clock TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 630 of 2389

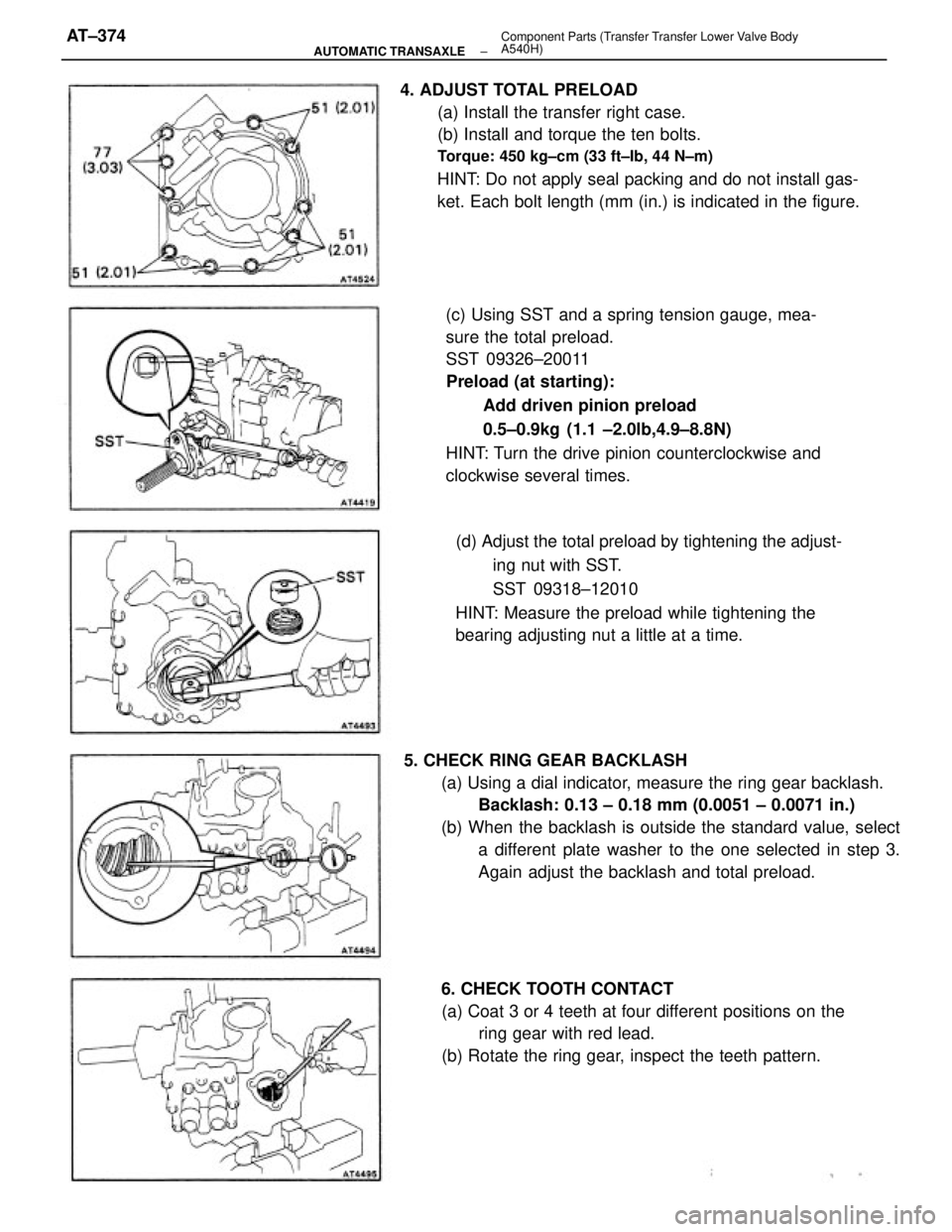

4. ADJUST TOTAL PRELOAD

(a) Install the transfer right case.

(b) Install and torque the ten bolts.

Torque: 450 kg±cm (33 ft±Ib, 44 N±m)

HINT: Do not apply seal packing and do not install gas-

ket. Each bolt length (mm (in.) is indicated in the figure.

