engine TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 978 of 2389

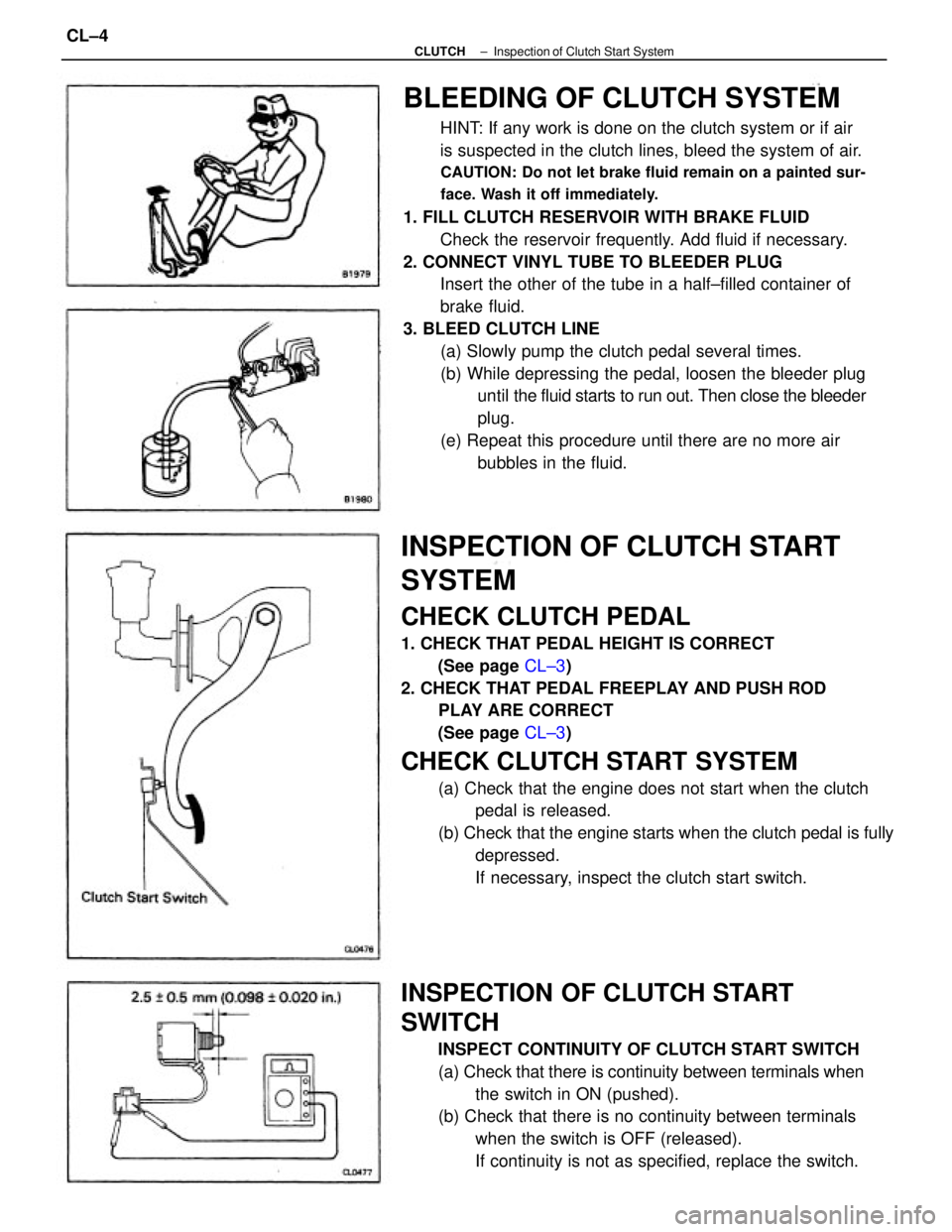

BLEEDING OF CLUTCH SYSTEM

HINT: If any work is done on the clutch system or if air

is suspected in the clutch lines, bleed the system of air.

CAUTION: Do not let brake fluid remain on a painted sur-

face. Wash it off immediately.

1. FILL CLUTCH RESERVOIR WITH BRAKE FLUID

Check the reservoir frequently. Add fluid if necessary.

2. CONNECT VINYL TUBE TO BLEEDER PLUG

Insert the other of the tube in a half±filled container of

brake fluid.

3. BLEED CLUTCH LINE

(a) Slowly pump the clutch pedal several times.

(b) While depressing the pedal, loosen the bleeder plug

until the fluid starts to run out. Then close the bleeder

plug.

(e) Repeat this procedure until there are no more air

bubbles in the fluid.

INSPECTION OF CLUTCH START

SYSTEM

CHECK CLUTCH PEDAL

1. CHECK THAT PEDAL HEIGHT IS CORRECT

(See page CL±3)

2. CHECK THAT PEDAL FREEPLAY AND PUSH ROD

PLAY ARE CORRECT

(See page CL±3)

CHECK CLUTCH START SYSTEM

(a) Check that the engine does not start when the clutch

pedal is released.

(b) Check that the engine starts when the clutch pedal is fully

depressed.

