clock TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1247 of 2389

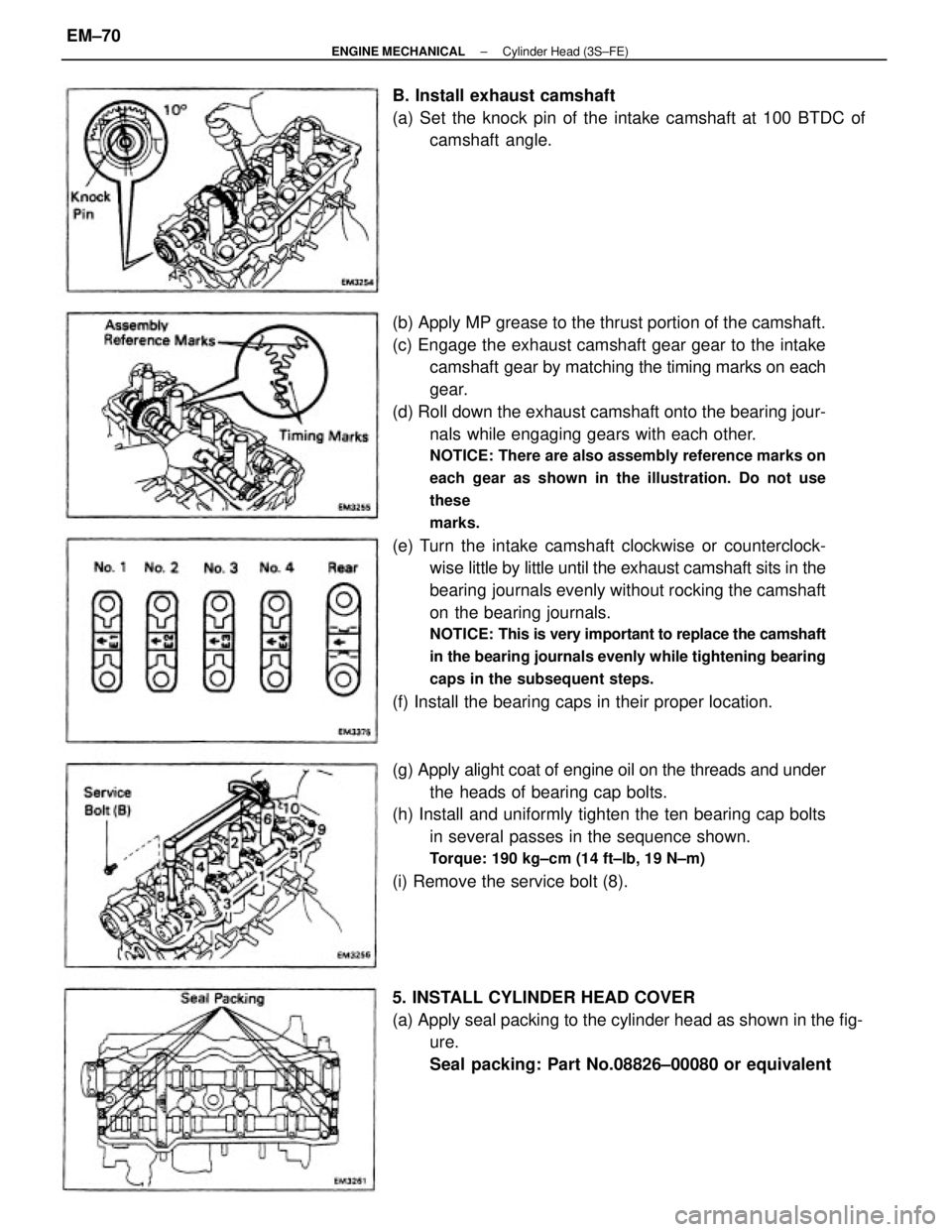

(b) Apply MP grease to the thrust portion of the camshaft.

(c) Engage the exhaust camshaft gear gear to the intake

camshaft gear by matching the timing marks on each

gear.

(d) Roll down the exhaust camshaft onto the bearing jour-

nals while engaging gears with each other.

NOTICE: There are also assembly reference marks on

each gear as shown in the illustration. Do not use

these

marks.

(e) Turn the intake camshaft clockwise or counterclock-

wise little by little until the exhaust camshaft sits in the

bearing journals evenly without rocking the camshaft

on the bearing journals.

NOTICE: This is very important to replace the camshaft

in the bearing journals evenly while tightening bearing

caps in the subsequent steps.

(f) Install the bearing caps in their proper location.

(g) Apply alight coat of engine oil on the threads and under

the heads of bearing cap bolts.

(h) Install and uniformly tighten the ten bearing cap bolts

in several passes in the sequence shown.

Torque: 190 kg±cm (14 ft±lb, 19 N±m)

(i) Remove the service bolt (8).

5. INSTALL CYLINDER HEAD COVER

(a) Apply seal packing to the cylinder head as shown in the fig-

ure.

