TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1311 of 2389

5. INSTALL PS OIL RESERVOIR TANK

Install the two bolts.

6. CONNECT ENGINE WIRE

(a) Push in the engine wire through the cowl panel.

(b) Connect the following connectors.

(1) Three TCCS ECU connectors

(2) Circuit opening relay connector

(3) Cowl wire connector

(4) Instrument panel wire connector

(c) Install the glove compartment box.

7. RAISE VEHICLE

NOTICE: Be sure vehicle is securely supported.

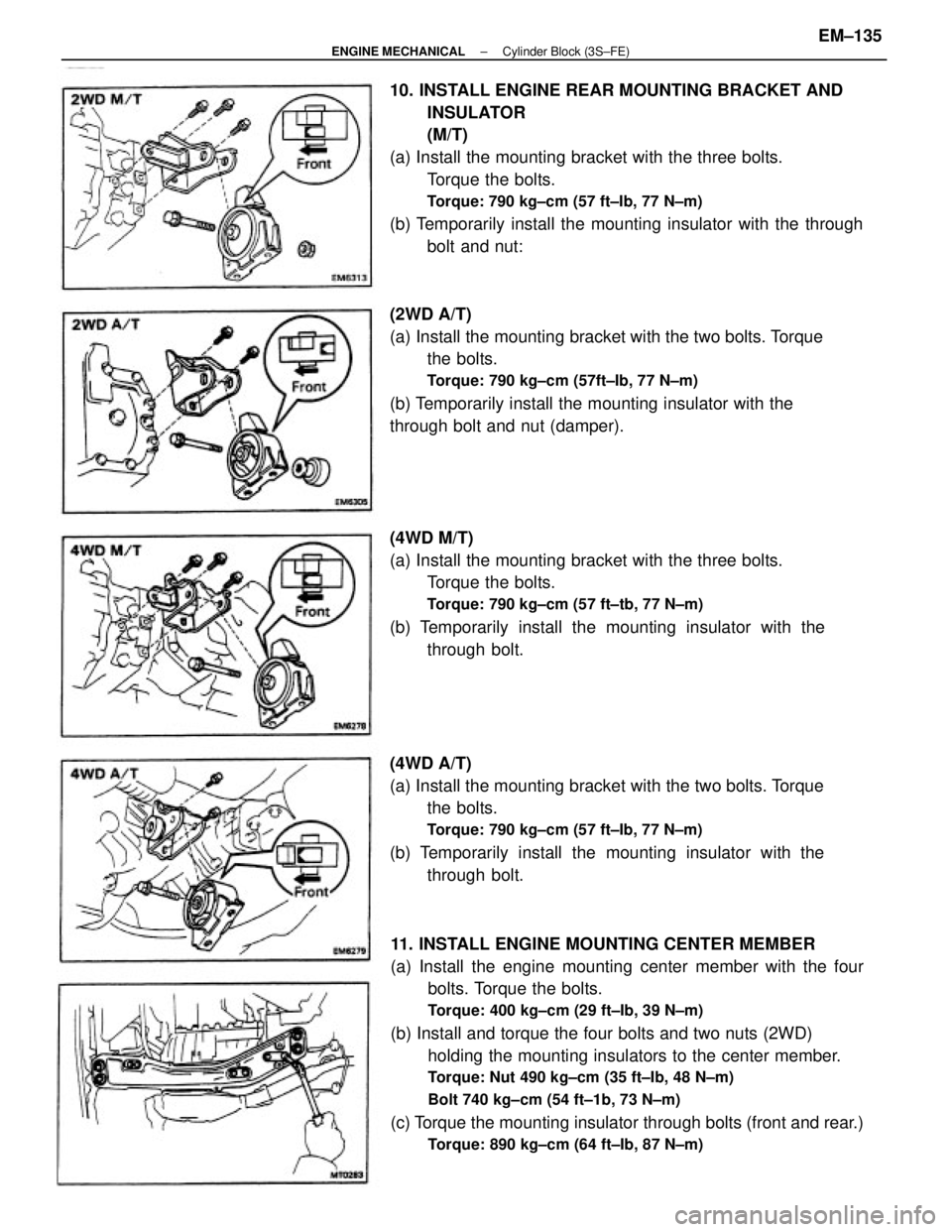

8. INSTALL ENGINE FRONT MOUNTING BRACKET AND

INSULATOR

(a) Install the mounting bracket with the two bolts. Torque the

bolts.

Torque: 790 kg±cm (57 ft±Ib, 77 N±m)

(b) Temporarily install the mounting insulator with the through

bolt and nut.

9. (2WD)

INSTALL ENGINE CENTER MOUNTING BRACKET

AND INSULATOR ASSEMBLY

Install the mounting bracket and insulator assembly with the

two bolts. Torque the bolts.

Torque: 490 kg±cm (35 ft±Ib, 48 N±m)

