engine TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1370 of 2389

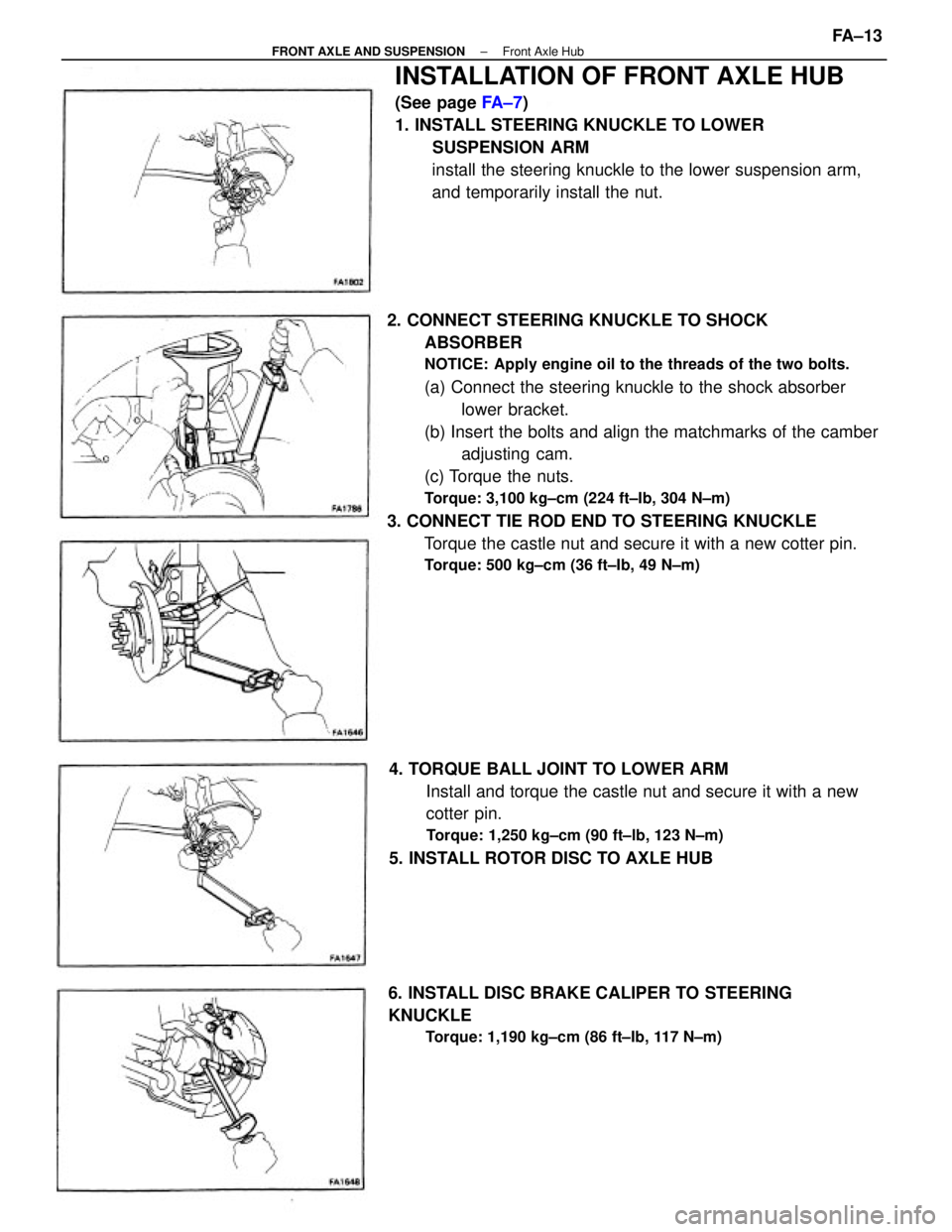

2. CONNECT STEERING KNUCKLE TO SHOCK

ABSORBER

NOTICE: Apply engine oil to the threads of the two bolts.

(a) Connect the steering knuckle to the shock absorber

lower bracket.

(b) Insert the bolts and align the matchmarks of the camber

adjusting cam.

(c) Torque the nuts.

Torque: 3,100 kg±cm (224 ft±Ib, 304 N±m)

3. CONNECT TIE ROD END TO STEERING KNUCKLE

Torque the castle nut and secure it with a new cotter pin.

Torque: 500 kg±cm (36 ft±Ib, 49 N±m)

INSTALLATION OF FRONT AXLE HUB

(See page FA ± 7)

1. INSTALL STEERING KNUCKLE TO LOWER

SUSPENSION ARM

install the steering knuckle to the lower suspension arm,

and temporarily install the nut.

4. TORQUE BALL JOINT TO LOWER ARM

Install and torque the castle nut and secure it with a new

cotter pin.

Torque: 1,250 kg±cm (90 ft±lb, 123 N±m)

5. INSTALL ROTOR DISC TO AXLE HUB

6. INSTALL DISC BRAKE CALIPER TO STEERING

KNUCKLE

Torque: 1,190 kg±cm (86 ft±Ib, 117 N±m)