Seal packing: Part No.08826±00080 or equivalent B. Install exhaust camshaft

(a) Set the knock pin of the intake camshaft at 100 BTDC of

camshaft angle.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±70

Page 1259 of 2389

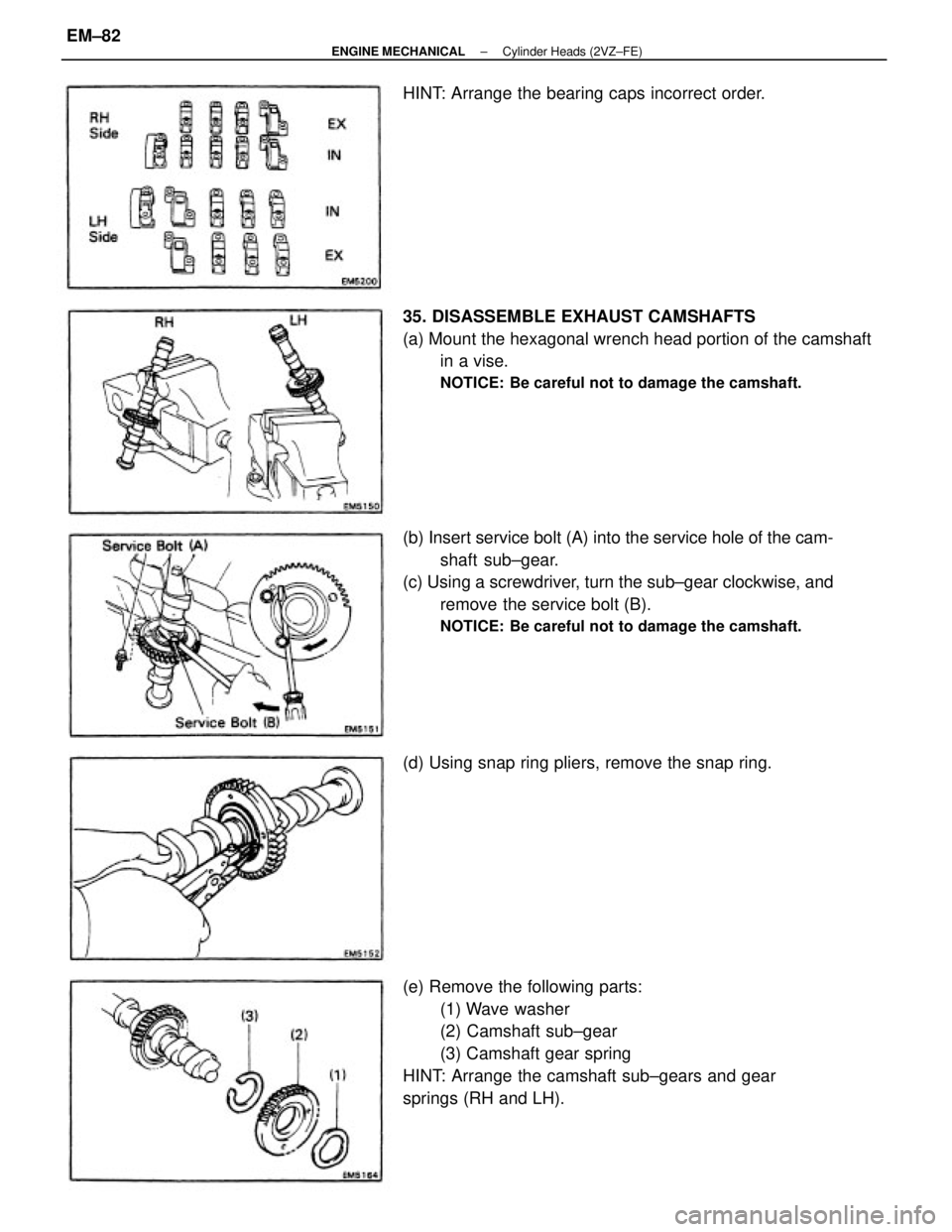

(e) Remove the following parts:

(1) Wave washer

(2) Camshaft sub±gear

(3) Camshaft gear spring

HINT: Arrange the camshaft sub±gears and gear

springs (RH and LH). (b) Insert service bolt (A) into the service hole of the cam-

shaft sub±gear.

(c) Using a screwdriver, turn the sub±gear clockwise, and

remove the service bolt (B).

NOTICE: Be careful not to damage the camshaft.

35. DISASSEMBLE EXHAUST CAMSHAFTS

(a) Mount the hexagonal wrench head portion of the camshaft

in a vise.

NOTICE: Be careful not to damage the camshaft.

(d) Using snap ring pliers, remove the snap ring. HINT: Arrange the bearing caps incorrect order.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±82

