light TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 479 of 2389

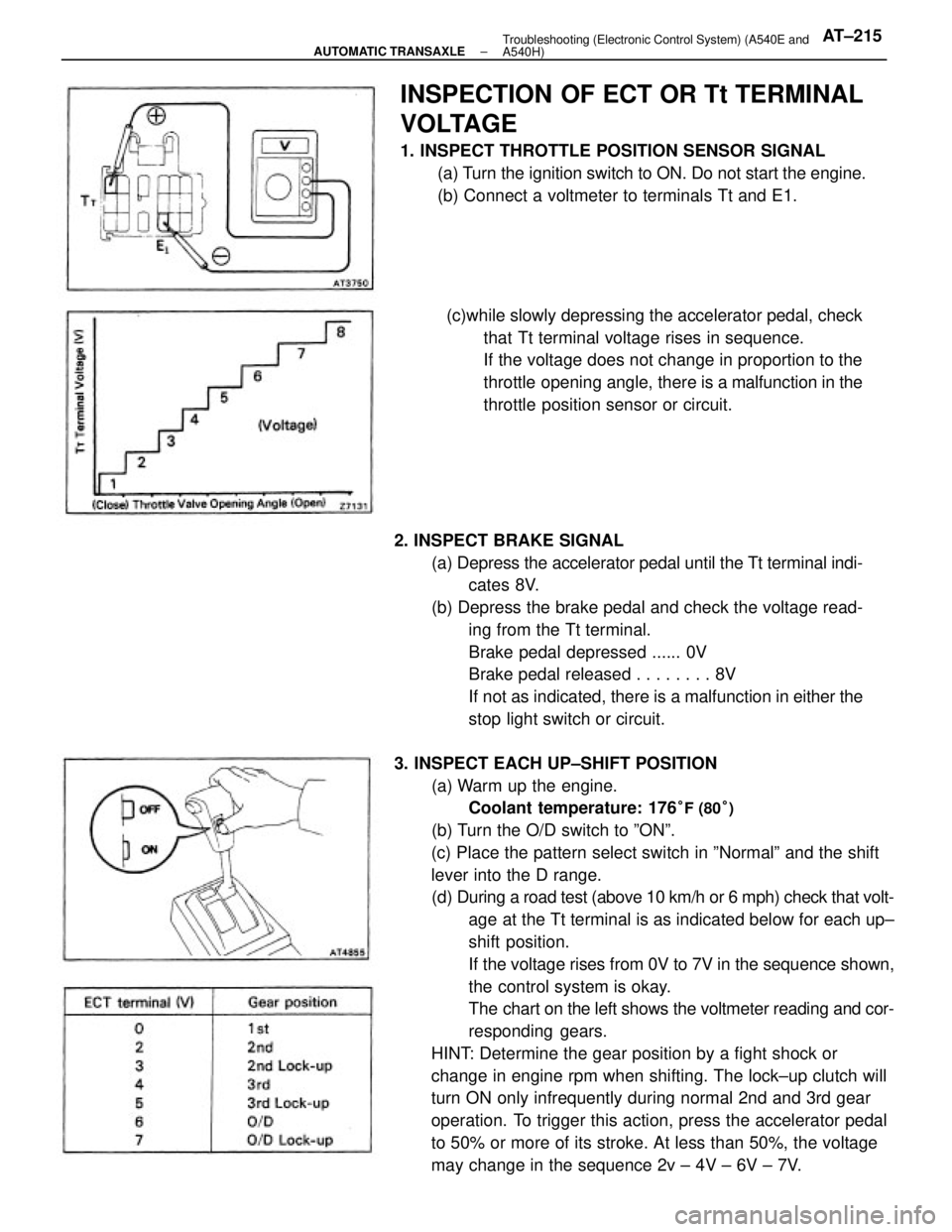

3. INSPECT EACH UP±SHIFT POSITION

(a) Warm up the engine.

Coolant temperature: 176

°F (80°)

(b) Turn the O/D switch to ºONº.

(c) Place the pattern select switch in ºNormalº and the shift

lever into the D range.

(d) During a road test (above 10 km/h or 6 mph) check that volt-

age at the Tt terminal is as indicated below for each up±

shift position.

If the voltage rises from 0V to 7V in the sequence shown,

the control system is okay.

The chart on the left shows the voltmeter reading and cor-

responding gears.

HINT: Determine the gear position by a fight shock or

change in engine rpm when shifting. The lock±up clutch will

turn ON only infrequently during normal 2nd and 3rd gear

operation. To trigger this action, press the accelerator pedal

to 50% or more of its stroke. At less than 50%, the voltage

may change in the sequence 2v ± 4V ± 6V ± 7V. 2. INSPECT BRAKE SIGNAL

(a) Depress the accelerator pedal until the Tt terminal indi-

cates 8V.

(b) Depress the brake pedal and check the voltage read-

ing from the Tt terminal.

Brake pedal depressed ...... 0V

Brake pedal released . . . . . . . . 8V

If not as indicated, there is a malfunction in either the

stop light switch or circuit.

INSPECTION OF ECT OR Tt TERMINAL

VOLTAGE

1. INSPECT THROTTLE POSITION SENSOR SIGNAL

(a) Turn the ignition switch to ON. Do not start the engine.

