TOYOTA CAMRY 1999 Service Repair Manual

CAMRY 1999

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57448/w960_57448-0.png

TOYOTA CAMRY 1999 Service Repair Manual

Trending: wheel torque, heater, transmission fill, weight, check engine light, coolant capacity, diagnostic menu

Page 371 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±65

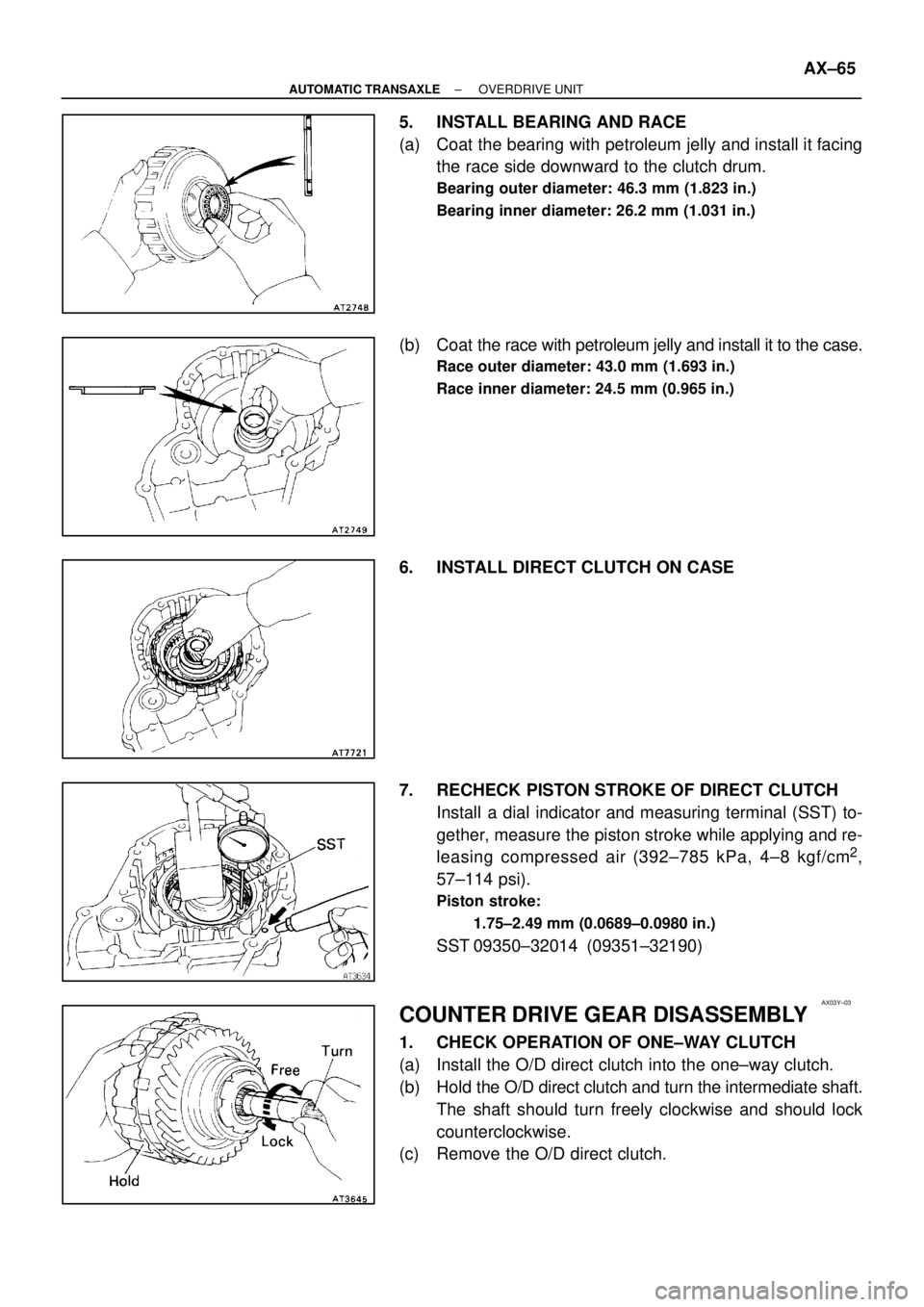

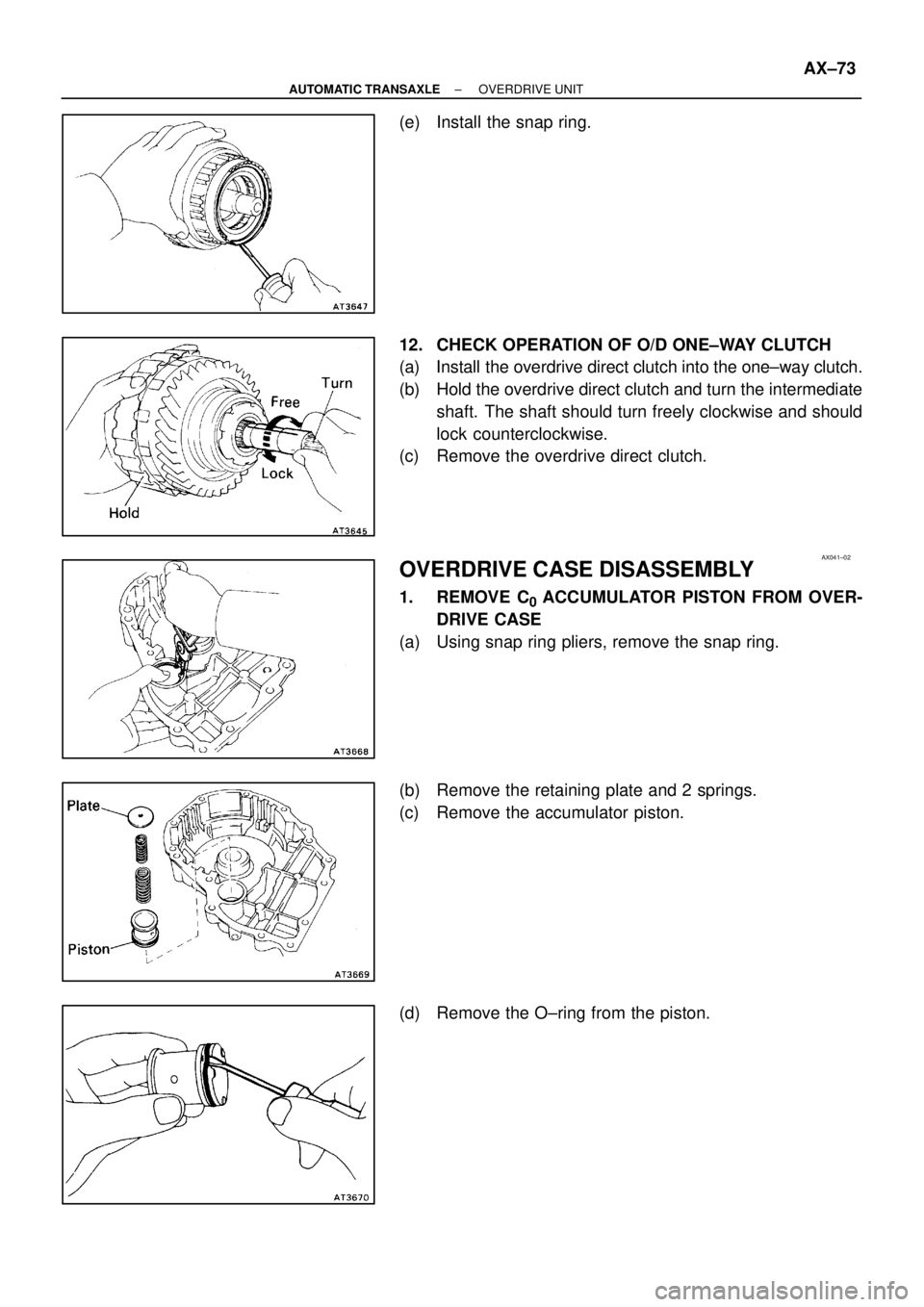

5. INSTALL BEARING AND RACE

(a) Coat the bearing with petroleum jelly and install it facing

the race side downward to the clutch drum.

Bearing outer diameter: 46.3 mm (1.823 in.)

Bearing inner diameter: 26.2 mm (1.031 in.)

(b) Coat the race with petroleum jelly and install it to the case.

Race outer diameter: 43.0 mm (1.693 in.)

Race inner diameter: 24.5 mm (0.965 in.)

6. INSTALL DIRECT CLUTCH ON CASE

