light TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 288 of 2389

3. INSPECT EACH UP±SHIFT POSITION

(a) Warm up the engine.

Coolant temperature: 176

°F (80°C)

(b) Turn the O/D switch to ºONº.

(c) Place the pattern select switch in ºNormalº and the shift

lever into the D range.

(d) During a road test (above 10 km/h or 6 mph) check that

voltage at the ECT terminal is as indicated below for

each up±shift position.

If the voltage rises from 0V to 7V in the sequence

shown, the control system is okay.

The chart on the left shows the voltmeter reading and

corresponding gears. .

HINT: Determine the gear position by a light shock or

change in engine rpm when shifting. The lock±up clutch

will turn ON only infrequently during normal 2nd and 3rd

gear operation. To trigger this action, press the acceler-

ator pedal to 50% or more of its stroke. At less than

50%, the voltage may change in the sequence 2V ± 4V

± 6V ± 7V. 2. INSPECT BRAKE SIGNAL

(a) Depress the accelerator pedal until the ECT terminal

indicates 8V.

(b) Depress the brake pedal and check the voltage read-

ing from the ECT terminal.

(c) Brake pedal depressed . . . . . . . . . . 0V

Brake pedal released . . . . . . . . . . . . 8V

If not as indicated, there is a malfunction in either the

stop light switch or circuit.

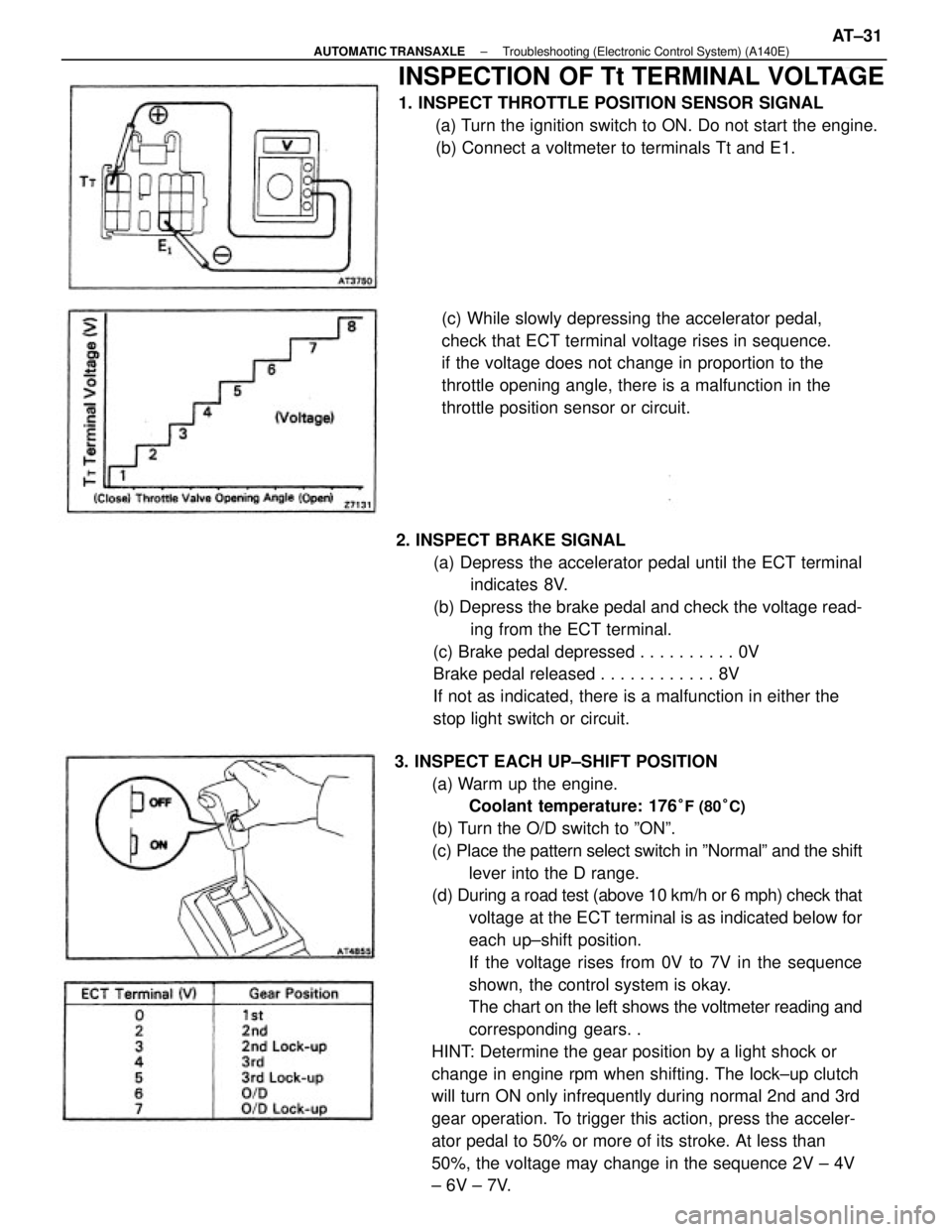

INSPECTION OF Tt TERMINAL VOLTAGE

1. INSPECT THROTTLE POSITION SENSOR SIGNAL

(a) Turn the ignition switch to ON. Do not start the engine.

(b) Connect a voltmeter to terminals Tt and E1.

(c) While slowly depressing the accelerator pedal,

check that ECT terminal voltage rises in sequence.

if the voltage does not change in proportion to the

throttle opening angle, there is a malfunction in the

throttle position sensor or circuit.

± AUTOMATIC TRANSAXLETroubleshooting (Electronic Control System) (A140E)AT±31

Page 292 of 2389

(e) Turn the O/D switch ON.

(d) Select the normal pattern.

(e) Drive .at around 50 km/h (31 mph) to where 7, 5 or 3

volts appears on the voltmeter (this is the lock±up

range) .

(f) Depress the accelerator pedal and read the tachometer.