(b) Connect a voltmeter to terminals Tt and E1.

(c)while slowly depressing the accelerator pedal, check

that Tt terminal voltage rises in sequence.

If the voltage does not change in proportion to the

throttle opening angle, there is a malfunction in the

throttle position sensor or circuit.

± AUTOMATIC TRANSAXLETroubleshooting (Electronic Control System) (A540E and

A540H)AT±215

Page 486 of 2389

INSTALLATION OF THROTTLE CABLE

1. INSTALL CABLE INTO TRANSMISSION CASE

2. INSTALL VALVE BODY

3. IF THROTTLE CABLE IS NEW, STAKE STOPPER OR

PAINT MARK ON INNER CABLE

HINT: New cable do not have a cable stopper staked.

(a) Bend the cable so there is a radius of about 200 mm(7.87 in.).

(b) Pull the inner cable lightly until a slight resistance is felt, and hold

it.

(e) Stake the stopper, 0.8 ± 1.5 mm (0.031 ± 0.059 in.)

from the end of outer cable.

4. CONNECT THROTTLE CABLE TO ENGINE

5. ADJUST THROTTLE CABLE (See page AT±201)

6. INSTALL AND ADJUST NEUTRAL START SWITCH

7. TEST DRIVE VEHICLE

Throttle Cable

REMOVAL OF THROTTLE CABLE

1. DISCONNECT THROTTLE CABLE FROM ENGINE

2. REMOVE NEUTRAL START SWITCH

3. REMOVE VALVE BODY

4. REMOVE THROTTLE CABLE

ON±VEHICLE REPAIR

HINT: The components mentioned below can be replaced on the vehicle without any necessity for

removal of the transaxle. For the respective operating procedures refer to the following pages:

Speedometer driven gear oil

seal

Extension housing oil

seal Side gear

shaft oil sealAT±232 and AT±233 AT±242 to AT±244

Throttle cable

Only A540H Components

Valve bodyInstallation

RemovalRemarks

AT±231AT±231

AT±233AT±232

AT±233AT±232

AT±232

± AUTOMATIC TRANSAXLEOn±Vehicle Repair (A540E and A540H)AT±231

Page 520 of 2389

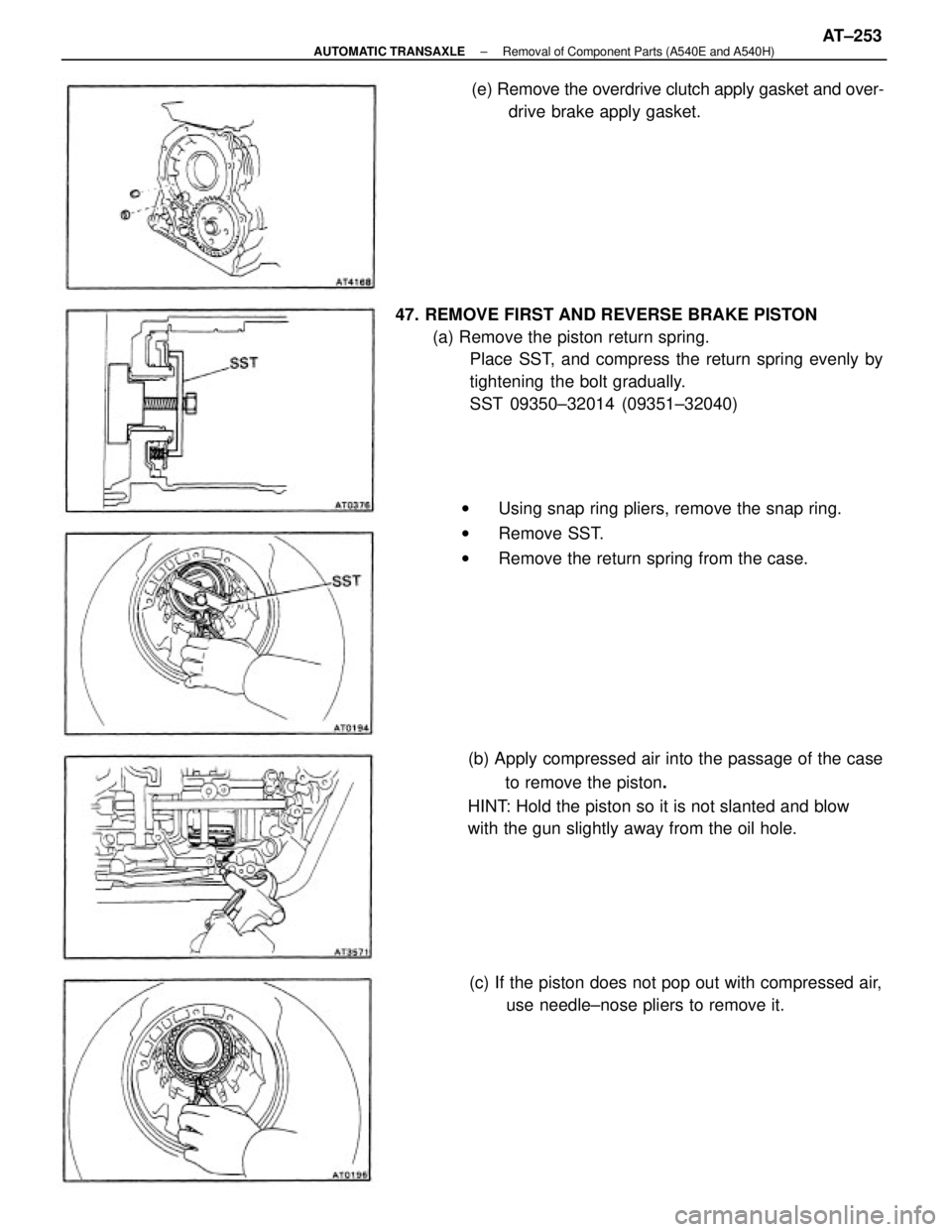

47. REMOVE FIRST AND REVERSE BRAKE PISTON

(a) Remove the piston return spring.

Place SST, and compress the return spring evenly by

tightening the bolt gradually.

SST 09350±32014 (09351±32040)

(b) Apply compressed air into the passage of the case

to remove the piston.

HINT: Hold the piston so it is not slanted and blow

with the gun slightly away from the oil hole. wUsing snap ring pliers, remove the snap ring.

wRemove SST.

wRemove the return spring from the case. (e) Remove the overdrive clutch apply gasket and over-

drive brake apply gasket.

(c) If the piston does not pop out with compressed air,

use needle±nose pliers to remove it.

± AUTOMATIC TRANSAXLERemoval of Component Parts (A540E and A540H)AT±253

Page 546 of 2389

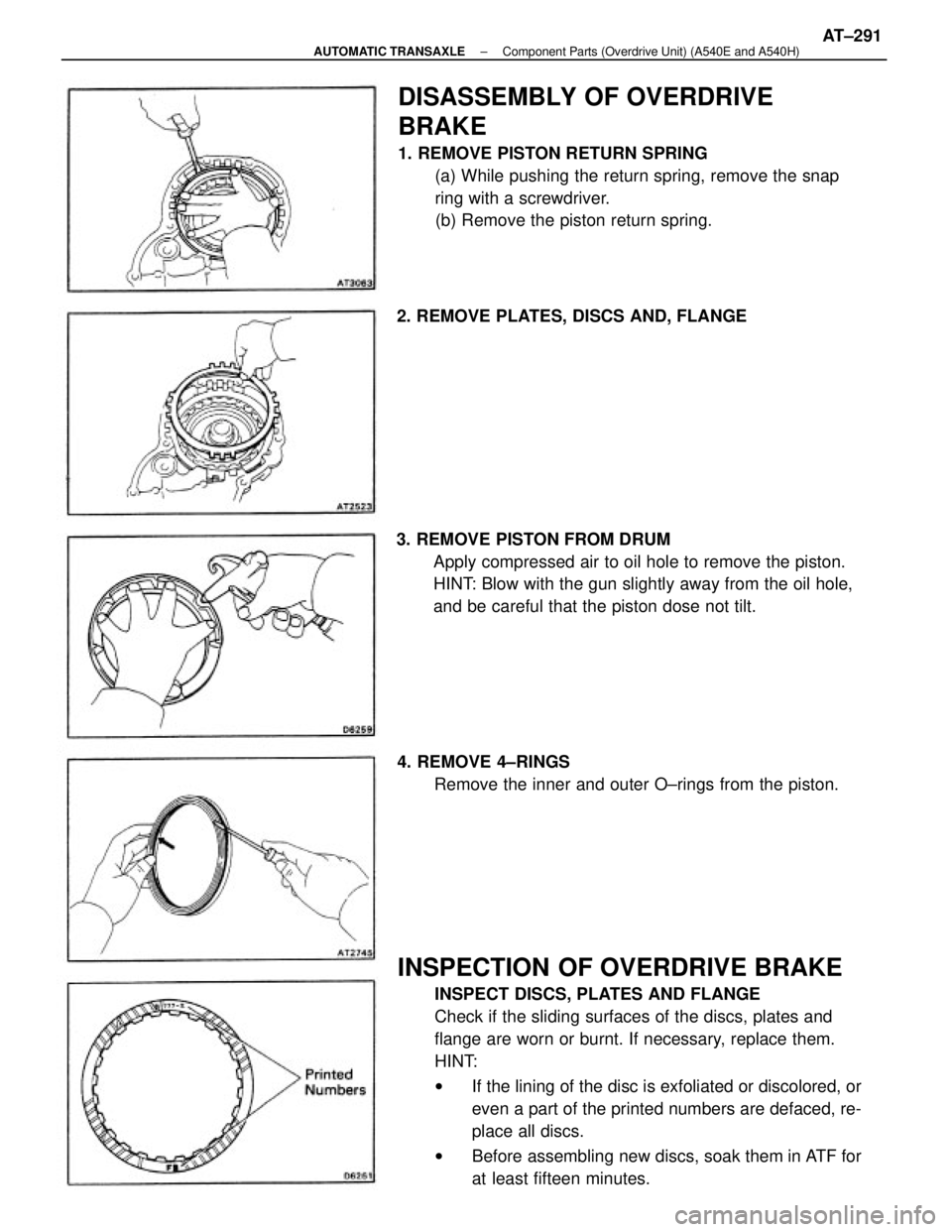

INSPECTION OF OVERDRIVE BRAKE

INSPECT DISCS, PLATES AND FLANGE

Check if the sliding surfaces of the discs, plates and

flange are worn or burnt. If necessary, replace them.

