TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Page 1966 of 2389

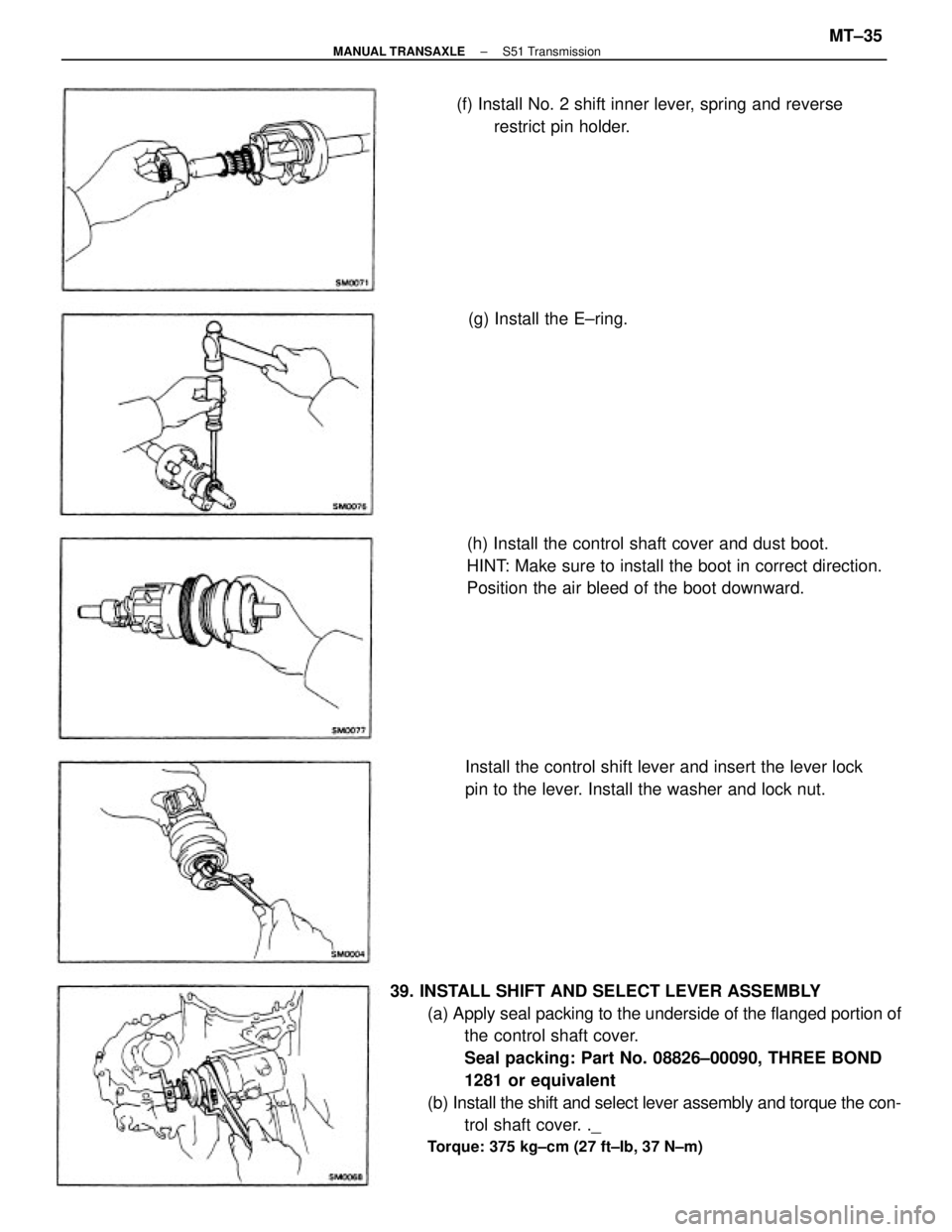

39. INSTALL SHIFT AND SELECT LEVER ASSEMBLY

(a) Apply seal packing to the underside of the flanged portion of

the control shaft cover.

Seal packing: Part No. 08826±00090, THREE BOND

1281 or equivalent

(b) Install the shift and select lever assembly and torque the con-

trol shaft cover. ._

Torque: 375 kg±cm (27 ft±Ib, 37 N±m)

(h) Install the control shaft cover and dust boot.

HINT: Make sure to install the boot in correct direction.

Position the air bleed of the boot downward. (f) Install No. 2 shift inner lever, spring and reverse

restrict pin holder.

Install the control shift lever and insert the lever lock

pin to the lever. Install the washer and lock nut.(g) Install the E±ring.