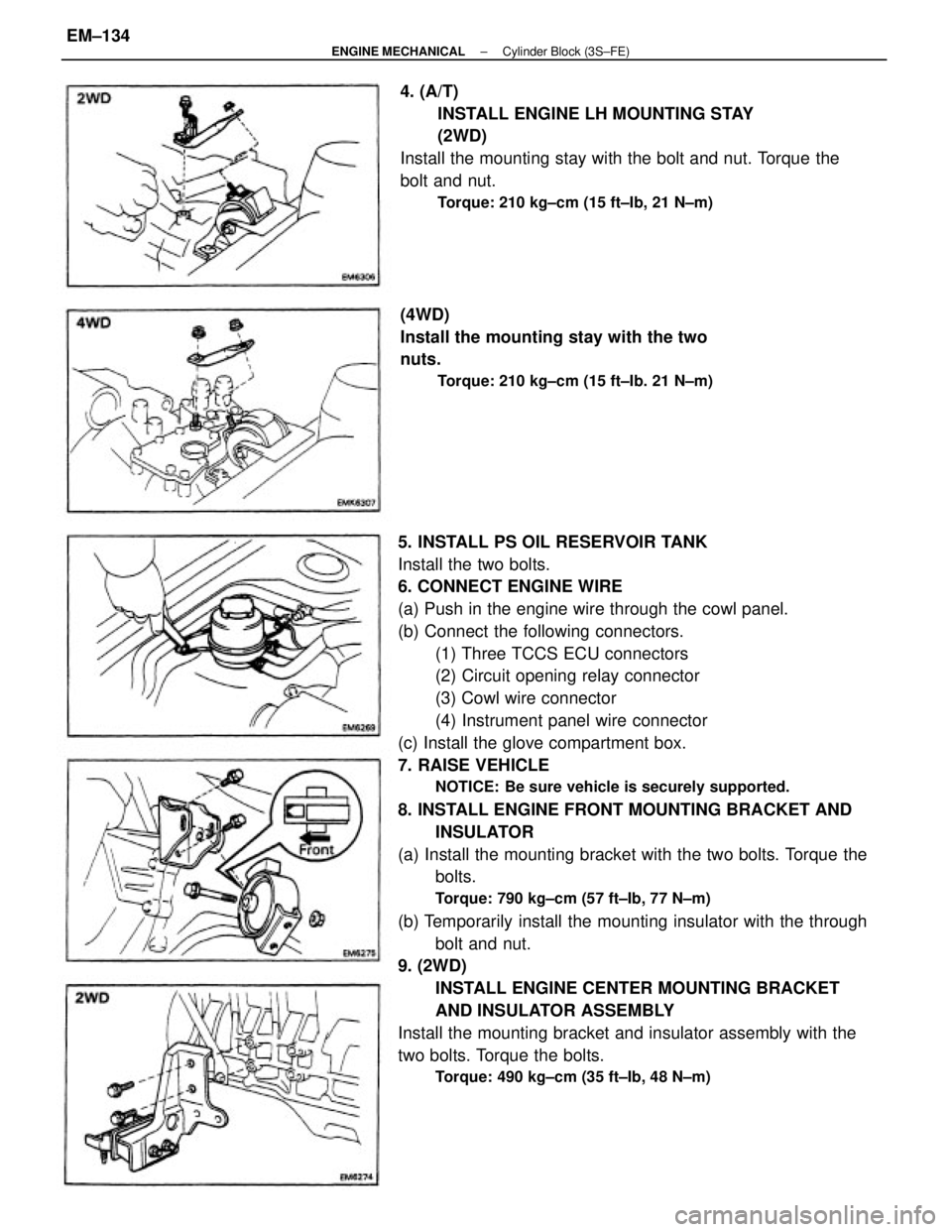

4. (A/T)

INSTALL ENGINE LH MOUNTING STAY

(2WD)

Install the mounting stay with the bolt and nut. Torque the

bolt and nut.

Torque: 210 kg±cm (15 ft±Ib, 21 N±m)

(4WD)

Install the mounting stay with the two

nuts.

Torque: 210 kg±cm (15 ft±Ib. 21 N±m)

