engine TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 285 of 346

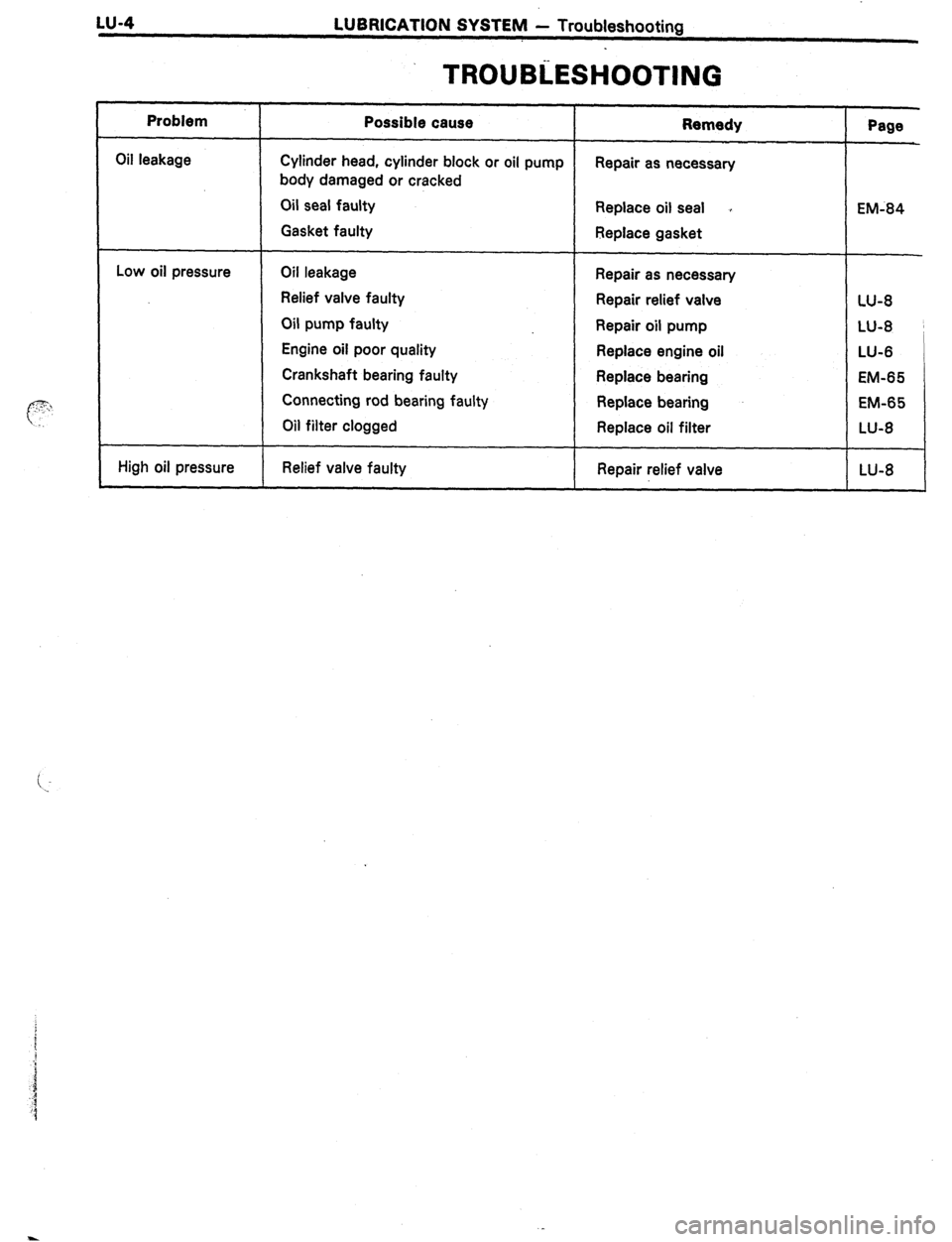

LU-4 LUBRICATION SYSTEM - Troubleshooting

Problem

Oil leakage

Low oil pressure

High oil pressure

TROUBilESHOOTlNG

Possible cause

Cylinder head, cylinder block or oil pump

body damaged or cracked

Oil seal faulty

Gasket faulty

Oil leakage

Relief valve faulty

Oil pump faulty

Engine oil poor quality

Crankshaft bearing faulty

Connecting rod bearing faulty

Oil filter clogged

Relief valve faulty Remedy

Repair as necessary

Replace oil seal I

Replace gasket

Repair as necessary

Repair relief valve

Repair oil pump

Replace engine oil

Replace bearing

Replace bearing

Replace oil filter

Repair relief valve Page

EM-84

LU-8

W-8 ~

Page 286 of 346

rutmwCiA rlON SYSTEM - Oil Pressure Che,ck’:q. .’ ‘f,“,; .! . ,_ _,, __ _ ,-tiu,e

