TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 141 of 2389

AT3698

Seal

Packing A540E

AT4577

A540H

AT4601

A540H

AT3583

A540E

AT4965

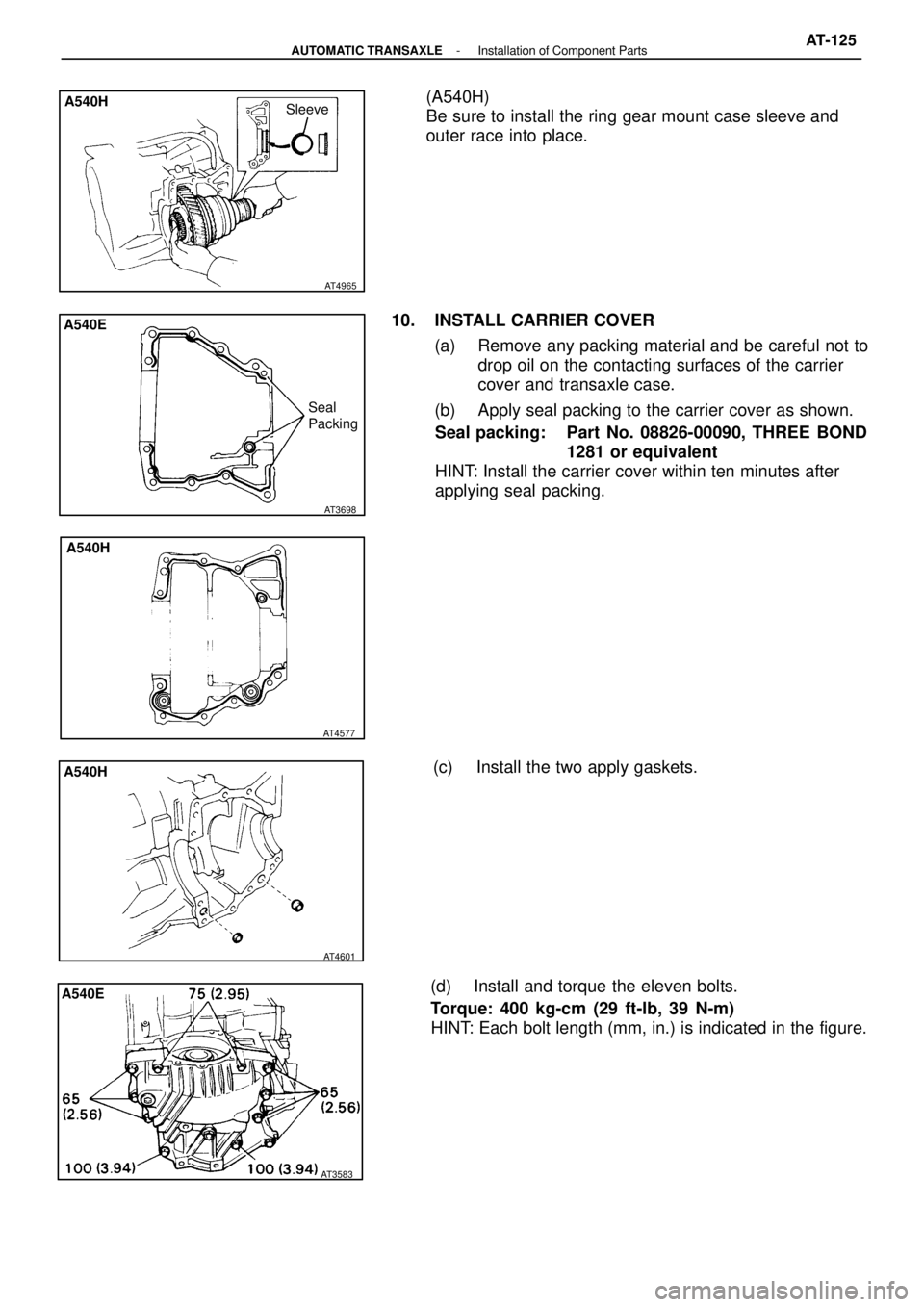

Sleeve A540H(A540H)

Be sure to install the ring gear mount case sleeve and

outer race into place.

10. INSTALL CARRIER COVER

(a) Remove any packing material and be careful not to

drop oil on the contacting surfaces of the carrier

cover and transaxle case.

(b) Apply seal packing to the carrier cover as shown.

Seal packing: Part No. 08826-00090, THREE BOND

1281 or equivalent

HINT: Install the carrier cover within ten minutes after

applying seal packing.

(c) Install the two apply gaskets.

(d) Install and torque the eleven bolts.

Torque: 400 kg-cm (29 ft-lb, 39 N-m)

HINT: Each bolt length (mm, in.) is indicated in the figure.

- AUTOMATIC TRANSAXLEInstallation of Component PartsAT-125

Page 142 of 2389

New BearingReused Bearing

A540E2.8 - 4.4

(2.4 - 3.8, 0.3 - 0.4)1.4 - 2.2

(1.2 - 1.9, 0.1 - 0.2)

A540H2.3 - 3.7

(2.0 - 3.2, 0.2 - 0.4)1.2 - 1.9

(1.0 - 1.6, 0.1 - 0.2)

AT4170

AT4171

AT3700

Adjusting Shim

MarkThicknessMarkThickness

0

1

2

3

4

5

6

7

82.00 (0.0787)

2.05 (0.0807)

2.10 (0.0827)

2.15 (0.0846)

2.20 (0.0866)

2.25 (0.0886)

2.30 (0.0906)

2.35 (0.0925)

2.40 (0.0945)9

A

B

C

D

E

F

G

H2.45 (0.0965)

2.50 (0.0984)

2.55 (0.1004)

2.60 (0.1024)

2.65 (0.1043)

2.70 (0.1063)

2.75 (0.1083)

2.80 (0.1102)

2.85 (0.1122)

A540H

AT4173

mm (in.)

