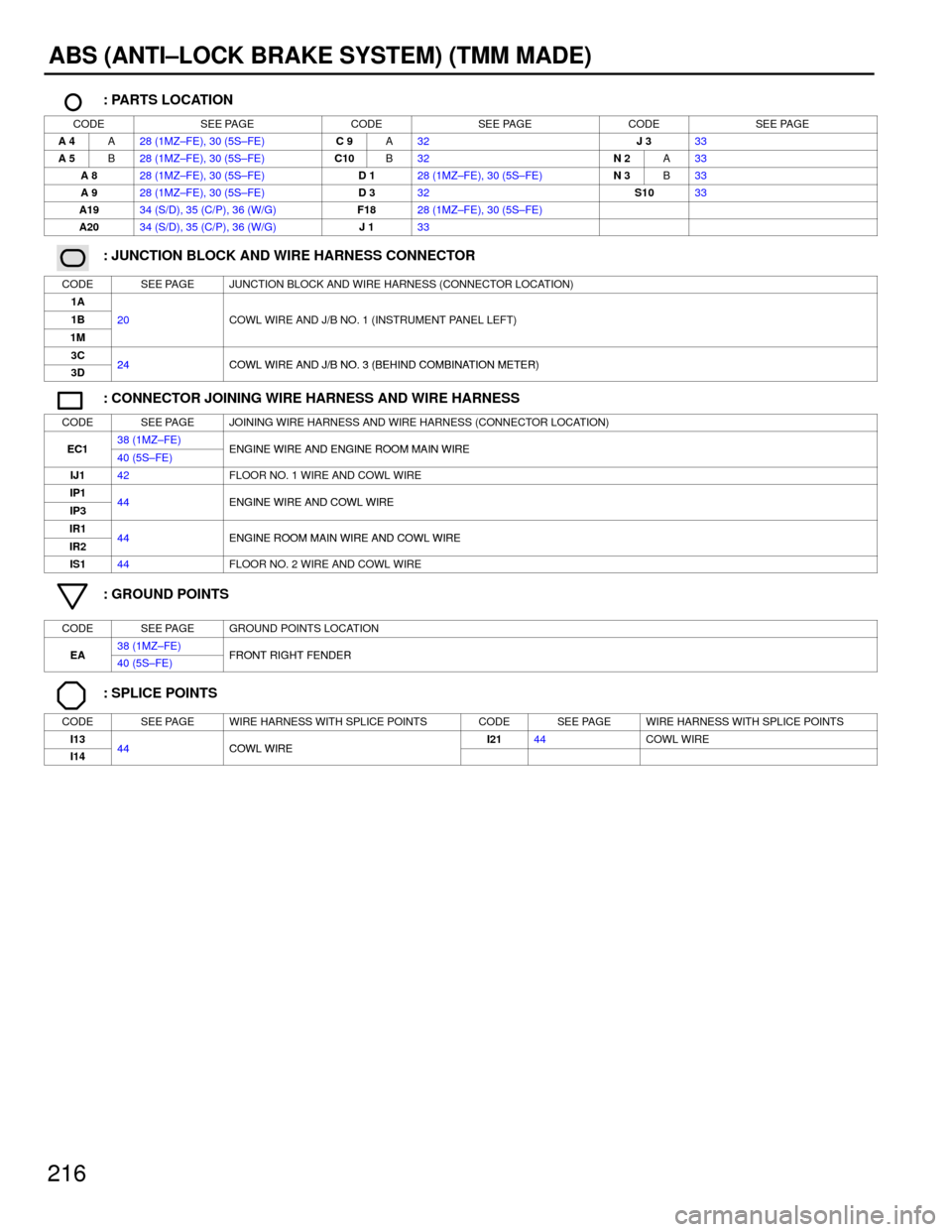

ABS (ANTI±LOCK BRAKE SYSTEM) (TMM MADE)