If there is a big jump in engine rpm there is not lock±

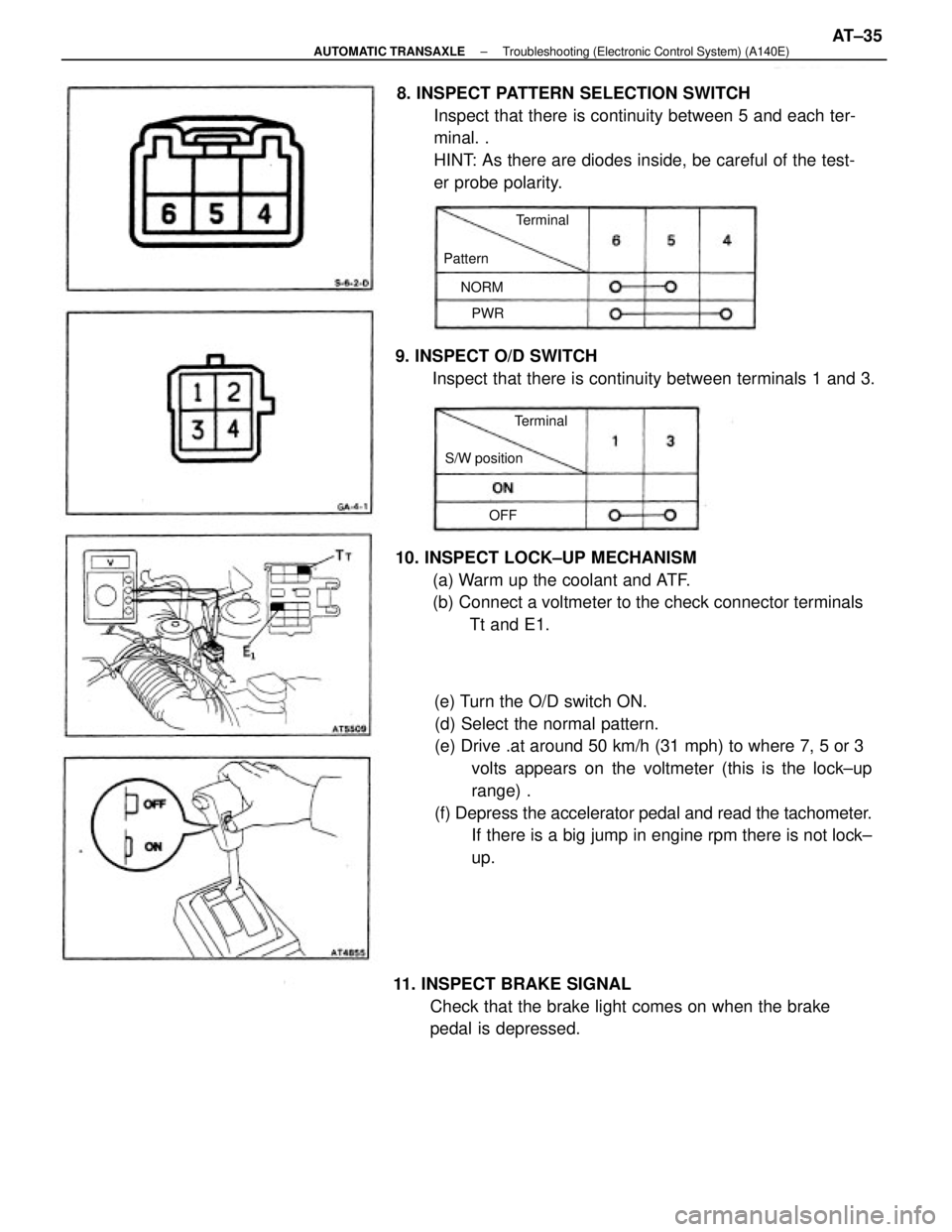

up. 8. INSPECT PATTERN SELECTION SWITCH

Inspect that there is continuity between 5 and each ter-

minal. .

HINT: As there are diodes inside, be careful of the test-

er probe polarity.

10. INSPECT LOCK±UP MECHANISM

(a) Warm up the coolant and ATF.

(b) Connect a voltmeter to the check connector terminals

Tt and E1.

11. INSPECT BRAKE SIGNAL

Check that the brake light comes on when the brake

pedal is depressed. 9. INSPECT O/D SWITCH

Inspect that there is continuity between terminals 1 and 3.