Recommended

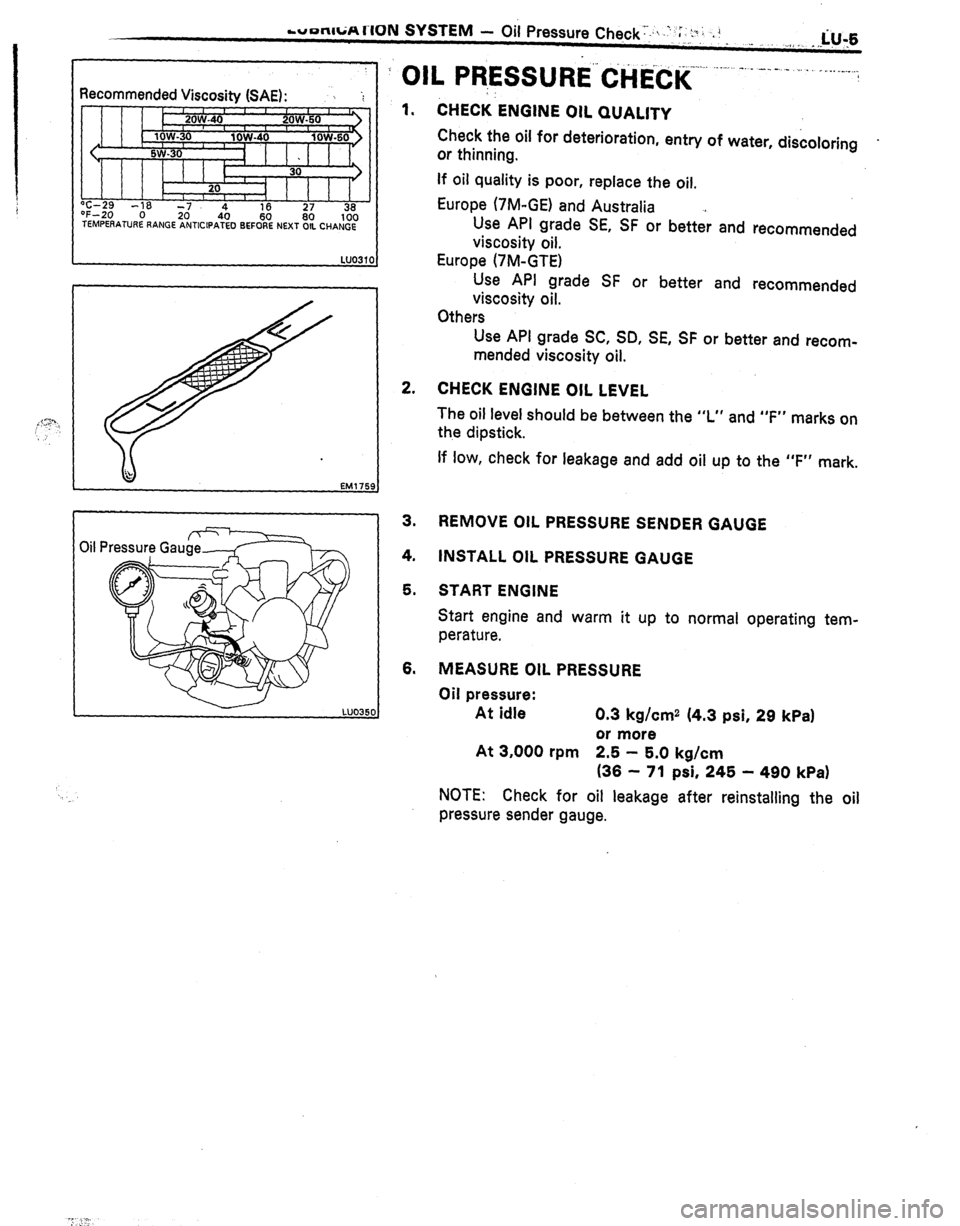

Viscositv (SAE):

I 1 1 1 h T-29 -,a 7 “F-20 0 TEMPEAATURE LY

I I b I I I I

I

z 4 16 36

/

RANGE ANTICIPA$O B&i% NEXT OIL CHANGE 100 ._. .-- . . .

?’ OIL PR,ESSURE’($liCK . .._.

-. - -_-. _

. _ _.. _ _...

1. 1 CHECK-ENGINE OIL QUALITY

Check the oil for deterioration, entry of water, discoloring .

or thinning.

2.

3.

4.

5.

6. If oil quality is poor, replace the oil,

Europe (‘IM-GE) and Australia *

Use API grade SE, SF or better and recommended

viscosity oil.

Europe (7M-GTE)

Use API grade SF or better and recommended

viscosity oil.

Others

Use API grade SC, SD, SE, SF or better and recom-

mended viscosity oil.

CHECK ENGINE OIL LEVEL

The oil level should be between the “L” and “F” marks on

the dipstick.

If low, check for leakage and add oil up to the “F” mark.

REMOVE OIL PRESSURE SENDER GAUGE

INSTALL OIL PRESSURE GAUGE

START ENGINE

Start engine and warm it up to normal operating tem-

perature.

MEASURE OIL PRESSURE

Oil pressure:

At idle 0.3 kg/cm2 (4.3 psi, 29 kPa1

or more

At 3,000 rpm 2.5 - 5.0 kg/cm

(36 - 71 psi, 245 - 490 kPa1

NOTE: Check for oil leakage after reinstalling the oil

pressure sender gauge.

Page 287 of 346

-.

LUBRICATION SYSTEM

- Replacement.of Engine Oil and Oil Filter

L&.7*.

