TOYOTA CAMRY 1999 Service Repair Manual

CAMRY 1999

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57448/w960_57448-0.png

TOYOTA CAMRY 1999 Service Repair Manual

Trending: hood release, spare tire, transmission line, wheel size, battery location, wiper and washer, fuel pump

Page 171 of 4592

AUTOMATIC TRANSAXLEGENERAL DESCRIPTION ±

AX±1

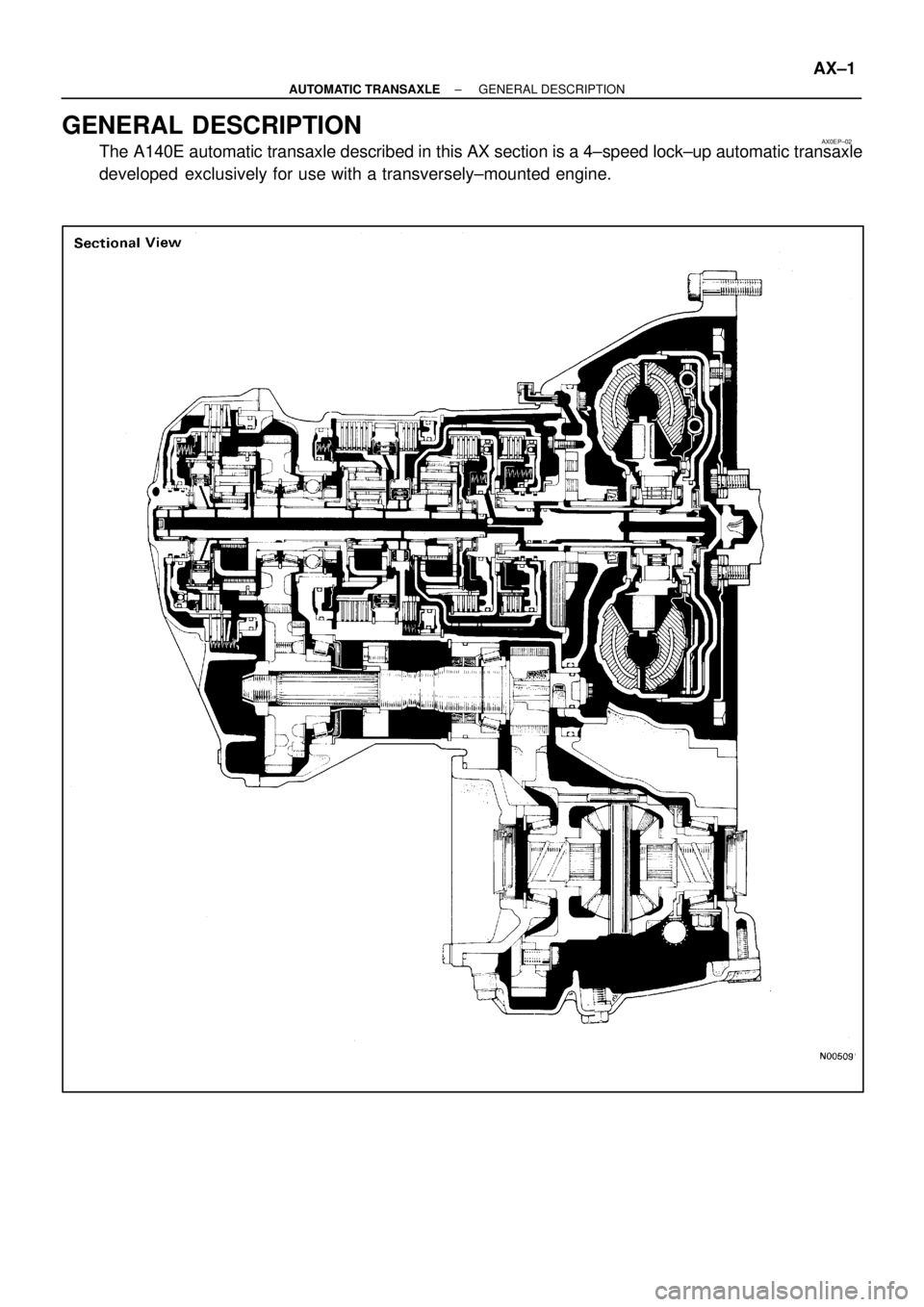

GENERAL DESCRIPTION

The A140E automatic transaxle described in this AX section is a 4±speed lock±up automatic transaxle

