ac relay replace TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 771 of 2389

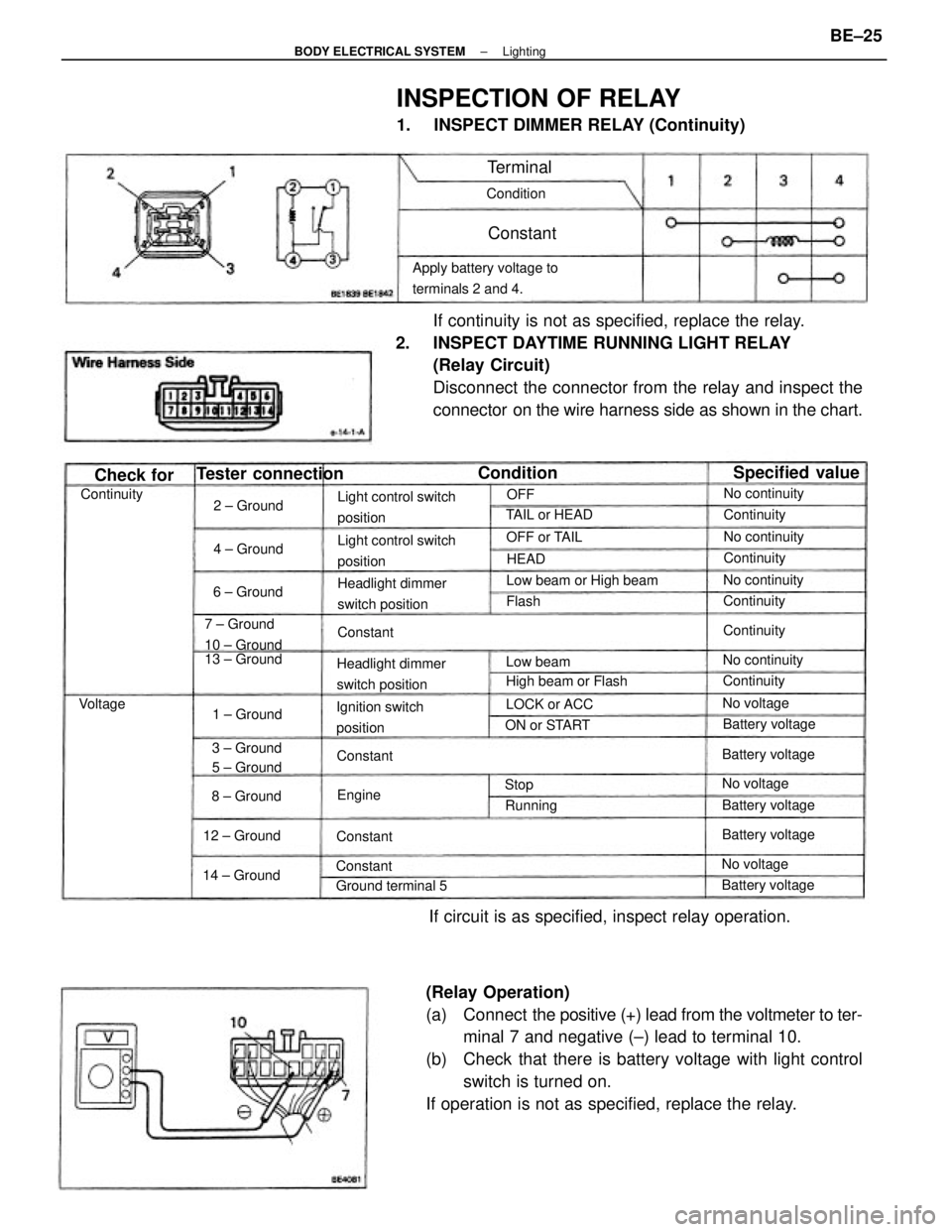

(Relay Operation)

(a) Connect the positive (+) lead from the voltmeter to ter-

minal 7 and negative (±) lead to terminal 10.

(b) Check that there is battery voltage with light control

switch is turned on.

If operation is not as specified, replace the relay.If continuity is not as specified, replace the relay.

2. INSPECT DAYTIME RUNNING LIGHT RELAY

(Relay Circuit)

Disconnect the connector from the relay and inspect the

connector on the wire harness side as shown in the chart.

INSPECTION OF RELAY

1. INSPECT DIMMER RELAY (Continuity)

If circuit is as specified, inspect relay operation.

Apply battery voltage to

terminals 2 and 4.