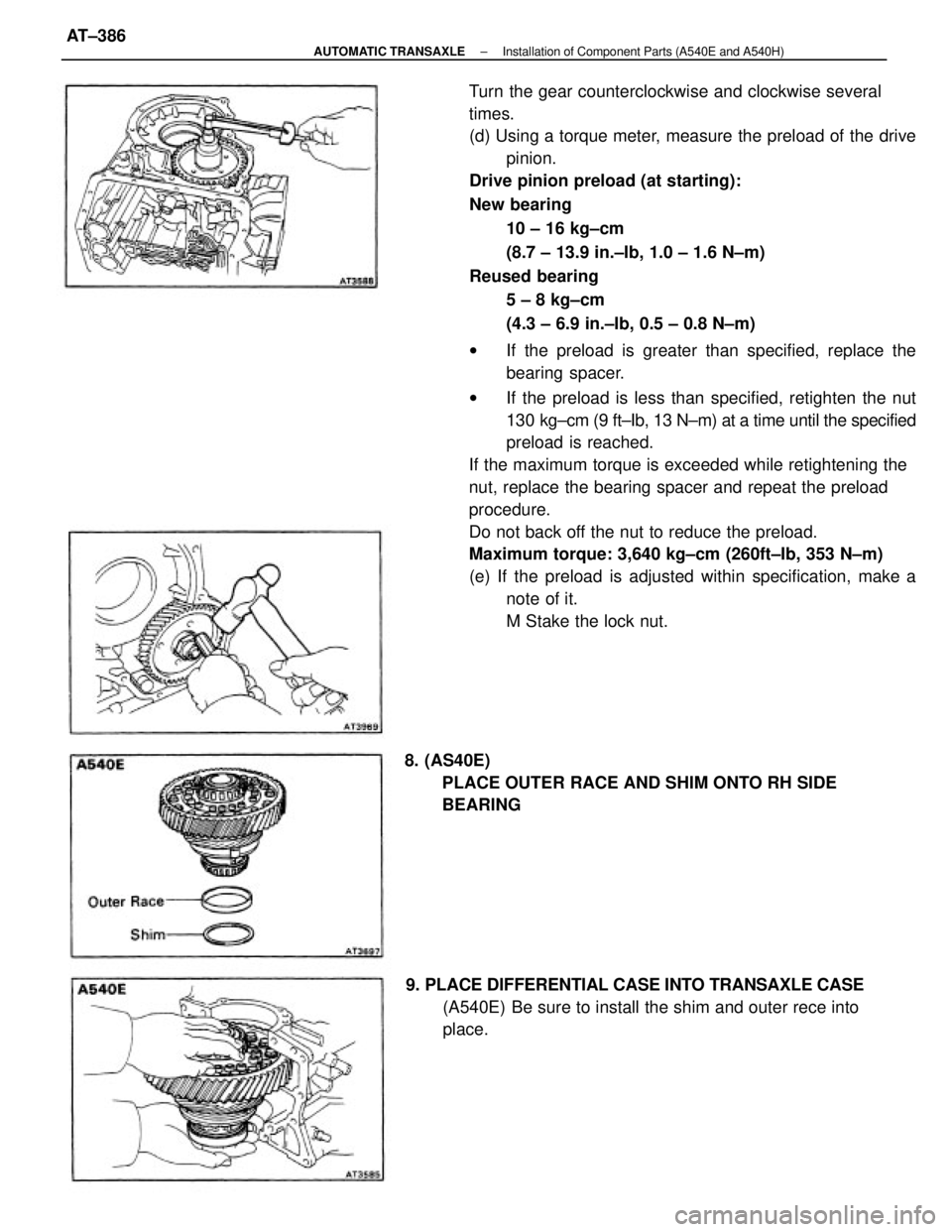

(c) Using SST and a spring tension gauge, mea-

sure the total preload.

SST 09326±20011

Preload (at starting):

Add driven pinion preload

0.5±0.9kg (1.1 ±2.0lb,4.9±8.8N)

HINT: Turn the drive pinion counterclockwise and

clockwise several times.

5. CHECK RING GEAR BACKLASH

(a) Using a dial indicator, measure the ring gear backlash.

Backlash: 0.13 ± 0.18 mm (0.0051 ± 0.0071 in.)

(b) When the backlash is outside the standard value, select

a different plate washer to the one selected in step 3.

Again adjust the backlash and total preload. (d) Adjust the total preload by tightening the adjust-

ing nut with SST.

SST 09318±12010

HINT: Measure the preload while tightening the

bearing adjusting nut a little at a time.

6. CHECK TOOTH CONTACT

(a) Coat 3 or 4 teeth at four different positions on the

ring gear with red lead.

(b) Rotate the ring gear, inspect the teeth pattern.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Lower Valve Body

A540H)AT±374

Page 644 of 2389

Turn the gear counterclockwise and clockwise several

times.

(d) Using a torque meter, measure the preload of the drive

pinion.

Drive pinion preload (at starting):

New bearing

10 ± 16 kg±cm

(8.7 ± 13.9 in.±Ib, 1.0 ± 1.6 N±m)

Reused bearing

5 ± 8 kg±cm

(4.3 ± 6.9 in.±Ib, 0.5 ± 0.8 N±m)

wIf the preload is greater than specified, replace the

bearing spacer.

wIf the preload is less than specified, retighten the nut

130 kg±cm (9 ft±Ib, 13 N±m) at a time until the specified

preload is reached.

If the maximum torque is exceeded while retightening the

nut, replace the bearing spacer and repeat the preload

procedure.

Do not back off the nut to reduce the preload.

Maximum torque: 3,640 kg±cm (260ft±Ib, 353 N±m)

(e) If the preload is adjusted within specification, make a

note of it.

M Stake the lock nut.

9. PLACE DIFFERENTIAL CASE INTO TRANSAXLE CASE

(A540E) Be sure to install the shim and outer rece into

place. 8. (AS40E)

