trouble shooting TOYOTA CAMRY 2000 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2000, Model line: CAMRY, Model: TOYOTA CAMRY 2000Pages: 4770, PDF Size: 86.41 MB

Page 432 of 4770

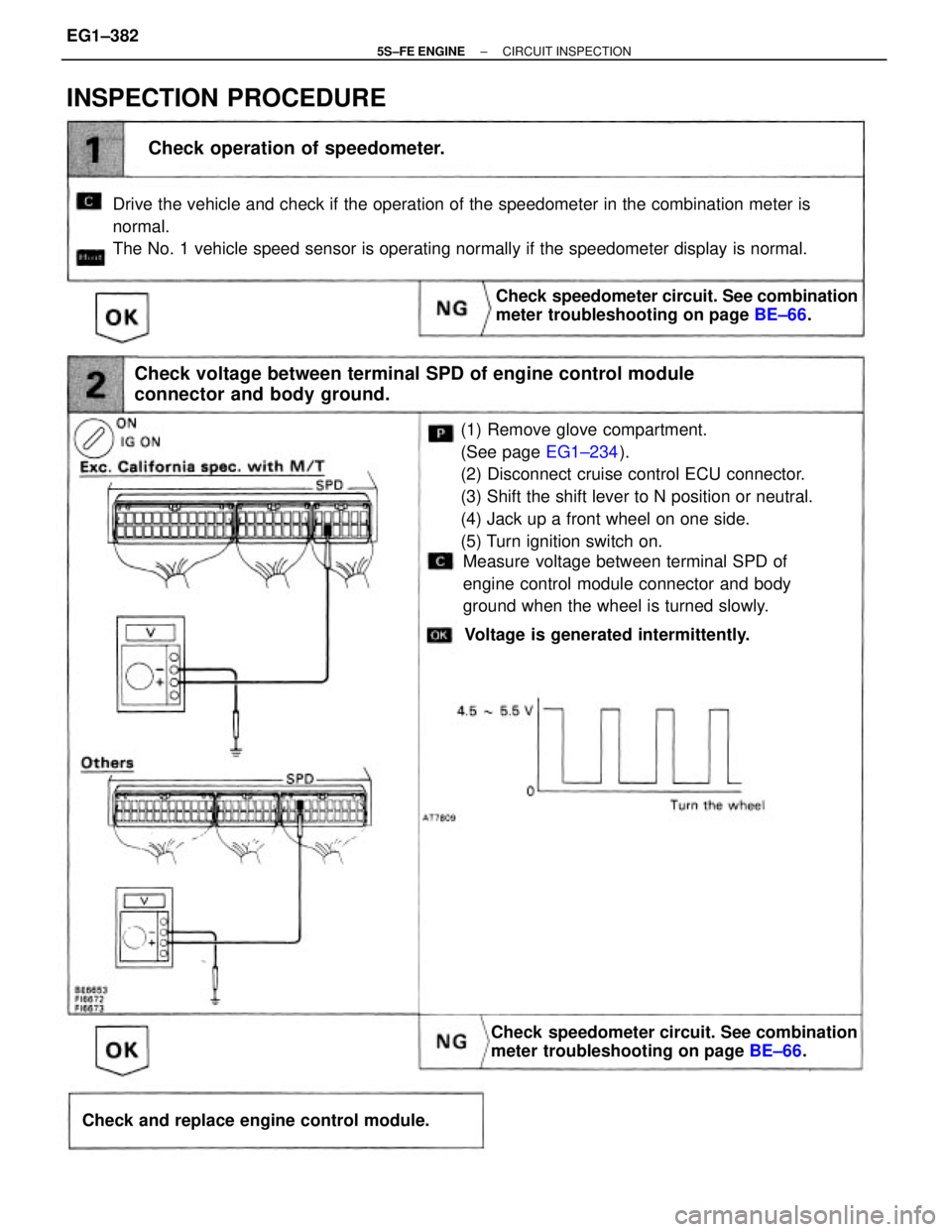

(1) Remove glove compartment.

(See page EG1±234).

(2) Disconnect cruise control ECU connector.

(3) Shift the shift lever to N position or neutral.

(4) Jack up a front wheel on one side.

(5) Turn ignition switch on. Drive the vehicle and check if the operation of the speedometer in the combination meter is

normal.

The No. 1 vehicle speed sensor is operating normally if the speedometer display is normal.

Check voltage between terminal SPD of engine control module

connector and body ground.

Check speedometer circuit. See combination

meter troubleshooting on page BE±66.

Check speedometer circuit. See combination

meter troubleshooting on page BE±66.

Check operation of speedometer.

Check and replace engine control module.

INSPECTION PROCEDURE

Measure voltage between terminal SPD of

engine control module connector and body

ground when the wheel is turned slowly.

Voltage is generated intermittently.