7. RECHECK PISTON STROKE OF DIRECT CLUTCH

Install a dial indicator and measuring terminal (SST) to-

gether, measure the piston stroke while applying and re-

leasing compressed air (392±785 kPa, 4±8 kgf/cm

2,

57±114 psi).

Piston stroke:

1.75±2.49 mm (0.0689±0.0980 in.)

SST 09350±32014 (09351±32190)

COUNTER DRIVE GEAR DISASSEMBLY

1. CHECK OPERATION OF ONE±WAY CLUTCH

(a) Install the O/D direct clutch into the one±way clutch.

(b) Hold the O/D direct clutch and turn the intermediate shaft.

The shaft should turn freely clockwise and should lock

counterclockwise.

(c) Remove the O/D direct clutch.

AX03Y±03

Page 372 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±66

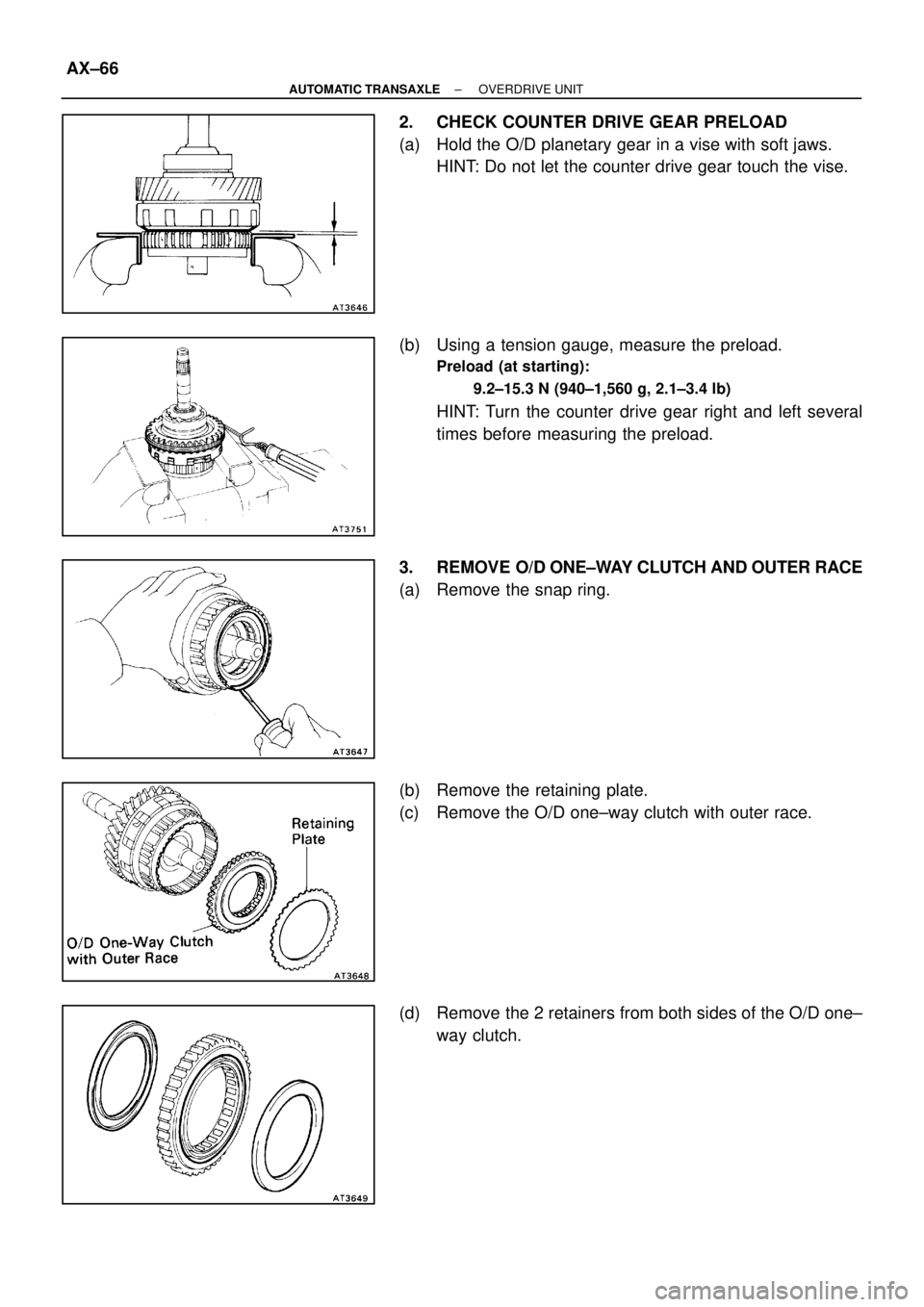

2. CHECK COUNTER DRIVE GEAR PRELOAD

(a) Hold the O/D planetary gear in a vise with soft jaws.