PLACE OUTER RACE AND SHIM ONTO RH SIDE

BEARING

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A540E and A540H)AT±386

Page 654 of 2389

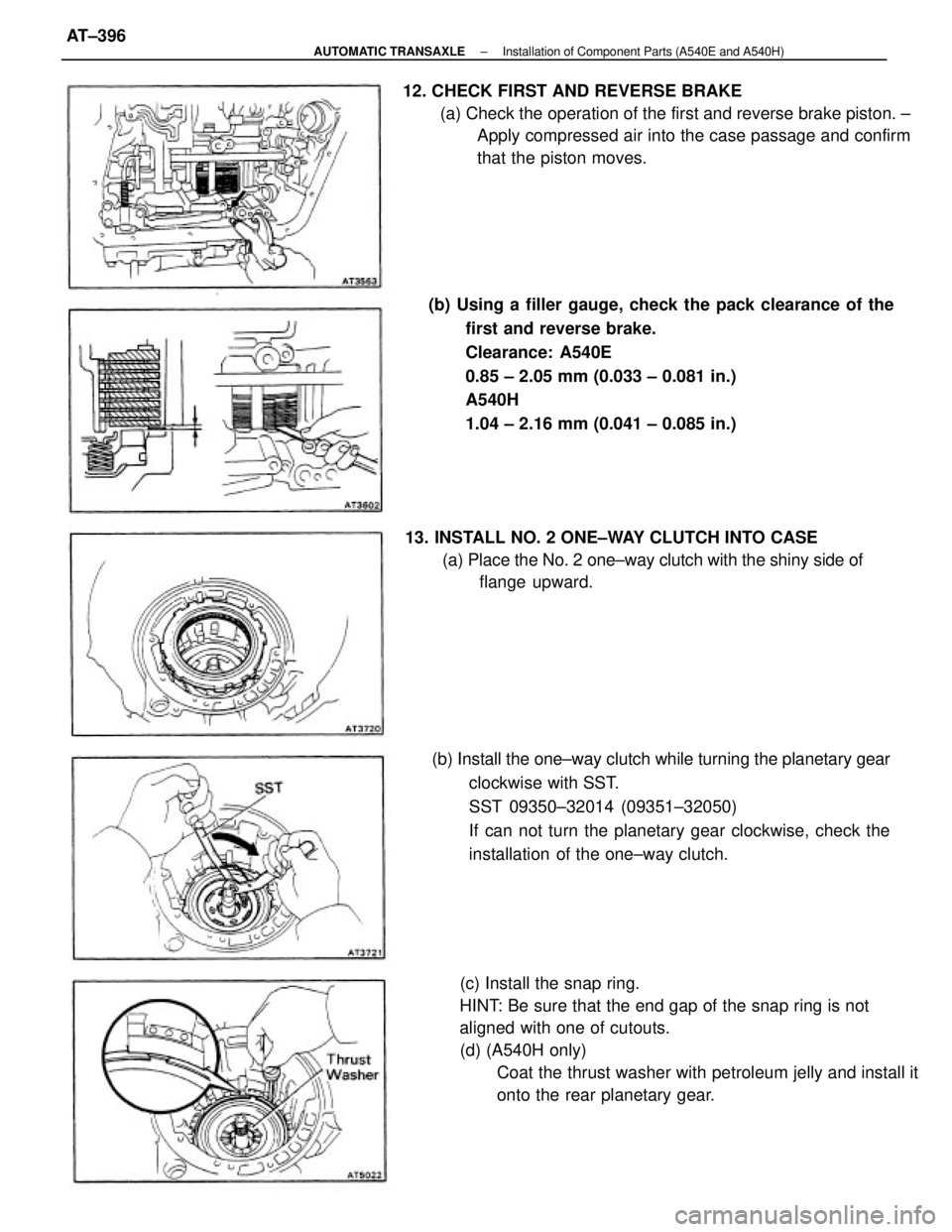

(c) Install the snap ring.

HINT: Be sure that the end gap of the snap ring is not

aligned with one of cutouts.

(d) (A540H only)

Coat the thrust washer with petroleum jelly and install it

onto the rear planetary gear. (b) Using a filler gauge, check the pack clearance of the

first and reverse brake.

Clearance: A540E

0.85 ± 2.05 mm (0.033 ± 0.081 in.)

A540H

1.04 ± 2.16 mm (0.041 ± 0.085 in.) 12. CHECK FIRST AND REVERSE BRAKE

(a) Check the operation of the first and reverse brake piston. ±

Apply compressed air into the case passage and confirm

that the piston moves.

(b) Install the one±way clutch while turning the planetary gear

clockwise with SST.

SST 09350±32014 (09351±32050)

If can not turn the planetary gear clockwise, check the

installation of the one±way clutch. 13. INSTALL NO. 2 ONE±WAY CLUTCH INTO CASE

(a) Place the No. 2 one±way clutch with the shiny side of

flange upward.

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A540E and A540H)AT±396

Page 657 of 2389

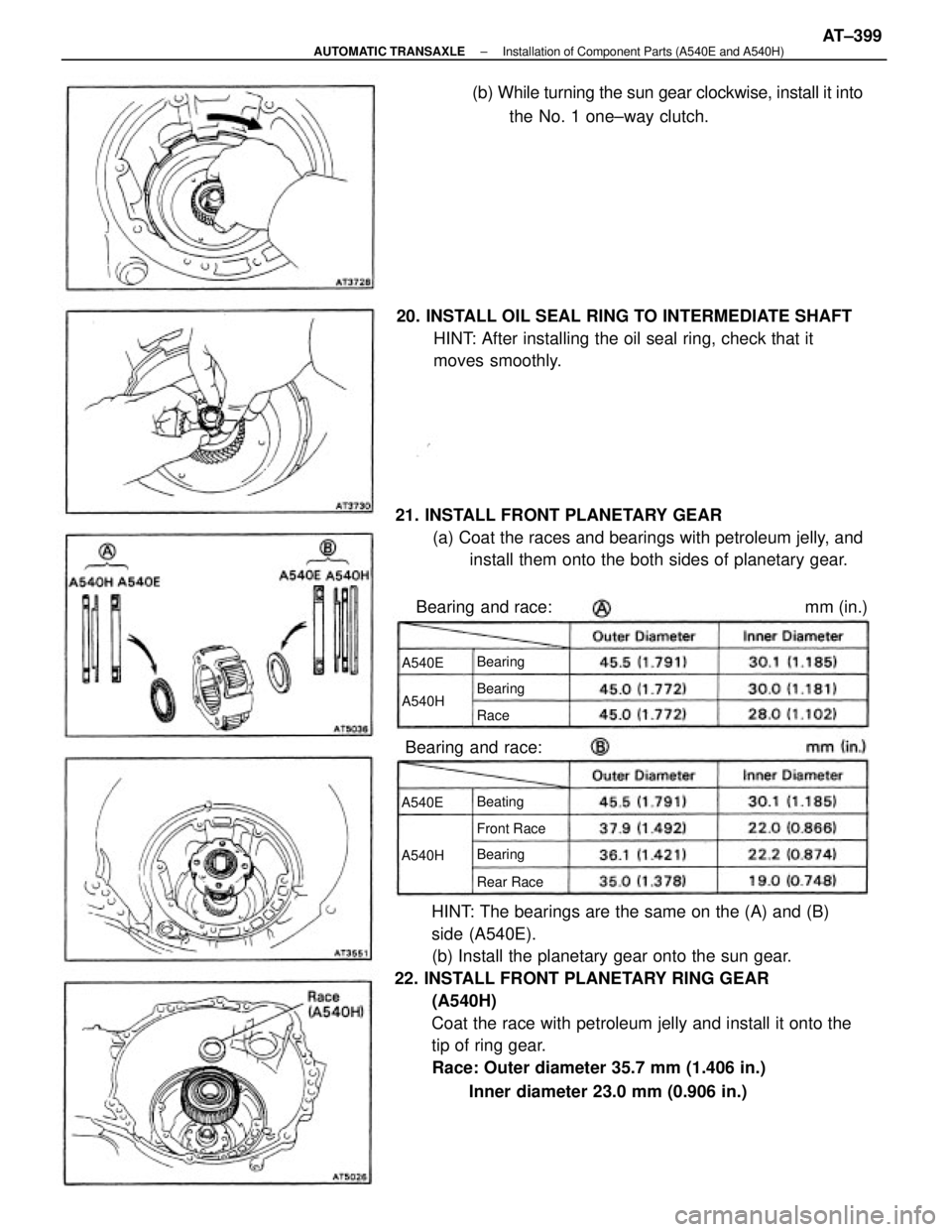

HINT: The bearings are the same on the (A) and (B)

side (A540E).

