sensor TOYOTA CAMRY 2000 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2000, Model line: CAMRY, Model: TOYOTA CAMRY 2000Pages: 4770, PDF Size: 86.41 MB

Page 1281 of 4770

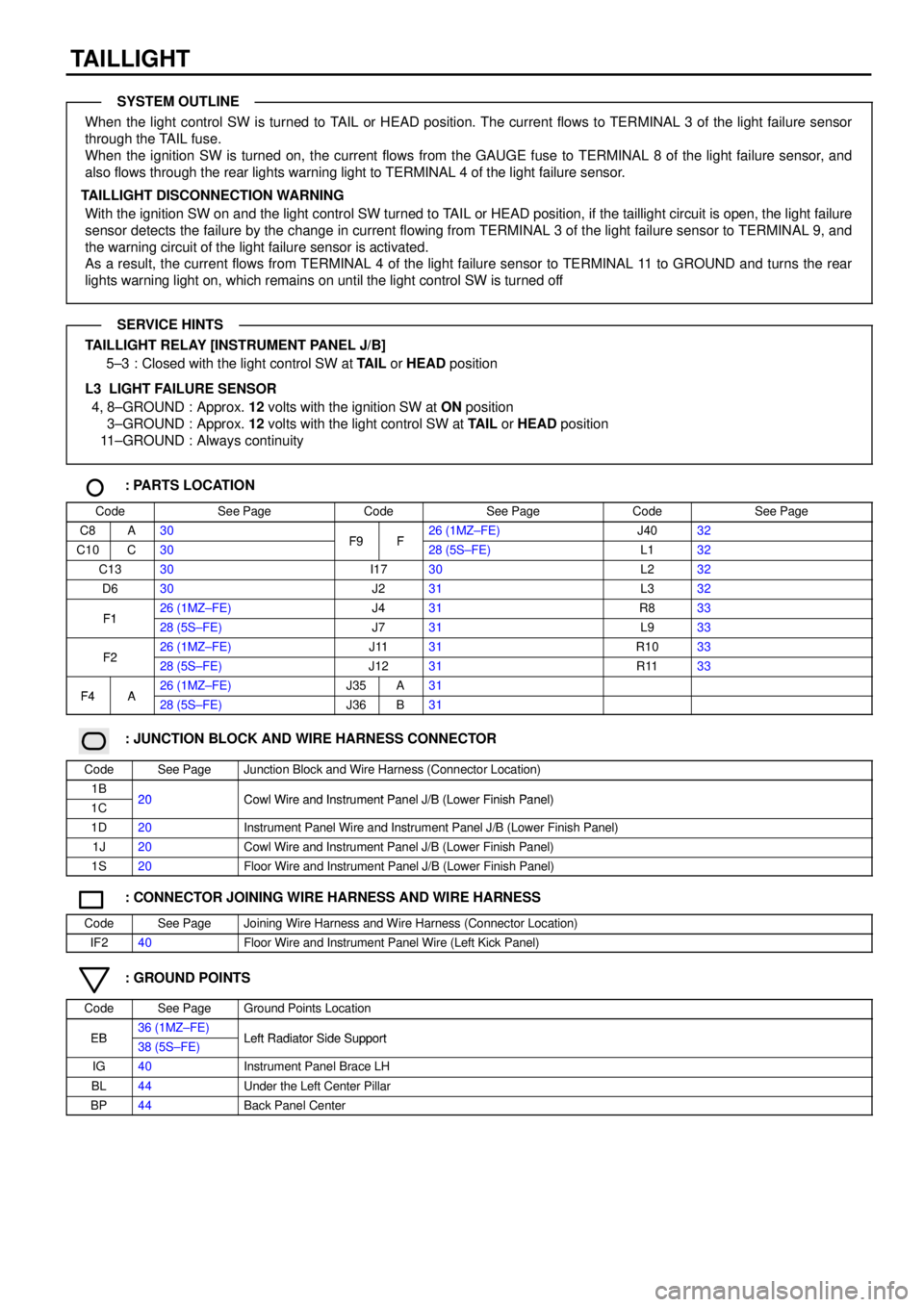

TAILLIGHT

When the light control SW is turned to TAIL or HEAD position. The current flows to TERMINAL 3 of the light failure sensor

through the TAIL fuse.

When the ignition SW is turned on, the current flows from the GAUGE fuse to TERMINAL 8 of the light failure sensor, and

also flows through the rear lights warning light to TERMINAL 4 of the light failure sensor.

TAILLIGHT DISCONNECTION WARNING

With the ignition SW on and the light control SW turned to TAIL or HEAD position, if the taillight circuit is open, the light failure

sensor detects the failure by the change in current flowing from TERMINAL 3 of the light failure sensor to TERMINAL 9, and

the warning circuit of the light failure sensor is activated.

As a result, the current flows from TERMINAL 4 of the light failure sensor to TERMINAL 11 to GROUND and turns the rear

lights warning light on, which remains on until the light control SW is turned off

TAILLIGHT RELAY [INSTRUMENT PANEL J/B]

5±3 : Closed with the light control SW at TAIL or HEAD position

L3 LIGHT FAILURE SENSOR

4, 8±GROUND : Approx. 12 volts with the ignition SW at ON position

3±GROUND : Approx. 12 volts with the light control SW at TAIL or HEAD position

11±GROUND : Always continuity

: PARTS LOCATION

CodeSee PageCodeSee PageCodeSee Page

C8A30F9F26 (1MZ±FE)J4032

C10C30F9F28 (5S±FE)L132

C1330I1730L232

D630J231L332

F126 (1MZ±FE)J431R833F128 (5S±FE)J731L933

F226 (1MZ±FE)J1131R1033F228 (5S±FE)J1231R1133

F4A26 (1MZ±FE)J35A31F4A28 (5S±FE)J36B31

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CodeSee PageJunction Block and Wire Harness (Connector Location)

1B20Cowl Wire and Instrument Panel J/B (Lower Finish Panel)1C20Cowl Wire and Instrument Panel J/B (Lower Finish Panel)

1D20Instrument Panel Wire and Instrument Panel J/B (Lower Finish Panel)

1J20Cowl Wire and Instrument Panel J/B (Lower Finish Panel)

1S20Floor Wire and Instrument Panel J/B (Lower Finish Panel)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CodeSee PageJoining Wire Harness and Wire Harness (Connector Location)

IF240Floor Wire and Instrument Panel Wire (Left Kick Panel)