S/W positionTerminal

Terminal Pattern

NORM

PWR

OFF

± AUTOMATIC TRANSAXLETroubleshooting (Electronic Control System) (A140E)AT±35

Page 299 of 2389

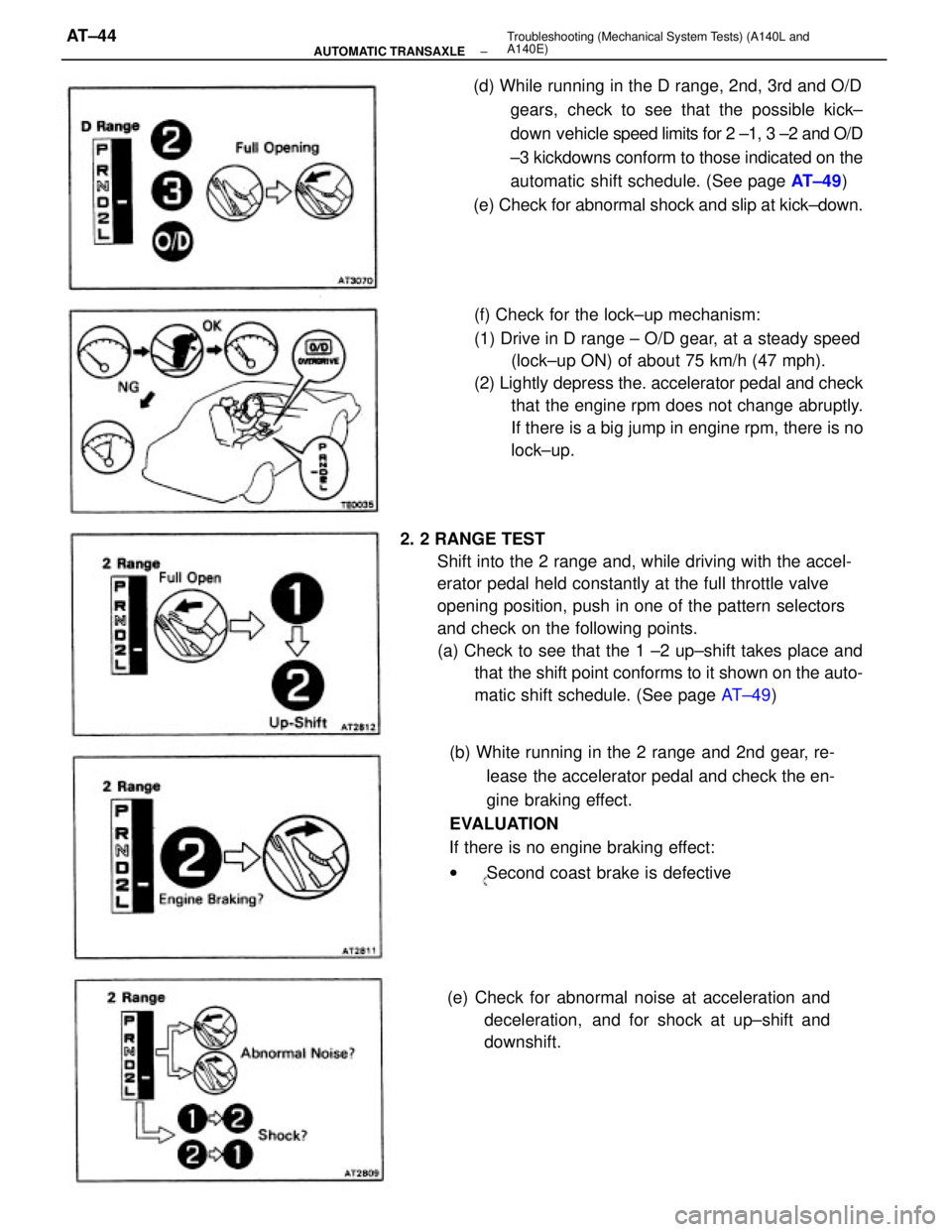

2. 2 RANGE TEST

Shift into the 2 range and, while driving with the accel-

erator pedal held constantly at the full throttle valve

opening position, push in one of the pattern selectors

and check on the following points.

(a) Check to see that the 1 ±2 up±shift takes place and

that the shift point conforms to it shown on the auto-

matic shift schedule. (See page AT±49)

(b) White running in the 2 range and 2nd gear, re-

lease the accelerator pedal and check the en-

gine braking effect.

EVALUATION

If there is no engine braking effect:

wSecond coast brake is defective (d) While running in the D range, 2nd, 3rd and O/D

gears, check to see that the possible kick±

down vehicle speed limits for 2 ±1, 3 ±2 and O/D

±3 kickdowns conform to those indicated on the

automatic shift schedule. (See page AT±49)

(e) Check for abnormal shock and slip at kick±down.

(f) Check for the lock±up mechanism:

(1) Drive in D range ± O/D gear, at a steady speed

(lock±up ON) of about 75 km/h (47 mph).

(2) Lightly depress the. accelerator pedal and check

that the engine rpm does not change abruptly.

If there is a big jump in engine rpm, there is no

lock±up.

(e) Check for abnormal noise at acceleration and

deceleration, and for shock at up±shift and

downshift.