Page 1275 of 2389

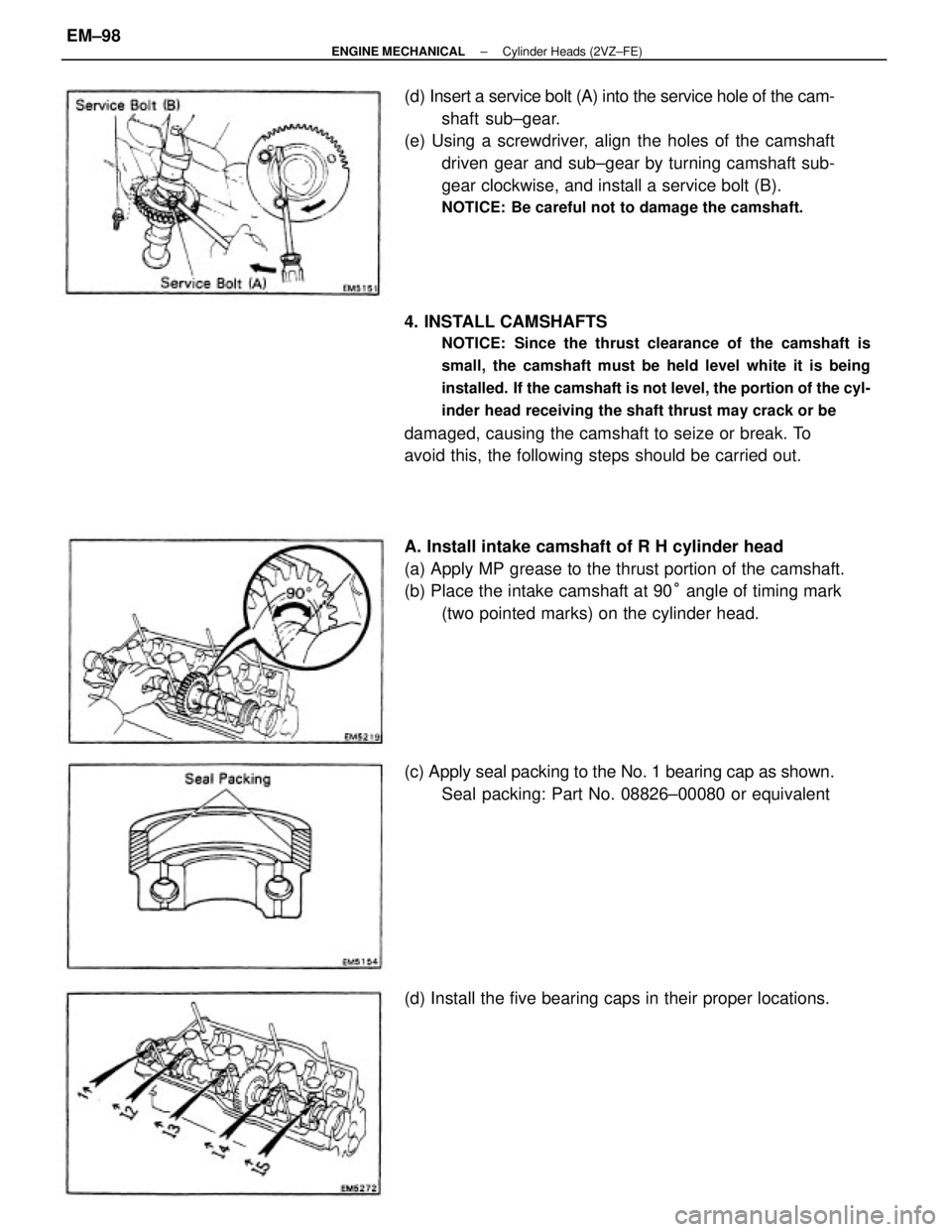

4. INSTALL CAMSHAFTS

NOTICE: Since the thrust clearance of the camshaft is

small, the camshaft must be held level white it is being

installed. If the camshaft is not level, the portion of the cyl-

inder head receiving the shaft thrust may crack or be

damaged, causing the camshaft to seize or break. To

avoid this, the following steps should be carried out. (d) Insert a service bolt (A) into the service hole of the cam-

shaft sub±gear.

(e) Using a screwdriver, align the holes of the camshaft

driven gear and sub±gear by turning camshaft sub-

gear clockwise, and install a service bolt (B).

NOTICE: Be careful not to damage the camshaft.

A. Install intake camshaft of R H cylinder head

(a) Apply MP grease to the thrust portion of the camshaft.

(b) Place the intake camshaft at 90° angle of timing mark

(two pointed marks) on the cylinder head.

(c) Apply seal packing to the No. 1 bearing cap as shown.

Seal packing: Part No. 08826±00080 or equivalent

(d) Install the five bearing caps in their proper locations.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±98