: GROUND POINTS

CodeSee PageGround Points Location

EB36 (1MZ±FE)Left Radiator Side SupportEB38 (5S±FE)Left Radiator Side Support

IG40Instrument Panel Brace LH

BL44Under the Left Center Pillar

BP44Back Panel Center

SYSTEM OUTLINE

SERVICE HINTS

Page 1349 of 4770

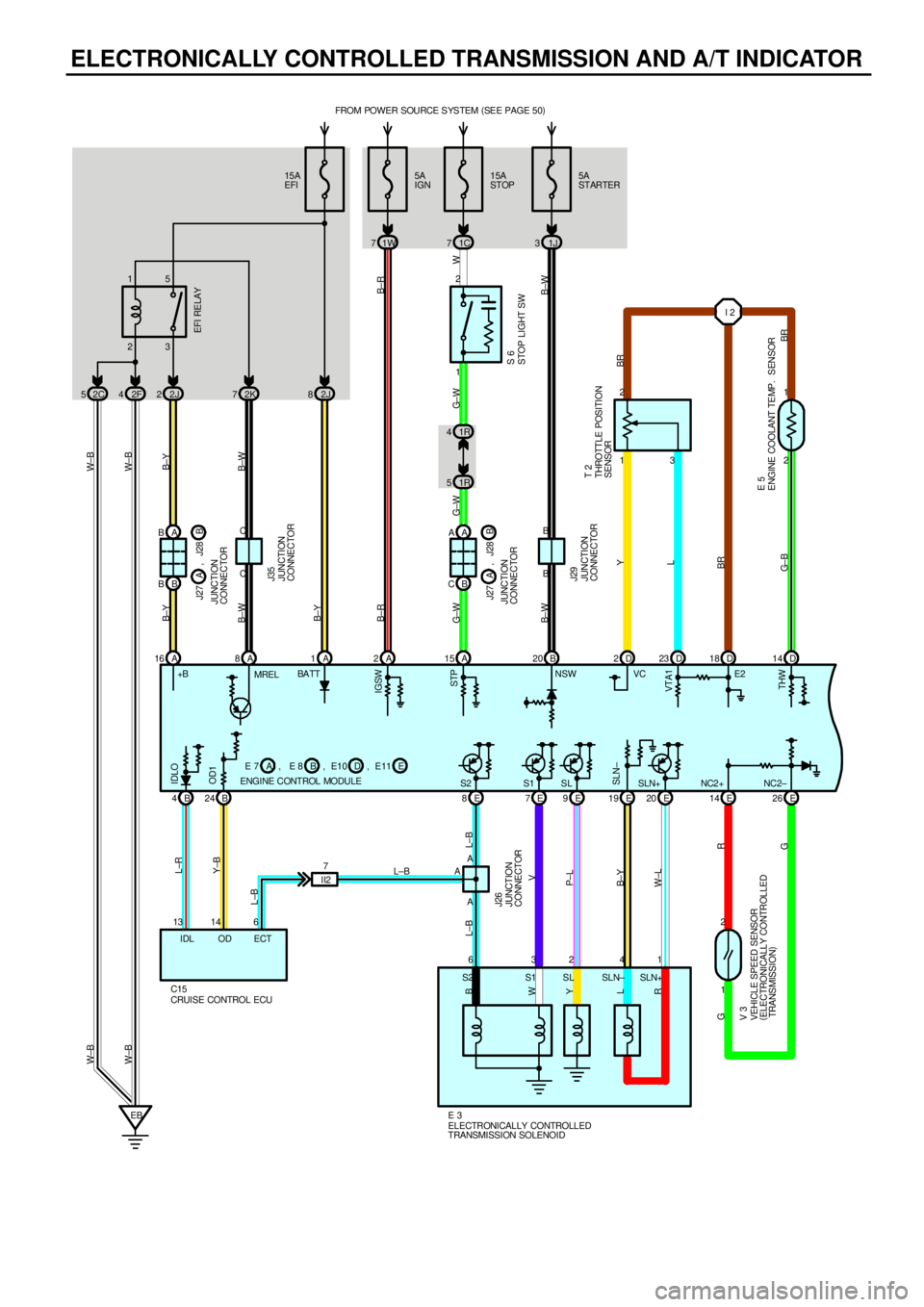

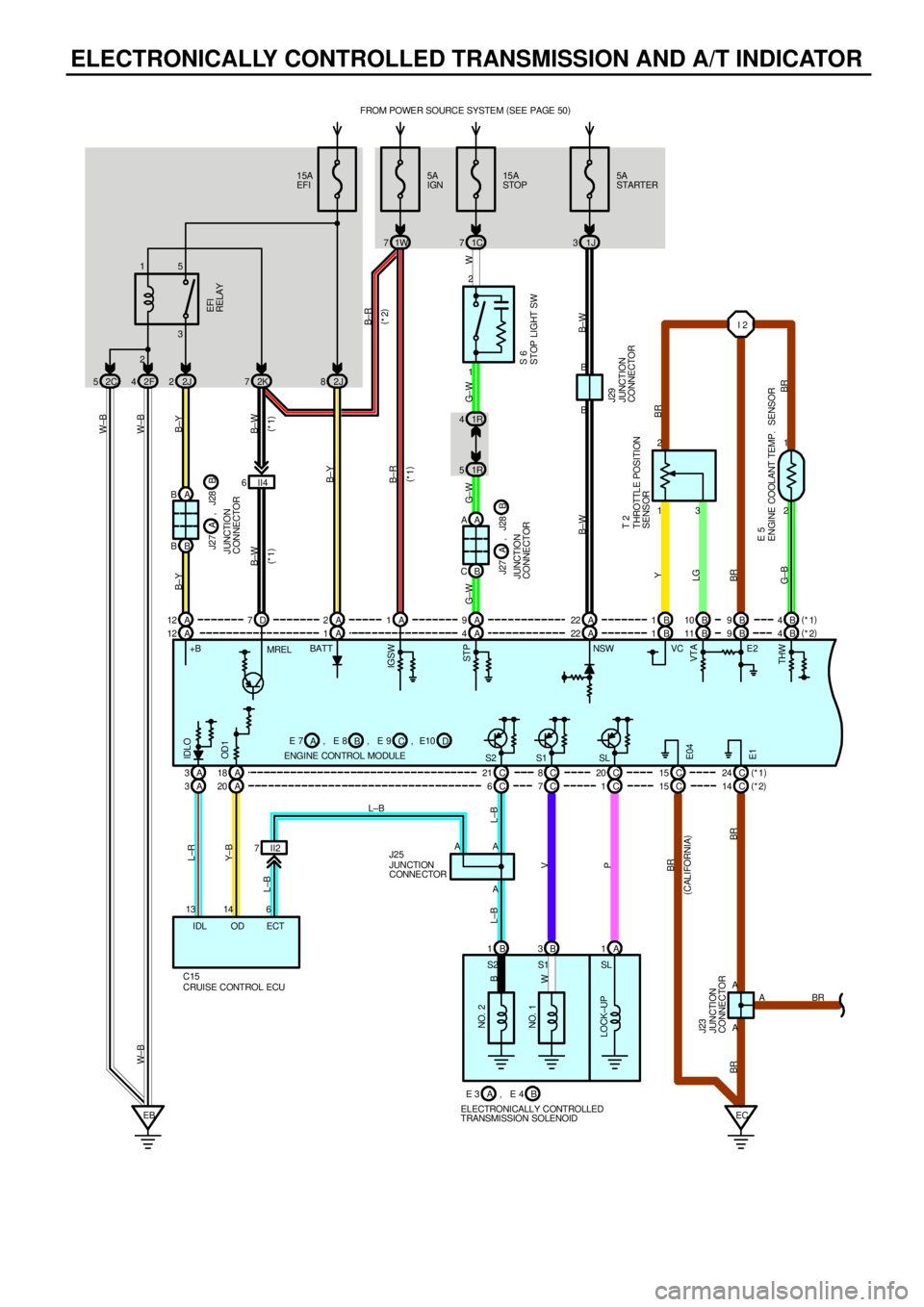

ELECTRONICALLY CONTROLLED TRANSMISSION AND A/T INDICATOR

15A

EFIFROM POWER SOURCE S YS TEM (

SEE PAGE 50)