HINT:

wIf the lining of the disc is exfoliated or discolored, or

even a part of the printed numbers are defaced, re-

place all discs.

wBefore assembling new discs, soak them in ATF for

at least fifteen minutes.

DISASSEMBLY OF OVERDRIVE

BRAKE

1. REMOVE PISTON RETURN SPRING

(a) While pushing the return spring, remove the snap

ring with a screwdriver.

(b) Remove the piston return spring.

3. REMOVE PISTON FROM DRUM

Apply compressed air to oil hole to remove the piston.

HINT: Blow with the gun slightly away from the oil hole,

and be careful that the piston dose not tilt.

4. REMOVE 4±RINGS

Remove the inner and outer O±rings from the piston. 2. REMOVE PLATES, DISCS AND, FLANGE

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit) (A540E and A540H)AT±291

Page 556 of 2389

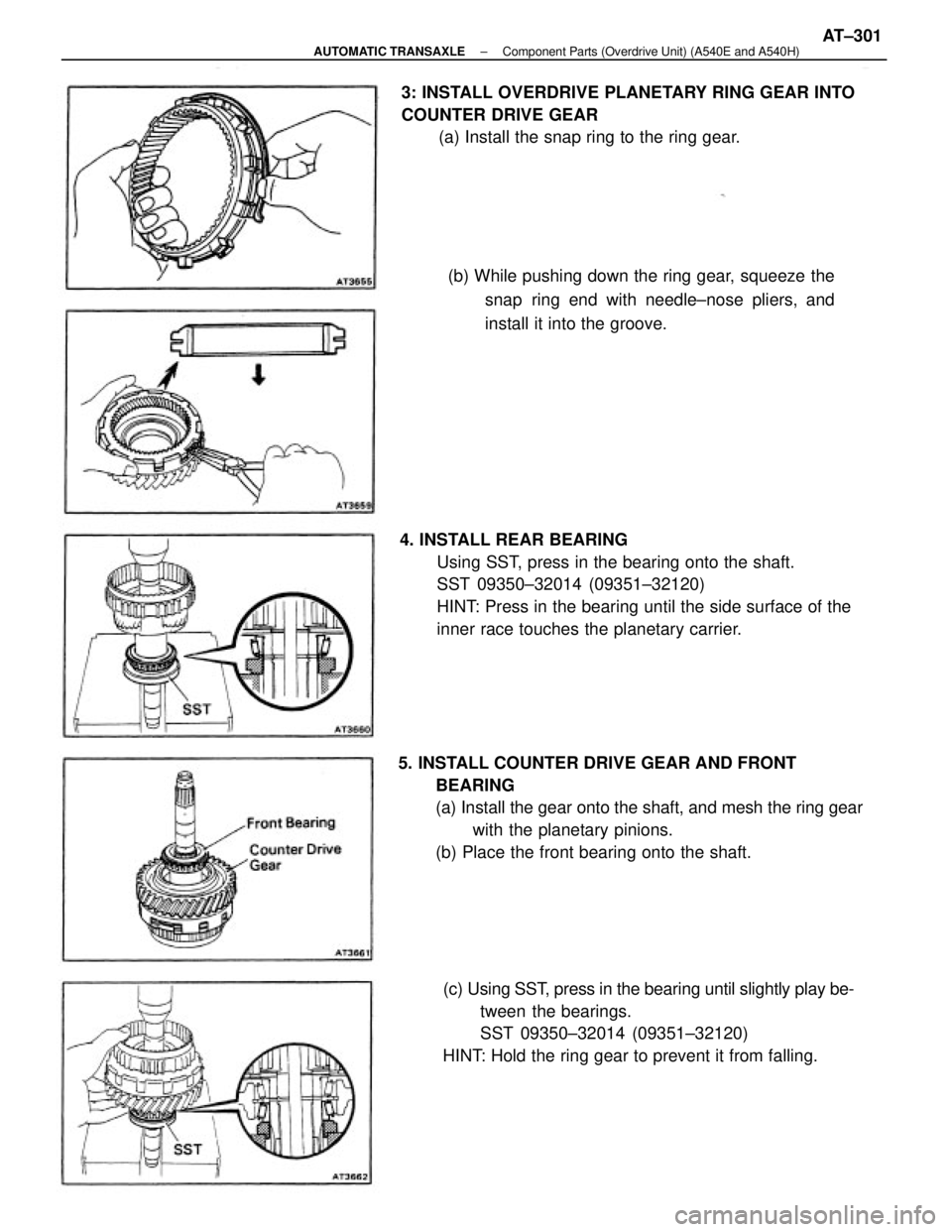

4. INSTALL REAR BEARING

Using SST, press in the bearing onto the shaft.