11. ADJUST SIDE SEARING PRELOAD

(a) Remove any packing material on the contacting

surfaces of the LH bearing retainer and transaxle

case.

HINT: Do not apply seal packing yet.

(b) Install the LH bearing retainer and torque the six

bolts.

Torque: 195 kg-cm (14 ft-lb, 19 N-m)

(c) Snap down the bearings by turning the differential

case several times.

(d) Using a torque meter, measure the differential total

preload.

Total preload (at starting)

Add drive pinion preload

kg-cm (in.-lb, N-m)

If the preload is not within specification, replace the

adjusting shim in the LH bearing retainer with another

thickness one.

AT-126- AUTOMATIC TRANSAXLEInstallation of Component Parts

Page 143 of 2389

AT4563

AT3711

AT3712

SST

AT4170

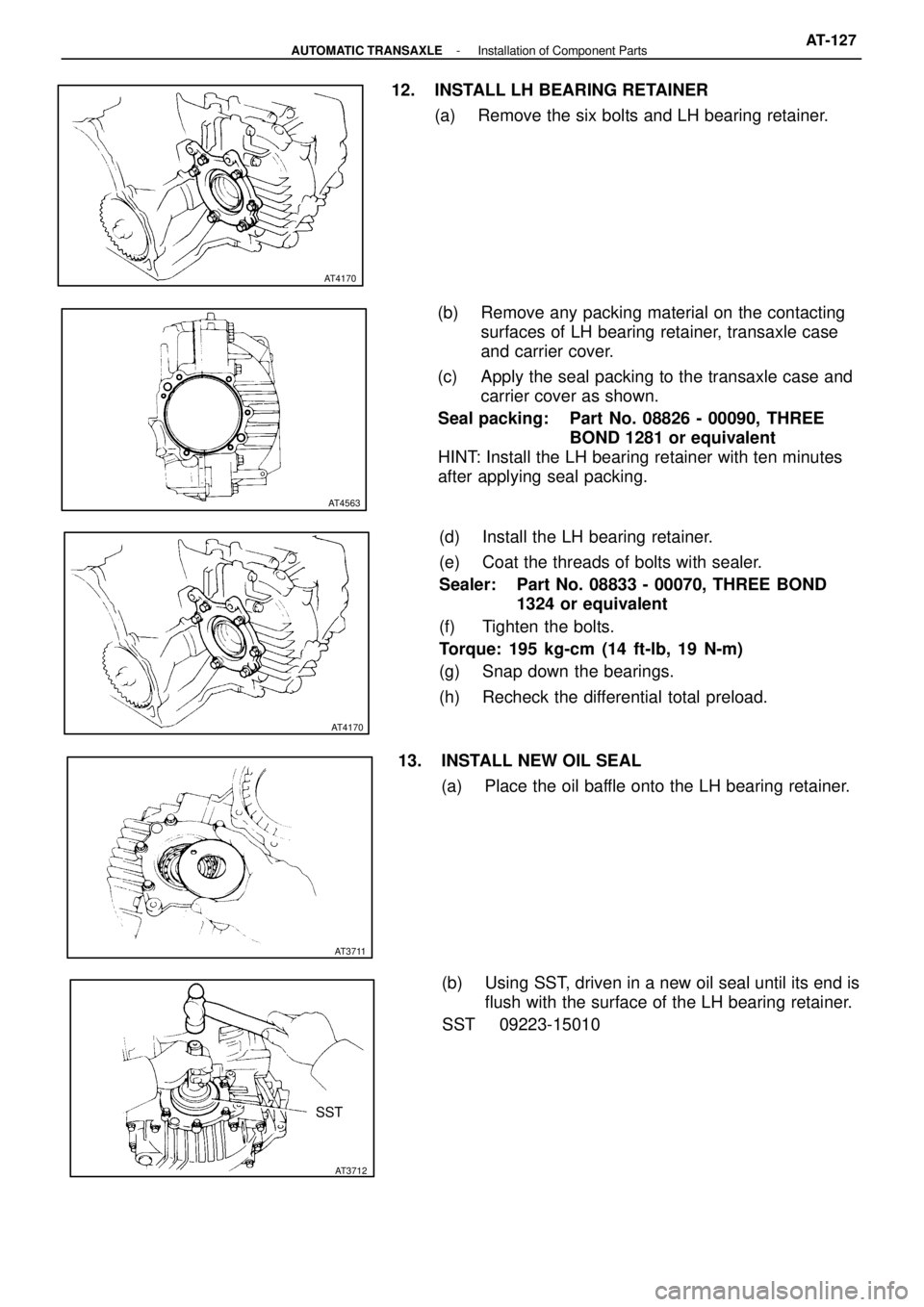

12. INSTALL LH BEARING RETAINER

(a) Remove the six bolts and LH bearing retainer.

(b) Remove any packing material on the contacting

surfaces of LH bearing retainer, transaxle case

and carrier cover.

(c) Apply the seal packing to the transaxle case and

carrier cover as shown.

Seal packing: Part No. 08826 - 00090, THREE

BOND 1281 or equivalent

HINT: Install the LH bearing retainer with ten minutes

after applying seal packing.

(d) Install the LH bearing retainer.

(e) Coat the threads of bolts with sealer.

Sealer: Part No. 08833 - 00070, THREE BOND

1324 or equivalent

(f) Tighten the bolts.

Torque: 195 kg-cm (14 ft-lb, 19 N-m)

(g) Snap down the bearings.

(h) Recheck the differential total preload.

AT4170

13. INSTALL NEW OIL SEAL

(a) Place the oil baffle onto the LH bearing retainer.

(b) Using SST, driven in a new oil seal until its end is

flush with the surface of the LH bearing retainer.