Light control switch

position

Light control switch

position

Headlight dimmer

switch positionHeadlight dimmer

switch positionLow beam or High beam

Ignition switch

position 7 ± Ground

10 ± Ground

High beam or Flash 13 ± Ground

3 ± Ground

5 ± Ground

Tester connection

Ground terminal 5

Specified value

Battery voltageBattery voltageBattery voltage

Battery voltage Battery voltageNo continuity

No continuity TAIL or HEADNo continuity

No continuity

14 ± Ground12 ± GroundON or STARTLOCK or ACC

1 ± GroundOFF or TAIL

8 ± Ground2 ± Ground

6 ± Ground4 ± Ground

No voltage

No voltage

No voltageContinuity

Continuity Continuity

Continuity

ContinuityContinuity

Condition

Check for

Low beam Condition

Running

Terminal

Constant

Constant

Constant

Constant

Constant Voltage

EngineHEAD

Flash

StopOFF

± BODY ELECTRICAL SYSTEMLightingBE±25

Page 772 of 2389

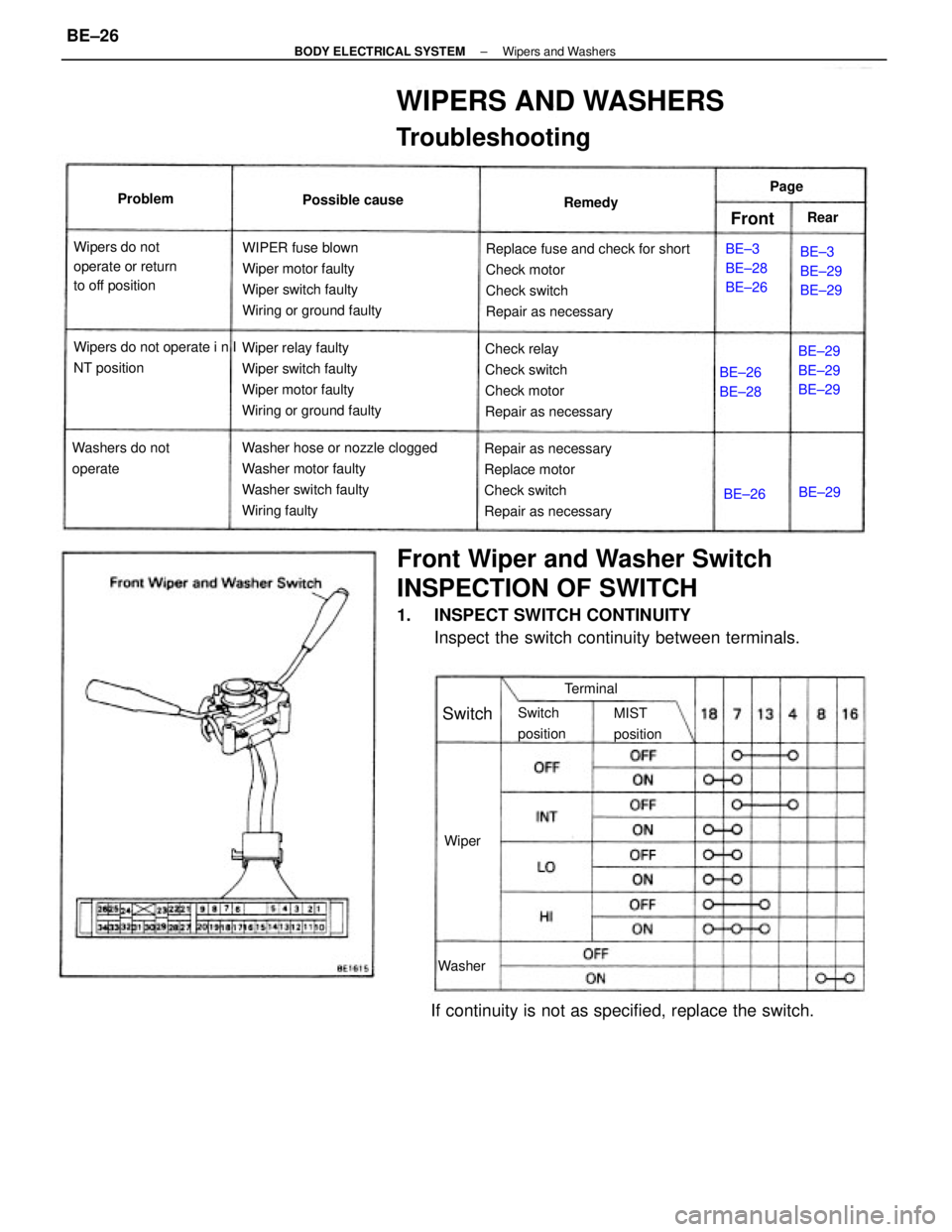

Front Wiper and Washer Switch

INSPECTION OF SWITCH

1. INSPECT SWITCH CONTINUITY

Inspect the switch continuity between terminals.

WIPERS AND WASHERS

Troubleshooting

Replace fuse and check for short

Check motor

Check switch

Repair as necessary

Washer hose or nozzle clogged

Washer motor faulty

Washer switch faulty

Wiring faultyWIPER fuse blown

Wiper motor faulty

Wiper switch faulty

Wiring or ground faulty

Wiper relay faulty

Wiper switch faulty

Wiper motor faulty

Wiring or ground faulty

Repair as necessary

Replace motor

Check switch

Repair as necessaryCheck relay

Check switch

Check motor

Repair as necessary

If continuity is not as specified, replace the switch.