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

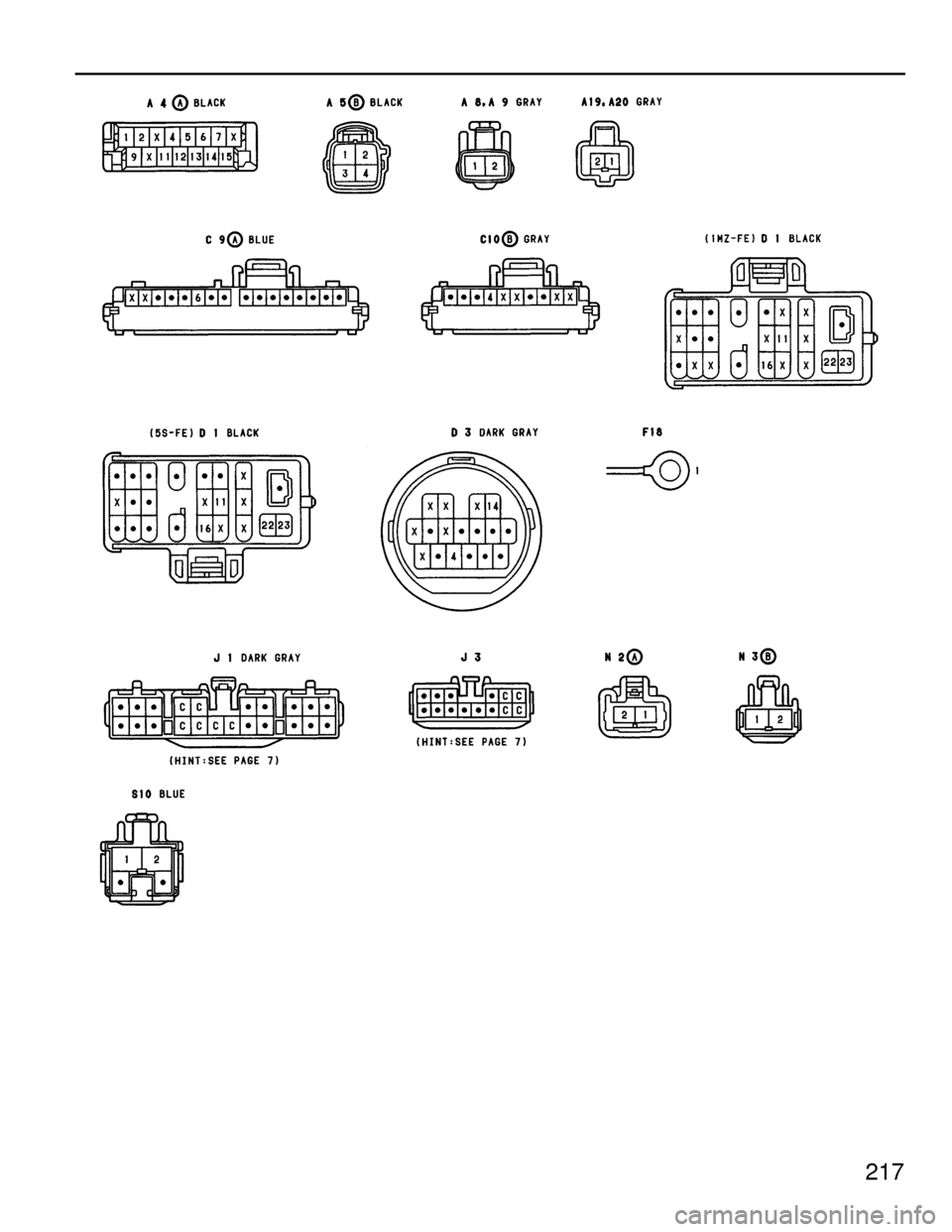

A 4A28 (1MZ±FE), 30 (5S±FE)C 9A32J 333

A 5B28 (1MZ±FE), 30 (5S±FE)C10B32N 2A33

A 828 (1MZ±FE), 30 (5S±FE)D 128 (1MZ±FE), 30 (5S±FE)N 3B33

A 928 (1MZ±FE), 30 (5S±FE)D 332S1033

A1934 (S/D), 35 (C/P), 36 (W/G)F1828 (1MZ±FE), 30 (5S±FE)

A2034 (S/D), 35 (C/P), 36 (W/G)J 133

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1A

1B20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1M

20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

3C24COWL WIRE AND J/B NO 3 (BEHIND COMBINATION METER)3D24COWL WIRE AND J/B NO. 3 (BEHIND COMBINATION METER)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

