TOYOTA CAMRY 1999 Service Repair Manual

CAMRY 1999

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57448/w960_57448-0.png

TOYOTA CAMRY 1999 Service Repair Manual

Trending: fluid capacity, Windows, oil level, diagnostic menu, oil reset, maintenance, change time

Page 351 of 4592

AUTOMATIC TRANSAXLEFORWARD CLUTCH ±

AX±45

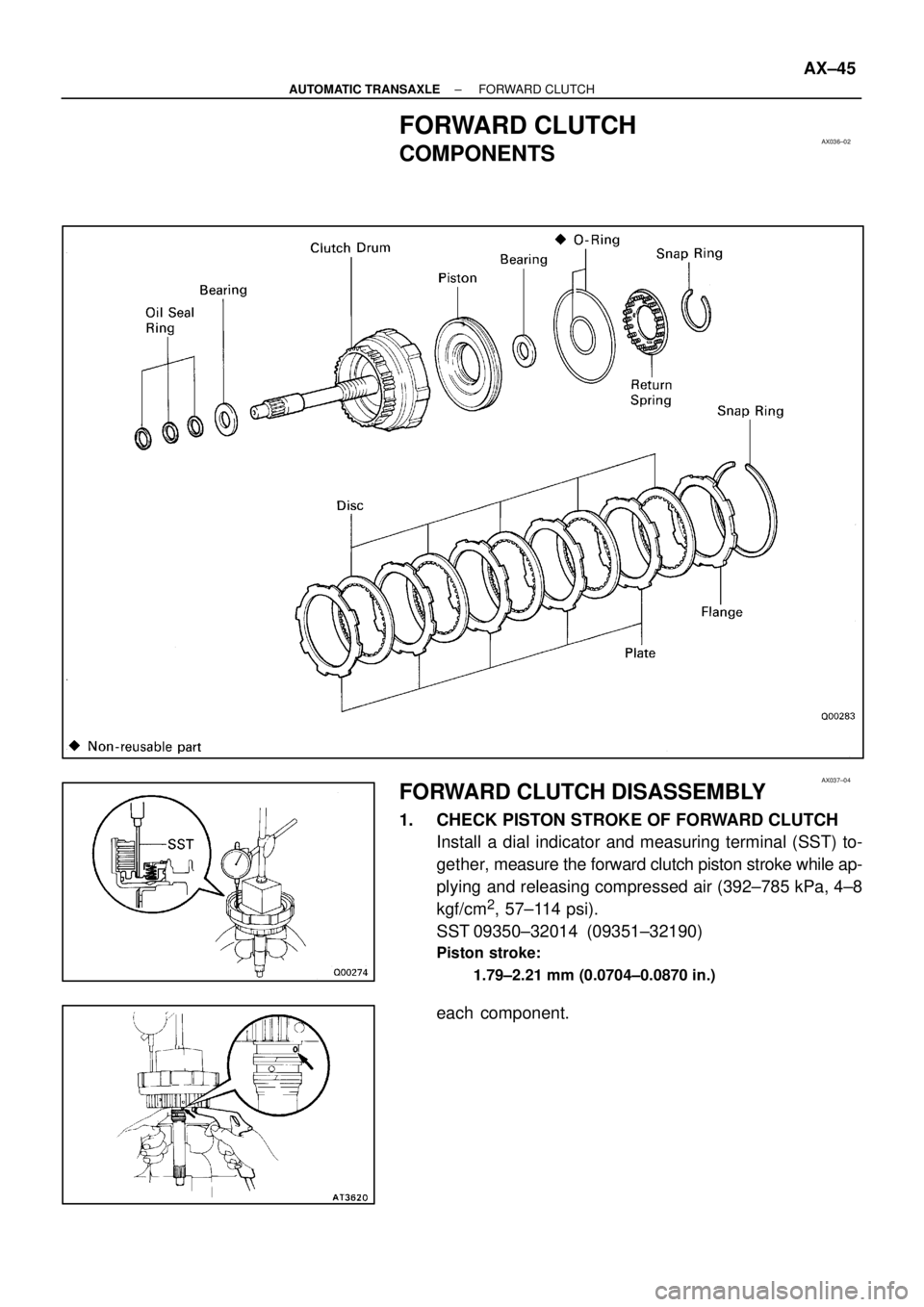

FORWARD CLUTCH

COMPONENTS

FORWARD CLUTCH DISASSEMBLY

1. CHECK PISTON STROKE OF FORWARD CLUTCH

Install a dial indicator and measuring terminal (SST) to-

gether, measure the forward clutch piston stroke while ap-

plying and releasing compressed air (392±785 kPa, 4±8

kgf/cm

2, 57±114 psi).

SST 09350±32014 (09351±32190)

Piston stroke:

1.79±2.21 mm (0.0704±0.0870 in.)

each component.