SST 09350±32014 (09351±32120)

HINT: Press in the bearing until the side surface of the

inner race touches the planetary carrier.

5. INSTALL COUNTER DRIVE GEAR AND FRONT

BEARING

(a) Install the gear onto the shaft, and mesh the ring gear

with the planetary pinions.

(b) Place the front bearing onto the shaft. 3: INSTALL OVERDRIVE PLANETARY RING GEAR INTO

COUNTER DRIVE GEAR

(a) Install the snap ring to the ring gear.

(c) Using SST, press in the bearing until slightly play be-

tween the bearings.

SST 09350±32014 (09351±32120)

HINT: Hold the ring gear to prevent it from falling.(b) While pushing down the ring gear, squeeze the

snap ring end with needle±nose pliers, and

install it into the groove.

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit) (A540E and A540H)AT±301

Page 557 of 2389

8. INSTALL ADJUSTING NUT AND ADJUST PRELOAD

OF COUNTER DRIVE GEAR

(a) Hold the overdrive planetary gear in a vise with soft

jaws.

(b) Using SST, tighten the adjusting nut until the following

gear starting load is reached on the tension gauge.

SST 09350±32014 I09351±32080

Preload (at starting) : 940 ± 1,560 g

(2.1 ± 3.4 Ib, 9.2 ± 15.3 N)

HINT: Turn the counter drive gear right and left several

times before measuring the preload.

(c)Lock the adjusting nut with one tab on locking washer.

Bend the locking washer tab until it is ever with the

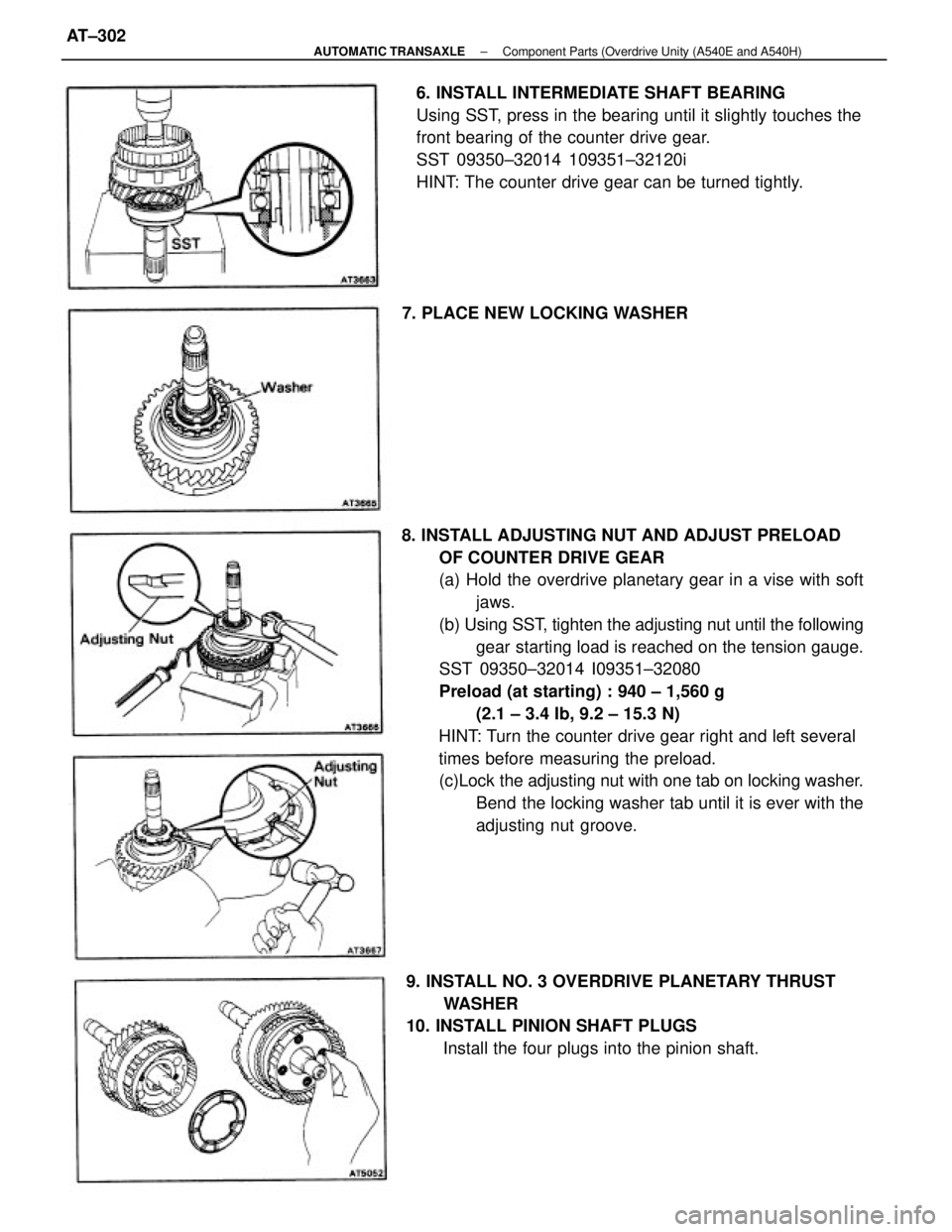

adjusting nut groove. 6. INSTALL INTERMEDIATE SHAFT BEARING

Using SST, press in the bearing until it slightly touches the

front bearing of the counter drive gear.