± ENGINE MECHANICALCylinder Block (3S±FE)EM±134

Page 1312 of 2389

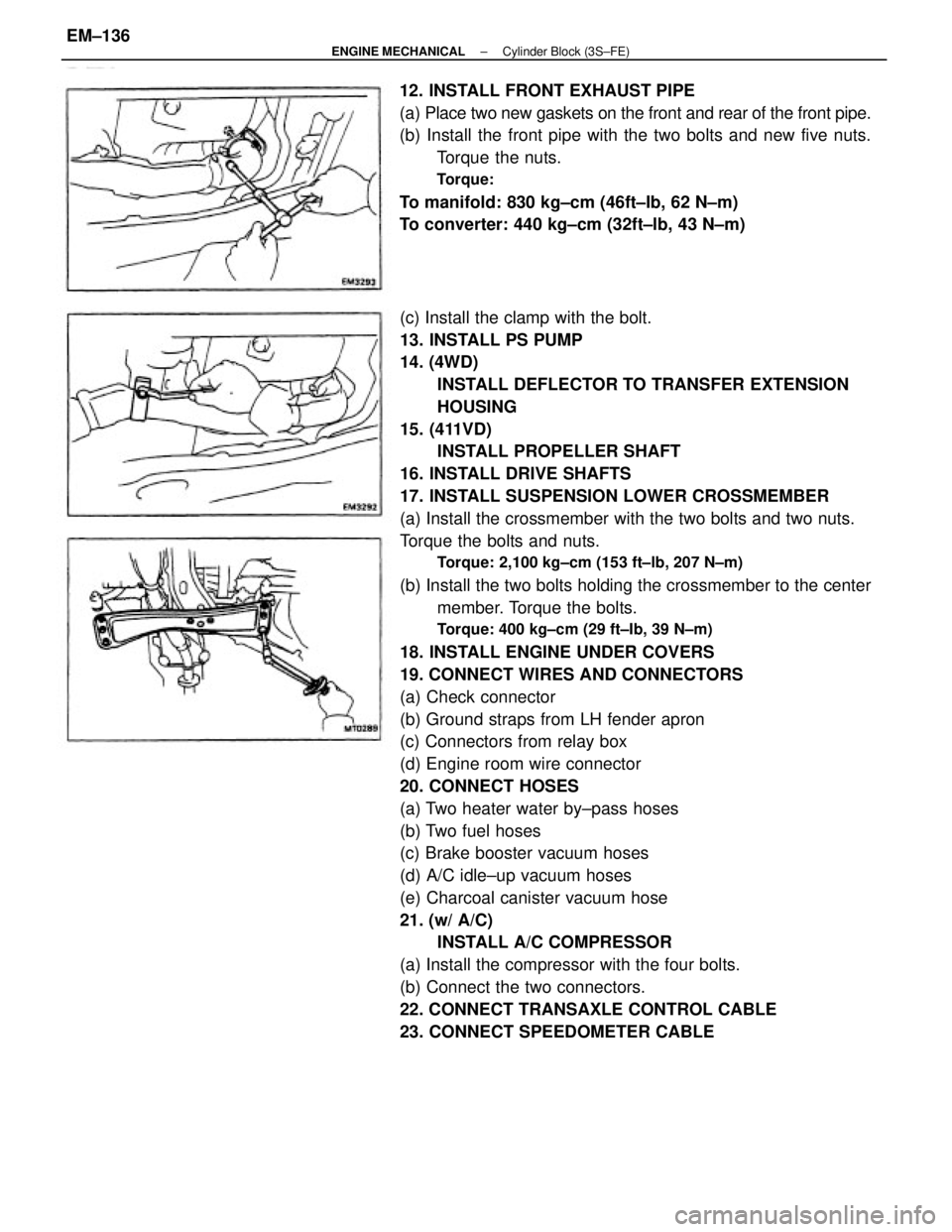

11. INSTALL ENGINE MOUNTING CENTER MEMBER

(a) Install the engine mounting center member with the four

bolts. Torque the bolts.

Torque: 400 kg±cm (29 ft±Ib, 39 N±m)

(b) Install and torque the four bolts and two nuts (2WD)

holding the mounting insulators to the center member.

Torque: Nut 490 kg±cm (35 ft±Ib, 48 N±m)

Bolt 740 kg±cm (54 ft±1b, 73 N±m)

(c) Torque the mounting insulator through bolts (front and rear.)

Torque: 890 kg±cm (64 ft±Ib, 87 N±m)

10. INSTALL ENGINE REAR MOUNTING BRACKET AND

INSULATOR

(M/T)

(a) Install the mounting bracket with the three bolts.

Torque the bolts.

Torque: 790 kg±cm (57 ft±Ib, 77 N±m)

(b) Temporarily install the mounting insulator with the through

bolt and nut:

(4WD M/T)

(a) Install the mounting bracket with the three bolts.

Torque the bolts.

Torque: 790 kg±cm (57 ft±tb, 77 N±m)

(b) Temporarily install the mounting insulator with the

through bolt. (2WD A/T)

(a) Install the mounting bracket with the two bolts. Torque

the bolts.

Torque: 790 kg±cm (57ft±Ib, 77 N±m)

(b) Temporarily install the mounting insulator with the

through bolt and nut (damper).

(4WD A/T)

(a) Install the mounting bracket with the two bolts. Torque

the bolts.

Torque: 790 kg±cm (57 ft±Ib, 77 N±m)

(b) Temporarily install the mounting insulator with the

through bolt.

± ENGINE MECHANICALCylinder Block (3S±FE)EM±135

Page 1313 of 2389

(c) Install the clamp with the bolt.

13. INSTALL PS PUMP

14. (4WD)

INSTALL DEFLECTOR TO TRANSFER EXTENSION

HOUSING

15. (411VD)

INSTALL PROPELLER SHAFT

16. INSTALL DRIVE SHAFTS

17. INSTALL SUSPENSION LOWER CROSSMEMBER

(a) Install the crossmember with the two bolts and two nuts.

Torque the bolts and nuts.

Torque: 2,100 kg±cm (153 ft±lb, 207 N±m)

(b) Install the two bolts holding the crossmember to the center

member. Torque the bolts.

Torque: 400 kg±cm (29 ft±Ib, 39 N±m)

18. INSTALL ENGINE UNDER COVERS

19. CONNECT WIRES AND CONNECTORS

(a) Check connector

(b) Ground straps from LH fender apron

(c) Connectors from relay box

(d) Engine room wire connector

20. CONNECT HOSES

(a) Two heater water by±pass hoses

(b) Two fuel hoses

(c) Brake booster vacuum hoses

(d) A/C idle±up vacuum hoses

(e) Charcoal canister vacuum hose

21. (w/ A/C)

INSTALL A/C COMPRESSOR

(a) Install the compressor with the four bolts.

(b) Connect the two connectors.

22. CONNECT TRANSAXLE CONTROL CABLE

23. CONNECT SPEEDOMETER CABLE 12. INSTALL FRONT EXHAUST PIPE

(a) Place two new gaskets on the front and rear of the front pipe.

(b) Install the front pipe with the two bolts and new five nuts.

Torque the nuts.

Torque:

To manifold: 830 kg±cm (46ft±Ib, 62 N±m)

To converter: 440 kg±cm (32ft±lb, 43 N±m)