AX036±02

AX037±04

Page 352 of 4592

AUTOMATIC TRANSAXLEFORWARD CLUTCH ±

AX±46

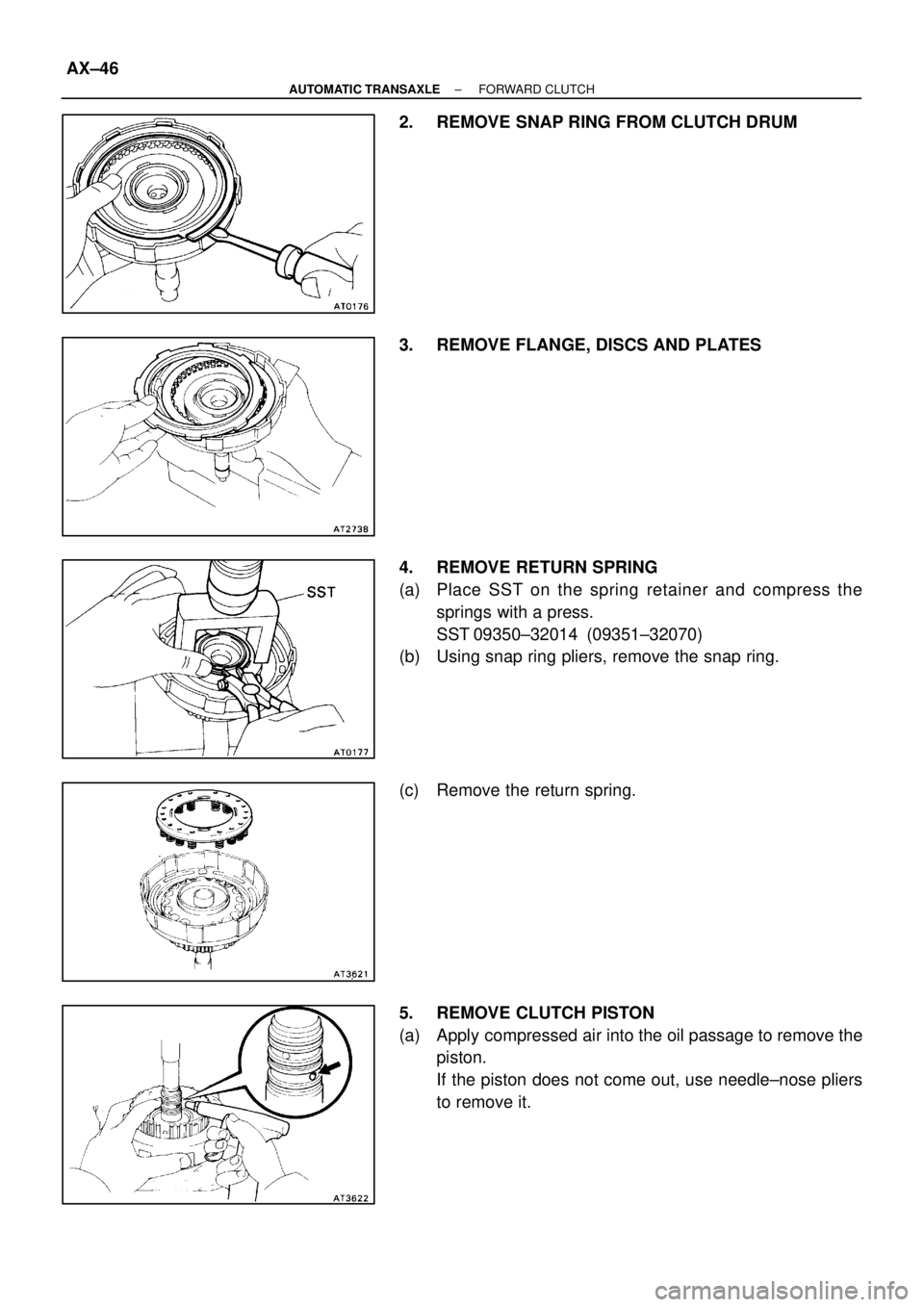

2. REMOVE SNAP RING FROM CLUTCH DRUM

3. REMOVE FLANGE, DISCS AND PLATES

4. REMOVE RETURN SPRING

(a) Place SST on the spring retainer and compress the

springs with a press.

SST 09350±32014 (09351±32070)

(b) Using snap ring pliers, remove the snap ring.

(c) Remove the return spring.

5. REMOVE CLUTCH PISTON

(a) Apply compressed air into the oil passage to remove the

piston.

If the piston does not come out, use needle±nose pliers

to remove it.

Page 353 of 4592

AUTOMATIC TRANSAXLEFORWARD CLUTCH ±

AX±47

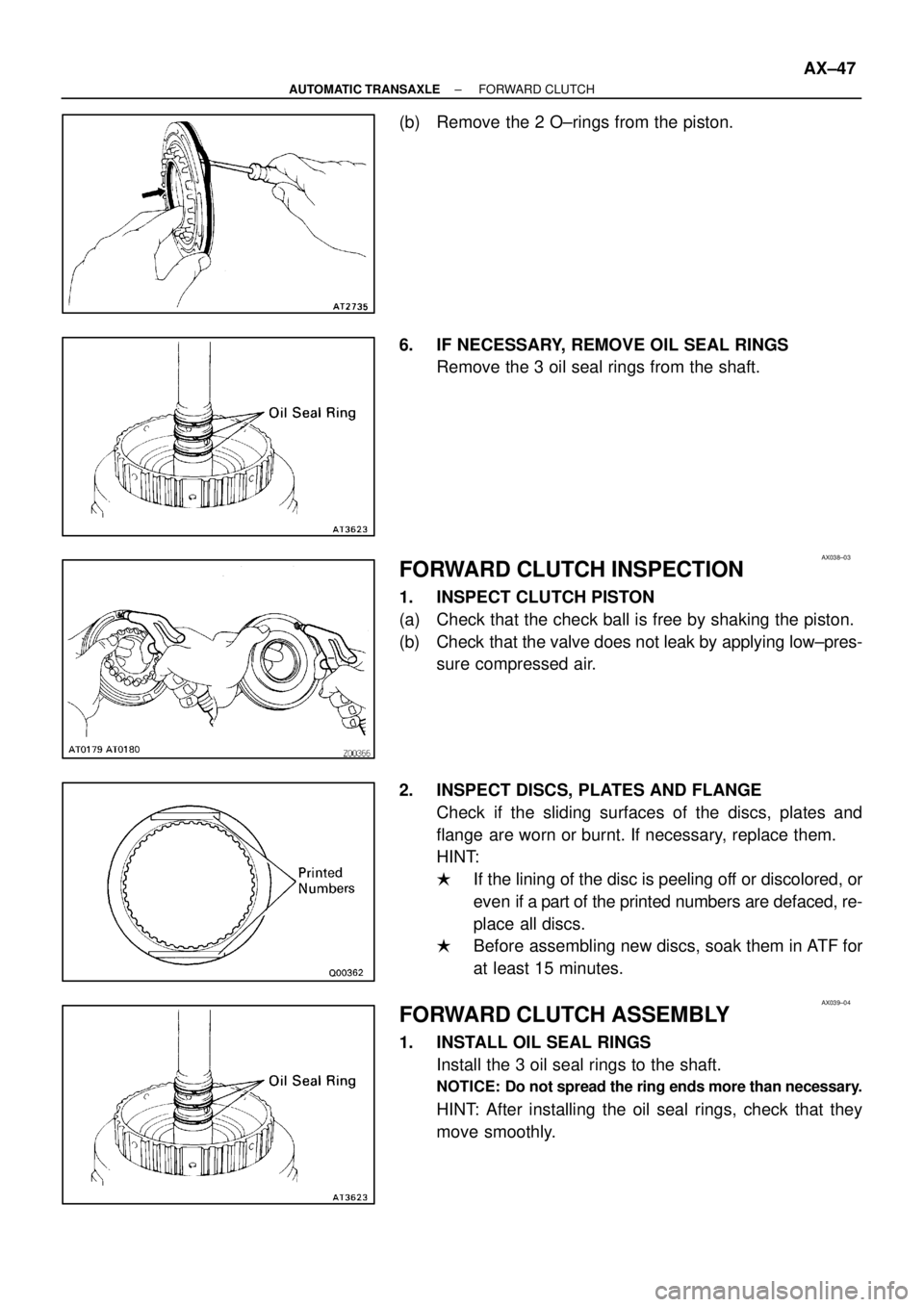

(b) Remove the 2 O±rings from the piston.

