fuse TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1026 of 2389

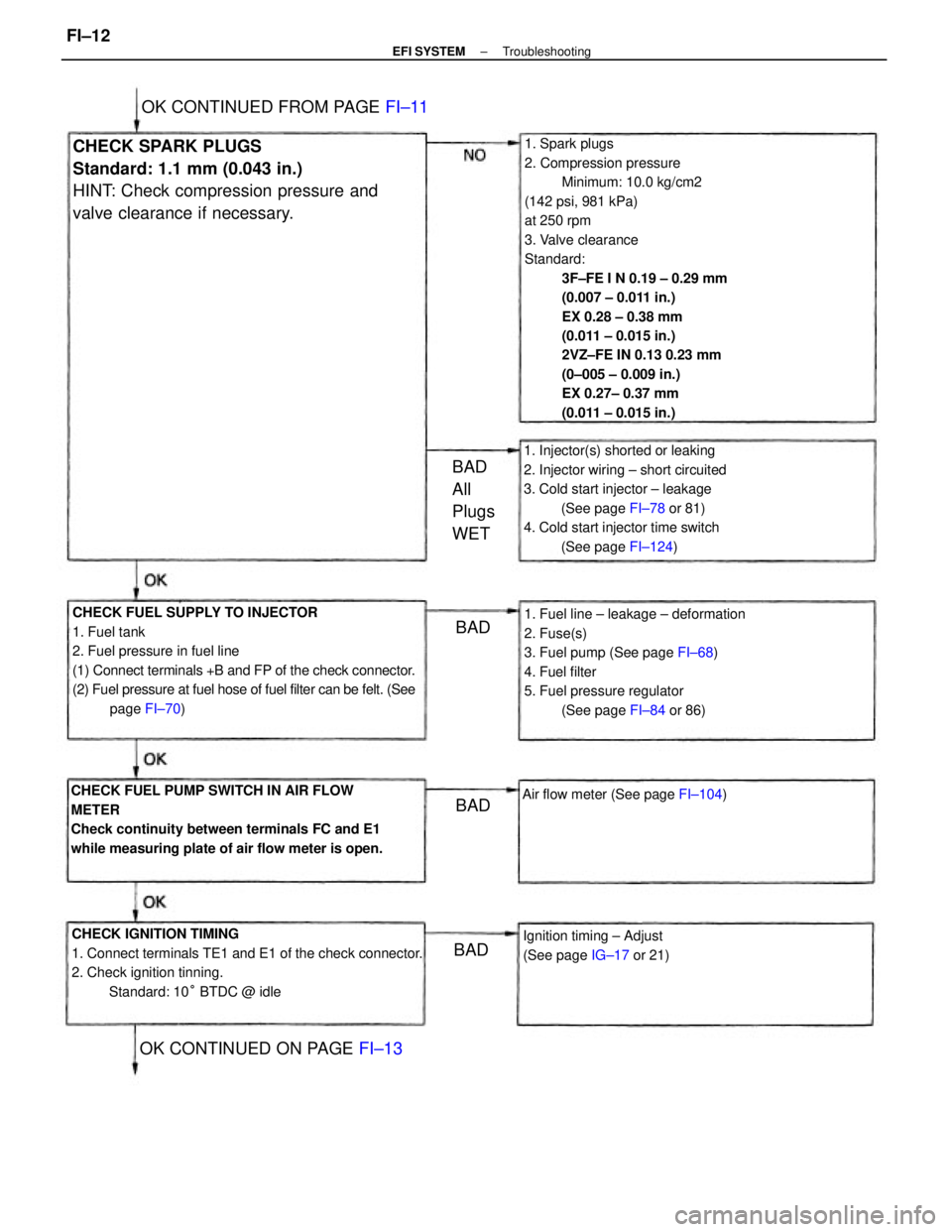

1. Spark plugs

2. Compression pressure

Minimum: 10.0 kg/cm2

(142 psi, 981 kPa)

at 250 rpm

3. Valve clearance

Standard:

3F±FE I N 0.19 ± 0.29 mm

(0.007 ± 0.011 in.)

EX 0.28 ± 0.38 mm

(0.011 ± 0.015 in.)

2VZ±FE IN 0.13 0.23 mm

(0±005 ± 0.009 in.)

EX 0.27± 0.37 mm

(0.011 ± 0.015 in.)

CHECK FUEL SUPPLY TO INJECTOR

1. Fuel tank

2. Fuel pressure in fuel line

(1) Connect terminals +B and FP of the check connector.

(2) Fuel pressure at fuel hose of fuel filter can be felt. (See

page FI±70)

CHECK IGNITION TIMING

1. Connect terminals TE1 and E1 of the check connector.

2. Check ignition tinning.

Standard: 10° BTDC @ idle CHECK FUEL PUMP SWITCH IN AIR FLOW

METER

Check continuity between terminals FC and E1

while measuring plate of air flow meter is open.1. Fuel line ± leakage ± deformation

2. Fuse(s)

3. Fuel pump (See page FI±68)

4. Fuel filter

5. Fuel pressure regulator

(See page FI±84 or 86) 1. Injector(s) shorted or leaking

2. Injector wiring ± short circuited

3. Cold start injector ± leakage

(See page FI±78 or 81)

4. Cold start injector time switch

(See page FI±124)CHECK SPARK PLUGS

Standard: 1.1 mm (0.043 in.)

HINT: Check compression pressure and

valve clearance if necessary.

Ignition timing ± Adjust

(See page IG±17 or 21)

OK CONTINUED FROM PAGE FI±11

OK CONTINUED ON PAGE FI±13

Air flow meter (See page FI±104)