(b) Install the planetary gear onto the sun gear.

22. INSTALL FRONT PLANETARY RING GEAR

(A540H)

Coat the race with petroleum jelly and install it onto the

tip of ring gear.

Race: Outer diameter 35.7 mm (1.406 in.)

Inner diameter 23.0 mm (0.906 in.) 21. INSTALL FRONT PLANETARY GEAR

(a) Coat the races and bearings with petroleum jelly, and

install them onto the both sides of planetary gear. 20. INSTALL OIL SEAL RING TO INTERMEDIATE SHAFT

HINT: After installing the oil seal ring, check that it

moves smoothly.(b) While turning the sun gear clockwise, install it into

the No. 1 one±way clutch.

Bearing and race:

Front Race

Rear Race Beating Bearing

Bearing Bearing

A540HA540H

A540EA540E

Race

Bearing and race: mm (in.)

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A540E and A540H)AT±399

Page 810 of 2389

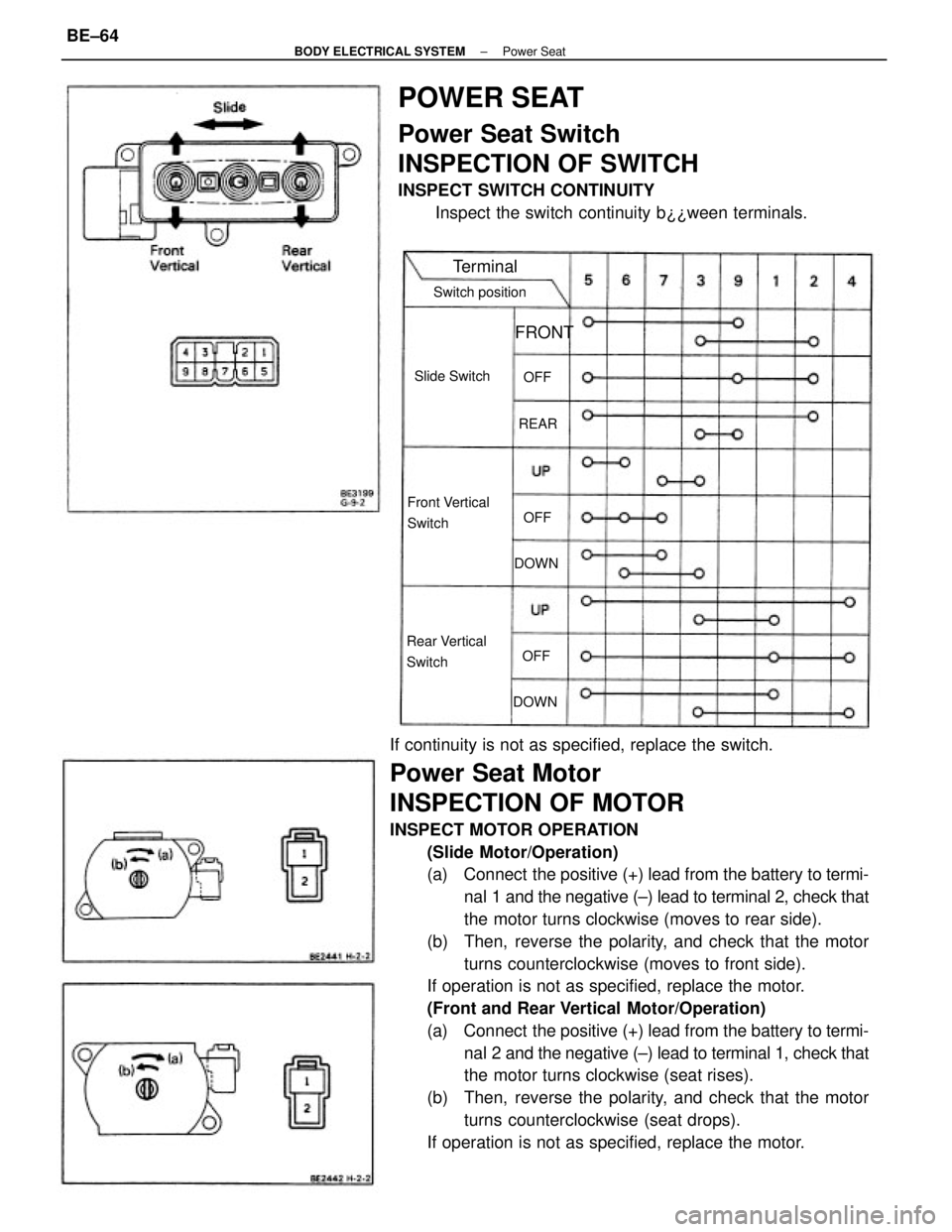

If continuity is not as specified, replace the switch.