6. IF NECESSARY, REMOVE OIL SEAL RINGS

Remove the 3 oil seal rings from the shaft.

FORWARD CLUTCH INSPECTION

1. INSPECT CLUTCH PISTON

(a) Check that the check ball is free by shaking the piston.

(b) Check that the valve does not leak by applying low±pres-

sure compressed air.

2. INSPECT DISCS, PLATES AND FLANGE

Check if the sliding surfaces of the discs, plates and

flange are worn or burnt. If necessary, replace them.

HINT:

�If the lining of the disc is peeling off or discolored, or

even if a part of the printed numbers are defaced, re-

place all discs.

�Before assembling new discs, soak them in ATF for

at least 15 minutes.

FORWARD CLUTCH ASSEMBLY

1. INSTALL OIL SEAL RINGS

Install the 3 oil seal rings to the shaft.

NOTICE: Do not spread the ring ends more than necessary.

HINT: After installing the oil seal rings, check that they

move smoothly.

AX038±03

AX039±04

Page 354 of 4592

AUTOMATIC TRANSAXLEFORWARD CLUTCH ±

AX±48

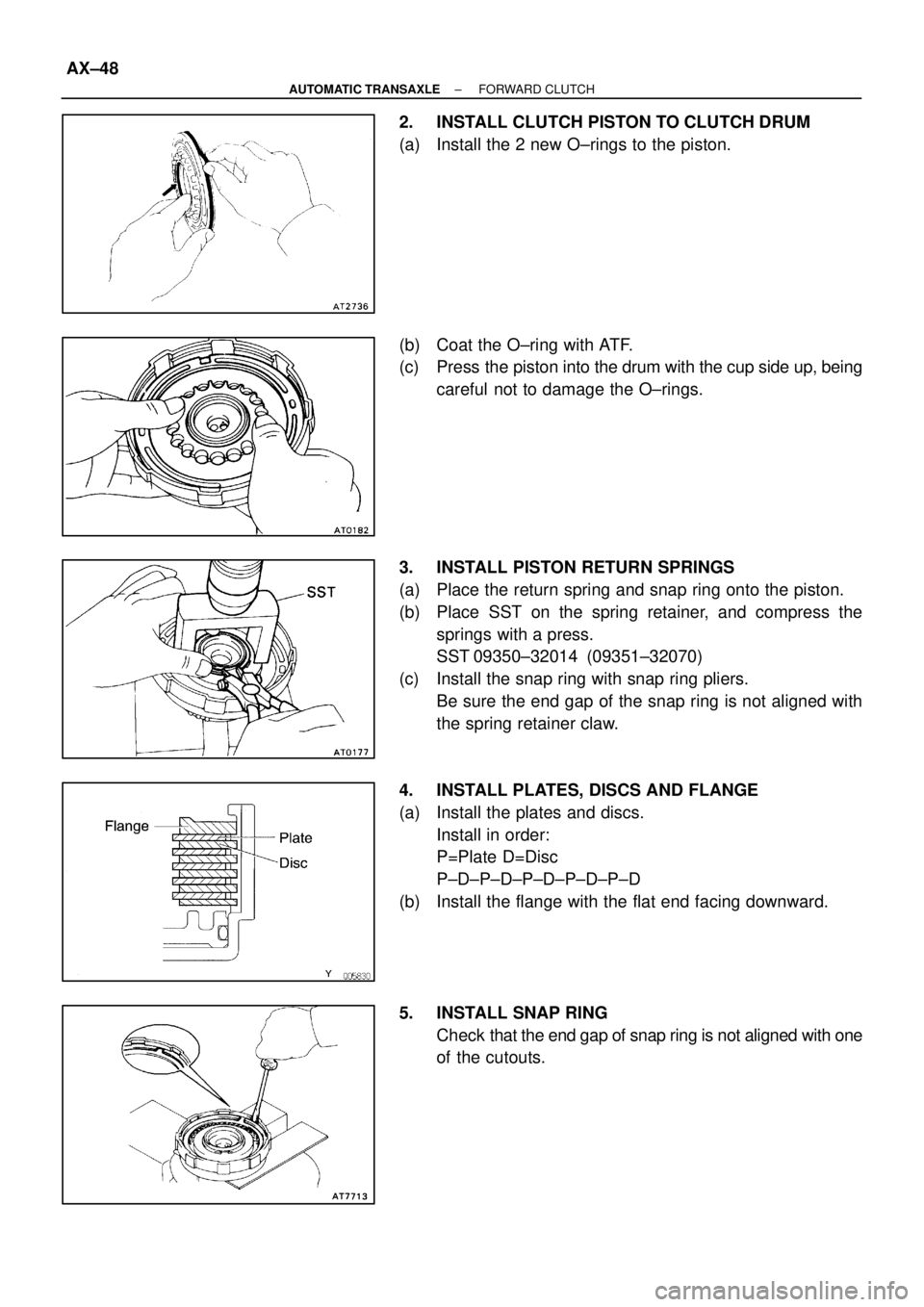

2. INSTALL CLUTCH PISTON TO CLUTCH DRUM

(a) Install the 2 new O±rings to the piston.

(b) Coat the O±ring with ATF.

(c) Press the piston into the drum with the cup side up, being

careful not to damage the O±rings.

3. INSTALL PISTON RETURN SPRINGS

(a) Place the return spring and snap ring onto the piston.

(b) Place SST on the spring retainer, and compress the

springs with a press.

SST 09350±32014 (09351±32070)

(c) Install the snap ring with snap ring pliers.

Be sure the end gap of the snap ring is not aligned with

the spring retainer claw.

4. INSTALL PLATES, DISCS AND FLANGE

(a) Install the plates and discs.

Install in order:

P=Plate D=Disc

P±D±P±D±P±D±P±D±P±D

(b) Install the flange with the flat end facing downward.

5. INSTALL SNAP RING

Check that the end gap of snap ring is not aligned with one

of the cutouts.