SST 09223-15010

- AUTOMATIC TRANSAXLEInstallation of Component PartsAT-127

Page 144 of 2389

AT3581

A540E

AT3586AT3713

Seal

Packing A540E

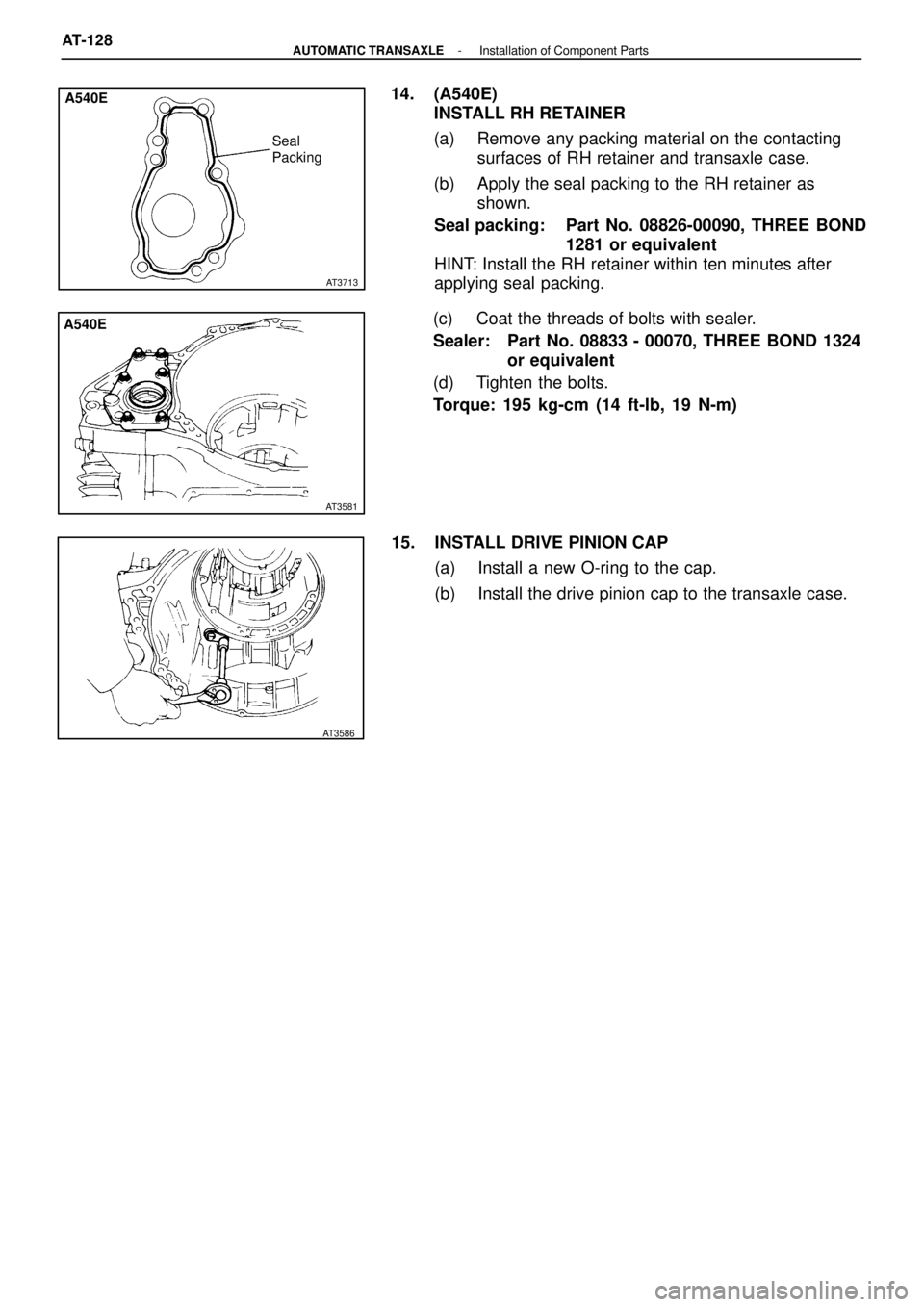

14. (A540E)

INSTALL RH RETAINER

(a) Remove any packing material on the contacting

surfaces of RH retainer and transaxle case.

(b) Apply the seal packing to the RH retainer as

shown.

Seal packing: Part No. 08826-00090, THREE BOND

1281 or equivalent

HINT: Install the RH retainer within ten minutes after

applying seal packing.

(c) Coat the threads of bolts with sealer.

Sealer: Part No. 08833 - 00070, THREE BOND 1324

or equivalent

(d) Tighten the bolts.

Torque: 195 kg-cm (14 ft-lb, 19 N-m)

15. INSTALL DRIVE PINION CAP

(a) Install a new O-ring to the cap.

(b) Install the drive pinion cap to the transaxle case.