± ENGINE MECHANICALCylinder Block (3S±FE)EM±136

Page 1314 of 2389

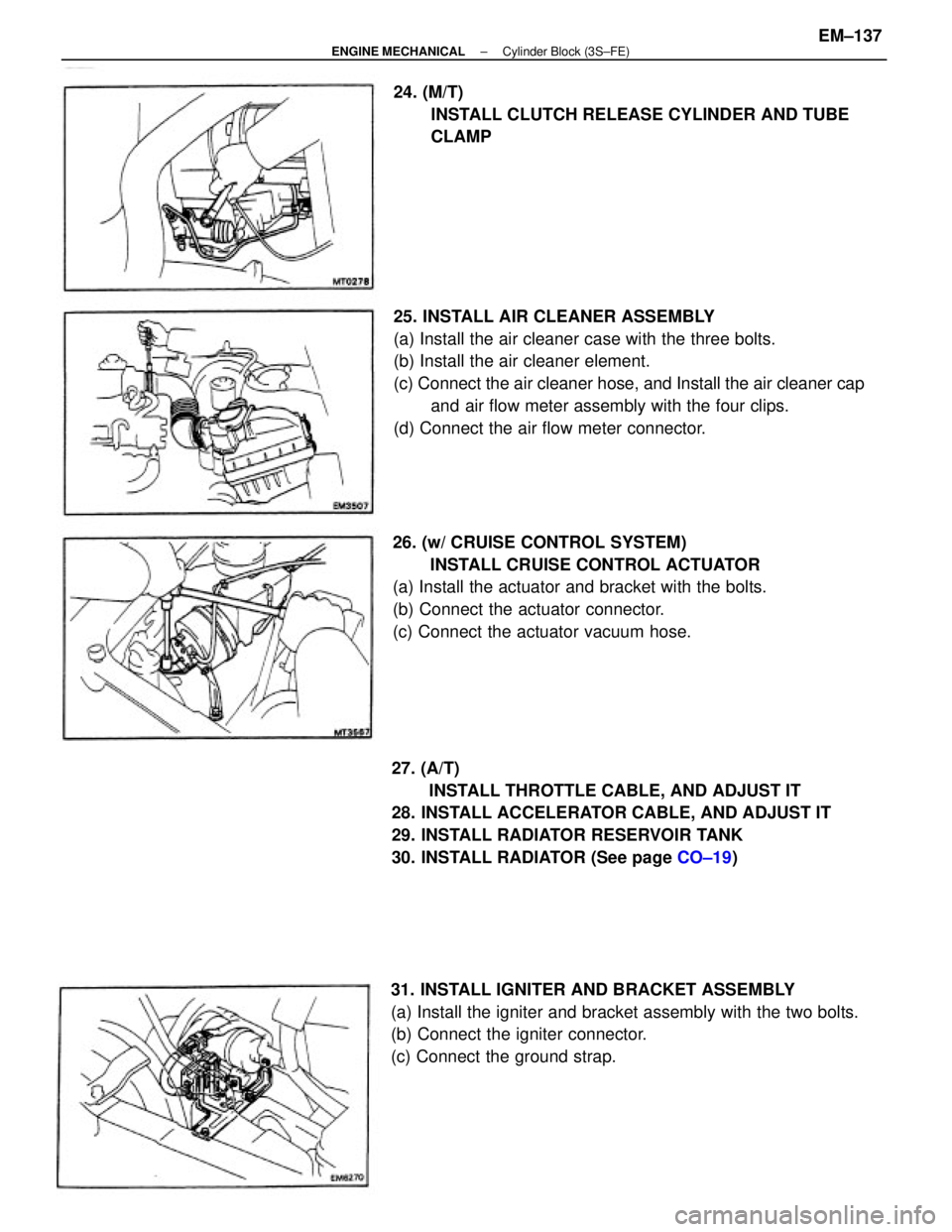

25. INSTALL AIR CLEANER ASSEMBLY

(a) Install the air cleaner case with the three bolts.

(b) Install the air cleaner element.

(c) Connect the air cleaner hose, and Install the air cleaner cap

and air flow meter assembly with the four clips.

(d) Connect the air flow meter connector.

27. (A/T)

INSTALL THROTTLE CABLE, AND ADJUST IT

28. INSTALL ACCELERATOR CABLE, AND ADJUST IT

29. INSTALL RADIATOR RESERVOIR TANK

30. INSTALL RADIATOR (See page CO±19)

31. INSTALL IGNITER AND BRACKET ASSEMBLY

(a) Install the igniter and bracket assembly with the two bolts.

(b) Connect the igniter connector.

(c) Connect the ground strap.26. (w/ CRUISE CONTROL SYSTEM)

INSTALL CRUISE CONTROL ACTUATOR

(a) Install the actuator and bracket with the bolts.

(b) Connect the actuator connector.

(c) Connect the actuator vacuum hose.24. (M/T)

INSTALL CLUTCH RELEASE CYLINDER AND TUBE

CLAMP

± ENGINE MECHANICALCylinder Block (3S±FE)EM±137

Page 1315 of 2389

32. INSTALL BATTERY

33. FILL WITH ENGINE COOLANT (See page CO±5)

Capacity (w/ Heater):

M/T 6.4 liters (6.8 US qts, 5.6 Imp. qts)

A/T (2WD) 6.3 liters (6.7 US qts, 5.5 Imp. qts)

A/T (4WD) 6.8 liters (7.2 US qts, 6.0 Imp. qts)

34. FILL WITH ENGINE OIL (See page LU±8)

Capacity:

Drain and refill

w/ Oil filter change

3.9 liters (4.1 US qts, 3.4 Imp. qts)

w/o Oil filter change

3.7 liters (3.9 US qts, 3.3 Imp. qts)

Dry fill 4.3 liters (4.5 US qts, 3.8 Imp. qts)

35. START ENGINE AND CHECK FOR LEAKS

36. PERFORM ENGINE ADJUSTMENT

(a) Adjust the alternator drive belt.

(See page CH±3)

Drive belt tension:

w/ A/C New belt 175 + 5 lb

Used belt 130 + 10 lb

w/o A/C New belt 125 + 25 lb

Used belt 95 + 20 lb

(b) Adjust the PS drive belt.

Drive belt tension: New belt 125 + 25 lb

Used belt 80 + 20 lb

(c) Adjust the ignition timing.

(See steps 7 to 10 on pages IG±16 and 17)

Ignition timing:

10° BTDC @ idle

(w/ Terminals TE 1 and E1 connected)

(d) Adjust the valve. clearance. (See page EM±11)

Valve clearance:

Intake 0.19 ± 0.29 mm (0.007 ± 0.011 in.)

Exhaust 0.28 ± 0.38 mm (0.011 ± 0.015 in.)