Page 355 of 4592

AUTOMATIC TRANSAXLEFORWARD CLUTCH ±

AX±49

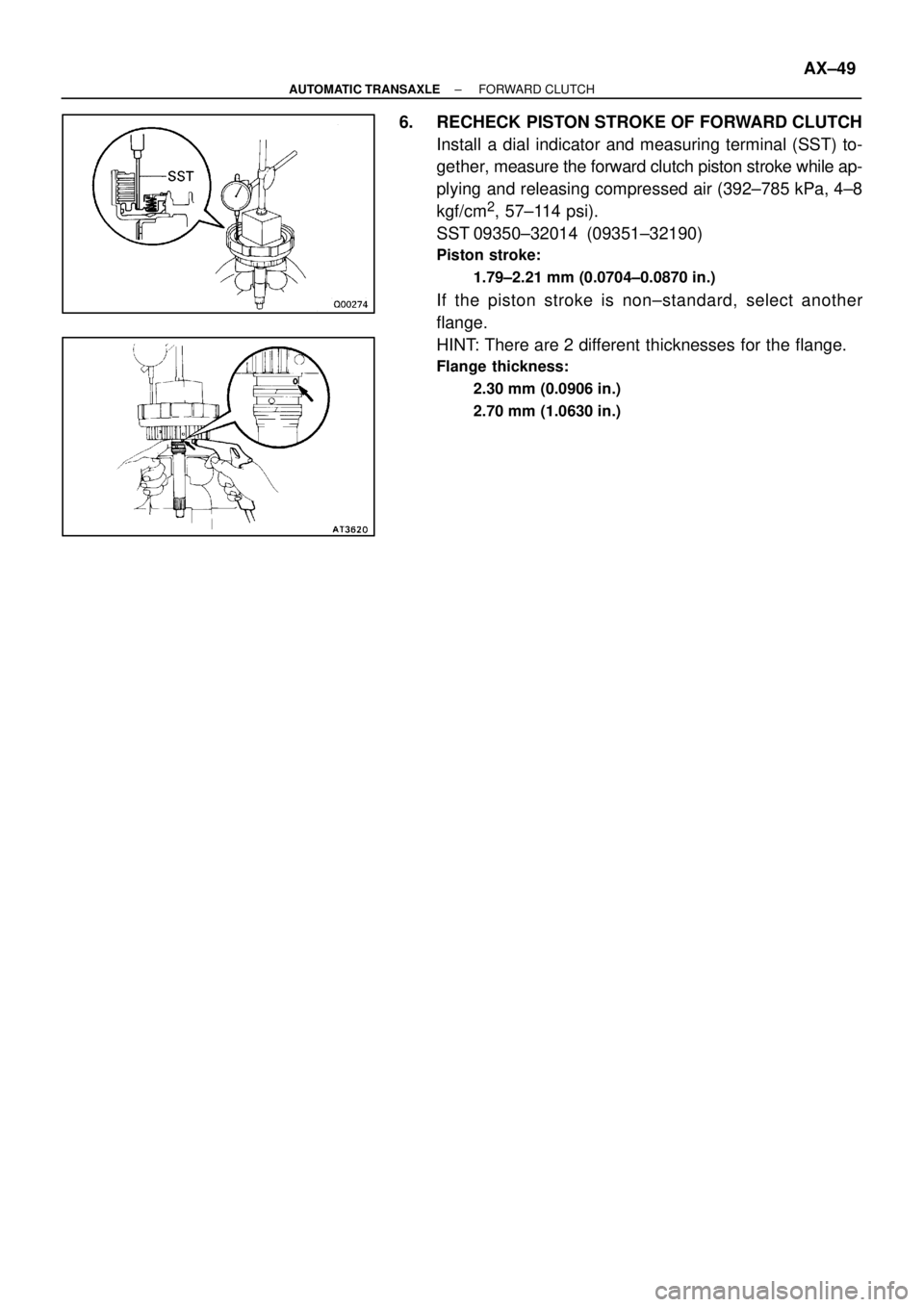

6. RECHECK PISTON STROKE OF FORWARD CLUTCH

Install a dial indicator and measuring terminal (SST) to-

gether, measure the forward clutch piston stroke while ap-

plying and releasing compressed air (392±785 kPa, 4±8

kgf/cm

2, 57±114 psi).

SST 09350±32014 (09351±32190)

Piston stroke:

1.79±2.21 mm (0.0704±0.0870 in.)

If the piston stroke is non±standard, select another

flange.

HINT: There are 2 different thicknesses for the flange.

Flange thickness:

2.30 mm (0.0906 in.)

2.70 mm (1.0630 in.)