± AUTOMATIC TRANSAXLETroubleshooting (Mechanical System Tests) (A140L and

A140E)AT±44

Page 302 of 2389

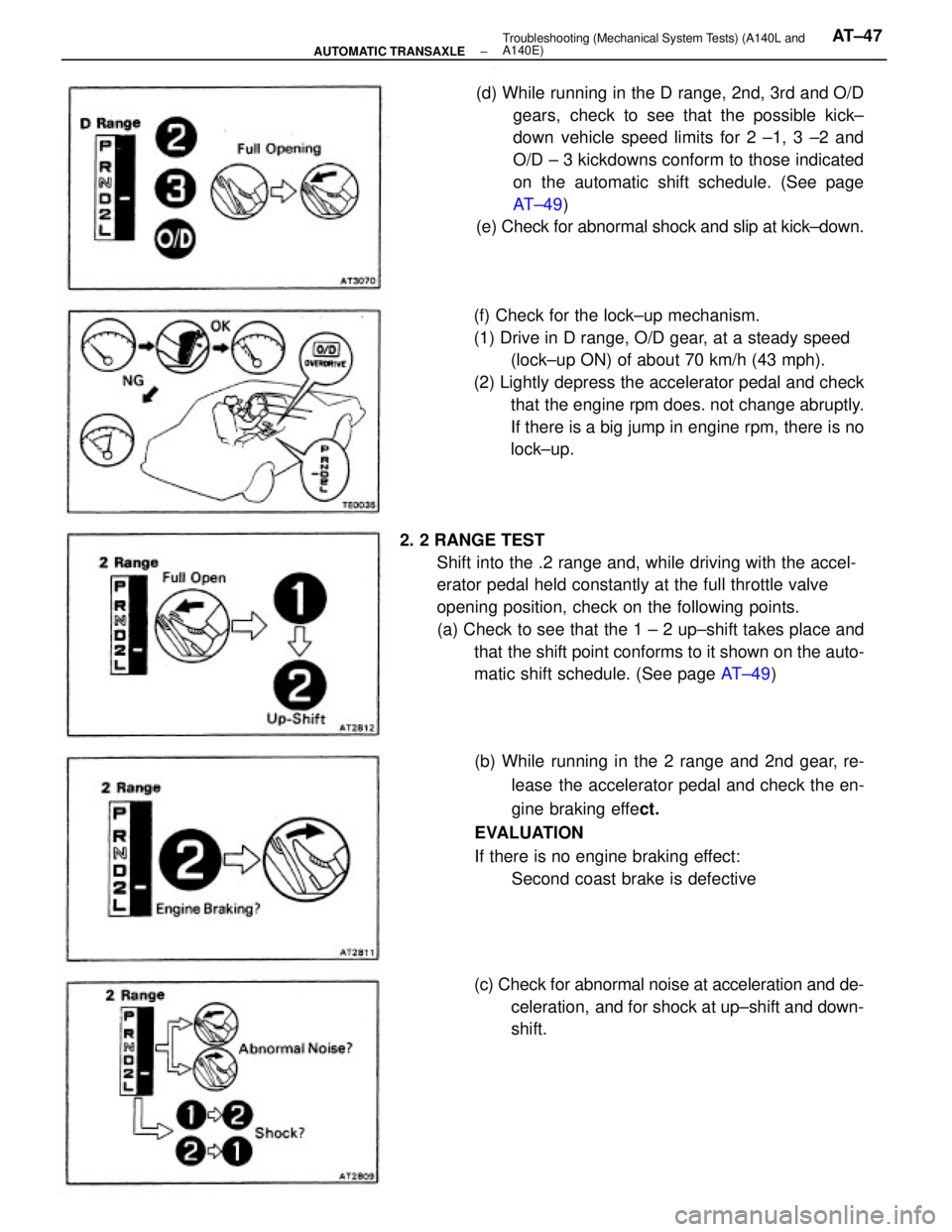

2. 2 RANGE TEST

Shift into the .2 range and, while driving with the accel-

erator pedal held constantly at the full throttle valve

opening position, check on the following points.

(a) Check to see that the 1 ± 2 up±shift takes place and

that the shift point conforms to it shown on the auto-

matic shift schedule. (See page AT±49) (f) Check for the lock±up mechanism.

(1) Drive in D range, O/D gear, at a steady speed

(lock±up ON) of about 70 km/h (43 mph).

(2) Lightly depress the accelerator pedal and check

that the engine rpm does. not change abruptly.

If there is a big jump in engine rpm, there is no

lock±up.

(b) While running in the 2 range and 2nd gear, re-

lease the accelerator pedal and check the en-

gine braking effect.

EVALUATION

If there is no engine braking effect:

Second coast brake is defective (d) While running in the D range, 2nd, 3rd and O/D

gears, check to see that the possible kick±

down vehicle speed limits for 2 ±1, 3 ±2 and

O/D ± 3 kickdowns conform to those indicated

on the automatic shift schedule. (See page

AT±49)

(e) Check for abnormal shock and slip at kick±down.

(c) Check for abnormal noise at acceleration and de-

celeration, and for shock at up±shift and down-

shift.

± AUTOMATIC TRANSAXLETroubleshooting (Mechanical System Tests) (A140L and

A140E)AT±47

Page 304 of 2389

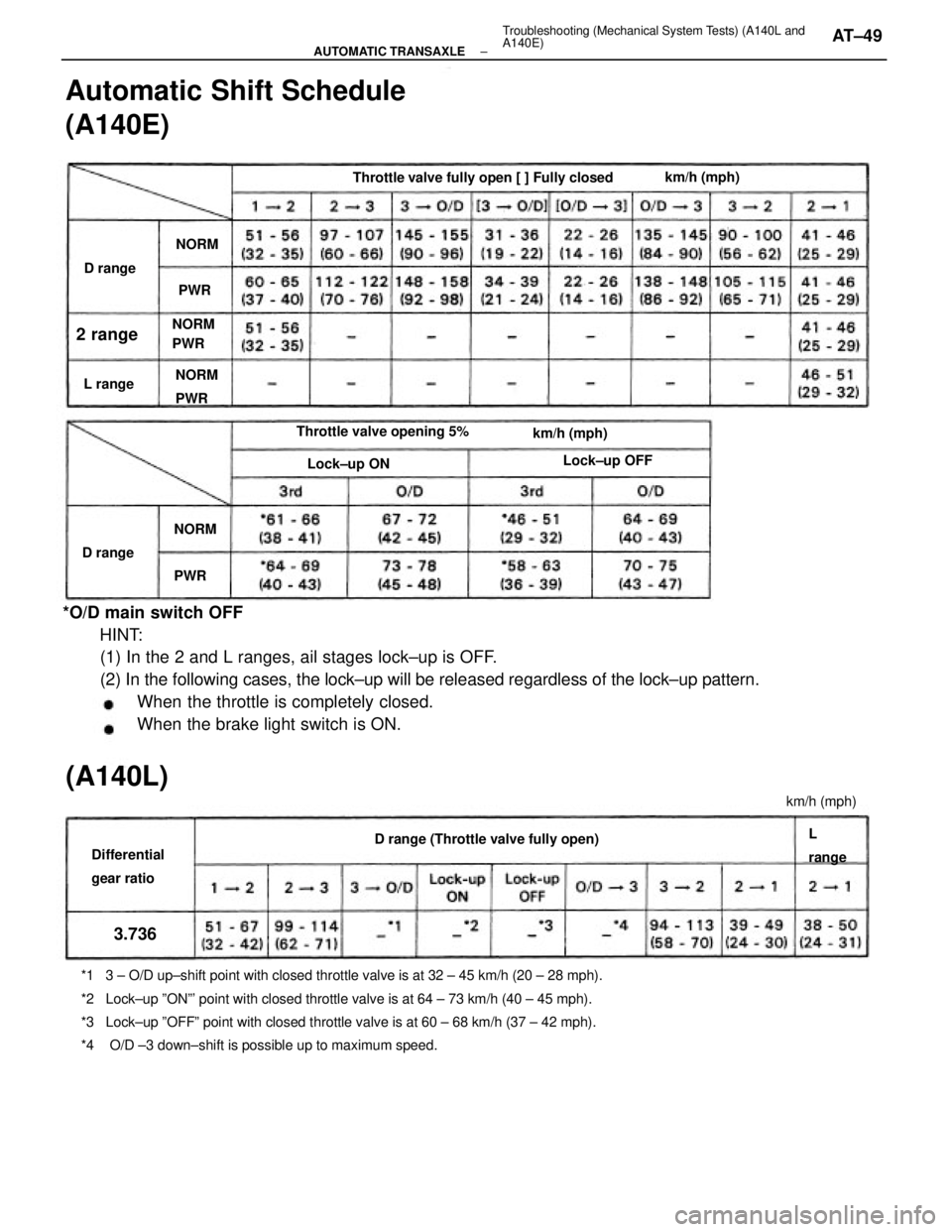

*O/D main switch OFF

HINT:

(1) In the 2 and L ranges, ail stages lock±up is OFF.