AT-128- AUTOMATIC TRANSAXLEInstallation of Component Parts

Page 145 of 2389

AT7759

AT0090

AT3576

Manual

Valve LeverParking

Lock Rod

AT3574 AT2731

Lock PawlPin

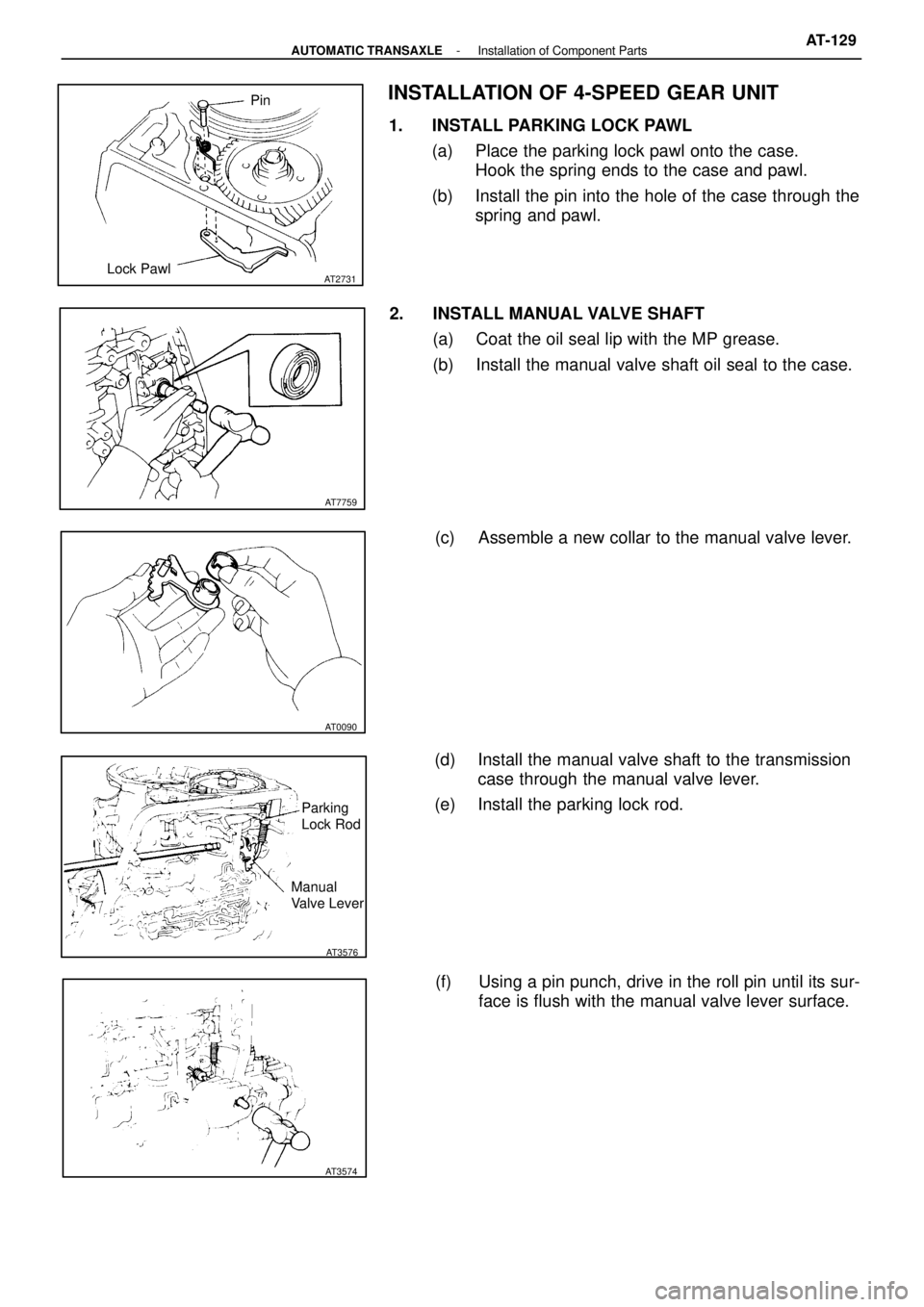

INSTALLATION OF 4-SPEED GEAR UNIT

1. INSTALL PARKING LOCK PAWL

(a) Place the parking lock pawl onto the case.

Hook the spring ends to the case and pawl.

(b) Install the pin into the hole of the case through the

spring and pawl.

2. INSTALL MANUAL VALVE SHAFT

(a) Coat the oil seal lip with the MP grease.

(b) Install the manual valve shaft oil seal to the case.

(c) Assemble a new collar to the manual valve lever.

(d) Install the manual valve shaft to the transmission

case through the manual valve lever.

(e) Install the parking lock rod.

(f) Using a pin punch, drive in the roll pin until its sur-

face is flush with the manual valve lever surface.