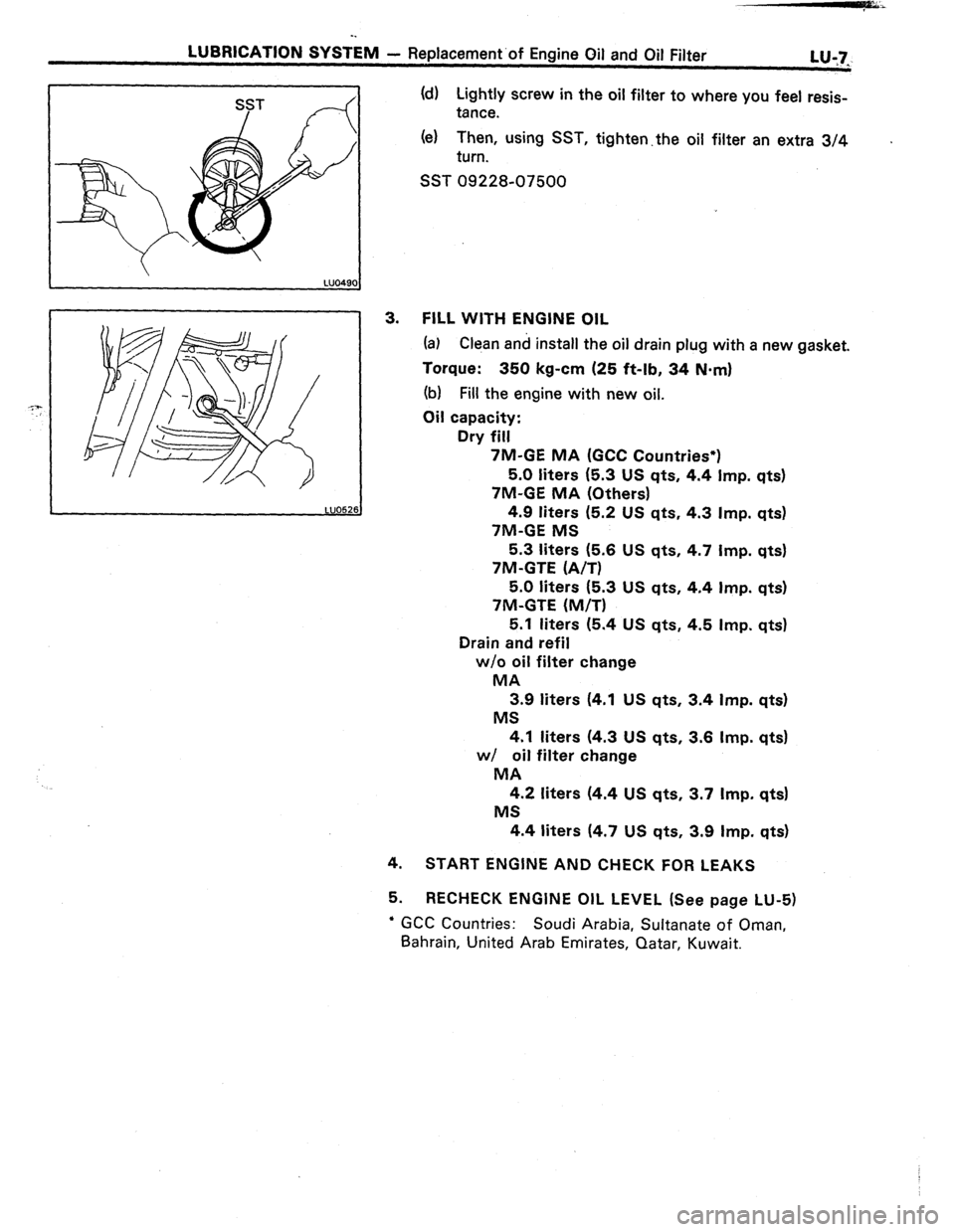

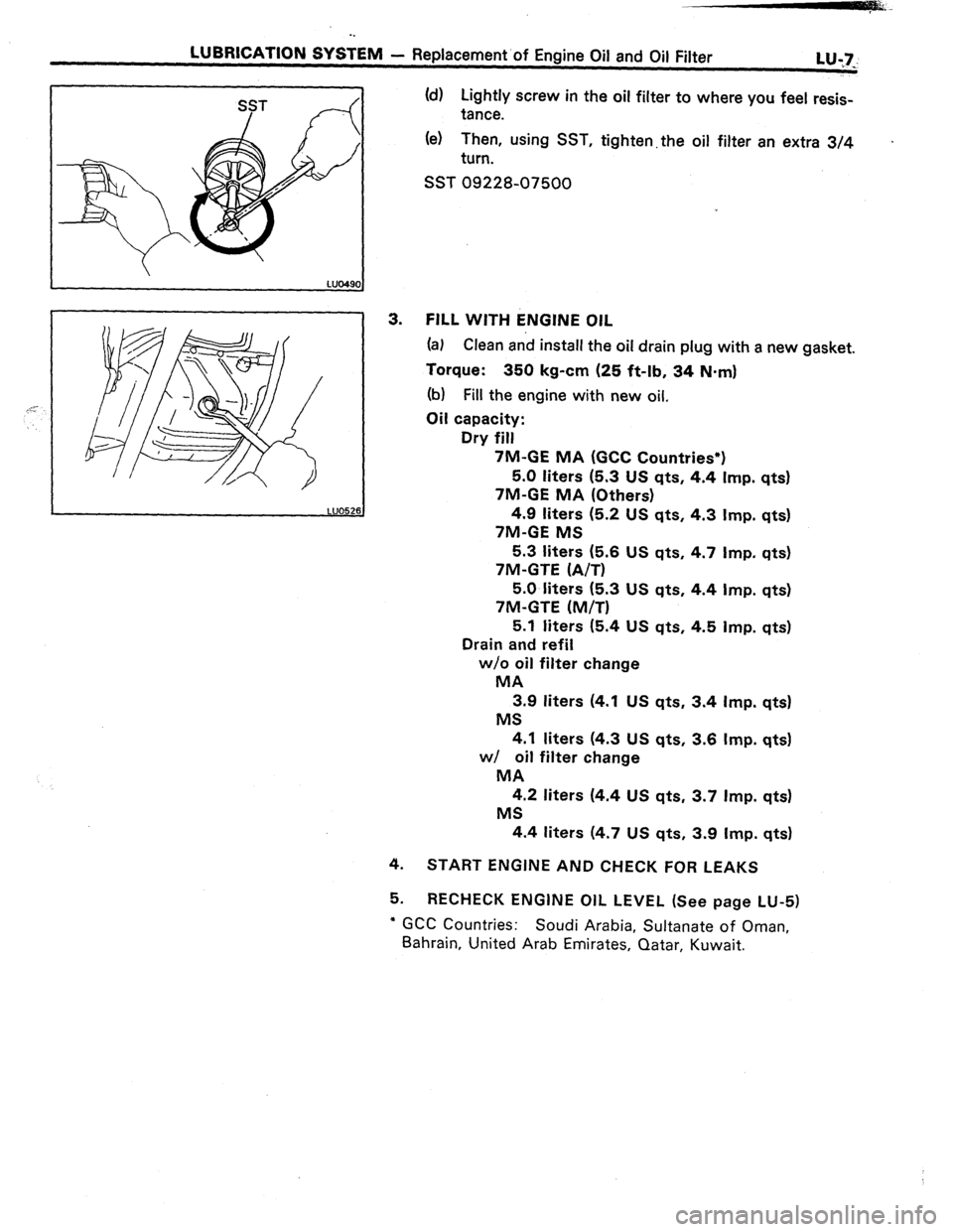

(d) Lightly screw in the oil filter to where you feel resis-

tance.

(el Then, using SST, tighten.the oil filter an extra 3/4

turn. .

SST 09228-07500

3. FILL WITH ENGINE OIL

(a) Clean and install the oil drain plug with a new gasket.

Torque: 350 kg-cm (25 ft-lb, 34 N.m)

(b) Fill the engine with new oil.

Oil capacity:

Dry fill

7M-GE MA (GCC Countries*)

5.0 liters (5.3 US qts, 4.4 Imp. qts)

‘/M-GE MA (Others)

4.9 liters (5.2 US qts, 4.3 Imp. qts)

7M-GE MS

5.3 liters (5.6 US qts, 4.7 Imp. qts)

7M-GTE (A/T)

5.0 liters (5.3 US qts, 4.4 Imp. qts)

7M-GTE (M/T)

5.1 liters (5.4 US qts, 4.5 Imp. qts)

Drain and refil

w/o oil filter change

MA

3.9 liters (4.1 US qts, 3.4 Imp. qts)

MS

4.1 liters (4.3 US qts, 3.6 Imp. qts)

w/ oil filter change

MA

4.2 liters (4.4 US qts, 3.7 Imp. qts)

MS

4.4 liters (4.7 US qts, 3.9 Imp. qts)

4.