37. INSTALL HOOD

38. PERFORM ROAD TEST

Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

39. RECHECK ENGINE COOLANT AND ENGINE OIL

LEVELS

± ENGINE MECHANICALCylinder Block (3S±FE)EM±138

Page 1316 of 2389

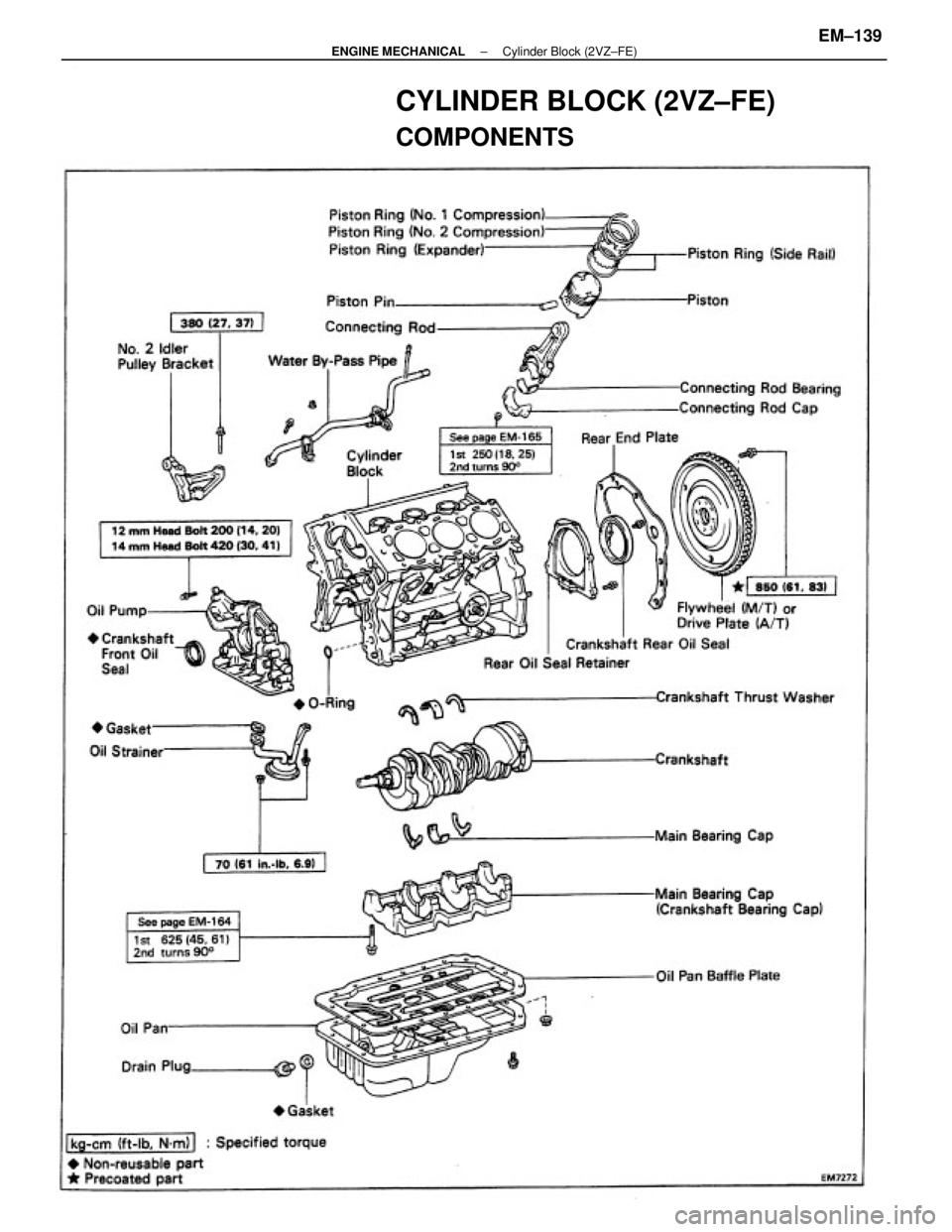

CYLINDER BLOCK (2VZ±FE)