2J 815A

STOP

1C 7

23 15

2F 42J2

1R 4

1R 51 2

1 2

2 1

A 15 A 1D 2D23 D14 D 18

E 7E9E19 E20 E14 E26 A B

B BI 2

1 2

EBA

63241 A3

G±WB±YB±Y W± B W±B

G± W G±W W

BR

BR G± BL Y

BR L±B L±B

V

P±L

B±Y

W±L

R

G GJUNCTION

CONNECTORB J27 J28AEFI RELAY

SLN+ NC2+ NC2± BA TTVC

STOP LIGHT SW

THROTTLE POSI TI ON

SENSOR

ENGINE COOLANT TEMP. SENSOR

ELECTRONICALLY CONTROLLED

TRANSMISSION SOLENOID

VEHICLE SPEED SENSOR

(

ELECTRONICALLY CONTROLLED

TRANSMISSION)

E 3

V 3S 6

T 2

E 5 B

W

Y

L

R

S2 S1 SL SLN± SLN+ BB24

CRUISE CONTROL ECU C156 13 14

L±BL±R

Y±B

ECT IDL ODA ENGINE CONTROL MODULEB E 7 E 8ADE10 EE11 A 16

B±Y

+B 2C 5

W± B W±B

STP

VTA1

THW IDLO

OD1

SLN± JUNCTION

CONNECTOR J26

L±B5A

IGN

1W 7

A 2

B±RB±R

2K 7

A 8

B±W B±W

C CJUNCTION

CONNECTOR J35

IGSW

S1 SLE2

S25A

STARTER

1J 3

B 20

B±WB±W

B BJUNCTION

CONNECTOR J29

II27

,

,

A A

B C

JUNCTION

CONNECTORB J27 J28A

, , , MRELNSW

4E8

Page 1350 of 4770

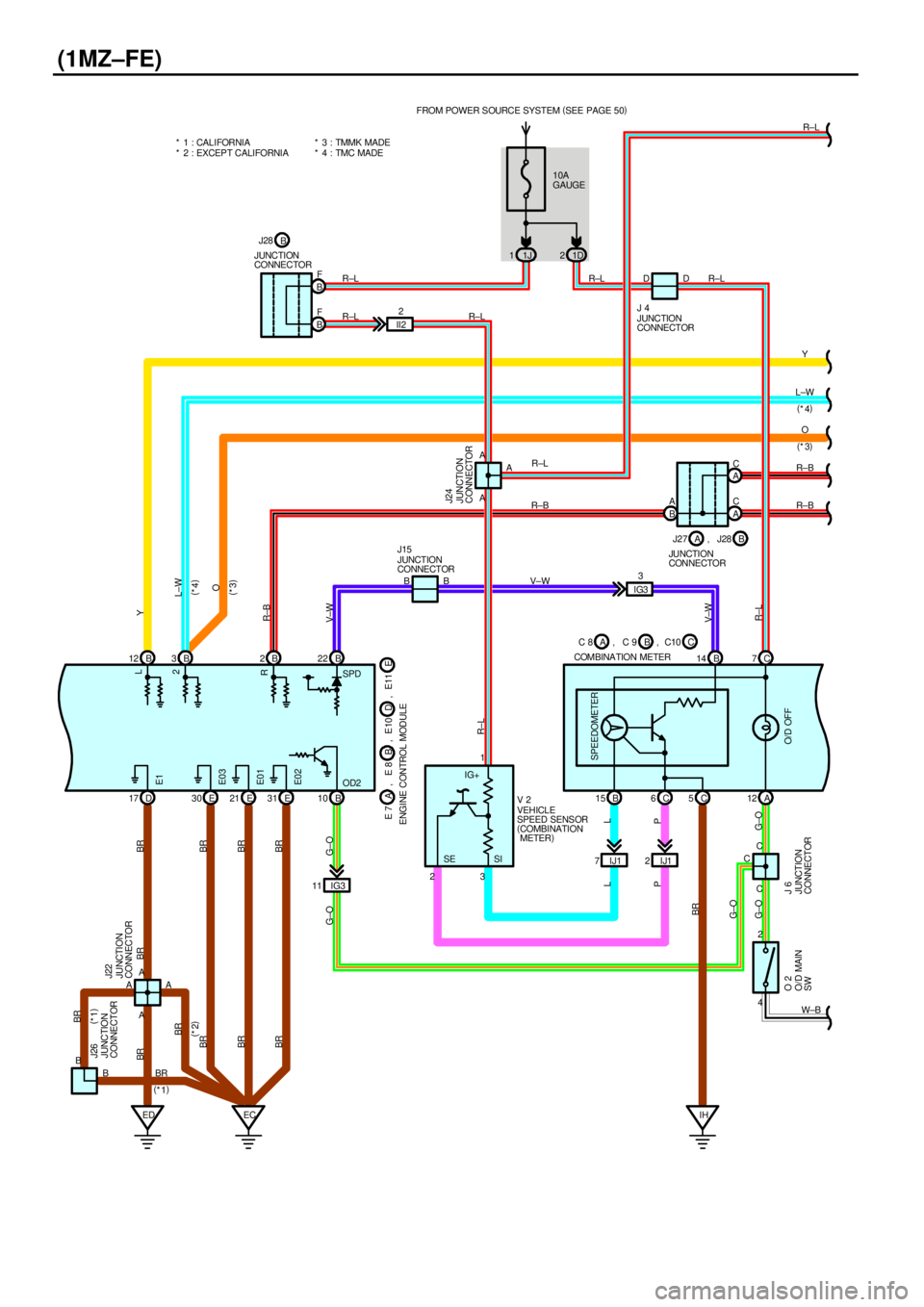

(1MZ±FE)

B 12 B3B2B22

D 17 E21 E31 B10

ED ECIG3 1110A

GAUGE FROM POWER SOURCE SYSTEM (

SEE PAGE 50)

1J 11D2

B 14 C7

B 15 C6A12

IJ1 7IJ12B A

A C A C

IG33

AD

A

B

CC

AA

AD

BA

C

V±W

Y

L±W

R±B

R±B R±L R±L

R±L

V±W

W±B

Y

L±W BR

BR

BR

G±O BR

BR

BR

BRBR

R±L

R±L R±L R±L

V±W

R±L L

P L

P

G±O G±OENGINE CONTROL MODULEB E 7 E 8ADE10 EE11

OD2 SPDJUNCTION

CONNECTORB J27 J28A

COMBINA TION METERB C 8 C 9ACC10 JUNCTION

CONNECTOR J 4

JUNCTION

CONNECTOR J15

JUNCTION

CONNECTOR J 6

O/D MAIN

SW O 2

VEHICLE

SPEED SENSOR

(

COMBINATION

METER) V 2

JUNCTION

CONNECTOR J24

SPEEDOMETER

O/ D OFF G±O G±O

R±L

R±B

R±B

JUNCTION

CONNECTORJ28

B

E 30

BR BRJUNCTION

CONNECTOR J22

C 5

IH

BR

SE SIIG+

L

2

R E1

E03

E01

E02

BF

BF

231

4 2O (

*4)

(

*3)

O

(

*3) (

*4)

,

, , ,

, , II22

B

B

JUNCTION

CONNECTOR J26

A

BR

(

*2) (

*1)

BR

(

*1)* 1 : CALIFORNIA

* 2 : EXCEPT CALIFORNIA* 3 : TMMK MADE

* 4 : TMC MADE

Page 1352 of 4770

(1MZ±FE)

Previous automatic transaxle have selected each gear shift using the mechanically controlled throttle hydraulic pressure,

governor hydraulic pressure and lock±up hydraulic pressure. The electronically controlled transmission, however, electrically

controls the line pressure and lock±up pressure etc., through the solenoid valve. Engine control module control of the

solenoid valve based on the input signals from each sensor makes smooth driving possible by shift selection for each gear

which is most appropriate to the driving conditions at that time.