developed exclusively for use with a transversely±mounted engine.AX0EP±02

Page 172 of 4592

AUTOMATIC TRANSAXLEGENERAL DESCRIPTION ±

AX±2

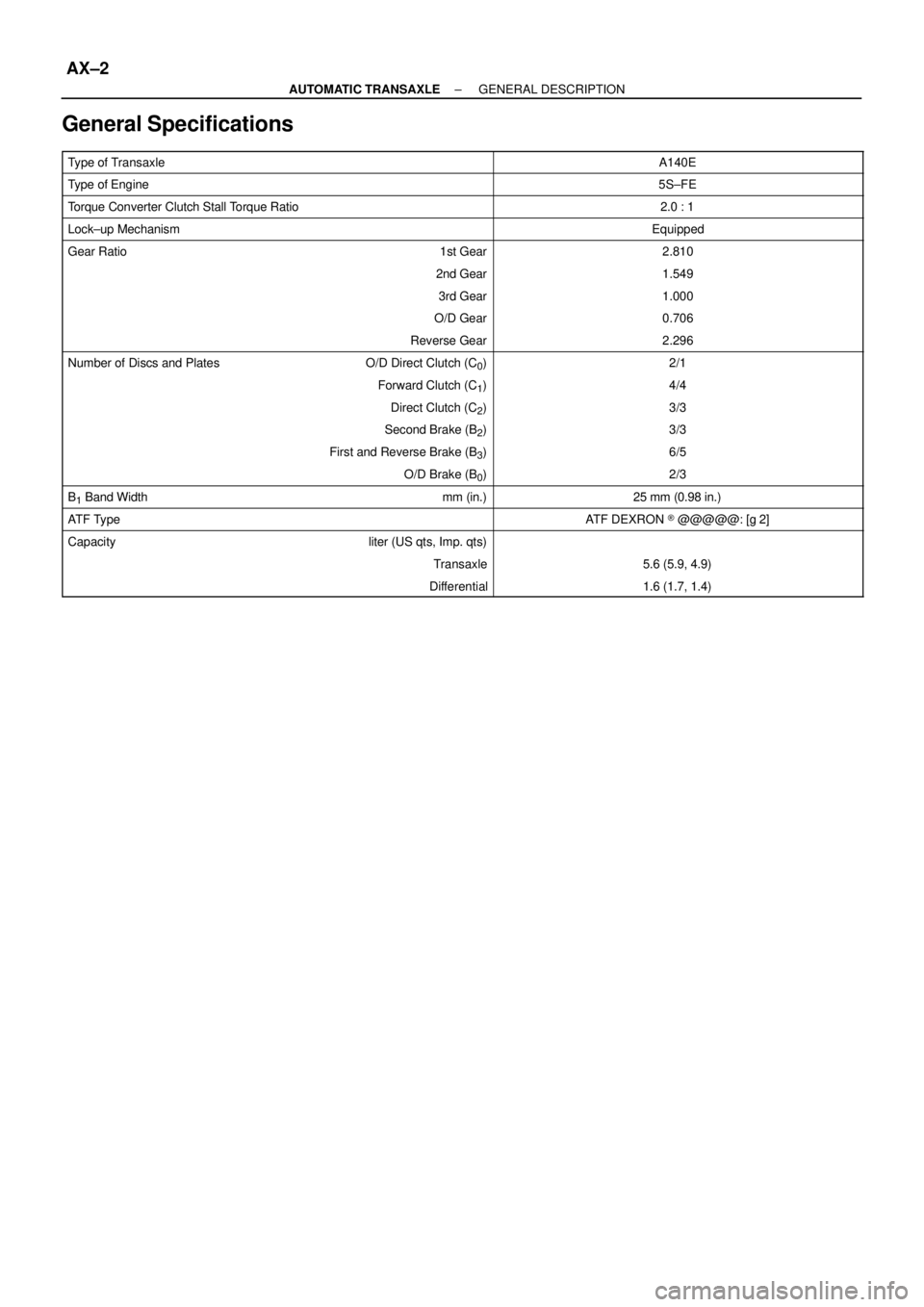

General Specifications

Type of TransaxleA140E

Type of Engine5S±FE

Torque Converter Clutch Stall Torque Ratio2.0 : 1

Lock±up MechanismEquipped

Gear Ratio 1st Gear

2nd Gear

3rd Gear

O/D Gear

Reverse Gear2.810

1.549

1.000

0.706

2.296

Number of Discs and Plates O/D Direct Clutch (C0)

Forward Clutch (C

1)

Direct Clutch (C

2)

Second Brake (B

2)

First and Reverse Brake (B

3)

O/D Brake (B

0)

2/1

4/4

3/3

3/3

6/5

2/3

B1 Band Width mm (in.)25 mm (0.98 in.)

ATF TypeATF DEXRON ® @@@@@: [g 2]

Capacity liter (US qts, Imp. qts)

Transaxle

Differential

5.6 (5.9, 4.9)

1.6 (1.7, 1.4)