± FRONT AXLE AND SUSPENSIONFront Axle HubFA±13

Page 1373 of 2389

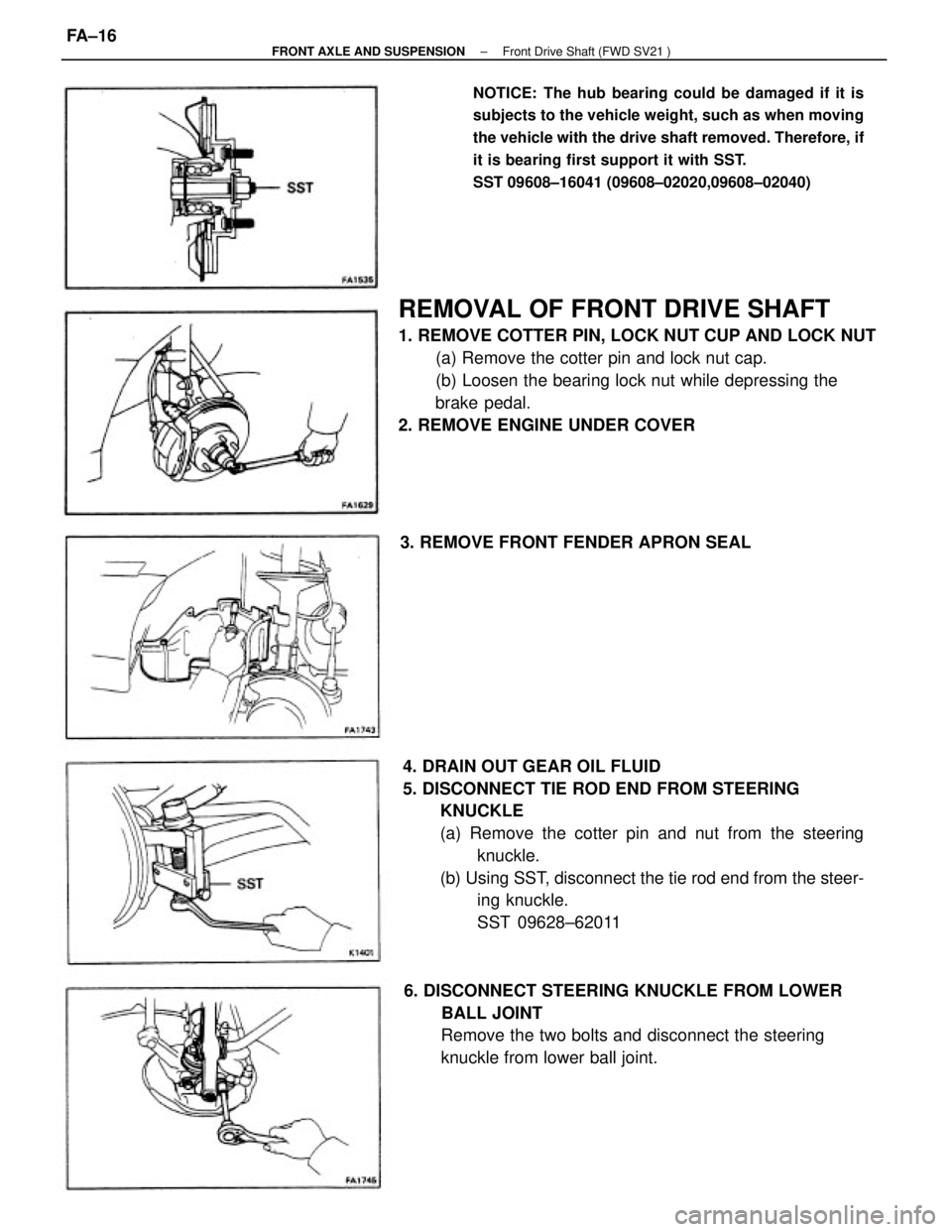

REMOVAL OF FRONT DRIVE SHAFT

1. REMOVE COTTER PIN, LOCK NUT CUP AND LOCK NUT

(a) Remove the cotter pin and lock nut cap.

(b) Loosen the bearing lock nut while depressing the

brake pedal.

2. REMOVE ENGINE UNDER COVER

4. DRAIN OUT GEAR OIL FLUID

5. DISCONNECT TIE ROD END FROM STEERING

KNUCKLE

(a) Remove the cotter pin and nut from the steering

knuckle.

(b) Using SST, disconnect the tie rod end from the steer-

ing knuckle.

SST 09628±62011

NOTICE: The hub bearing could be damaged if it is

subjects to the vehicle weight, such as when moving

the vehicle with the drive shaft removed. Therefore, if

it is bearing first support it with SST.

SST 09608±16041 (09608±02020,09608±02040)