1. GEAR SHIFT OPERATION

During driving, the engine control module selects the shift for each gear which is most appropriate to the driving conditions,

based on input signals from the engine coolant temp. sensor to TERMINAL THW of the engine control module, and also the

input signals to TERMINAL NC2+ of the engine control module from the vehicle speed sensor devoted to the O/D direct

clutch. Current is then output to the electronically controlled transmission solenoid. When shifting to 1st speed, current flows

from TERMINAL S1 of the engine control module to TERMINAL 3 of the electronically controlled transmission solenoid to

GROUND, and continuity to the No.1 solenoid causes the shift.

For the 2nd speed, current flows from TERMINAL S1 of the engine control module to TERMINAL 3 of the electronically

controlled transmission solenoid to GROUND, and from TERMINAL S2 of the engine control module to TERMINAL 6 of the

electronically controlled transmission solenoid to GROUND, and continuity to solenoids No.1 and No.2 causes the shift.

For the 3rd speed, there is no continuity to No.1 solenoid, only to No.2, causing the shift.

Shifting into 4th speed (Overdrive) takes place when there is no continuity to either No.1 or No.2 solenoid.

2. LOCK±UP OPERATION

When the engine control module judges from each signal that lock±up operation conditions have been met, current flows

from TERMINAL SL of the engine control module to TERMINAL 2 of the electronically controlled transmission solenoid to

GROUND, causing continuity to the lock±up solenoid and causing lock±up operation.

3. STOP LIGHT SW CIRCUIT

If the brake pedal is depressed (Stop light SW on) when driving in lock±up condition, a signal is input to TERMINAL STP of

the engine control module, the engine control module operates and continuity to the lock±up solenoid is cut.

4. OVERDRIVE CIRCUIT

*Overdrive on

When the O/D main SW is turned on (O/D off indicator light turns off), a signal is input to TERMINAL OD2 of the engine

control module and engine control module operation causes gear shift when the conditions for overdrive are met.

*Overdrive off

When the O/D main SW is turned to off (O/D off indicator light turns on), the current flowing through the O/D off indicator

light flows through the O/D main SW to GROUND. Causing the indicator light to light up. At the same time, a signal is

input to TERMINAL OD2 of the engine control module and engine control module operation prevents shift into overdrive.

E7 (A), E8 (B), E10 (D), E11 (E) ENGINE CONTROL MODULE (TURN ON THE IGNITION SW)

S1, S2±E1 :9.0±14.0 volts with the solenoid on

0±1.5 volts with the solenoid off

L±E1 :7.5±14.0 volts with the shift lever at L position

2±E1 :7.5±14.0 volts with the shift lever at 2 position

R±E1 :7.5±14.0 volts with the shift lever at R position

STP±E1 :7.5±14.0 volts with the brake pedal depressed

THW±E2 :0.2±1.0 volts with the engine coolant temp. 80°C (176°F)

