trouble shooting TOYOTA CAMRY 2000 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2000, Model line: CAMRY, Model: TOYOTA CAMRY 2000Pages: 4770, PDF Size: 86.41 MB

Page 72 of 4770

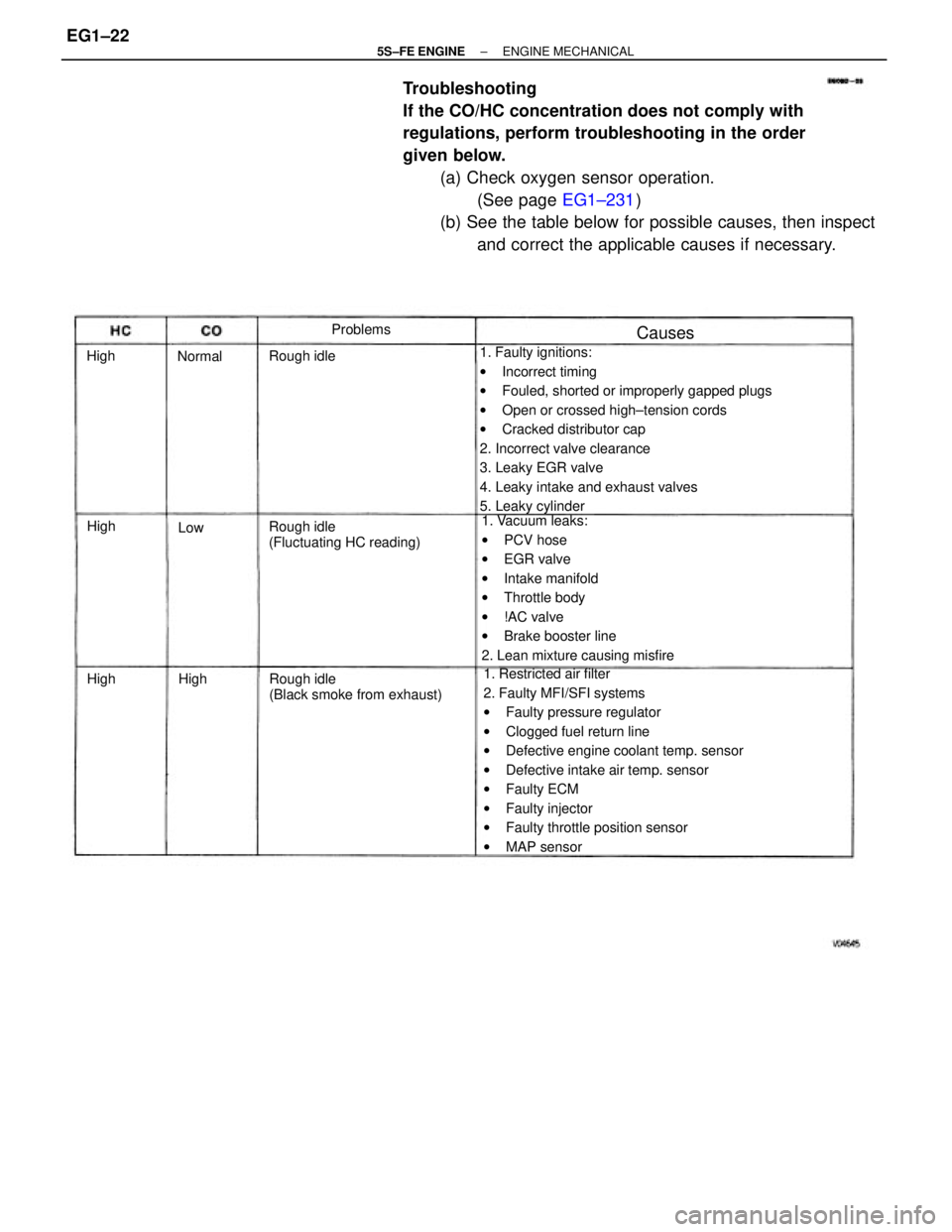

Troubleshooting

If the CO/HC concentration does not comply with

regulations, perform troubleshooting in the order

given below.

(a) Check oxygen sensor operation.

(See page EG1±231)

(b) See the table below for possible causes, then inspect

and correct the applicable causes if necessary.