Page 173 of 4592

AUTOMATIC TRANSAXLEOPERATION ±

AX±3

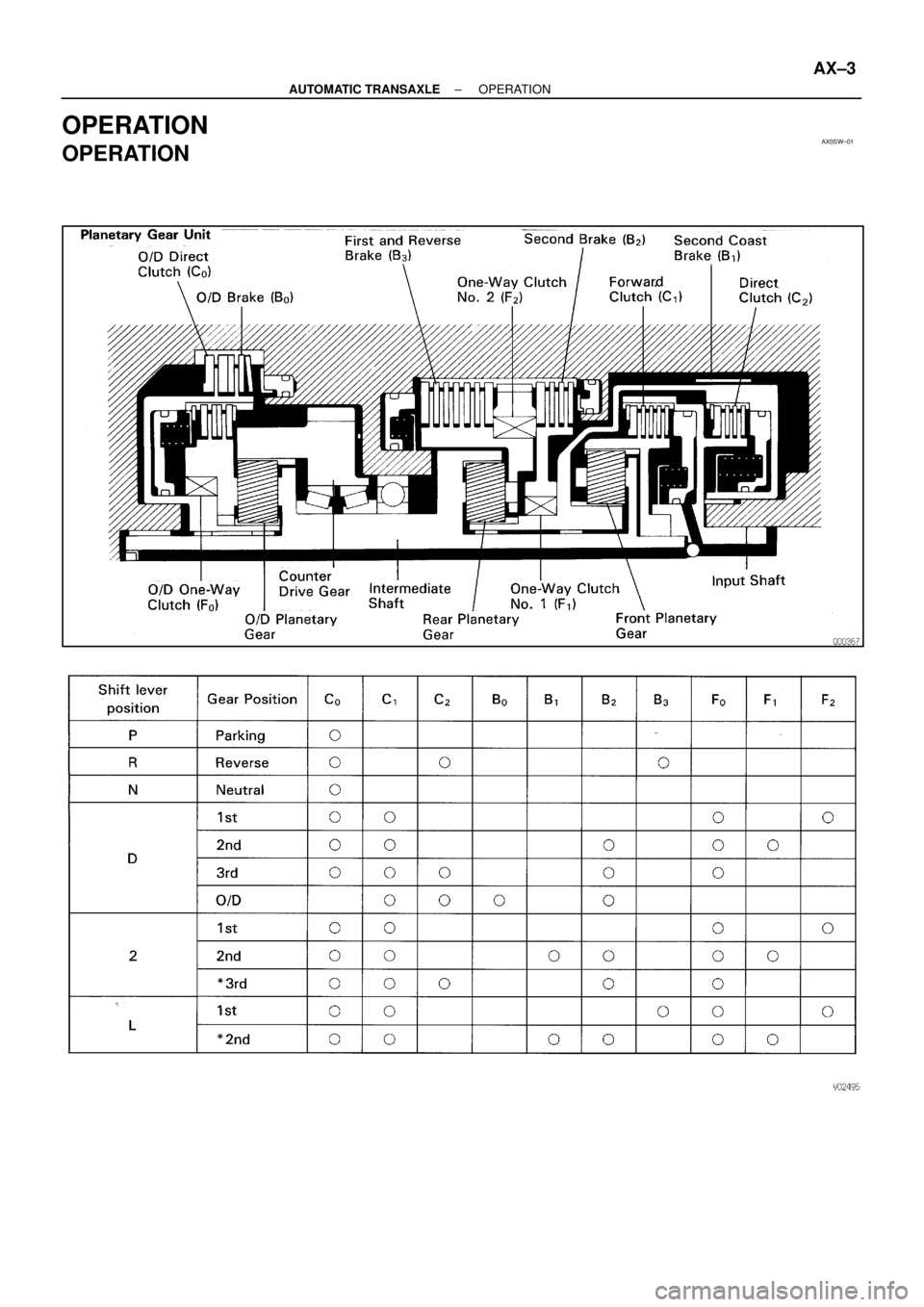

OPERATION

OPERATION

AX0SW±01

Page 174 of 4592

AUTOMATIC TRANSAXLEOPERATION ±

AX±4

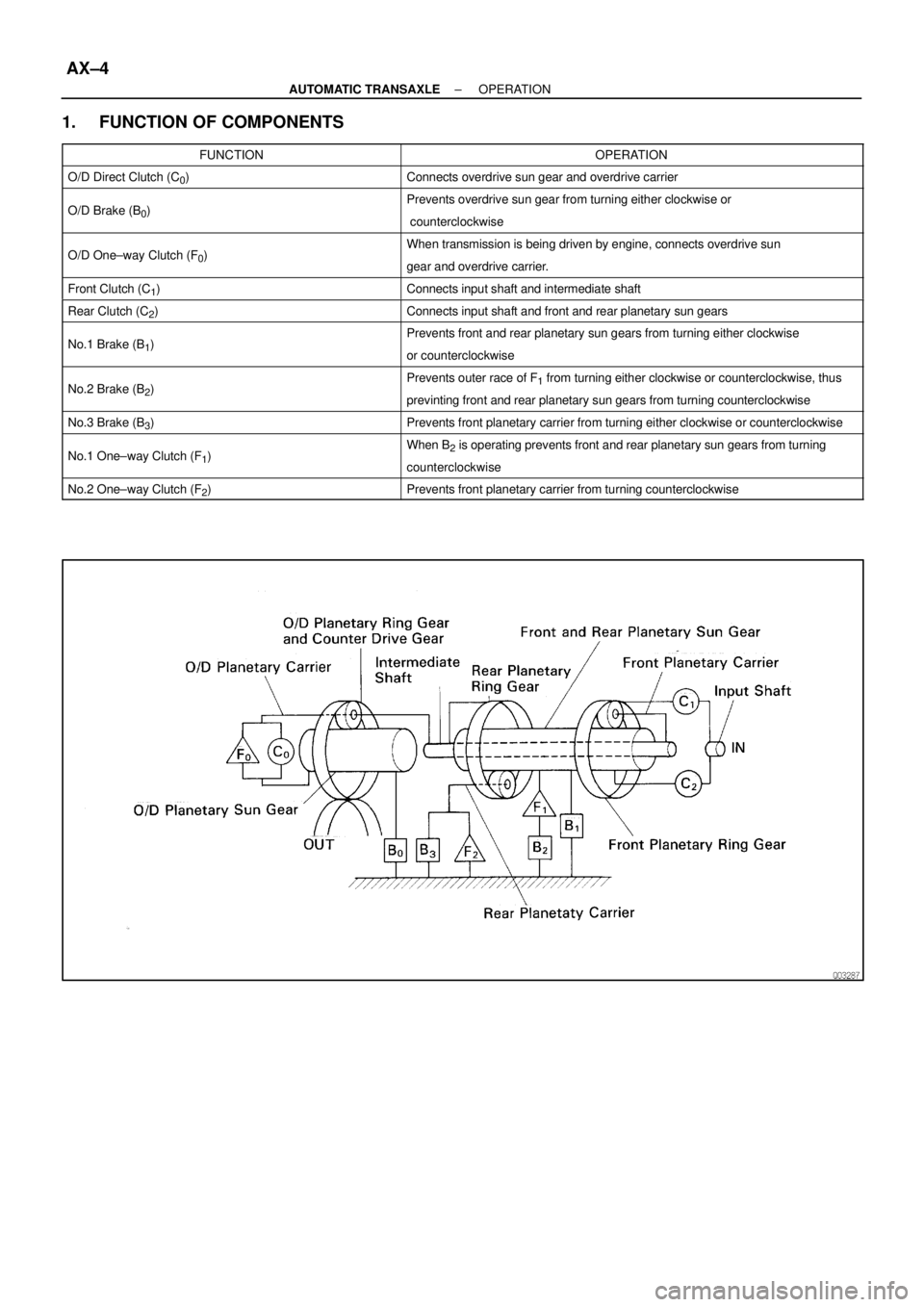

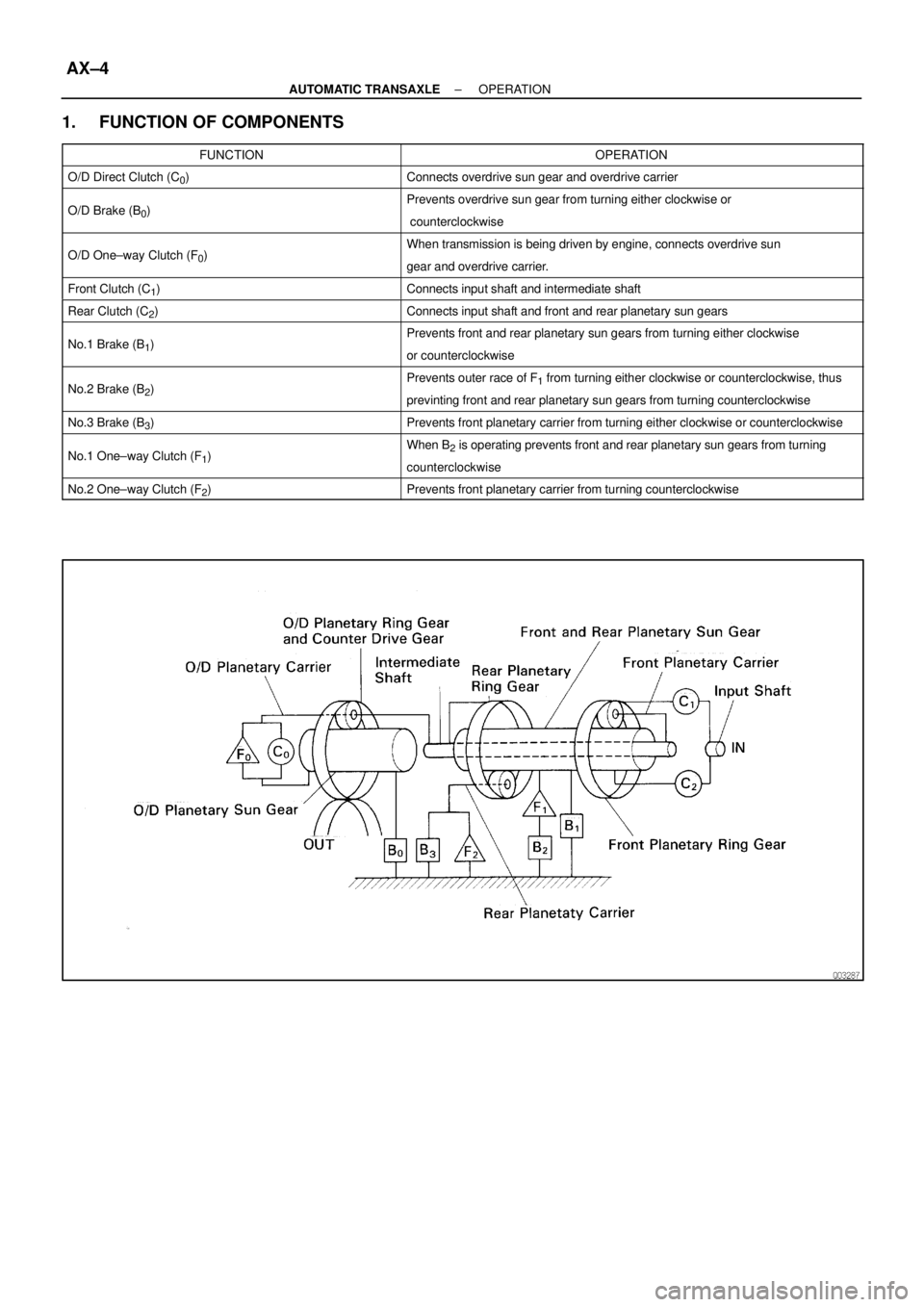

1. FUNCTION OF COMPONENTS

FUNCTIONOPERATION

O/D Direct Clutch (C0)Connects overdrive sun gear and overdrive carrier

O/D Brake (B0)Prevents overdrive sun gear from turning either clockwise or

counterclockwise

O/D One±way Clutch (F0)When transmission is being driven by engine, connects overdrive sun

gear and overdrive carrier.

Front Clutch (C1)Connects input shaft and intermediate shaft

Rear Clutch (C2)Connects input shaft and front and rear planetary sun gears

No.1 Brake (B1)Prevents front and rear planetary sun gears from turning either clockwise

or counterclockwise

No.2 Brake (B2)Prevents outer race of F1 from turning either clockwise or counterclockwise, thus

previnting front and rear planetary sun gears from turning counterclockwise

No.3 Brake (B3)Prevents front planetary carrier from turning either clockwise or counterclockwise

No.1 One±way Clutch (F1)When B2 is operating prevents front and rear planetary sun gears from turning

counterclockwise

No.2 One±way Clutch (F2)Prevents front planetary carrier from turning counterclockwise