BAD

All

Plugs

WET

BAD

BADBAD

± EFI SYSTEMTroubleshootingFI±12

Page 1027 of 2389

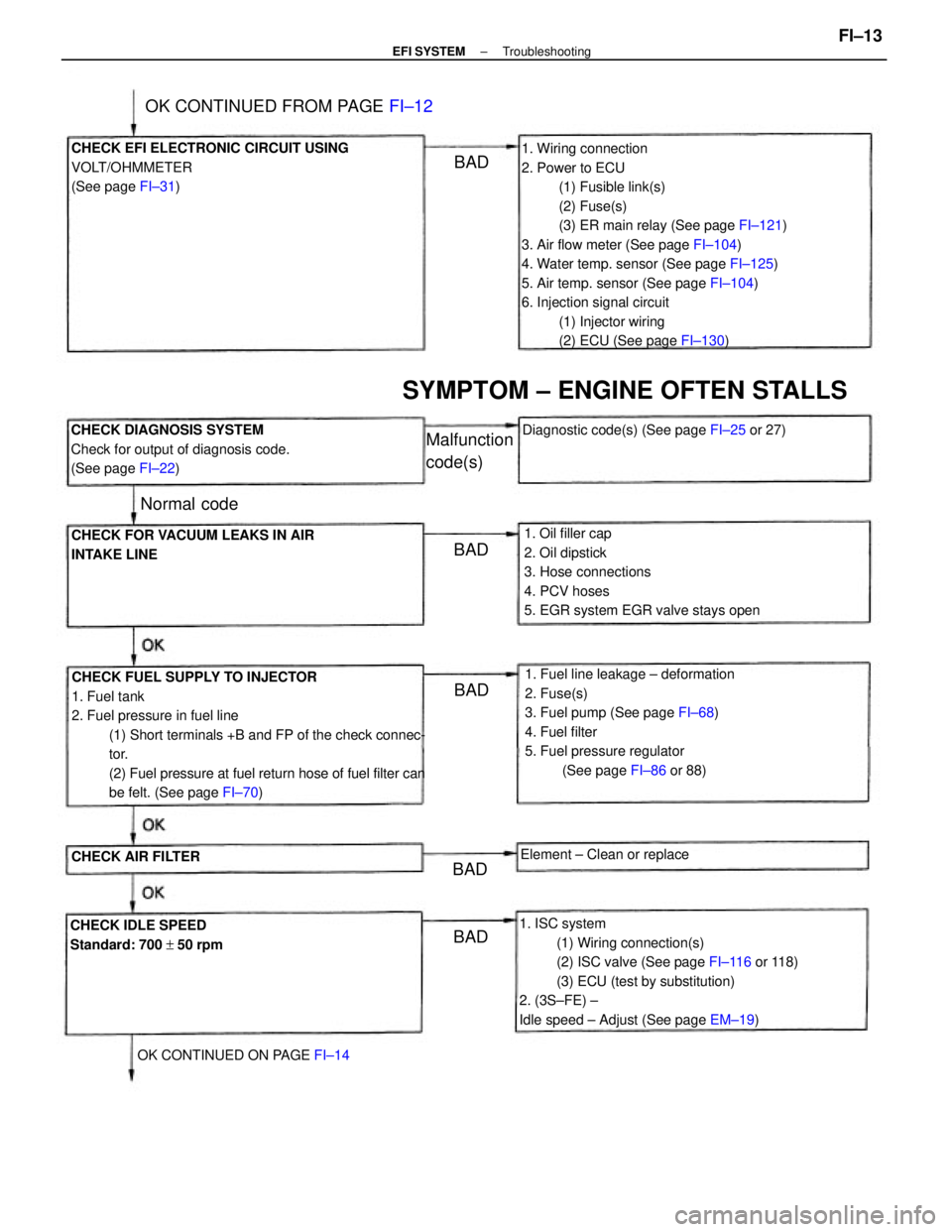

1. Wiring connection

2. Power to ECU

(1) Fusible link(s)

(2) Fuse(s)

(3) ER main relay (See page FI±121)

3. Air flow meter (See page FI±104)

4. Water temp. sensor (See page FI±125)

5. Air temp. sensor (See page FI±104)

6. Injection signal circuit

(1) Injector wiring

(2) ECU (See page FI±130)

CHECK FUEL SUPPLY TO INJECTOR

1. Fuel tank

2. Fuel pressure in fuel line

(1) Short terminals +B and FP of the check connec-

tor.

(2) Fuel pressure at fuel return hose of fuel filter can

be felt. (See page FI±70)

1. ISC system

(1) Wiring connection(s)

(2) ISC valve (See page FI±116 or 118)

(3) ECU (test by substitution)

2. (3S±FE) ±

Idle speed ± Adjust (See page EM±19) 1. Fuel line leakage ± deformation

2. Fuse(s)

3. Fuel pump (See page FI±68)

4. Fuel filter

5. Fuel pressure regulator

(See page FI±86 or 88) 1. Oil filler cap

2. Oil dipstick

3. Hose connections

4. PCV hoses

5. EGR system EGR valve stays open CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31)

CHECK DIAGNOSIS SYSTEM

Check for output of diagnosis code.

(See page FI±22)

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

SYMPTOM ± ENGINE OFTEN STALLS

CHECK IDLE SPEED

Standard: 700 + 50 rpmDiagnostic code(s) (See page FI±25 or 27)

OK CONTINUED FROM PAGE FI±12

OK CONTINUED ON PAGE FI±14Element ± Clean or replace

CHECK AIR FILTER

Malfunction

code(s)