± 5S±FE ENGINECIRCUIT INSPECTIONEG1±382

Page 450 of 4770

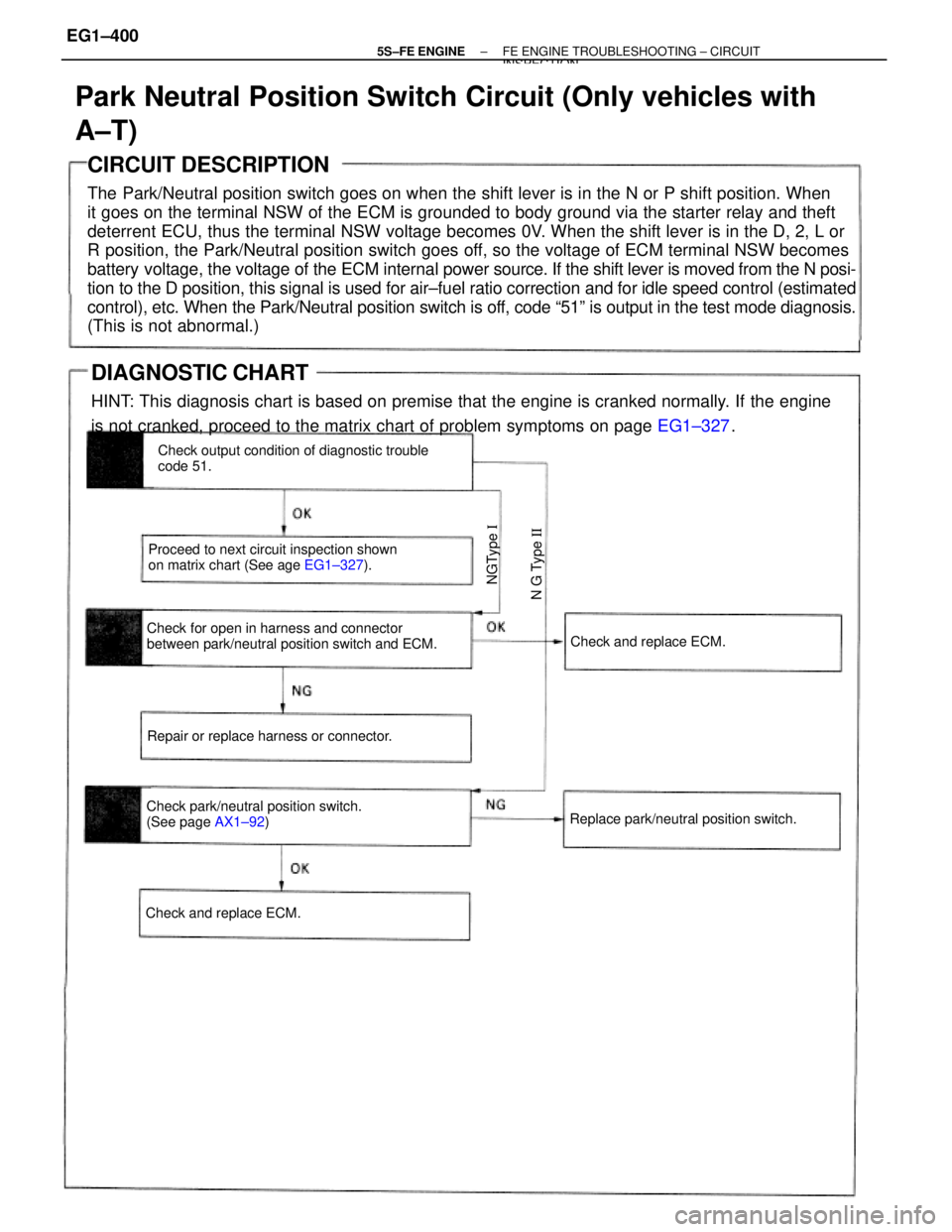

CIRCUIT DESCRIPTION

The Park/Neutral position switch goes on when the shift lever is in the N or P shift position. When

it goes on the terminal NSW of the ECM is grounded to body ground via the starter relay and theft

deterrent ECU, thus the terminal NSW voltage becomes 0V. When the shift lever is in the D, 2, L or

R position, the Park/Neutral position switch goes off, so the voltage of ECM terminal NSW becomes

battery voltage, the voltage of the ECM internal power source. If the shift lever is moved from the N posi-

tion to the D position, this signal is used for air±fuel ratio correction and for idle speed control (estimated

control), etc. When the Park/Neutral position switch is off, code ª51º is output in the test mode diagnosis.

(This is not abnormal.)

Park Neutral Position Switch Circuit (Only vehicles with

A±T)

Check for open in harness and connector

between park/neutral position switch and ECM.Check output condition of diagnostic trouble

code 51.

Proceed to next circuit inspection shown

on matrix chart (See age EG1±327).

Check park/neutral position switch.

(See page AX1±92) Repair or replace harness or connector.

Replace park/neutral position switch.Check and replace ECM.

Check and replace ECM.

N G Type II NGType I

DIAGNOSTIC CHART

HINT: This diagnosis chart is based on premise that the engine is cranked normally. If the engine

is not cranked, proceed to the matrix chart of problem symptoms on page EG1±327.

± 5S±FE ENGINEFE ENGINE TROUBLESHOOTING ± CIRCUITINSPECTION

EG1±400

Page 1107 of 4770

If you’ ll be doing some of your own maintenance and repair work

on your vehicle, a Toyota service manual will be one of your most

valuable tools. Toyota offers three types of manuals to assist

do- it- yourselfers. To order any of the following manuals, call

Toyota’s service publications department at (800) 622- 2033.