1. Faulty ignitions:

wIncorrect timing

wFouled, shorted or improperly gapped plugs

wOpen or crossed high±tension cords

wCracked distributor cap

2. Incorrect valve clearance

3. Leaky EGR valve

4. Leaky intake and exhaust valves

5. Leaky cylinder

1. Restricted air filter

2. Faulty MFI/SFI systems

wFaulty pressure regulator

wClogged fuel return line

wDefective engine coolant temp. sensor

wDefective intake air temp. sensor

wFaulty ECM

wFaulty injector

wFaulty throttle position sensor

wMAP sensor 1. Vacuum leaks:

wPCV hose

wEGR valve

wIntake manifold

wThrottle body

w!AC valve

wBrake booster line

2. Lean mixture causing misfire

Rough idle

(Black smoke from exhaust) Rough idle

(Fluctuating HC reading) Rough idleProblems

Causes

Normal

High High High

HighLow

± 5S±FE ENGINEENGINE MECHANICALEG1±22

Page 223 of 4770

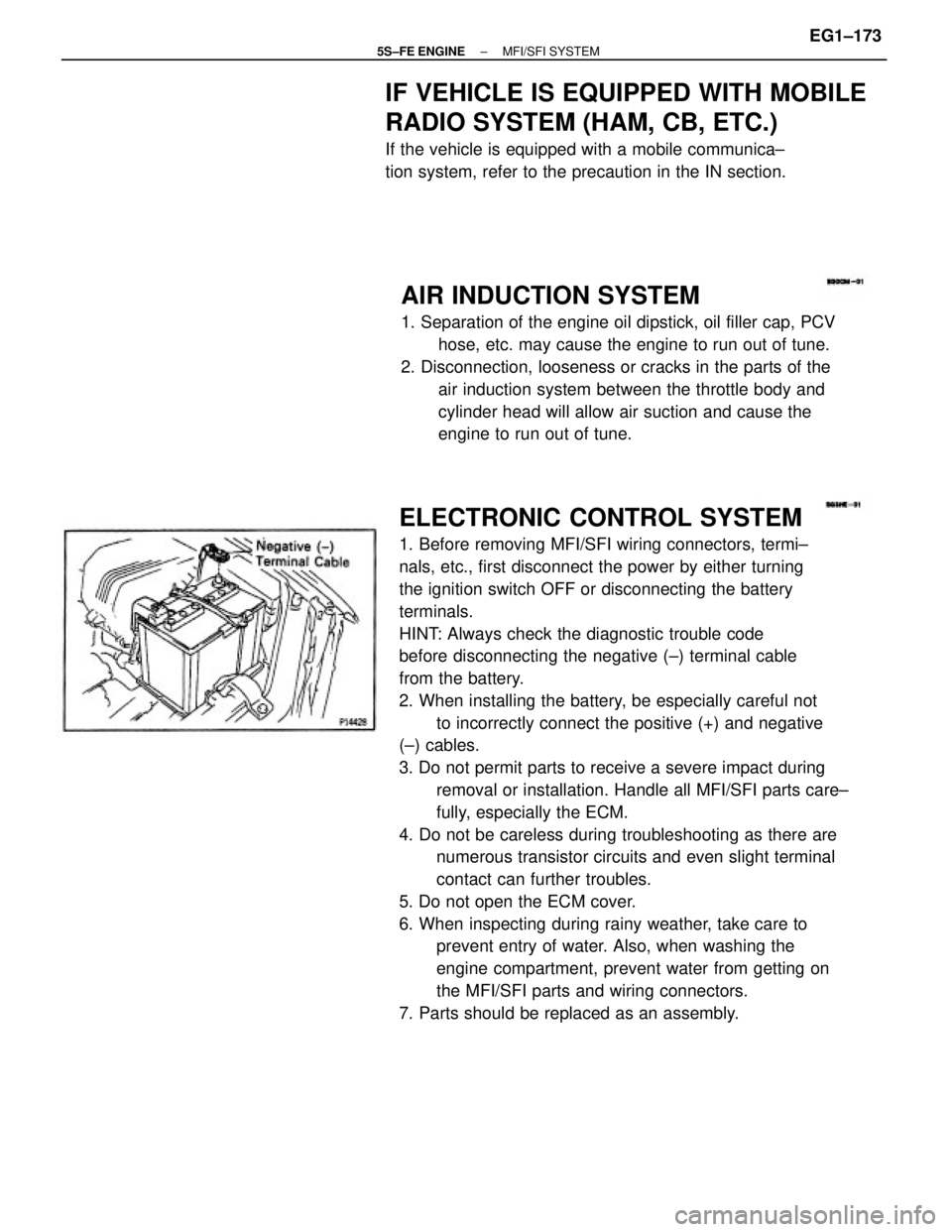

ELECTRONIC CONTROL SYSTEM

1. Before removing MFI/SFI wiring connectors, termi±

nals, etc., first disconnect the power by either turning

the ignition switch OFF or disconnecting the battery

terminals.