Normal code

BADBAD

BAD

BADBAD

± EFI SYSTEMTroubleshootingFI±13

Page 1028 of 2389

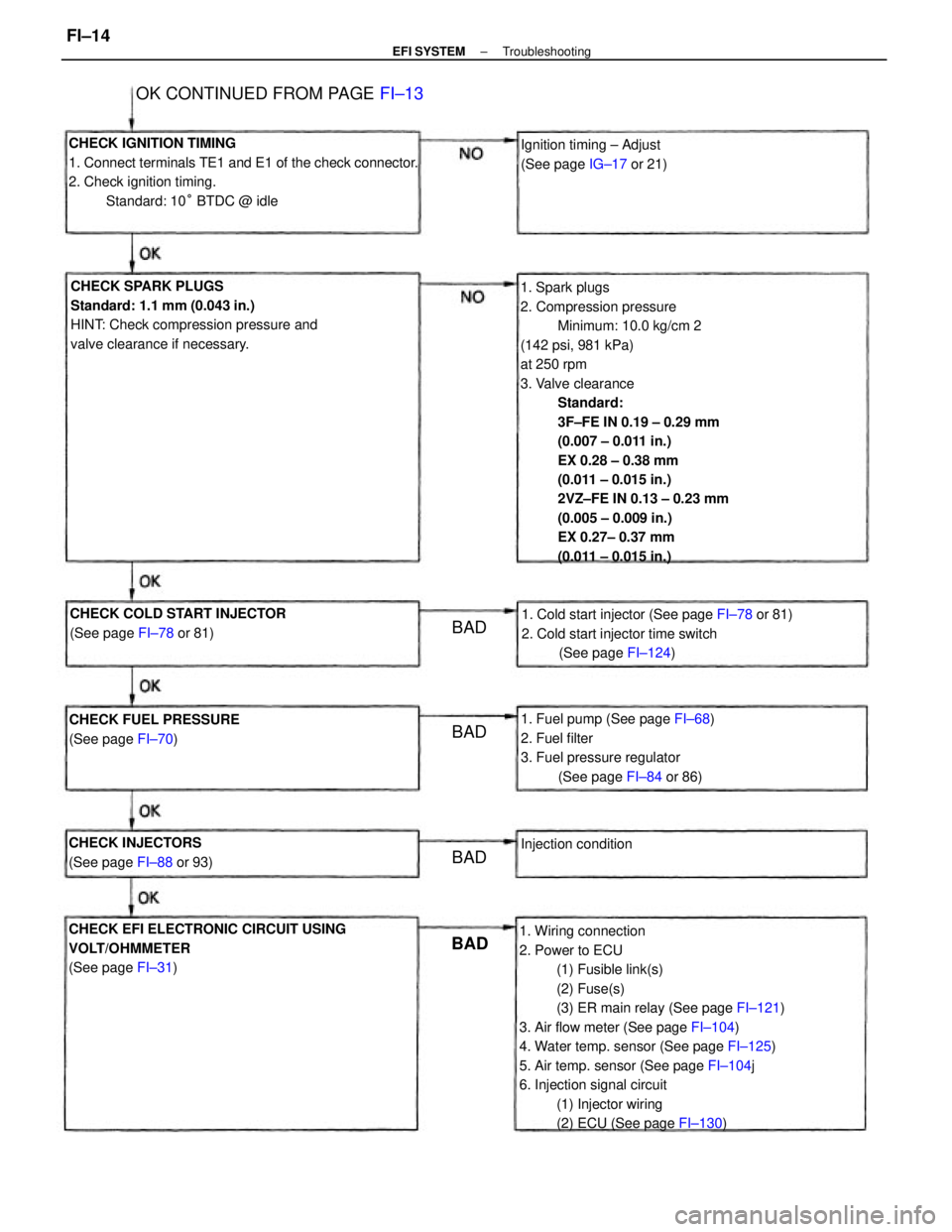

1. Spark plugs

2. Compression pressure

Minimum: 10.0 kg/cm 2

(142 psi, 981 kPa)

at 250 rpm

3. Valve clearance

Standard:

3F±FE IN 0.19 ± 0.29 mm

(0.007 ± 0.011 in.)

EX 0.28 ± 0.38 mm

(0.011 ± 0.015 in.)

2VZ±FE IN 0.13 ± 0.23 mm

(0.005 ± 0.009 in.)

EX 0.27± 0.37 mm

(0.011 ± 0.015 in.)

1. Wiring connection

2. Power to ECU

(1) Fusible link(s)

(2) Fuse(s)

(3) ER main relay (See page FI±121)

3. Air flow meter (See page FI±104)

4. Water temp. sensor (See page FI±125)

5. Air temp. sensor (See page FI±104j

6. Injection signal circuit

(1) Injector wiring

(2) ECU (See page FI±130) CHECK IGNITION TIMING

1. Connect terminals TE1 and E1 of the check connector.

2. Check ignition timing.

Standard: 10° BTDC @ idle

CHECK SPARK PLUGS

Standard: 1.1 mm (0.043 in.)

HINT: Check compression pressure and

valve clearance if necessary.

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31)1. Cold start injector (See page FI±78 or 81)

2. Cold start injector time switch

(See page FI±124)

1. Fuel pump (See page FI±68)

2. Fuel filter

3. Fuel pressure regulator

(See page FI±84 or 86) CHECK COLD START INJECTOR

(See page FI±78 or 81)

OK CONTINUED FROM PAGE FI±13

CHECK FUEL PRESSURE

(See page FI±70)Ignition timing ± Adjust

(See page IG±17 or 21)

CHECK INJECTORS

(See page FI±88 or 93)Injection condition

BADBAD

BAD BAD

± EFI SYSTEMTroubleshootingFI±14

Page 1030 of 2389

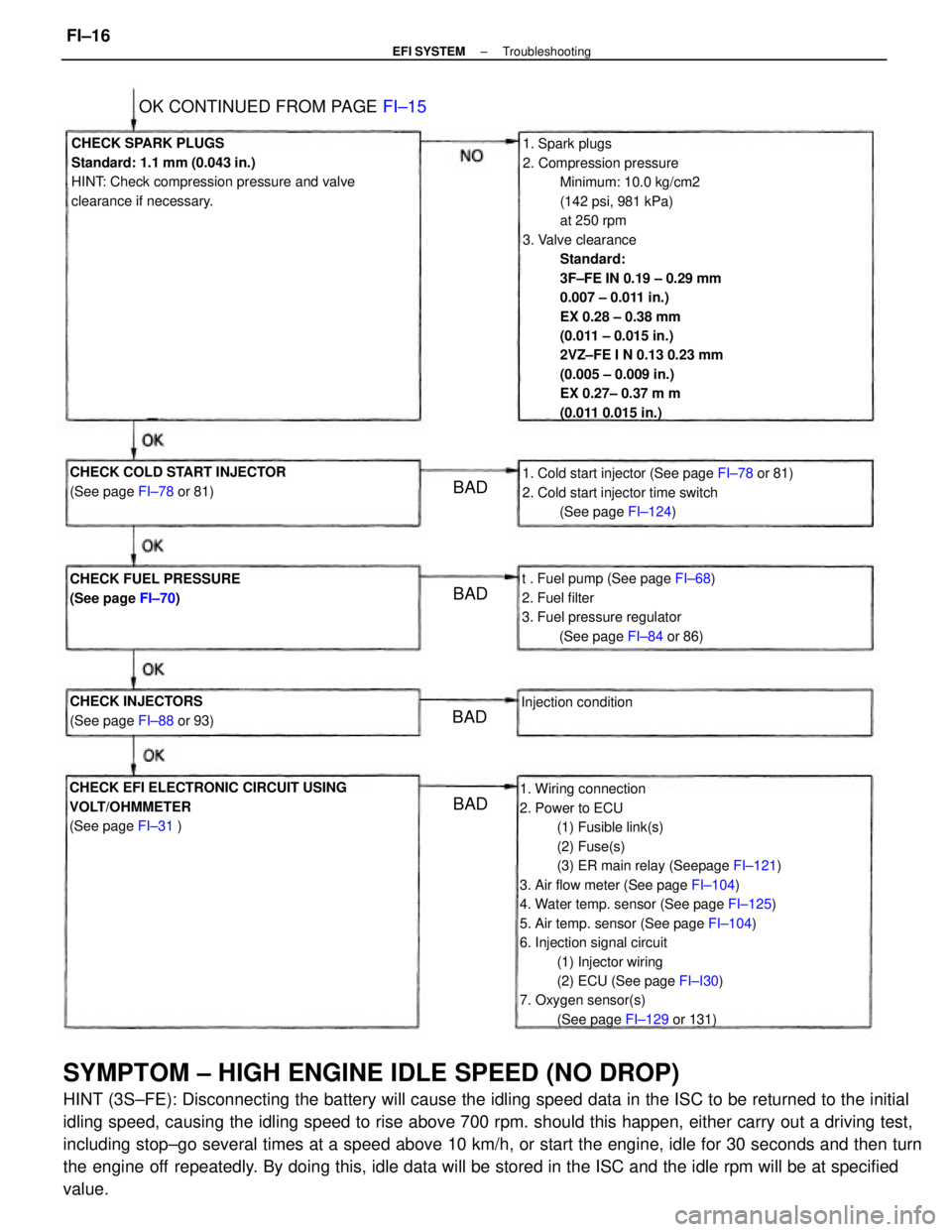

SYMPTOM ± HIGH ENGINE IDLE SPEED (NO DROP)

HINT (3S±FE): Disconnecting the battery will cause the idling speed data in the ISC to be returned to the initial

idling speed, causing the idling speed to rise above 700 rpm. should this happen, either carry out a driving test,

including stop±go several times at a speed above 10 km/h, or start the engine, idle for 30 seconds and then turn

the engine off repeatedly. By doing this, idle data will be stored in the ISC and the idle rpm will be at specified

value.