Page 1849 of 2389

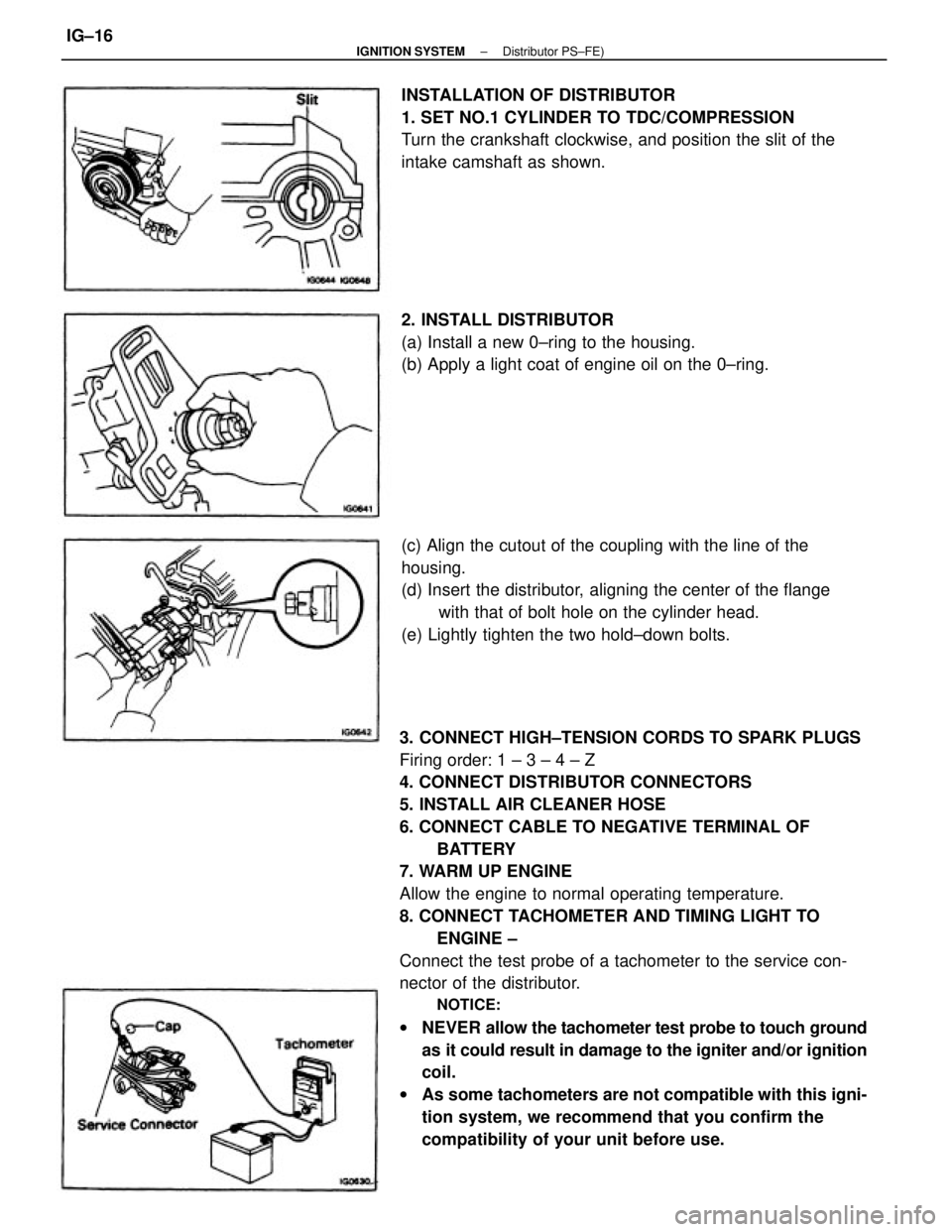

3. CONNECT HIGH±TENSION CORDS TO SPARK PLUGS

Firing order: 1 ± 3 ± 4 ± Z

4. CONNECT DISTRIBUTOR CONNECTORS

5. INSTALL AIR CLEANER HOSE

6. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY

7. WARM UP ENGINE

Allow the engine to normal operating temperature.

8. CONNECT TACHOMETER AND TIMING LIGHT TO

ENGINE ±

Connect the test probe of a tachometer to the service con-

nector of the distributor.

NOTICE:

wNEVER allow the tachometer test probe to touch ground

as it could result in damage to the igniter and/or ignition

coil.

wAs some tachometers are not compatible with this igni-

tion system, we recommend that you confirm the

compatibility of your unit before use. (c) Align the cutout of the coupling with the line of the

housing.

(d) Insert the distributor, aligning the center of the flange

with that of bolt hole on the cylinder head.

(e) Lightly tighten the two hold±down bolts. INSTALLATION OF DISTRIBUTOR

1. SET NO.1 CYLINDER TO TDC/COMPRESSION

Turn the crankshaft clockwise, and position the slit of the

intake camshaft as shown.

2. INSTALL DISTRIBUTOR

(a) Install a new 0±ring to the housing.

(b) Apply a light coat of engine oil on the 0±ring.