Wipers do not

operate or return

to off position

Wipers do not operate i n I

NT position

Washers do not

operateBE±29

BE±29

BE±29BE±3

BE±29

BE±29 BE±3

BE±28

BE±26 Possible cause

BE±26

BE±28

Switch

positionMIST

position Terminal Remedy Problem

Washer

Switch

WiperBE±26BE±29 Page

FrontRear

± BODY ELECTRICAL SYSTEMWipers and WashersBE±26

Page 775 of 2389

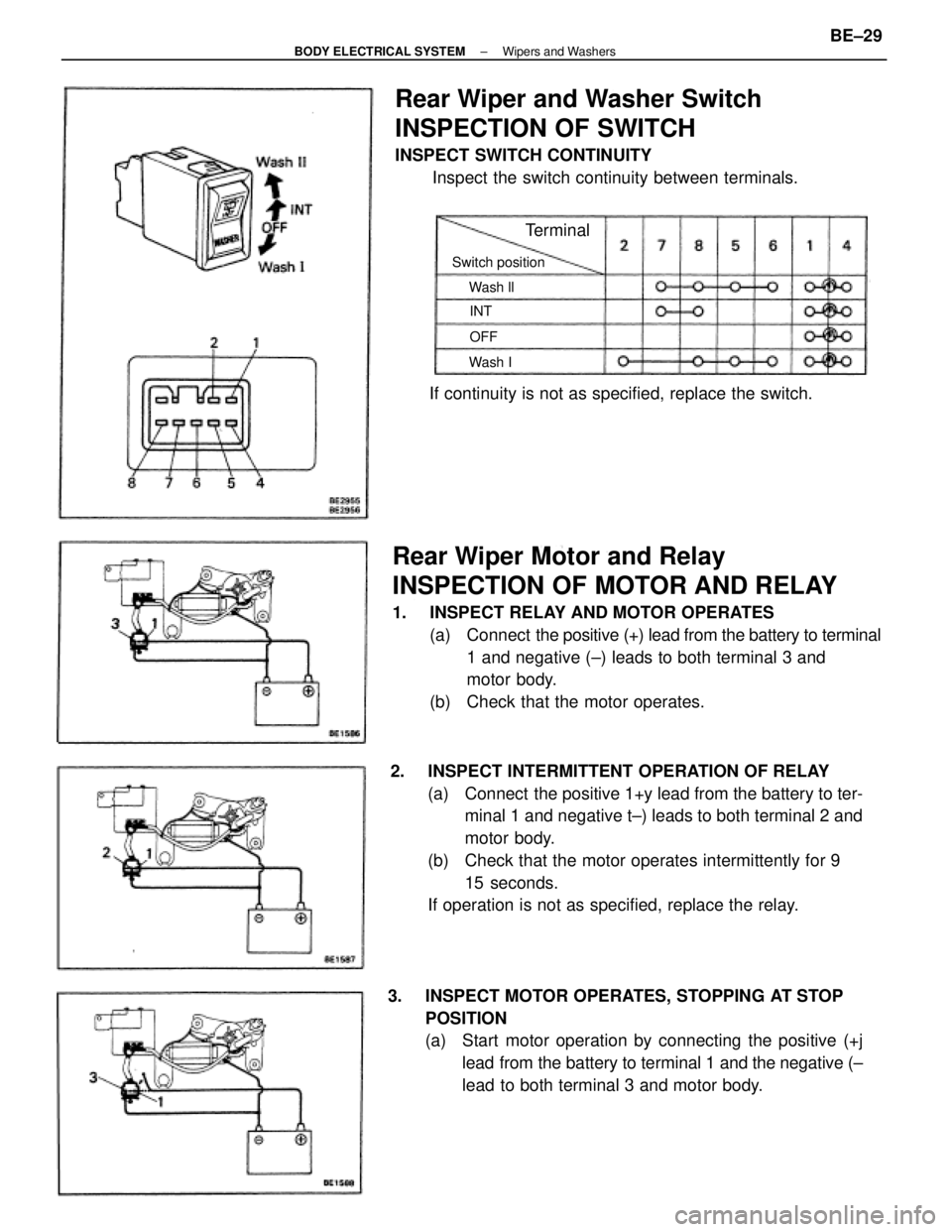

Rear Wiper Motor and Relay

INSPECTION OF MOTOR AND RELAY

1. INSPECT RELAY AND MOTOR OPERATES

(a) Connect the positive (+) lead from the battery to terminal

1 and negative (±) leads to both terminal 3 and

motor body.

(b) Check that the motor operates.

2. INSPECT INTERMITTENT OPERATION OF RELAY

(a) Connect the positive 1+y lead from the battery to ter-

minal 1 and negative t±) leads to both terminal 2 and

motor body.

(b) Check that the motor operates intermittently for 9

15 seconds.

If operation is not as specified, replace the relay.

3. INSPECT MOTOR OPERATES, STOPPING AT STOP

POSITION

(a) Start motor operation by connecting the positive (+j

lead from the battery to terminal 1 and the negative (±

lead to both terminal 3 and motor body.

Rear Wiper and Washer Switch

INSPECTION OF SWITCH

INSPECT SWITCH CONTINUITY

Inspect the switch continuity between terminals.

If continuity is not as specified, replace the switch.