HINT: Do not let the counter drive gear touch the vise.

(b) Using a tension gauge, measure the preload.

Preload (at starting):

9.2±15.3 N (940±1,560 g, 2.1±3.4 lb)

HINT: Turn the counter drive gear right and left several

times before measuring the preload.

3. REMOVE O/D ONE±WAY CLUTCH AND OUTER RACE

(a) Remove the snap ring.

(b) Remove the retaining plate.

(c) Remove the O/D one±way clutch with outer race.

(d) Remove the 2 retainers from both sides of the O/D one±

way clutch.

Page 373 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±67

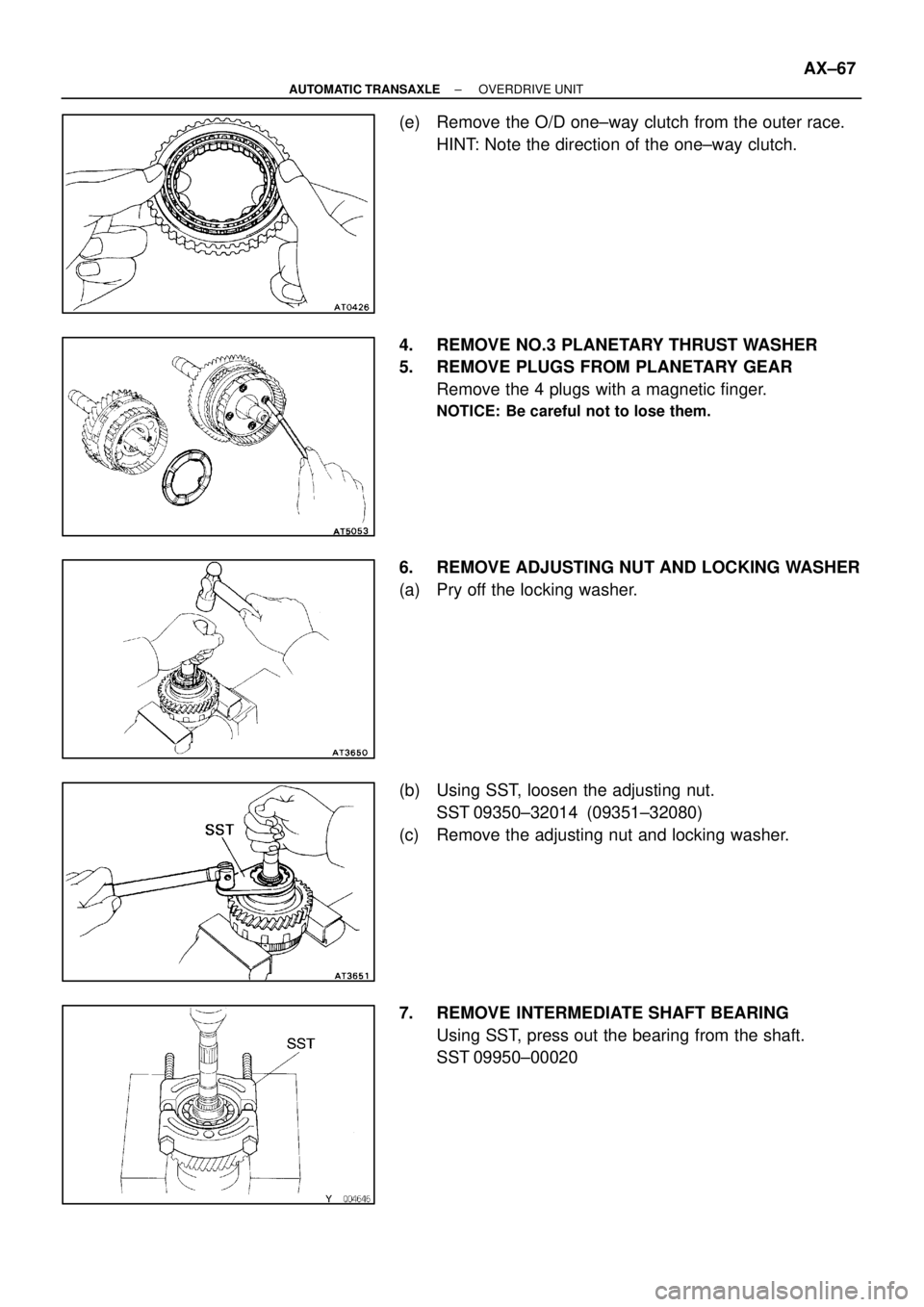

(e) Remove the O/D one±way clutch from the outer race.

HINT: Note the direction of the one±way clutch.

4. REMOVE NO.3 PLANETARY THRUST WASHER

5. REMOVE PLUGS FROM PLANETARY GEAR

Remove the 4 plugs with a magnetic finger.

NOTICE: Be careful not to lose them.

6. REMOVE ADJUSTING NUT AND LOCKING WASHER

(a) Pry off the locking washer.

(b) Using SST, loosen the adjusting nut.

SST 09350±32014 (09351±32080)

(c) Remove the adjusting nut and locking washer.

7. REMOVE INTERMEDIATE SHAFT BEARING

Using SST, press out the bearing from the shaft.