Page 175 of 4592

AUTOMATIC TRANSAXLEOPERATION ±

AX±5

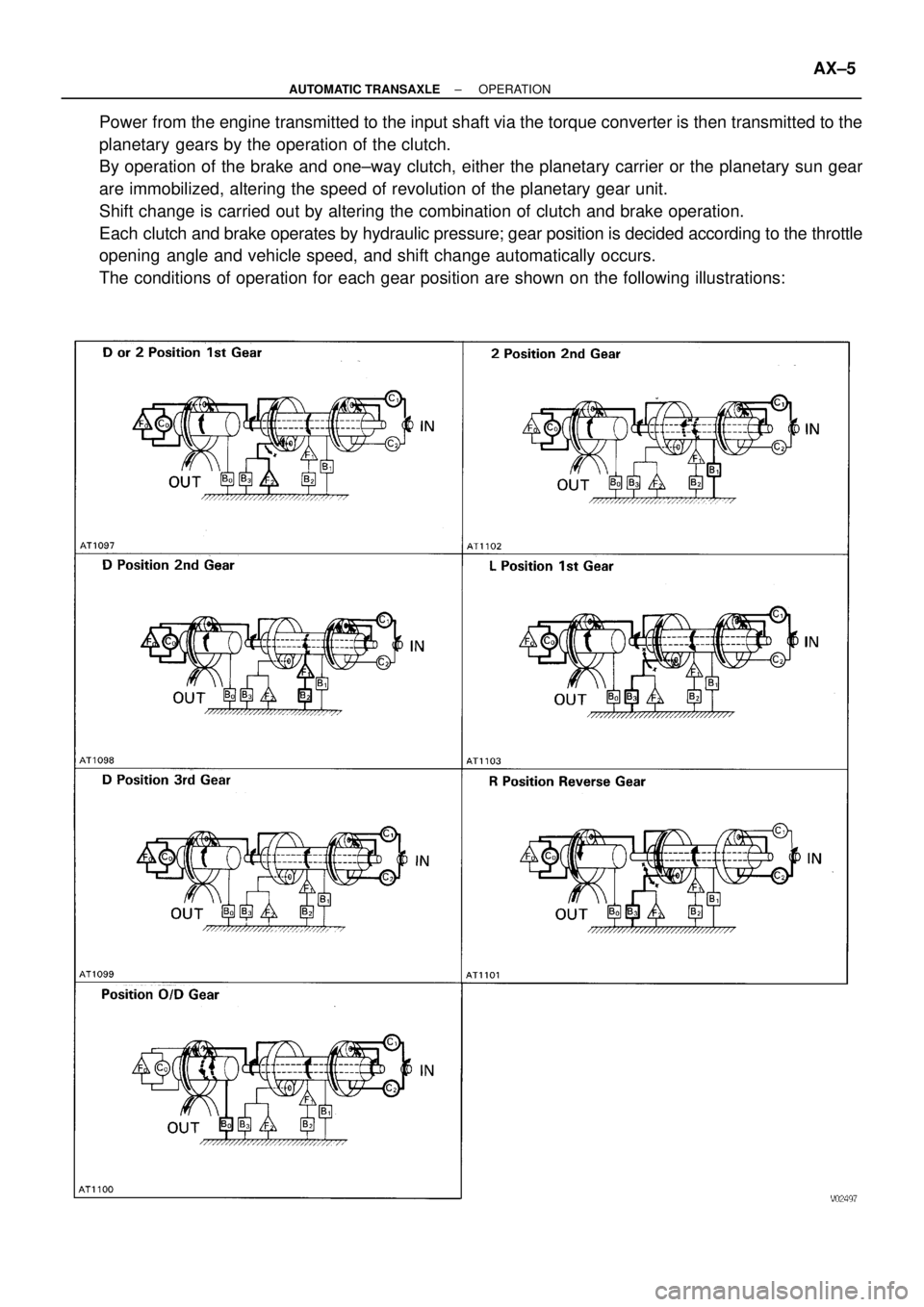

Power from the engine transmitted to the input shaft via the torque converter is then transmitted to the

planetary gears by the operation of the clutch.

By operation of the brake and one±way clutch, either the planetary carrier or the planetary sun gear

are immobilized, altering the speed of revolution of the planetary gear unit.

Shift change is carried out by altering the combination of clutch and brake operation.

Each clutch and brake operates by hydraulic pressure; gear position is decided according to the throttle

opening angle and vehicle speed, and shift change automatically occurs.

The conditions of operation for each gear position are shown on the following illustrations:

Page 176 of 4592

AUTOMATIC TRANSAXLEOPERATION ±

AX±6

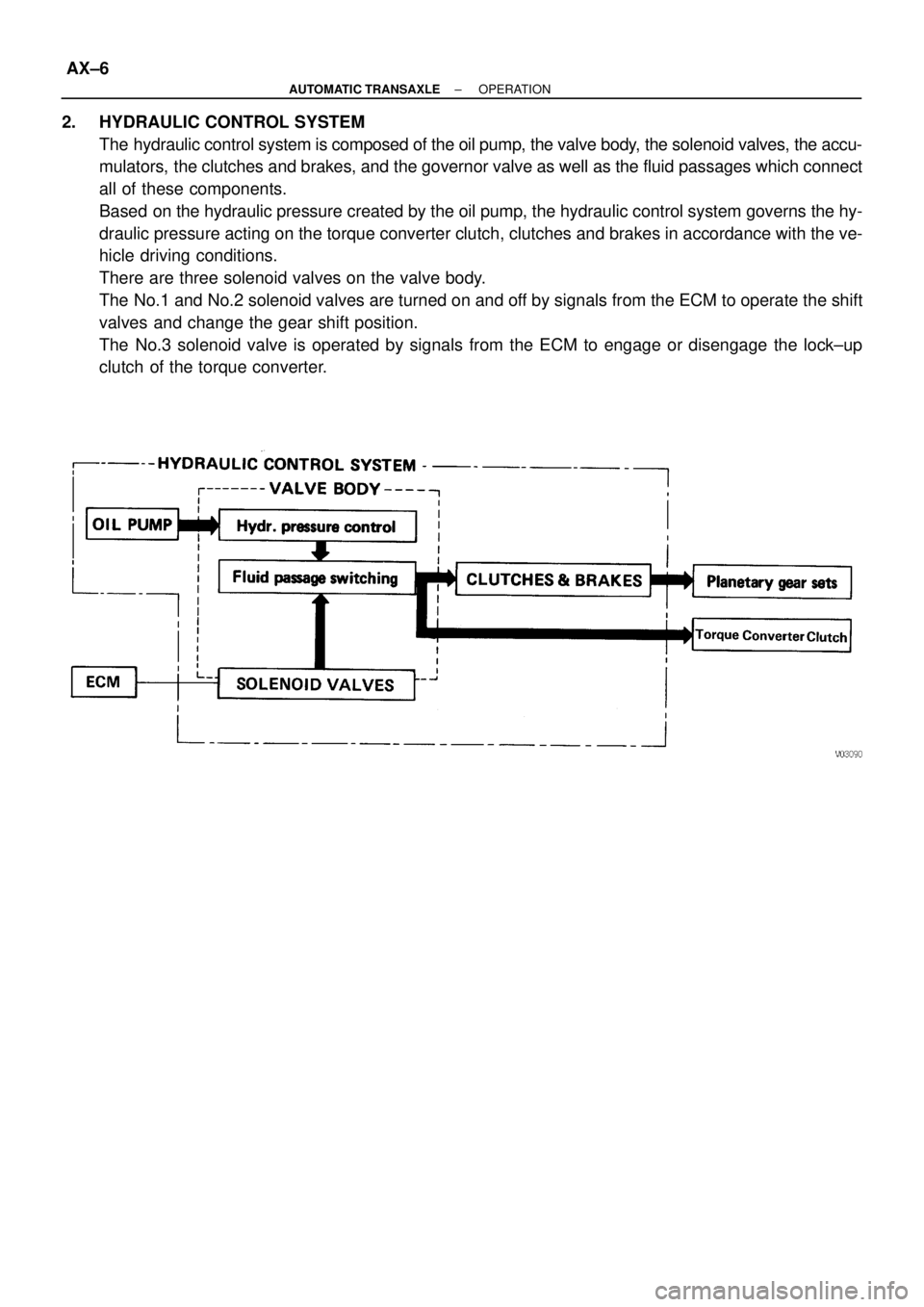

2. HYDRAULIC CONTROL SYSTEM

The hydraulic control system is composed of the oil pump, the valve body, the solenoid valves, the accu-

mulators, the clutches and brakes, and the governor valve as well as the fluid passages which connect

all of these components.

Based on the hydraulic pressure created by the oil pump, the hydraulic control system governs the hy-

draulic pressure acting on the torque converter clutch, clutches and brakes in accordance with the ve-

hicle driving conditions.

There are three solenoid valves on the valve body.

The No.1 and No.2 solenoid valves are turned on and off by signals from the ECM to operate the shift

valves and change the gear shift position.