Page 356 of 4592

AUTOMATIC TRANSAXLEFRONT PLANETARY GEAR ±

AX±50

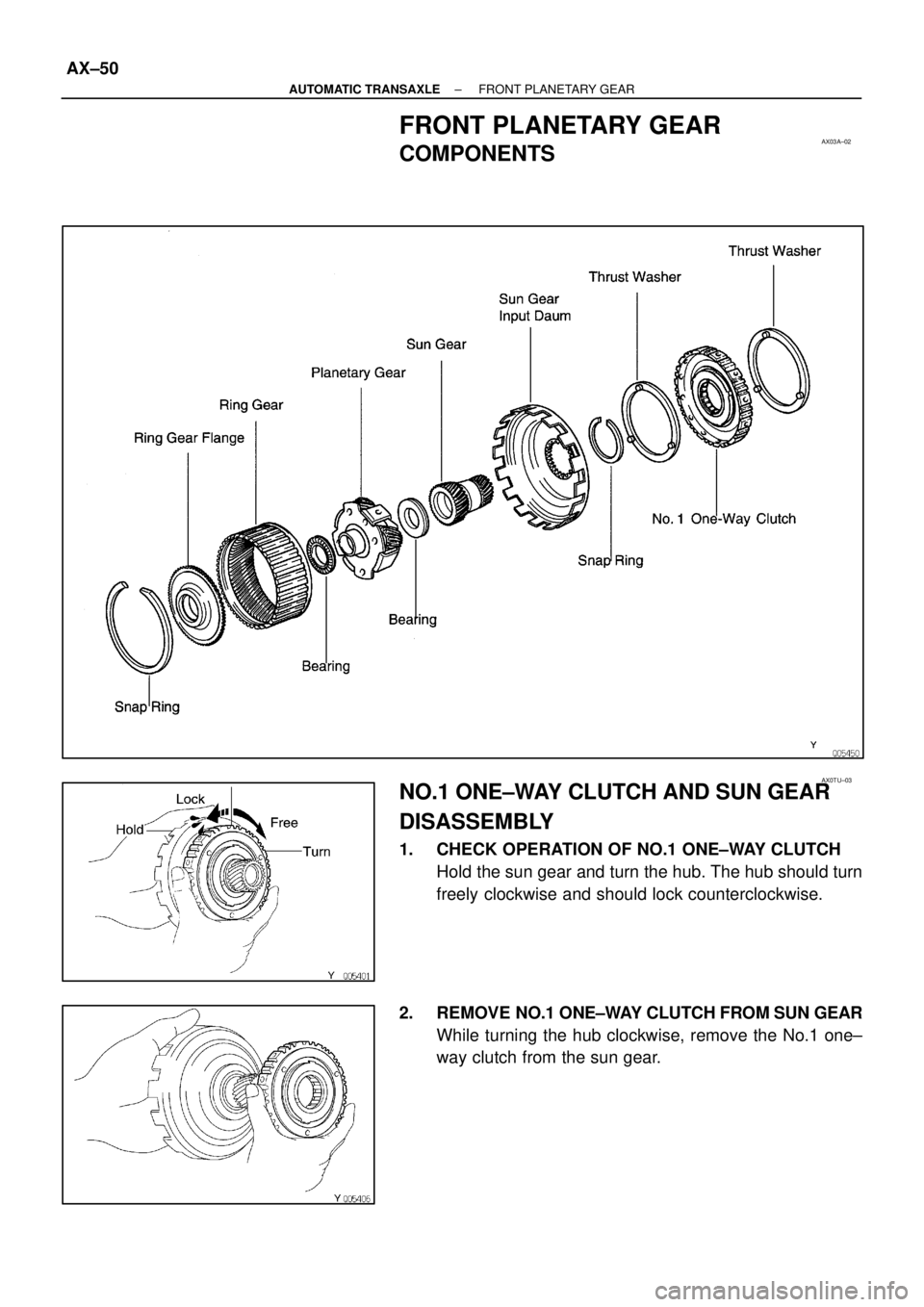

FRONT PLANETARY GEAR

COMPONENTS

NO.1 ONE±WAY CLUTCH AND SUN GEAR

DISASSEMBLY

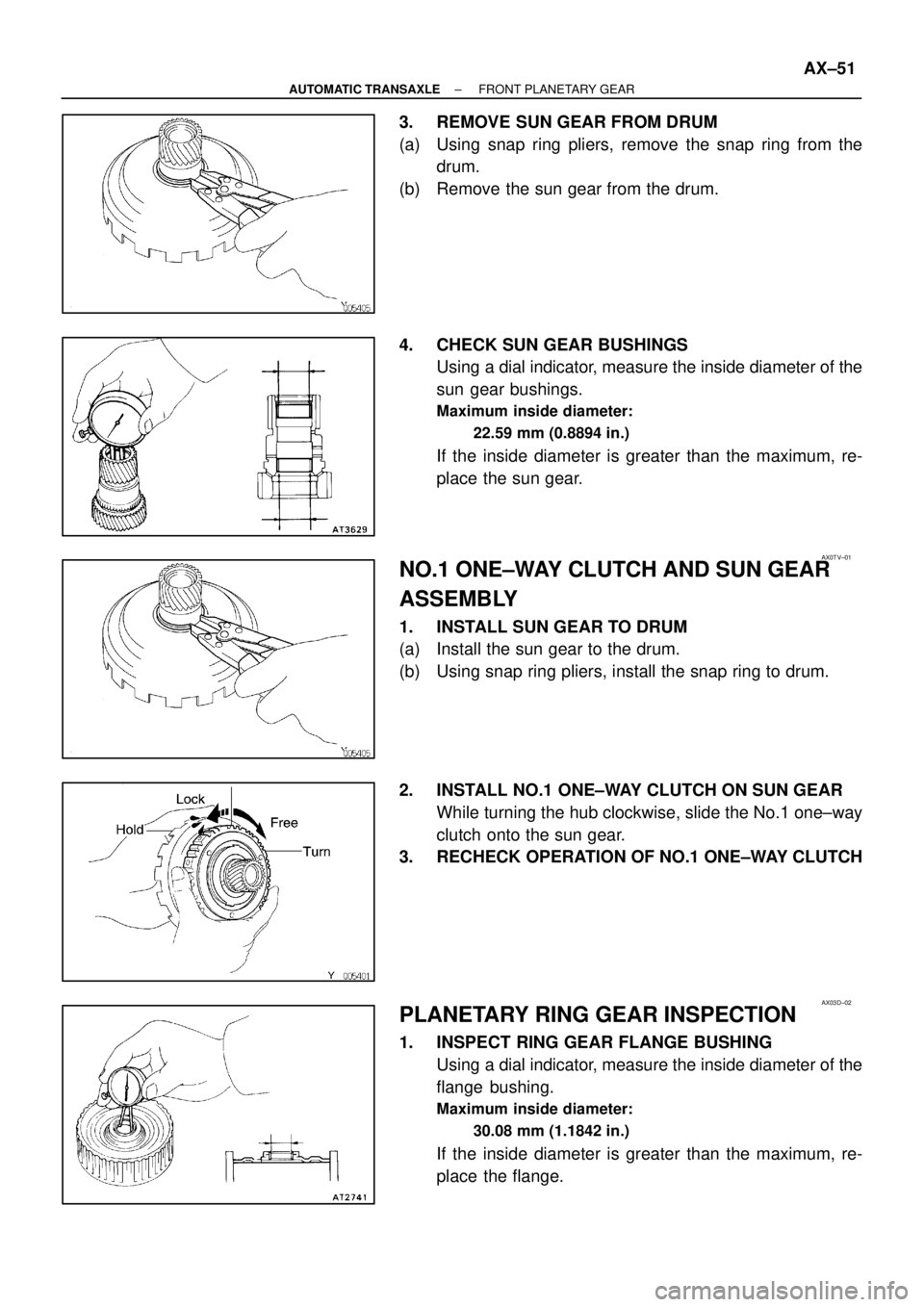

1. CHECK OPERATION OF NO.1 ONE±WAY CLUTCH

Hold the sun gear and turn the hub. The hub should turn

freely clockwise and should lock counterclockwise.