EC138 (1MZ±FE)ENGINE WIRE AND ENGINE ROOM MAIN WIREEC140 (5S±FE)ENGINE WIRE AND ENGINE ROOM MAIN WIRE

IJ142FLOOR NO. 1 WIRE AND COWL WIRE

IP144ENGINE WIRE AND COWL WIREIP344ENGINE WIRE AND COWL WIRE

IR144ENGINE ROOM MAIN WIRE AND COWL WIREIR244ENGINE ROOM MAIN WIRE AND COWL WIRE

IS144FLOOR NO. 2 WIRE AND COWL WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

EA38 (1MZ±FE)FRONT RIGHT FENDEREA40 (5S±FE)FRONT RIGHT FENDER

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

I1344COWL WIREI2144COWL WIRE

I1444COWL WIRE

Page 217 of 307

217

Page 218 of 307

218

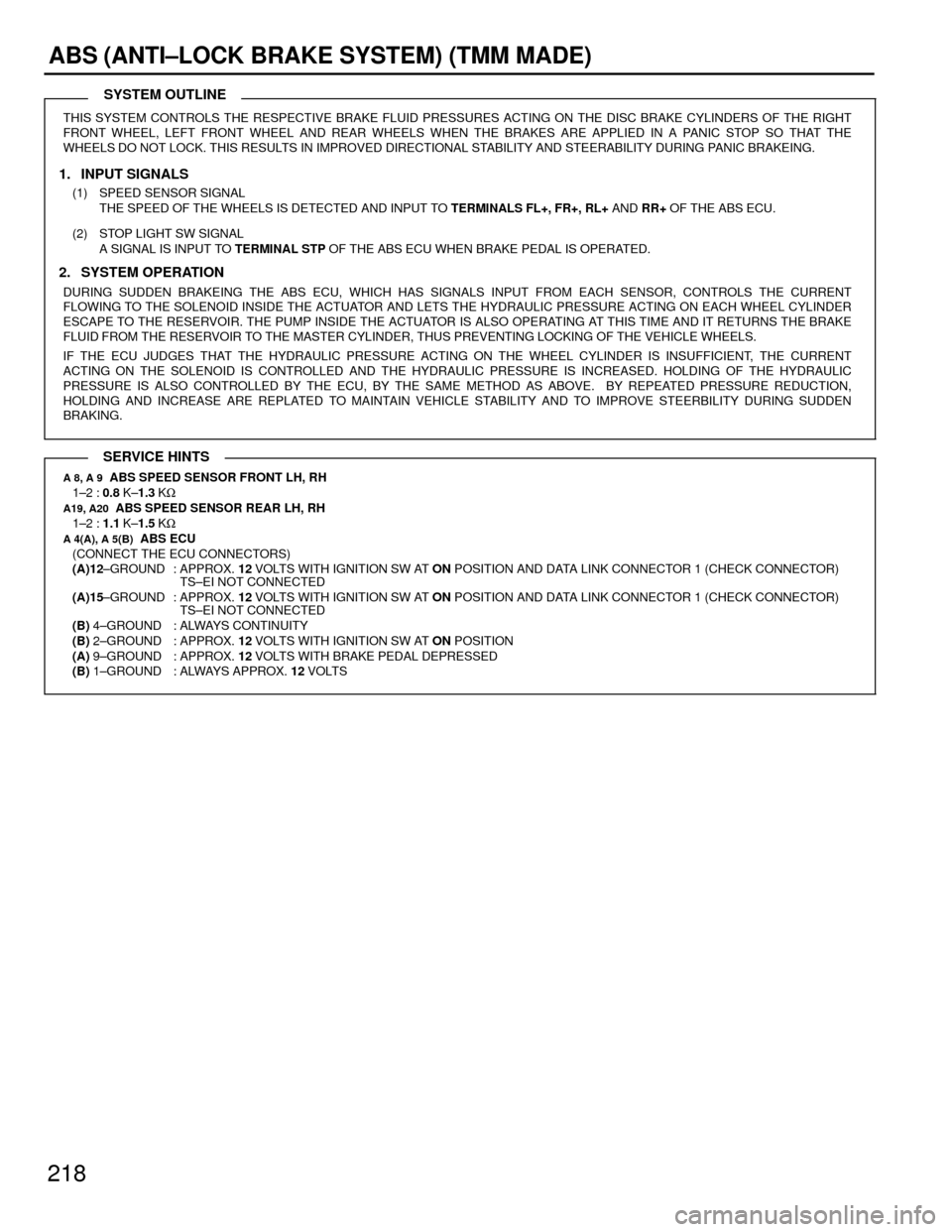

ABS (ANTI±LOCK BRAKE SYSTEM) (TMM MADE)