6. DISCONNECT STEERING KNUCKLE FROM LOWER

BALL JOINT

Remove the two bolts and disconnect the steering

knuckle from lower ball joint. 3. REMOVE FRONT FENDER APRON SEAL

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD SV21 )FA±16

Page 1384 of 2389

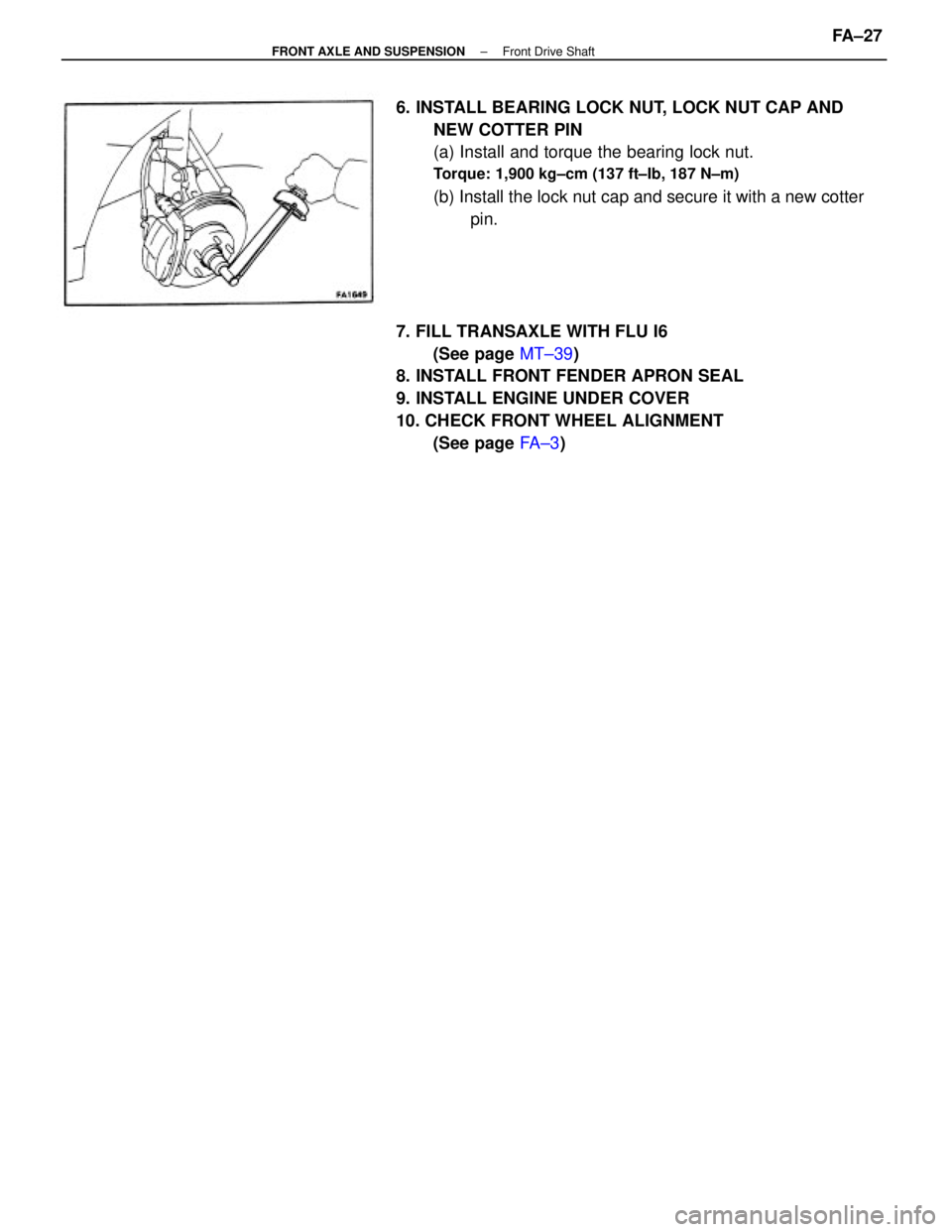

6. INSTALL BEARING LOCK NUT, LOCK NUT CAP AND

NEW COTTER PIN

(a) Install and torque the bearing lock nut.

Torque: 1,900 kg±cm (137 ft±Ib, 187 N±m)

(b) Install the lock nut cap and secure it with a new cotter

pin.

7. FILL TRANSAXLE WITH FLU I6

(See page MT±39)

8. INSTALL FRONT FENDER APRON SEAL

9. INSTALL ENGINE UNDER COVER

10. CHECK FRONT WHEEL ALIGNMENT

(See page FA±3)

± FRONT AXLE AND SUSPENSIONFront Drive ShaftFA±27

Page 1386 of 2389

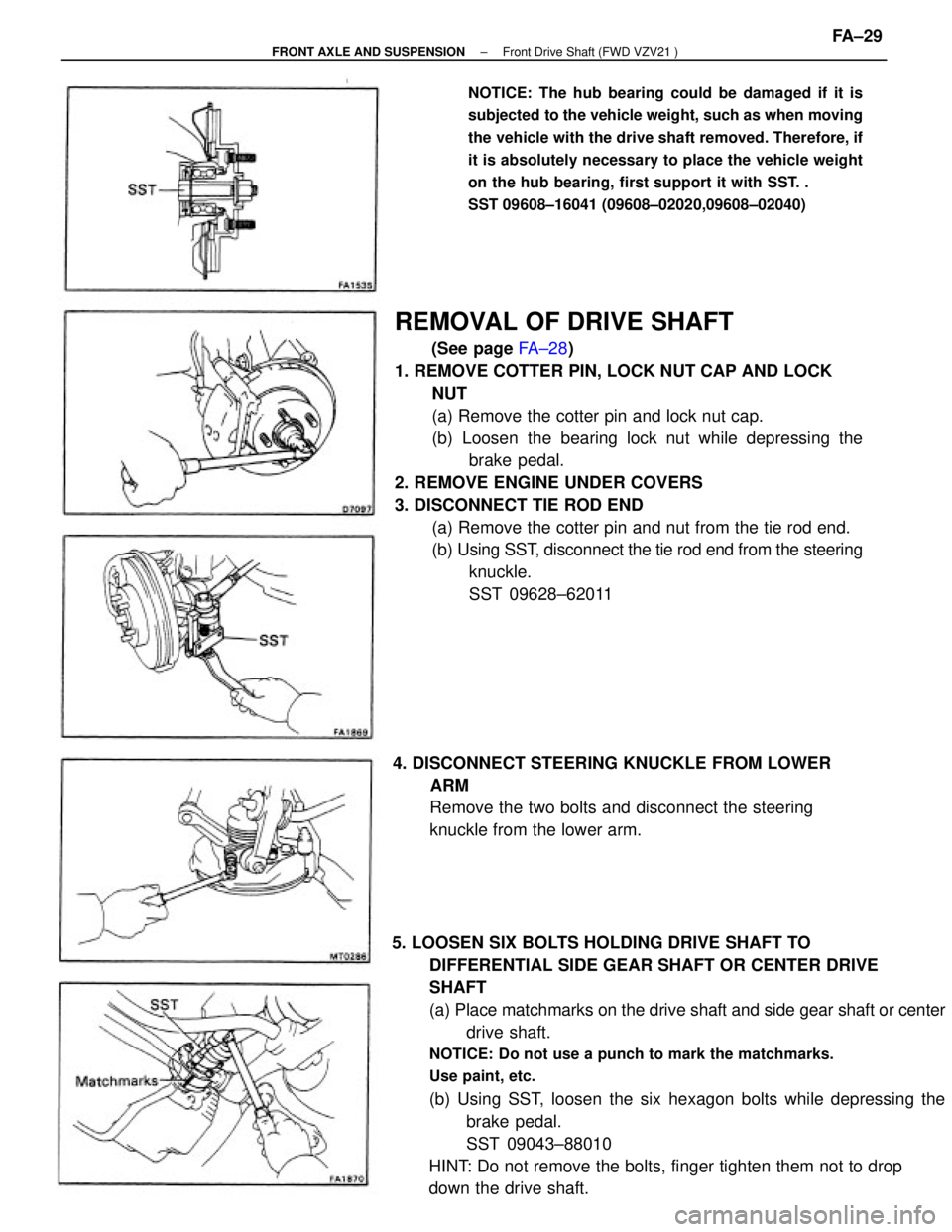

REMOVAL OF DRIVE SHAFT

(See page FA±28)

1. REMOVE COTTER PIN, LOCK NUT CAP AND LOCK

NUT

(a) Remove the cotter pin and lock nut cap.