If necessary, inspect the clutch start switch.

INSPECTION OF CLUTCH START

SWITCH

INSPECT CONTINUITY OF CLUTCH START SWITCH

(a) Check that there is continuity between terminals when

the switch in ON (pushed).

(b) Check that there is no continuity between terminals

when the switch is OFF (released).

If continuity is not as specified, replace the switch.

± CLUTCHInspection of Clutch Start SystemCL±4

Page 983 of 2389

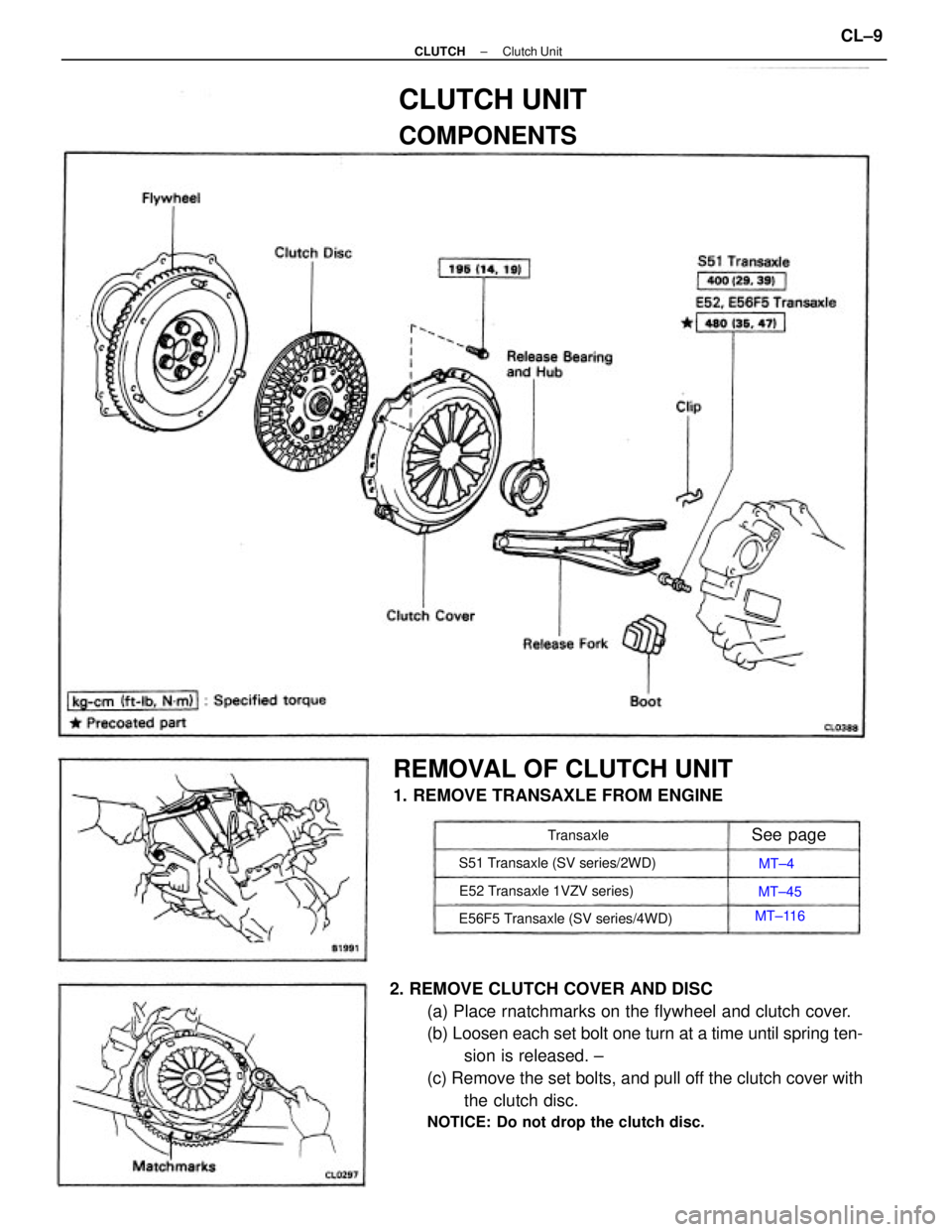

2. REMOVE CLUTCH COVER AND DISC

(a) Place rnatchmarks on the flywheel and clutch cover.

(b) Loosen each set bolt one turn at a time until spring ten-

sion is released. ±

(c) Remove the set bolts, and pull off the clutch cover with

the clutch disc.

NOTICE: Do not drop the clutch disc.