± MANUAL TRANSAXLES51 TransmissionMT±35

Page 2010 of 2389

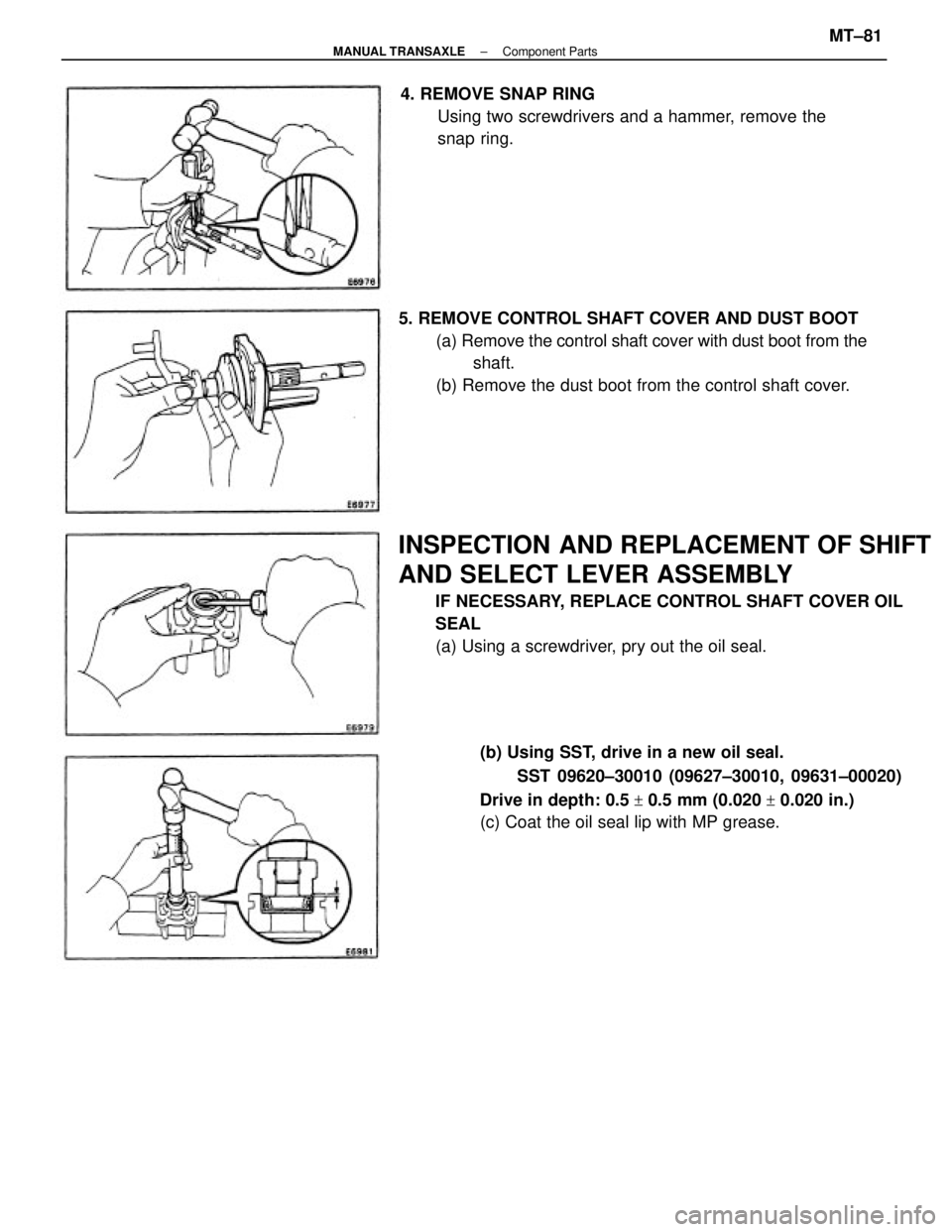

INSPECTION AND REPLACEMENT OF SHIFT

AND SELECT LEVER ASSEMBLY

IF NECESSARY, REPLACE CONTROL SHAFT COVER OIL

SEAL

(a) Using a screwdriver, pry out the oil seal. 5. REMOVE CONTROL SHAFT COVER AND DUST BOOT

(a) Remove the control shaft cover with dust boot from the

shaft.

(b) Remove the dust boot from the control shaft cover.

(b) Using SST, drive in a new oil seal.

SST 09620±30010 (09627±30010, 09631±00020)

Drive in depth: 0.5

+ 0.5 mm (0.020 + 0.020 in.)

(c) Coat the oil seal lip with MP grease. 4. REMOVE SNAP RING

Using two screwdrivers and a hammer, remove the

snap ring.