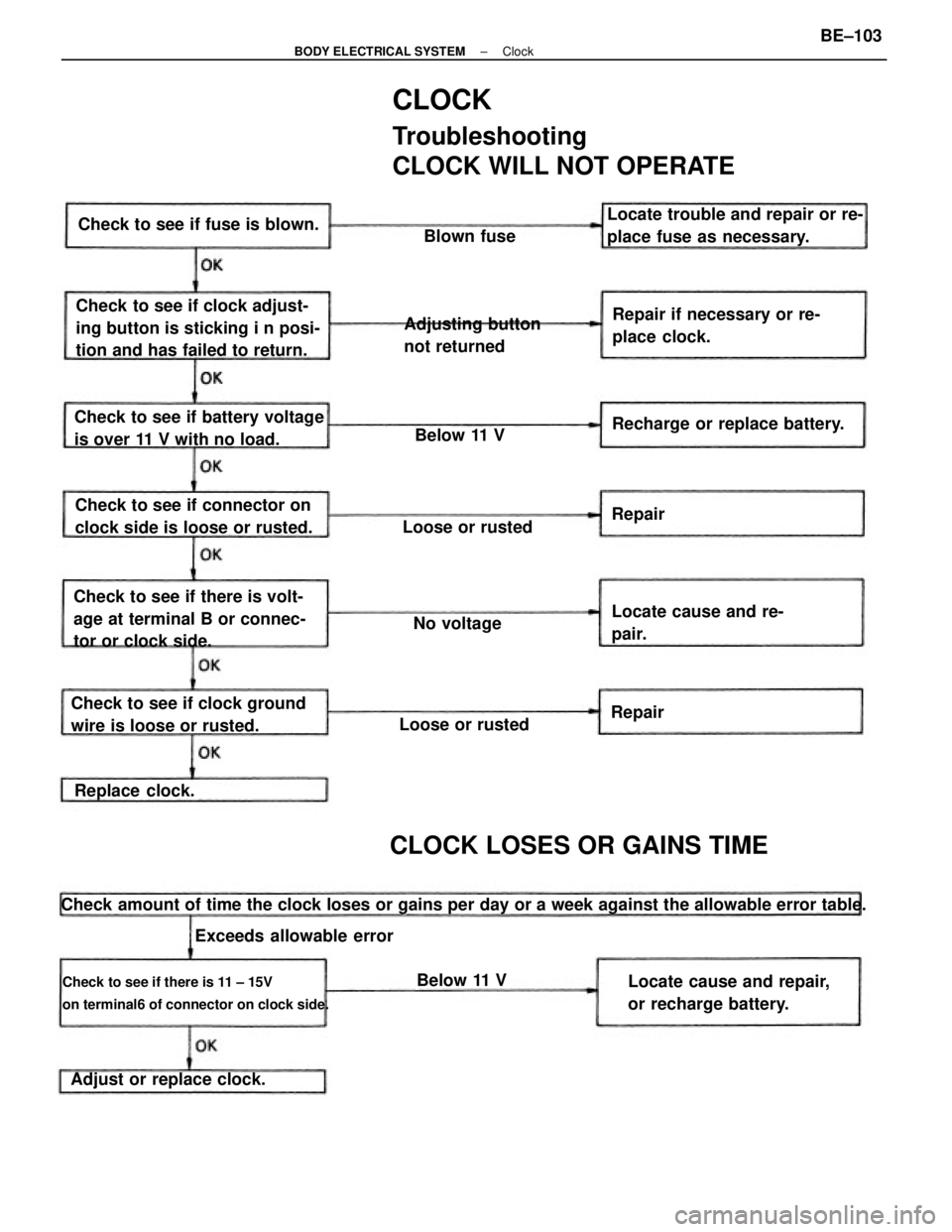

Power Seat Motor

INSPECTION OF MOTOR

INSPECT MOTOR OPERATION

(Slide Motor/Operation)

(a) Connect the positive (+) lead from the battery to termi-

nal 1 and the negative (±) lead to terminal 2, check that

the motor turns clockwise (moves to rear side).

(b) Then, reverse the polarity, and check that the motor

turns counterclockwise (moves to front side).

If operation is not as specified, replace the motor.

(Front and Rear Vertical Motor/Operation)

(a) Connect the positive (+) lead from the battery to termi-

nal 2 and the negative (±) lead to terminal 1, check that

the motor turns clockwise (seat rises).

(b) Then, reverse the polarity, and check that the motor

turns counterclockwise (seat drops).

If operation is not as specified, replace the motor.

POWER SEAT

Power Seat Switch

INSPECTION OF SWITCH

INSPECT SWITCH CONTINUITY

Inspect the switch continuity b¿¿ween terminals.