The No.3 solenoid valve is operated by signals from the ECM to engage or disengage the lock±up

clutch of the torque converter.

Page 177 of 4592

AUTOMATIC TRANSAXLEOPERATION ±

AX±7

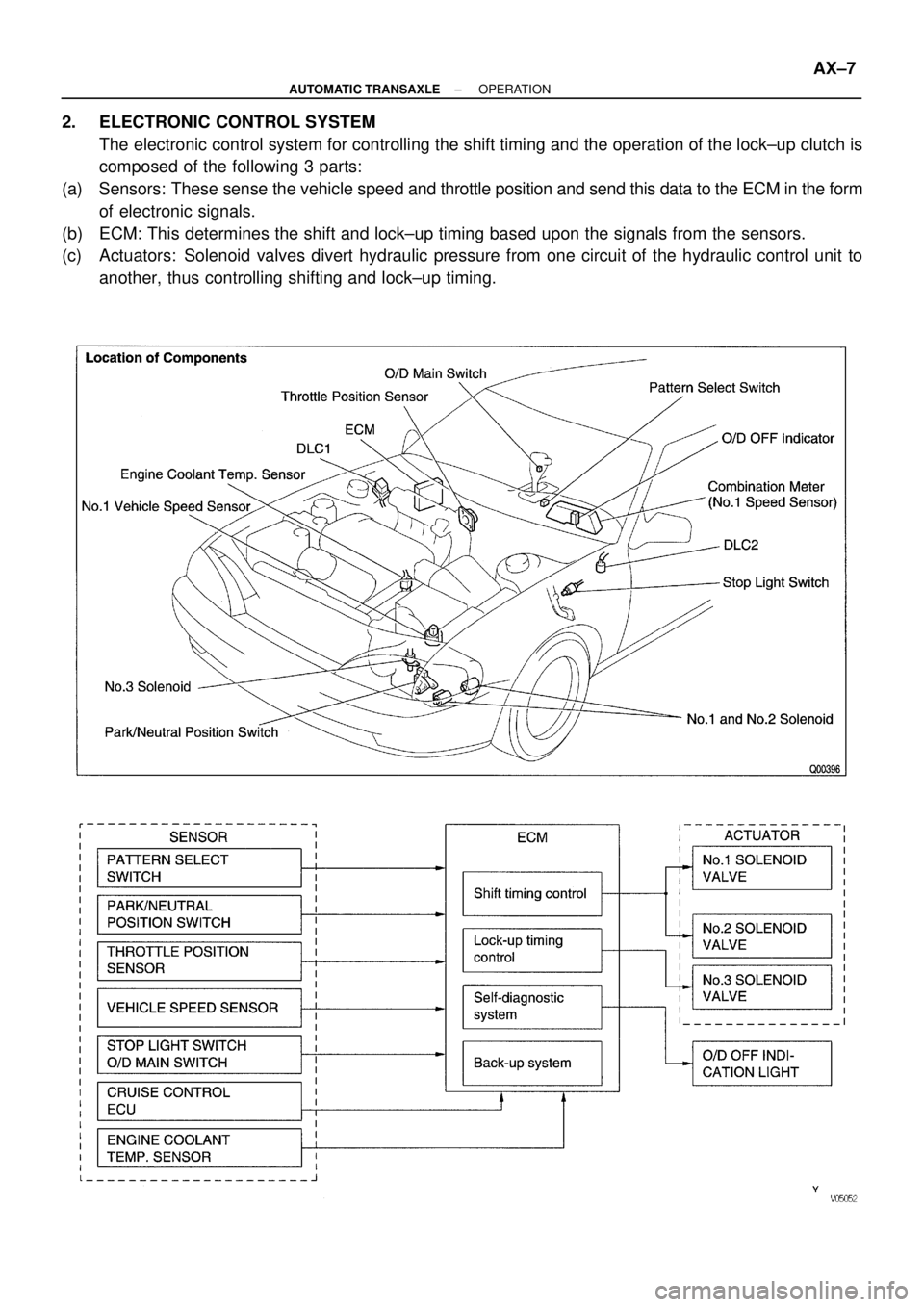

2. ELECTRONIC CONTROL SYSTEM

The electronic control system for controlling the shift timing and the operation of the lock±up clutch is

composed of the following 3 parts:

(a) Sensors: These sense the vehicle speed and throttle position and send this data to the ECM in the form

of electronic signals.

(b) ECM: This determines the shift and lock±up timing based upon the signals from the sensors.

(c) Actuators: Solenoid valves divert hydraulic pressure from one circuit of the hydraulic control unit to

another, thus controlling shifting and lock±up timing.