- AUTOMATIC TRANSAXLEInstallation of Component PartsAT-129

Page 146 of 2389

AT5025

Retaining

Spring

AT0312

AT0969

AT2757AT0093

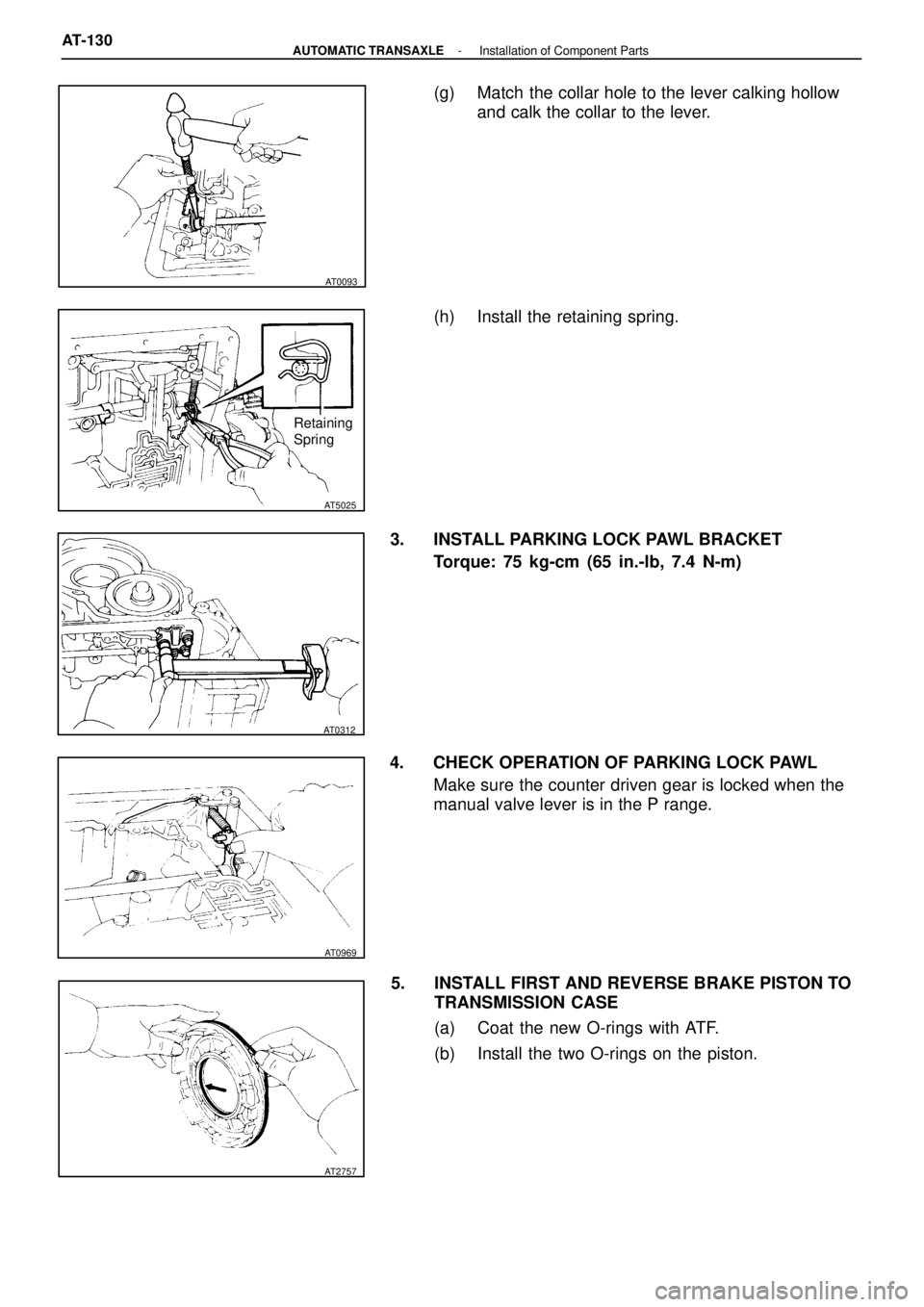

(g) Match the collar hole to the lever calking hollow

and calk the collar to the lever.

(h) Install the retaining spring.

3. INSTALL PARKING LOCK PAWL BRACKET

Torque: 75 kg-cm (65 in.-lb, 7.4 N-m)

4. CHECK OPERATION OF PARKING LOCK PAWL

Make sure the counter driven gear is locked when the

manual valve lever is in the P range.

5. INSTALL FIRST AND REVERSE BRAKE PISTON TO

TRANSMISSION CASE

(a) Coat the new O-rings with ATF.

(b) Install the two O-rings on the piston.