(b) Loosen the bearing lock nut while depressing the

brake pedal.

2. REMOVE ENGINE UNDER COVERS

3. DISCONNECT TIE ROD END

(a) Remove the cotter pin and nut from the tie rod end.

(b) Using SST, disconnect the tie rod end from the steering

knuckle.

SST 09628±62011

5. LOOSEN SIX BOLTS HOLDING DRIVE SHAFT TO

DIFFERENTIAL SIDE GEAR SHAFT OR CENTER DRIVE

SHAFT

(a) Place matchmarks on the drive shaft and side gear shaft or center

drive shaft.

NOTICE: Do not use a punch to mark the matchmarks.

Use paint, etc.

(b) Using SST, loosen the six hexagon bolts while depressing the

brake pedal.

SST 09043±88010

HINT: Do not remove the bolts, finger tighten them not to drop

down the drive shaft.

NOTICE: The hub bearing could be damaged if it is

subjected to the vehicle weight, such as when moving

the vehicle with the drive shaft removed. Therefore, if

it is absolutely necessary to place the vehicle weight

on the hub bearing, first support it with SST. .

SST 09608±16041 (09608±02020,09608±02040)

4. DISCONNECT STEERING KNUCKLE FROM LOWER

ARM

Remove the two bolts and disconnect the steering

knuckle from the lower arm.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD VZV21 )FA±29

Page 1397 of 2389

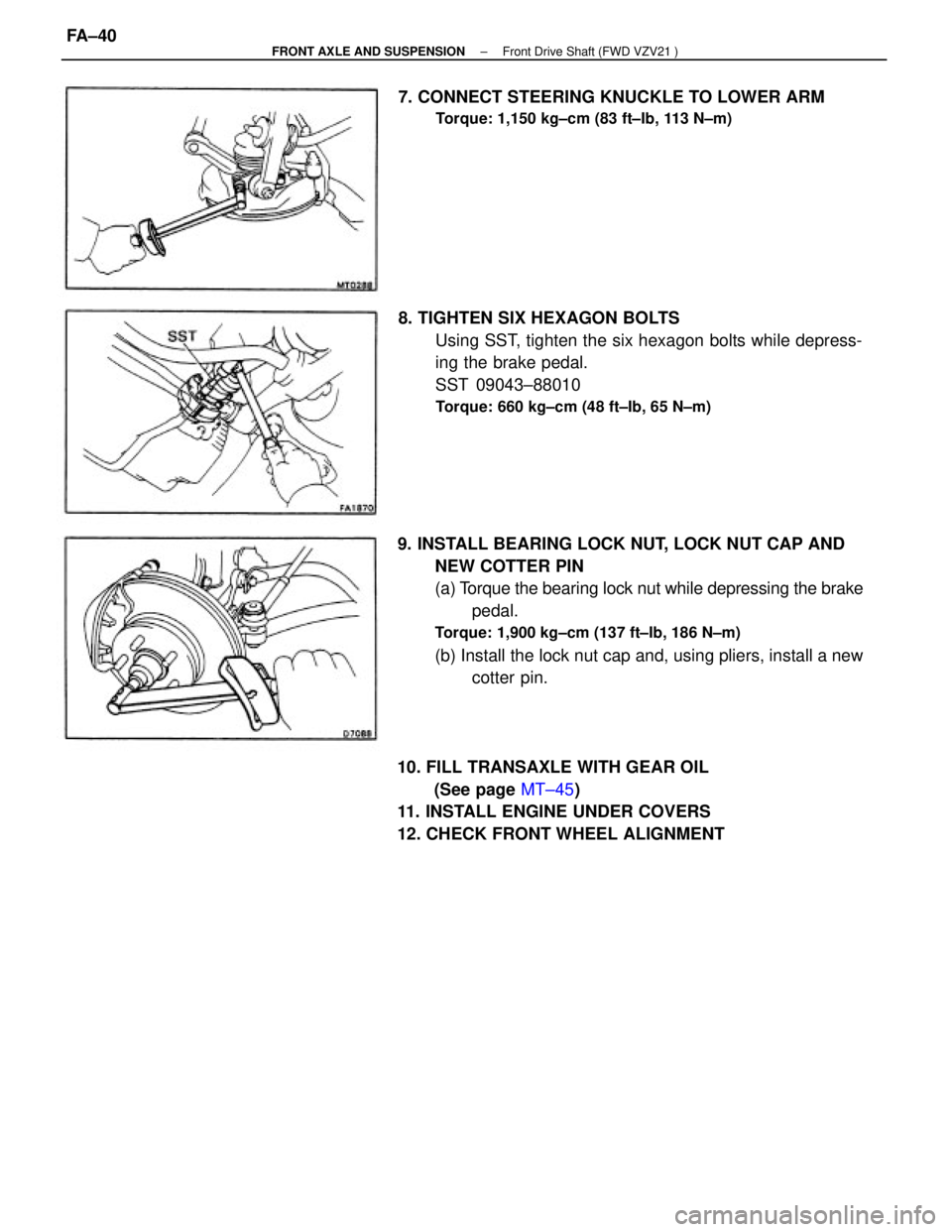

9. INSTALL BEARING LOCK NUT, LOCK NUT CAP AND

NEW COTTER PIN

(a) Torque the bearing lock nut while depressing the brake

pedal.

Torque: 1,900 kg±cm (137 ft±Ib, 186 N±m)

(b) Install the lock nut cap and, using pliers, install a new

cotter pin. 8. TIGHTEN SIX HEXAGON BOLTS

Using SST, tighten the six hexagon bolts while depress-

ing the brake pedal.