Switch position

Terminal

Wash ll

Wash IOFF INT

± BODY ELECTRICAL SYSTEMWipers and WashersBE±29

Page 777 of 2389

Replace fuse and check for short

Replace bulb

Check switch

Check switch

Check switch

Check relay

Repair a s necessary ºDOMEº fuse blown

Bulb burned out

Door courtesy switch faulty

Unlock warning switch faulty

Buckle switch faulty

Seat belt warning relay faulty

Wiring or ground faultyºGAUGEº fuse blown

Bulb burned out

Brake fluid level warning switch faulty

Parking brake switch faulty

Wiring or ground faultyReplace fuse and check for short

Replace bulb

Check switch

Check switch

Repair as necessary ºGAUGEº fuse blown

Water temperature gauge faulty

Water temperature sender gauge faulty

Wiring or ground faulty

ºGAUGEº fuse blown

Buibburned out

oil pressure warning switch faulty

Wiring or ground faultyºGAUGEº fuse blown

Bulb burned out

Fuel level warning switch faulty

Wiring or ground faulty

Replace fuse and check for short

Replace bulb

Check switch

±Repair as necessaryReplace fuse and check for short

Replace bulb

Check switch

Repair as necessary

Replace fuse and check for short

Replace bulb

Check switch

Repair as necessaryReplace fuse and check for short

Check gauge

Check sender gauge

Repair as necessaryReplace fuse .and check for short

Check gauge

Check sender gauge

Repair as necessary

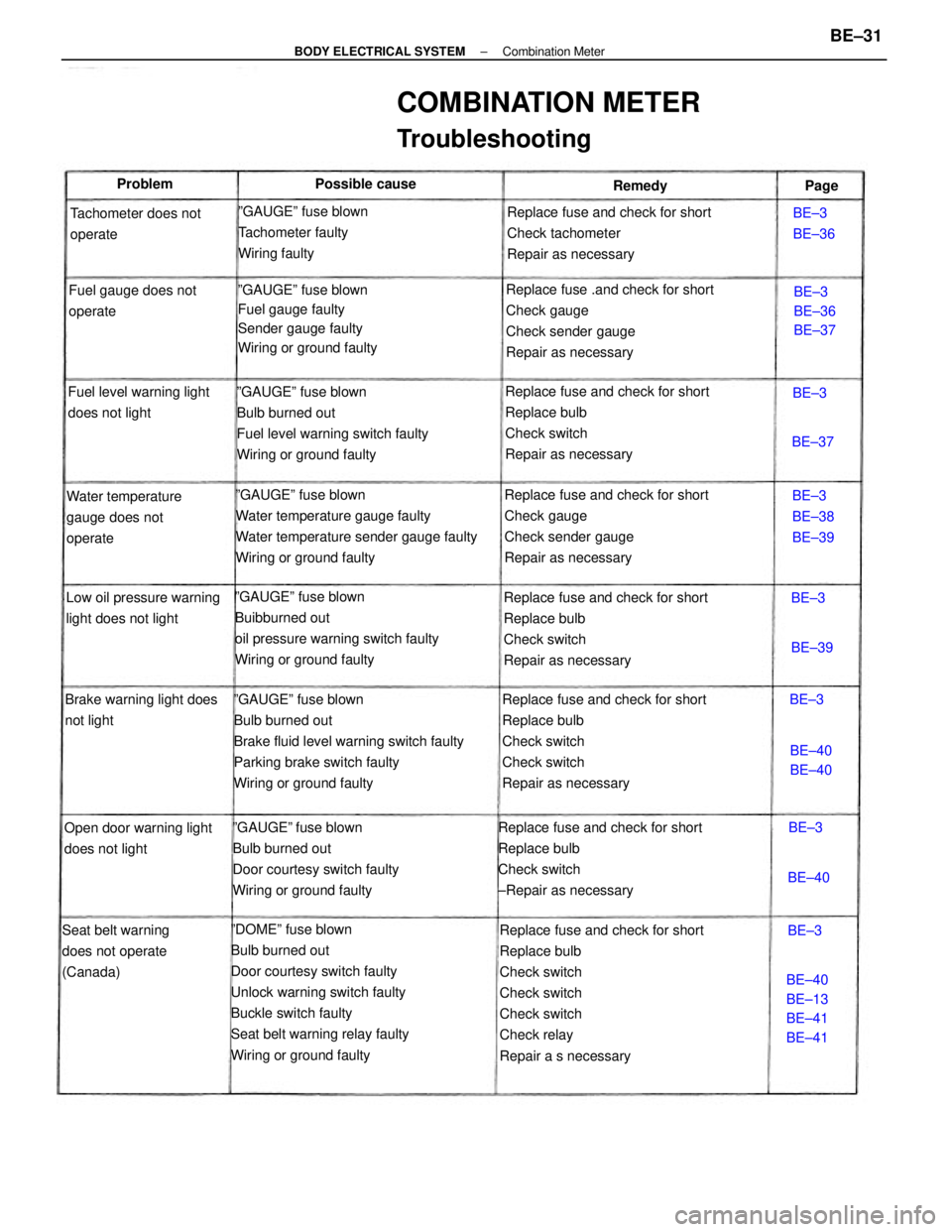

COMBINATION METER

Troubleshooting

ºGAUGEº fuse blown

Bulb burned out

Door courtesy switch faulty

Wiring or ground faultyReplace fuse and check for short

Check tachometer

Repair as necessary

ºGAUGEº fuse blown

Fuel gauge faulty

Sender gauge faulty

Wiring or ground faultyºGAUGEº fuse blown

Tachometer faulty

Wiring faulty

Low oil pressure warning

light does not lightWater temperature

gauge does not

operate

Seat belt warning

does not operate

(Canada)Tachometer does not

operate

Brake warning light does

not lightFuel gauge does not

operate

Open door warning light

does not lightFuel level warning light

does not light

BE±40

BE±13

BE±41

BE±41BE±3

BE±38

BE±39BE±3

BE±36

BE±37 Possible cause

BE±3

BE±36

BE±40

BE±40 Problem

Remedy

BE±40BE±39BE±37Page

BE±3BE±3

BE±3

BE±3

BE±3

± BODY ELECTRICAL SYSTEMCombination MeterBE±31

Page 787 of 2389

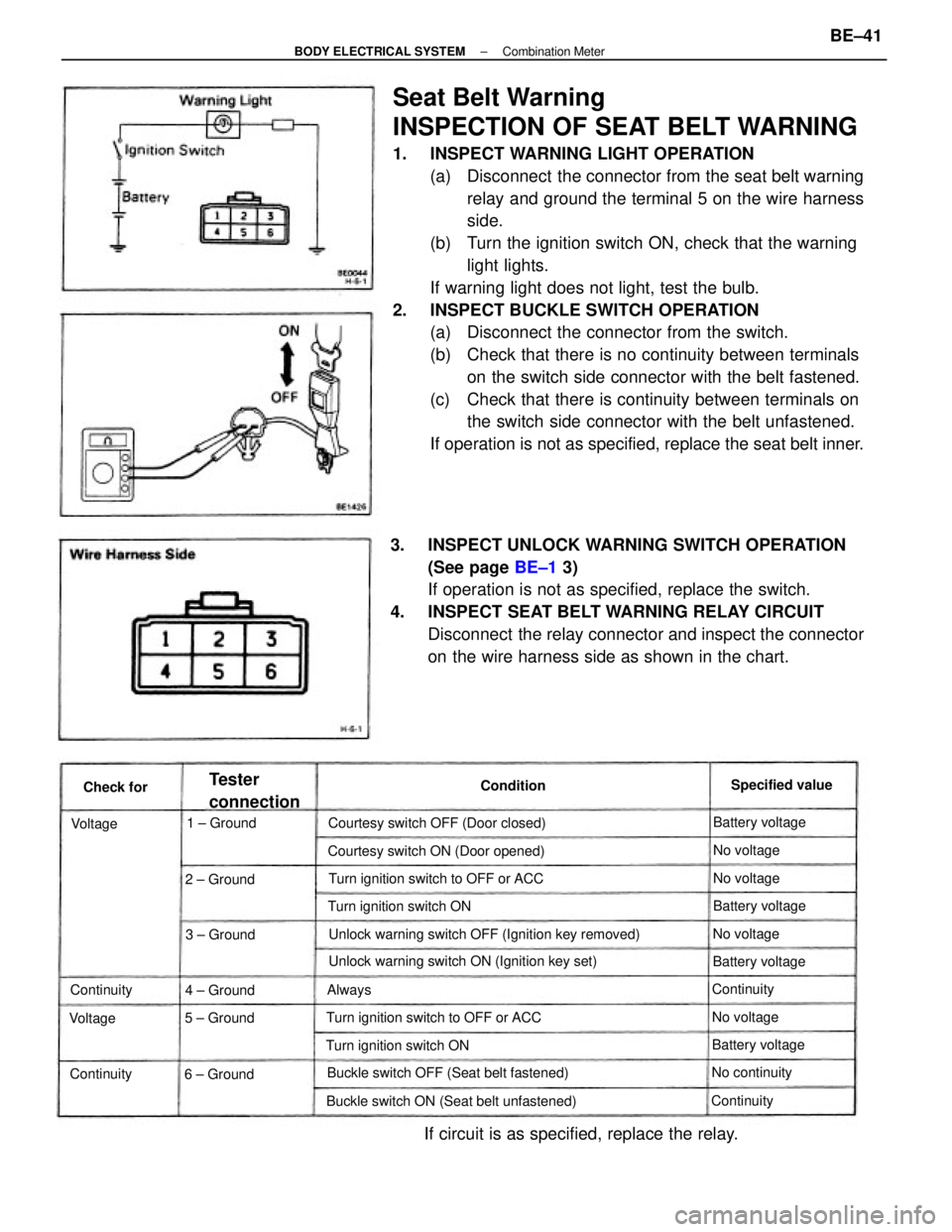

Seat Belt Warning

INSPECTION OF SEAT BELT WARNING

1. INSPECT WARNING LIGHT OPERATION

(a) Disconnect the connector from the seat belt warning

relay and ground the terminal 5 on the wire harness

side.

(b) Turn the ignition switch ON, check that the warning

light lights.

If warning light does not light, test the bulb.

2. INSPECT BUCKLE SWITCH OPERATION

(a) Disconnect the connector from the switch.

(b) Check that there is no continuity between terminals

on the switch side connector with the belt fastened.

(c) Check that there is continuity between terminals on

the switch side connector with the belt unfastened.

If operation is not as specified, replace the seat belt inner.

3. INSPECT UNLOCK WARNING SWITCH OPERATION

(See page BE±1 3)

If operation is not as specified, replace the switch.

4. INSPECT SEAT BELT WARNING RELAY CIRCUIT

Disconnect the relay connector and inspect the connector

on the wire harness side as shown in the chart.