AT-130- AUTOMATIC TRANSAXLEInstallation of Component Parts

Page 147 of 2389

AT0198 AT0376

SST

AT0199

AT3572

AT2729 AT0197

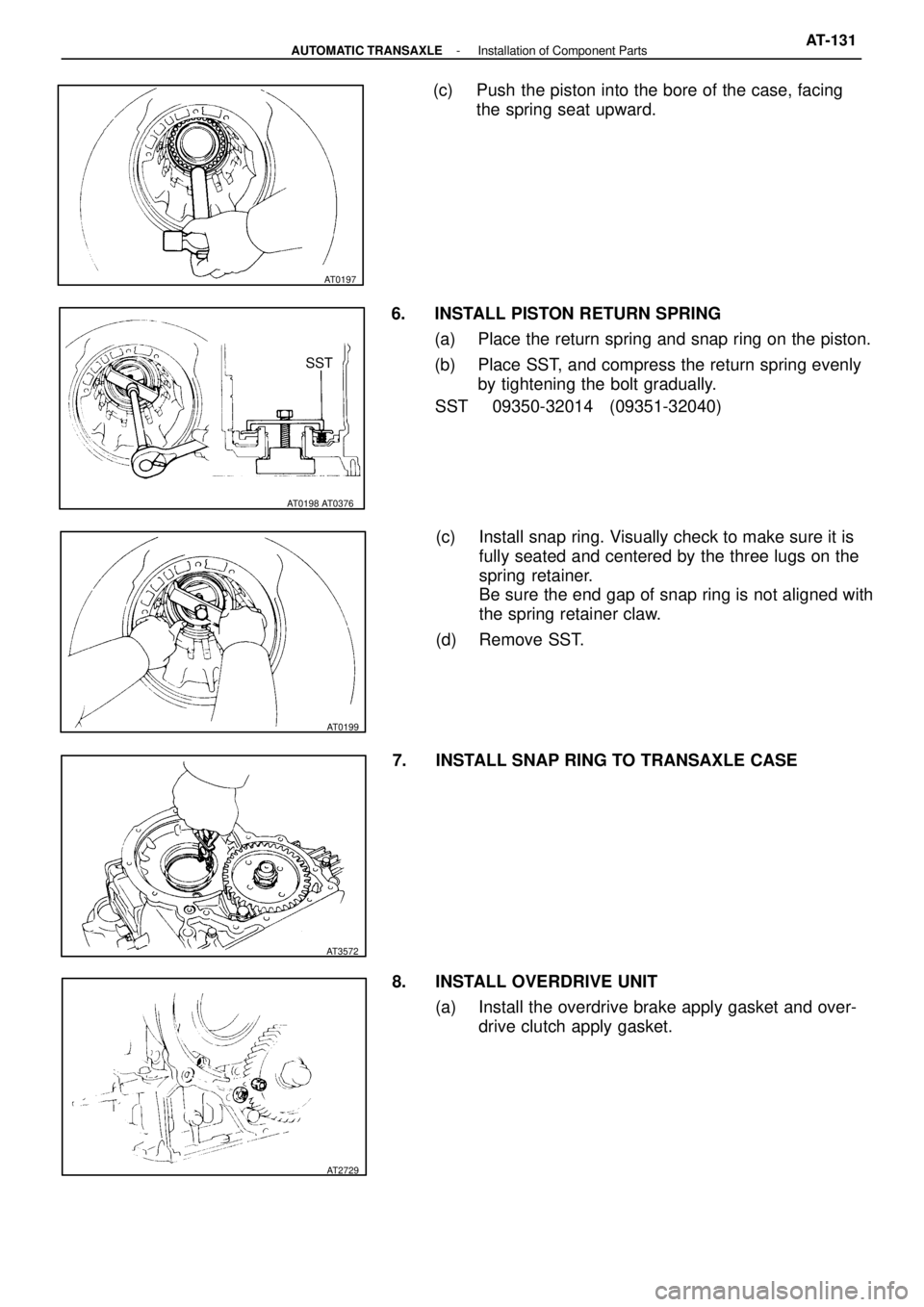

(c) Push the piston into the bore of the case, facing

the spring seat upward.

6. INSTALL PISTON RETURN SPRING

(a) Place the return spring and snap ring on the piston.

(b) Place SST, and compress the return spring evenly

by tightening the bolt gradually.

SST 09350-32014 (09351-32040)

(c) Install snap ring. Visually check to make sure it is

fully seated and centered by the three lugs on the

spring retainer.

Be sure the end gap of snap ring is not aligned with

the spring retainer claw.

(d) Remove SST.

7. INSTALL SNAP RING TO TRANSAXLE CASE

8. INSTALL OVERDRIVE UNIT

(a) Install the overdrive brake apply gasket and over-

drive clutch apply gasket.

- AUTOMATIC TRANSAXLEInstallation of Component PartsAT-131

Page 148 of 2389

AT7731

AT3714

AT4169

AT7760 AT2728

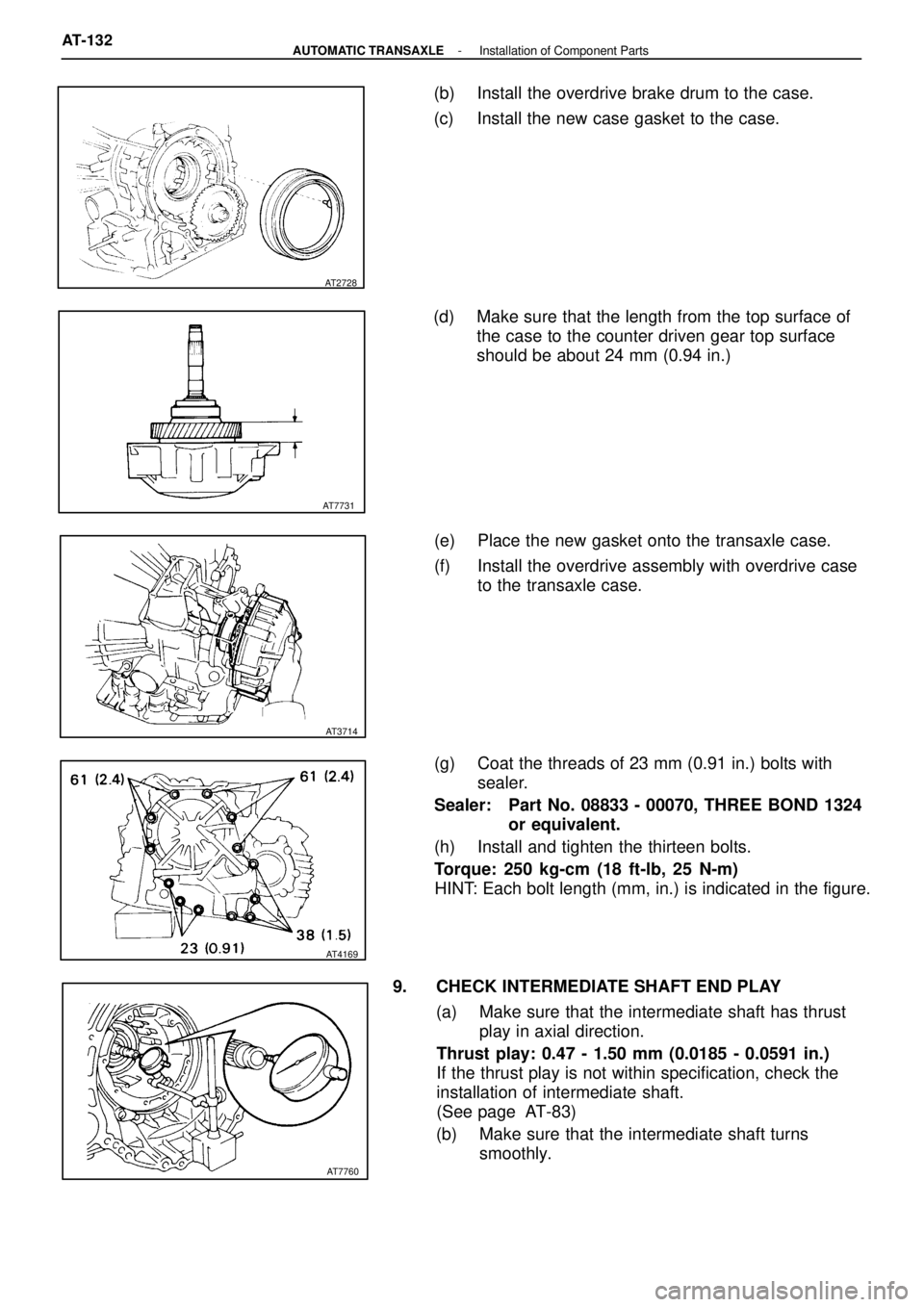

(b) Install the overdrive brake drum to the case.