REMOVAL OF CLUTCH UNIT

1. REMOVE TRANSAXLE FROM ENGINE

CLUTCH UNIT

COMPONENTS

E56F5 Transaxle (SV series/4WD) S51 Transaxle (SV series/2WD)

E52 Transaxle 1VZV series)

See pageTransaxle

MT±116MT±45MT±4

± CLUTCHClutch UnitCL±9

Page 986 of 2389

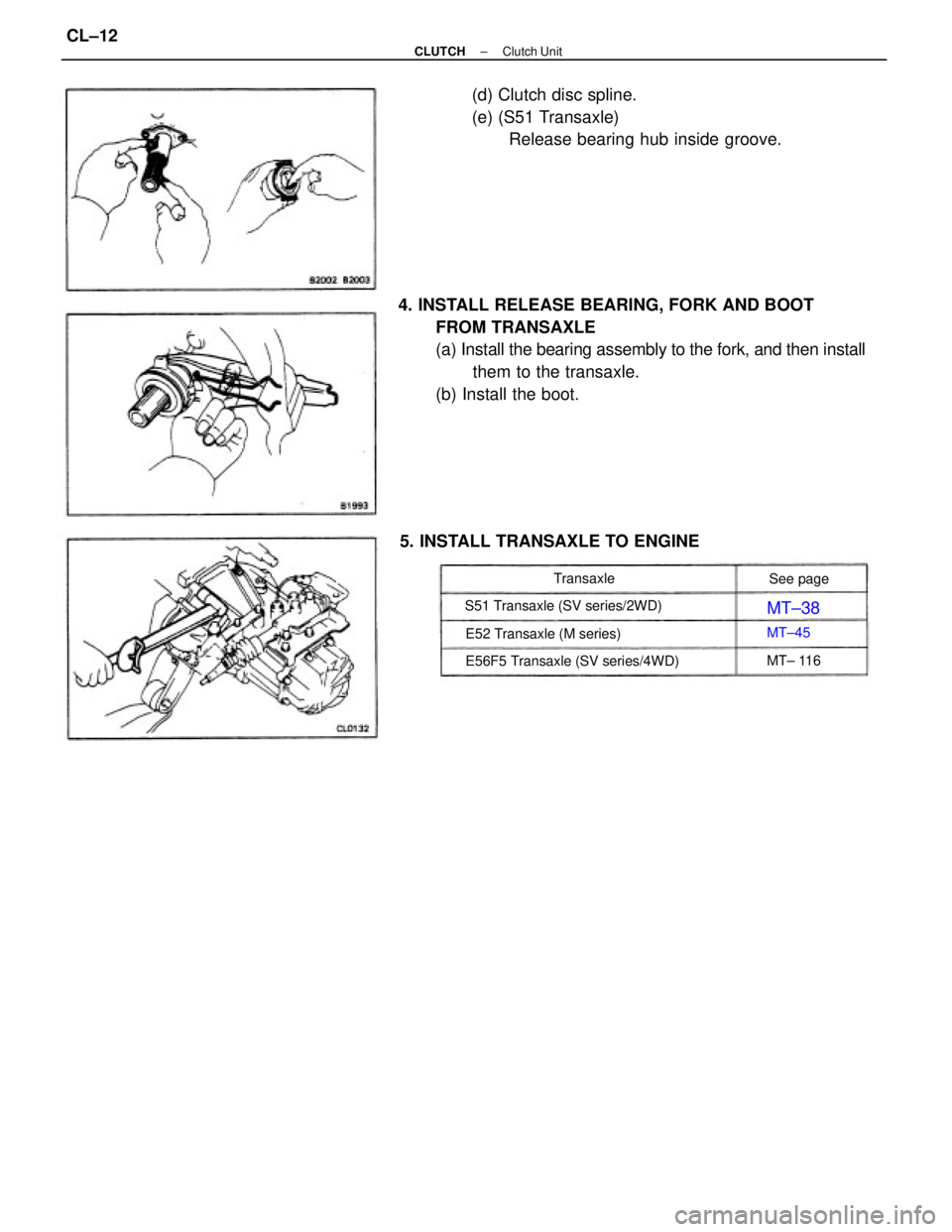

4. INSTALL RELEASE BEARING, FORK AND BOOT

FROM TRANSAXLE

(a) Install the bearing assembly to the fork, and then install

them to the transaxle.

(b) Install the boot.(d) Clutch disc spline.

(e) (S51 Transaxle)

Release bearing hub inside groove.

5. INSTALL TRANSAXLE TO ENGINE

E56F5 Transaxle (SV series/4WD) S51 Transaxle (SV series/2WD)