± MANUAL TRANSAXLEComponent PartsMT±81

Page 2011 of 2389

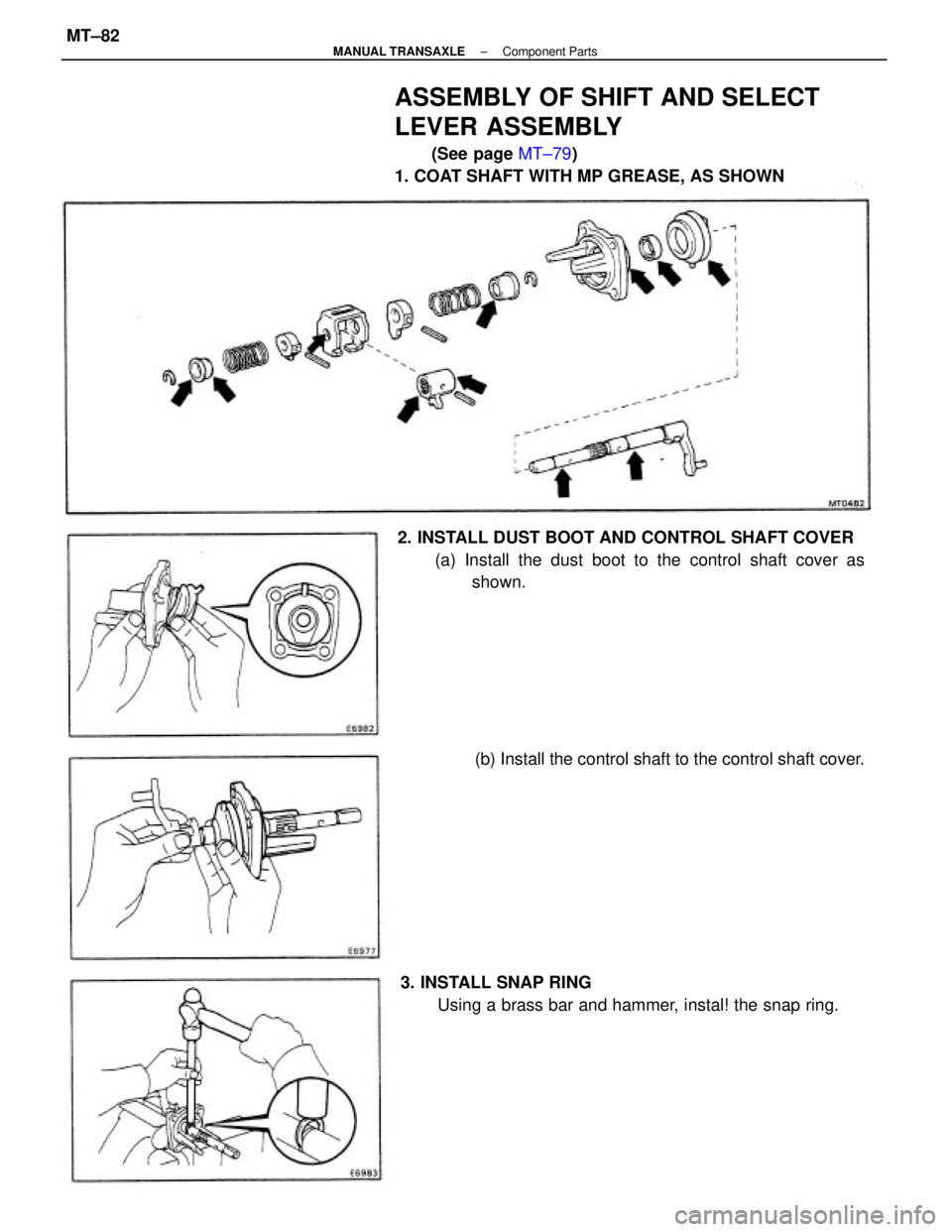

ASSEMBLY OF SHIFT AND SELECT

LEVER ASSEMBLY

(See page MT±79)

1. COAT SHAFT WITH MP GREASE, AS SHOWN

2. INSTALL DUST BOOT AND CONTROL SHAFT COVER

(a) Install the dust boot to the control shaft cover as

shown.

3. INSTALL SNAP RING

Using a brass bar and hammer, instal! the snap ring.(b) Install the control shaft to the control shaft cover.

± MANUAL TRANSAXLEComponent PartsMT±82

Page 2062 of 2389

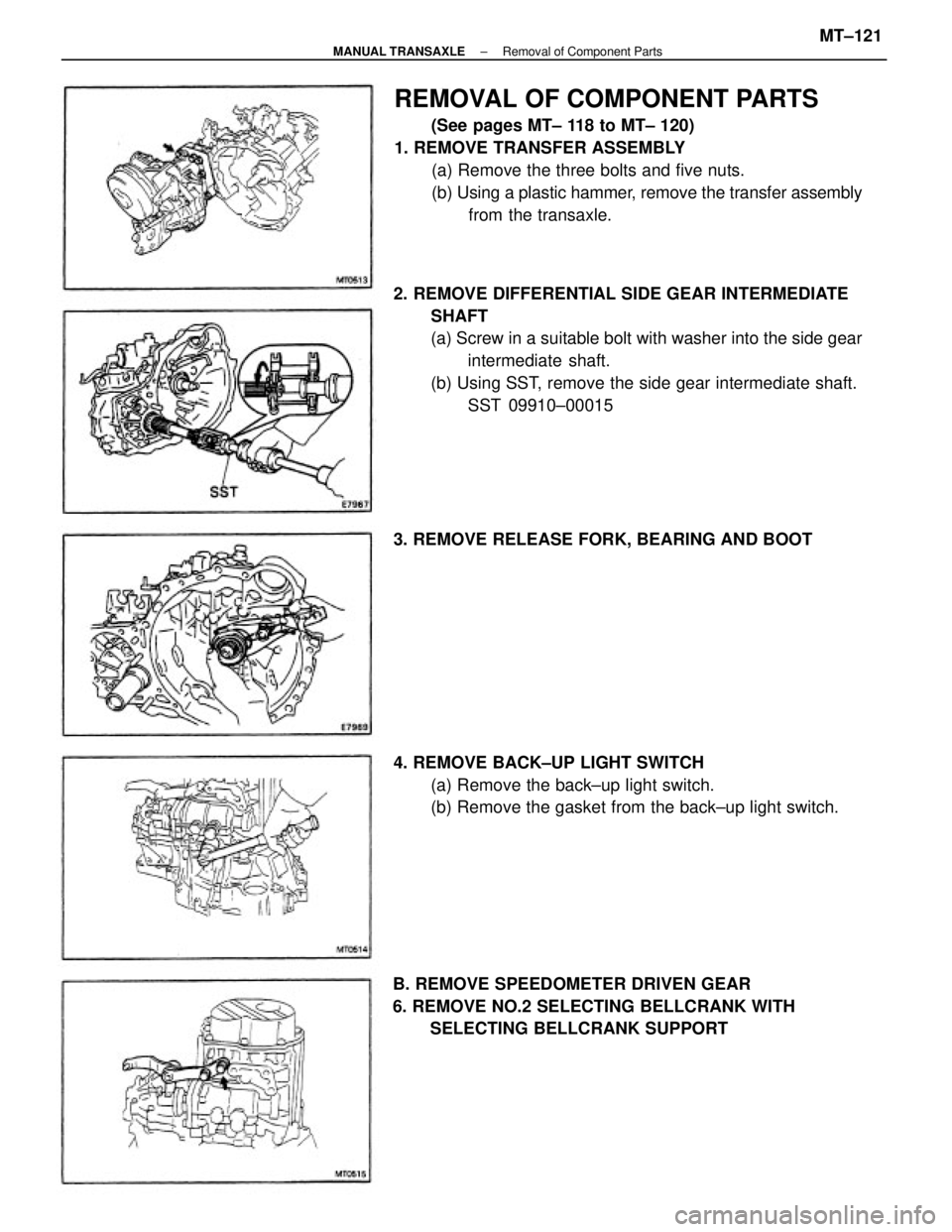

2. REMOVE DIFFERENTIAL SIDE GEAR INTERMEDIATE

SHAFT

(a) Screw in a suitable bolt with washer into the side gear

intermediate shaft.