(c) Install the new case gasket to the case.

(d) Make sure that the length from the top surface of

the case to the counter driven gear top surface

should be about 24 mm (0.94 in.)

(e) Place the new gasket onto the transaxle case.

(f) Install the overdrive assembly with overdrive case

to the transaxle case.

(g) Coat the threads of 23 mm (0.91 in.) bolts with

sealer.

Sealer: Part No. 08833 - 00070, THREE BOND 1324

or equivalent.

(h) Install and tighten the thirteen bolts.

Torque: 250 kg-cm (18 ft-lb, 25 N-m)

HINT: Each bolt length (mm, in.) is indicated in the figure.

9. CHECK INTERMEDIATE SHAFT END PLAY

(a) Make sure that the intermediate shaft has thrust

play in axial direction.

Thrust play: 0.47 - 1.50 mm (0.0185 - 0.0591 in.)

If the thrust play is not within specification, check the

installation of intermediate shaft.

(See page AT-83)

(b) Make sure that the intermediate shaft turns

smoothly.

AT-132- AUTOMATIC TRANSAXLEInstallation of Component Parts

Page 149 of 2389

Outer Diameter

Inner Diameter

A540E

Bearing38.7 (1.524)

22.6 (0.890)

A540HFront Race37.3 (1.469)

24.1 (0.949)

Bearing37.6 (1.480)

24.0 (0.945)

Rear Race37.6 (1.480)

22.2 (0.874)

AT3717

AT3716

AT3718

Plate

DiscFlange

AT3719AT5037

A540H A540E

Bearing and race:mm (in.)

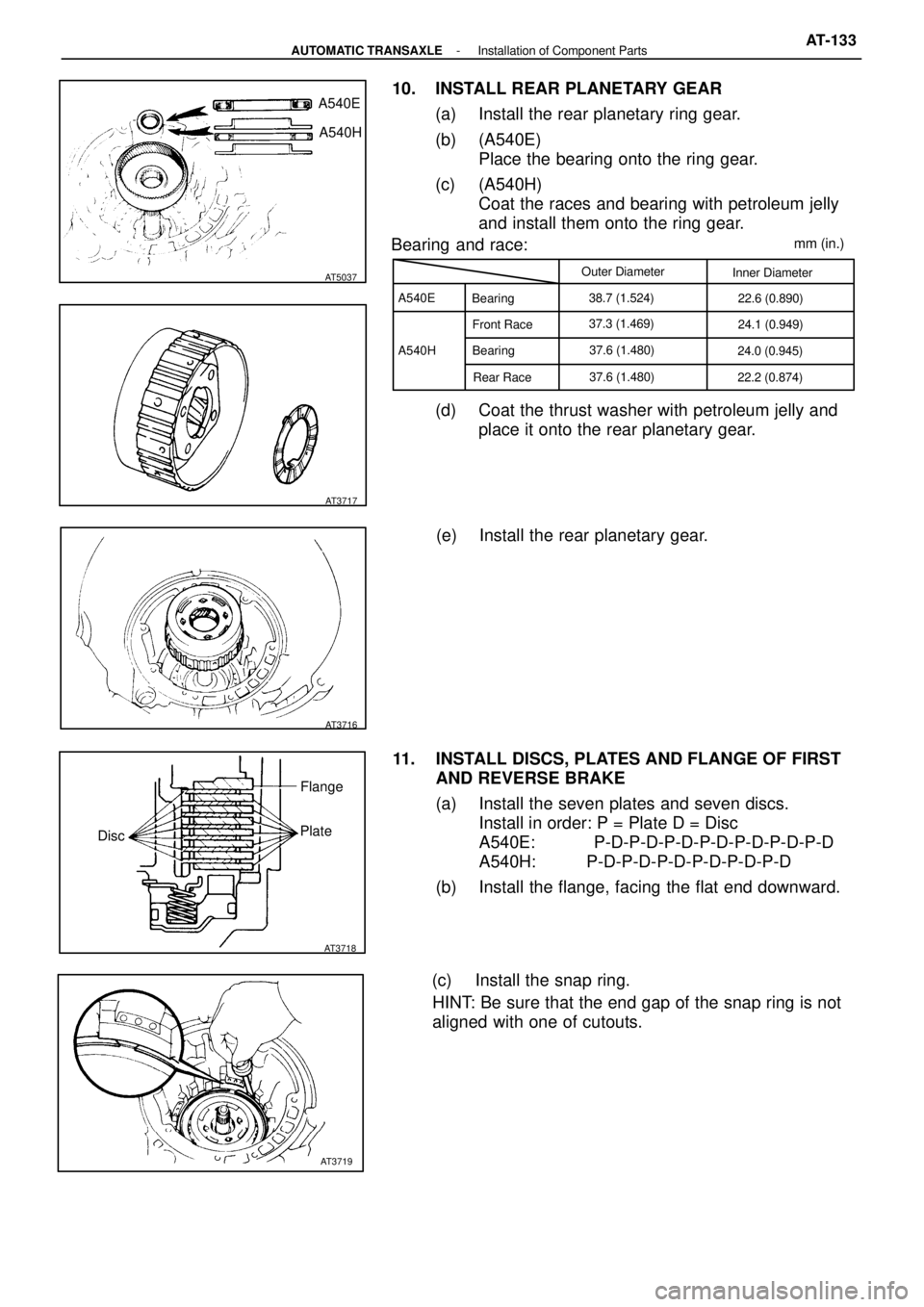

10. INSTALL REAR PLANETARY GEAR

(a) Install the rear planetary ring gear.

(b) (A540E)

Place the bearing onto the ring gear.

(c) (A540H)

Coat the races and bearing with petroleum jelly

and install them onto the ring gear.