2. REMOVE NO.1 ONE±WAY CLUTCH FROM SUN GEAR

While turning the hub clockwise, remove the No.1 one±

way clutch from the sun gear.

AX03A±02

AX0TU±03

Page 357 of 4592

AUTOMATIC TRANSAXLEFRONT PLANETARY GEAR ±

AX±51

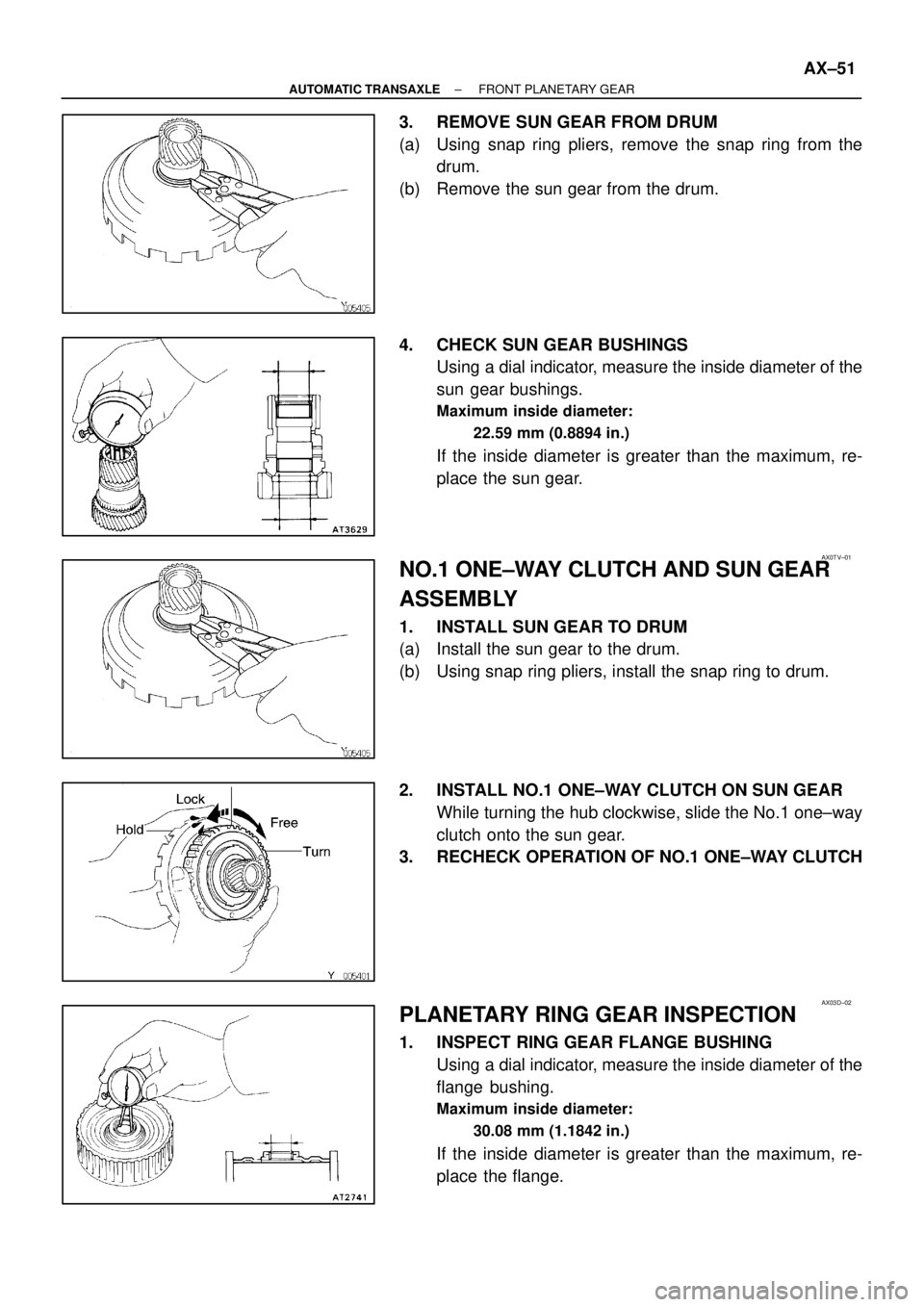

3. REMOVE SUN GEAR FROM DRUM

(a) Using snap ring pliers, remove the snap ring from the

drum.

(b) Remove the sun gear from the drum.

4. CHECK SUN GEAR BUSHINGS

Using a dial indicator, measure the inside diameter of the

sun gear bushings.

Maximum inside diameter:

22.59 mm (0.8894 in.)

If the inside diameter is greater than the maximum, re-

place the sun gear.

NO.1 ONE±WAY CLUTCH AND SUN GEAR

ASSEMBLY

1. INSTALL SUN GEAR TO DRUM

(a) Install the sun gear to the drum.

(b) Using snap ring pliers, install the snap ring to drum.

2. INSTALL NO.1 ONE±WAY CLUTCH ON SUN GEAR

While turning the hub clockwise, slide the No.1 one±way

clutch onto the sun gear.