Front Vertical

Switch

Rear Vertical

SwitchSwitch position

Slide Switch

Terminal

FRONT

DOWNDOWNREAROFF

OFFOFF

± BODY ELECTRICAL SYSTEMPower SeatBE±64

Page 825 of 2389

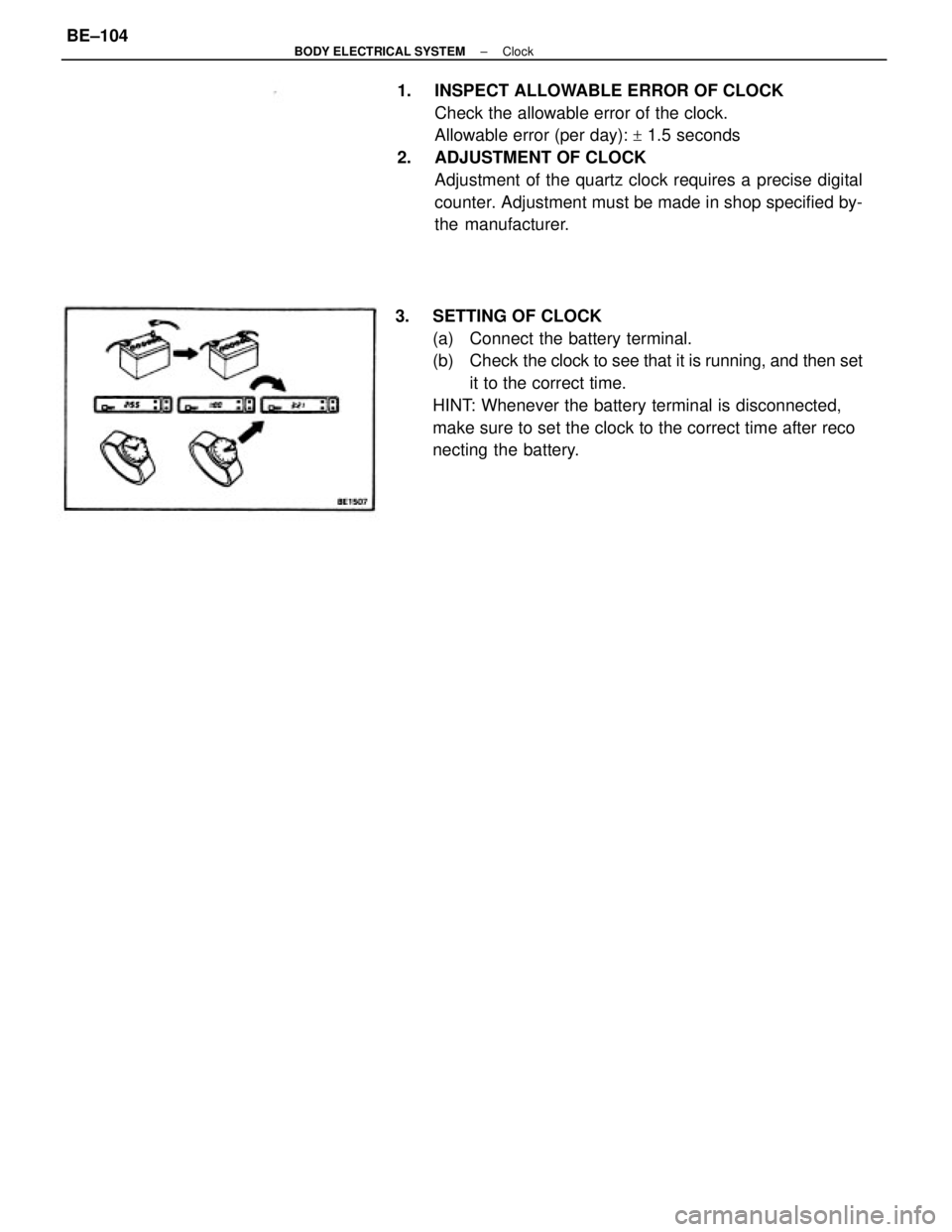

CLOCK

Troubleshooting

CLOCK WILL NOT OPERATE

Check amount of time the clock loses or gains per day or a week against the allowable error table.

Check to see if there is 11 ± 15V

on terminal6 of connector on clock side.

Check to see if clock adjust-

ing button is sticking i n posi-

tion and has failed to return.

Check to see if there is volt-

age at terminal B or connec-

tor or clock side.

Check to see if clock ground

wire is loose or rusted.Check to see if battery voltage

is over 11 V with no load.Repair if necessary or re-

place clock. Locate trouble and repair or re-

place fuse as necessary.

Locate cause and repair,

or recharge battery. Check to see if connector on

clock side is loose or rusted.

CLOCK LOSES OR GAINS TIME

Adjusting button

not returned Check to see if fuse is blown.

Recharge or replace battery.

Adjust or replace clock.Locate cause and re-

pair.

Exceeds allowable errorLoose or rustedLoose or rusted

Replace clock.No voltageBlown fuse

Below 11 V

Below 11 VRepair

Repair

± BODY ELECTRICAL SYSTEMClockBE±103

Page 826 of 2389

1. INSPECT ALLOWABLE ERROR OF CLOCK

Check the allowable error of the clock.

Allowable error (per day):

+ 1.5 seconds

2. ADJUSTMENT OF CLOCK

Adjustment of the quartz clock requires a precise digital

counter. Adjustment must be made in shop specified by-

the manufacturer.

3. SETTING OF CLOCK

(a) Connect the battery terminal.

(b) Check the clock to see that it is running, and then set

it to the correct time.

HINT: Whenever the battery terminal is disconnected,

make sure to set the clock to the correct time after reco

necting the battery.

± BODY ELECTRICAL SYSTEMClockBE±104

Page 966 of 2389

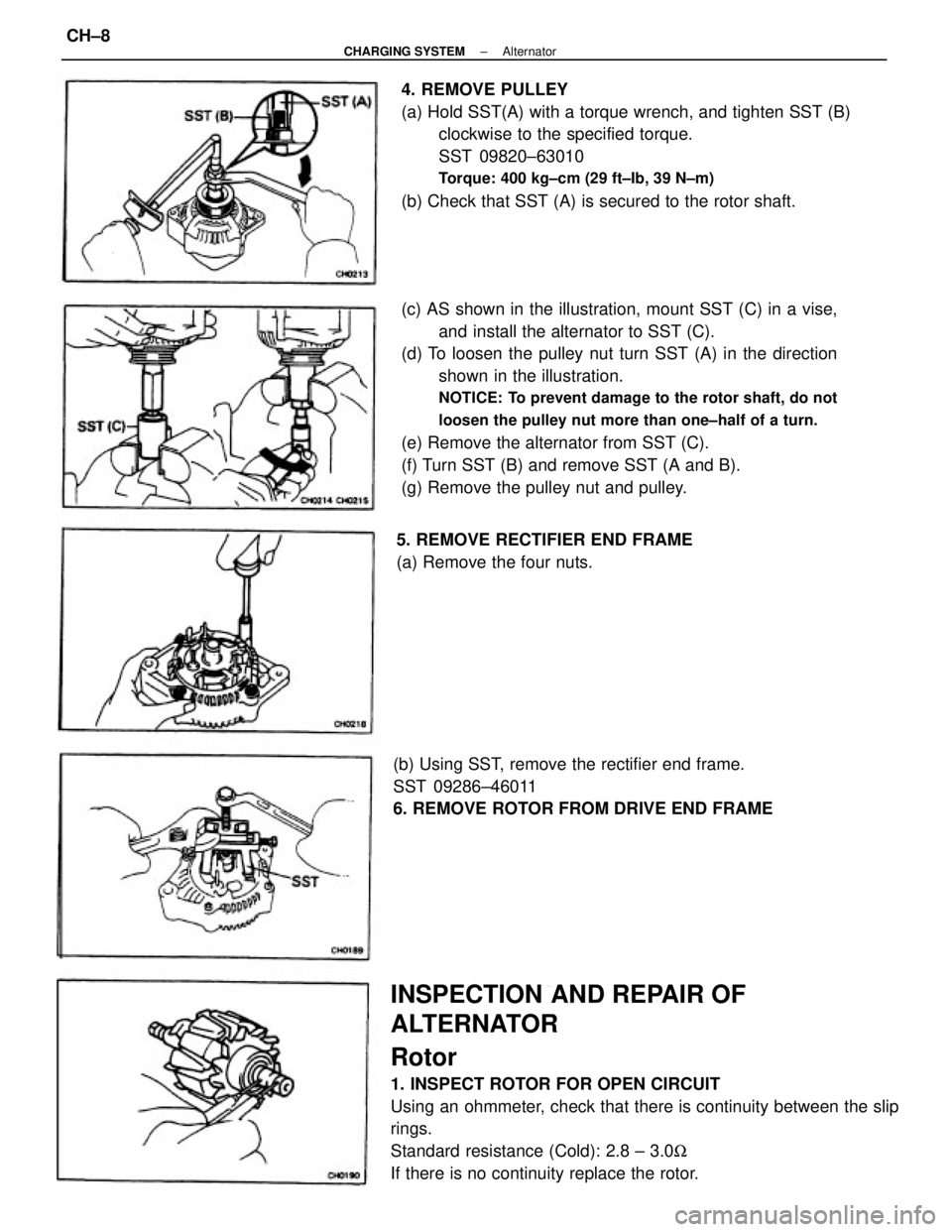

(c) AS shown in the illustration, mount SST (C) in a vise,

and install the alternator to SST (C).