E52 Transaxle (M series)Transaxle

See page

MT± 116 MT±45

MT±38

± CLUTCHClutch UnitCL±12

Page 988 of 2389

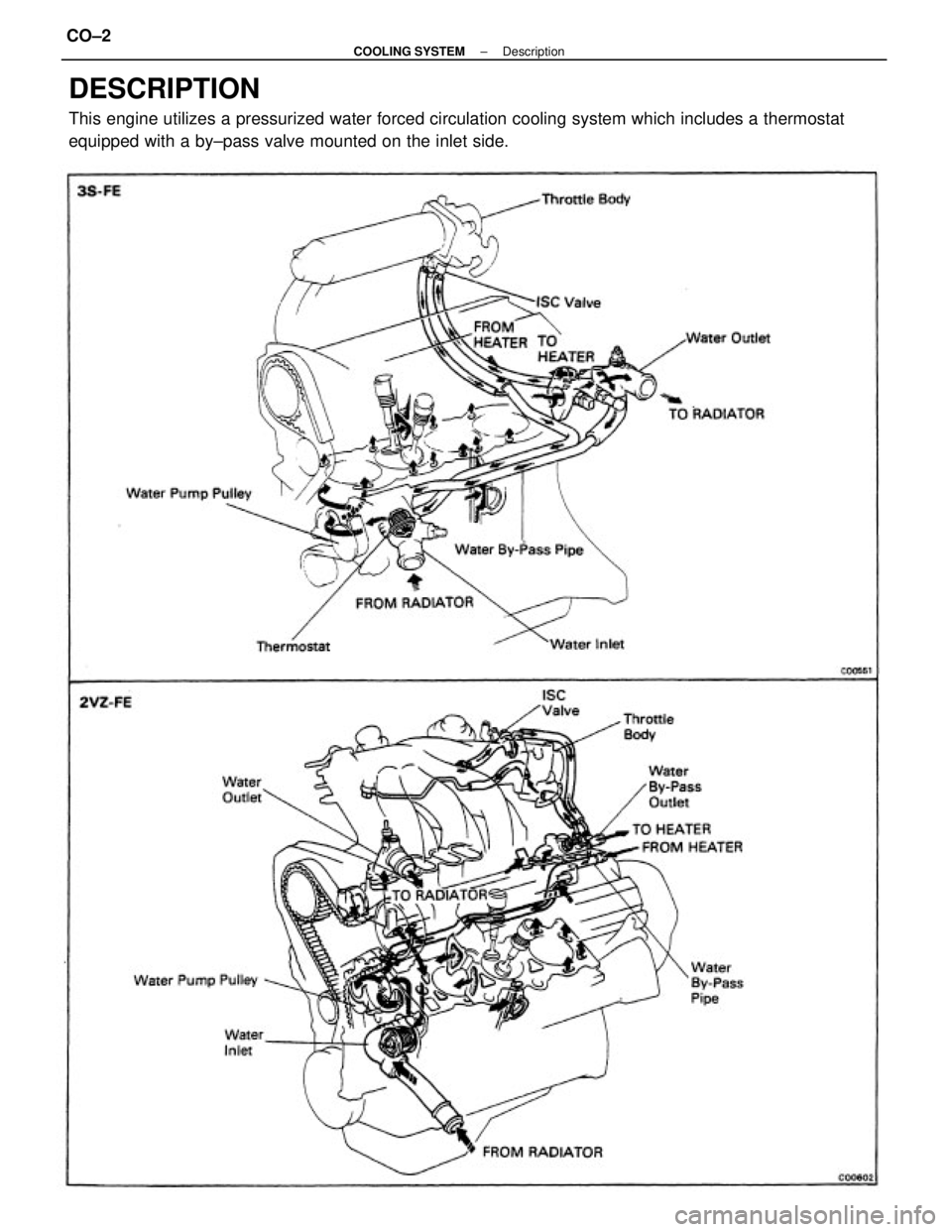

DESCRIPTION

This engine utilizes a pressurized water forced circulation cooling system which includes a thermostat

equipped with a by±pass valve mounted on the inlet side.

± COOLING SYSTEMDescriptionCO±2

Page 989 of 2389

The cooling system is composed of the water jacket (inside the cylinder block and cylinder head), radiator,

water pump, thermostat, electric fan, hoses and other components.

Coolant which is heated in the water jacket is pumped to the radiator, through which an electric fan blows air

to cool the coolant as it passes through. Coolant which has been cooled is then sent back to the engine by

the water pump, where it cools the engine.

The water jacket is a network of channels in the shell of the cylinder block and cylinder head through which

coolant passes. It is designed to provide adequate cooling of the cylinders and combustion chambers which

become heated during engine operation.

RADIATOR

The radiator performs the function of cooling the coolant which has passed through the water jacket and be-

come hot, and it is mounted in the front of the vehicle. The radiator consists of an upper tank and lower tank,

and a core which connects the two tanks. The upper tank contains the inlet for coolant from the water jacket

and the filler inlet. It also has a hose attached through which excess coolant or steam can flow. The lower

tank has an outlet and drain cock for the coolant. The core contains many tubes through which coolant flows

from the upper tank to the lower tank as well as cooling fins which radiate heat away from the coolant in the

tubes.

The air sucked through the radiator by the electric fan, as well as the wind generated by the vehicle's travel,

passes through the radiator, cooling the coolant. Models with automatic transmission include an automatic

transmission fluid cooler built into the lower tank of the radiator. A fan with an electric motor is mounted be-

hind the radiator to assist the flow of air through the radiator. The fan operates when the coolant tempera-

ture becomes high in order to prevent it from becoming too high.

RADIATOR CAP

The radiator cap is a pressure type cap which seals the radiator, resulting in pressurization of the radiator as

the coolant expands. The pressurization prevents the coolant from boiling even when the coolant tempera-

ture exceeds 100°C (212°F). A relief valve (pressurization valve) and a vacuum valve (negative pressure

valve) are built into the radiator cap. The relief valve opens and lets steam escape through the overflow pipe

when the pressure generated inside the cooling system exceeds the limit (coolant temperature: 110 ±

120°C, 230 ± 248°F, pressure; 0.3 ±1.0 kg/cm

2, 4.3 ±14.2 psi, 29.4 ± 98.1 kPa). The vacuum valve opens to

alleviate the vacuum which develops in the coolant system after the engine is stopped and the coolant tem-

perature drops.