SST 09950±00020

Page 374 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±68

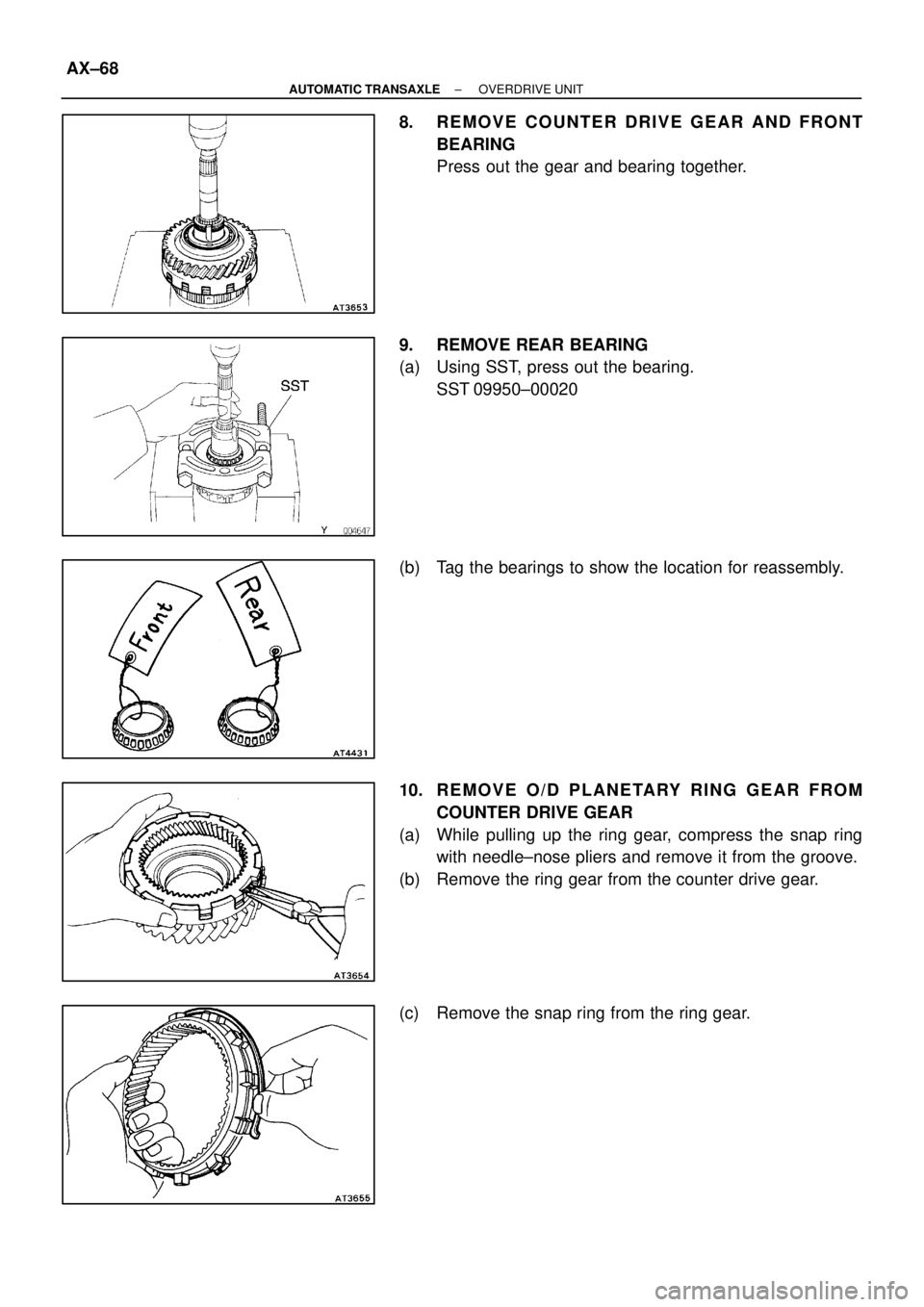

8. REMOVE COUNTER DRIVE GEAR AND FRONT

BEARING

Press out the gear and bearing together.

9. REMOVE REAR BEARING

(a) Using SST, press out the bearing.

SST 09950±00020

(b) Tag the bearings to show the location for reassembly.

10. REMOVE O/D PLANETARY RING GEAR FROM

COUNTER DRIVE GEAR

(a) While pulling up the ring gear, compress the snap ring

with needle±nose pliers and remove it from the groove.

(b) Remove the ring gear from the counter drive gear.

(c) Remove the snap ring from the ring gear.