(2) In the following cases, the lock±up will be released regardless of the lock±up pattern.

When the throttle is completely closed.

When the brake light switch is ON.

*1 3 ± O/D up±shift point with closed throttle valve is at 32 ± 45 km/h (20 ± 28 mph).

*2 Lock±up ºONº' point with closed throttle valve is at 64 ± 73 km/h (40 ± 45 mph).

*3 Lock±up ºOFFº point with closed throttle valve is at 60 ± 68 km/h (37 ± 42 mph).

*4 O/D ±3 down±shift is possible up to maximum speed.

Automatic Shift Schedule

(A140E)

Throttle valve fully open [ ] Fully closed

D range (Throttle valve fully open) Throttle valve opening 5%

Differential

gear ratio

(A140L)

km/h (mph)

Lock±up OFF

km/h (mph) km/h (mph)

Lock±up ON NORM

PWR NORM

PWR

L

range D range

2 range

D range

L range

NORMNORM

3.736

PWRPWR

± AUTOMATIC TRANSAXLETroubleshooting (Mechanical System Tests) (A140L and

A140E)AT±49

Page 307 of 2389

6. INSTALL NEUTRAL START SWITCH

(a) Install the neutral start switch.

(b) Install the manual shift lever.

(c) Adjust the neutral start switch.

(See page AT±22)

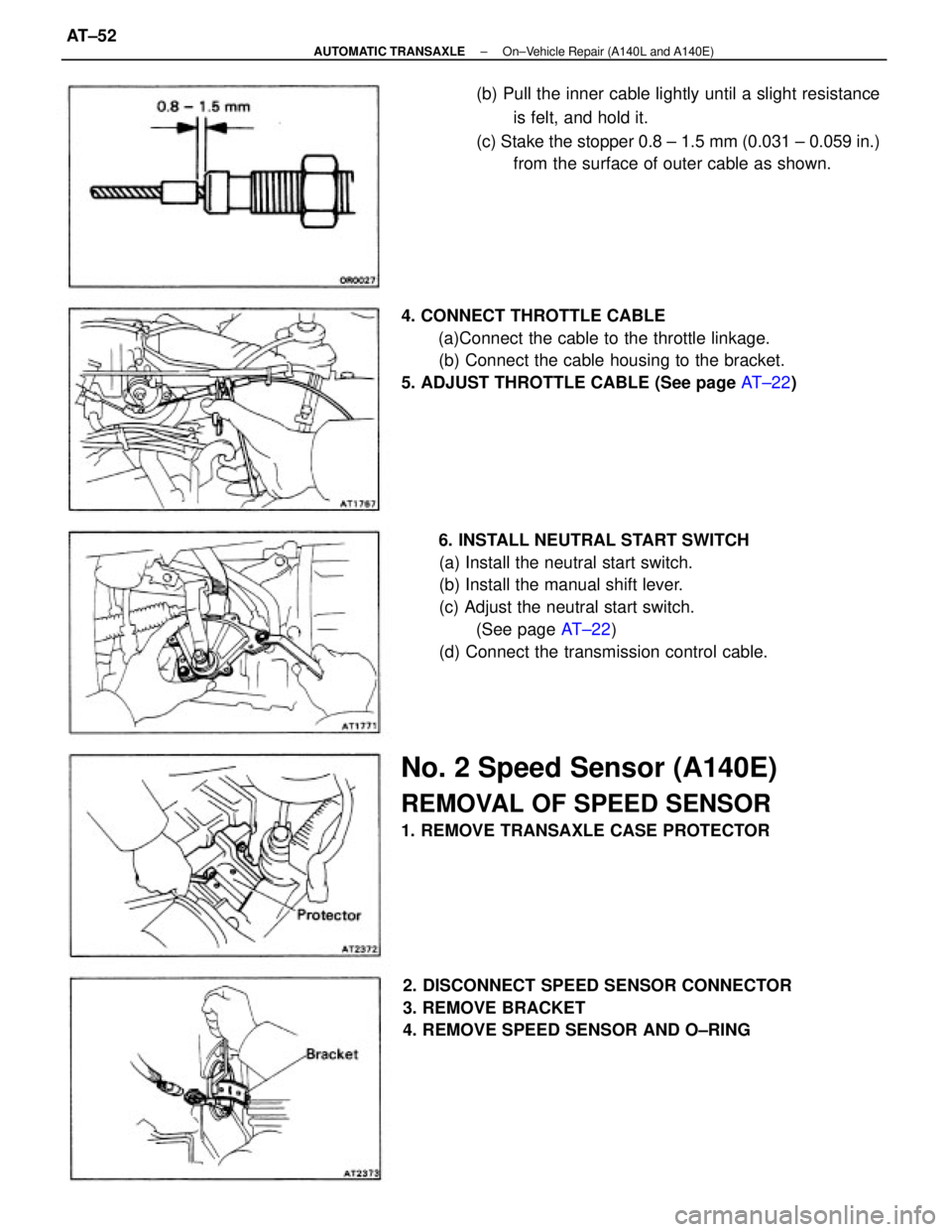

(d) Connect the transmission control cable. 4. CONNECT THROTTLE CABLE

(a)Connect the cable to the throttle linkage.

(b) Connect the cable housing to the bracket.

5. ADJUST THROTTLE CABLE (See page AT±22) (b) Pull the inner cable lightly until a slight resistance

is felt, and hold it.

(c) Stake the stopper 0.8 ± 1.5 mm (0.031 ± 0.059 in.)

from the surface of outer cable as shown.