The valves's opening allows the coolant in the reservoir tank to return to the cooling system.

RESERVOIR TANK

The reservoir tank is used to catch coolant which overflows the cooling system as a result of volumetric ex-

pansion when the coolant is heated. The coolant in the reservoir rank returns to the radiator when the cool-

ant temperature drops, thus keeping the radiator full at all times and avoiding needless coolant loss. Check

the reservoir tank level to find out if the coolant needs to be replenished.

WATER PUMP

The water pump is used for forced circulation of coolant through the cooling system. It is mounted on the

front of the cylinder block and driven by a timing belt.

THERMOSTAT

The thermostat has a wax type by±pass valve and is mounted in the water inlet housing. The thermostat in-

cludes a type of automatic valve operated by fluctuations in the coolant temperature. This valve closes when

the coolant temperature drops, preventing the circulation of coolant through the engine and thus permitting

the engine to warm up rapidly. The valve opens when the coolant temperature has risen, allowing the cir-

culation of coolant. Wax inside the thermostat expands when heated and contracts when cooled. Heating

the wax thus generates pressure which overpowers the force of the spring which keeps±the valve closed,

thus opening the valve. When the wax cools, its contraction causes the force of the spring to take effect

once more, closing the valve. The thermostat in this engine operates at a temperature of 82°C (180°F).

± COOLING SYSTEMDescriptionCO±3

Page 990 of 2389

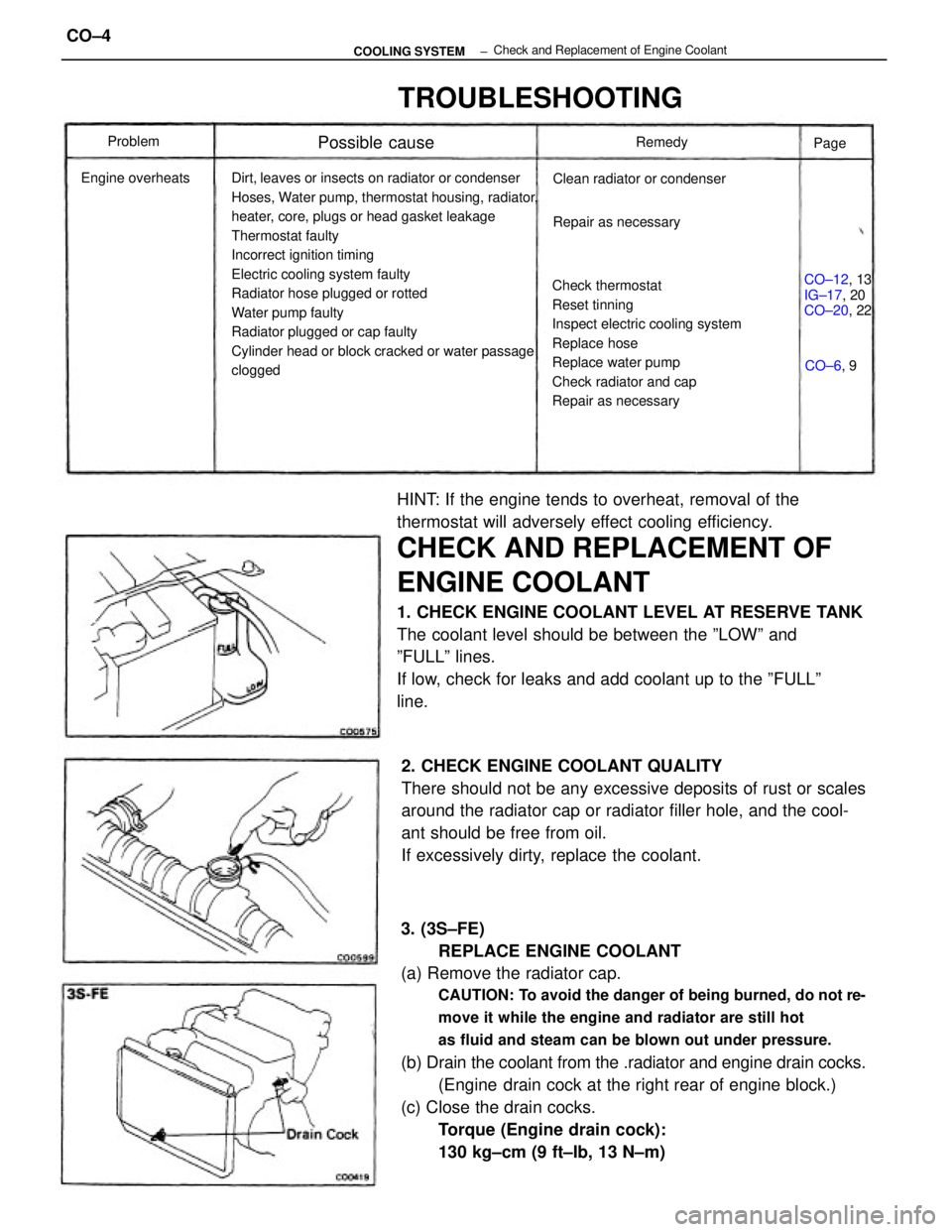

3. (3S±FE)

REPLACE ENGINE COOLANT

(a) Remove the radiator cap.