COMPONENTS

± ENGINE MECHANICALCylinder Block (2VZ±FE)EM±139

Page 1317 of 2389

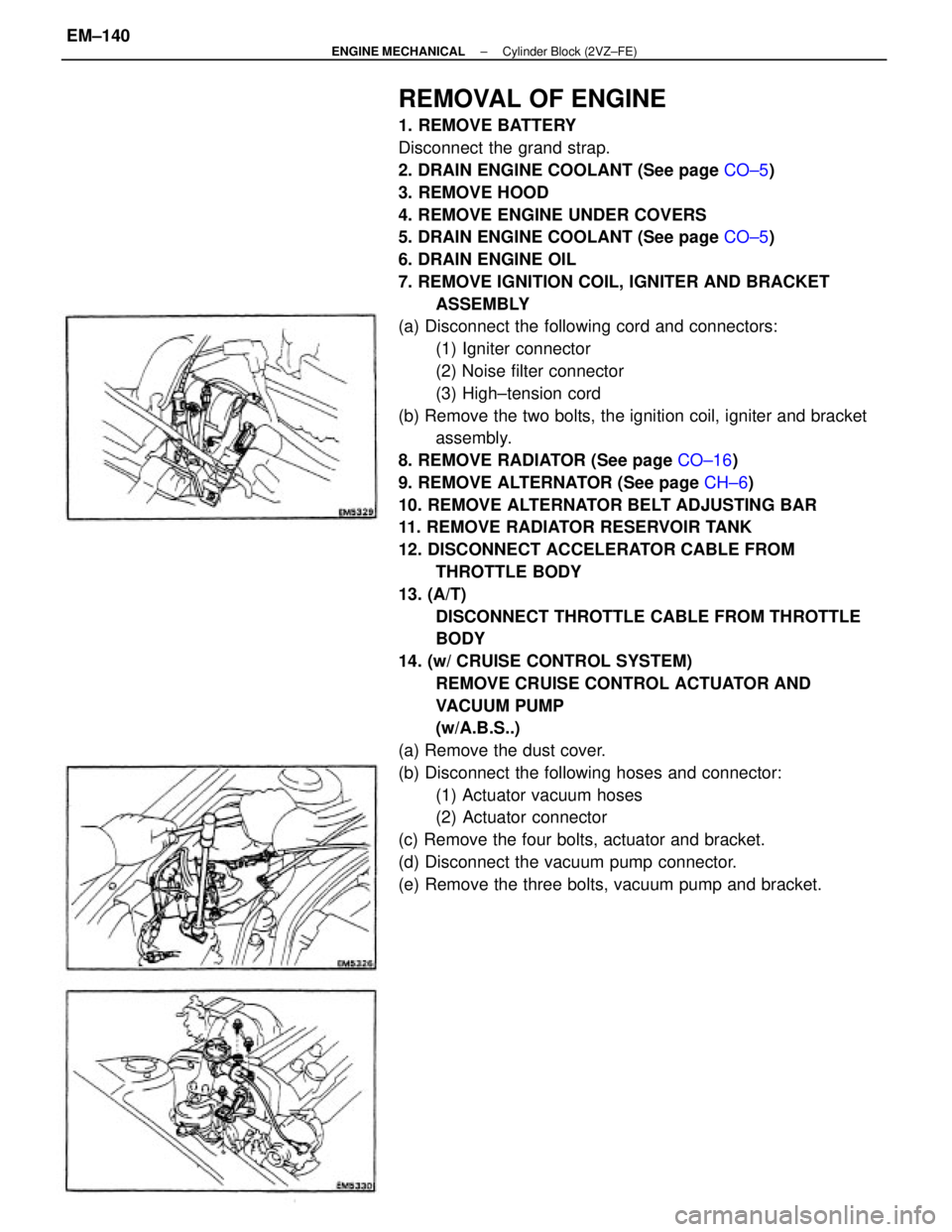

REMOVAL OF ENGINE

1. REMOVE BATTERY

Disconnect the grand strap.

2. DRAIN ENGINE COOLANT (See page CO±5)

3. REMOVE HOOD

4. REMOVE ENGINE UNDER COVERS

5. DRAIN ENGINE COOLANT (See page CO±5)

6. DRAIN ENGINE OIL

7. REMOVE IGNITION COIL, IGNITER AND BRACKET

ASSEMBLY

(a) Disconnect the following cord and connectors:

(1) Igniter connector

(2) Noise filter connector

(3) High±tension cord

(b) Remove the two bolts, the ignition coil, igniter and bracket

assembly.

8. REMOVE RADIATOR (See page CO±16)

9. REMOVE ALTERNATOR (See page CH±6)

10. REMOVE ALTERNATOR BELT ADJUSTING BAR

11. REMOVE RADIATOR RESERVOIR TANK

12. DISCONNECT ACCELERATOR CABLE FROM

THROTTLE BODY

13. (A/T)

DISCONNECT THROTTLE CABLE FROM THROTTLE

BODY

14. (w/ CRUISE CONTROL SYSTEM)

REMOVE CRUISE CONTROL ACTUATOR AND

VACUUM PUMP

(w/A.B.S..)

(a) Remove the dust cover.

(b) Disconnect the following hoses and connector:

(1) Actuator vacuum hoses

(2) Actuator connector

(c) Remove the four bolts, actuator and bracket.

(d) Disconnect the vacuum pump connector.

(e) Remove the three bolts, vacuum pump and bracket.

± ENGINE MECHANICALCylinder Block (2VZ±FE)EM±140

Page 1318 of 2389

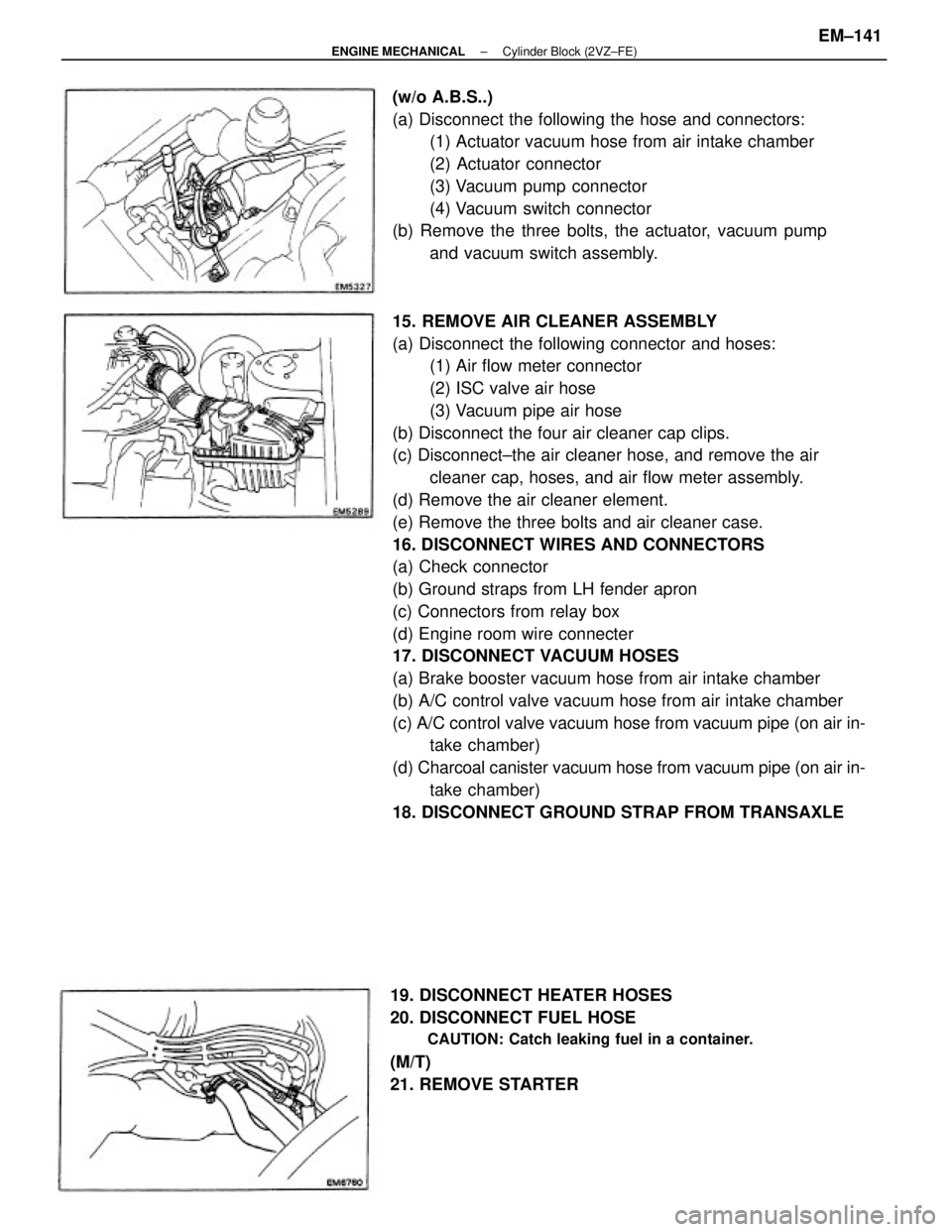

15. REMOVE AIR CLEANER ASSEMBLY

(a) Disconnect the following connector and hoses:

(1) Air flow meter connector

(2) ISC valve air hose

(3) Vacuum pipe air hose

(b) Disconnect the four air cleaner cap clips.