1. Spark plugs

2. Compression pressure

Minimum: 10.0 kg/cm2

(142 psi, 981 kPa)

at 250 rpm

3. Valve clearance

Standard:

3F±FE IN 0.19 ± 0.29 mm

0.007 ± 0.011 in.)

EX 0.28 ± 0.38 mm

(0.011 ± 0.015 in.)

2VZ±FE I N 0.13 0.23 mm

(0.005 ± 0.009 in.)

EX 0.27± 0.37 m m

(0.011 0.015 in.)

1. Wiring connection

2. Power to ECU

(1) Fusible link(s)

(2) Fuse(s)

(3) ER main relay (Seepage FI±121)

3. Air flow meter (See page FI±104)

4. Water temp. sensor (See page FI±125)

5. Air temp. sensor (See page FI±104)

6. Injection signal circuit

(1) Injector wiring

(2) ECU (See page FI±I30)

7. Oxygen sensor(s)

(See page FI±129 or 131) CHECK SPARK PLUGS

Standard: 1.1 mm (0.043 in.)

HINT: Check compression pressure and valve

clearance if necessary.

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31 )1. Cold start injector (See page FI±78 or 81)

2. Cold start injector time switch

(See page FI±124)

t . Fuel pump (See page FI±68)

2. Fuel filter

3. Fuel pressure regulator

(See page FI±84 or 86) CHECK COLD START INJECTOR

(See page FI±78 or 81)

CHECK FUEL PRESSURE

(See page FI±70)

OK CONTINUED FROM PAGE FI±15

CHECK INJECTORS

(See page FI±88 or 93)Injection condition

BADBAD

BAD

BAD

± EFI SYSTEMTroubleshootingFI±16

Page 1031 of 2389

1. Wiring connection

2. Power to ECU

(1) Fusible link(s)

(2) Fuse(s)

(3) ER main relay (See page FI±121)

3. Air flow meter (See page FI±104)

4. Water temp. sensor (See page FI±125)

5. Air temp. sensor (See page FI±104)

6. Injection signal circuit

(1) Injector wiring

(2) ECU (See page FI±130)CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31)

1. Fuel pump (See page FI±68)

2. Fuel filter

3. Fuel pressure regulator

(See page FI±84 or 86) 1. Wiring connection(s) .

2. ISC valve (See page FI±116 or 118)

3. Air conditioner switch

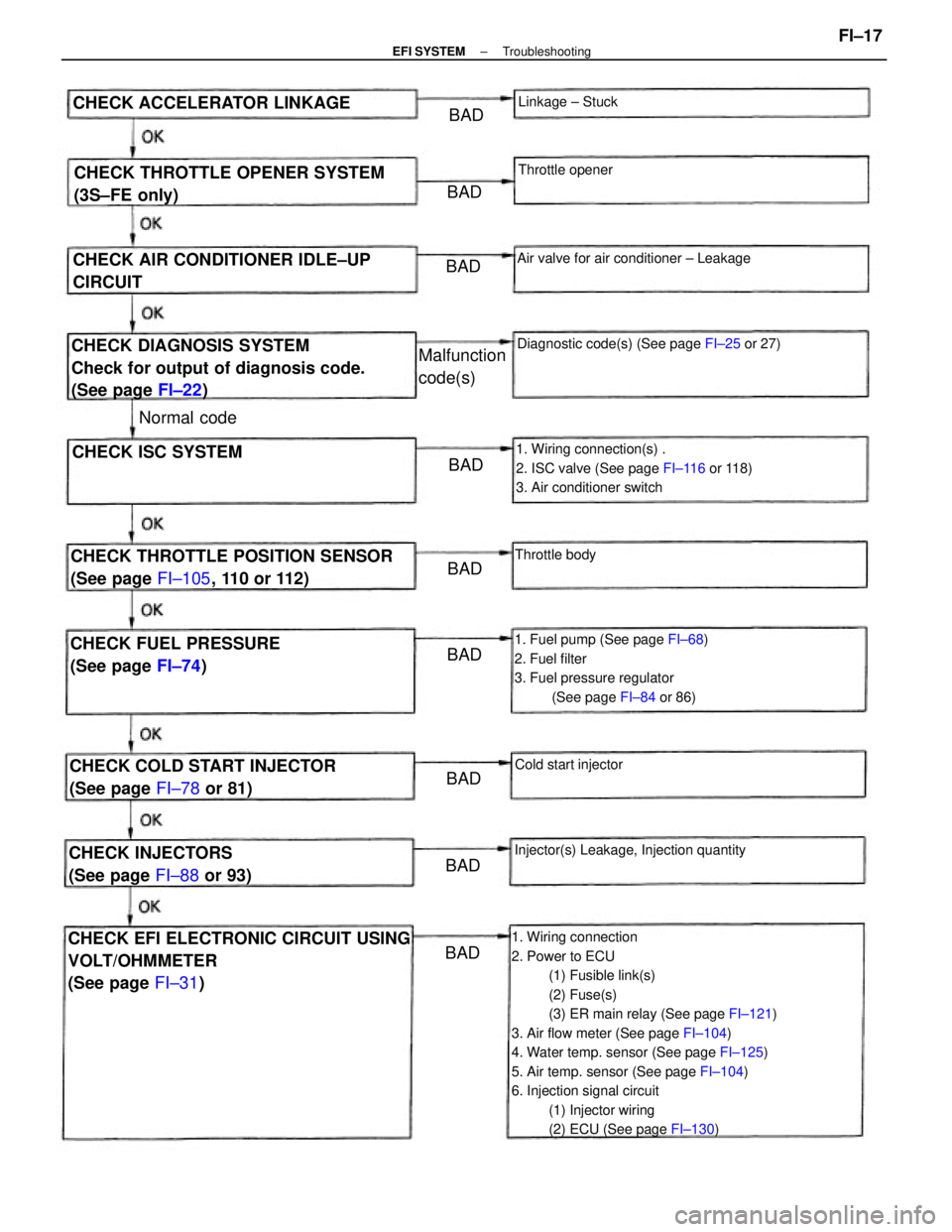

CHECK DIAGNOSIS SYSTEM

Check for output of diagnosis code.