(b) Using SST, remove the side gear intermediate shaft.

SST 09910±00015

REMOVAL OF COMPONENT PARTS

(See pages MT± 118 to MT± 120)

1. REMOVE TRANSFER ASSEMBLY

(a) Remove the three bolts and five nuts.

(b) Using a plastic hammer, remove the transfer assembly

from the transaxle.

B. REMOVE SPEEDOMETER DRIVEN GEAR

6. REMOVE NO.2 SELECTING BELLCRANK WITH

SELECTING BELLCRANK SUPPORT 4. REMOVE BACK±UP LIGHT SWITCH

(a) Remove the back±up light switch.

(b) Remove the gasket from the back±up light switch. 3. REMOVE RELEASE FORK, BEARING AND BOOT

± MANUAL TRANSAXLERemoval of Component PartsMT±121

Page 2081 of 2389

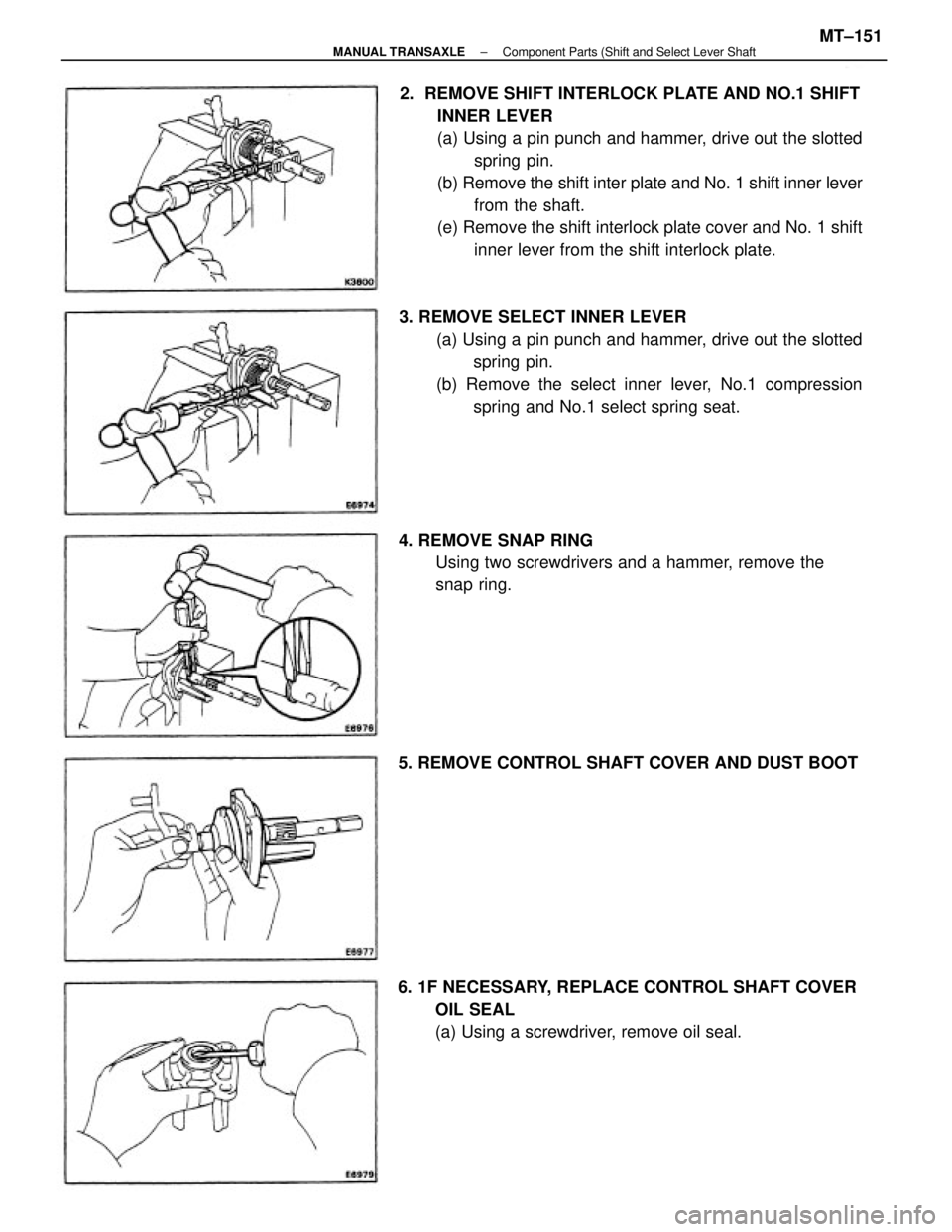

2. REMOVE SHIFT INTERLOCK PLATE AND NO.1 SHIFT

INNER LEVER

(a) Using a pin punch and hammer, drive out the slotted

spring pin.

(b) Remove the shift inter plate and No. 1 shift inner lever

from the shaft.

(e) Remove the shift interlock plate cover and No. 1 shift

inner lever from the shift interlock plate.

3. REMOVE SELECT INNER LEVER

(a) Using a pin punch and hammer, drive out the slotted

spring pin.

(b) Remove the select inner lever, No.1 compression

spring and No.1 select spring seat.