(c) Disconnect±the air cleaner hose, and remove the air

cleaner cap, hoses, and air flow meter assembly.

(d) Remove the air cleaner element.

(e) Remove the three bolts and air cleaner case.

16. DISCONNECT WIRES AND CONNECTORS

(a) Check connector

(b) Ground straps from LH fender apron

(c) Connectors from relay box

(d) Engine room wire connecter

17. DISCONNECT VACUUM HOSES

(a) Brake booster vacuum hose from air intake chamber

(b) A/C control valve vacuum hose from air intake chamber

(c) A/C control valve vacuum hose from vacuum pipe (on air in-

take chamber)

(d) Charcoal canister vacuum hose from vacuum pipe (on air in-

take chamber)

18. DISCONNECT GROUND STRAP FROM TRANSAXLE (w/o A.B.S..)

(a) Disconnect the following the hose and connectors:

(1) Actuator vacuum hose from air intake chamber

(2) Actuator connector

(3) Vacuum pump connector

(4) Vacuum switch connector

(b) Remove the three bolts, the actuator, vacuum pump

and vacuum switch assembly.

19. DISCONNECT HEATER HOSES

20. DISCONNECT FUEL HOSE

CAUTION: Catch leaking fuel in a container.

(M/T)

21. REMOVE STARTER

± ENGINE MECHANICALCylinder Block (2VZ±FE)EM±141

Page 1319 of 2389

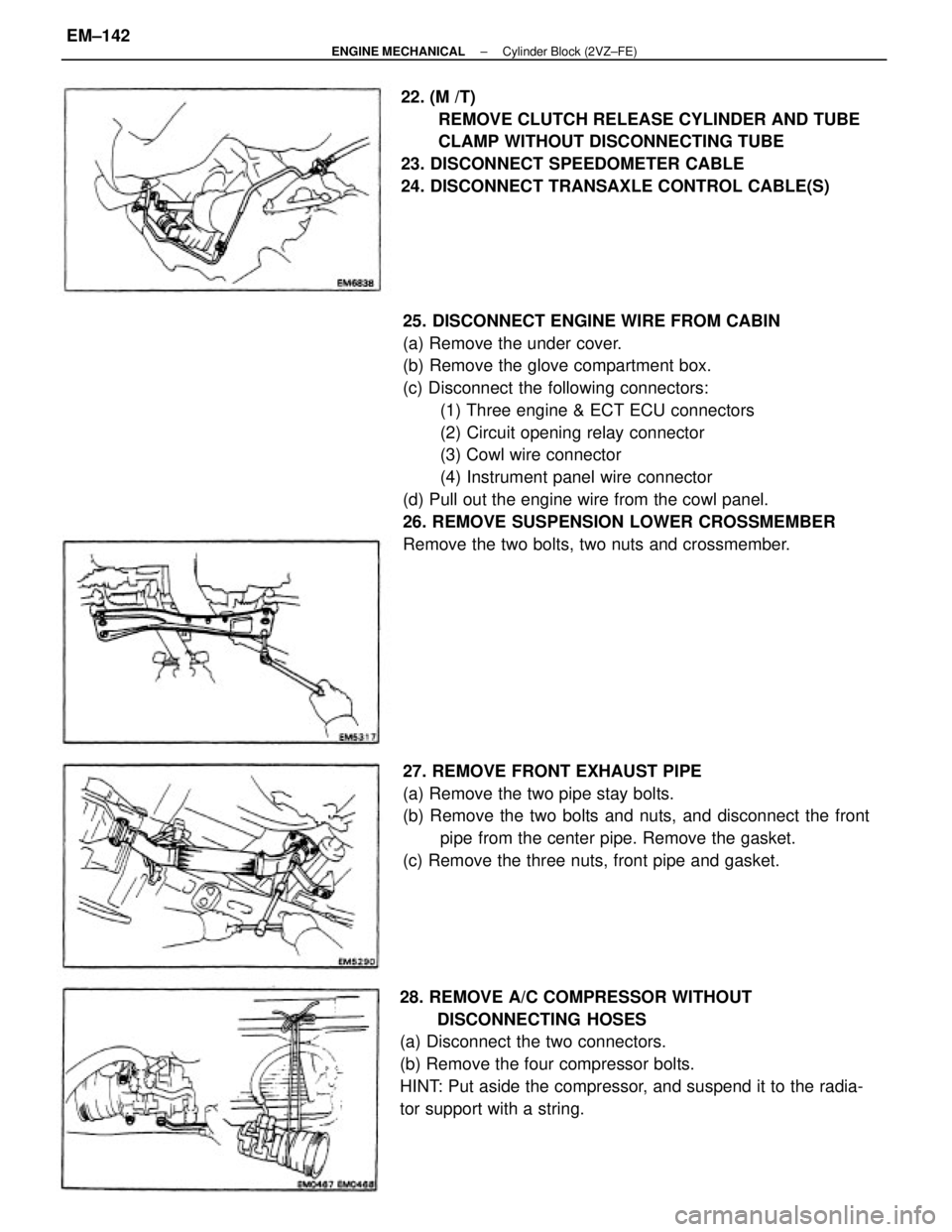

25. DISCONNECT ENGINE WIRE FROM CABIN

(a) Remove the under cover.