Vehicle Repair Manual

This is the same manual used by professional technicians in Toyota

dealerships throughout the United States. It is fully illustrated and

includes maintenance and repair procedures for all vehicle mechan-

ical systems. It also includes instructions for vehicle tune- ups.

Electrical Systems Manual

This manual provides detailed wiring diagrams for each electri-

cal system in your vehicle, along with troubleshooting tips and

repair procedures.

Automatic Transmission/Transaxle Repair Manual

This manual includes complete procedures for overhauling the

automatic transmission/transaxle of your vehicle.For information on basic do- it- yourself maintenance items,

see the “General Maintenance and Care” and “Do- It-

Yourself Maintenance” sections of your

Owner’s Manual.

Toyota Service Manuals

TOYOTA MAINTENANCE & REPAIR SUPPORT15

Page 1151 of 4770

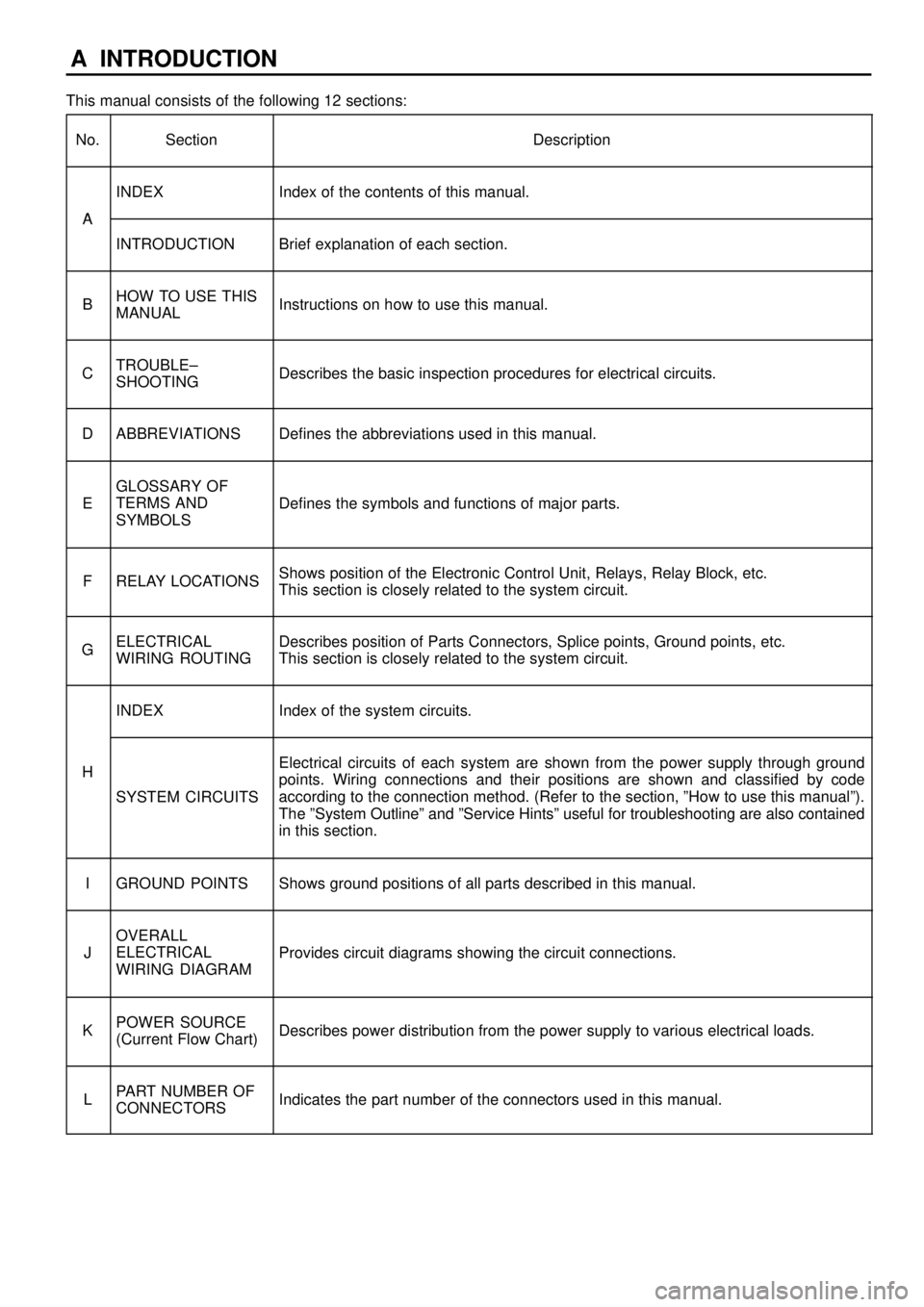

A INTRODUCTION

This manual consists of the following 12 sections:

No.

SectionDescription

A

INDEXIndex of the contents of this manual.

A

INTRODUCTIONBrief explanation of each section.