6. 1F NECESSARY, REPLACE CONTROL SHAFT COVER

OIL SEAL

(a) Using a screwdriver, remove oil seal. 4. REMOVE SNAP RING

Using two screwdrivers and a hammer, remove the

snap ring.

5. REMOVE CONTROL SHAFT COVER AND DUST BOOT

± MANUAL TRANSAXLEComponent Parts (Shift and Select Lever ShaftMT±151

Page 2082 of 2389

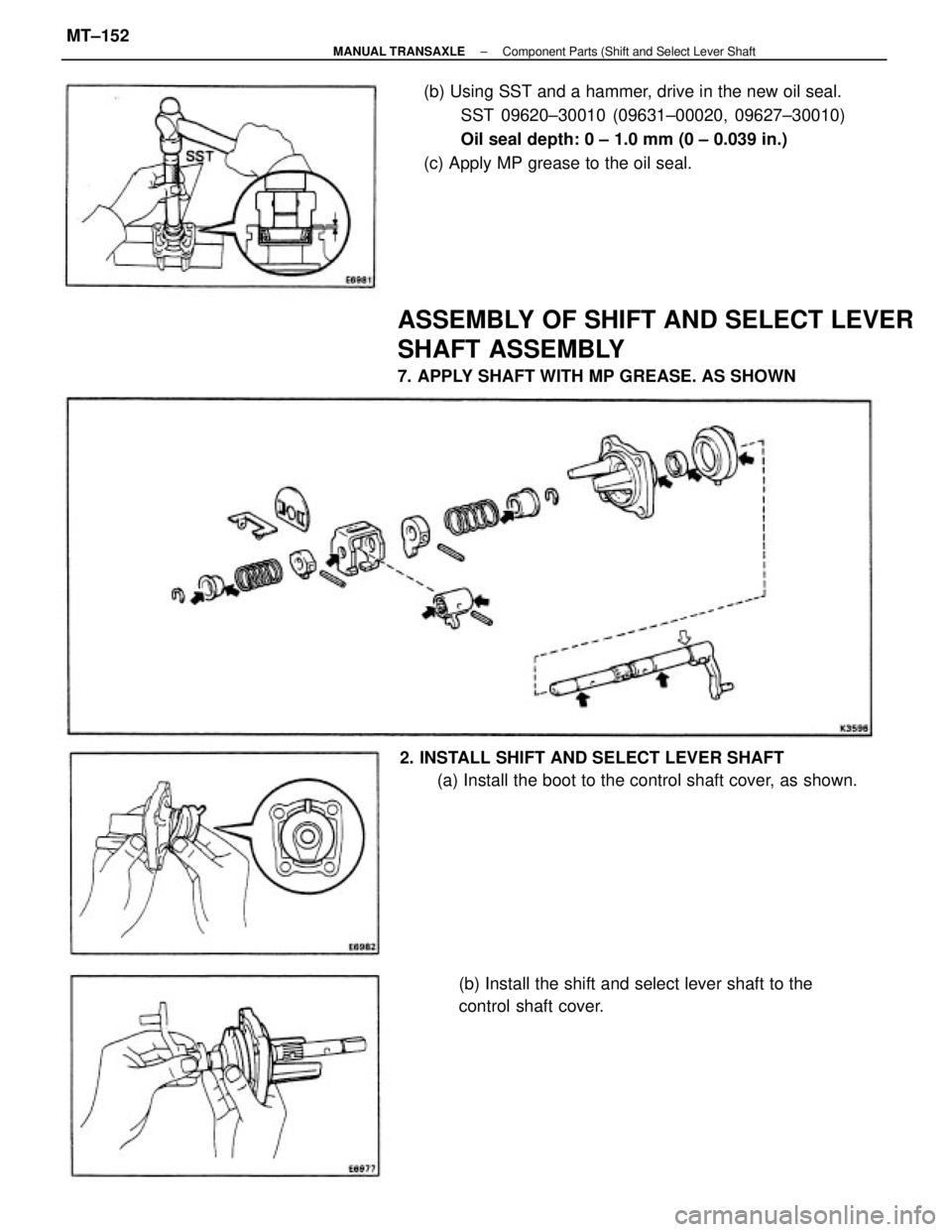

(b) Using SST and a hammer, drive in the new oil seal.

SST 09620±30010 (09631±00020, 09627±30010)

Oil seal depth: 0 ± 1.0 mm (0 ± 0.039 in.)

(c) Apply MP grease to the oil seal.

ASSEMBLY OF SHIFT AND SELECT LEVER

SHAFT ASSEMBLY

7. APPLY SHAFT WITH MP GREASE. AS SHOWN

2. INSTALL SHIFT AND SELECT LEVER SHAFT

(a) Install the boot to the control shaft cover, as shown.

(b) Install the shift and select lever shaft to the

control shaft cover.