VAT1±E2 :0.3±0.8 volts with the throttle valve fully closed

3.2±4.9 volts with the throttle valve fully opened

VC±E2 :4.5±5.5 volts

OD2±E1 :9.0±14.0 volts with the O/D main SW turned off

0±3.0 volts with the O/D main SW turned on

+B±E1 :9.0±14.0 volts

OD1±E1 :9.0±14.0 volts

E3 ELECTRONICALLY CONTROLLED TRANSMISSION SOLENOID

2, 3, 6±GROUND : Each 11±15 W

O2 O/D MAIN SW

2±4 : Closed with the O/D main SW off, open with the O/D main SW on

SYSTEM OUTLINE

SERVICE HINTS

Page 1357 of 4770

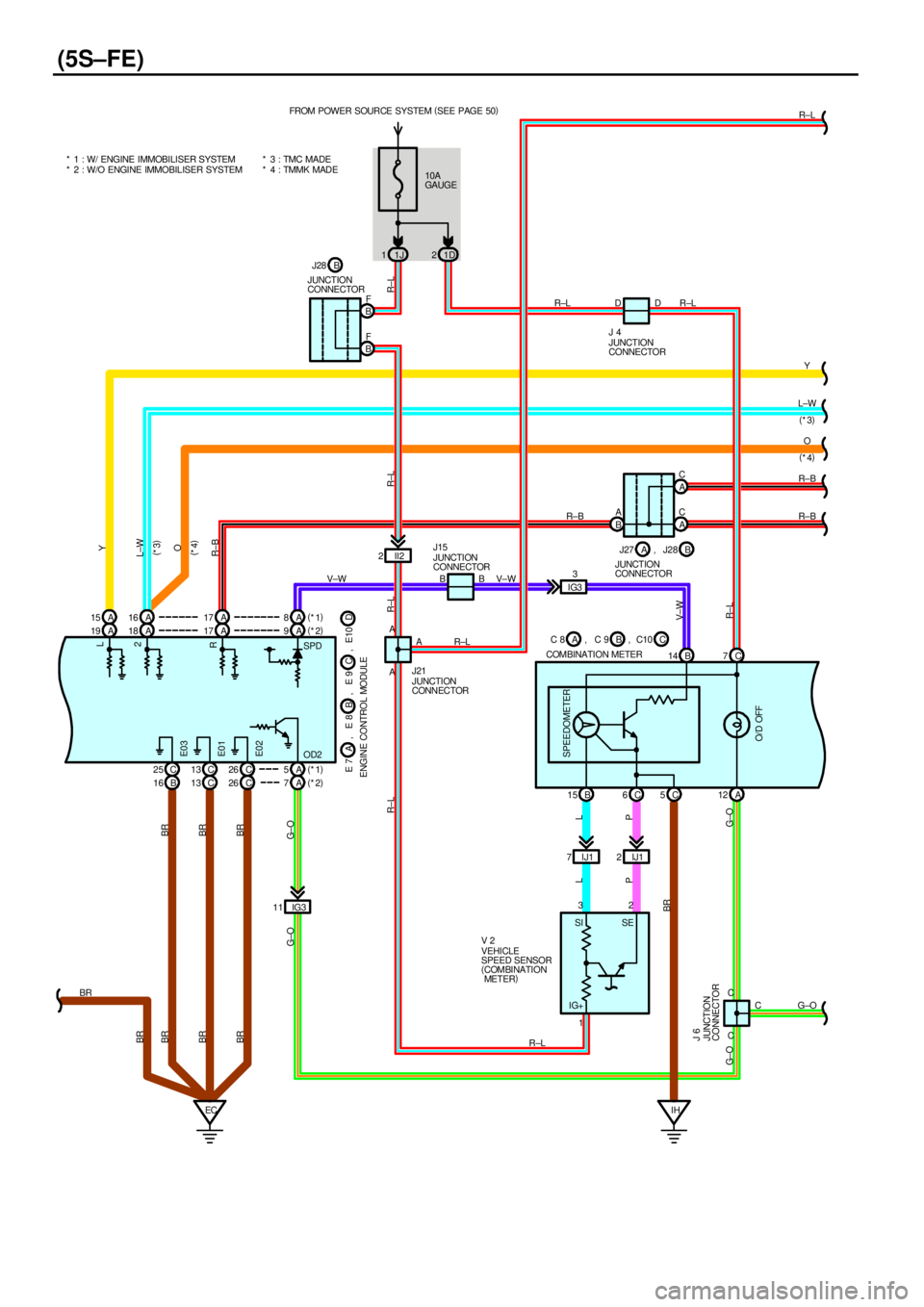

ELECTRONICALLY CONTROLLED TRANSMISSION AND A/T INDICATOR

15A

EFIFROM POWER SOURCE SYSTEM (

SEE PAGE 50)

2J 815A

STOP

1C 7

23 15

2F 42J2

1R 4

1R 51 2

1 2

2 1

A 4 A 1B 1B11 B4 B 9

C 21 C8C20 C24 A B

B BI 2

EBEC A

A A3

AA

G±WB±YB±Y W±B W± B

G± W G± W W

BR

BR G±BLGY

BR L±B L±B

V

P

BR BREFI

RELAY

BATTVC

STOP LIGHT SW

THROTTLE POSITION

SENSOR

ENGINE COOLANT TEMP. SENSORS 6

T 2

E 5 B

W

S2 S1 II2 7 A 3A18

CRUISE CONTROL ECU C156 13 14

L±BL±R

Y± B

ECT IDL ODA ENGINE CONTROL MODULEB ACD A 12

B±Y

+B

JUNCTION

CONNECTOR J23STP

VTA

THW IDLO

OD 1

E1

JUNCTION

CONNE CTOR J25 L±B5A

IGN

1W 7

B±R

2K 7

B±W B±W

IGSW

S1 SLE2

S2B 4 B 9 B 10 B 1 A 9 A 1 A 2 D 7 A 12(

*1)

(

*2) A A

B C

SL

NO. 2

NO. 1

LOCK±UP

B 1B3A1

E 3

ELECTRONICALLY CONTROLLED

TRANSMISSION SOLENOIDB A, E 4C 1 C 7 C 6 A 20 A 3E 7 , E 8 , E 9 , E10

B± R

(

*2)

(

*1)

J27

JUNCTION

CONNECTORB A, J28J27

J UNCTION

CONNECTORB A, J28

II4 6

(

*1) (

*1)

A 22A 225A

STARTER

1J 3

B±W B±W

JUNCTION

CONNECTOR J29

C 14 C 15

C 15

BR

(

CALIFORNIA)

(

*1)

(

*2)

BR B B

E04

MRELNSW 2C 5

W±B

Page 1358 of 4770

(5S±FE)

A 19 A18 A17 A9

C 13 C26 A5

ECIG3 1110A

GAUGE FROM POWER SOURCE SYSTEM (

SEE PAGE 50)

1J 11D2

B 14 C7

B 15 C6A12 II2 2

IJ1 7IJ12 B A

A CA C D

AB

32

C A

1D

B

A

C V±WY

L±W

R±B

R±B R±L R±L

R±LV±W

G±O

R±L

Y

L±W

BR

BR

G± O BR

BR

BR

R±L R±L R±L R±L

V±W

R±L L

P L

P

G±O G± O

OD2 SPDJUNCTION

CONNECTOR

COMBINATION METERJUNCTION

CONNECTOR J 4

JUNCTION

CONNECTOR J15

VEHICLE

SPEED SENSOR

(

COMBINATION

MET ER) V 2 JUNCTION

CONNECTOR J21SPEEDOMETER

O/ D OFF G±O

R±L

R±B

R±B

C 25

BR BR

C 5

IH

BRSE SI

IG+

L

2

R E03

E01

E02

BF

BF J28

JUNCTION

CONNECTORB

E 7

ENGINE CONTROL MODULEB A, E 8 , CE 9 D, E10B 16 C13 C26 A7(

*1)

(

*2)

BRA 15 A16 A17 A8

C

JUNCTION

CONNECTOR J 6

B C 8 A , C 9 C, C10 (

*1)

(

*2)O

OB J27 A , J28(

*3)

(

*4)(

*3)

(

*4)