± IGNITION SYSTEMDistributor PS±FE)IG±16

Page 1852 of 2389

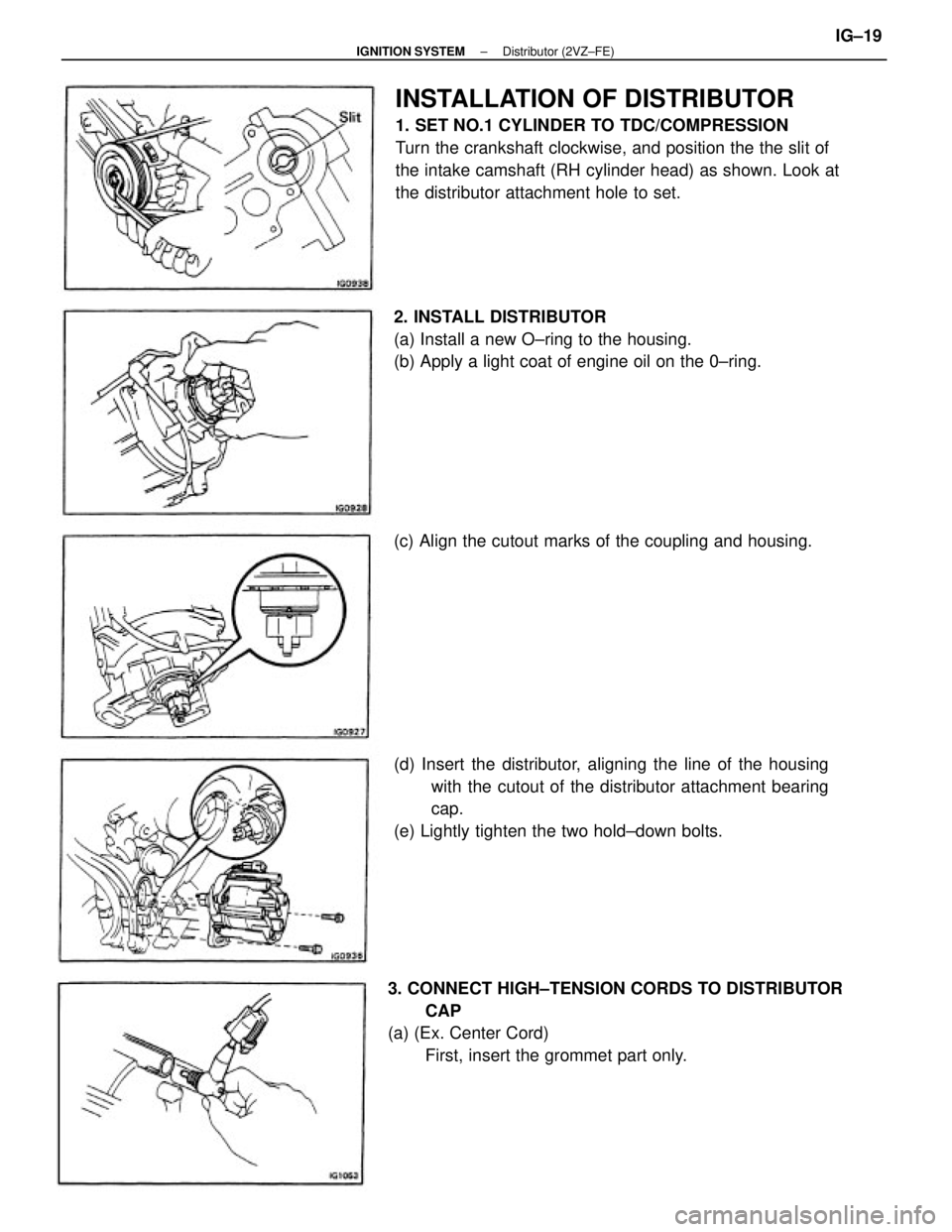

INSTALLATION OF DISTRIBUTOR

1. SET NO.1 CYLINDER TO TDC/COMPRESSION

Turn the crankshaft clockwise, and position the the slit of

the intake camshaft (RH cylinder head) as shown. Look at

the distributor attachment hole to set.

3. CONNECT HIGH±TENSION CORDS TO DISTRIBUTOR

CAP

(a) (Ex. Center Cord)

First, insert the grommet part only. (d) Insert the distributor, aligning the line of the housing

with the cutout of the distributor attachment bearing

cap.

(e) Lightly tighten the two hold±down bolts. 2. INSTALL DISTRIBUTOR

(a) Install a new O±ring to the housing.

(b) Apply a light coat of engine oil on the 0±ring.

(c) Align the cutout marks of the coupling and housing.

± IGNITION SYSTEMDistributor (2VZ±FE)IG±19

Page 2098 of 2389

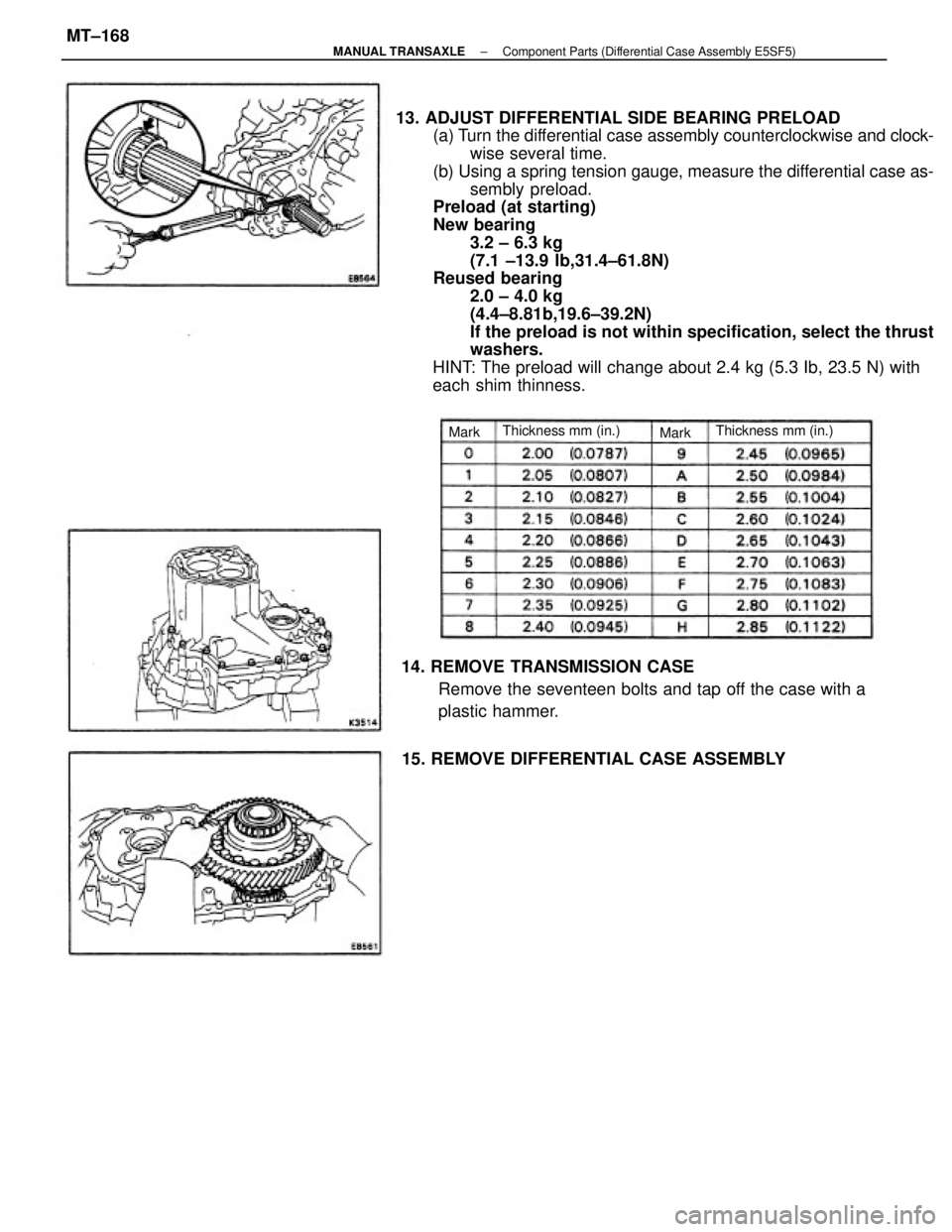

13. ADJUST DIFFERENTIAL SIDE BEARING PRELOAD

(a) Turn the differential case assembly counterclockwise and clock-

wise several time.