(d) To loosen the pulley nut turn SST (A) in the direction

shown in the illustration.

NOTICE: To prevent damage to the rotor shaft, do not

loosen the pulley nut more than one±half of a turn.

(e) Remove the alternator from SST (C).

(f) Turn SST (B) and remove SST (A and B).

(g) Remove the pulley nut and pulley.

INSPECTION AND REPAIR OF

ALTERNATOR

Rotor

1. INSPECT ROTOR FOR OPEN CIRCUIT

Using an ohmmeter, check that there is continuity between the slip

rings.

Standard resistance (Cold): 2.8 ± 3.0W

If there is no continuity replace the rotor.4. REMOVE PULLEY

(a) Hold SST(A) with a torque wrench, and tighten SST (B)

clockwise to the specified torque.

SST 09820±63010

Torque: 400 kg±cm (29 ft±Ib, 39 N±m)

(b) Check that SST (A) is secured to the rotor shaft.

(b) Using SST, remove the rectifier end frame.

SST 09286±46011

6. REMOVE ROTOR FROM DRIVE END FRAME5. REMOVE RECTIFIER END FRAME

(a) Remove the four nuts.

± CHARGING SYSTEMAlternatorCH±8

Page 970 of 2389

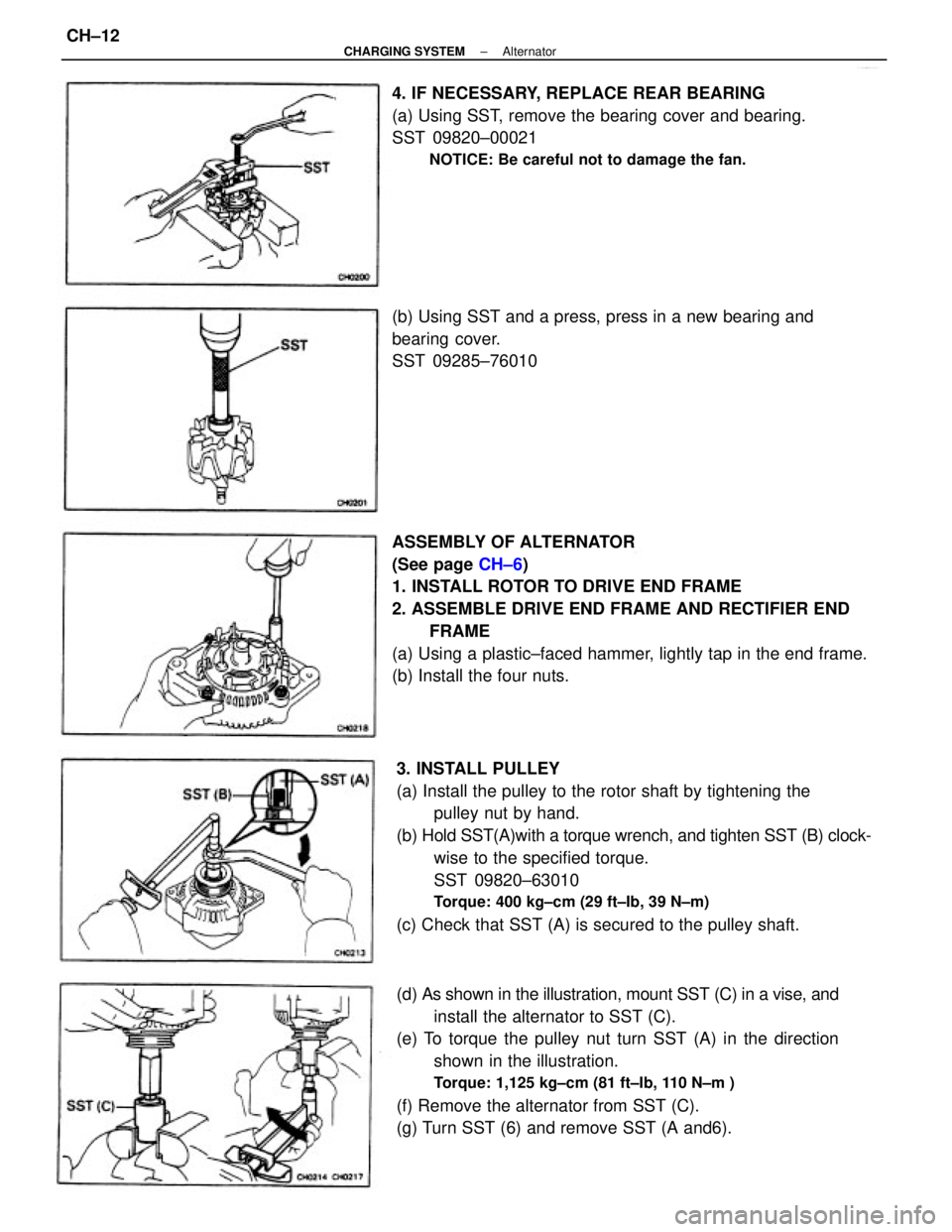

ASSEMBLY OF ALTERNATOR

(See page CH±6)

1. INSTALL ROTOR TO DRIVE END FRAME

2. ASSEMBLE DRIVE END FRAME AND RECTIFIER END

FRAME

(a) Using a plastic±faced hammer, lightly tap in the end frame.

(b) Install the four nuts.

3. INSTALL PULLEY

(a) Install the pulley to the rotor shaft by tightening the

pulley nut by hand.

(b) Hold SST(A)with a torque wrench, and tighten SST (B) clock-

wise to the specified torque.