HINT: Always check the diagnostic trouble code

before disconnecting the negative (±) terminal cable

from the battery.

2. When installing the battery, be especially careful not

to incorrectly connect the positive (+) and negative

(±) cables.

3. Do not permit parts to receive a severe impact during

removal or installation. Handle all MFI/SFI parts care±

fully, especially the ECM.

4. Do not be careless during troubleshooting as there are

numerous transistor circuits and even slight terminal

contact can further troubles.

5. Do not open the ECM cover.

6. When inspecting during rainy weather, take care to

prevent entry of water. Also, when washing the

engine compartment, prevent water from getting on

the MFI/SFI parts and wiring connectors.

7. Parts should be replaced as an assembly.

AIR INDUCTION SYSTEM

1. Separation of the engine oil dipstick, oil filler cap, PCV

hose, etc. may cause the engine to run out of tune.

2. Disconnection, looseness or cracks in the parts of the

air induction system between the throttle body and

cylinder head will allow air suction and cause the

engine to run out of tune.

IF VEHICLE IS EQUIPPED WITH MOBILE

RADIO SYSTEM (HAM, CB, ETC.)

If the vehicle is equipped with a mobile communica±

tion system, refer to the precaution in the IN section.

± 5S±FE ENGINEMFI/SFI SYSTEMEG1±173

Page 341 of 4770

5S±FE ENGINE TROUBLESHOOTING

± 5S±FE ENGINEEG1±291

Page 342 of 4770

HOW TO PROCEED WITH TROUBLESHOOTING

The Engine Control System broadly consists of the sensors, Engine Control Module (ECM) and actuators.

The ECM receives signals from various sensors, judges the operating conditions and determines the

optimum injection duration, timing, ignition timing and idle speed.

In general, the Engine Control System is considered to be a very intricate system to troubleshoot. But, the

fact is that if you proceed to inspect the circuit one by one following the procedures directed in this manu-

al, troubleshooting of this system is not complex.

This section explains the most ideal method of troubleshooting and tells how to carry out the necessary

repairs.

1. CUSTOMER PROBLEM ANALYSIS

Using the customer problem analysis check sheet for reference, ask the customer in as much details

as possible about the problem.

2. CHECK AND CLEAR DIAGNOSTIC TROUBLE CODE (PRECHECK)

Before confirming the problem symptom, first check the diagnostic trouble code and make a note of

any malfunction code which is output, then clear the code.

HINT: Output of the malfunction code indicates that there is a malfunction in the circuit indicated.

However, it does not indicate whether the malfunction is still occurring or occurred in the past and

returned to normal. In order to determine this, the problem sym toms should be confirmed in step 4

first and the diagnostic trouble code be rechecked in step [6].

Accordingly, if troubleshooting is begun based on the malfunction code only in diagnostic trouble

code check in step [2], it could result in a misdiagnosis, leading to troubleshooting of circuits which

are normal and making it more difficult to locate the cause of the problem.

3. SETTING THE TEST MODE DIAGNOSIS, [4] PROBLEM SYMPTOM CONFIRMATION,

[5] SYMPTOM SIMULATION

In order to find out the trouble more quickly, set the diagnosis check in test mode and with higher

sensing ability of the ECM, confirm the problem symptoms. If the trouble does not reappear, use the

symptom simulation method to make sure the trouble is reproduced.

6. DIAGNOSTIC TROUBLE CODE CHECK IN TEST MODE

Check the diagnostic trouble code in test mode. If the malfunction code is output, proceed to step. If the

normal code is output, proceed to step [7].

7. BASIC INSPECTION

Carry out basic inspection such as the spark check and fuel pressure check, etc.

8. DIAGNOSTIC TROUBLE CODE CHART

If the malfunction code is displayed, proceed to inspect the circuit indicated by the chart for each

code.

9. MATRIX CHART OF PROBLEM SYMPTOMS

If the normal code is displayed in the diagnosis in test mode, perform troubleshooting according to

the inspection order in the Matrix Chart of Problem Symptoms.

10. PARTS INSPECTION

When the Matrix Chart of Problem Symptoms instructs to check the parts, proceed to parts inspection

section included in this manual.

11. CIRCUIT INSPECTION

Determine if the malfunction is the sensor, actuator, wire harness, connector or the ECM.

± 5S±FE ENGINEHOW TO PROCEED WITH TROUBLESHOOTINGEG1±292

Page 343 of 4770

CHECK FOR MOMENTARY INTERRUPTION

By performing the check for momentary interruption, the place where momentary interruptions or

momentary shorts are occurring due to poor contacts can be isolated.