(b) Using a spring tension gauge, measure the differential case as-

sembly preload.

Preload (at starting)

New bearing

3.2 ± 6.3 kg

(7.1 ±13.9 lb,31.4±61.8N)

Reused bearing

2.0 ± 4.0 kg

(4.4±8.81b,19.6±39.2N)

If the preload is not within specification, select the thrust

washers.

HINT: The preload will change about 2.4 kg (5.3 Ib, 23.5 N) with

each shim thinness.

14. REMOVE TRANSMISSION CASE

Remove the seventeen bolts and tap off the case with a

plastic hammer.

15. REMOVE DIFFERENTIAL CASE ASSEMBLY

Thickness mm (in.) Thickness mm (in.)

Mark Mark

± MANUAL TRANSAXLEComponent Parts (Differential Case Assembly E5SF5)MT±168

Page 2100 of 2389

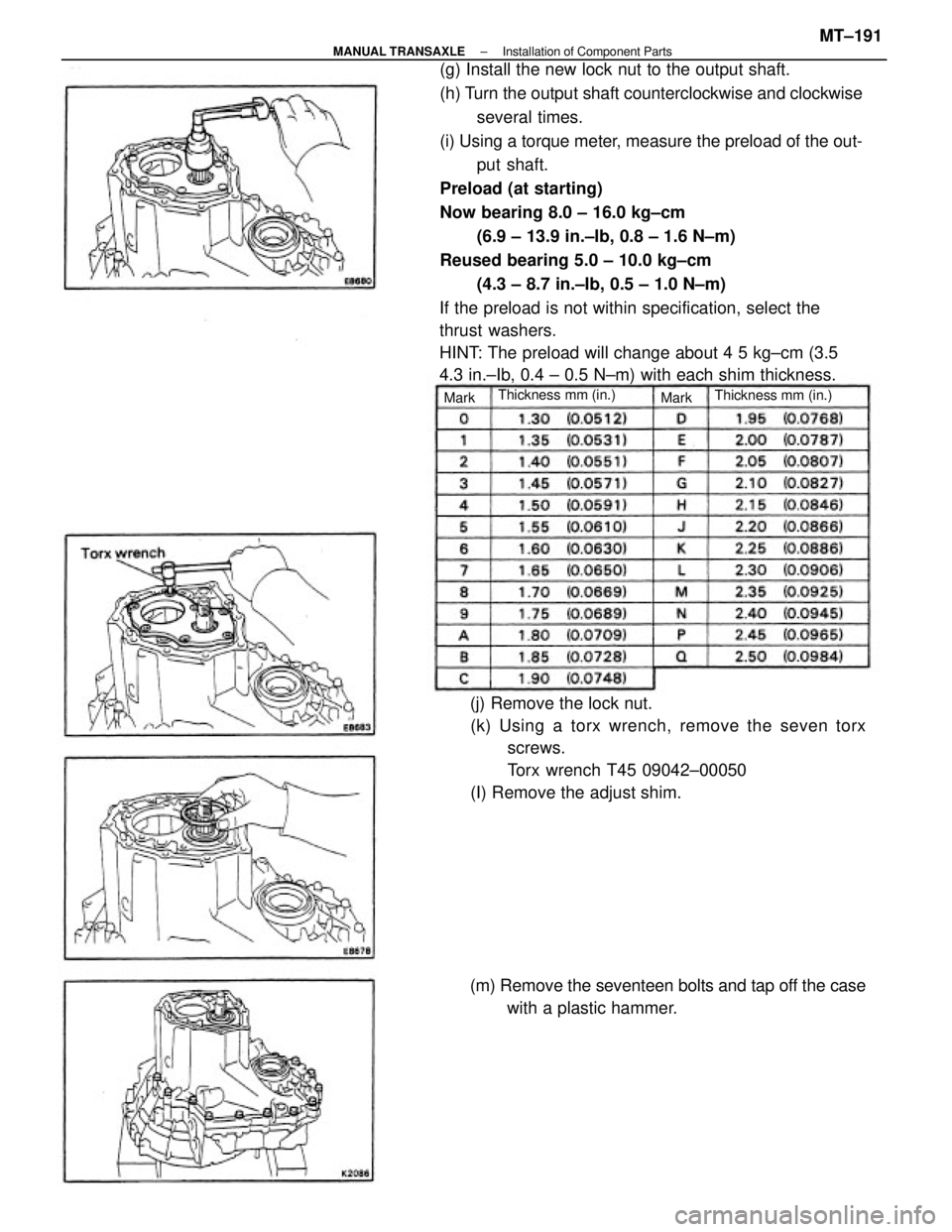

(g) Install the new lock nut to the output shaft.

(h) Turn the output shaft counterclockwise and clockwise

several times.

(i) Using a torque meter, measure the preload of the out-

put shaft.