(See page FI±22)

CHECK THROTTLE POSITION SENSOR

(See page FI±105, 110 or 112) CHECK THROTTLE OPENER SYSTEM

(3S±FE only)

CHECK AIR CONDITIONER IDLE±UP

CIRCUIT

CHECK COLD START INJECTOR

(See page FI±78 or 81) CHECK FUEL PRESSURE

(See page FI±74)Diagnostic code(s) (See page FI±25 or 27)

Injector(s) Leakage, Injection quantityAir valve for air conditioner ± Leakage

CHECK INJECTORS

(See page FI±88 or 93) CHECK ACCELERATOR LINKAGE

CHECK ISC SYSTEMMalfunction

code(s)

Cold start injectorLinkage ± Stuck

Throttle opener

Throttle body

Normal code

BADBAD

BAD

BADBADBADBAD

BADBAD

± EFI SYSTEMTroubleshootingFI±17

Page 1032 of 2389

1. Wiring connection

2. Power to ECU

(1) Fusible link(s)

(2) Fuse(s)

(3) ER main relay (See page FI±121)

3. Air flow meter (See page FI±104)

4. Water temp. sensor (See page FI±125)

5. Air temp. sensor (See page FI±104)

6. Injection signal circuit

(1) Injection wiring

(2) ECU (See page FI±130)

7. Oxygen sensor(s)

(Seepage FI±129 or 131)

CHECK IGNITION TIMING

1. Connect terminals TE1 and E1 of the check con-

nector.

2. Check ignition timing.

Standard: 10

° BTDC @ idle

1. Oil filler cap

2. Oil dipstick

3. Hose connections

4. PCV hoses

5. EGR system ± EGR valve stays open

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31)

1. Cold start injector (See page FI±78 or 81)

2. Cold start injector time switch

(See page FI±124)

1. Fuel pump (See page FI±68)

2. Fuel filter

3. Fuel pressure regulator

(See page FI±84 or 86)

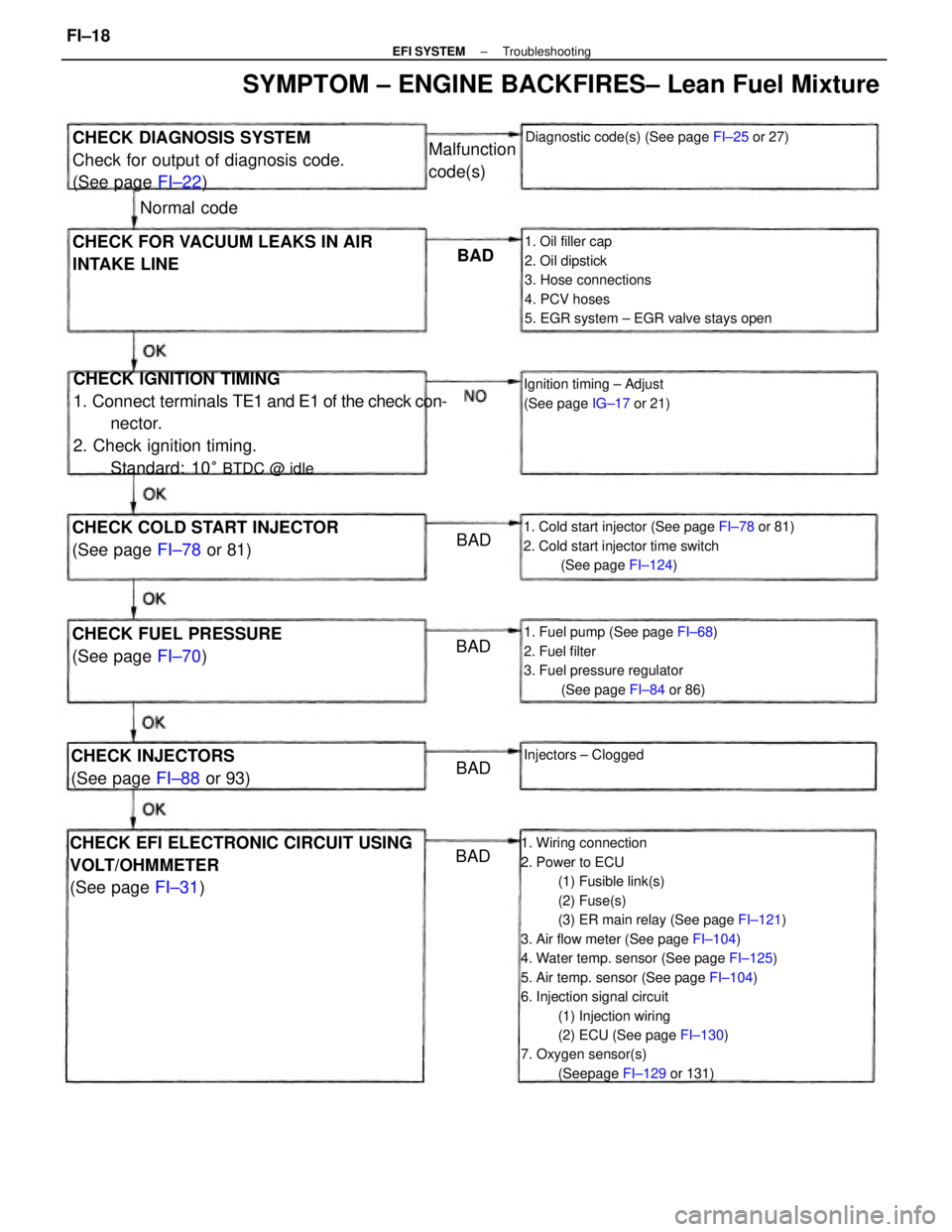

CHECK DIAGNOSIS SYSTEM

Check for output of diagnosis code.