(b) Remove the glove compartment box.

(c) Disconnect the following connectors:

(1) Three engine & ECT ECU connectors

(2) Circuit opening relay connector

(3) Cowl wire connector

(4) Instrument panel wire connector

(d) Pull out the engine wire from the cowl panel.

26. REMOVE SUSPENSION LOWER CROSSMEMBER

Remove the two bolts, two nuts and crossmember.

28. REMOVE A/C COMPRESSOR WITHOUT

DISCONNECTING HOSES

(a) Disconnect the two connectors.

(b) Remove the four compressor bolts.

HINT: Put aside the compressor, and suspend it to the radia-

tor support with a string.22. (M /T)

REMOVE CLUTCH RELEASE CYLINDER AND TUBE

CLAMP WITHOUT DISCONNECTING TUBE

23. DISCONNECT SPEEDOMETER CABLE

24. DISCONNECT TRANSAXLE CONTROL CABLE(S)

27. REMOVE FRONT EXHAUST PIPE

(a) Remove the two pipe stay bolts.

(b) Remove the two bolts and nuts, and disconnect the front

pipe from the center pipe. Remove the gasket.

(c) Remove the three nuts, front pipe and gasket.

± ENGINE MECHANICALCylinder Block (2VZ±FE)EM±142

Page 1320 of 2389

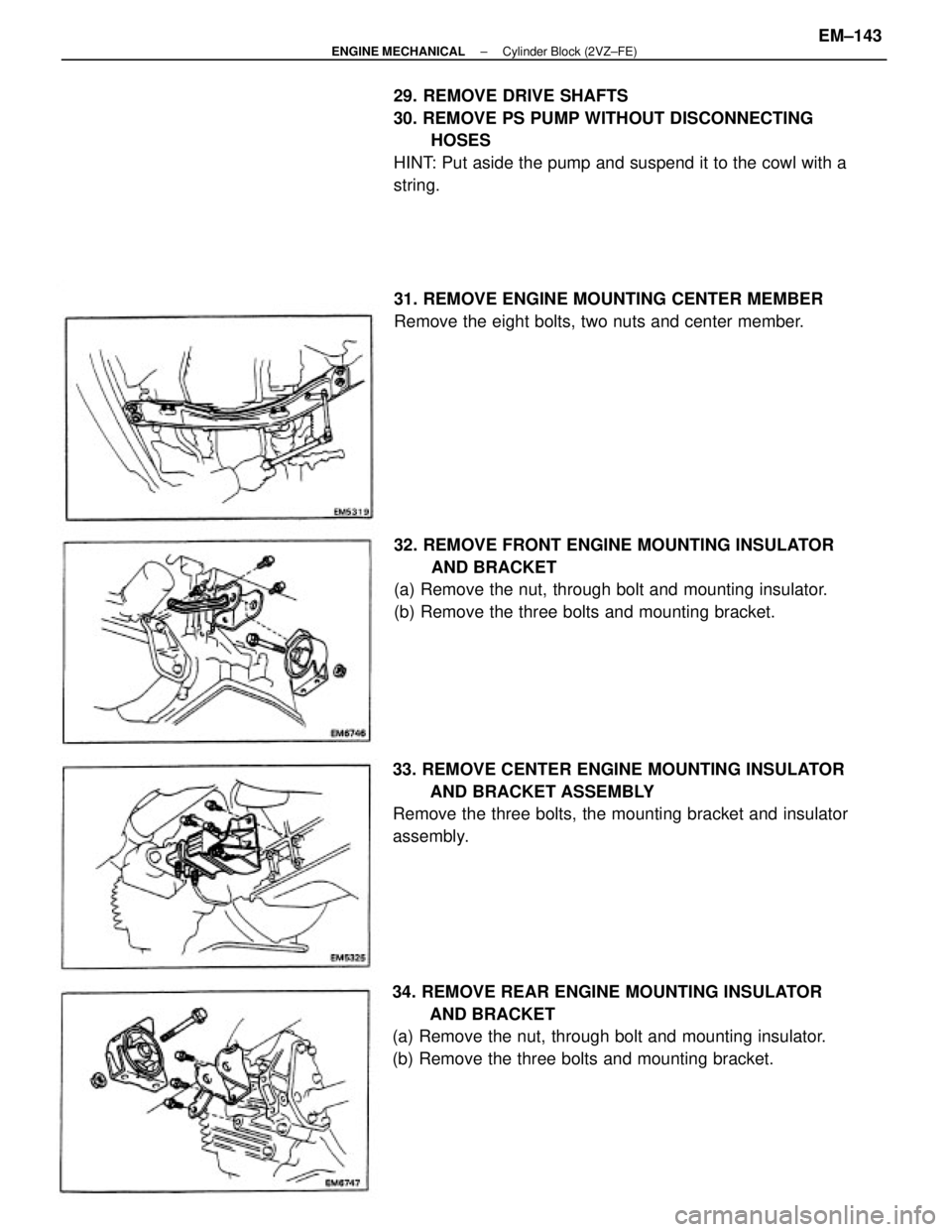

29. REMOVE DRIVE SHAFTS

30. REMOVE PS PUMP WITHOUT DISCONNECTING

HOSES

HINT: Put aside the pump and suspend it to the cowl with a

string.

34. REMOVE REAR ENGINE MOUNTING INSULATOR

AND BRACKET

(a) Remove the nut, through bolt and mounting insulator.

(b) Remove the three bolts and mounting bracket.32. REMOVE FRONT ENGINE MOUNTING INSULATOR

AND BRACKET

(a) Remove the nut, through bolt and mounting insulator.

(b) Remove the three bolts and mounting bracket.

33. REMOVE CENTER ENGINE MOUNTING INSULATOR

AND BRACKET ASSEMBLY

Remove the three bolts, the mounting bracket and insulator

assembly.31. REMOVE ENGINE MOUNTING CENTER MEMBER

Remove the eight bolts, two nuts and center member.

± ENGINE MECHANICALCylinder Block (2VZ±FE)EM±143