ADJUSTMENT, REPAIR

After the cause of the problem is located, perform adjustment or repairs by following the inspection

and replacement procedures in this manual.

CONFIRMATION TEST

After completing adjustment or repairs, confirm not only that the malfunction is eliminated, but also

conduct a test drive, etc., to make sure the entire Engine Control System is operating normally.

± 5S±FE ENGINEHOW TO PROCEED WITH TROUBLESHOOTINGEG1±293

Page 344 of 4770

Titles inside are titles of pages

in this manual, with the page number

indicated in the bottom portion.

See the indicated pages for detailed

explanations

: Diagnostic steps per±

mitting the use of the

TOYOTA hand±held

tester or TOYOTA

break±out±box. Setting the Test Mode Diagnosis

P. EG1±298 Check and clear Diagnostic Trouble Code (Pre-

check.)

Check for Momentary Interruption Malfunction does not occur.

Matrix Chart of Problem SymptomsProblem Symptom ConfirmationVehicle Brought to Workshop

Diagnostic Trouble Code Chart Diagnostic Trouble Code Check Customer Problem Analysis

Symptom Simulation

Identification of ProblemCircuit Inspection Malfunction

occurs:

Adjustment, Repair

Confirmation Test Parts InspectionMalfunction code

Basic InspectionP. EG1±297, 299

P. EG1±309 p.

EG1±310P. EG1±298

Normal codeP. EG1±295

P. EG1±327P. EG1±300

P. EG1±336P. IN±24

EndStep