Page 375 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±69

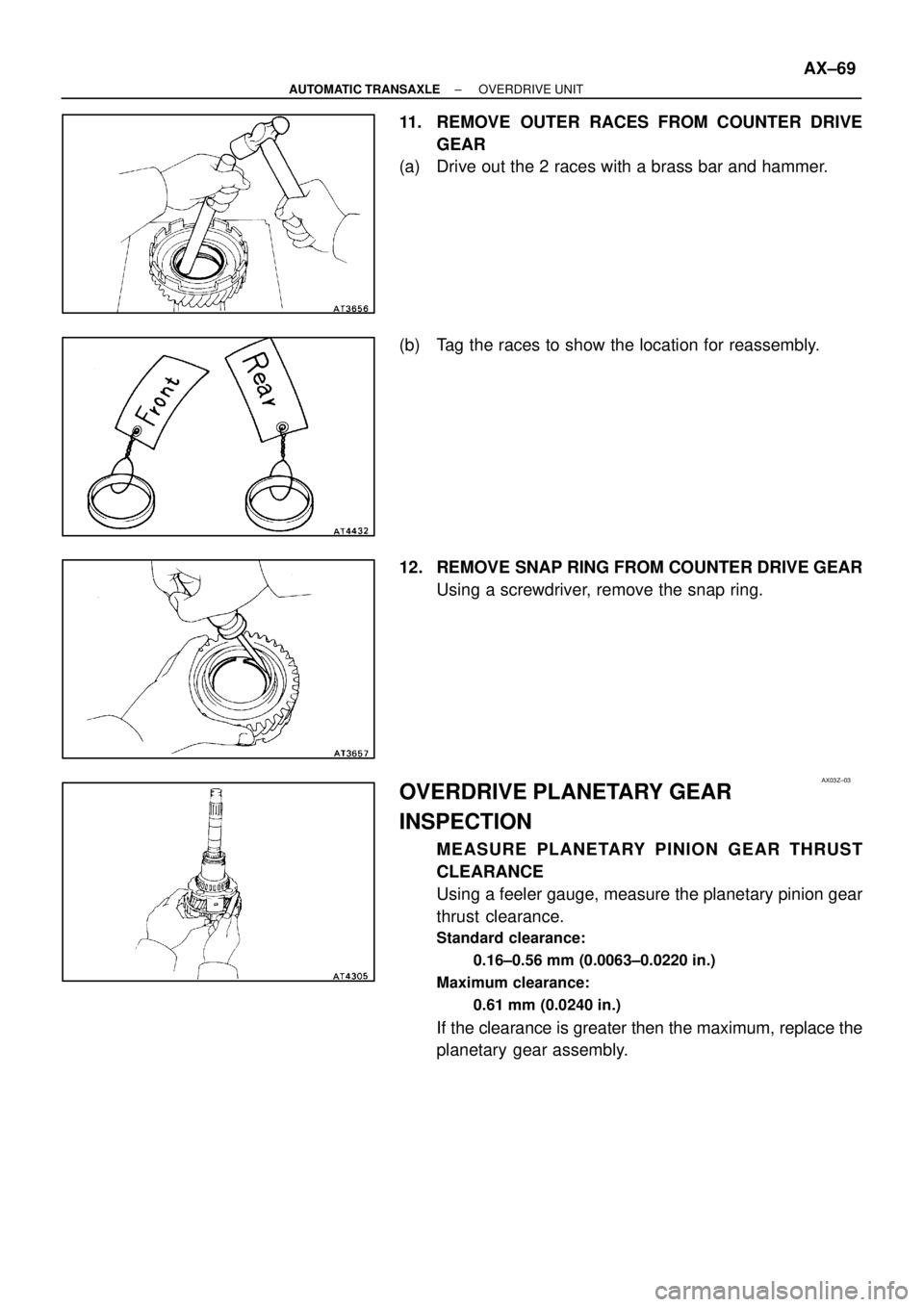

11. REMOVE OUTER RACES FROM COUNTER DRIVE

GEAR

(a) Drive out the 2 races with a brass bar and hammer.

(b) Tag the races to show the location for reassembly.

12. REMOVE SNAP RING FROM COUNTER DRIVE GEAR

Using a screwdriver, remove the snap ring.

OVERDRIVE PLANETARY GEAR

INSPECTION

MEASURE PLANETARY PINION GEAR THRUST

CLEARANCE

Using a feeler gauge, measure the planetary pinion gear

thrust clearance.

Standard clearance:

0.16±0.56 mm (0.0063±0.0220 in.)

Maximum clearance:

0.61 mm (0.0240 in.)

If the clearance is greater then the maximum, replace the

planetary gear assembly.

AX03Z±03

Page 376 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±70

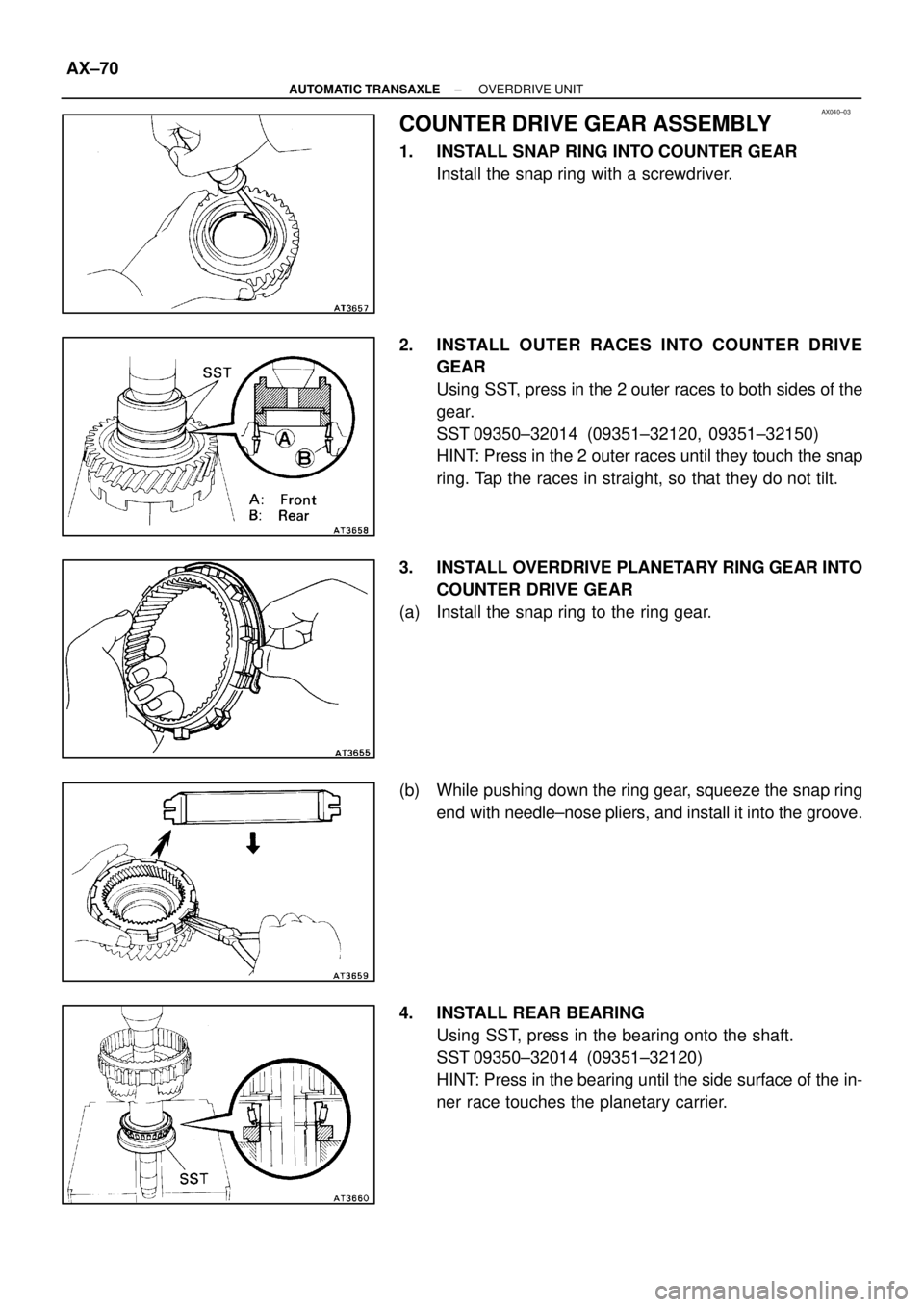

COUNTER DRIVE GEAR ASSEMBLY

1. INSTALL SNAP RING INTO COUNTER GEAR

Install the snap ring with a screwdriver.

2. INSTALL OUTER RACES INTO COUNTER DRIVE

GEAR

Using SST, press in the 2 outer races to both sides of the

gear.

SST 09350±32014 (09351±32120, 09351±32150)

HINT: Press in the 2 outer races until they touch the snap

ring. Tap the races in straight, so that they do not tilt.

3. INSTALL OVERDRIVE PLANETARY RING GEAR INTO

COUNTER DRIVE GEAR

(a) Install the snap ring to the ring gear.