Page 178 of 4592

AUTOMATIC TRANSAXLEPREPARATION ±

AX±8

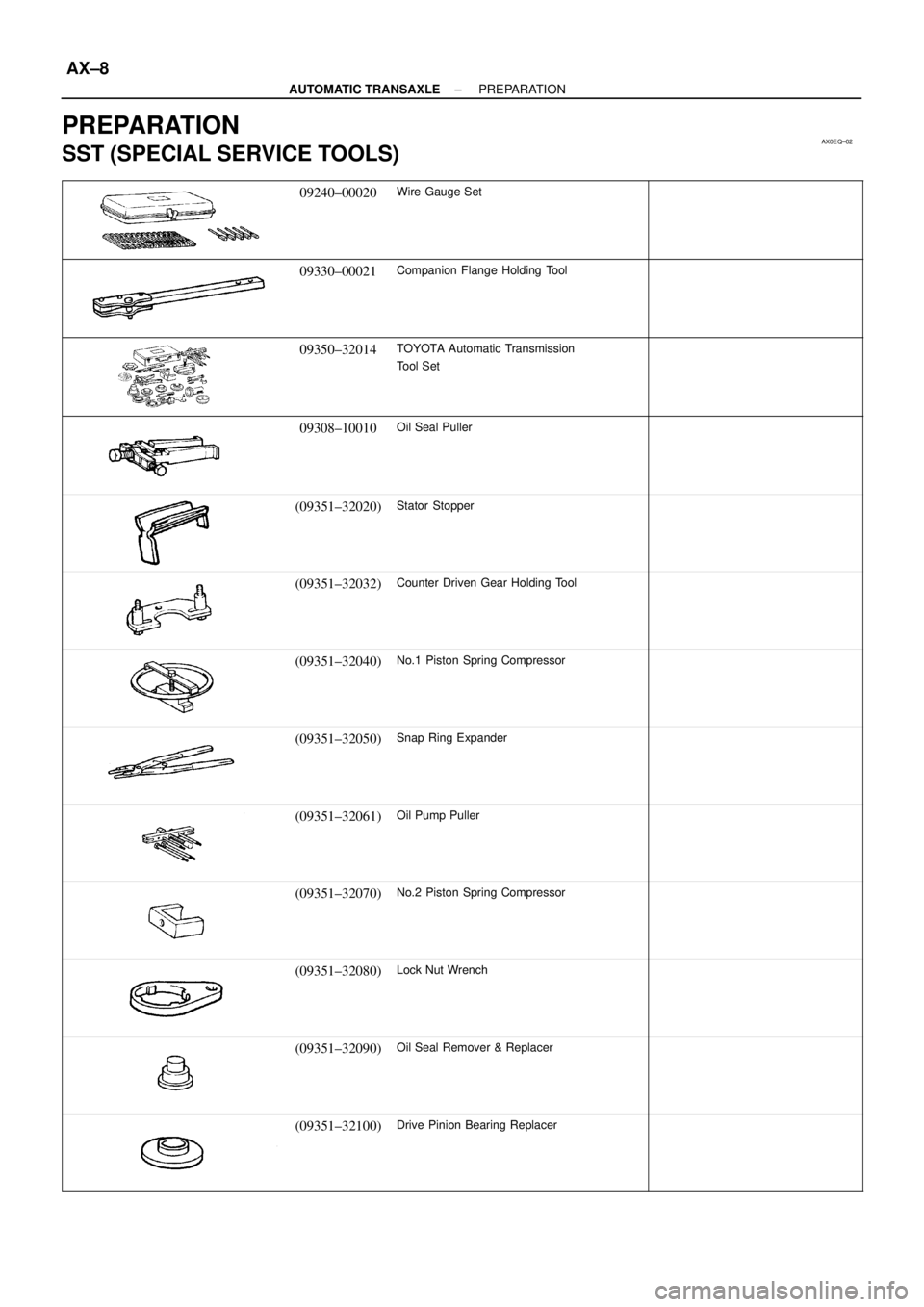

PREPARATION

SST (SPECIAL SERVICE TOOLS)