± 5S±FE ENGINEHOW TO PROCEED WITH TROUBLESHOOTINGEG1±294

Page 347 of 4770

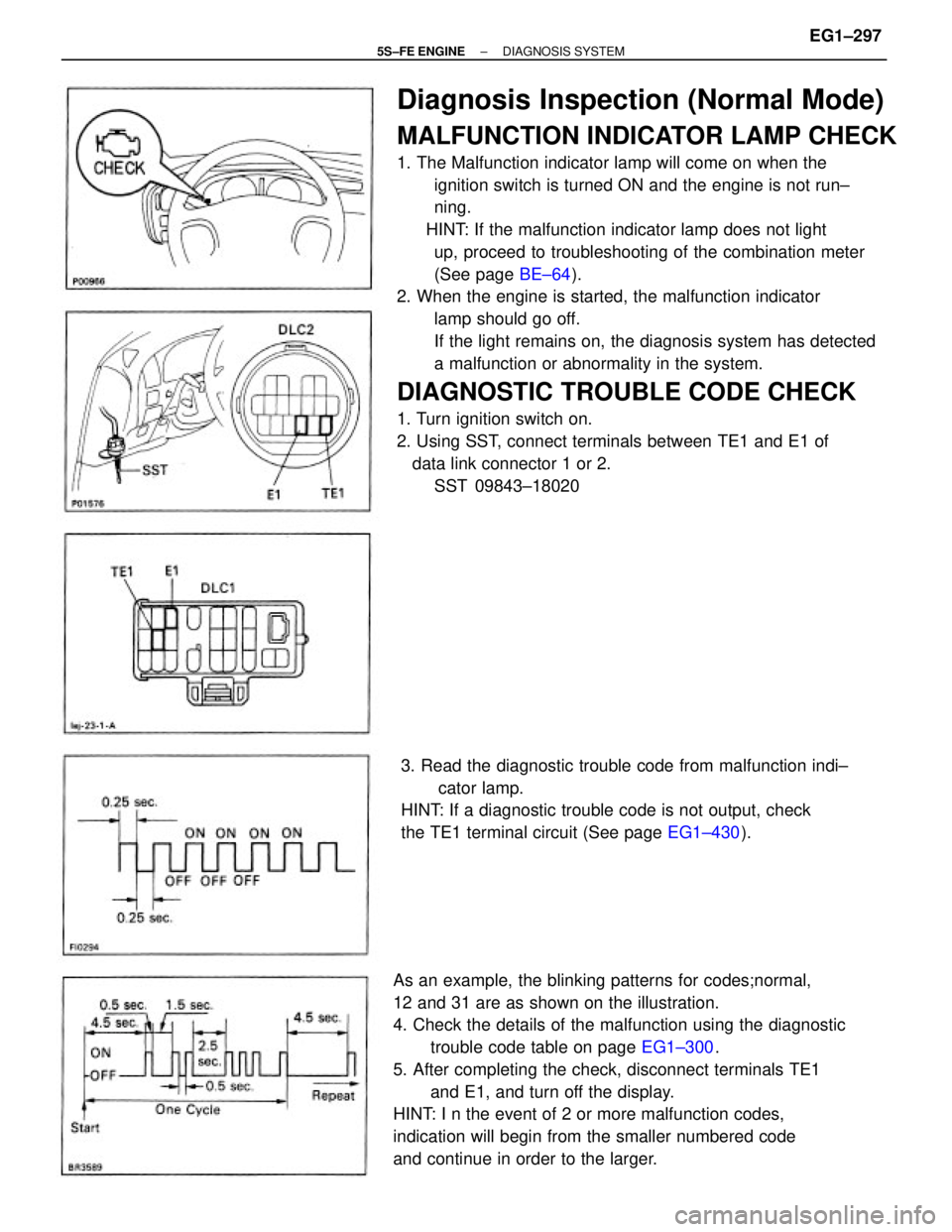

Diagnosis Inspection (Normal Mode)

MALFUNCTION INDICATOR LAMP CHECK

1. The Malfunction indicator lamp will come on when the

ignition switch is turned ON and the engine is not run±

ning.

HINT: If the malfunction indicator lamp does not light

up, proceed to troubleshooting of the combination meter

(See page BE±64).

2. When the engine is started, the malfunction indicator

lamp should go off.

If the light remains on, the diagnosis system has detected

a malfunction or abnormality in the system.

DIAGNOSTIC TROUBLE CODE CHECK

1. Turn ignition switch on.

2. Using SST, connect terminals between TE1 and E1 of

data link connector 1 or 2.

SST 09843±18020

As an example, the blinking patterns for codes;normal,

12 and 31 are as shown on the illustration.

4. Check the details of the malfunction using the diagnostic

trouble code table on page EG1±300.

5. After completing the check, disconnect terminals TE1

and E1, and turn off the display.

HINT: I n the event of 2 or more malfunction codes,

indication will begin from the smaller numbered code

and continue in order to the larger.3. Read the diagnostic trouble code from malfunction indi±

cator lamp.

HINT: If a diagnostic trouble code is not output, check

the TE1 terminal circuit (See page EG1±430).