(b) While pushing down the ring gear, squeeze the snap ring

end with needle±nose pliers, and install it into the groove.

4. INSTALL REAR BEARING

Using SST, press in the bearing onto the shaft.

SST 09350±32014 (09351±32120)

HINT: Press in the bearing until the side surface of the in-

ner race touches the planetary carrier.

AX040±03

Page 377 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±71

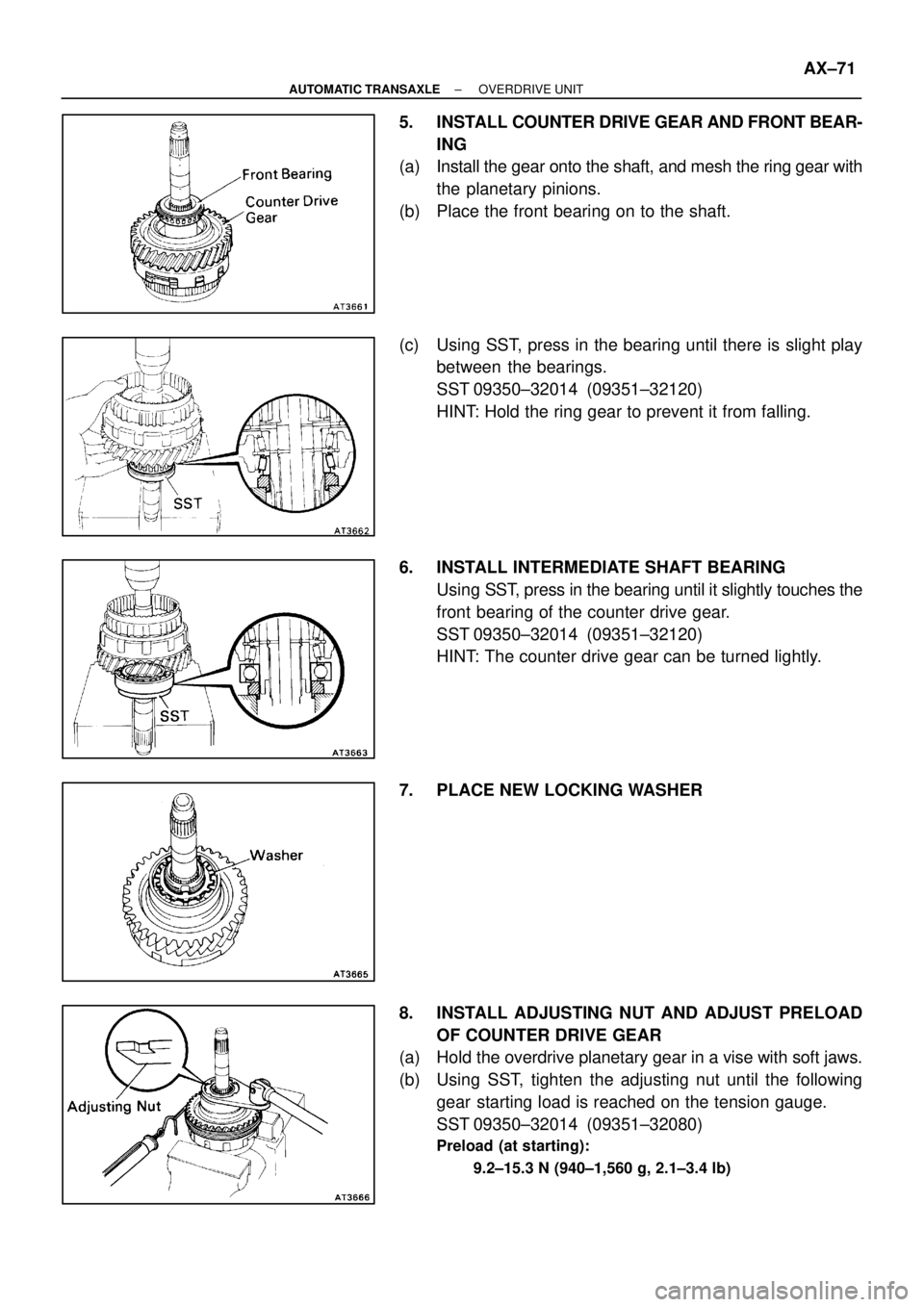

5. INSTALL COUNTER DRIVE GEAR AND FRONT BEAR-

ING

(a) Install the gear onto the shaft, and mesh the ring gear with

the planetary pinions.

(b) Place the front bearing on to the shaft.

(c) Using SST, press in the bearing until there is slight play

between the bearings.

SST 09350±32014 (09351±32120)

HINT: Hold the ring gear to prevent it from falling.

6. INSTALL INTERMEDIATE SHAFT BEARING

Using SST, press in the bearing until it slightly touches the

front bearing of the counter drive gear.

SST 09350±32014 (09351±32120)

HINT: The counter drive gear can be turned lightly.

7. PLACE NEW LOCKING WASHER

8. INSTALL ADJUSTING NUT AND ADJUST PRELOAD

OF COUNTER DRIVE GEAR

(a) Hold the overdrive planetary gear in a vise with soft jaws.

(b) Using SST, tighten the adjusting nut until the following

gear starting load is reached on the tension gauge.

SST 09350±32014 (09351±32080)

Preload (at starting):

9.2±15.3 N (940±1,560 g, 2.1±3.4 lb)