SST 09043±88010

Torque: 660 kg±cm (48 ft±Ib, 65 N±m)

10. FILL TRANSAXLE WITH GEAR OIL

(See page MT±45)

11. INSTALL ENGINE UNDER COVERS

12. CHECK FRONT WHEEL ALIGNMENT7. CONNECT STEERING KNUCKLE TO LOWER ARM

Torque: 1,150 kg±cm (83 ft±Ib, 113 N±m)

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD VZV21 )FA±40

Page 1399 of 2389

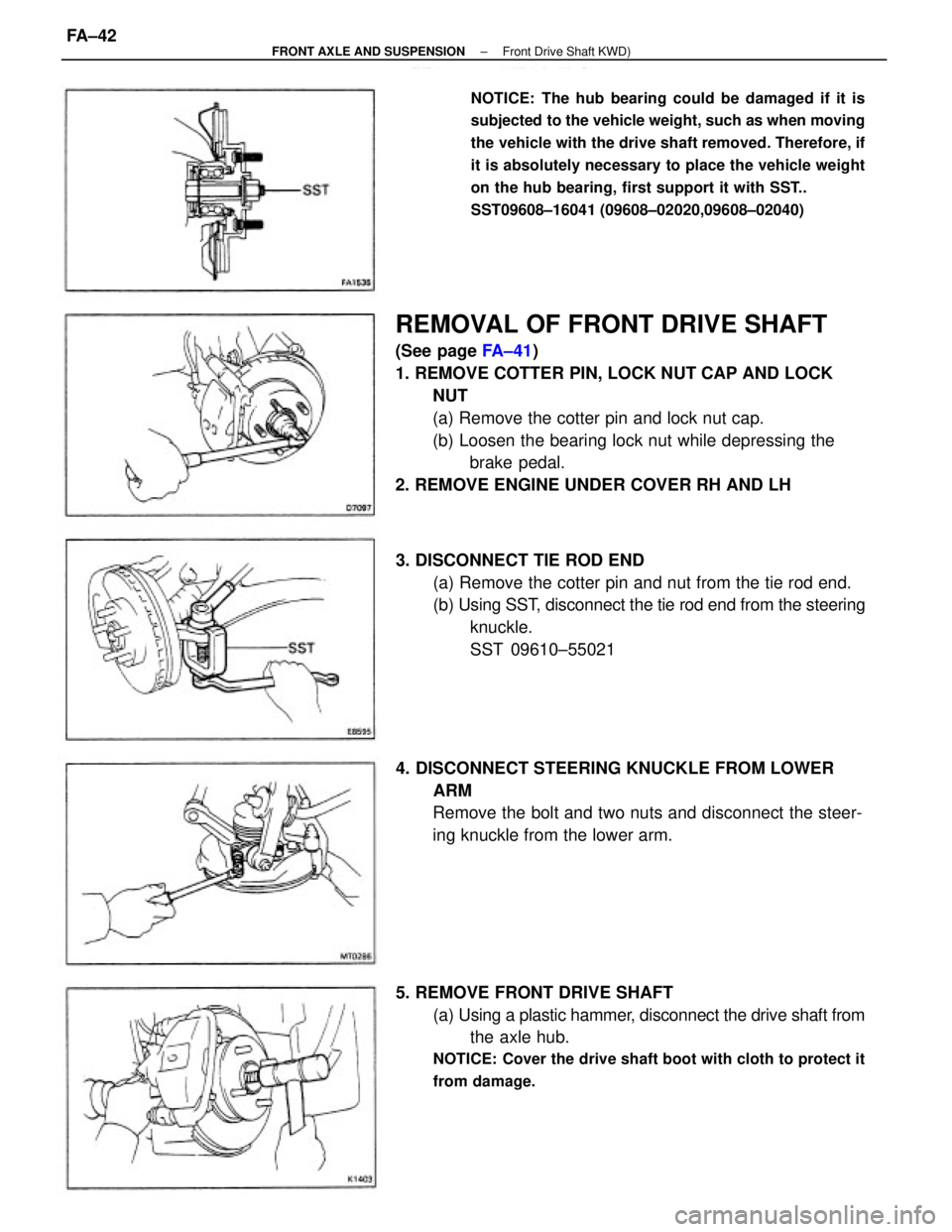

REMOVAL OF FRONT DRIVE SHAFT

(See page FA±41)

1. REMOVE COTTER PIN, LOCK NUT CAP AND LOCK

NUT

(a) Remove the cotter pin and lock nut cap.

(b) Loosen the bearing lock nut while depressing the

brake pedal.

2. REMOVE ENGINE UNDER COVER RH AND LH

3. DISCONNECT TIE ROD END

(a) Remove the cotter pin and nut from the tie rod end.

(b) Using SST, disconnect the tie rod end from the steering

knuckle.

SST 09610±55021

NOTICE: The hub bearing could be damaged if it is

subjected to the vehicle weight, such as when moving

the vehicle with the drive shaft removed. Therefore, if

it is absolutely necessary to place the vehicle weight

on the hub bearing, first support it with SST..

SST09608±16041 (09608±02020,09608±02040)

5. REMOVE FRONT DRIVE SHAFT

(a) Using a plastic hammer, disconnect the drive shaft from

the axle hub.

NOTICE: Cover the drive shaft boot with cloth to protect it

from damage.

4. DISCONNECT STEERING KNUCKLE FROM LOWER

ARM

Remove the bolt and two nuts and disconnect the steer-

ing knuckle from the lower arm.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft KWD)FA±42