Unlock warning switch OFF (Ignition key removed)

If circuit is as specified, replace the relay.

Unlock warning switch ON (Ignition key set)

Buckle switch ON (Seat belt unfastened)Buckle switch OFF (Seat belt fastened)Courtesy switch ON (Door opened)

Turn ignition switch to OFF or ACCTurn ignition switch to OFF or ACC Courtesy switch OFF (Door closed)

Turn ignition switch ONTurn ignition switch ON

6 ± Ground

Tester

connectionSpecified value

Battery voltage

Battery voltage

Battery voltageBattery voltage

No continuity 1 ± Ground

2 ± Ground

3 ± Ground

5 ± Ground4 ± GroundContinuity

Continuity

ContinuityNo voltageNo voltageNo voltage

No voltage

Continuity Condition

Check for

VoltageVoltage

Always

± BODY ELECTRICAL SYSTEMCombination MeterBE±41

Page 788 of 2389

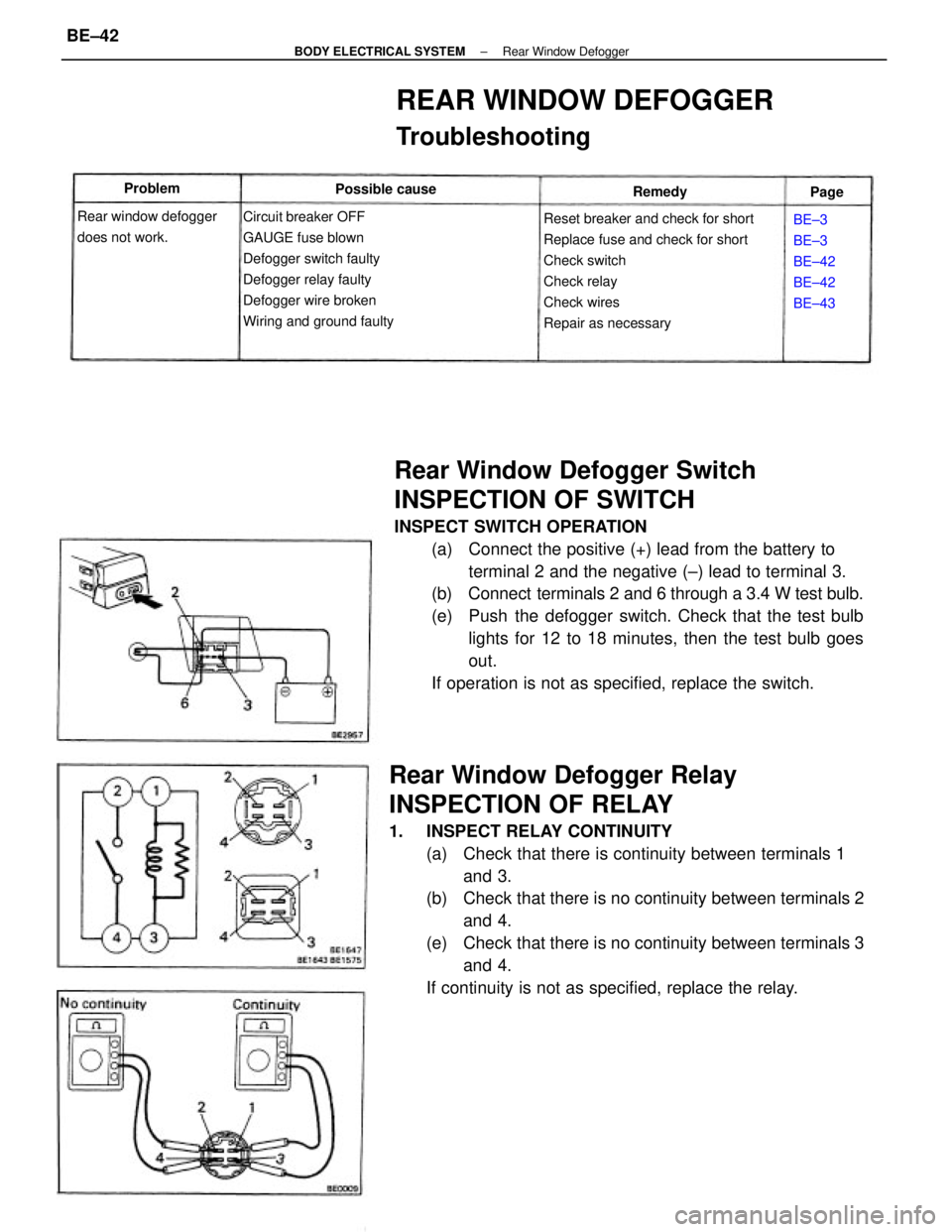

Rear Window Defogger Switch

INSPECTION OF SWITCH

INSPECT SWITCH OPERATION

(a) Connect the positive (+) lead from the battery to

terminal 2 and the negative (±) lead to terminal 3.

(b) Connect terminals 2 and 6 through a 3.4 W test bulb.

(e) Push the defogger switch. Check that the test bulb

lights for 12 to 18 minutes, then the test bulb goes

out.

If operation is not as specified, replace the switch.

Rear Window Defogger Relay

INSPECTION OF RELAY

1. INSPECT RELAY CONTINUITY

(a) Check that there is continuity between terminals 1

and 3.

(b) Check that there is no continuity between terminals 2

and 4.

(e) Check that there is no continuity between terminals 3

and 4.

If continuity is not as specified, replace the relay.