Page 378 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±72

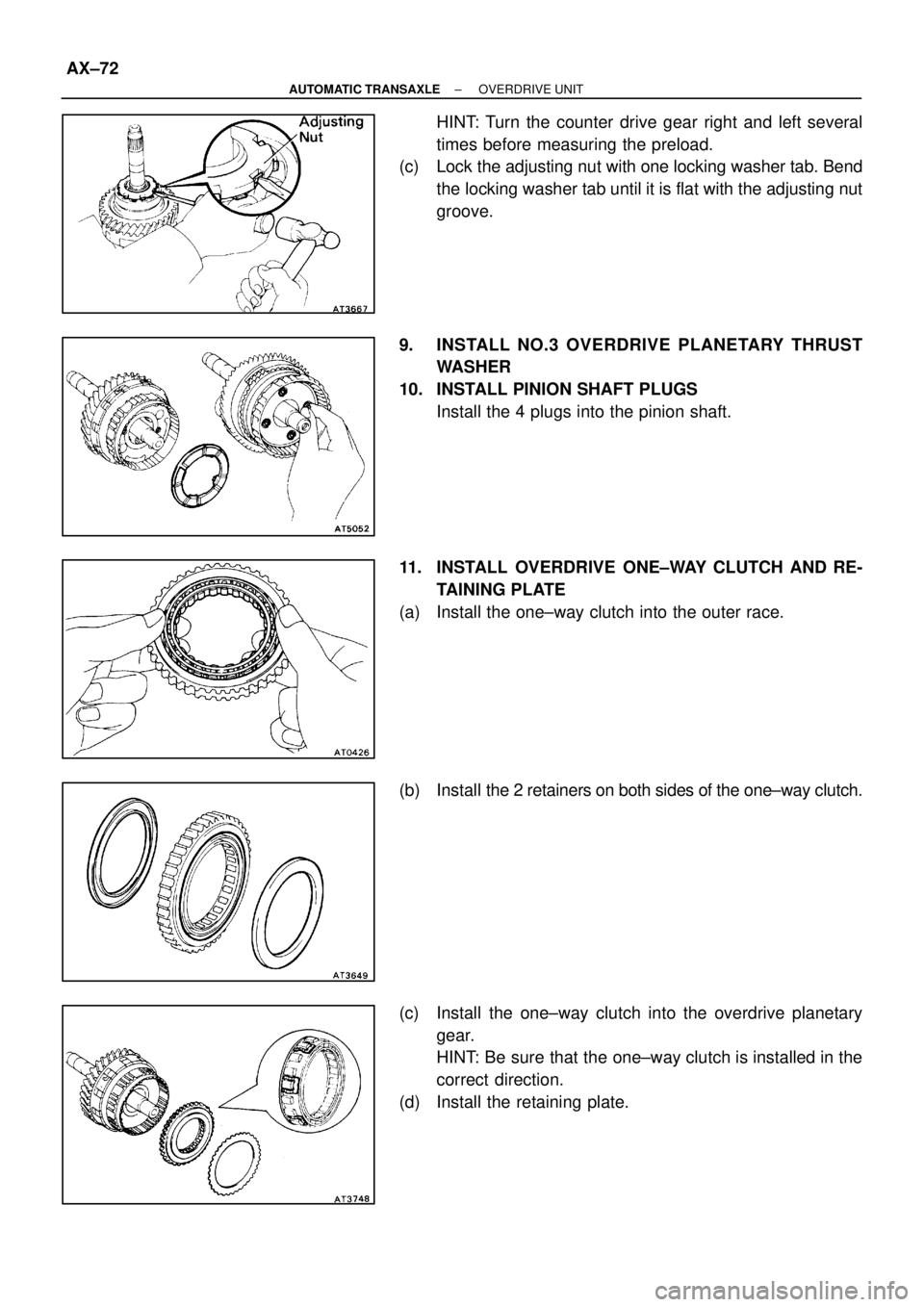

HINT: Turn the counter drive gear right and left several

times before measuring the preload.

(c) Lock the adjusting nut with one locking washer tab. Bend

the locking washer tab until it is flat with the adjusting nut

groove.

9. INSTALL NO.3 OVERDRIVE PLANETARY THRUST

WASHER

10. INSTALL PINION SHAFT PLUGS

Install the 4 plugs into the pinion shaft.

11. INSTALL OVERDRIVE ONE±WAY CLUTCH AND RE-

TAINING PLATE

(a) Install the one±way clutch into the outer race.

(b) Install the 2 retainers on both sides of the one±way clutch.

(c) Install the one±way clutch into the overdrive planetary

gear.

HINT: Be sure that the one±way clutch is installed in the

correct direction.

(d) Install the retaining plate.