± MANUAL TRANSAXLEComponent Parts (Shift and Select Lever ShaftMT±152

Page 2115 of 2389

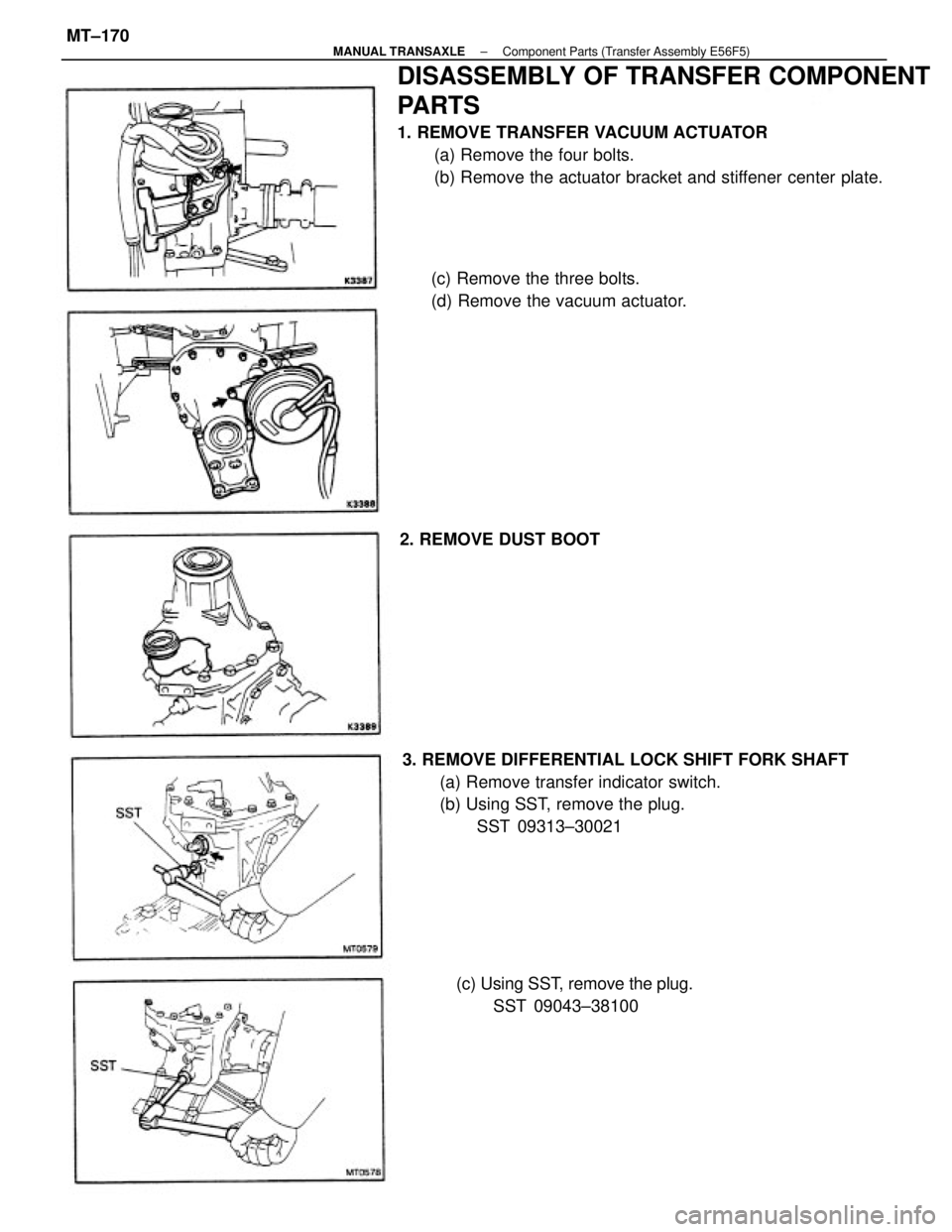

DISASSEMBLY OF TRANSFER COMPONENT

PARTS

1. REMOVE TRANSFER VACUUM ACTUATOR

(a) Remove the four bolts.

(b) Remove the actuator bracket and stiffener center plate.

3. REMOVE DIFFERENTIAL LOCK SHIFT FORK SHAFT

(a) Remove transfer indicator switch.

(b) Using SST, remove the plug.

SST 09313±30021 (c) Remove the three bolts.

(d) Remove the vacuum actuator.

(c) Using SST, remove the plug.