SST 09350±32014 109351±32120i

HINT: The counter drive gear can be turned tightly.

9. INSTALL NO. 3 OVERDRIVE PLANETARY THRUST

WASHER

10. INSTALL PINION SHAFT PLUGS

Install the four plugs into the pinion shaft. 7. PLACE NEW LOCKING WASHER

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unity (A540E and A540H)AT±302

Page 578 of 2389

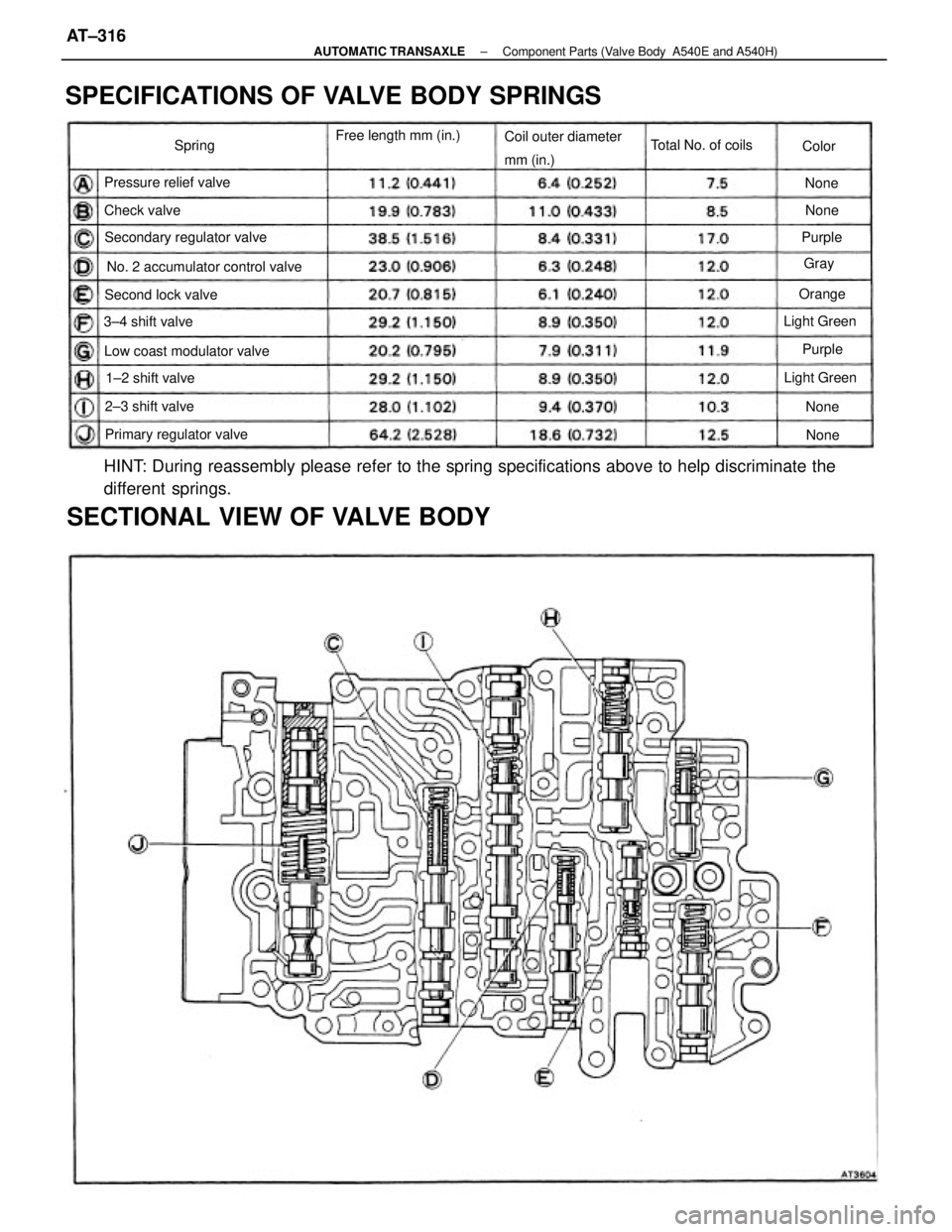

HINT: During reassembly please refer to the spring specifications above to help discriminate the

different springs.

SECTIONAL VIEW OF VALVE BODY SPECIFICATIONS OF VALVE BODY SPRINGS

No. 2 accumulator control valveCoil outer diameter

mm (in.) Free length mm (in.)