± 5S±FE ENGINEDIAGNOSIS SYSTEMEG1±297

Page 348 of 4770

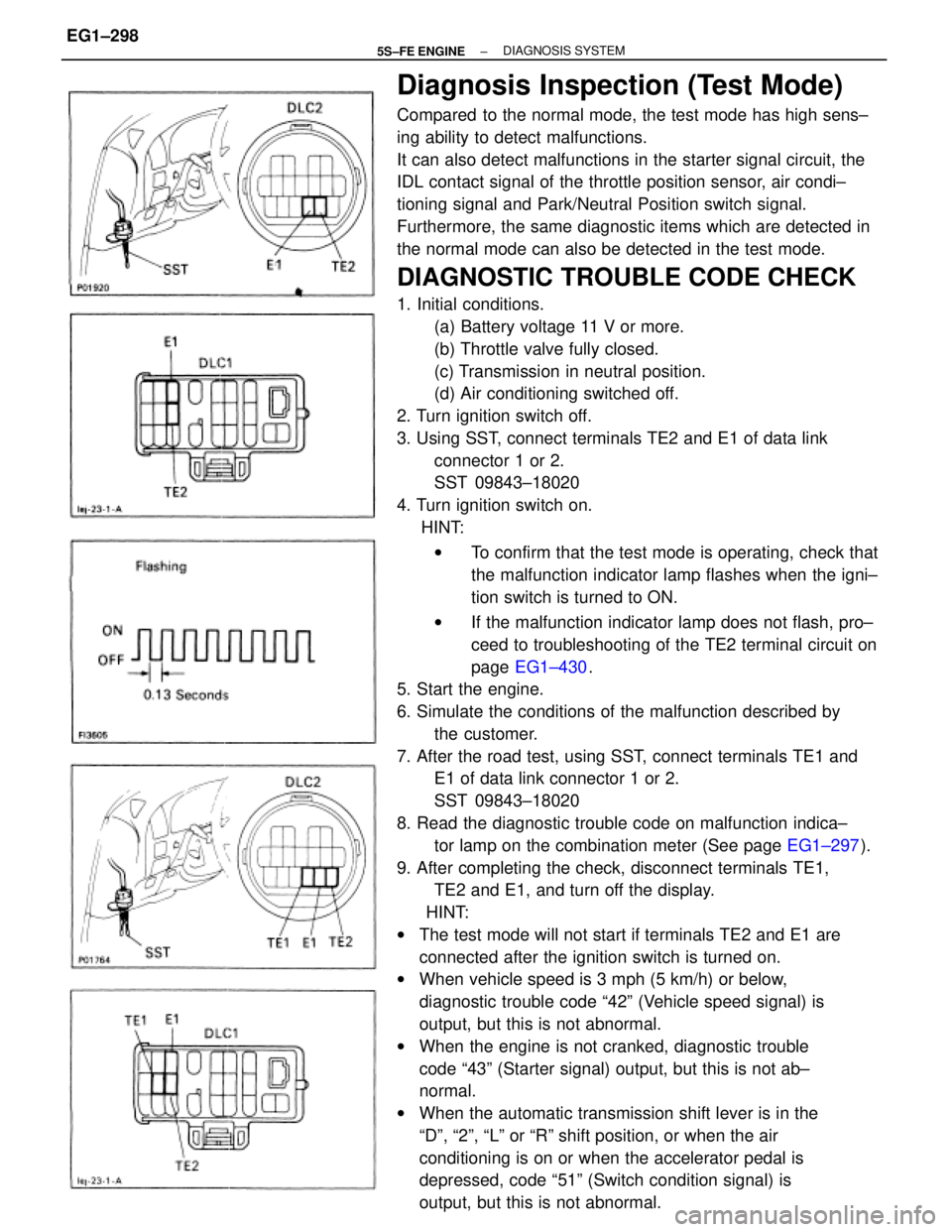

Diagnosis Inspection (Test Mode)

Compared to the normal mode, the test mode has high sens±

ing ability to detect malfunctions.

It can also detect malfunctions in the starter signal circuit, the

IDL contact signal of the throttle position sensor, air condi±

tioning signal and Park/Neutral Position switch signal.

Furthermore, the same diagnostic items which are detected in

the normal mode can also be detected in the test mode.

DIAGNOSTIC TROUBLE CODE CHECK

1. Initial conditions.

(a) Battery voltage 11 V or more.

(b) Throttle valve fully closed.

(c) Transmission in neutral position.

(d) Air conditioning switched off.

2. Turn ignition switch off.

3. Using SST, connect terminals TE2 and E1 of data link

connector 1 or 2.

SST 09843±18020

4. Turn ignition switch on.

HINT:

wTo confirm that the test mode is operating, check that

the malfunction indicator lamp flashes when the igni±

tion switch is turned to ON.

wIf the malfunction indicator lamp does not flash, pro±

ceed to troubleshooting of the TE2 terminal circuit on

page EG1±430.

5. Start the engine.

6. Simulate the conditions of the malfunction described by

the customer.

7. After the road test, using SST, connect terminals TE1 and

E1 of data link connector 1 or 2.

SST 09843±18020

8. Read the diagnostic trouble code on malfunction indica±

tor lamp on the combination meter (See page EG1±297).

9. After completing the check, disconnect terminals TE1,

TE2 and E1, and turn off the display.

HINT:

wThe test mode will not start if terminals TE2 and E1 are

connected after the ignition switch is turned on.

wWhen vehicle speed is 3 mph (5 km/h) or below,

diagnostic trouble code ª42º (Vehicle speed signal) is

output, but this is not abnormal.

wWhen the engine is not cranked, diagnostic trouble

code ª43º (Starter signal) output, but this is not ab±

normal.

wWhen the automatic transmission shift lever is in the

ªDº, ª2º, ªLº or ªRº shift position, or when the air

conditioning is on or when the accelerator pedal is

depressed, code ª51º (Switch condition signal) is

output, but this is not abnormal.