Page 379 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±73

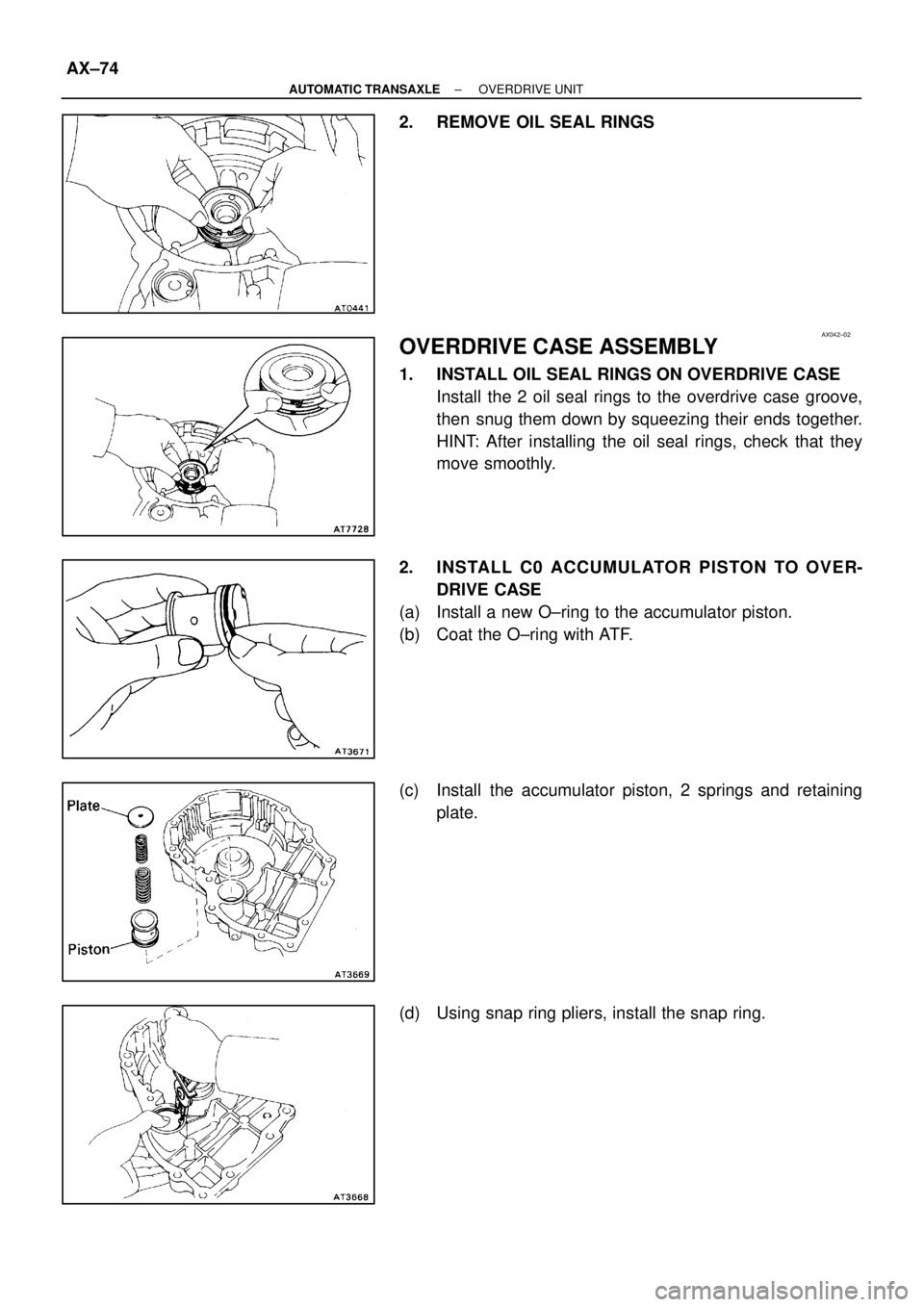

(e) Install the snap ring.

12. CHECK OPERATION OF O/D ONE±WAY CLUTCH

(a) Install the overdrive direct clutch into the one±way clutch.

(b) Hold the overdrive direct clutch and turn the intermediate

shaft. The shaft should turn freely clockwise and should

lock counterclockwise.

(c) Remove the overdrive direct clutch.

OVERDRIVE CASE DISASSEMBLY

1. REMOVE C0 ACCUMULATOR PISTON FROM OVER-

DRIVE CASE

(a) Using snap ring pliers, remove the snap ring.

(b) Remove the retaining plate and 2 springs.

(c) Remove the accumulator piston.

(d) Remove the O±ring from the piston.

AX041±02

Page 380 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±74

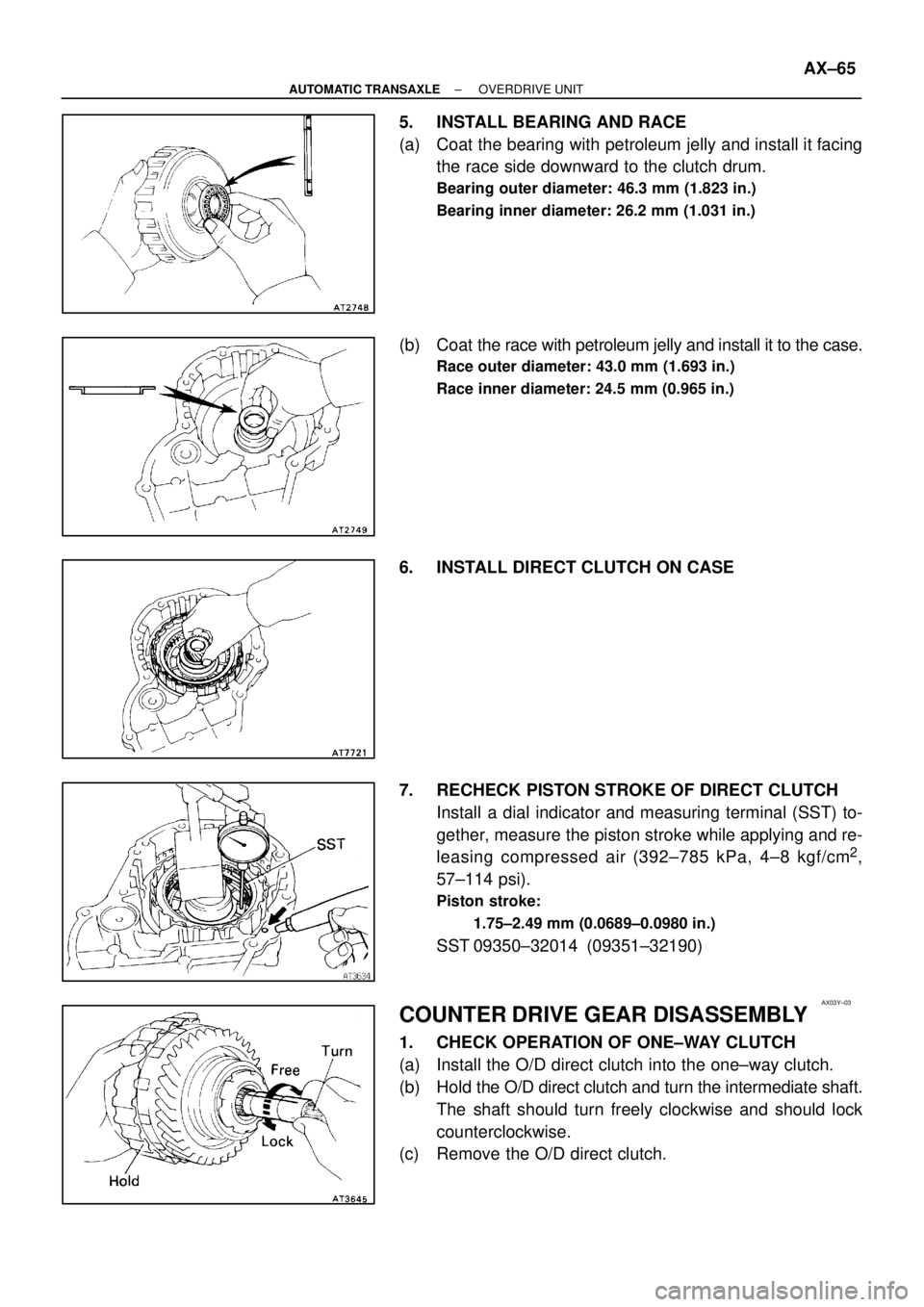

2. REMOVE OIL SEAL RINGS

OVERDRIVE CASE ASSEMBLY

1. INSTALL OIL SEAL RINGS ON OVERDRIVE CASE

Install the 2 oil seal rings to the overdrive case groove,

then snug them down by squeezing their ends together.

HINT: After installing the oil seal rings, check that they

move smoothly.

2. INSTALL C0 ACCUMULATOR PISTON TO OVER-

DRIVE CASE

(a) Install a new O±ring to the accumulator piston.

(b) Coat the O±ring with ATF.

(c) Install the accumulator piston, 2 springs and retaining

plate.

(d) Using snap ring pliers, install the snap ring.

AX042±02

Trending: oil viscosity, key battery, hood open, airbag, a541e, battery location, child lock