BHOW TO USE THIS

MANUALInstructions on how to use this manual.

CTROUBLE±

SHOOTINGDescribes the basic inspection procedures for electrical circuits.

DABBREVIATIONSDefines the abbreviations used in this manual.

E

GLOSSARY OF

TERMS AND

SYMBOLS

Defines the symbols and functions of major parts.

FRELAY LOCATIONSShows position of the Electronic Control Unit, Relays, Relay Block, etc.

This section is closely related to the system circuit.

GELECTRICAL

WIRING ROUTINGDescribes position of Parts Connectors, Splice points, Ground points, etc.

This section is closely related to the system circuit.

INDEXIndex of the system circuits.

H

SYSTEM CIRCUITS

Electrical circuits of each system are shown from the power supply through ground

points. Wiring connections and their positions are shown and classified by code

according to the connection method. (Refer to the section, ºHow to use this manualº).

The ºSystem Outlineº and ºService Hintsº useful for troubleshooting are also contained

in this section.

IGROUND POINTSShows ground positions of all parts described in this manual.

J

OVERALL

ELECTRICAL

WIRING DIAGRAM

Provides circuit diagrams showing the circuit connections.

KPOWER SOURCE

(Current Flow Chart)Describes power distribution from the power supply to various electrical loads.

LPART NUMBER OF

CONNECTORSIndicates the part number of the connectors used in this manual.

Page 1152 of 4770

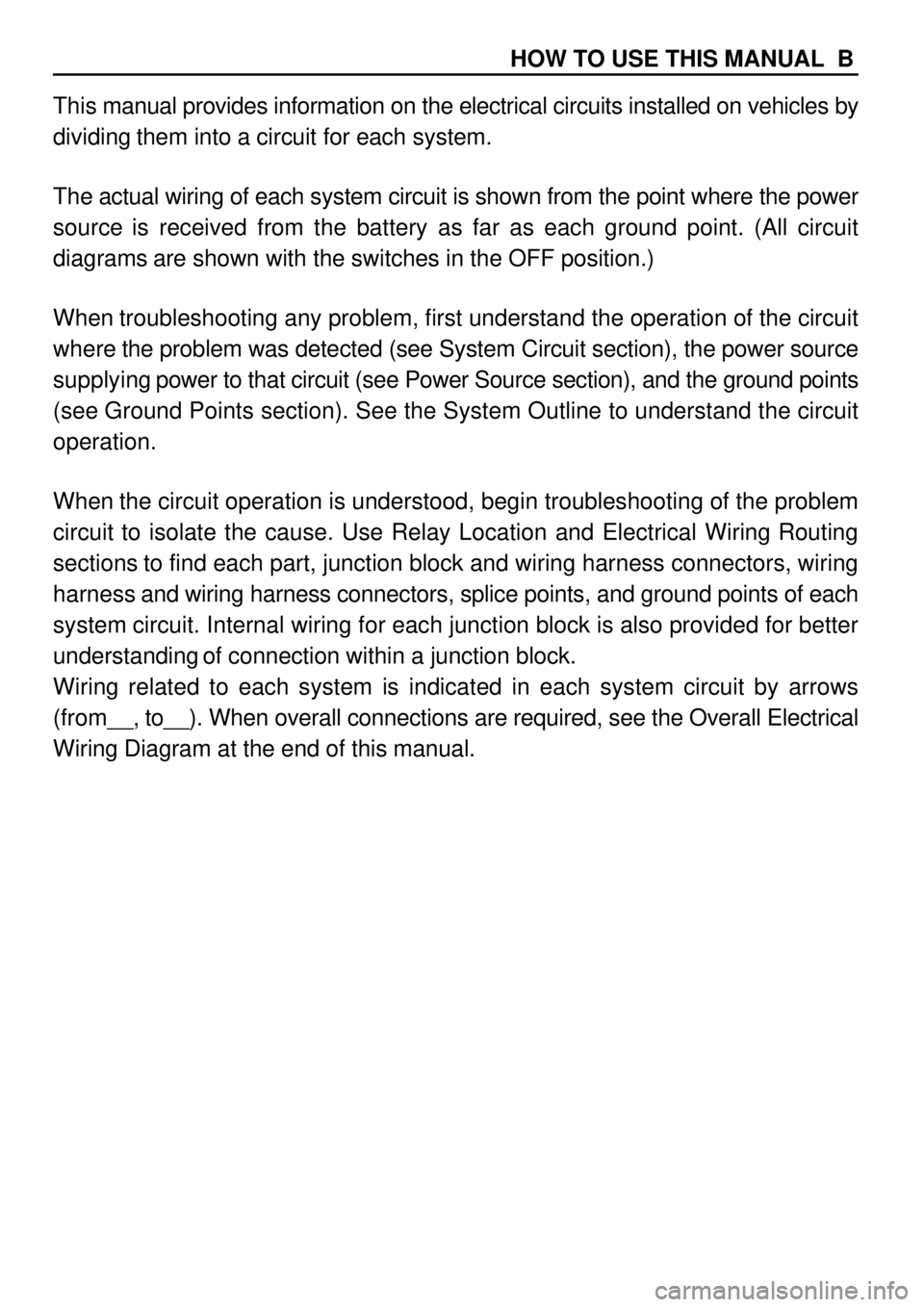

HOW TO USE THIS MANUAL B

This manual provides information on the electrical circuits installed on vehicles by

dividing them into a circuit for each system.