START ENGINE AND CHECK FOR LEAKS

5. RECHECK ENGINE OIL LEVEL (See page LU-5)

’ GCC Countries: Soudi Arabia, Sultanate of Oman,

Bahrain, United Arab Emirates, Qatar, Kuwait.

Page 288 of 346

-.

LU-6

LUBRICATION SYSTEM - Replacement-of Engine Oil and Oil Filter

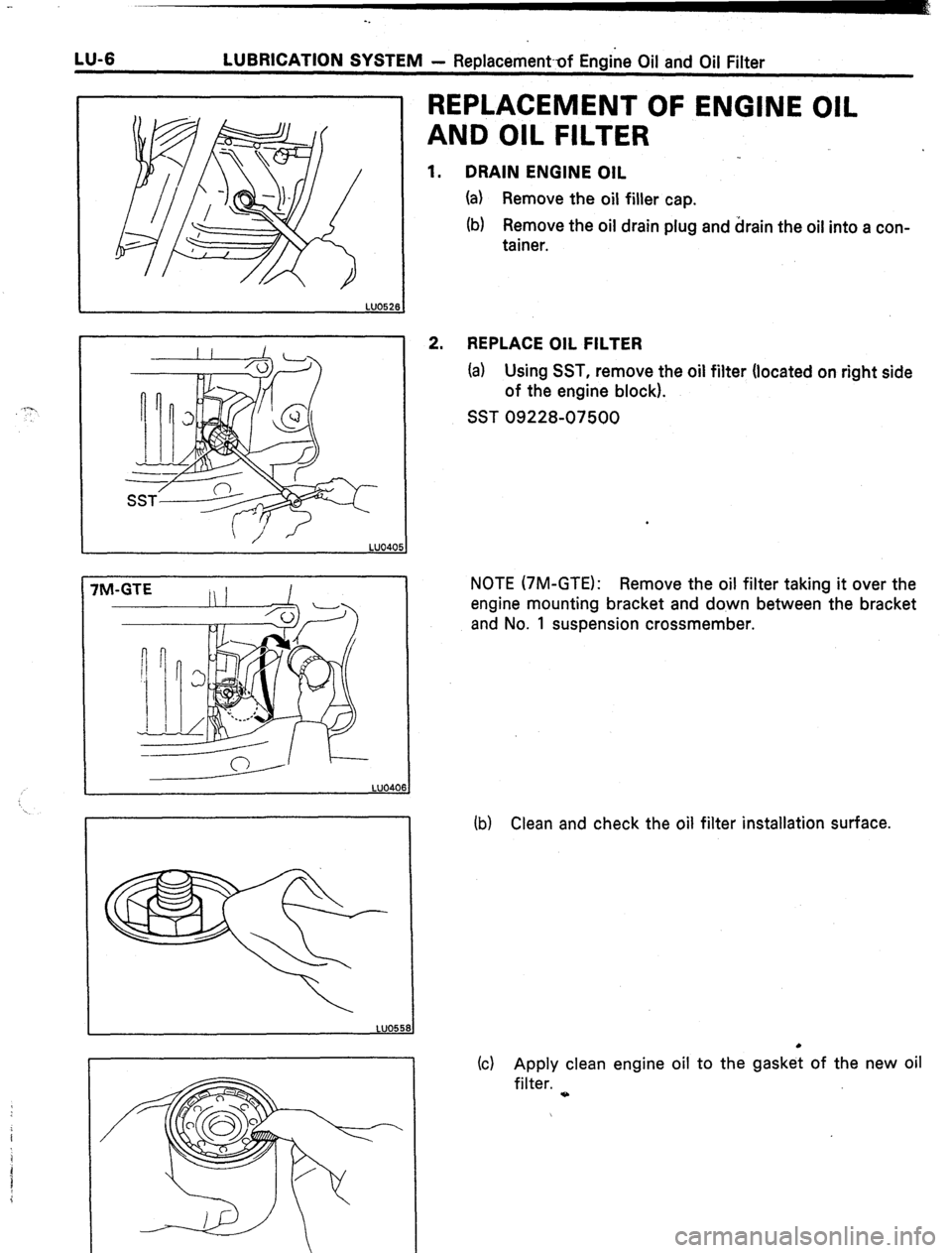

REPLACEMENT OF ENGINE OIL

AND OIL FILTER

1.

DRAIN ENGINE OIL

(a) Remove the oil filler cap.

(b) Remove the oil drain plug and drain the oil into a con-

tainer.

2.

REPLACE OIL FILTER

(a) Using SST, remove the oil filter (located on right side

of the engine block).

SST 09228-07500

NOTE (7M-GTE):

Remove the oil filter taking it over the

engine mounting bracket and down between the bracket

and No. 1 suspension crossmember.

(b)

Clean and check the oil filter installation surface.

(c) Apply clean engine oil to the gasket of the new oil

filter. o

Page 289 of 346

-.

LUBRICATION SYSTEM

- Replacement.of Engine Oil and Oil Filter

L&7_

4.

5. (d) Lightly screw in the oil filter to where you feel resis-

tance.

(e) Then, using SST, tighten. the oil filter an extra 3/4 .

turn.

SST 09228-07500

FILL WITH ENGINE OIL

(a) Clean and install the oil drain plug with a new gasket.

Torque: 350 kg-cm (25 ft-lb, 34 N-m)

(b) Fill the engine with new oil,

Oil capacity:

Dry fill

7M-GE MA (GCC Countries*)

5.0 liters (5.3 US qts, 4.4 Imp. qts)

7M-GE MA (Others)

4.9 liters (5.2 US qts, 4.3 Imp. qts)

7M-GE MS

5.3 liters (5.6 US qts, 4.7 Imp. qts)

7M-GTE (A/T)

5.0 liters (5.3 US qts, 4.4 Imp. qts)

7M-GTE (M/T)

5.1 liters (5.4 US qts, 4.5 Imp. qts)

Drain and refil

w/o oil filter change

MA

3.9 liters (4.1 US qts, 3.4 Imp. qts)

MS

4.1 liters (4.3 US qts, 3.6 Imp. qts)

w/ oil filter change

MA

4.2 liters (4.4 US qts, 3.7 Imp. qts)

MS

4.4 liters (4.7 US qts, 3.9 Imp. qtsl

START ENGINE AND CHECK FOR LEAKS

RECHECK ENGINE OIL LEVEL (See page LU-5)

l GCC Countries: Soudi Arabia, Sultanate of Oman,

Bahrain, United Arab Emirates, Qatar, Kuwait.