No. 2 Speed Sensor (A140E)

REMOVAL OF SPEED SENSOR

1. REMOVE TRANSAXLE CASE PROTECTOR

2. DISCONNECT SPEED SENSOR CONNECTOR

3. REMOVE BRACKET

4. REMOVE SPEED SENSOR AND O±RING

± AUTOMATIC TRANSAXLEOn±Vehicle Repair (A140L and A140E)AT±52

Page 331 of 2389

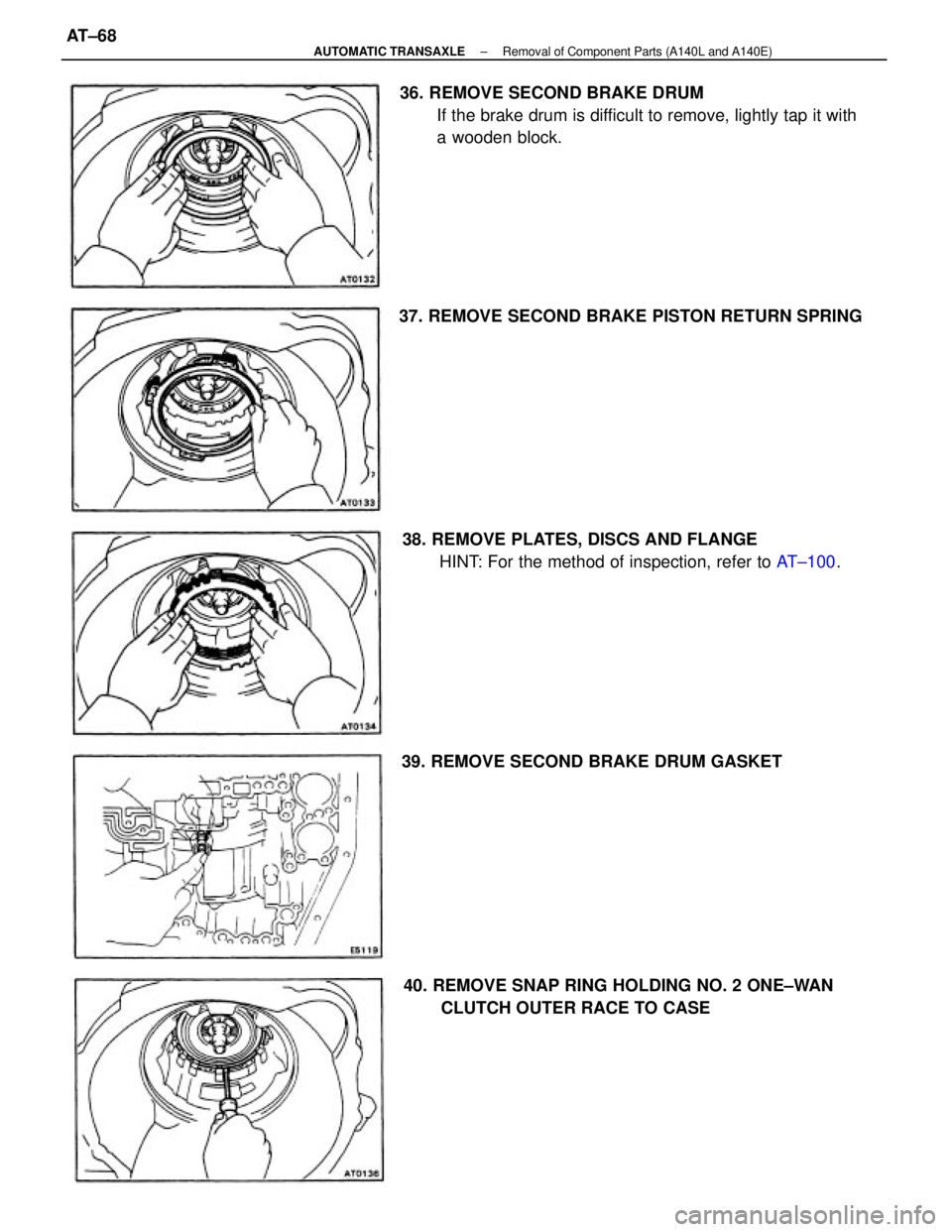

36. REMOVE SECOND BRAKE DRUM

If the brake drum is difficult to remove, lightly tap it with

a wooden block.

38. REMOVE PLATES, DISCS AND FLANGE

HINT: For the method of inspection, refer to AT±100.