THIS SYSTEM CONTROLS THE RESPECTIVE BRAKE FLUID PRESSURES ACTING ON THE DISC BRAKE CYLINDERS OF THE RIGHT

FRONT WHEEL, LEFT FRONT WHEEL AND REAR WHEELS WHEN THE BRAKES ARE APPLIED IN A PANIC STOP SO THAT THE

WHEELS DO NOT LOCK. THIS RESULTS IN IMPROVED DIRECTIONAL STABILITY AND STEERABILITY DURING PANIC BRAKEING.

1. INPUT SIGNALS

(1) SPEED SENSOR SIGNAL

THE SPEED OF THE WHEELS IS DETECTED AND INPUT TO TERMINALS FL+, FR+, RL+ AND RR+ OF THE ABS ECU.

(2) STOP LIGHT SW SIGNAL

A SIGNAL IS INPUT TO TERMINAL STP OF THE ABS ECU WHEN BRAKE PEDAL IS OPERATED.

2. SYSTEM OPERATION

DURING SUDDEN BRAKEING THE ABS ECU, WHICH HAS SIGNALS INPUT FROM EACH SENSOR, CONTROLS THE CURRENT

FLOWING TO THE SOLENOID INSIDE THE ACTUATOR AND LETS THE HYDRAULIC PRESSURE ACTING ON EACH WHEEL CYLINDER

ESCAPE TO THE RESERVOIR. THE PUMP INSIDE THE ACTUATOR IS ALSO OPERATING AT THIS TIME AND IT RETURNS THE BRAKE

FLUID FROM THE RESERVOIR TO THE MASTER CYLINDER, THUS PREVENTING LOCKING OF THE VEHICLE WHEELS.

IF THE ECU JUDGES THAT THE HYDRAULIC PRESSURE ACTING ON THE WHEEL CYLINDER IS INSUFFICIENT, THE CURRENT

ACTING ON THE SOLENOID IS CONTROLLED AND THE HYDRAULIC PRESSURE IS INCREASED. HOLDING OF THE HYDRAULIC

PRESSURE IS ALSO CONTROLLED BY THE ECU, BY THE SAME METHOD AS ABOVE. BY REPEATED PRESSURE REDUCTION,

HOLDING AND INCREASE ARE REPLATED TO MAINTAIN VEHICLE STABILITY AND TO IMPROVE STEERBILITY DURING SUDDEN

BRAKING.

A 8, A 9 ABS SPEED SENSOR FRONT LH, RH

1±2 : 0.8 K±1.3 KW

A19, A20 ABS SPEED SENSOR REAR LH, RH

1±2 : 1.1 K±1.5 KW

A 4(A), A 5(B) ABS ECU

(CONNECT THE ECU CONNECTORS)

(A)12±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND DATA LINK CONNECTOR 1 (CHECK CONNECTOR)

TS±EI NOT CONNECTED

(A)15±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND DATA LINK CONNECTOR 1 (CHECK CONNECTOR)

TS±EI NOT CONNECTED

(B) 4±GROUND : ALWAYS CONTINUITY

(B) 2±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

(A) 9±GROUND : APPROX. 12 VOLTS WITH BRAKE PEDAL DEPRESSED

(B) 1±GROUND : ALWAYS APPROX. 12 VOLTS

SYSTEM OUTLINE

SERVICE HINTS

Page 219 of 307

ABS ( ANTI – LOCK BRAKE SYSTEM) (TMM MADE)