IG33 * 1 : W/ ENGINE IMMOBILISER SYSTEM

* 2 : W/O ENGINE IMMOBILISER SYSTEM* 3 : TMC MADE

* 4 : TMMK MADE

Page 1360 of 4770

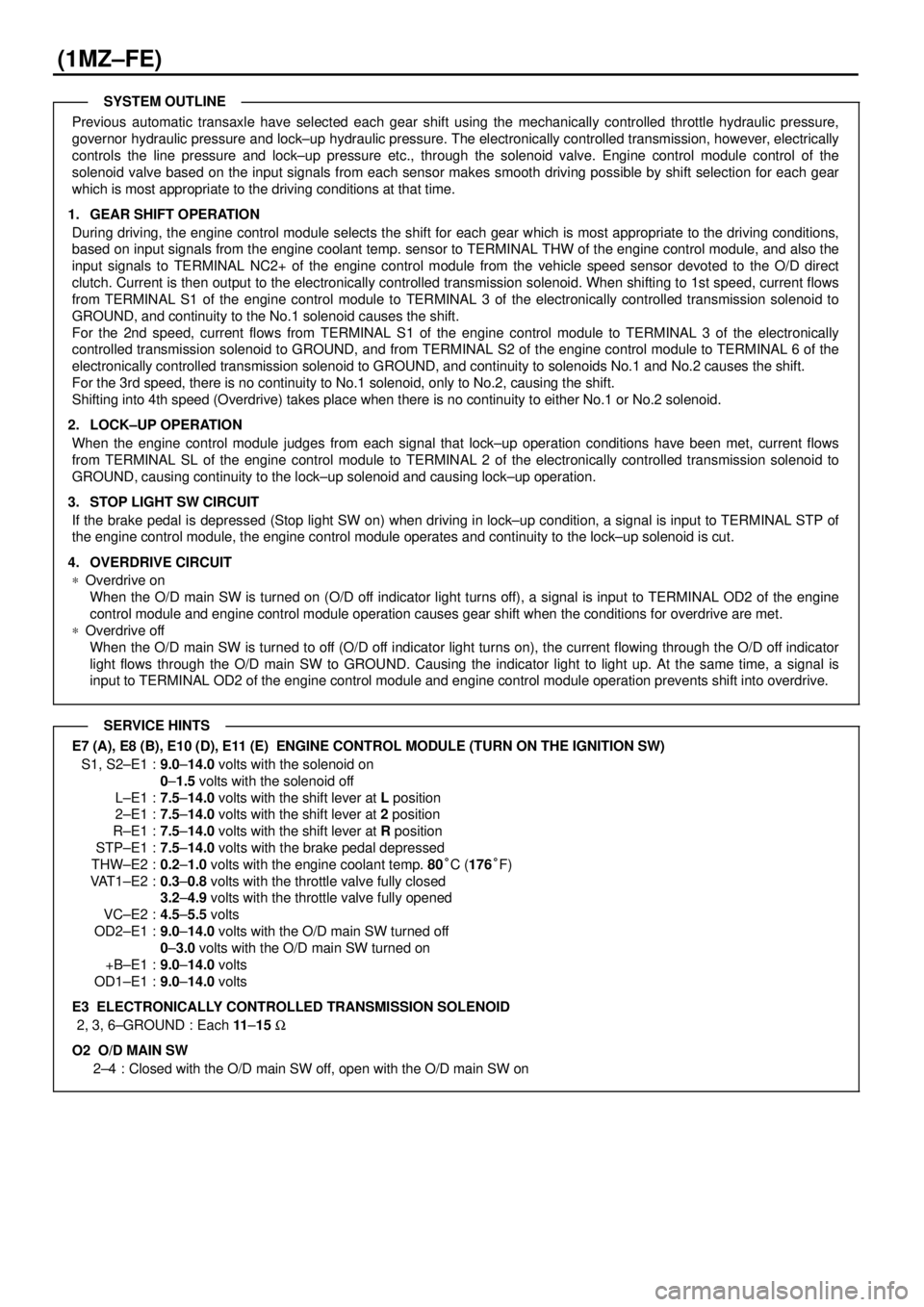

(5S±FE)

Previous automatic transaxle have selected each gear shift using mechanically controlled throttle hydraulic pressure,

governor hydraulic pressure and lock±up hydraulic pressure. The electronically controlled transmission, however, electrically

controls the line pressure and lock±up pressure etc., through the solenoid valve. Engine control module controls of the

solenoid valve based on the input signals from each sensor which makes smooth driving possible by shift selection for each

gear which is most appropriate to the driving conditions at that time.

1. GEAR SHIFT OPERATION

During driving, the engine control module selects the shift for each gear which is most appropriate to the driving conditions,

based on input signals from the engine coolant temp. sensor to TERMINAL THW of the engine control module, and also the

input signals to TERMINAL SPD of the engine control module from the vehicle speed sensor devoted to the electronically

controlled transmission. Current is then output to the electronically controlled transmission solenoid. When shifting to 1st

speed, current flows from TERMINAL S1 of the engine control module to TERMINAL (B) 3 of the solenoid to GROUND, and

continuity to the No.1 solenoid causes the shift.

For 2nd speed, current flows from TERMINAL S1 of the engine control module to TERMINAL (B) 3 of the solenoid to

GROUND, and from TERMINAL S2 of the engine control module to TERMINAL (B) 1 of the solenoid to GROUND, and

continuity to solenoids No.1 and No.2 causes the shift.

For 3rd speed, there is no continuity to No.1 solenoid, only to No.2, causing the shift.

Shifting into 4th speed (Overdrive) takes place when there is no continuity to either No.1 or No.2 solenoid.

2. LOCK±UP OPERATION

When the engine control module judges from each signal that lock±up operation conditions have been met, current flows

from TERMINAL SL of the engine control module to TERMINAL (A) 1 of the electronically controlled transmission solenoid to

GROUND, causing continuity to the lock±up solenoid and causing lock±up operation.

3. STOP LIGHT SW CIRCUIT

If the brake pedal is depressed (Stop light SW on) when driving in lock±up condition, a signal is input to TERMINAL STP of

the engine control module, the engine control module operates and continuity to the lock±up solenoid is cut.

4. OVERDRIVE CIRCUIT

*O/D main SW on

When the O/D main SW is turned on (O/D off indicator light turns off), a signal is input into TERMINAL OD2 of the engine

control module and engine control module operation causes gear shift when the conditions for overdrive are met.

*O/D main SW off

When the O/D main SW is turned to off, the current through the O/D off indicator light flows through the O/D main SW to

GROUND, causing the indicator light to light up. At the same time, a signal is input into TERMINAL OD2 of the engine

control module and engine control module operation prevents shift into overdrive.

E7 (A), E8 (B), E9 (C) ENGINE CONTROL MODULE (TURN ON THE IGNITION SW)

S1, S2±E1 :9.0±14.0 volts with the solenoid on

0±1.5 volts with the solenoid off

L±E1 :7.5±14.0 volts with the shift lever at L position

2±E1 :7.5±14.0 volts with the shift lever at 2 position

R±E1 :7.5±14.0 volts with the shift lever at R position

STP±E1 :9.0±14.0 volts with the brake pedal depressed

THW±E2 :0.2±1.0 volts with the engine coolant temp. 60°C (140°F) ± 120°C (248°F)

VTA±E2 :0.3±0.8 volts with the throttle valve fully closed

3.2±4.9 volts with the throttle valve fully opened

VC±E2 :4.5±5.5 volts

OD2±E1 :9.0±14.0 volts with the O/D main SW turned on

0±3.0 volts with the O/D main SW turned off

+B±E1 :9.0±14.0 volts

E3 (A), E4 (B) ELECTRONICALLY CONTROLLED TRANSMISSION SOLENOID

(A) 1, (B) 1, (B) 3±GROUND : Each 11±15 W

O2 O/D MAIN SW

2±4 : Closed with the O/D main SW off, open with the O/D main SW on

SYSTEM OUTLINE

SERVICE HINTS

Page 1365 of 4770

![TOYOTA CAMRY 2000 Service Repair Manual CRUISE CONTROL

SPEEDOMETER

B 15 C6B14 C10 C 5

IJ1 7IJ12IG33IG25

IH4 5

CRUISE CONTROL

SW [COMB. SW]

CRUISE

CANCELSET/

COAST RESUME/

ACCEL

C12 CMS CCS

3 EP 2 1

D 10A

GAUGE FROM POWER SOURCE SYSTEM (

S TOYOTA CAMRY 2000 Service Repair Manual CRUISE CONTROL

SPEEDOMETER

B 15 C6B14 C10 C 5

IJ1 7IJ12IG33IG25

IH4 5

CRUISE CONTROL

SW [COMB. SW]

CRUISE

CANCELSET/

COAST RESUME/

ACCEL

C12 CMS CCS

3 EP 2 1

D 10A

GAUGE FROM POWER SOURCE SYSTEM (

S](/img/14/57447/w960_57447-1364.png)

CRUISE CONTROL

SPEEDOMETER

B 15 C6B14 C10 C 5

IJ1 7IJ12IG33IG25

IH4 5

CRUISE CONTROL

SW [COMB. SW]

CRUISE

CANCELSET/

COAST RESUME/

ACCEL

C12 CMS CCS

3 EP 2 1

D 10A

GAUGE FROM POWER SOURCE SYSTEM (

SEE PAGE 50)

1D 2

C 71J 1

B FBF

A D

B B D

1 DAA

10

A2 A

A

D

32DDBB3 A

10 11 12 5 4

10 4 11A

A

A

PI TC SPD CMS CCSD

W±B

R±L

R±L

R±L R±L

R±L

R±L

R±L

B±R

B±R B±R

W W±L V±W LG±RO O

LG±R

LG±R

V±WO V±WBRPL L

P

V±W

O

R±L

R±LR±L

R±L R±L

(

*1 A/T)