Page 291 of 346

LUbRlCATlON SYSTEM - Oil Pump

._ ul~9

LUO526

REMOVAL,OF OIli Prli&lP

(See page LU-8)

-, . .--- -._.____.

-.

1.

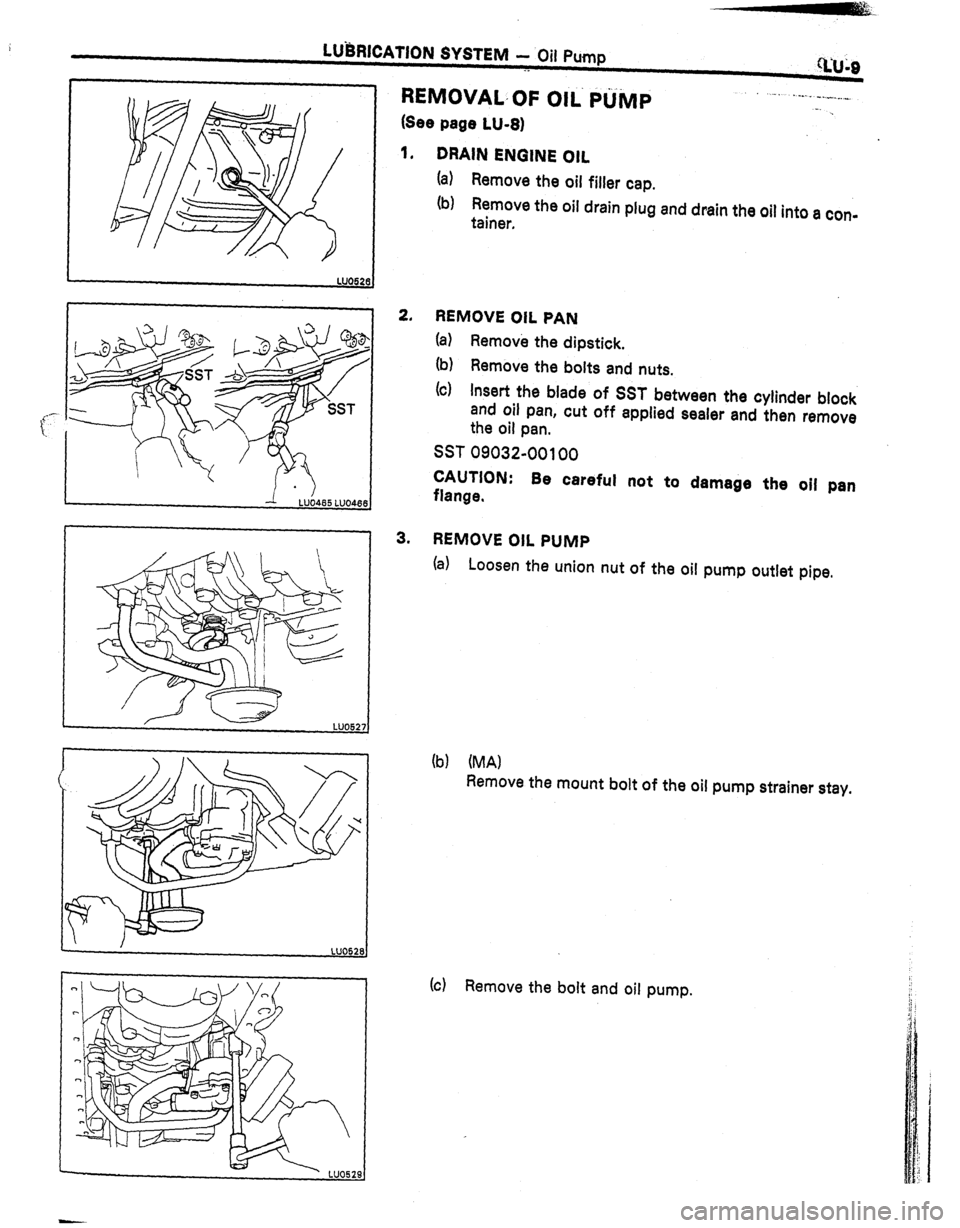

DRAIN ENGINE OIL

(a) Remove the oil filler cap.

(b) Remove the oil drain plug and drain the oil into a con-

tainer.

2. REMOVE OIL PAN

(a) Remove the dipstick.

(b) Remove the bolts and nuts.

(c) Insert the blade of SST between the cylinder block

and oil pan, cut off applied sealer and then remove

the oil pan.

SST 09032-00100

CAUTION: Be careful not to damage the oil pan

flange.

3. REMOVE OIL PUMP

(a) Loosen the union nut of the oil pump outlet pipe.

(b) (MA)

Remove the mount bolt of the oil pump strainer stay.

(c) Remove the bolt and oil pump.

Page 293 of 346

LG&RICATION SYSTEM - Oil Pump

L.!J:ll

.... ..- .._.~.“.“._ _ ,.. _,-

INSPECTION OF OIL PUMP

1.

2.

3.

4.

~. -.--. . ._. I ”