The actual wiring of each system circuit is shown from the point where the power

source is received from the battery as far as each ground point. (All circuit

diagrams are shown with the switches in the OFF position.)

When troubleshooting any problem, first understand the operation of the circuit

where the problem was detected (see System Circuit section), the power source

supplying power to that circuit (see Power Source section), and the ground points

(see Ground Points section). See the System Outline to understand the circuit

operation.

When the circuit operation is understood, begin troubleshooting of the problem

circuit to isolate the cause. Use Relay Location and Electrical Wiring Routing

sections to find each part, junction block and wiring harness connectors, wiring

harness and wiring harness connectors, splice points, and ground points of each

system circuit. Internal wiring for each junction block is also provided for better

understanding of connection within a junction block.

Wiring related to each system is indicated in each system circuit by arrows

(from__, to__). When overall connections are required, see the Overall Electrical

Wiring Diagram at the end of this manual.

Page 1156 of 4770

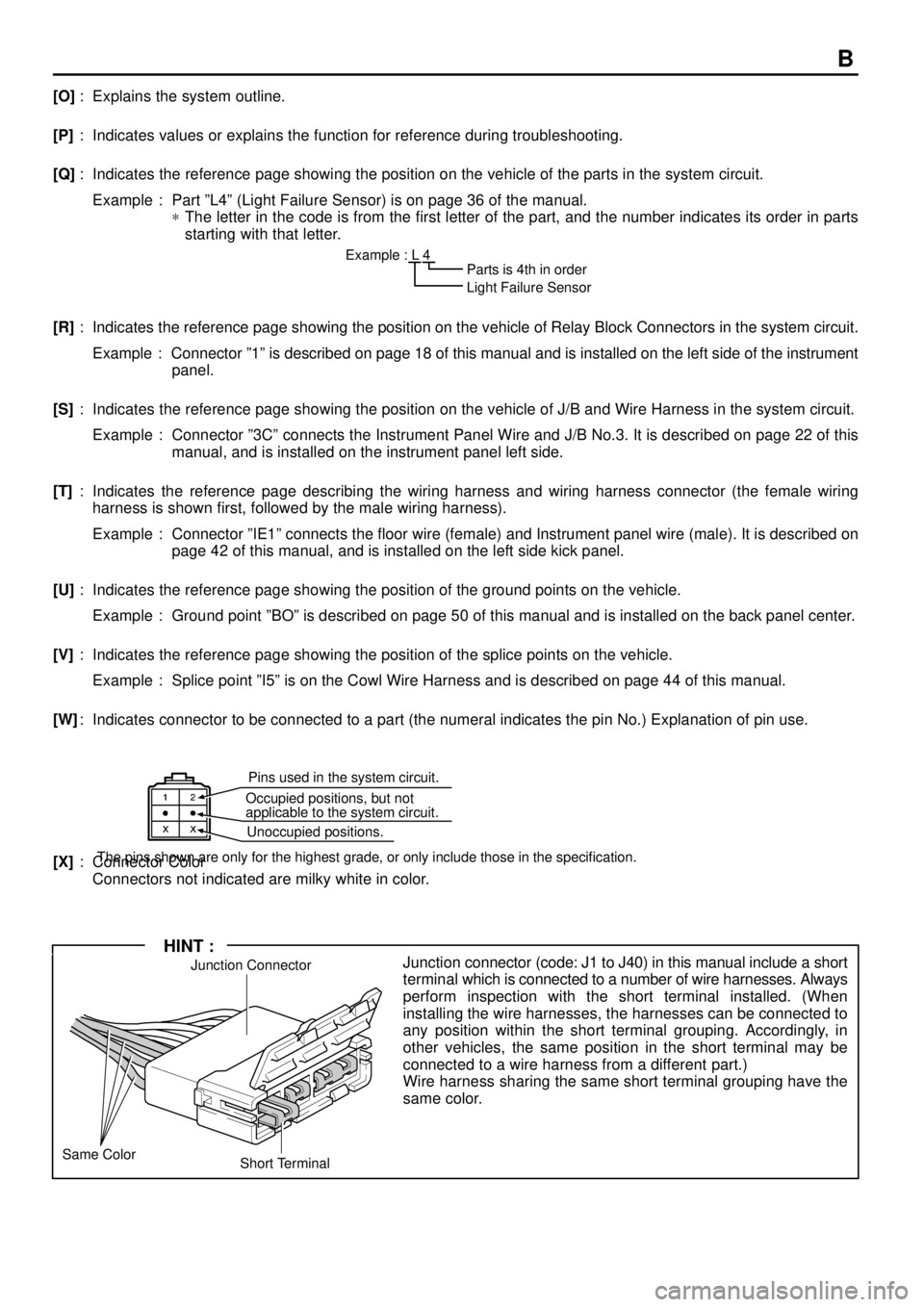

Pins used in the system circuit.