(See page FI±22)

SYMPTOM ± ENGINE BACKFIRES± Lean Fuel Mixture

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

CHECK COLD START INJECTOR

(See page FI±78 or 81)

CHECK FUEL PRESSURE

(See page FI±70)

Diagnostic code(s) (See page FI±25 or 27)

Ignition timing ± Adjust

(See page IG±17 or 21)

CHECK INJECTORS

(See page FI±88 or 93)Injectors ± Clogged

Malfunction

code(s)

Normal code

BAD

BAD

BAD BAD

BAD

± EFI SYSTEMTroubleshootingFI±18

Page 1035 of 2389

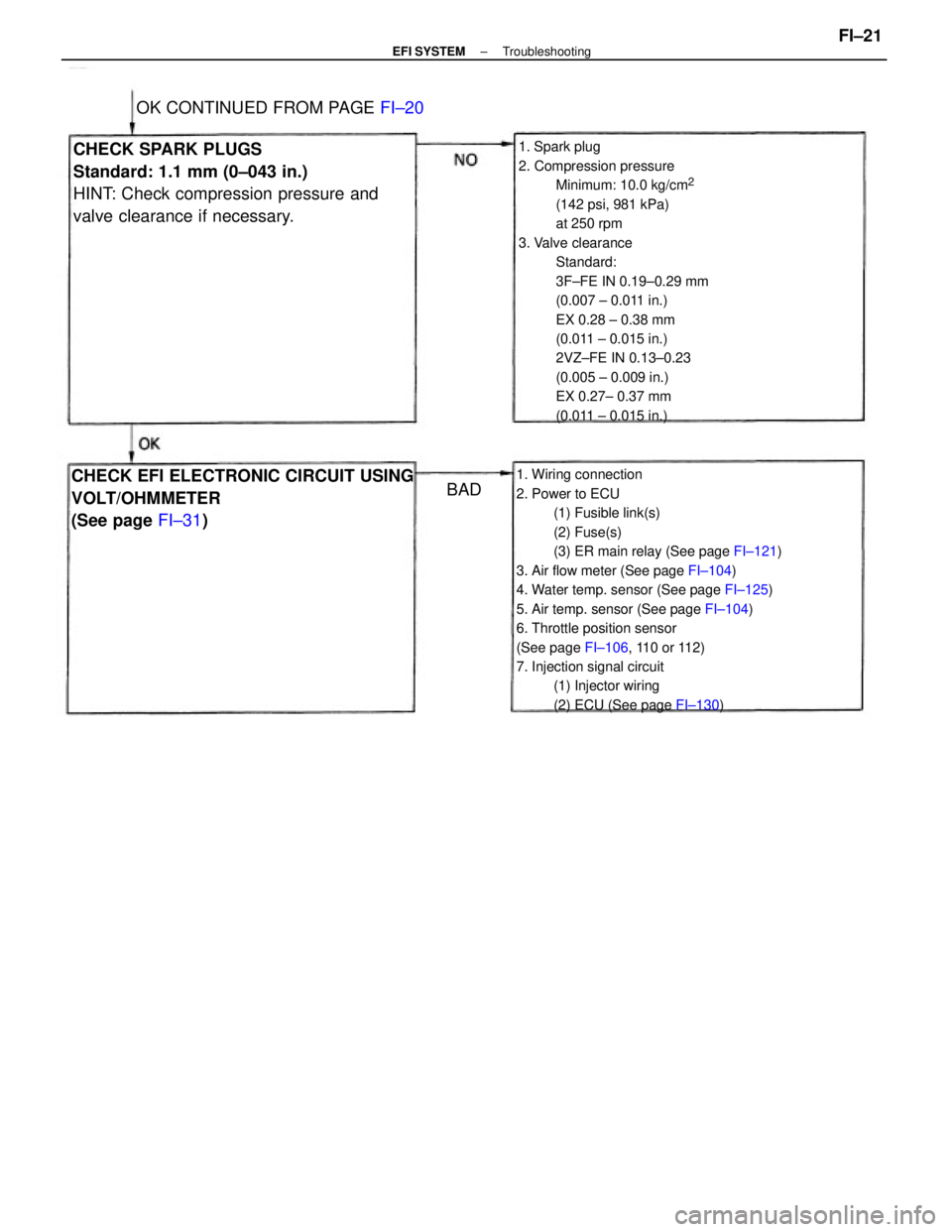

1. Spark plug

2. Compression pressure

Minimum: 10.0 kg/cm

2

(142 psi, 981 kPa)

at 250 rpm

3. Valve clearance

Standard:

3F±FE IN 0.19±0.29 mm

(0.007 ± 0.011 in.)

EX 0.28 ± 0.38 mm

(0.011 ± 0.015 in.)

2VZ±FE IN 0.13±0.23

(0.005 ± 0.009 in.)

EX 0.27± 0.37 mm

(0.011 ± 0.015 in.)

1. Wiring connection

2. Power to ECU

(1) Fusible link(s)

(2) Fuse(s)

(3) ER main relay (See page FI±121)

3. Air flow meter (See page FI±104)

4. Water temp. sensor (See page FI±125)

5. Air temp. sensor (See page FI±104)

6. Throttle position sensor

(See page FI±106, 110 or 112)

7. Injection signal circuit

(1) Injector wiring

(2) ECU (See page FI±130)

CHECK SPARK PLUGS

Standard: 1.1 mm (0±043 in.)

HINT: Check compression pressure and

valve clearance if necessary.

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31) OK CONTINUED FROM PAGE FI±20