Preload (at starting)

Now bearing 8.0 ± 16.0 kg±cm

(6.9 ± 13.9 in.±Ib, 0.8 ± 1.6 N±m)

Reused bearing 5.0 ± 10.0 kg±cm

(4.3 ± 8.7 in.±Ib, 0.5 ± 1.0 N±m)

If the preload is not within specification, select the

thrust washers.

HINT: The preload will change about 4 5 kg±cm (3.5

4.3 in.±Ib, 0.4 ± 0.5 N±m) with each shim thickness.

(j) Remove the lock nut.

(k) Using a torx wrench, remove the seven torx

screws.

Torx wrench T45 09042±00050

(I) Remove the adjust shim.

(m) Remove the seventeen bolts and tap off the case

with a plastic hammer.

Thickness mm (in.)

Thickness mm (in.)

Mark Mark

± MANUAL TRANSAXLEInstallation of Component PartsMT±191

Page 2129 of 2389

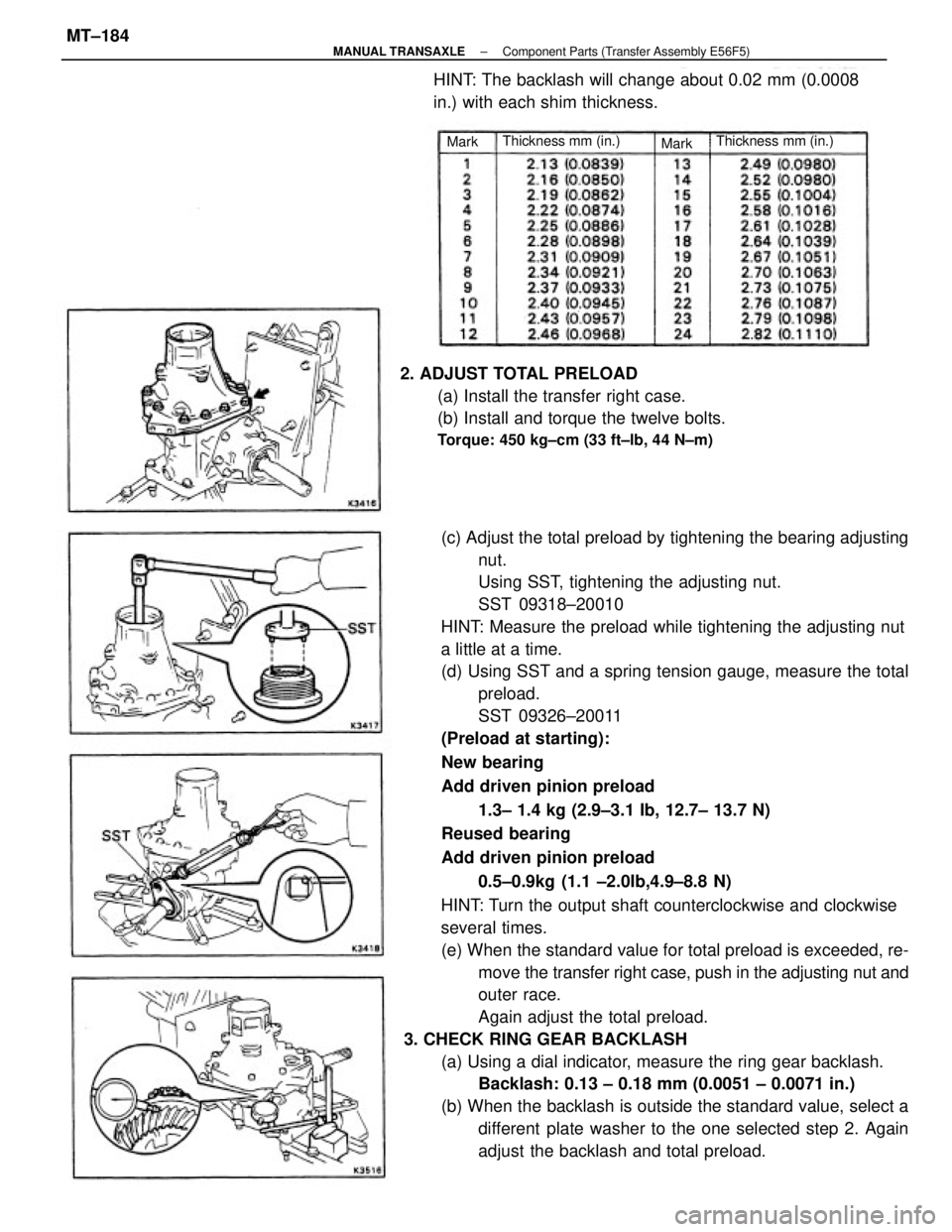

(c) Adjust the total preload by tightening the bearing adjusting

nut.

Using SST, tightening the adjusting nut.

SST 09318±20010

HINT: Measure the preload while tightening the adjusting nut

a little at a time.

(d) Using SST and a spring tension gauge, measure the total

preload.

SST 09326±20011

(Preload at starting):

New bearing

Add driven pinion preload

1.3± 1.4 kg (2.9±3.1 Ib, 12.7± 13.7 N)

Reused bearing

Add driven pinion preload

0.5±0.9kg (1.1 ±2.0Ib,4.9±8.8 N)

HINT: Turn the output shaft counterclockwise and clockwise

several times.

(e) When the standard value for total preload is exceeded, re-

move the transfer right case, push in the adjusting nut and

outer race.

Again adjust the total preload.

3. CHECK RING GEAR BACKLASH

(a) Using a dial indicator, measure the ring gear backlash.