Page 1407 of 2389

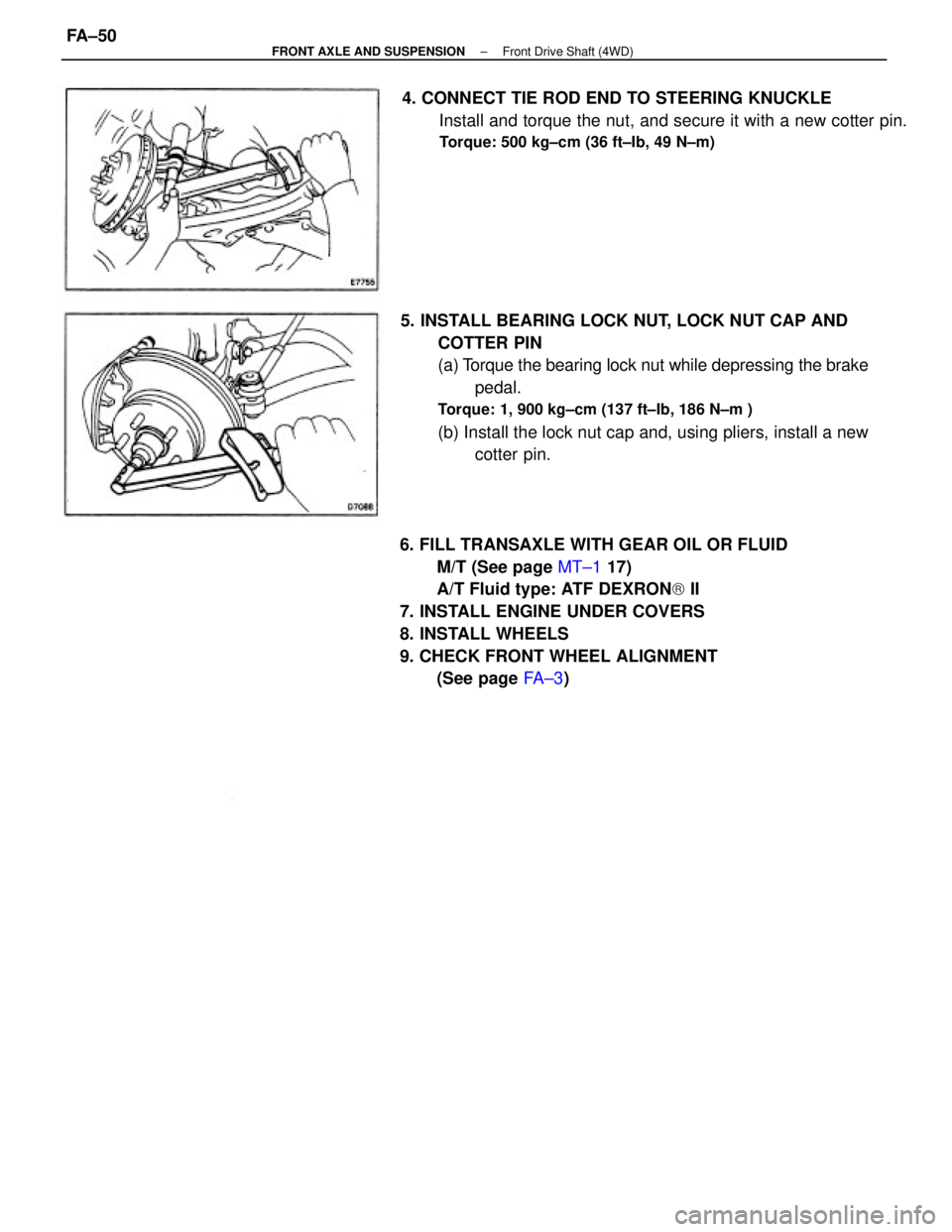

6. FILL TRANSAXLE WITH GEAR OIL OR FLUID

M/T (See page MT±1 17)

A/T Fluid type: ATF DEXRON) II

7. INSTALL ENGINE UNDER COVERS

8. INSTALL WHEELS

9. CHECK FRONT WHEEL ALIGNMENT

(See page FA ± 3) 5. INSTALL BEARING LOCK NUT, LOCK NUT CAP AND

COTTER PIN

(a) Torque the bearing lock nut while depressing the brake

pedal.

Torque: 1, 900 kg±cm (137 ft±Ib, 186 N±m )

(b) Install the lock nut cap and, using pliers, install a new

cotter pin. 4. CONNECT TIE ROD END TO STEERING KNUCKLE

Install and torque the nut, and secure it with a new cotter pin.

Torque: 500 kg±cm (36 ft±Ib, 49 N±m)