(d) Coat the thrust washer with petroleum jelly and

place it onto the rear planetary gear.

(e) Install the rear planetary gear.

11. INSTALL DISCS, PLATES AND FLANGE OF FIRST

AND REVERSE BRAKE

(a) Install the seven plates and seven discs.

Install in order: P = Plate D = Disc

A540E: P-D-P-D-P-D-P-D-P-D-P-D-P-D

A540H: P-D-P-D-P-D-P-D-P-D-P-D

(b) Install the flange, facing the flat end downward.

(c) Install the snap ring.

HINT: Be sure that the end gap of the snap ring is not

aligned with one of cutouts.

- AUTOMATIC TRANSAXLEInstallation of Component PartsAT-133

Page 150 of 2389

AT3602

AT3720

AT3721

SST

AT5022

Thrust

Washer

AT3563

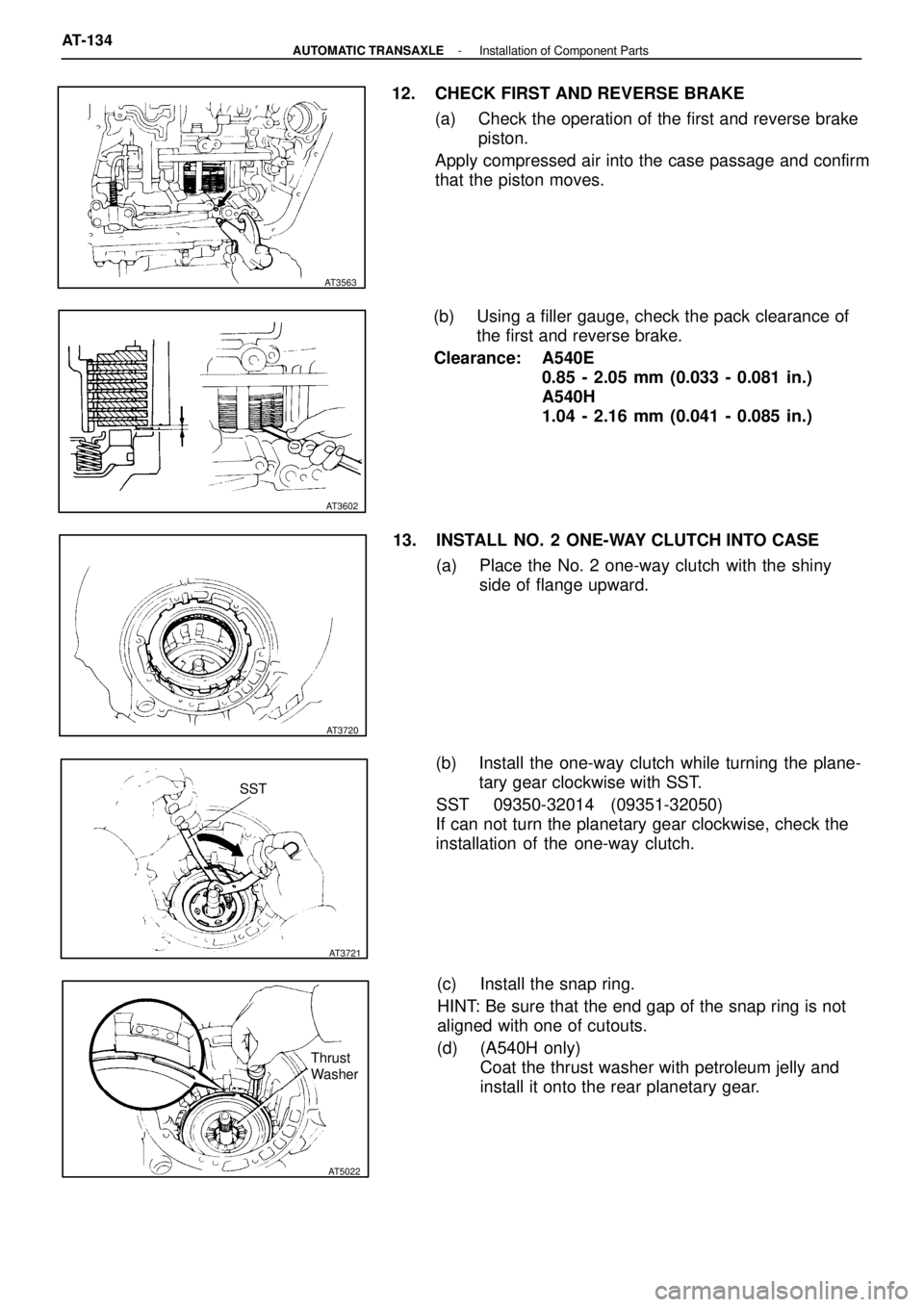

12. CHECK FIRST AND REVERSE BRAKE

(a) Check the operation of the first and reverse brake

piston.

Apply compressed air into the case passage and confirm

that the piston moves.

(b) Using a filler gauge, check the pack clearance of

the first and reverse brake.

Clearance: A540E

0.85 - 2.05 mm (0.033 - 0.081 in.)

A540H

1.04 - 2.16 mm (0.041 - 0.085 in.)

13. INSTALL NO. 2 ONE-WAY CLUTCH INTO CASE

(a) Place the No. 2 one-way clutch with the shiny

side of flange upward.

(b) Install the one-way clutch while turning the plane-

tary gear clockwise with SST.

SST 09350-32014 (09351-32050)

If can not turn the planetary gear clockwise, check the

installation of the one-way clutch.

(c) Install the snap ring.

HINT: Be sure that the end gap of the snap ring is not

aligned with one of cutouts.

(d) (A540H only)

Coat the thrust washer with petroleum jelly and

install it onto the rear planetary gear.

AT-134- AUTOMATIC TRANSAXLEInstallation of Component Parts