(

*2 A/T) (

*2) (

*1)

(

M/T)

(

M/T)

(

A/ T)

JUNCTION

CONNECTOR J24

JUNCTION

CONNECTOR J21

CRUISE CONTROL

CLUTCH SW C14

D POSITION SW

[PARK/NEUTRAL POSITION SW] P 1 JUNCTION

CONNECTOR J 4

VEHICLE SPEED SENSOR

(

COMBINATION METER) V 2

DATA LINK

CONNECTOR 2 D 4

DATA LINK

CONNECTOR 1 D 1

JUNCTION CONNECTOR J 2

JUNCTION CONNECTOR J 3

JUNCTION CONNECTOR J1 5

JUNCTION

CONNECTOR J29

JUNCTION

CONNECTOR

R±L

(

*2)

(

*1)

CRUISE CONTROL ECU C15 COMBINATION METER

BR

CRUISE(

*1)

(

*2)A/D TC TCB

SI SE

IG+II2 2

II3 11 C C 9

B, C10

B J27 A , J28

II2 9

B±R

(

A/T) LG±R

(

*4)

P±B

(

*3)

Page 1367 of 4770

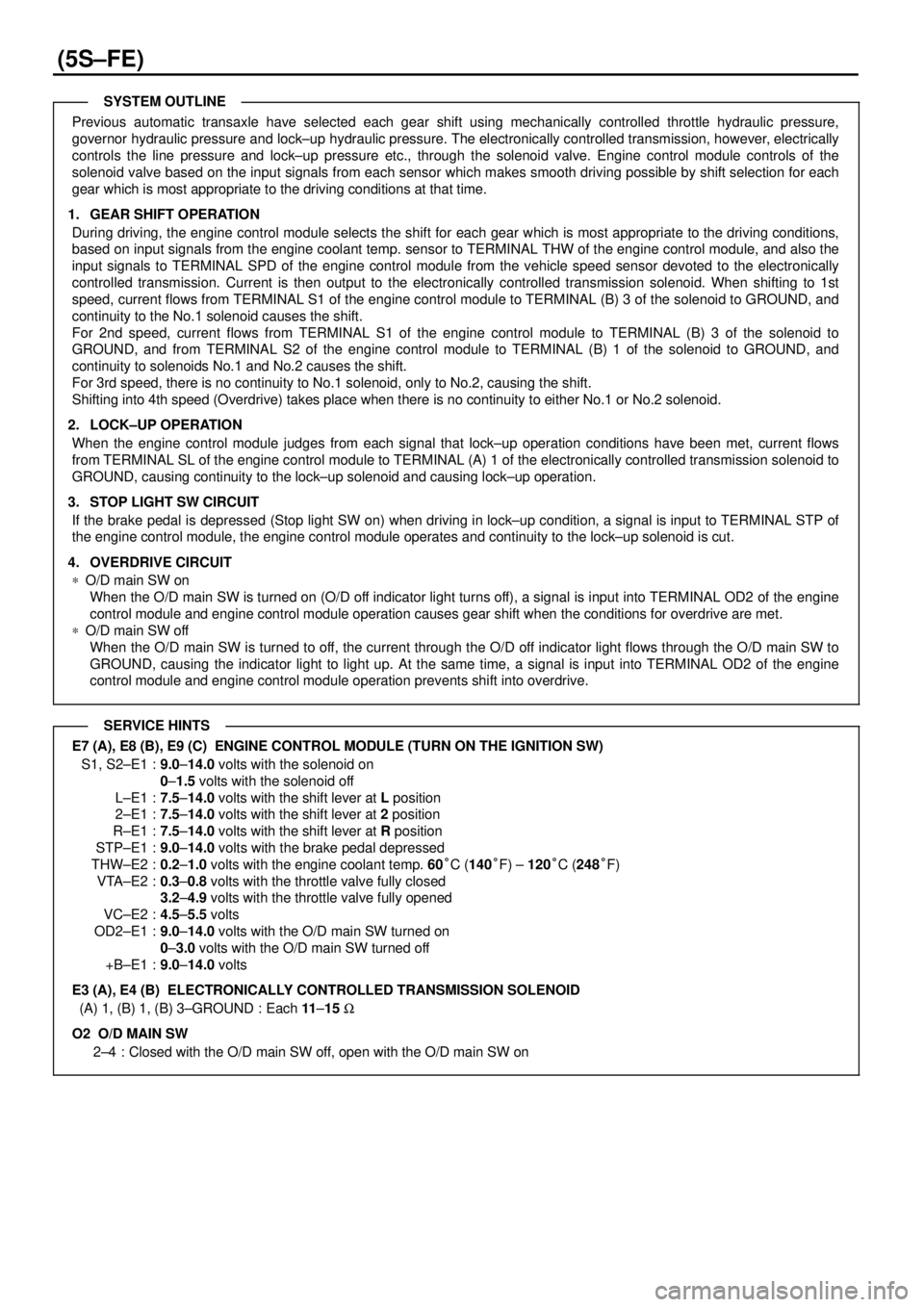

CRUISE CONTROL

Current is applied at all times through the STOP fuse to TERMINAL 2 of the stop light SW.

With the ignition SW turned to on, current flows through the GAUGE fuse to TERMINAL (C) 7 of the combination meter and

the current through the ECU±IG fuse flows to TERMINAL 9 of the cruise control ECU.

When the ignition SW is on and the cruise control SW is turned on, a signal is input from TERMINAL 5 of the cruise control

SW to TERMINAL 11 of the cruise control ECU. As a result, the cruise control ECU functions and the current flows from the

ECU±IG fuse to TERMINAL 9 of the cruise control ECU to TERMINAL 16 to GROUND, and the cruise control system is in a

condition ready for operation.

At the same time, the current through the GAUGE fuse flows to TERMINAL (C) 7 of the cruise control indicator light to

TERMINAL (C) 10 to TERMINAL 4 of the cruise control ECU to TERMINAL 16 to GROUND, causing the cruise control

indicator light to light up, indicating that cruise control is ready for operation.

1. SET OPERATION

When the cruise control SW is turned on and the set SW is pushed with the vehicle speed within the set limit (Approx. 40

km/h, 25 mph to 200 km/h, 124 mph), a signal is input to TERMINAL 10 of the cruise control ECU and the vehicle speed at

the time the set SW is released is memorized in the ECU as the set speed.

2. SET SPEED CONTROL

During cruise control driving, the cruise control ECU compares the set speed memorized in the cruise control ECU with the

actual vehicle speed input into TERMINAL 12 of the cruise control ECU from the speed sensor, and controls the cruise

control actuator to maintain the set speed.

When the actual speed is lower than the set speed, the ECU causes the current to the cruise control actuator to flow from

TERMINAL 15 of the cruise control ECU to TERMINAL 1 of the cruise control actuator to TERMINAL 2 to TERMINAL 7 of

the cruise control ECU. As a result, the motor in the cruise control actuator is rotated to open the than the set speed, the

current to the cruise control actuator flows from TERMINAL 7 of the cruise control ECU to TERMINAL 2 of the cruise control

actuator to TERMINAL 1 to TERMINAL 15 of the cruise control ECU.

This causes the motor in the cruise control actuator to rotate to close the throttle valve and return the throttle cable to

decrease the vehicle speed.