Occupied positions, but not

applicable to the system circuit.

Unoccupied positions.

The pins shown are only for the highest grade, or only include those in the specification.

Junction Connector

Short Terminal Same ColorJunction connector (code: J1 to J40) in this manual include a short

terminal which is connected to a number of wire harnesses. Always

perform inspection with the short terminal installed. (When

installing the wire harnesses, the harnesses can be connected to

any position within the short terminal grouping. Accordingly, in

other vehicles, the same position in the short terminal may be

connected to a wire harness from a different part.)

Wire harness sharing the same short terminal grouping have the

same color.

HINT :

B

[O]: Explains the system outline.

[P]: Indicates values or explains the function for reference during troubleshooting.

[Q]: Indicates the reference page showing the position on the vehicle of the parts in the system circuit.

Example : Part ºL4º (Light Failure Sensor) is on page 36 of the manual.

*The letter in the code is from the first letter of the part, and the number indicates its order in parts

starting with that letter.

Example : L 4

� �Parts is 4th in order

Light Failure Sensor

[R]: Indicates the reference page showing the position on the vehicle of Relay Block Connectors in the system circuit.

Example : Connector º1º is described on page 18 of this manual and is installed on the left side of the instrument

panel.

[S]: Indicates the reference page showing the position on the vehicle of J/B and Wire Harness in the system circuit.

Example : Connector º3Cº connects the Instrument Panel Wire and J/B No.3. It is described on page 22 of this

manual, and is installed on the instrument panel left side.

[T]: Indicates the reference page describing the wiring harness and wiring harness connector (the female wiring

harness is shown first, followed by the male wiring harness).

Example : Connector ºIE1º connects the floor wire (female) and Instrument panel wire (male). It is described on

page 42 of this manual, and is installed on the left side kick panel.

[U]: Indicates the reference page showing the position of the ground points on the vehicle.

Example : Ground point ºBOº is described on page 50 of this manual and is installed on the back panel center.

[V]: Indicates the reference page showing the position of the splice points on the vehicle.

Example : Splice point ºI5º is on the Cowl Wire Harness and is described on page 44 of this manual.

[W]: Indicates connector to be connected to a part (the numeral indicates the pin No.) Explanation of pin use.

[X]: Connector Color

Connectors not indicated are milky white in color.