3. RECHECK OPERATION OF NO.1 ONE±WAY CLUTCH

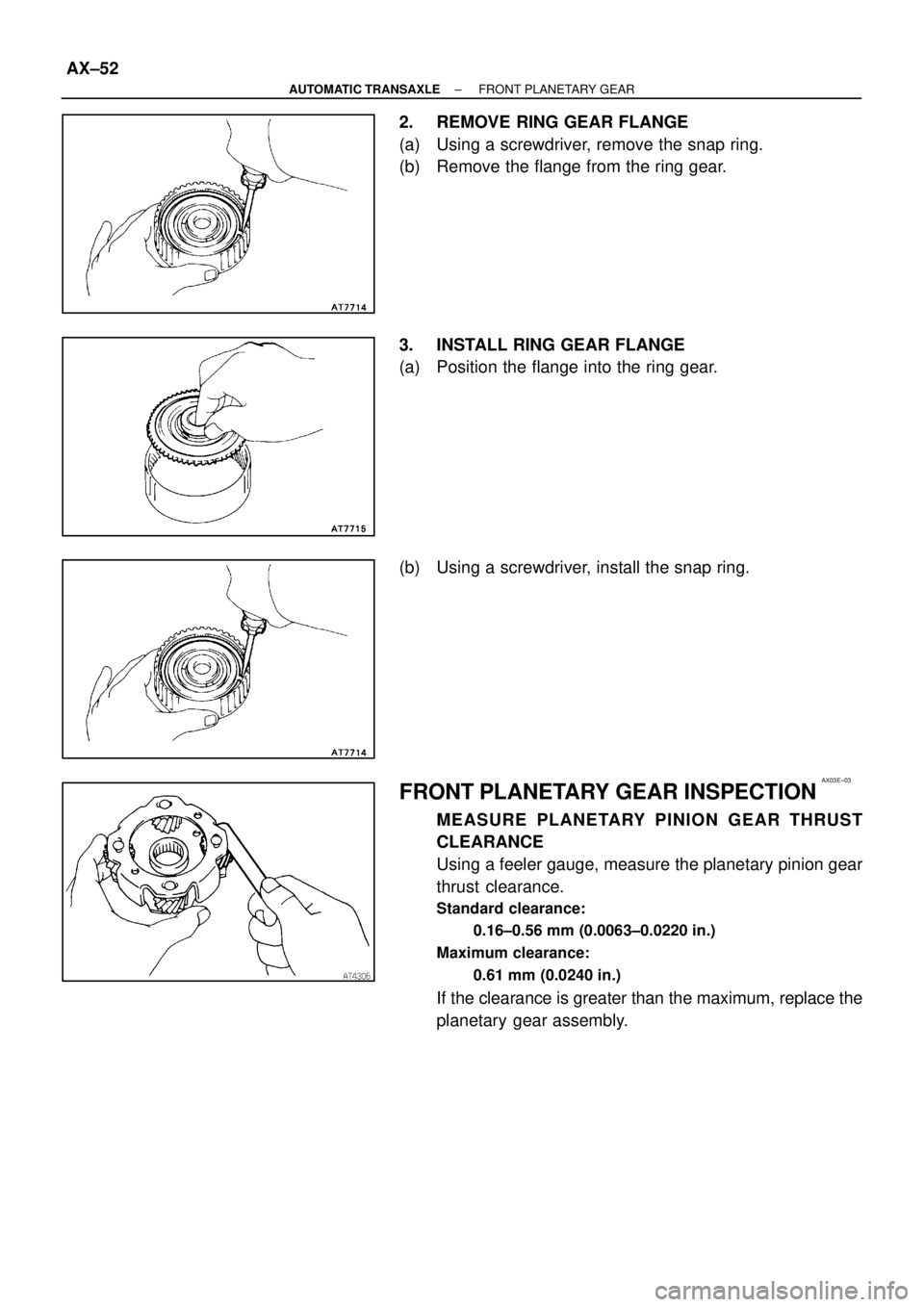

PLANETARY RING GEAR INSPECTION

1. INSPECT RING GEAR FLANGE BUSHING

Using a dial indicator, measure the inside diameter of the

flange bushing.

Maximum inside diameter:

30.08 mm (1.1842 in.)

If the inside diameter is greater than the maximum, re-

place the flange.

AX0TV±01

AX03D±02

Page 358 of 4592

AUTOMATIC TRANSAXLEFRONT PLANETARY GEAR ±

AX±52

2. REMOVE RING GEAR FLANGE

(a) Using a screwdriver, remove the snap ring.

(b) Remove the flange from the ring gear.

3. INSTALL RING GEAR FLANGE

(a) Position the flange into the ring gear.

(b) Using a screwdriver, install the snap ring.

FRONT PLANETARY GEAR INSPECTION

MEASURE PLANETARY PINION GEAR THRUST

CLEARANCE

Using a feeler gauge, measure the planetary pinion gear

thrust clearance.

Standard clearance:

0.16±0.56 mm (0.0063±0.0220 in.)

Maximum clearance:

0.61 mm (0.0240 in.)

If the clearance is greater than the maximum, replace the

planetary gear assembly.