SST 09820±63010

Torque: 400 kg±cm (29 ft±Ib, 39 N±m)

(c) Check that SST (A) is secured to the pulley shaft.

(d) As shown in the illustration, mount SST (C) in a vise, and

install the alternator to SST (C).

(e) To torque the pulley nut turn SST (A) in the direction

shown in the illustration.

Torque: 1,125 kg±cm (81 ft±Ib, 110 N±m )

(f) Remove the alternator from SST (C).

(g) Turn SST (6) and remove SST (A and6). 4. IF NECESSARY, REPLACE REAR BEARING

(a) Using SST, remove the bearing cover and bearing.

SST 09820±00021

NOTICE: Be careful not to damage the fan.

(b) Using SST and a press, press in a new bearing and

bearing cover.

SST 09285±76010

± CHARGING SYSTEMAlternatorCH±12

Page 1038 of 2389

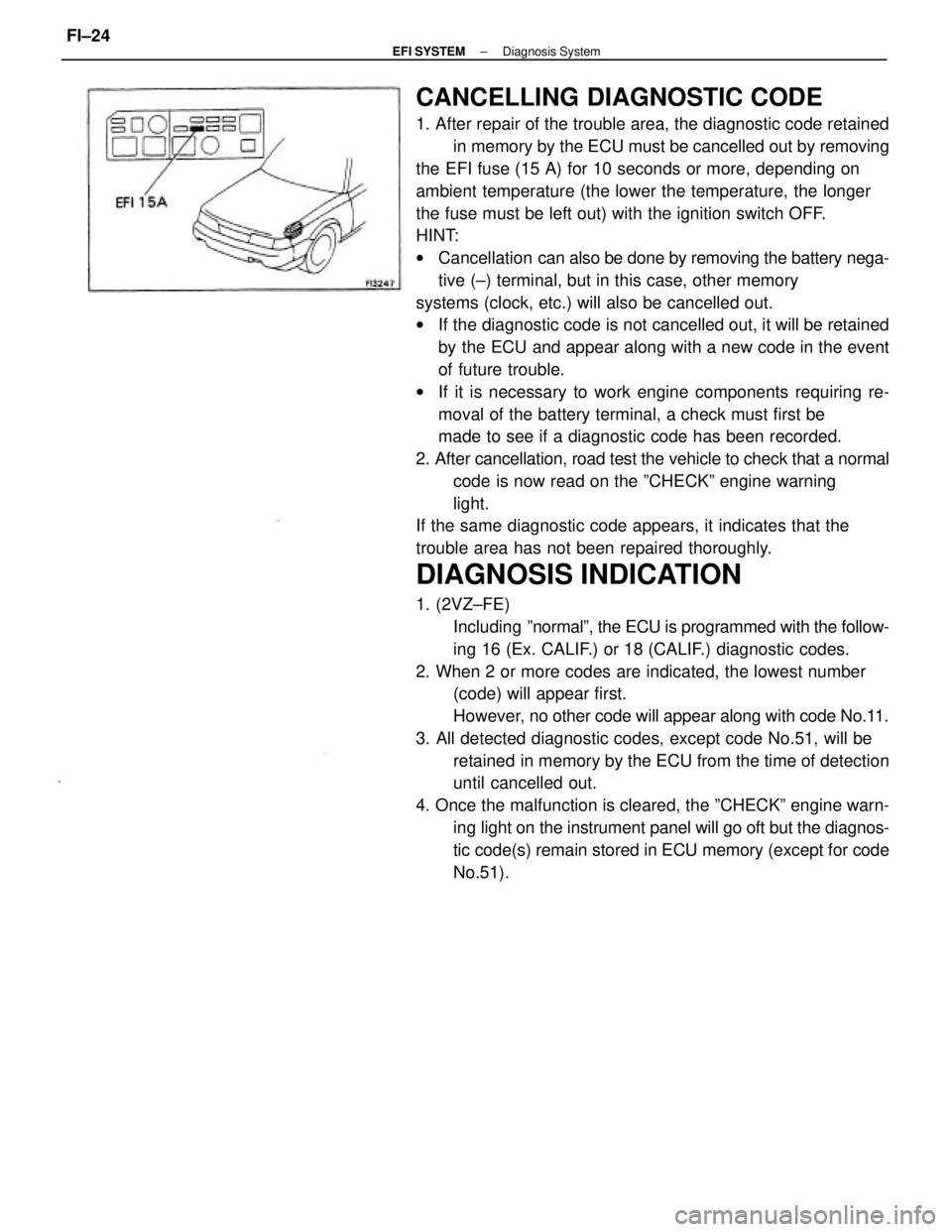

CANCELLING DIAGNOSTIC CODE

1. After repair of the trouble area, the diagnostic code retained

in memory by the ECU must be cancelled out by removing

the EFI fuse (15 A) for 10 seconds or more, depending on

ambient temperature (the lower the temperature, the longer

the fuse must be left out) with the ignition switch OFF.

HINT:

wCancellation can also be done by removing the battery nega-

tive (±) terminal, but in this case, other memory

systems (clock, etc.) will also be cancelled out.

wIf the diagnostic code is not cancelled out, it will be retained

by the ECU and appear along with a new code in the event

of future trouble.

wIf it is necessary to work engine components requiring re-

moval of the battery terminal, a check must first be

made to see if a diagnostic code has been recorded.

2. After cancellation, road test the vehicle to check that a normal

code is now read on the ºCHECKº engine warning

light.

If the same diagnostic code appears, it indicates that the

trouble area has not been repaired thoroughly.

DIAGNOSIS INDICATION

1. (2VZ±FE)

Including ºnormalº, the ECU is programmed with the follow-

ing 16 (Ex. CALIF.) or 18 (CALIF.) diagnostic codes.

2. When 2 or more codes are indicated, the lowest number

(code) will appear first.

However, no other code will appear along with code No.11.

3. All detected diagnostic codes, except code No.51, will be

retained in memory by the ECU from the time of detection

until cancelled out.

4. Once the malfunction is cleared, the ºCHECKº engine warn-

ing light on the instrument panel will go oft but the diagnos-

tic code(s) remain stored in ECU memory (except for code

No.51).

± EFI SYSTEMDiagnosis SystemFI±24