Page 1157 of 4770

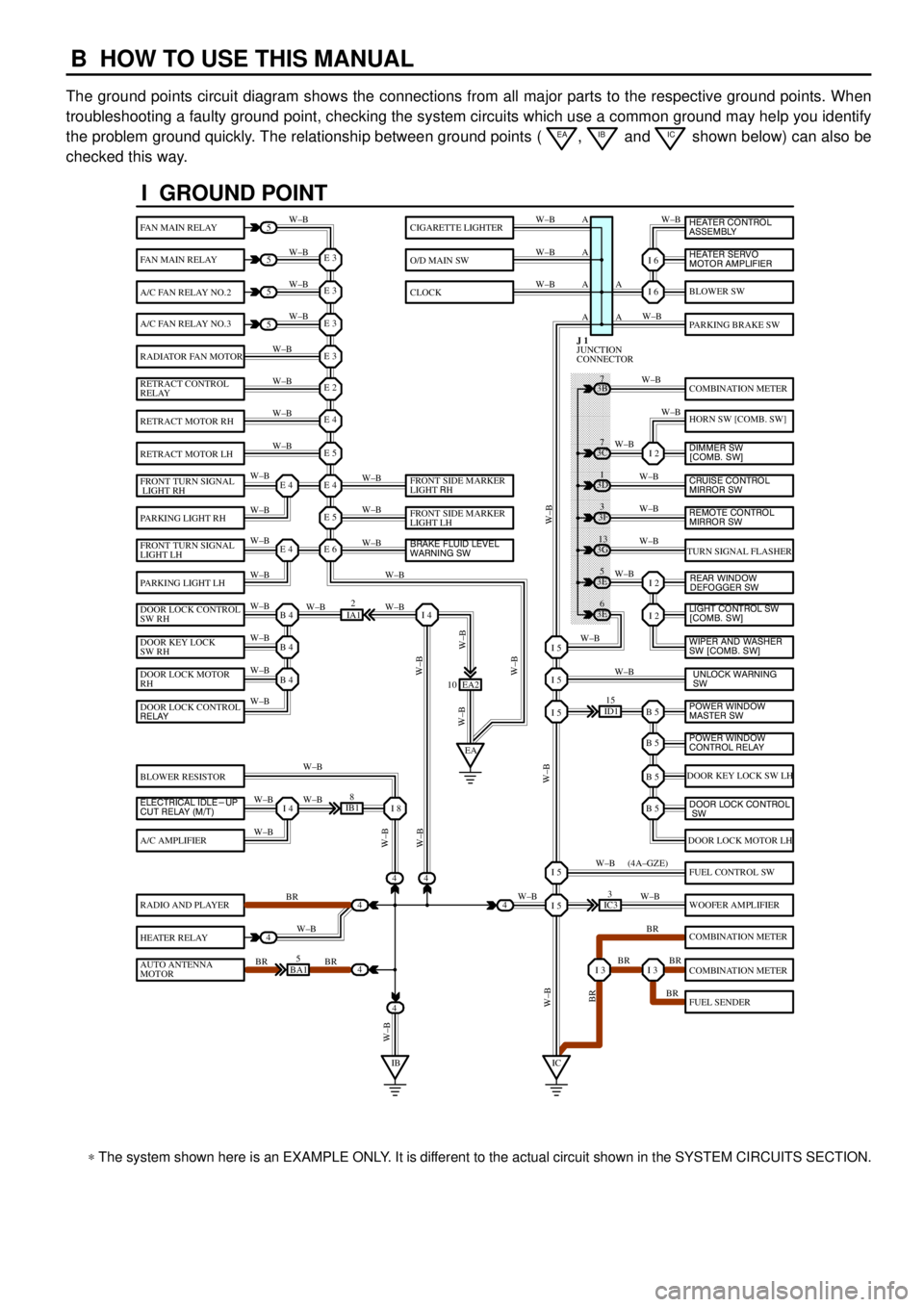

B HOW TO USE THIS MANUAL

The ground points circuit diagram shows the connections from all major parts to the respective ground points. When

troubleshooting a faulty ground point, checking the system circuits which use a common ground may help you identify

the problem ground quickly. The relationship between ground points (

EA, IB and IC shown below) can also be

checked this way.

���� ���� ���� ���� ���� ���� ���� ���� ���� ���� ���� ���� ���� ���� ���� ���� ���� ���� ����

I GROUND POINT

FAN MAIN RELAY

FAN MAIN RELAY

A/C FAN RELAY NO.2

A/C FAN RELAY NO.3

RADIATOR FAN MOTOR

RETRACT CONTROL

RELAY

RETRACT MOTOR RH

RETRACT MOTOR LH

FRONT TURN SIGNAL

LIGHT RH

PARKING LIGHT RH

FRONT TURN SIGNAL

LIGHT LH

PARKING LIGHT LH

DOOR LOCK CONTROL

SW RH

DOOR KEY LOCK

SW RH

DOOR LOCK MOTOR

RH

BLOWER RESISTOR

A/C AMPLIFIER

RADIO AND PLAYER

HEATER RELAY

AUTO ANTENNA

MOTOR

BLOWER SW

PARKING BRAKE SW

COMBINATION METER

HORN SW [COMB. SW]

TURN SIGNAL FLASHER

DOOR KEY LOCK SW LH

DOOR LOCK MOTOR LH

FUEL CONTROL SW

WOOFER AMPLIFIER

COMBINATION METER

COMBINATION METER

FUEL SENDER

CIGARETTE LIGHTER

O/D MAIN SW

CLOCK

5

5

5

5

4

4

4

4

4BA15

IB18

EA2 10

3E5

3E

6 3G

13 3F

3 3D

1 3B

7

ID115

IC33

IA12

E 3

A

A AW±B

W±BW±B W±B

W±B W±B

W±B

W±B

W±B

W±B

W±B

W±B

W±B

W±B

W±B W±BW±B W±B W±B W±B

W±B W±B

W±BW±B

W±B

W±B

W±B W±B

W±B

BR

W±B

BR BRW±BW±B

W±B

W±B

W±B

W±B

W±B

W±B

W±B

W±B

W±B W±B

W±B

W±B

W±B

W±B

BR W±B

BR BR

BR W±B W±BW±B

W±BW±BBR W±B (4A±GZE)

W±B A A A

I 6

I 6

I 2

I 2

I 2

B 5I 5

I 5

I 5

B 5

B 5

B 5

I 5

I 5

I 3I 3

E 3

E 3

E 3

E 2

E 4

E 5

E 4

E 5

E 6E 4

E 4

B 4

EAI 4

B 4

B 4

I 4I 8

IBIC

3C7

4

JUNCTION

CONNECTOR J 1

4

DOOR LOCK CONTROL

RELAY

ELECTRICAL IDLE-UP

CUT RELAY (M/T)FRONT SIDE MARKER

LIGHT RH

FRONT SIDE MARKER

LIGHT LH

BRAKE FLUID LEVEL

WARNING SW

UNLOCK WARNING

SW WIPER AND WASHER

SW [COMB. SW] LIGHT CONTROL SW

[COMB. SW] HEATER CONTROL

ASSEMBLY

HEATER SERVO

MOTOR AMPLIFIER

DIMMER SW

[COMB. SW]

CRUISE CONTROL

MIRROR SW

REAR WINDOW

DEFOGGER SW

POWER WINDOW

MASTER SW

POWER WINDOW

CONTROL RELAY

DOOR LOCK CONTROL

SW

REMOTE CONTROL

MIRROR SW

* The system shown here is an EXAMPLE ONLY. It is different to the actual circuit shown in the SYSTEM CIRCUITS SECTION.