Reset breaker and check for short

Replace fuse and check for short

Check switch

Check relay

Check wires

Repair as necessary

REAR WINDOW DEFOGGER

Troubleshooting

Circuit breaker OFF

GAUGE fuse blown

Defogger switch faulty

Defogger relay faulty

Defogger wire broken

Wiring and ground faulty Rear window defogger

does not work.BE±3

BE±3

BE±42

BE±42

BE±43 Possible cause Problem

Remedy

Page

± BODY ELECTRICAL SYSTEMRear Window DefoggerBE±42

Page 789 of 2389

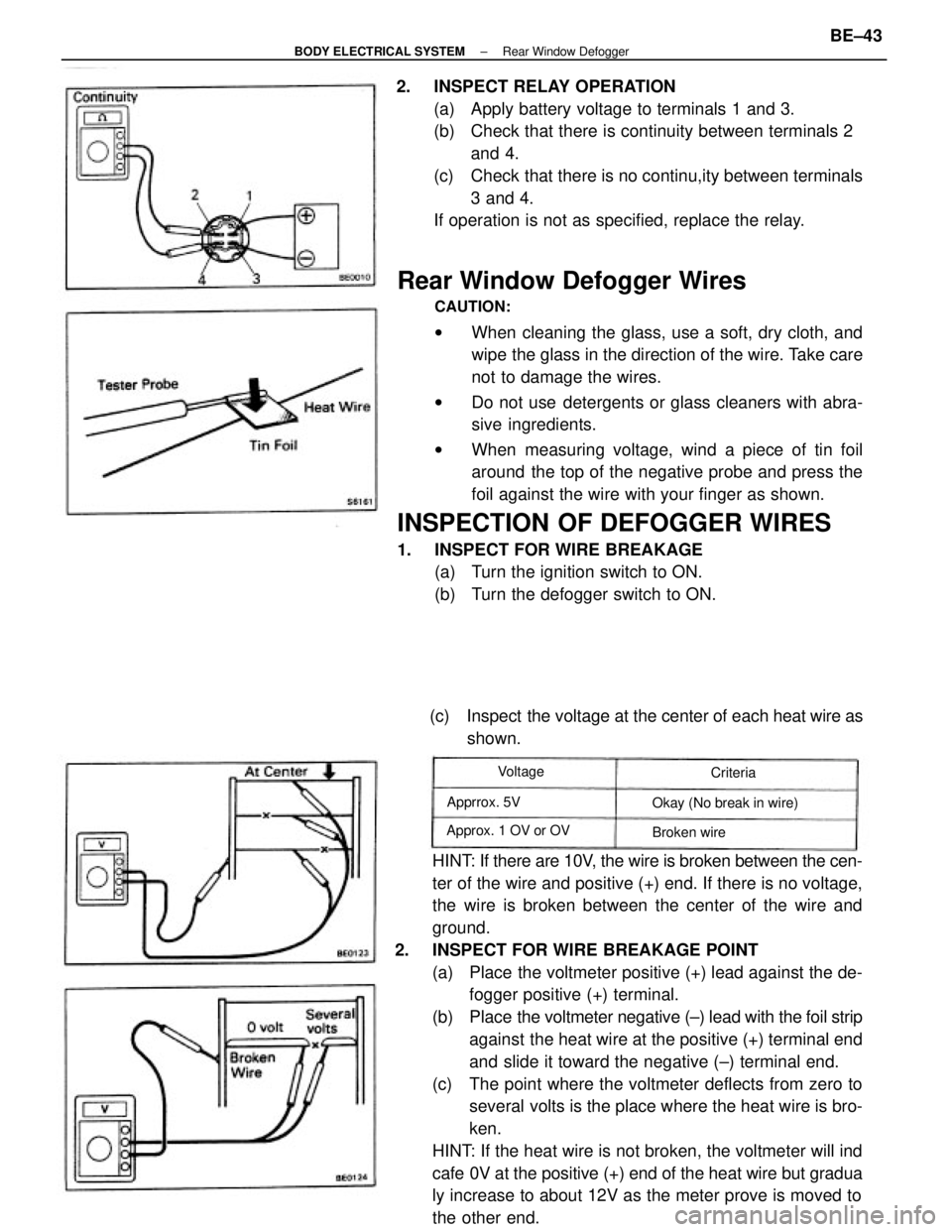

Rear Window Defogger Wires

CAUTION:

wWhen cleaning the glass, use a soft, dry cloth, and

wipe the glass in the direction of the wire. Take care

not to damage the wires.

wDo not use detergents or glass cleaners with abra-

sive ingredients.

wWhen measuring voltage, wind a piece of tin foil

around the top of the negative probe and press the

foil against the wire with your finger as shown.

INSPECTION OF DEFOGGER WIRES

1. INSPECT FOR WIRE BREAKAGE

(a) Turn the ignition switch to ON.

(b) Turn the defogger switch to ON.

HINT: If there are 10V, the wire is broken between the cen-

ter of the wire and positive (+) end. If there is no voltage,

the wire is broken between the center of the wire and

ground.

2. INSPECT FOR WIRE BREAKAGE POINT

(a) Place the voltmeter positive (+) lead against the de-

fogger positive (+) terminal.

(b) Place the voltmeter negative (±) lead with the foil strip

against the heat wire at the positive (+) terminal end

and slide it toward the negative (±) terminal end.

(c) The point where the voltmeter deflects from zero to

several volts is the place where the heat wire is bro-

ken.

HINT: If the heat wire is not broken, the voltmeter will ind

cafe 0V at the positive (+) end of the heat wire but gradua

ly increase to about 12V as the meter prove is moved to

the other end. 2. INSPECT RELAY OPERATION

(a) Apply battery voltage to terminals 1 and 3.

(b) Check that there is continuity between terminals 2

and 4.

(c) Check that there is no continu,ity between terminals

3 and 4.

If operation is not as specified, replace the relay.

(c) Inspect the voltage at the center of each heat wire as

shown.

Okay (No break in wire)