CAUTION: To avoid the danger of being burned, do not re-

move it while the engine and radiator are still hot

as fluid and steam can be blown out under pressure.

(b) Drain the coolant from the .radiator and engine drain cocks.

(Engine drain cock at the right rear of engine block.)

(c) Close the drain cocks.

Torque (Engine drain cock):

130 kg±cm (9 ft±Ib, 13 N±m) HINT: If the engine tends to overheat, removal of the

thermostat will adversely effect cooling efficiency.

CHECK AND REPLACEMENT OF

ENGINE COOLANT

1. CHECK ENGINE COOLANT LEVEL AT RESERVE TANK

The coolant level should be between the ºLOWº and

ºFULLº lines.

If low, check for leaks and add coolant up to the ºFULLº

line.

Dirt, leaves or insects on radiator or condenser

Hoses, Water pump, thermostat housing, radiator,

heater, core, plugs or head gasket leakage

Thermostat faulty

Incorrect ignition timing

Electric cooling system faulty

Radiator hose plugged or rotted

Water pump faulty

Radiator plugged or cap faulty

Cylinder head or block cracked or water passage

clogged

2. CHECK ENGINE COOLANT QUALITY

There should not be any excessive deposits of rust or scales

around the radiator cap or radiator filler hole, and the cool-

ant should be free from oil.

If excessively dirty, replace the coolant.

Check thermostat

Reset tinning

Inspect electric cooling system

Replace hose

Replace water pump

Check radiator and cap

Repair as necessary

TROUBLESHOOTING

CO±12, 13

IG±17, 20

CO±20, 22 Clean radiator or condenser

Repair as necessary Engine overheats

Possible causeRemedy Problem

CO±6, 9 Page

± COOLING SYSTEM

TroubleshootingCO±4

Page 991 of 2389

3. (3S±FE)

REPLACE ENGINE COOLANT

(a) Remove the radiator cap.

CAUTION: To avoid the danger of being burned, do not re-

move it while the engine and radiator are still hot

as fluid and steam can be blown out under pressure.

(b) Drain the coolant from the .radiator and engine drain cocks.

(Engine drain cock at the right rear of engine block.)

(c) Close the drain cocks.

Torque (Engine drain cock):

130 kg±cm (9 ft±Ib, 13 N±m) HINT: If the engine tends to overheat, removal of the

thermostat will adversely effect cooling efficiency.

CHECK AND REPLACEMENT OF

ENGINE COOLANT

1. CHECK ENGINE COOLANT LEVEL AT RESERVE TANK

The coolant level should be between the ºLOWº and

ºFULLº lines.

If low, check for leaks and add coolant up to the ºFULLº

line.

Dirt, leaves or insects on radiator or condenser

Hoses, Water pump, thermostat housing, radiator,

heater, core, plugs or head gasket leakage

Thermostat faulty

Incorrect ignition timing

Electric cooling system faulty

Radiator hose plugged or rotted

Water pump faulty

Radiator plugged or cap faulty

Cylinder head or block cracked or water passage

clogged

2. CHECK ENGINE COOLANT QUALITY

There should not be any excessive deposits of rust or scales

around the radiator cap or radiator filler hole, and the cool-

ant should be free from oil.

If excessively dirty, replace the coolant.