Page 1159 of 4770

![TOYOTA CAMRY 2000 Service User Guide To Ignition SW

IG Terminal

Fuse

Voltmeter SW 1

Relay

SW 2Solenoid[A]

[B]

[C]

Ohmmeter

SW

Ohmmeter

Diode

Digital Type Analog Type

C TROUBLESHOOTING

VOLTAGE CHECK

(a)Establish conditions in which volta TOYOTA CAMRY 2000 Service User Guide To Ignition SW

IG Terminal

Fuse

Voltmeter SW 1

Relay

SW 2Solenoid[A]

[B]

[C]

Ohmmeter

SW

Ohmmeter

Diode

Digital Type Analog Type

C TROUBLESHOOTING

VOLTAGE CHECK

(a)Establish conditions in which volta](/img/14/57447/w960_57447-1158.png)

To Ignition SW

IG Terminal

Fuse

Voltmeter SW 1

Relay

SW 2Solenoid[A]

[B]

[C]

Ohmmeter

SW

Ohmmeter

Diode

Digital Type Analog Type

C TROUBLESHOOTING

VOLTAGE CHECK

(a)Establish conditions in which voltage is present at the check

point.

Example:

[A] ± Ignition SW on

[B] ± Ignition SW and SW 1 on

[C] ± Ignition SW, SW 1 and Relay on (SW 2 off)

(b)Using a voltmeter, connect the negative lead to a good ground

point or negative battery terminal, and the positive lead to the

connector or component terminal.

This check can be done with a test light instead of a voltmeter.

CONTINUITY AND RESISTANCE CHECK

(a)Disconnect the battery terminal or wire so there is no voltage

between the check points.

(b)Contact the two leads of an ohmmeter to each of the check

points.

If the circuit has diodes, reverse the two leads and check

again.

When contacting the negative lead to the diode positive side

and the positive lead to the negative side, there should be

continuity.

When contacting the two leads in reverse, there should be no

continuity.

(c)Use a volt/ohmmeter with high impedance (10 kW/V

minimum) for troubleshooting of the electrical circuit.

Page 1161 of 4770

![TOYOTA CAMRY 2000 Service User Guide 10

3

0.2

11

(mm) Reference:

Tool Up Example:

(Case 1)

Terminal Retainer

Terminal Retainer

[Retainer at Full Lock Position]

[Retainer at Temporary Lock Position]StopperTerminal

Retainer

Secondary

Locki TOYOTA CAMRY 2000 Service User Guide 10

3

0.2

11

(mm) Reference:

Tool Up Example:

(Case 1)

Terminal Retainer

Terminal Retainer

[Retainer at Full Lock Position]

[Retainer at Temporary Lock Position]StopperTerminal

Retainer

Secondary

Locki](/img/14/57447/w960_57447-1160.png)

10

3

0.2

11

(mm) Reference:

Tool Up Example:

(Case 1)

Terminal Retainer

Terminal Retainer

[Retainer at Full Lock Position]

[Retainer at Temporary Lock Position]StopperTerminal

Retainer

Secondary

Locking Device Example:

(Case 2)

C TROUBLESHOOTING

HOW TO REPLACE TERMINAL

(with terminal retainer or secondary locking device)

1.PREPARE THE SPECIAL TOOL

HINT : To remove the terminal from the connector, please

construct and use the special tool or like object shown on

the left.

2.DISCONNECT CONNECTOR

3.DISENGAGE THE SECONDARY LOCKING DEVICE OR

TERMINAL RETAINER.

(a)Locking device must be disengaged before the terminal

locking clip can be released and the terminal removed from

the connector.

(b)Use a special tool or the terminal pick to unlock the secondary

locking device or terminal retainer.

NOTICE:

Do not remove the terminal retainer from connector body.

[A] For Non±Waterproof Type Connector

HINT : The needle insertion position varies according to the

connector's shape (number of terminals etc.), so

check the position before inserting it.

ºCase 1º

Raise the terminal retainer up to the temporary lock

position.

ºCase 2º

Open the secondary locking device.

Page 1163 of 4770

![TOYOTA CAMRY 2000 Service User Guide Retainer at

Full Lock Position

[Male] [Female]

Retainer at

Temporary Lock Position

Locking Lug

Tool

C TROUBLESHOOTING

Push the terminal retainer down to the temporary lock position.

(c)Release the lo TOYOTA CAMRY 2000 Service User Guide Retainer at

Full Lock Position

[Male] [Female]

Retainer at

Temporary Lock Position

Locking Lug

Tool

C TROUBLESHOOTING

Push the terminal retainer down to the temporary lock position.

(c)Release the lo](/img/14/57447/w960_57447-1162.png)

Retainer at

Full Lock Position

[Male] [Female]

Retainer at

Temporary Lock Position

Locking Lug

Tool

C TROUBLESHOOTING

Push the terminal retainer down to the temporary lock position.

(c)Release the locking lug from terminal and pull the terminal out

from rear.

4.INSTALL TERMINAL TO CONNECTOR

(a)Insert the terminal.

HINT:

1. Make sure the terminal is positioned correctly.

2. Insert the terminal until the locking lug locks firmly.

3. Insert the terminal with terminal retainer in the temporary lock

position.

(b)Push the secondary locking device or terminal retainer in to

the full lock position.

5.CONNECT CONNECTOR