-Memo

37

Page 220 of 307

220

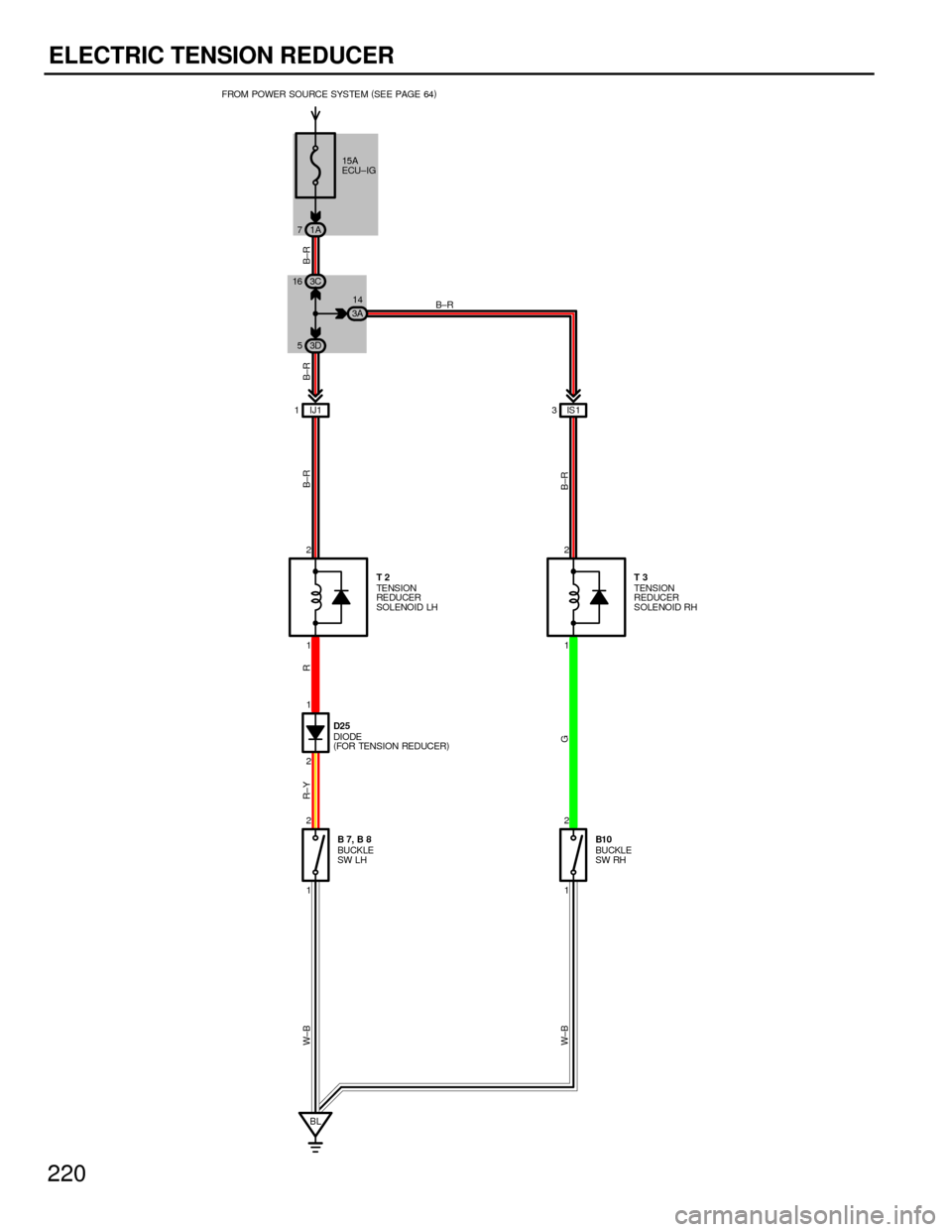

ELECTRIC TENSION REDUCER

1 2

1 2 1 2

1 2IS 1 3

BLTE NSI ON

RE DUCER

SOLENOID LHTENSION

REDUCER

SOLENOID RH

BUCKLE

SW LHBUCKLE

SW RH FROM POWE

R

GB±RB±R W±B

B7,B8 B10T3 T2B±R

B±R

IJ1 1

B±R

2 1

R±Y

D25

DIODE

(

FOR TENSION REDUCER)

W±B

15A

ECU±IG R SOURCE SYSTEM(

SEE PAGE 64)

1A 7

3A14

3D 53C 16