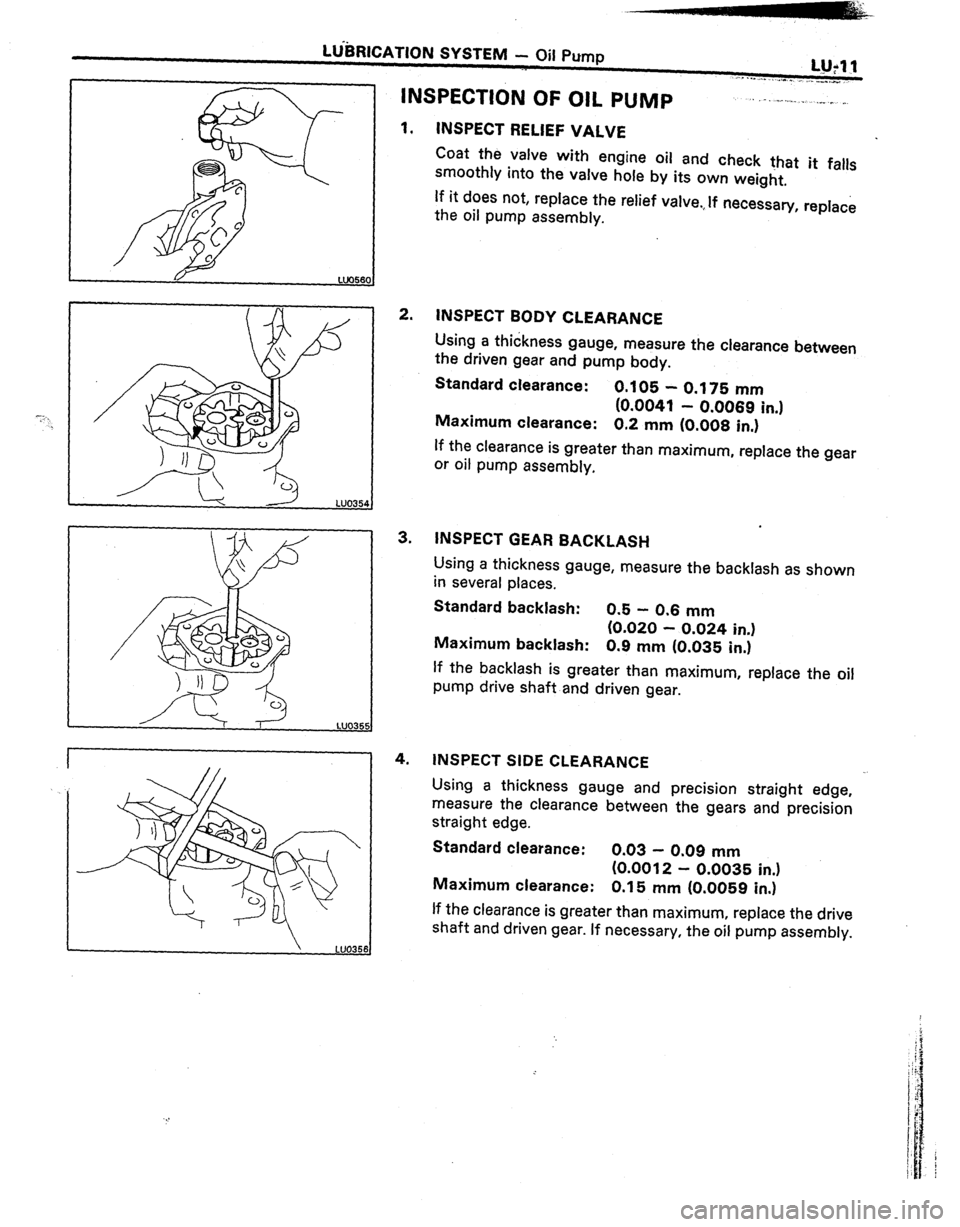

INSPECT RELIEF VALVE

Coat the valve with engine oil and check that it falls

smoothly into the valve hole by its own weight,

If it does not, replace the relief valve.,If necessary, replace

the oil pump assembly.

INSPECT BODY CLEARANCE

Using a thickness gauge, measure the clearance between

the driven gear and pump body.

Standard clearance:

0.105 - 0.175 mm

(0.0041 - 0.0069 in.1

Maximum clearance: 0.2 mm (0.008 in.)

If the clearance is greater than maximum, replace the gear

or oil pump assembly.

INSPECT GEAR BACKLASH

Using a thickness gauge, measure the backlash as shown

in several places.

Standard backlash: 0.5 - 0.6 mm

(0.020 - 0.024 in.)

Maximum backlash: 0.9 mm (0.035 in.)

If the backlash is greater than maximum, replace the oil

pump drive shaft and driven gear.

INSPECT SIDE CLEARANCE

Using a thickness gauge and precision straight edge,

measure the clearance between the gears and precision

straight edge.

Standard clearance:

0.03 - 0.09 mm

(0.0012 - 0.0035 in.)

Maximum clearance: 0.15 mm (0.0059 in.)

If the clearance is greater than maximum, replace the drive

shaft and driven gear. If necessary, the oil pump assembly.

Page 294 of 346

LU-12

-.

LUBRICATION SYSTEM - Oij Pump

LUOJS

ASSEMBLY AND OPERATION CHECK OF OIL

”

PUMP

(See page LU-8)