SST 09043±38100 2. REMOVE DUST BOOT

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly E56F5)MT±170

Page 2134 of 2389

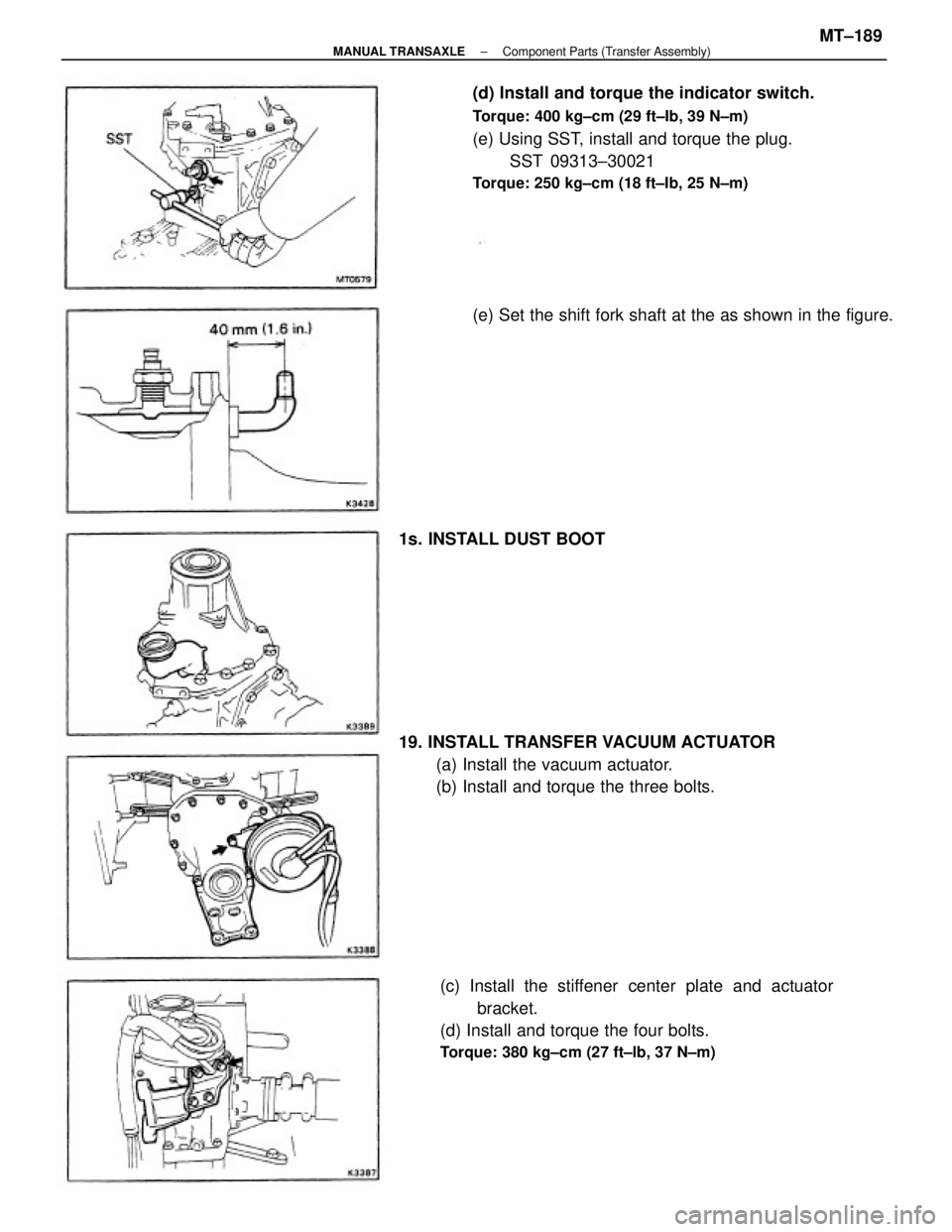

19. INSTALL TRANSFER VACUUM ACTUATOR

(a) Install the vacuum actuator.

(b) Install and torque the three bolts.(d) Install and torque the indicator switch.

Torque: 400 kg±cm (29 ft±Ib, 39 N±m)

(e) Using SST, install and torque the plug.

SST 09313±30021

Torque: 250 kg±cm (18 ft±Ib, 25 N±m)

(c) Install the stiffener center plate and actuator

bracket.

(d) Install and torque the four bolts.

Torque: 380 kg±cm (27 ft±lb, 37 N±m)

(e) Set the shift fork shaft at the as shown in the figure.