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (4WD)FA±50

Page 1417 of 2389

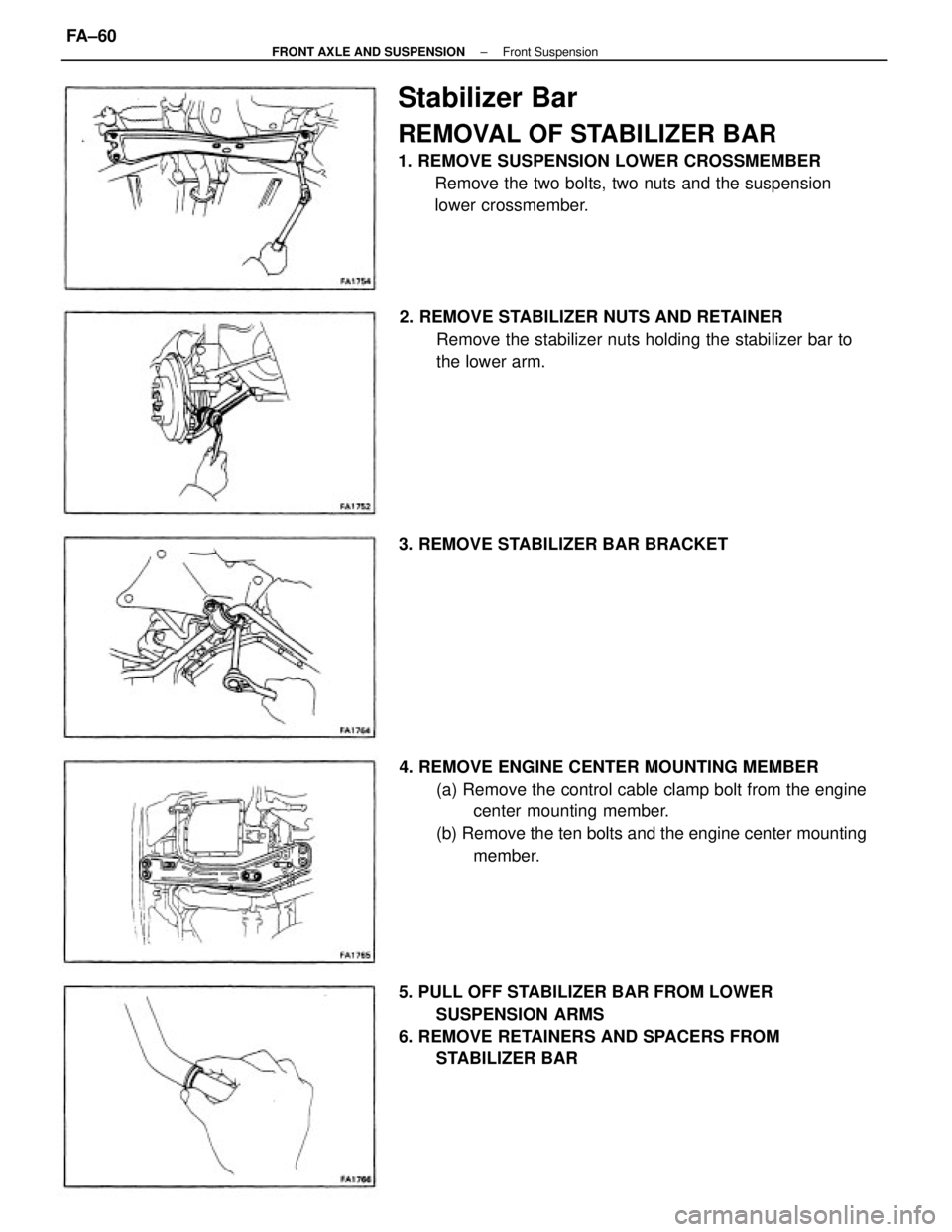

Stabilizer Bar

REMOVAL OF STABILIZER BAR

1. REMOVE SUSPENSION LOWER CROSSMEMBER

Remove the two bolts, two nuts and the suspension

lower crossmember.

4. REMOVE ENGINE CENTER MOUNTING MEMBER

(a) Remove the control cable clamp bolt from the engine

center mounting member.

(b) Remove the ten bolts and the engine center mounting

member.

5. PULL OFF STABILIZER BAR FROM LOWER

SUSPENSION ARMS

6. REMOVE RETAINERS AND SPACERS FROM

STABILIZER BAR 2. REMOVE STABILIZER NUTS AND RETAINER

Remove the stabilizer nuts holding the stabilizer bar to

the lower arm.

3. REMOVE STABILIZER BAR BRACKET

± FRONT AXLE AND SUSPENSIONFront SuspensionFA±60

Page 1418 of 2389

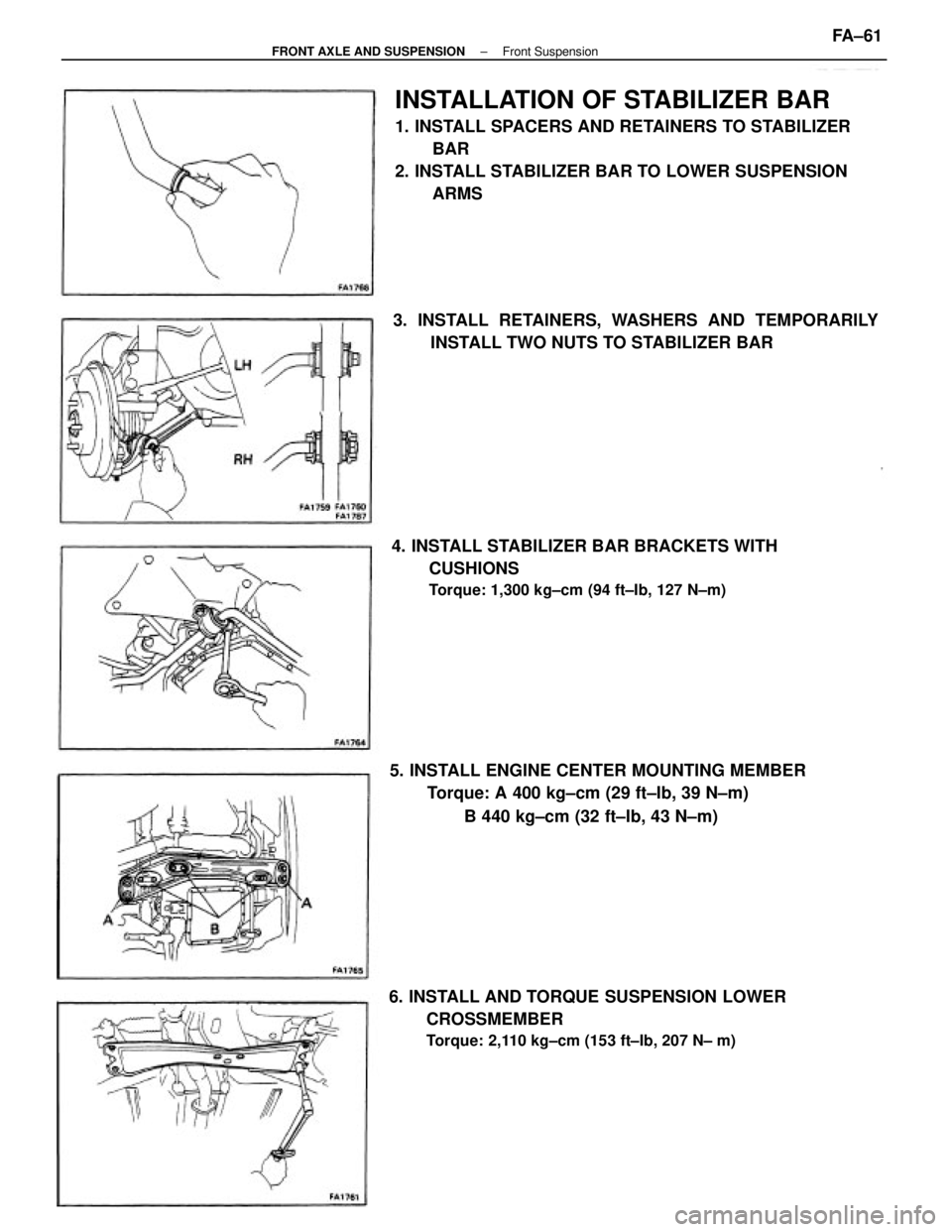

INSTALLATION OF STABILIZER BAR

1. INSTALL SPACERS AND RETAINERS TO STABILIZER

BAR

2. INSTALL STABILIZER BAR TO LOWER SUSPENSION

ARMS

5. INSTALL ENGINE CENTER MOUNTING MEMBER

Torque: A 400 kg±cm (29 ft±Ib, 39 N±m)