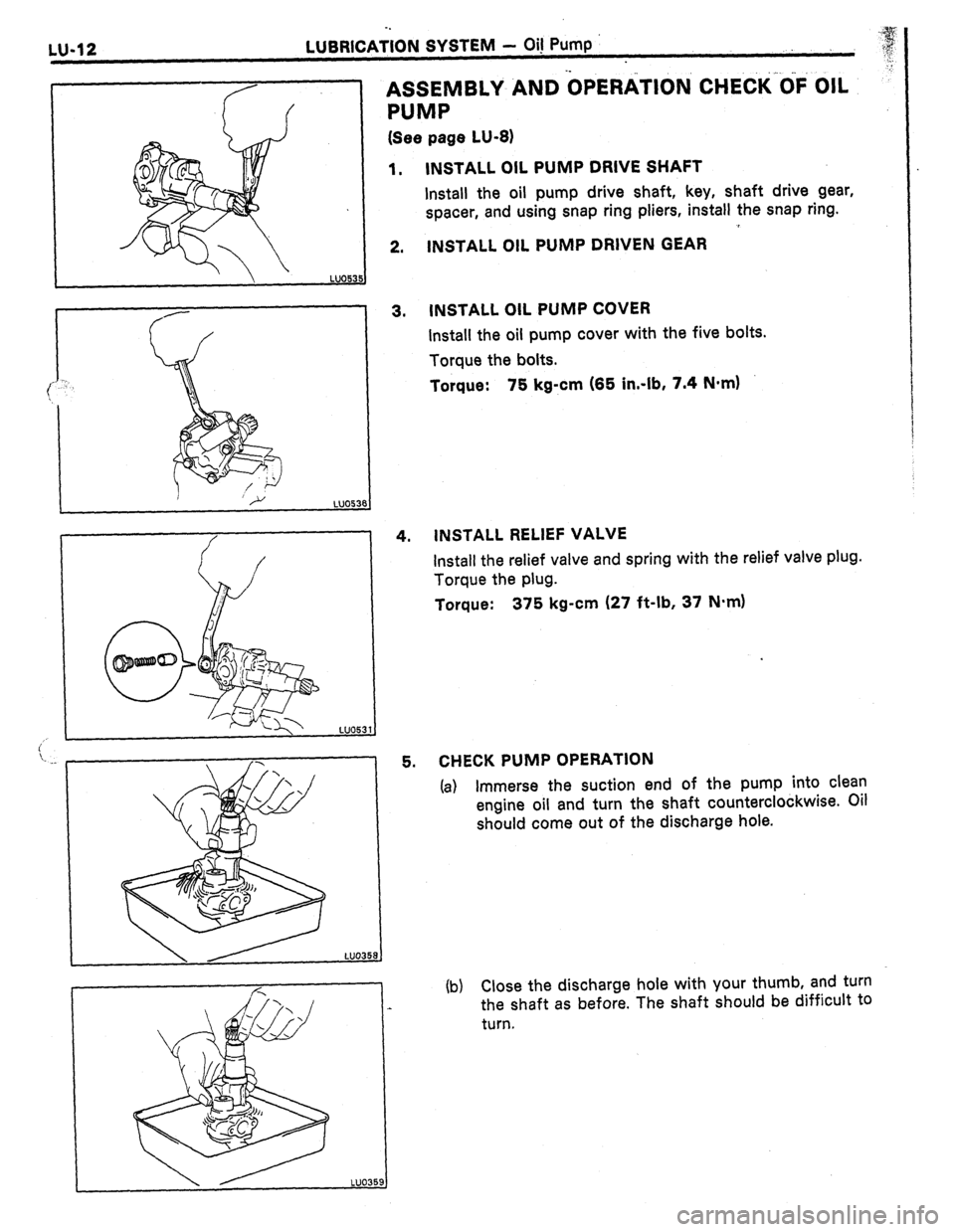

5. INSTALL OIL PUMP DRIVE SHAFT

Install the oil pump drive shaft, key, shaft drive gear,

spacer, and using snap ring pliers, install the snap ring.

INSTALL OIL PUMP DRIVEN GEAR

INSTALL OIL PUMP COVER

Install the oil pump cover with the five bolts.

Torque the bolts.

Torque: 75 kg-cm (65 in.-lb, 7.4 N-m)

INSTALL RELIEF VALVE

Install the relief valve and spring with the relief valve plug.

Torque the plug.

Torque:

375 kg-cm (27 ft-lb, 37 N.m)

CHECK PUMP OPERATION

(a) Immerse the suction end of the pump into clean

engine oil and turn the shaft counterclockwise. Oil

should come out of the discharge hole.

(b) Close the discharge hole with your thumb, and turn

the shaft as before. The shaft should be difficult to

turn.

Page 296 of 346

bf3lCA~l0N SYSTEM - Oil Pump

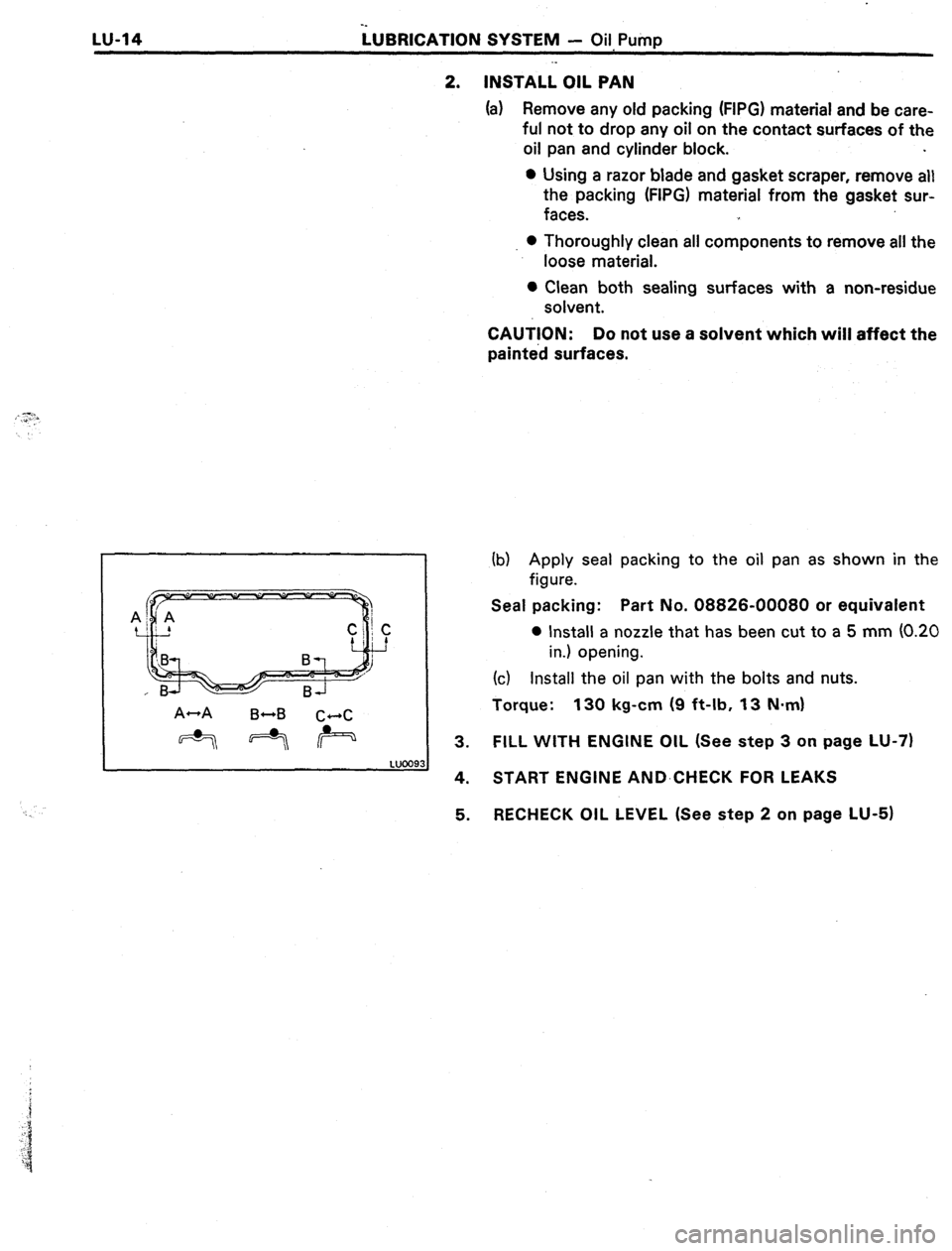

2. INSTALL OIL PAN

(a) Remove any old packing (FIPG) material and be care-

ful not to drop any oil on the contact surfaces of the

oil pan and cylinder block.

l Using a razor blade and gasket scraper, remove all

the packing (FIPG) material from the gasket sur-

faces.