1s. INSTALL DUST BOOT

± MANUAL TRANSAXLEComponent Parts (Transfer Assembly)MT±189

Page 2141 of 2389

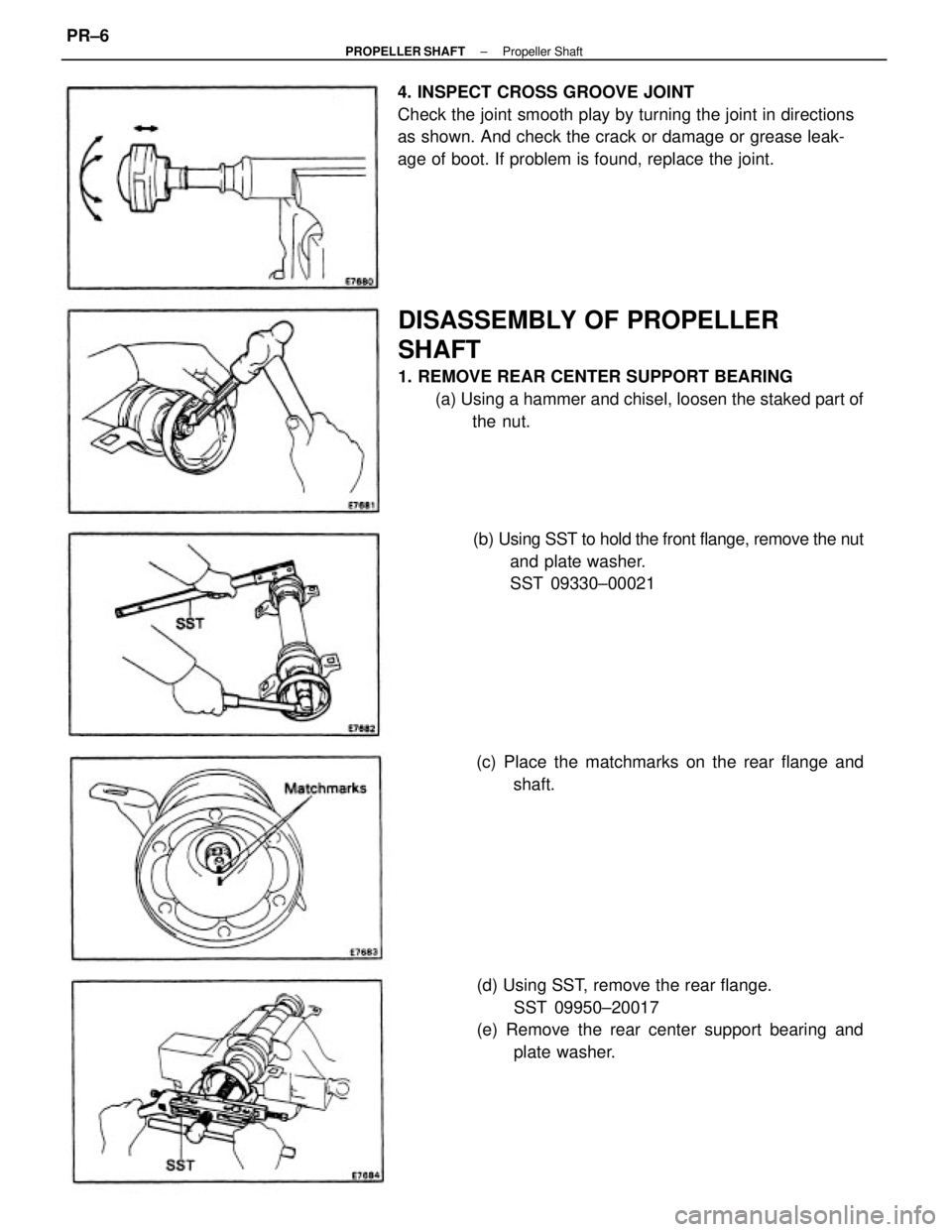

DISASSEMBLY OF PROPELLER

SHAFT

1. REMOVE REAR CENTER SUPPORT BEARING

(a) Using a hammer and chisel, loosen the staked part of

the nut. 4. INSPECT CROSS GROOVE JOINT

Check the joint smooth play by turning the joint in directions

as shown. And check the crack or damage or grease leak-

age of boot. If problem is found, replace the joint.

(d) Using SST, remove the rear flange.

SST 09950±20017

(e) Remove the rear center support bearing and

plate washer. (b) Using SST to hold the front flange, remove the nut

and plate washer.

SST 09330±00021

(c) Place the matchmarks on the rear flange and

shaft.

± PROPELLER SHAFTPropeller ShaftPR±6

Page 2146 of 2389

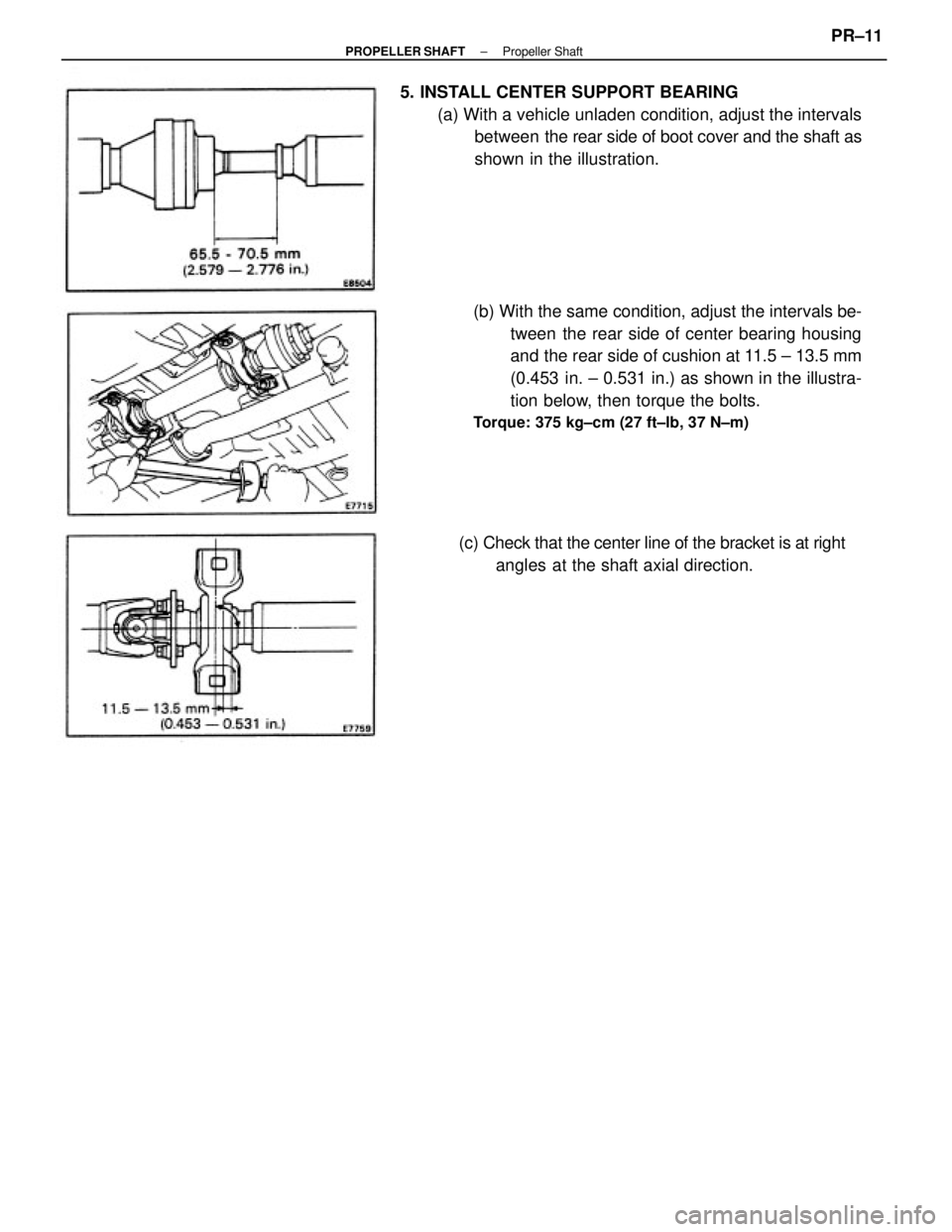

(b) With the same condition, adjust the intervals be-

tween the rear side of center bearing housing

and the rear side of cushion at 11.5 ± 13.5 mm

(0.453 in. ± 0.531 in.) as shown in the illustra-

tion below, then torque the bolts.

Torque: 375 kg±cm (27 ft±lb, 37 N±m)

5. INSTALL CENTER SUPPORT BEARING

(a) With a vehicle unladen condition, adjust the intervals

between the rear side of boot cover and the shaft as

shown in the illustration.

(c) Check that the center line of the bracket is at right

angles at the shaft axial direction.

± PROPELLER SHAFTPropeller ShaftPR±11