B 440 kg±cm (32 ft±Ib, 43 N±m)

6. INSTALL AND TORQUE SUSPENSION LOWER

CROSSMEMBER

Torque: 2,110 kg±cm (153 ft±Ib, 207 N± m)

4. INSTALL STABILIZER BAR BRACKETS WITH

CUSHIONS

Torque: 1,300 kg±cm (94 ft±Ib, 127 N±m)

3. INSTALL RETAINERS, WASHERS AND TEMPORARILY

INSTALL TWO NUTS TO STABILIZER BAR

± FRONT AXLE AND SUSPENSIONFront SuspensionFA±61

Page 1423 of 2389

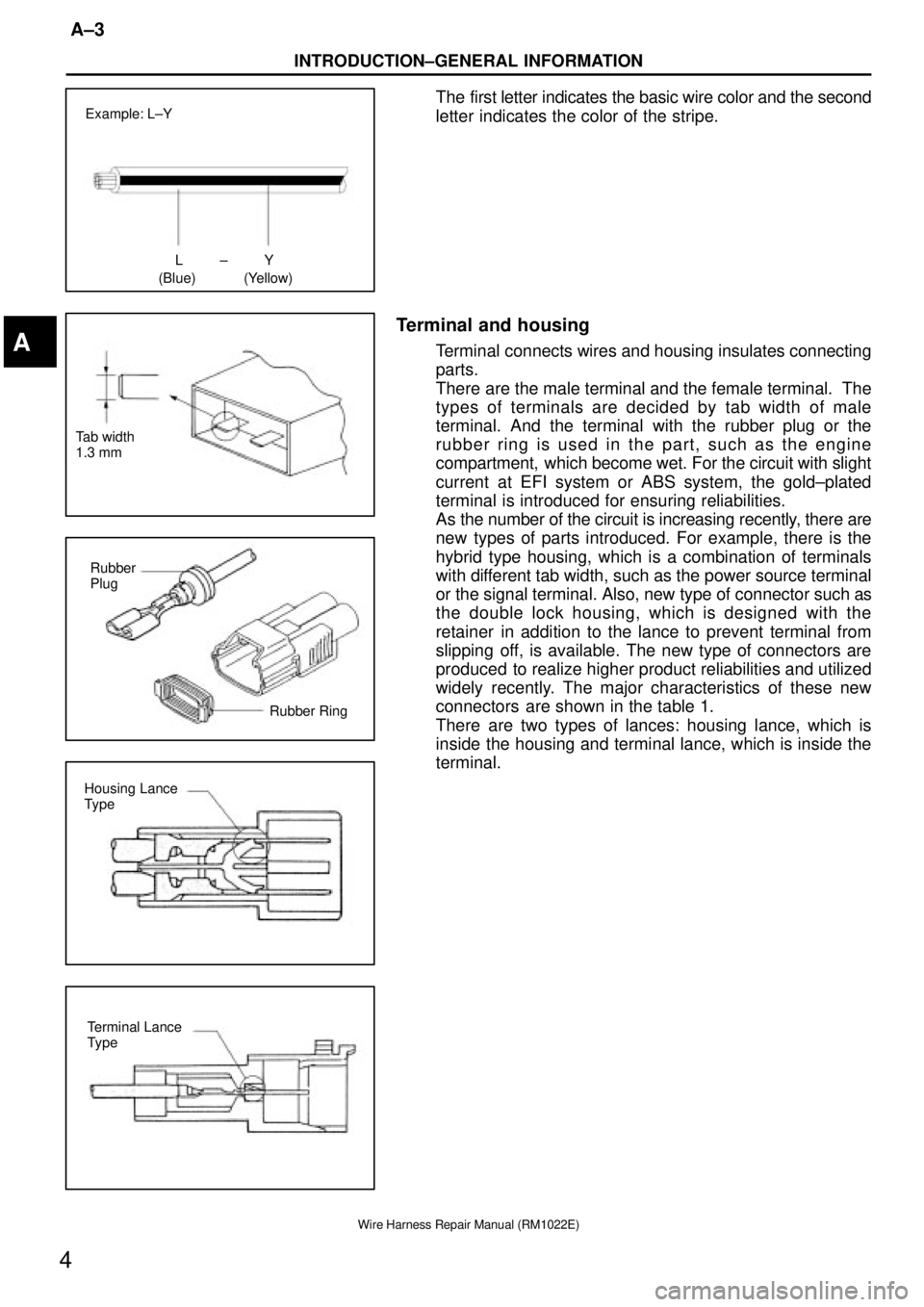

LY±

(Blue) (Yellow) Example: L±Y

Tab width

1.3 mm

Rubber

Plug

Rubber Ring

Housing Lance

Type

Terminal Lance

Type

INTRODUCTION±GENERAL INFORMATION

A±3

4

Wire Harness Repair Manual (RM1022E)

The first letter indicates the basic wire color and the second

letter indicates the color of the stripe.

Terminal and housing

Terminal connects wires and housing insulates connecting

parts.

There are the male terminal and the female terminal. The

types of terminals are decided by tab width of male

terminal. And the terminal with the rubber plug or the

rubber ring is used in the part, such as the engine

compartment, which become wet. For the circuit with slight

current at EFI system or ABS system, the gold±plated

terminal is introduced for ensuring reliabilities.

As the number of the circuit is increasing recently, there are

new types of parts introduced. For example, there is the

hybrid type housing, which is a combination of terminals

with different tab width, such as the power source terminal

or the signal terminal. Also, new type of connector such as

the double lock housing, which is designed with the

retainer in addition to the lance to prevent terminal from

slipping off, is available. The new type of connectors are

produced to realize higher product reliabilities and utilized

widely recently. The major characteristics of these new

connectors are shown in the table 1.

There are two types of lances: housing lance, which is

inside the housing and terminal lance, which is inside the

terminal.A