AX03E±03

Page 359 of 4592

AUTOMATIC TRANSAXLESECOND BRAKE ±

AX±53

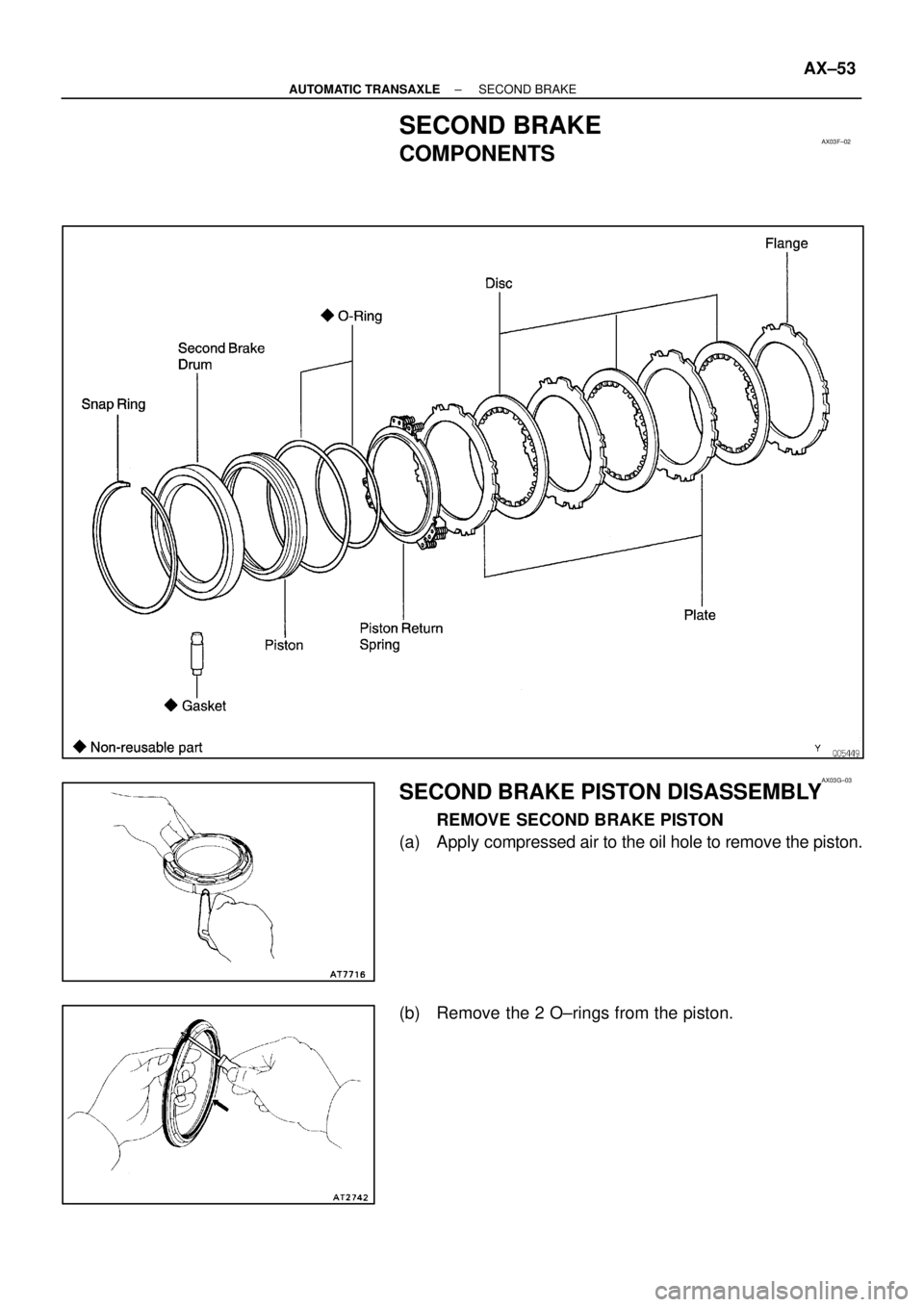

SECOND BRAKE

COMPONENTS

SECOND BRAKE PISTON DISASSEMBLY

REMOVE SECOND BRAKE PISTON

(a) Apply compressed air to the oil hole to remove the piston.

(b) Remove the 2 O±rings from the piston.

AX03F±02

AX03G±03

Page 360 of 4592

AUTOMATIC TRANSAXLESECOND BRAKE ±

AX±54

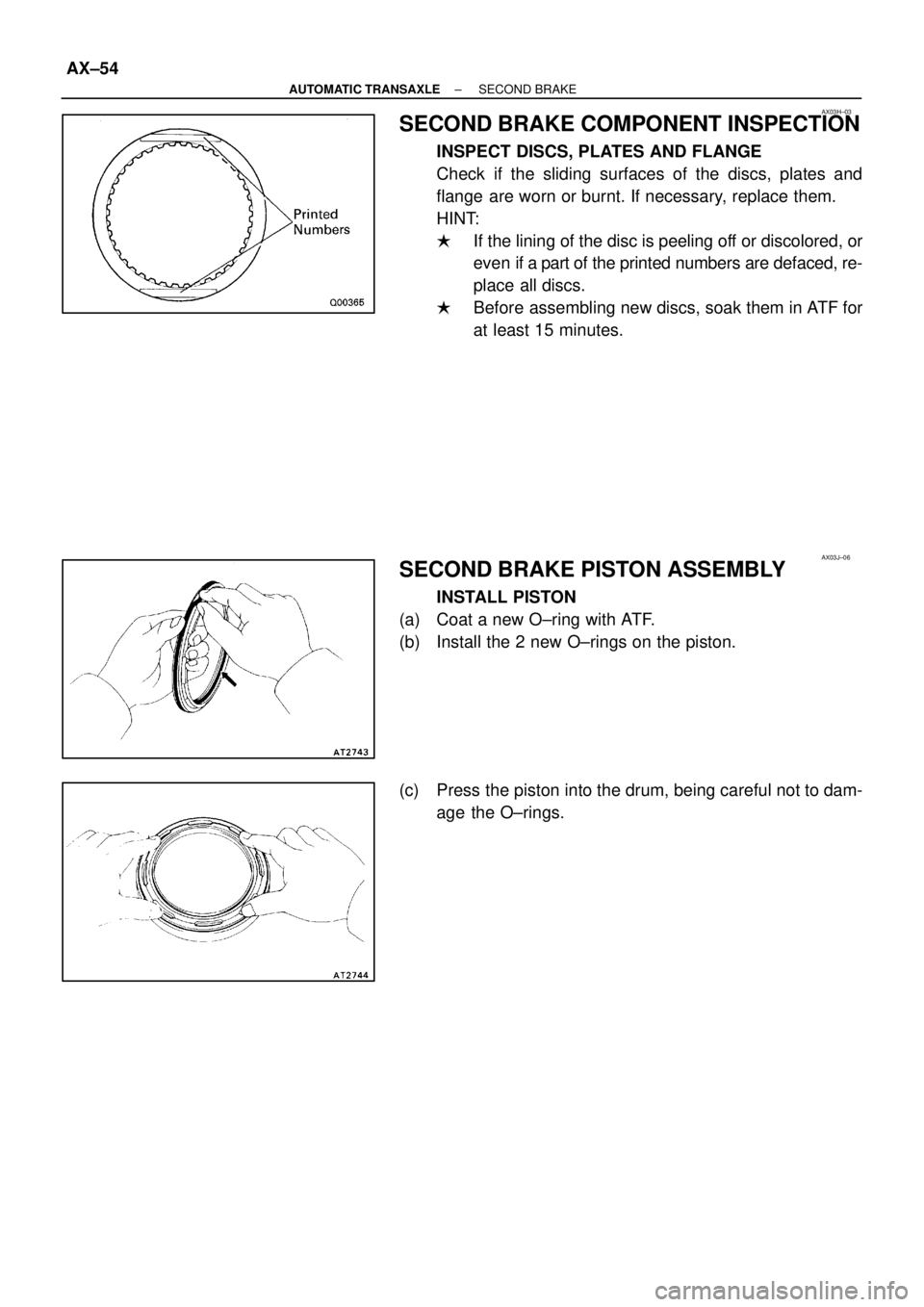

SECOND BRAKE COMPONENT INSPECTION

INSPECT DISCS, PLATES AND FLANGE

Check if the sliding surfaces of the discs, plates and

flange are worn or burnt. If necessary, replace them.

HINT:

�If the lining of the disc is peeling off or discolored, or

even if a part of the printed numbers are defaced, re-

place all discs.

�Before assembling new discs, soak them in ATF for

at least 15 minutes.

SECOND BRAKE PISTON ASSEMBLY

INSTALL PISTON

(a) Coat a new O±ring with ATF.

(b) Install the 2 new O±rings on the piston.

(c) Press the piston into the drum, being careful not to dam-

age the O±rings.

AX03H±03

AX03J±06

Trending: control arm, engine oil capacity, oil change, low oil pressure, clutch starter switch, dimensions, hood open