± 5S±FE ENGINE DIAGNOSIS SYSTEMEG1±298

Page 360 of 4770

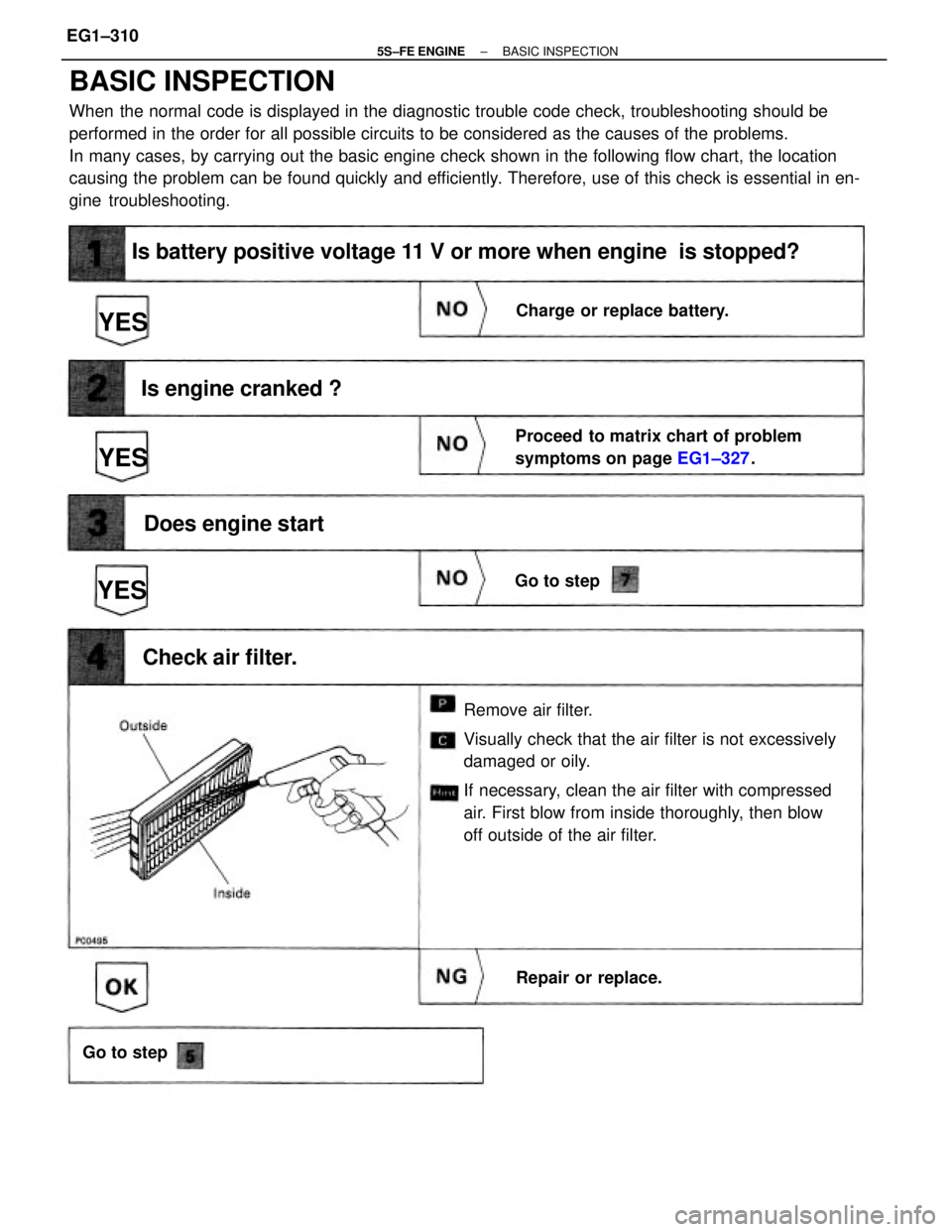

BASIC INSPECTION

When the normal code is displayed in the diagnostic trouble code check, troubleshooting should be

performed in the order for all possible circuits to be considered as the causes of the problems.

In many cases, by carrying out the basic engine check shown in the following flow chart, the location

causing the problem can be found quickly and efficiently. Therefore, use of this check is essential in en-

gine troubleshooting.

Remove air filter.

Visually check that the air filter is not excessively

damaged or oily.

If necessary, clean the air filter with compressed

air. First blow from inside thoroughly, then blow

off outside of the air filter.

Is battery positive voltage 11 V or more when engine is stopped?

Proceed to matrix chart of problem

symptoms on page EG1±327.

Is engine cranked ?

Does engine start

Charge or replace battery.

Check air filter.