3. COAST CONTROL

During cruise control driving, while the coast SW is on, the cruise control actuator returns the throttle cable to close the

throttle valve and decrease the driving speed. The vehicle speed when the coast SW is turned off is memorized and the

vehicle continues at the new set speed.

4. ACCEL CONTROL

During cruise control driving, while the accel SW is turned on, the cruise control actuator pulls the throttle cable to open the

throttle valve and increase the driving speed.

The vehicle speed when the accel SW is turned off is memorized and the vehicle continues at the new set speed.

5. RESUME CONTROL

Unless the vehicle speed falls below the minimum speed limit (Approx. 40km/h, 25mph) after canceling the set speed by the

cancel SW, pushing the resume SW will cause the vehicle to resume the speed set before cancellation.

6. MANUAL CANCEL MECHANISM

If any of the following operations occurs during cruise control operation, the magnetic clutch of the actuator turns off and the

motor rotates to close the throttle valve and the cruise control is released.

*Placing the shift lever except D position (Park/Neutral position SW except D position). ºSignal is not input to TERMINAL 3

of the cruise control ECUº (A/T)

*Depressing the clutch pedal (Cruise control clutch SW off). ºSignal input to TERMINAL 3 of the cruise control ECUº (M/T)

*Depressing the brake pedal (Stop light SW on). ºSignal input to TERMINAL 2 of the cruise control ECUº

*Pushing the cancel switch (Cancel SW on). ºSignal input to TERMINAL 10 of the cruise control ECUº

*Pushing the cruise switch off ºsignal input to TERMINAL 11 of the cruise control ECUº.

SYSTEM OUTLINE

Page 1375 of 4770

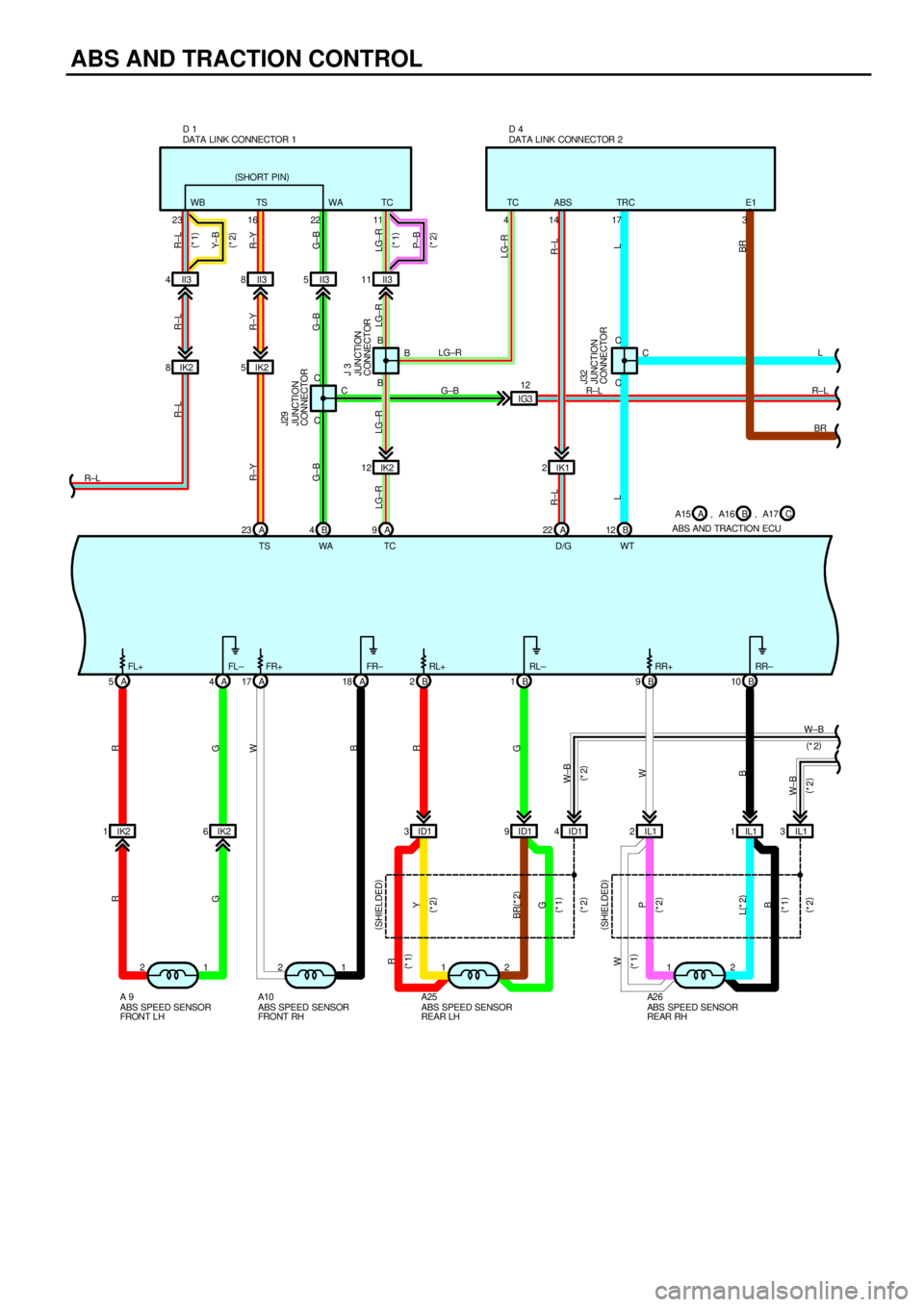

ABS AND TRACTION CONTROL

II3 4II38II35II311

IK2 8IK25

A 23 B4A9IK2 12 IK12

A 22 B12 CB CB

B

C 23 16 22 11 4 14 17

TS WA TC D/G WT TS TC TC ABS TRC

L G±BR±YR±L R±L

R±Y

G±B

LG±R LG±R LG±RR±Y

G±B

R±L

LR±L LG±R

L

R±L DATA LINK CONNECTOR 1 D 1

DATA LINK CONNECTOR 2 D 4

JUNCTION

CONNECTOR J 3 JUNCTION

CONNECTOR J29

ABS AND TRACTION ECU R±L(

SHORT PIN)

WB WA

G±B LG±R

R±L

A 5A4A17 A18 B2B1

1 21221 ID1 3ID19ID14

ABS SPEED SENSOR

FRONT L H A 9

ABS SPEED SENSOR

FRONT RH A10

ABS SPEED SENSOR

REAR LH A25B 9B10

2 1 IL1 2IL11IL13

ABS SPEED SENSOR

REAR RH A2 6 FL+ FL± FR+ FR± RL+ RL± RR+ RR±

B W W±BR

G

W

B

R

G R

G

Y

BR(

*2)

P

L(

*2) (

SHIELDED) (

SHIELDED)

W± B

IG312

R±LE1

BR 3

C C

C

JUNCTION

CONNECTOR J32

A A15 BA16 , C, A17

BRY± B

(

*2)

P± B

(

*2) (

*1)

LG±R

(

*1)

IK2 1IK26

R

(

*1)

G

(

*1) (

*2)

(

*2)

(

*2) W

(

*1)

(

*1) B

(

*2)

W±B

(

*2)

(

*2) (

*2)