Secondary regulator valve

Low coast modulator valve

Primary regulator valve Pressure relief valve

Second lock valveTotal No. of coils

1±2 shift valve 3±4 shift valve

2±3 shift valveLight Green

Light Green Check valve

Orange Spring

Purple PurpleColor

None None

None None Gray

± AUTOMATIC TRANSAXLEComponent Parts (Valve Body A540E and A540H)AT±316

Page 642 of 2389

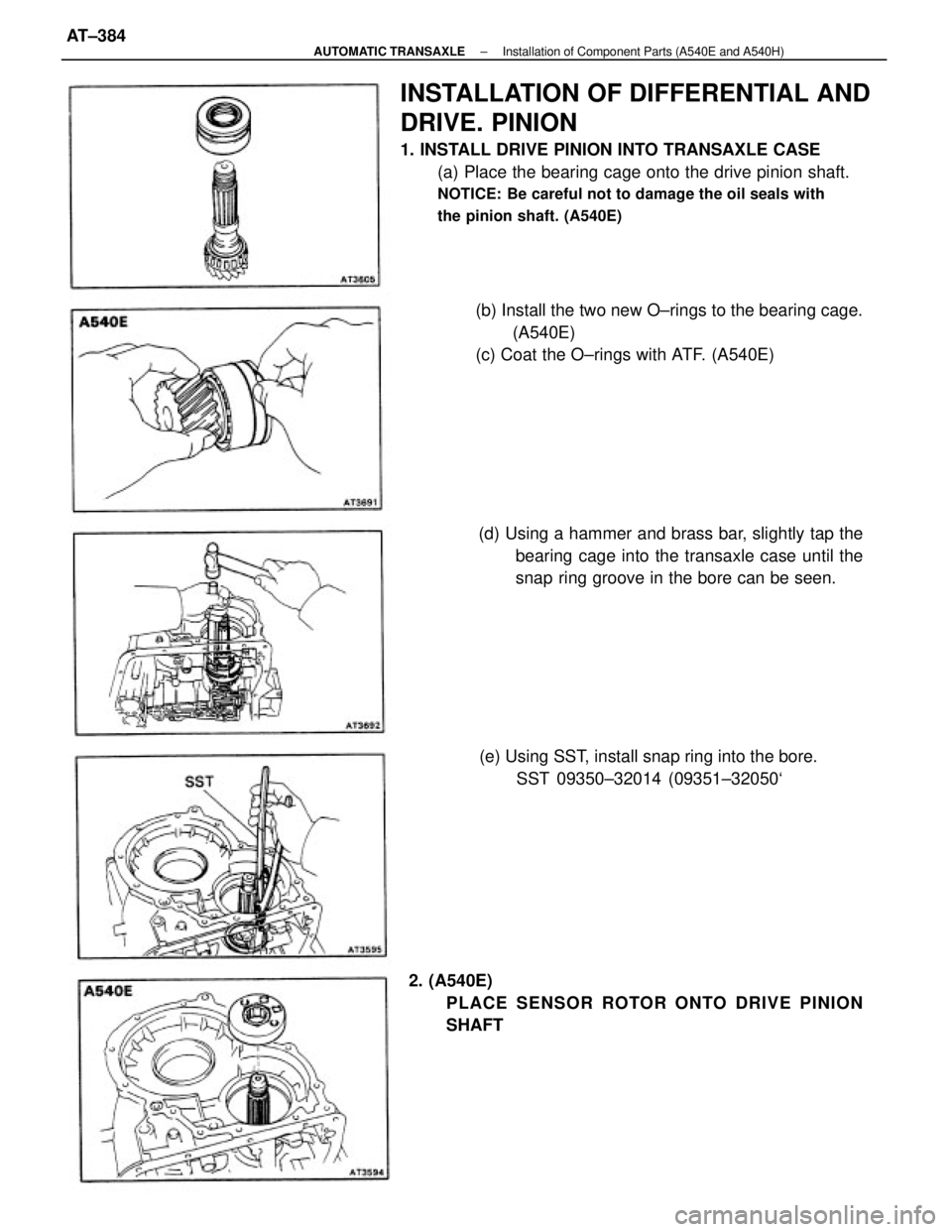

INSTALLATION OF DIFFERENTIAL AND

DRIVE. PINION

1. INSTALL DRIVE PINION INTO TRANSAXLE CASE

(a) Place the bearing cage onto the drive pinion shaft.

NOTICE: Be careful not to damage the oil seals with

the pinion shaft. (A540E)

(b) Install the two new O±rings to the bearing cage.

(A540E)

(c) Coat the O±rings with ATF. (A540E)

(d) Using a hammer and brass bar, slightly tap the

bearing cage into the transaxle case until the

snap ring groove in the bore can be seen.

(e) Using SST, install snap ring into the bore.

SST 09350±32014 (09351±32050`

2. (A540E)