Approx. 1 OV or OVApprrox. 5V

Broken wire Voltage

Criteria

± BODY ELECTRICAL SYSTEMRear Window DefoggerBE±43

Page 793 of 2389

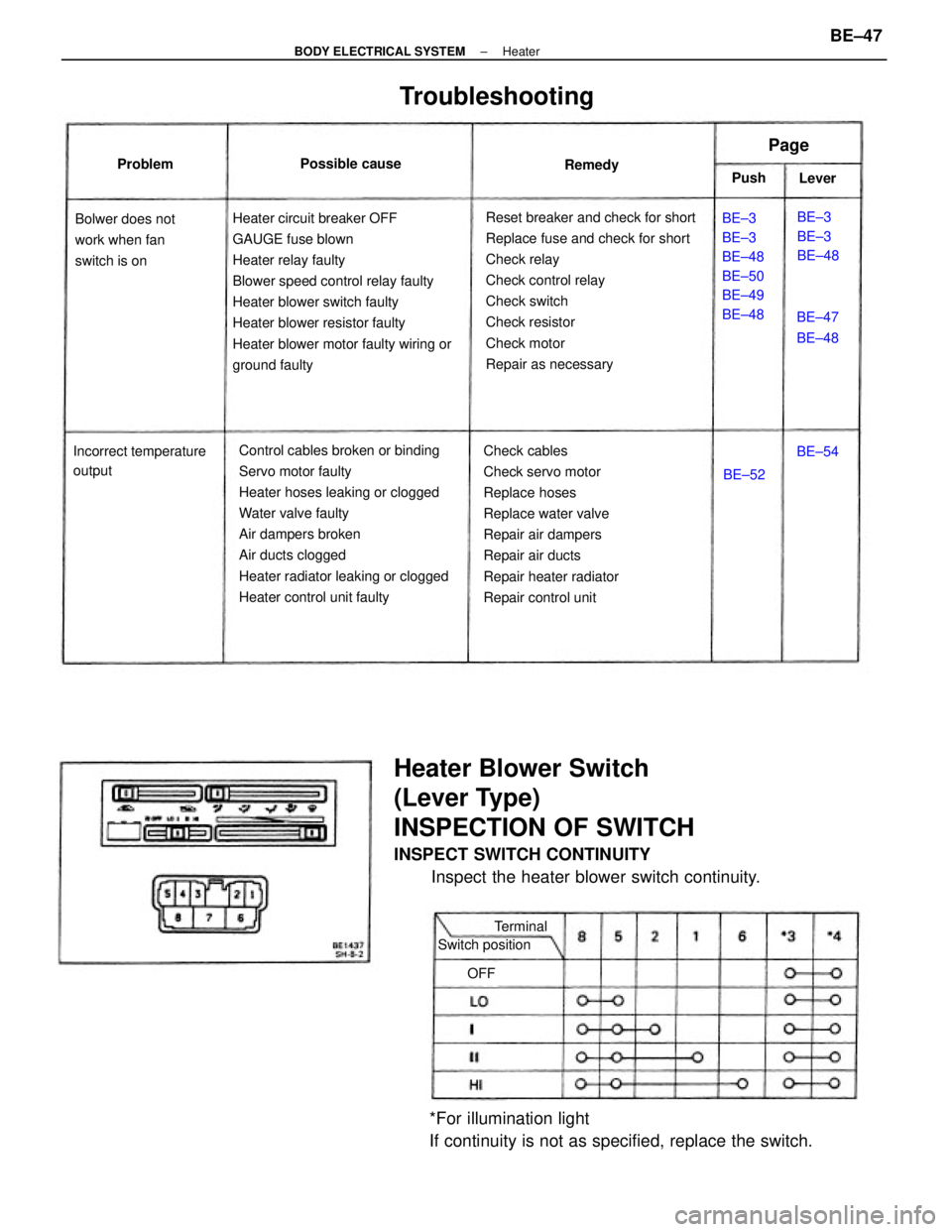

Heater Blower Switch

(Lever Type)

INSPECTION OF SWITCH

INSPECT SWITCH CONTINUITY

Inspect the heater blower switch continuity.

Control cables broken or binding

Servo motor faulty

Heater hoses leaking or clogged

Water valve faulty

Air dampers broken

Air ducts clogged

Heater radiator leaking or clogged

Heater control unit faulty Heater circuit breaker OFF

GAUGE fuse blown

Heater relay faulty

Blower speed control relay faulty

Heater blower switch faulty

Heater blower resistor faulty

Heater blower motor faulty wiring or

ground faultyReset breaker and check for short

Replace fuse and check for short

Check relay

Check control relay

Check switch

Check resistor

Check motor

Repair as necessary

Check cables

Check servo motor

Replace hoses

Replace water valve

Repair air dampers

Repair air ducts

Repair heater radiator

Repair control unit

*For illumination light

If continuity is not as specified, replace the switch.