Check thermostat

Reset tinning

Inspect electric cooling system

Replace hose

Replace water pump

Check radiator and cap

Repair as necessary

TROUBLESHOOTING

CO±12, 13

IG±17, 20

CO±20, 22 Clean radiator or condenser

Repair as necessary Engine overheats

Possible causeRemedy Problem

CO±6, 9 Page

± COOLING SYSTEMCheck and Replacement of Engine CoolantCO±4

Page 992 of 2389

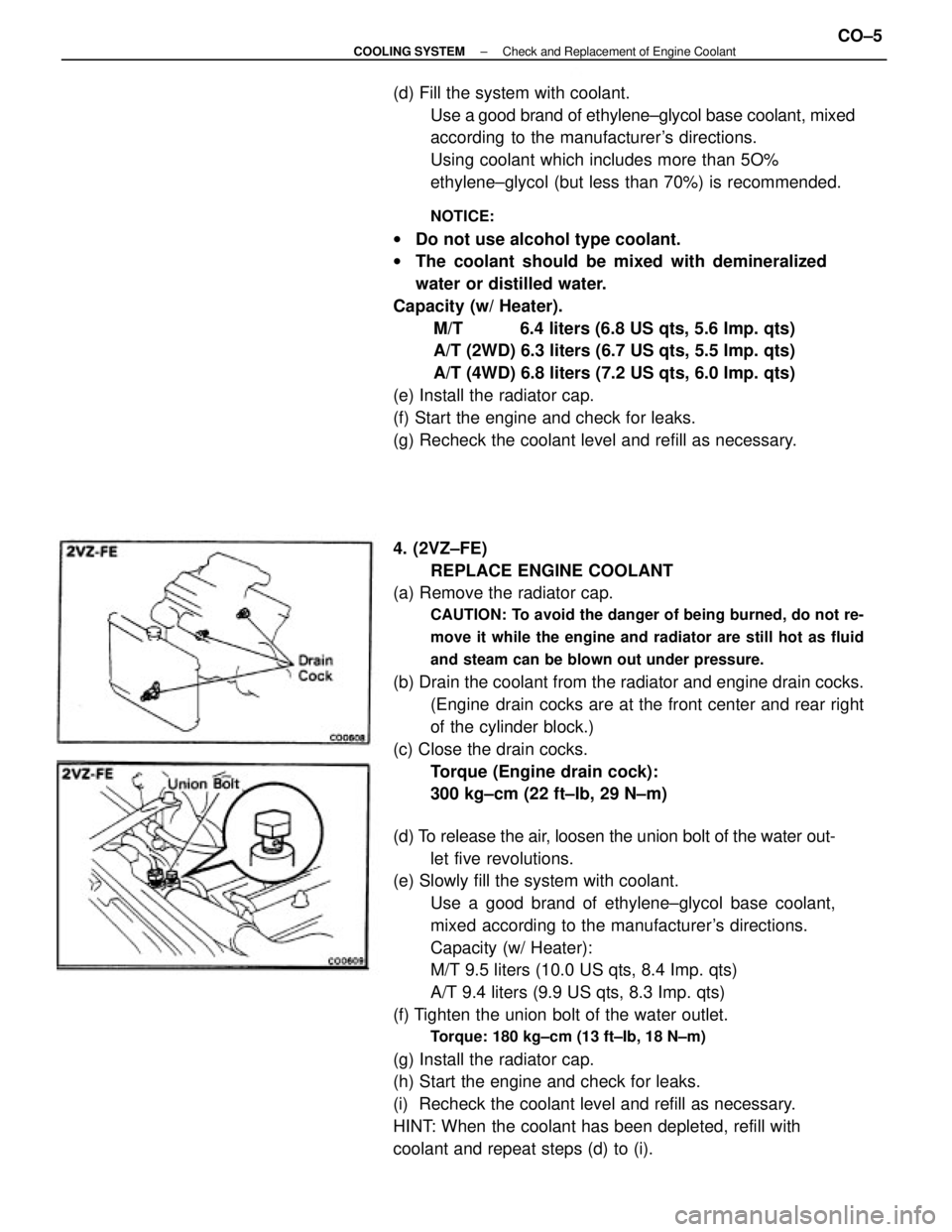

(d) To release the air, loosen the union bolt of the water out-

let five revolutions.

(e) Slowly fill the system with coolant.

Use a good brand of ethylene±glycol base coolant,

mixed according to the manufacturer's directions.

Capacity (w/ Heater):

M/T 9.5 liters (10.0 US qts, 8.4 Imp. qts)

A/T 9.4 liters (9.9 US qts, 8.3 Imp. qts)

(f) Tighten the union bolt of the water outlet.

Torque: 180 kg±cm (13 ft±Ib, 18 N±m)

(g) Install the radiator cap.

(h) Start the engine and check for leaks.

(i) Recheck the coolant level and refill as necessary.

HINT: When the coolant has been depleted, refill with

coolant and repeat steps (d) to (i). 4. (2VZ±FE)

REPLACE ENGINE COOLANT

(a) Remove the radiator cap.

CAUTION: To avoid the danger of being burned, do not re-

move it while the engine and radiator are still hot as fluid

and steam can be blown out under pressure.

(b) Drain the coolant from the radiator and engine drain cocks.

(Engine drain cocks are at the front center and rear right

of the cylinder block.)

(c) Close the drain cocks.

Torque (Engine drain cock):

300 kg±cm (22 ft±Ib, 29 N±m)

NOTICE:

wDo not use alcohol type coolant.

wThe coolant should be mixed with demineralized

water or distilled water.

Capacity (w/ Heater).

M/T 6.4 liters (6.8 US qts, 5.6 Imp. qts)

A/T (2WD) 6.3 liters (6.7 US qts, 5.5 Imp. qts)

A/T (4WD) 6.8 liters (7.2 US qts, 6.0 Imp. qts)

(e) Install the radiator cap.

(f) Start the engine and check for leaks.

(g) Recheck the coolant level and refill as necessary. (d) Fill the system with coolant.

Use a good brand of ethylene±glycol base coolant, mixed

according to the manufacturer's directions.

Using coolant which includes more than 5O%

ethylene±glycol (but less than 70%) is recommended.