40. REMOVE SNAP RING HOLDING NO. 2 ONE±WAN

CLUTCH OUTER RACE TO CASE 37. REMOVE SECOND BRAKE PISTON RETURN SPRING

39. REMOVE SECOND BRAKE DRUM GASKET

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±68

Page 334 of 2389

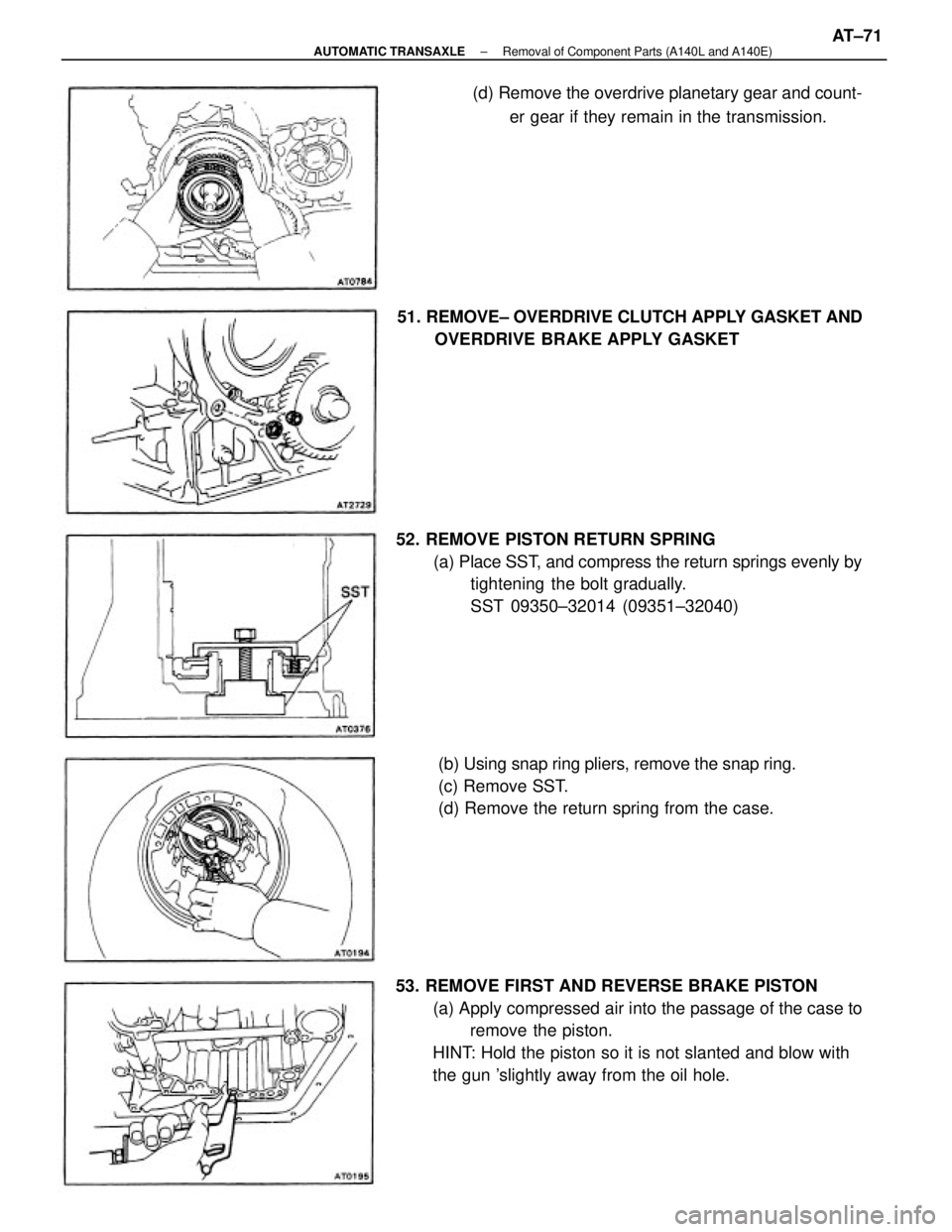

53. REMOVE FIRST AND REVERSE BRAKE PISTON

(a) Apply compressed air into the passage of the case to

remove the piston.

HINT: Hold the piston so it is not slanted and blow with

the gun 'slightly away from the oil hole. 52. REMOVE PISTON RETURN SPRING

(a) Place SST, and compress the return springs evenly by

tightening the bolt gradually.

SST 09350±32014 (09351±32040)

(b) Using snap ring pliers, remove the snap ring.

(c) Remove SST.

(d) Remove the return spring from the case. 51. REMOVE± OVERDRIVE CLUTCH APPLY GASKET AND

OVERDRIVE BRAKE APPLY GASKET(d) Remove the overdrive planetary gear and count-

er gear if they remain in the transmission.

± AUTOMATIC TRANSAXLERemoval of Component Parts (A140L and A140E)AT±71

Page 361 of 2389

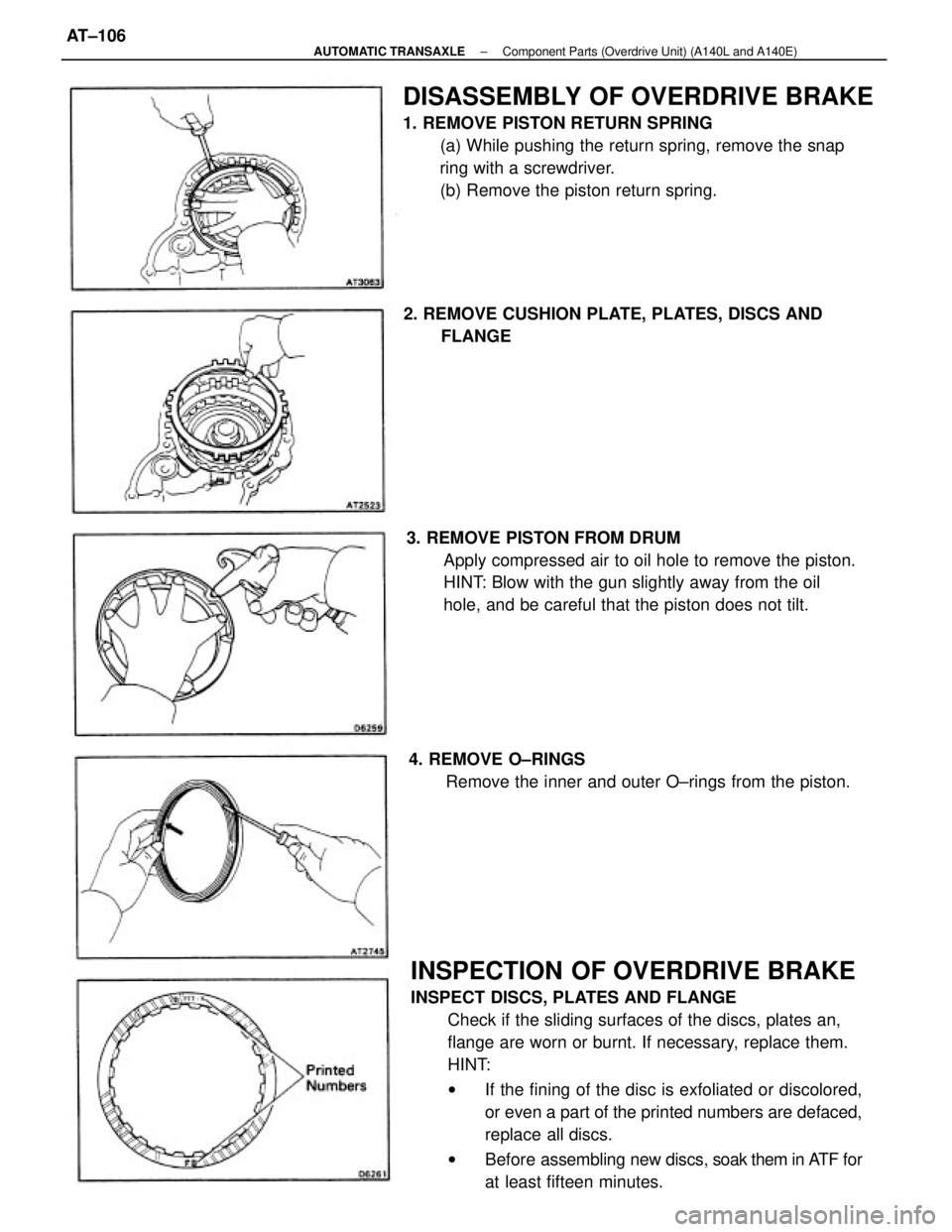

INSPECTION OF OVERDRIVE BRAKE

INSPECT DISCS, PLATES AND FLANGE

Check if the sliding surfaces of the discs, plates an,

flange are worn or burnt. If necessary, replace them.