09240±00020Wire Gauge Set

09330±00021Companion Flange Holding Tool

09350±32014TOYOTA Automatic Transmission

Tool Set

09308±10010Oil Seal Puller

(09351±32020)Stator Stopper

(09351±32032)Counter Driven Gear Holding Tool

(09351±32040)No.1 Piston Spring Compressor

(09351±32050)Snap Ring Expander

(09351±32061)Oil Pump Puller

(09351±32070)No.2 Piston Spring Compressor

(09351±32080)Lock Nut Wrench

(09351±32090)Oil Seal Remover & Replacer

(09351±32100)Drive Pinion Bearing Replacer

AX0EQ±02

Page 179 of 4592

AUTOMATIC TRANSAXLEPREPARATION ±

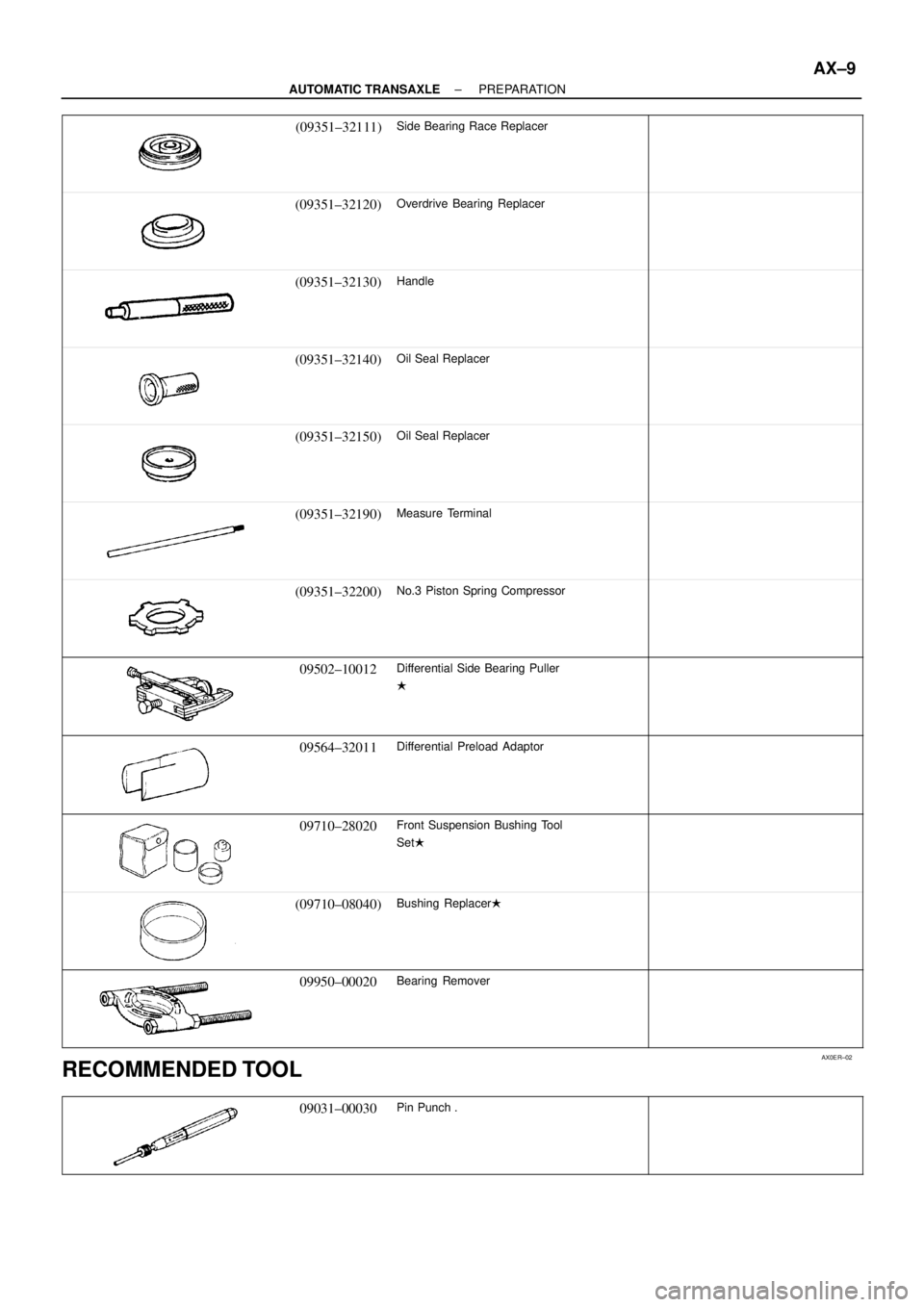

AX±9

(09351±32111)Side Bearing Race Replacer

(09351±32120)Overdrive Bearing Replacer

(09351±32130)Handle

(09351±32140)Oil Seal Replacer

(09351±32150)Oil Seal Replacer

(09351±32190)Measure Terminal

(09351±32200)No.3 Piston Spring Compressor

09502±10012Differential Side Bearing Puller

�

09564±32011Differential Preload Adaptor

09710±28020Front Suspension Bushing Tool

Set�

(09710±08040)Bushing Replacer�

09950±00020Bearing Remover

RECOMMENDED TOOL

09031±00030Pin Punch .

AX0ER±02

Page 180 of 4592

AUTOMATIC TRANSAXLEPREPARATION ±

AX±10

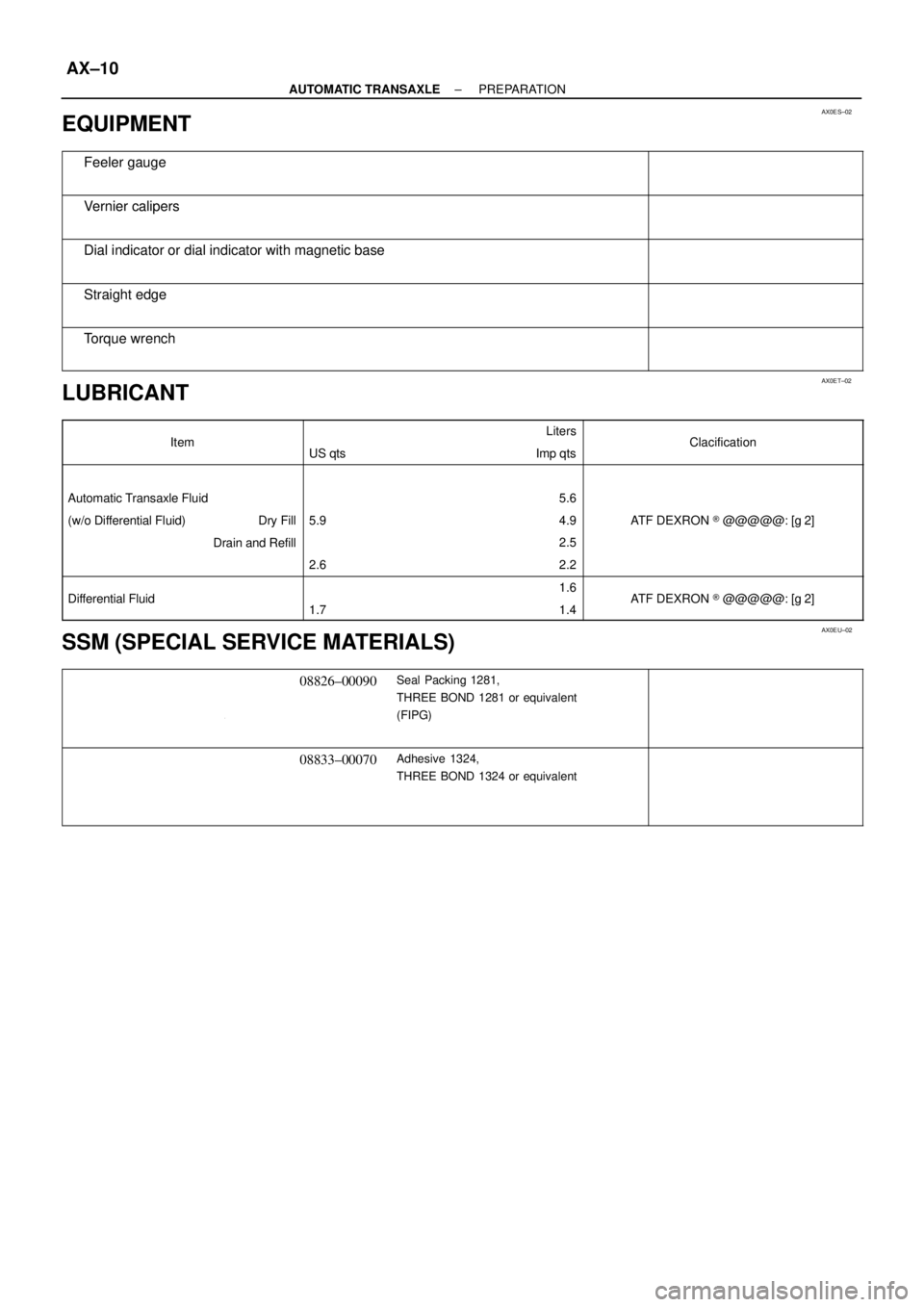

EQUIPMENT

Feeler gauge

Vernier calipers

Dial indicator or dial indicator with magnetic base

Straight edge

Torque wrench

LUBRICANT

ItemLiters

US qts Imp qtsClacification

Automatic Transaxle Fluid

(w/o Differential Fluid) Dry Fill

Drain and Refill5.6

5.9 4.9

2.5

2.6 2.2

ATF DEXRON ® @@@@@: [g 2]

Differential Fluid1.6

1.7 1.4ATF DEXRON ® @@@@@: [g 2]

SSM (SPECIAL SERVICE MATERIALS)

08826±00090Seal Packing 1281,

THREE BOND 1281 or equivalent

(FIPG)

08833±00070Adhesive 1324,

THREE BOND 1324 or equivalent

AX0ES±02

AX0ET±02

AX0EU±02

Trending: remote start, inflation pressure, turn signal, transmission fluid, differential, fill transmission, trunk release