± COOLING SYSTEMCheck and Replacement of Engine CoolantCO±5

Page 993 of 2389

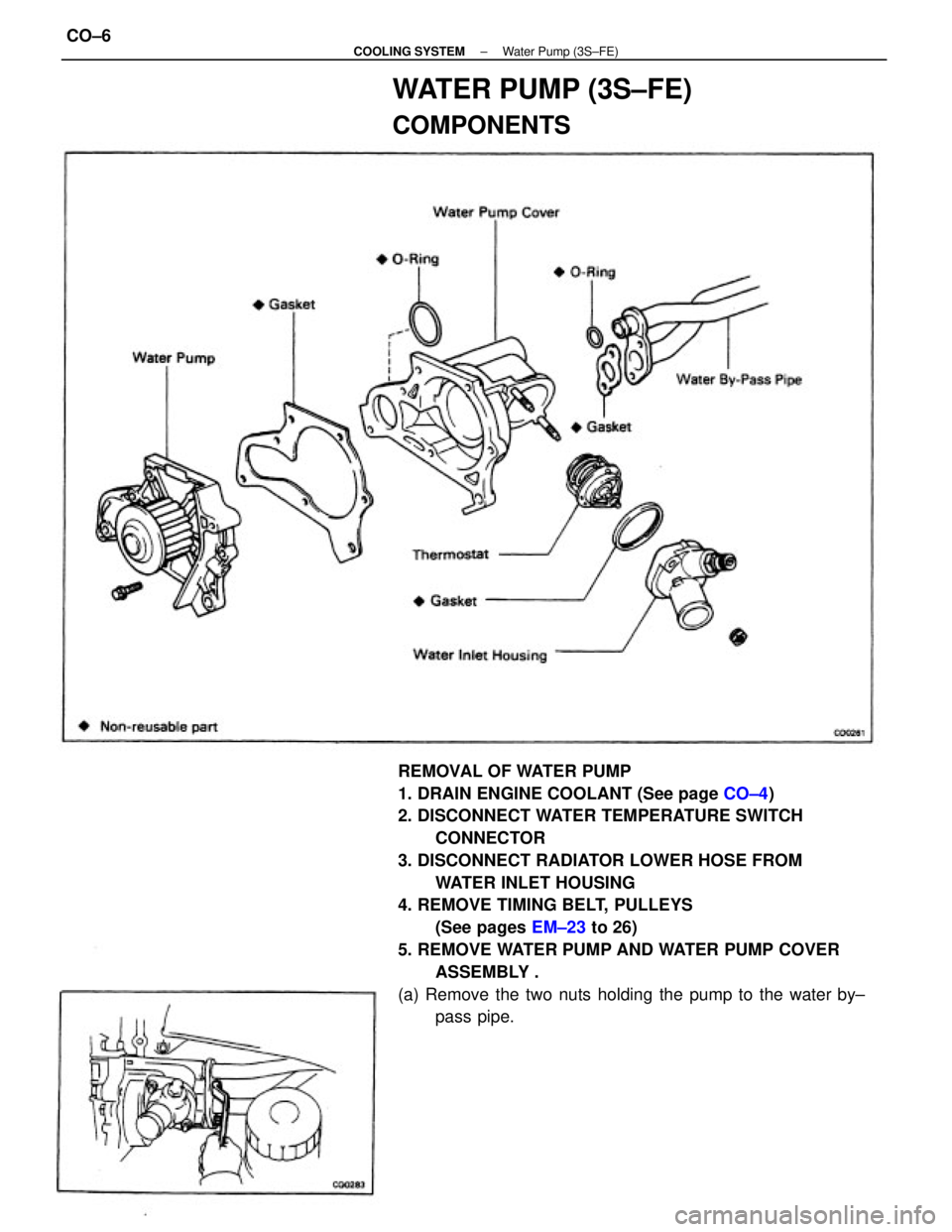

REMOVAL OF WATER PUMP

1. DRAIN ENGINE COOLANT (See page CO±4)

2. DISCONNECT WATER TEMPERATURE SWITCH

CONNECTOR

3. DISCONNECT RADIATOR LOWER HOSE FROM

WATER INLET HOUSING

4. REMOVE TIMING BELT, PULLEYS

(See pages EM±23 to 26)

5. REMOVE WATER PUMP AND WATER PUMP COVER

ASSEMBLY .

(a) Remove the two nuts holding the pump to the water by±

pass pipe.

WATER PUMP (3S±FE)

COMPONENTS

± COOLING SYSTEMWater Pump (3S±FE)CO±6

Page 995 of 2389

(b) Apply a fight coat of engine oil on the 4±ring of the water

by±pass pipe.

(c) Connect the pump cover to the water by±pass pipe. Do

not install the nuts yet.

(d) Install the water pump with the three bolts. Torque the

bolts in the sequence shown.

Torque: 95 kg±cm (82 in.±Ib, 9.3 N±m)

3. INSTALL PULLEYS AND TIMING BELT (See pages

EM±29 to 33)

4. CONNECT RADIATOR LOWER HOSE

5. CONNECT WATER TEMPERATURE SWITCH

CONNECTOR

6. FILL WITH ENGINE COOLANT (See page CO±5) (e) Install the two nuts holding the pump cover to the water

by±pass pipe.

Torque: 95 kg±cm (82 in.±Ib, 9.3 N±m)

± COOLING SYSTEMWater Pump PS±FE)CO±8