HINT:

wIf the fining of the disc is exfoliated or discolored,

or even a part of the printed numbers are defaced,

replace all discs.

wBefore assembling new discs, soak them in ATF for

at least fifteen minutes.

DISASSEMBLY OF OVERDRIVE BRAKE

1. REMOVE PISTON RETURN SPRING

(a) While pushing the return spring, remove the snap

ring with a screwdriver.

(b) Remove the piston return spring.

3. REMOVE PISTON FROM DRUM

Apply compressed air to oil hole to remove the piston.

HINT: Blow with the gun slightly away from the oil

hole, and be careful that the piston does not tilt.

4. REMOVE O±RINGS

Remove the inner and outer O±rings from the piston. 2. REMOVE CUSHION PLATE, PLATES, DISCS AND

FLANGE

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit) (A140L and A140E)AT±106

Page 370 of 2389

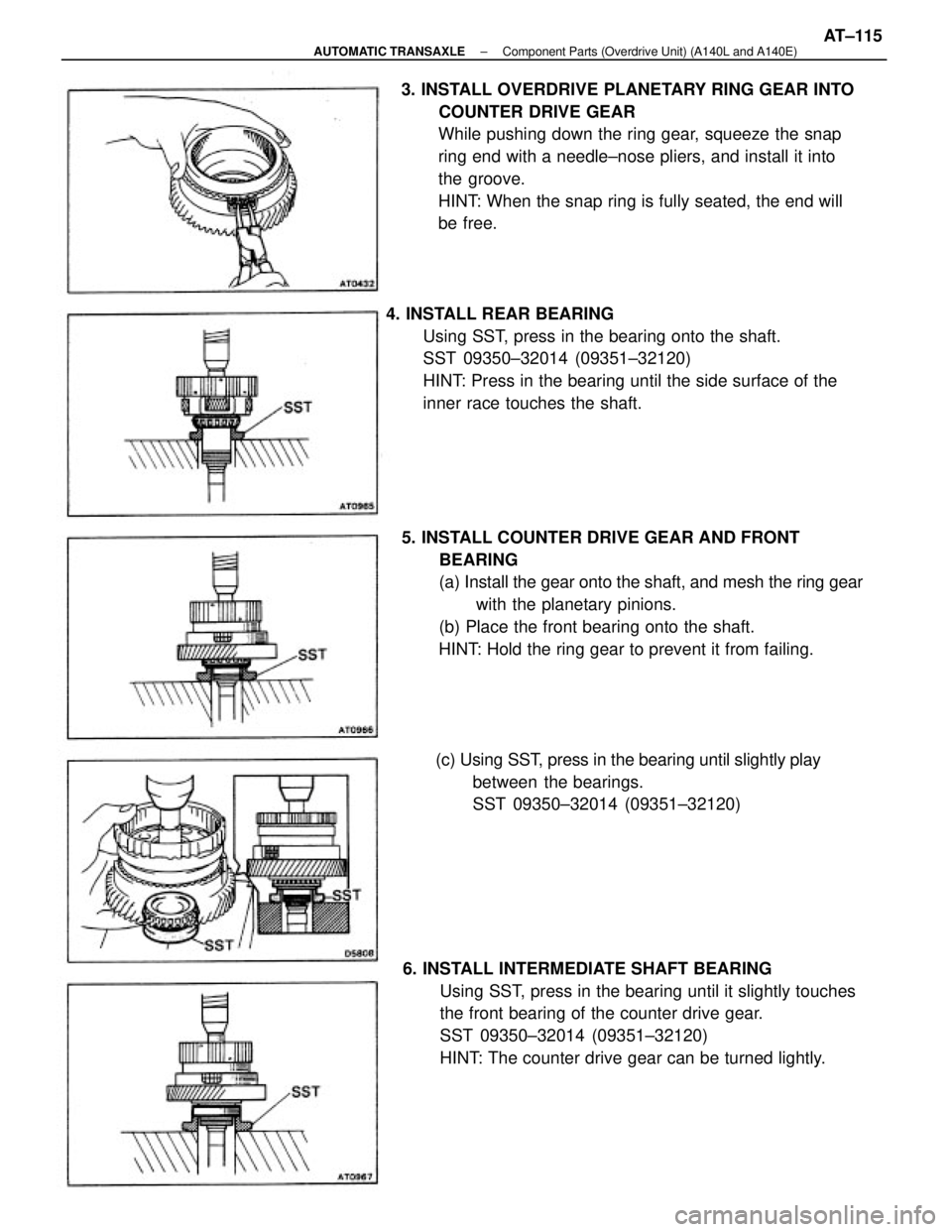

5. INSTALL COUNTER DRIVE GEAR AND FRONT

BEARING

(a) Install the gear onto the shaft, and mesh the ring gear

with the planetary pinions.

(b) Place the front bearing onto the shaft.

HINT: Hold the ring gear to prevent it from failing.

6. INSTALL INTERMEDIATE SHAFT BEARING

Using SST, press in the bearing until it slightly touches

the front bearing of the counter drive gear.

SST 09350±32014 (09351±32120)

HINT: The counter drive gear can be turned lightly. 3. INSTALL OVERDRIVE PLANETARY RING GEAR INTO

COUNTER DRIVE GEAR

While pushing down the ring gear, squeeze the snap

ring end with a needle±nose pliers, and install it into

the groove.

HINT: When the snap ring is fully seated, the end will

be free.

4. INSTALL REAR BEARING

Using SST, press in the bearing onto the shaft.

SST 09350±32014 (09351±32120)

HINT: Press in the bearing until the side surface of the

inner race touches the shaft.

(c) Using SST, press in the bearing until slightly play

between the bearings.

SST 09350±32014 (09351±32120)

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit) (A140L and A140E)AT±115