0 Thoroughly clean all components to remove all the

loose material.

l Clean both sealing surfaces with a non-residue

solvent.

CAUTION: Do not use a solvent which will affect the

painted surfaces.

ib) Apply seal packing to the oil pan as shown in the

figure.

Seal packing: Part No. 08826-00080 or equivalent

0 Install a nozzle that has been cut to a 5 mm (0.20

in.) opening.

(c) Install the oil pan with the bolts and nuts.

Torque : 130 kg-cm (9 ft-lb, ‘I3 N-m)

3. FILL WITH ENGINE OIL (See step 3 on page LU-7)

4. START ENGINE AND.CHECK FOR LEAKS

‘. 5. RECHECK OIL LEVEL (See step 2 on page LU-5)

Page 299 of 346

LUBRICATION SYSTENl

- Qii Cooler and oil Pressure. Regulator (-/M-GE)

LU-17.

._ .

w

e

0

LUO48f

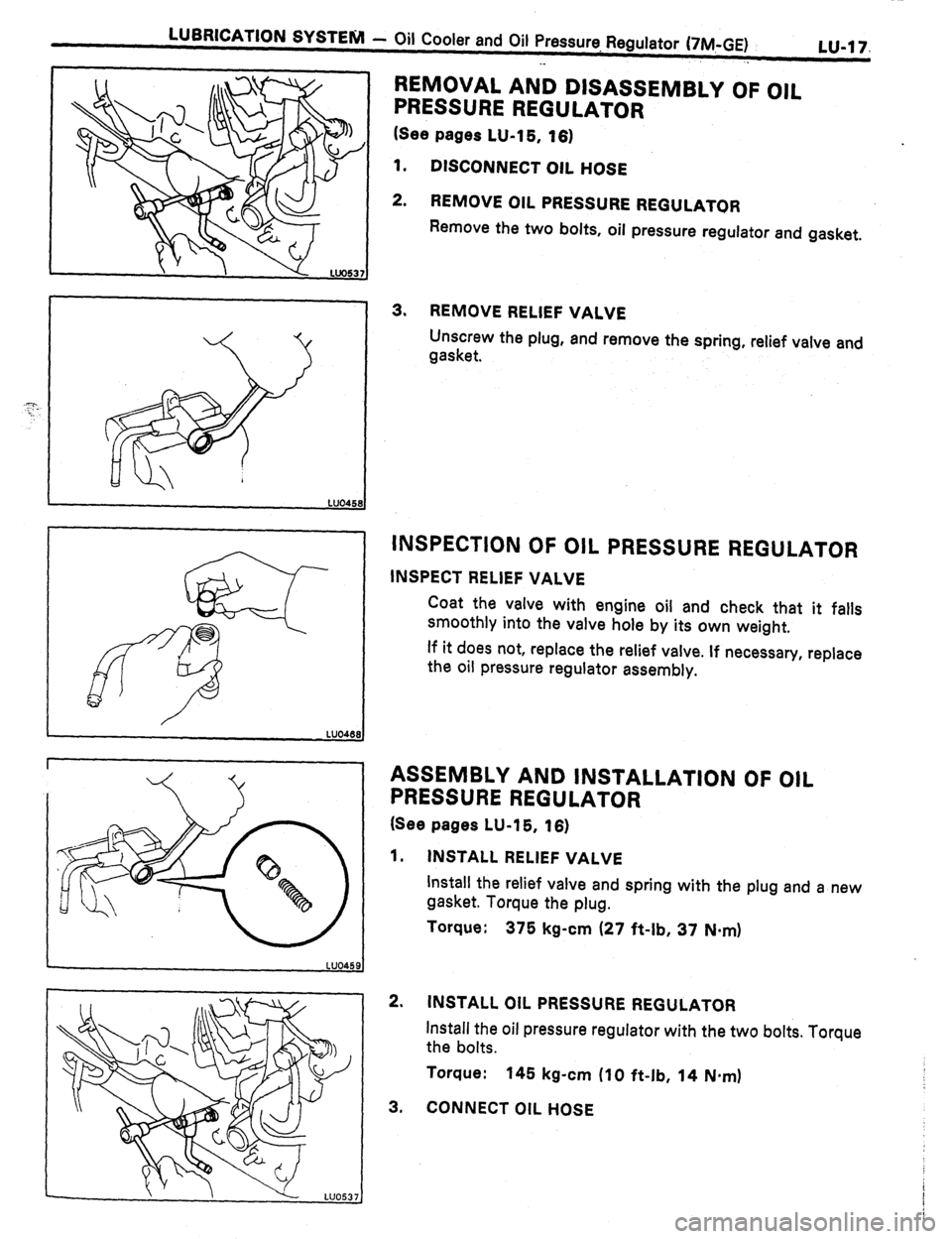

REMOVAL AND DISASSEMBLY OF OIL

PRESSURE REGULATOR

(See pages LU-15, 16)

1. DISCONNECT OIL HOSE

2. REMOVE OIL PRESSURE REGULATOR

Remove the two bolts, oil pressure regulator and gasket.

3. REMOVE RELIEF VALVE

Unscrew the plug, and remove the spring, relief valve and

gasket.

INSPECTION OF OIL PRESSURE REGULATOR

INSPECT RELIEF VALVE

Coat the valve with engine oil and check that it falls

smoothly into the valve hole by its own weight.

If it does not, replace the relief valve. If necessary, replace

the oil pressure regulator assembly.

ASSEMBLY AND INSTALLATION OF OIL

PRESSURE REGULATOR

(See pages LU-15, 16)

1. INSTALL RELIEF VALVE

Install the relief valve and spring with the plug and a new

gasket. Torque the plug.

Torque:

375 kg-cm (27 ft-lb, 37 N-m)

2. INSTALL OIL PRESSURE REGULATOR

Install the oil pressure regulator with the two bolts. Torque

the bolts.

Torque:

145 kg-cm (10 ft-lb, 14 N.m)

3, CONNECT OIL HOSE