PLACE SENSOR ROTOR ONTO DRIVE PINION

SHAFT

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A540E and A540H)AT±384

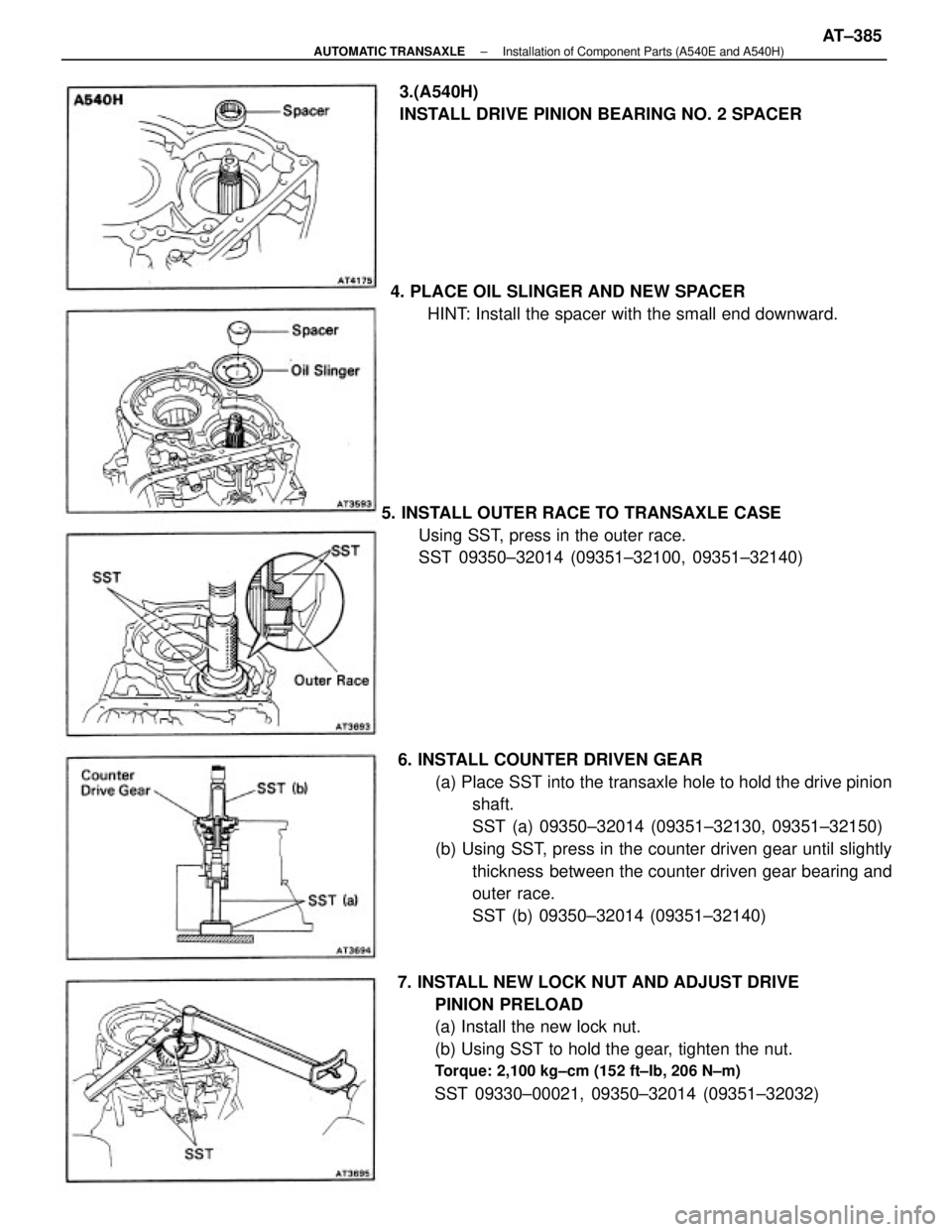

Page 643 of 2389

6. INSTALL COUNTER DRIVEN GEAR

(a) Place SST into the transaxle hole to hold the drive pinion

shaft.

SST (a) 09350±32014 (09351±32130, 09351±32150)

(b) Using SST, press in the counter driven gear until slightly

thickness between the counter driven gear bearing and

outer race.

SST (b) 09350±32014 (09351±32140)

7. INSTALL NEW LOCK NUT AND ADJUST DRIVE

PINION PRELOAD

(a) Install the new lock nut.

(b) Using SST to hold the gear, tighten the nut.

Torque: 2,100 kg±cm (152 ft±Ib, 206 N±m)

SST 09330±00021, 09350±32014 (09351±32032) 5. INSTALL OUTER RACE TO TRANSAXLE CASE

Using SST, press in the outer race.

SST 09350±32014 (09351±32100, 09351±32140) 4. PLACE OIL SLINGER AND NEW SPACER

HINT: Install the spacer with the small end downward. 3.(A540H)

INSTALL DRIVE PINION BEARING NO. 2 SPACER

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A540E and A540H)AT±385

Page 675 of 2389

(b) With the door glass fully closed, .adjust the door glass

stopper so it lightly makes contact with the glass

plate.

11. INSTALL OPENING CONTROL LINK

12. INSTALL SERVICE HOLE COVER

13. INSTALL DOOR TRIM8. INSTALL DOOR GLASS

(a) Place the glass in the door cavity.

(b) Install the glass to the regulator with the two mount-

ing nuts.

9. INSTALL DOOR GLASS RUN

14. INSTALL REAR VIEW MIRROR

(a) Install the mirror with the three screws.

(b) (Electrical type)

Connect the connector.

(c) Install the cover.

(d) (Manual type)

Install the knob with the setting screw.

15. INSTALL DOOR INSIDE HANDLE

(a) Connect the handle to the control link.

(b) Install the handle, slide it rearward, and install the

screw. 10. ADJUST DOOR GLASS

(a) Adjust the equalizer arm up or down and tighten it

where dimensions A and6, as shown, are equal.

± BODYFront DoorBO±9