Backlash: 0.13 ± 0.18 mm (0.0051 ± 0.0071 in.)

(b) When the backlash is outside the standard value, select a

different plate washer to the one selected step 2. Again

adjust the backlash and total preload. 2. ADJUST TOTAL PRELOAD

(a) Install the transfer right case.

(b) Install and torque the twelve bolts.

Torque: 450 kg±cm (33 ft±lb, 44 N±m)

HINT: The backlash will change about 0.02 mm (0.0008

in.) with each shim thickness.

Thickness mm (in.) Thickness mm (in.)

Mark

Mark

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly E56F5)MT±184

Page 2316 of 2389

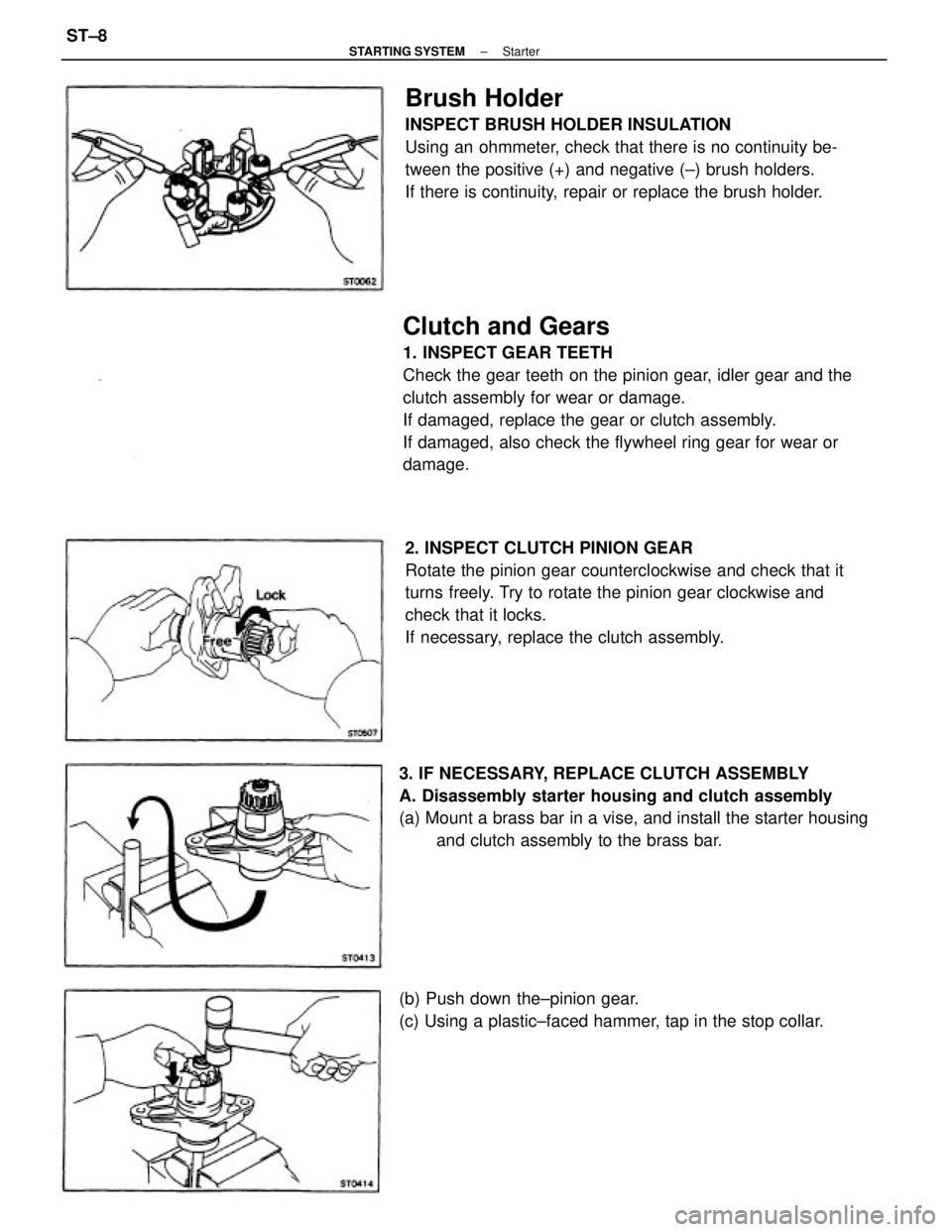

Clutch and Gears

1. INSPECT GEAR TEETH

Check the gear teeth on the pinion gear, idler gear and the

clutch assembly for wear or damage.

If damaged, replace the gear or clutch assembly.

If damaged, also check the flywheel ring gear for wear or

damage.

2. INSPECT CLUTCH PINION GEAR

Rotate the pinion gear counterclockwise and check that it

turns freely. Try to rotate the pinion gear clockwise and

check that it locks.

If necessary, replace the clutch assembly.

Brush Holder

INSPECT BRUSH HOLDER INSULATION

Using an ohmmeter, check that there is no continuity be-

tween the positive (+) and negative (±) brush holders.

If there is continuity, repair or replace the brush holder.

3. IF NECESSARY, REPLACE CLUTCH ASSEMBLY

A. Disassembly starter housing and clutch assembly

(a) Mount a brass bar in a vise, and install the starter housing

and clutch assembly to the brass bar.

(b) Push down the±pinion gear.

(c) Using a plastic±faced hammer, tap in the stop collar.

± STARTING SYSTEMStarterST±8