Repair or replace. Go to step

Go to step

YESYES

YES

± 5S±FE ENGINEBASIC INSPECTIONEG1±310

Page 377 of 4770

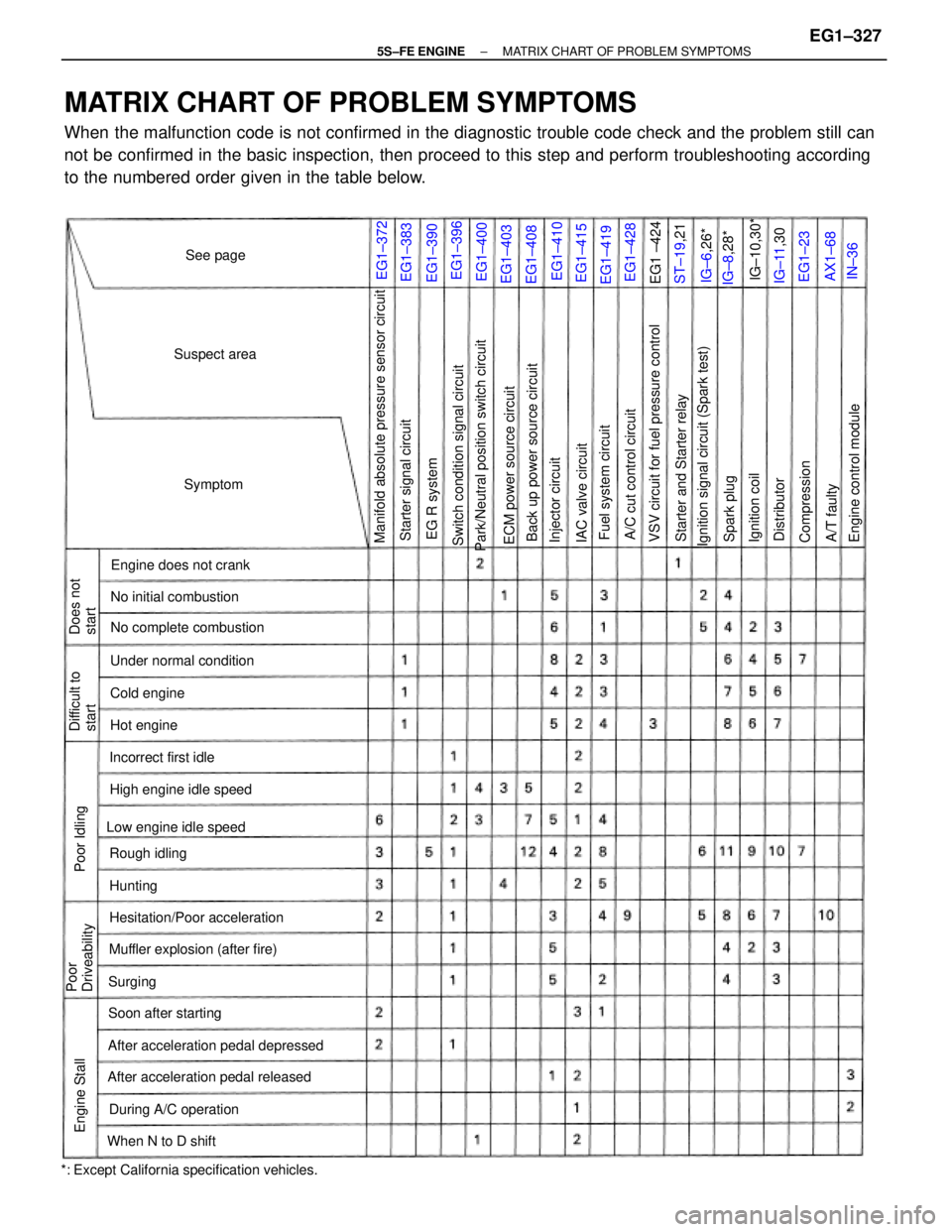

MATRIX CHART OF PROBLEM SYMPTOMS

When the malfunction code is not confirmed in the diagnostic trouble code check and the problem still can

not be confirmed in the basic inspection, then proceed to this step and perform troubleshooting according

to the numbered order given in the table below.

*: Except California specification vehicles.

Park/Neutral position switch circuitManifold absolute pressure sensor circuit

VSV circuit for fuel pressure control

Ignition signal circuit (Spark test)

After acceleration pedal depressed

After acceleration pedal released

Switch condition signal circuit

Muffler explosion (after fire)No initial combustion

Back up power source circuit

Hesitation/Poor accelerationNo complete combustion

ECM power source circuit

Starter and Starter relay

Engine control module

High engine idle speed

Low engine idle speedUnder normal condition

During A/C operationEngine does not crank

A/C cut control circuit Starter signal circuit

Soon after starting

Fuel system circuit

When N to D shiftIncorrect first idle

Poor

Driveability

IAC valve circuit Difficult to

start

Injector circuit

Rough idling

Does not

start

Compression

Suspect area

Cold engine

Ignition coil Engine Stall

EG R system

Hot engine

Poor Idling

Spark plug

A/T faultylG±10,30*

IG±11,30 Distributor

Symptom

ST±19,21

See page

IG±8,28* IG±6,26*

Hunting

Surging

EG1±400

EG1±410 EG1±390

EG1±403

EG1±408

EG1±415

EG1±419EG1±383EG1±372

EG1±428EG1±396

EG1 ±424

AX1±68 EG1±23

IN±36

± 5S±FE ENGINEMATRIX CHART OF PROBLEM SYMPTOMSEG1±327