BAD

± EFI SYSTEMTroubleshootingFI±21

Page 1036 of 2389

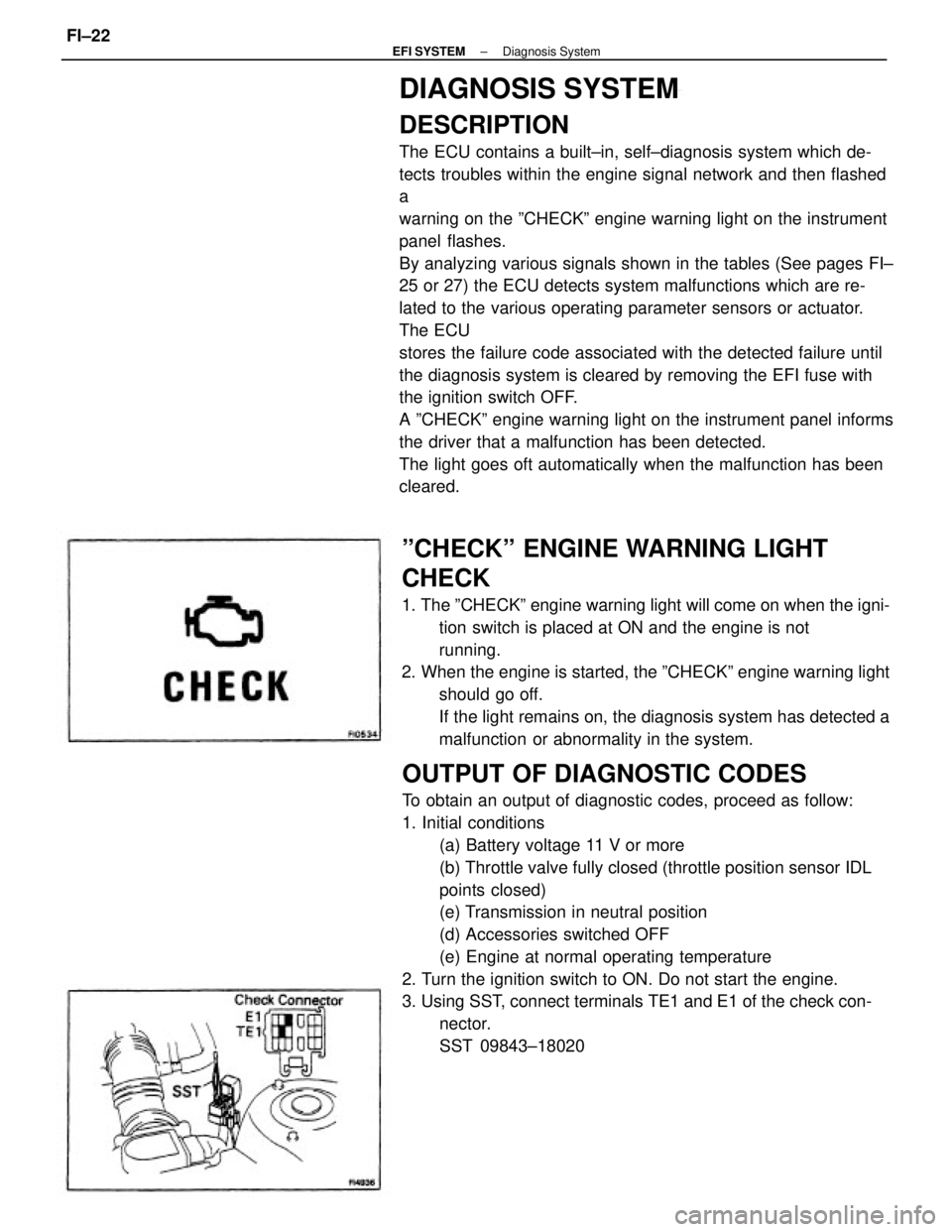

DIAGNOSIS SYSTEM

DESCRIPTION

The ECU contains a built±in, self±diagnosis system which de-

tects troubles within the engine signal network and then flashed

a

warning on the ºCHECKº engine warning light on the instrument

panel flashes.

By analyzing various signals shown in the tables (See pages FI±

25 or 27) the ECU detects system malfunctions which are re-

lated to the various operating parameter sensors or actuator.

The ECU

stores the failure code associated with the detected failure until

the diagnosis system is cleared by removing the EFI fuse with

the ignition switch OFF.

A ºCHECKº engine warning light on the instrument panel informs

the driver that a malfunction has been detected.

The light goes oft automatically when the malfunction has been

cleared.

OUTPUT OF DIAGNOSTIC CODES

To obtain an output of diagnostic codes, proceed as follow:

1. Initial conditions

(a) Battery voltage 11 V or more

(b) Throttle valve fully closed (throttle position sensor IDL

points closed)

(e) Transmission in neutral position

(d) Accessories switched OFF

(e) Engine at normal operating temperature

2. Turn the ignition switch to ON. Do not start the engine.

3. Using SST, connect terminals TE1 and E1 of the check con-

nector.

SST 09843±18020

ºCHECKº ENGINE WARNING LIGHT

CHECK

1. The ºCHECKº engine warning light will come on when the igni-

tion switch is placed at ON and the engine is not

running.

2. When the engine is started, the ºCHECKº engine warning light

should go off.

If the light remains on, the diagnosis system has detected a

malfunction or abnormality in the system.

± EFI SYSTEMDiagnosis SystemFI±22

Page 1038 of 2389

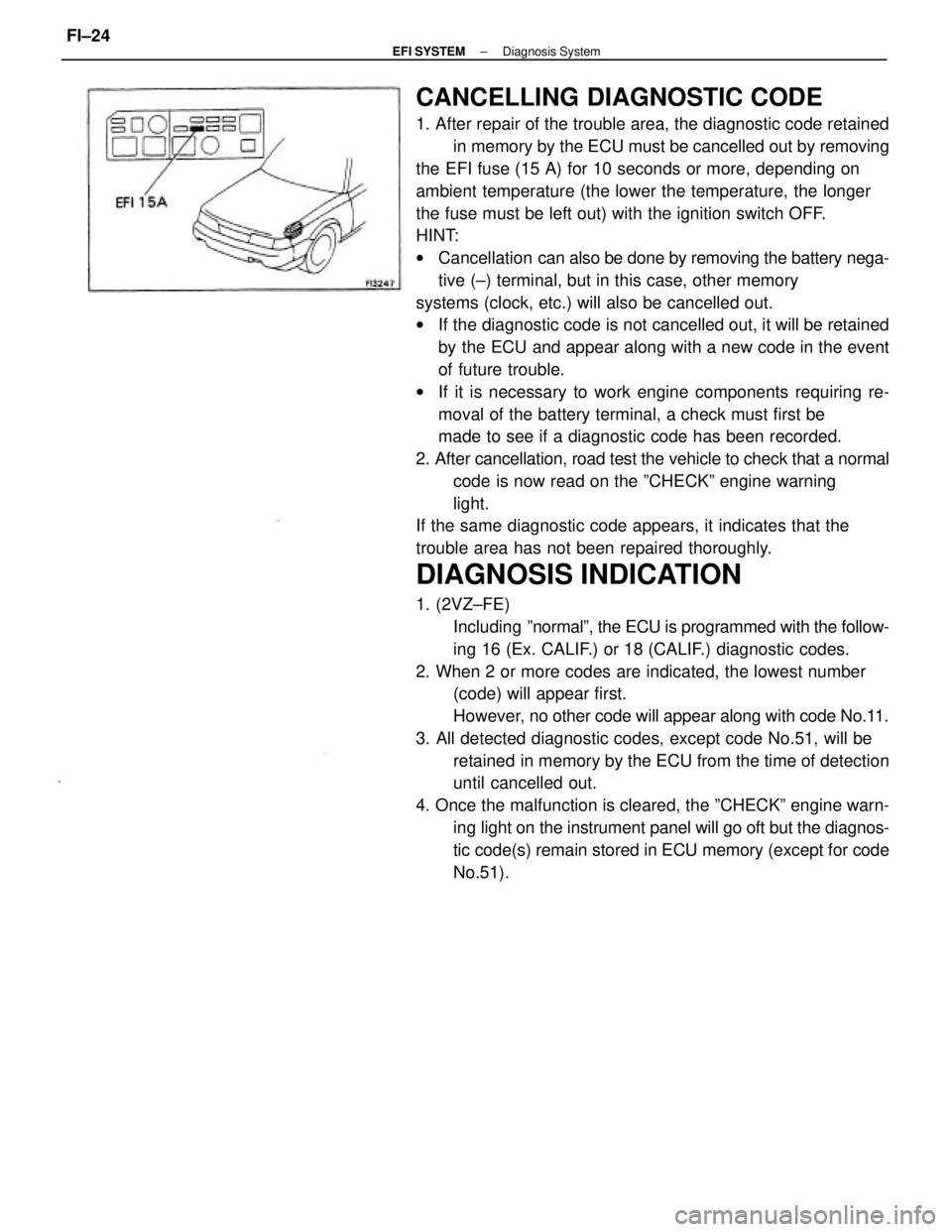

CANCELLING DIAGNOSTIC CODE

1. After repair of the trouble area, the diagnostic code retained

in memory by the ECU must be cancelled out by removing

the EFI fuse (15 A) for 10 seconds or more, depending on

ambient temperature (the lower the temperature, the longer

the fuse must be left out) with the ignition switch OFF.