Troubleshooting

BE±3

BE±3

BE±48

BE±50

BE±49

BE±48 Bolwer does not

work when fan

switch is on

Incorrect temperature

outputBE±3

BE±3

BE±48

Switch position Possible cause

BE±47

BE±48

Terminal Problem

Remedy

Lever

BE±52

Page

BE±54 Push

OFF

± BODY ELECTRICAL SYSTEMHeaterBE±47

Page 794 of 2389

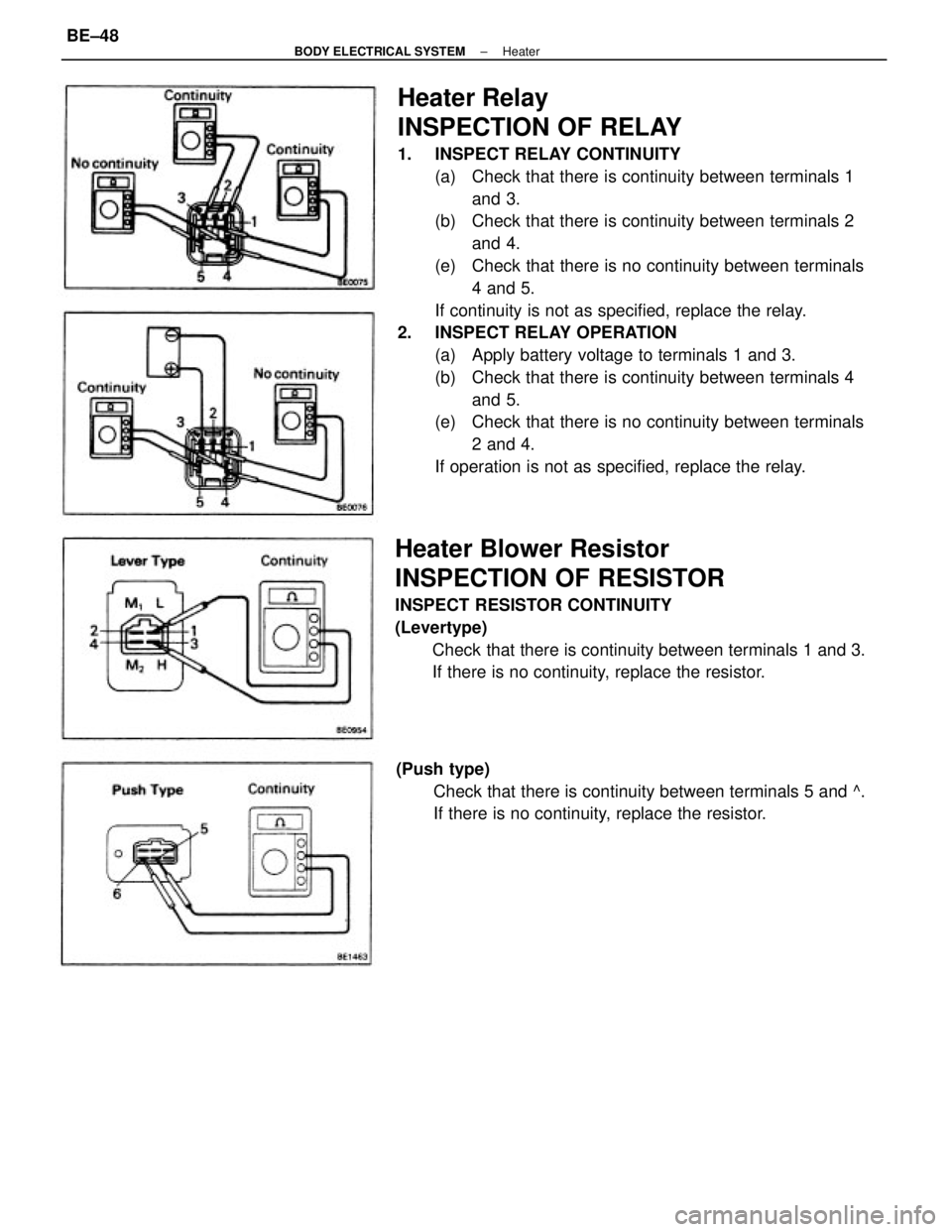

Heater Relay

INSPECTION OF RELAY

1. INSPECT RELAY CONTINUITY

(a) Check that there is continuity between terminals 1

and 3.

(b) Check that there is continuity between terminals 2

and 4.

(e) Check that there is no continuity between terminals

4 and 5.

If continuity is not as specified, replace the relay.

2. INSPECT RELAY OPERATION

(a) Apply battery voltage to terminals 1 and 3.

(b) Check that there is continuity between terminals 4

and 5.

(e) Check that there is no continuity between terminals

2 and 4.

If operation is not as specified, replace the relay.

Heater Blower Resistor

INSPECTION OF RESISTOR

INSPECT RESISTOR CONTINUITY

(Levertype)

Check that there is continuity between terminals 1 and 3.

If there is no continuity, replace the resistor.

(Push type)

Check that there is continuity between terminals 5 and ^.

If there is no continuity, replace the resistor.

± BODY ELECTRICAL SYSTEMHeaterBE±48

Page 796 of 2389

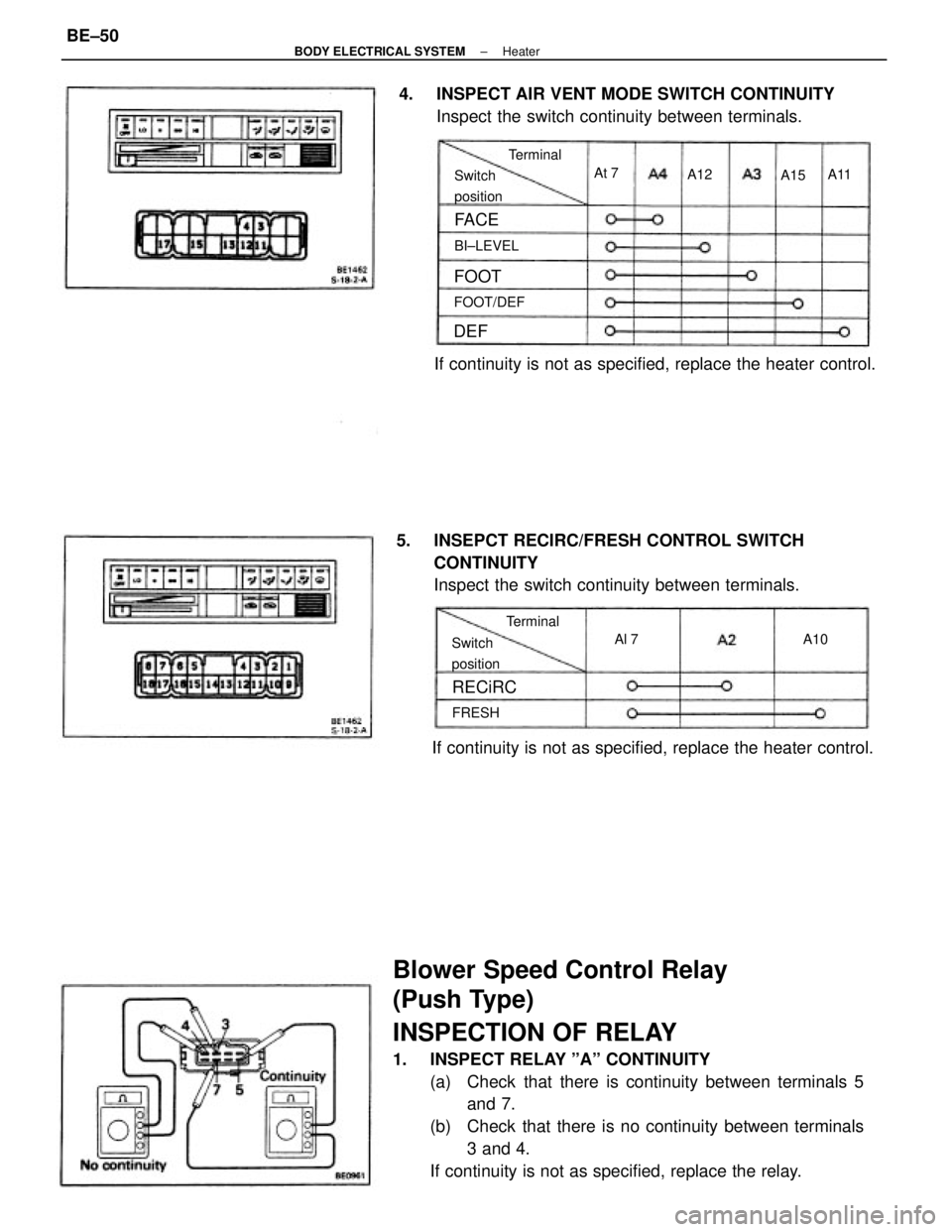

Blower Speed Control Relay

(Push Type)

INSPECTION OF RELAY

1. INSPECT RELAY ºAº CONTINUITY

(a) Check that there is continuity between terminals 5

and 7.

(b) Check that there is no continuity between terminals

3 and 4.

If continuity is not as specified, replace the relay. 5. INSEPCT RECIRC/FRESH CONTROL SWITCH

CONTINUITY

Inspect the switch continuity between terminals. 4. INSPECT AIR VENT MODE SWITCH CONTINUITY

Inspect the switch continuity between terminals.

If continuity is not as specified, replace the heater control.

If continuity is not as specified, replace the heater control.

Switch

positionSwitch

position

FOOT/DEFBI±LEVELTerminal

Terminal

RECiRC

FRESH

FA C E

FOOT

Al 7 A10 At 7

A11

DEF

A12

A15

± BODY ELECTRICAL SYSTEMHeaterBE±50