HINT:

wCancellation can also be done by removing the battery nega-

tive (±) terminal, but in this case, other memory

systems (clock, etc.) will also be cancelled out.

wIf the diagnostic code is not cancelled out, it will be retained

by the ECU and appear along with a new code in the event

of future trouble.

wIf it is necessary to work engine components requiring re-

moval of the battery terminal, a check must first be

made to see if a diagnostic code has been recorded.

2. After cancellation, road test the vehicle to check that a normal

code is now read on the ºCHECKº engine warning

light.

If the same diagnostic code appears, it indicates that the

trouble area has not been repaired thoroughly.

DIAGNOSIS INDICATION

1. (2VZ±FE)

Including ºnormalº, the ECU is programmed with the follow-

ing 16 (Ex. CALIF.) or 18 (CALIF.) diagnostic codes.

2. When 2 or more codes are indicated, the lowest number

(code) will appear first.

However, no other code will appear along with code No.11.

3. All detected diagnostic codes, except code No.51, will be

retained in memory by the ECU from the time of detection

until cancelled out.

4. Once the malfunction is cleared, the ºCHECKº engine warn-

ing light on the instrument panel will go oft but the diagnos-

tic code(s) remain stored in ECU memory (except for code

No.51).

± EFI SYSTEMDiagnosis SystemFI±24

Page 1044 of 2389

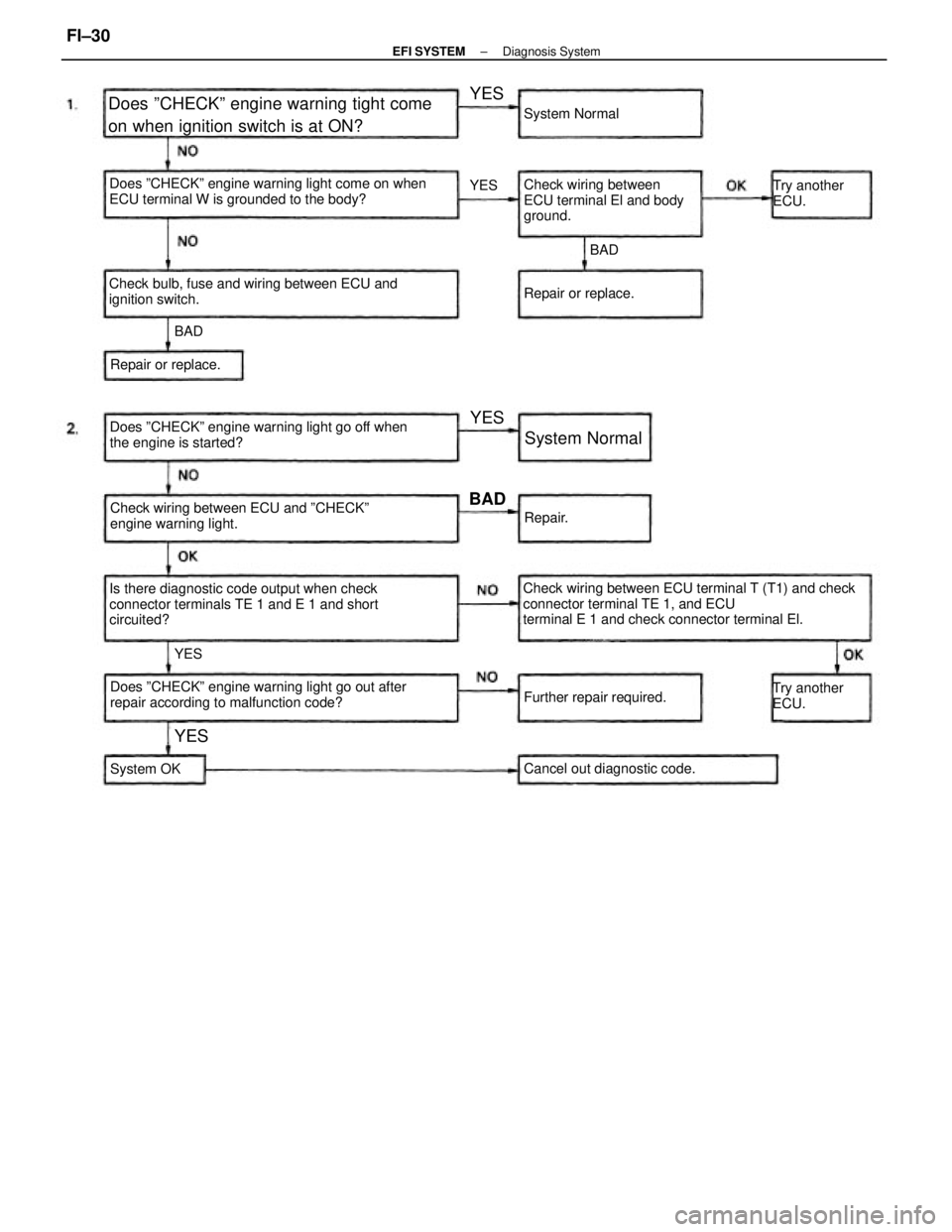

Check wiring between ECU terminal T (T1) and check

connector terminal TE 1, and ECU

terminal E 1 and check connector terminal El. Is there diagnostic code output when check

connector terminals TE 1 and E 1 and short

circuited? Does ºCHECKº engine warning light come on when

ECU terminal W is grounded to the body?

Does ºCHECKº engine warning tight come

on when ignition switch is at ON?

Check bulb, fuse and wiring between ECU and

ignition switch.

Does ºCHECKº engine warning light go out after

repair according to malfunction code? Does ºCHECKº engine warning light go off when

the engine is started?

Check wiring between ECU and ºCHECKº

engine warning light.Check wiring between

ECU terminal El and body

ground.

Cancel out diagnostic code. Further repair required.Try another

ECU.Try another

ECU.

Repair or replace.Repair or replace.

System Normal

System Normal

System OKRepair.

BAD

BAD

BAD

YES YES

YESYES

YES

± EFI SYSTEMDiagnosis SystemFI±30