engine TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 301 of 346

LUBRICATION SYSTENI - Oil Cooler and Oil Pressurr+ Regulator (7M-GTE)

’ 1” - 06Lu-19

---. “, -“-~~yII.

. .

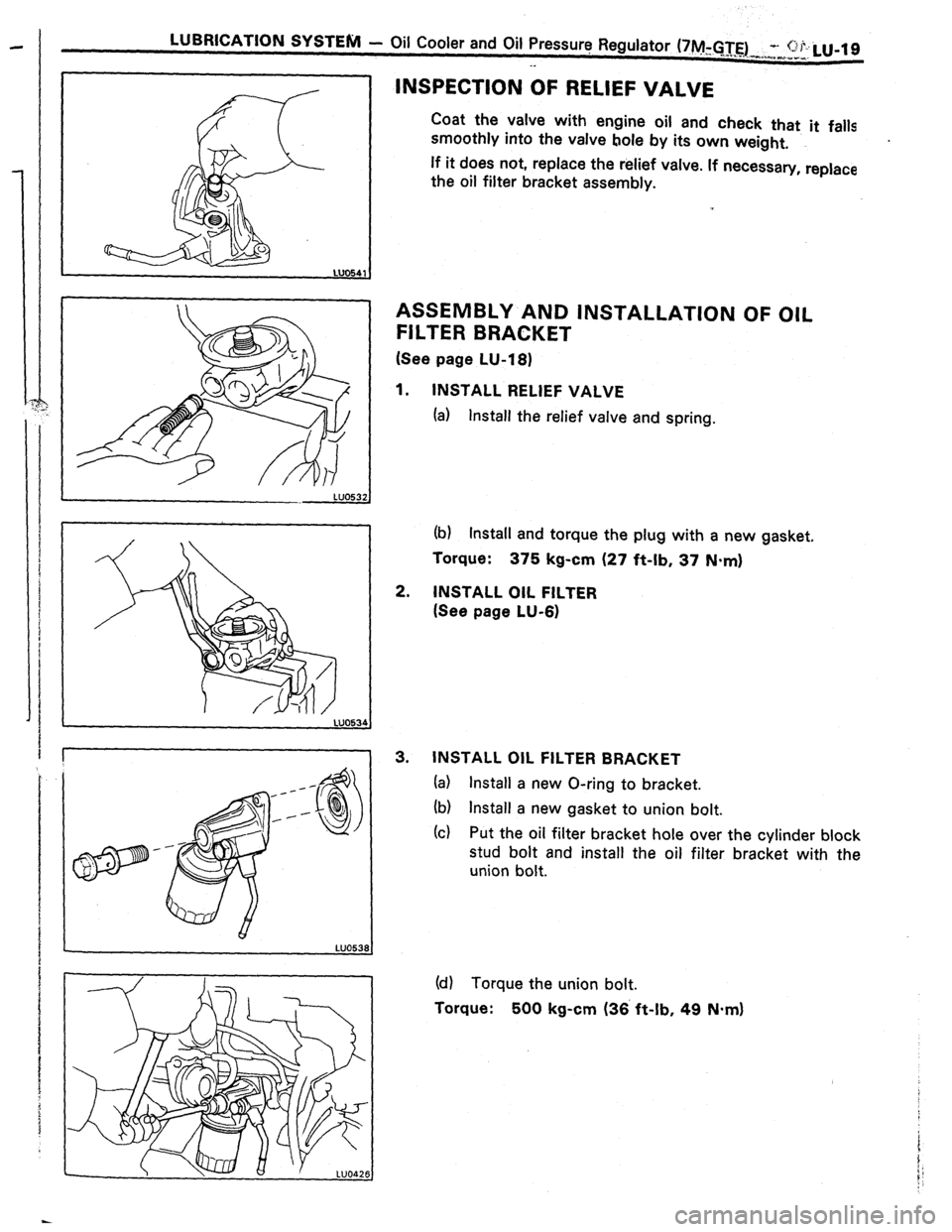

INSPECTION OF RELIEF VALVE

Coat the valve with engine oil and check that it falls

smoothly into the valve hole by its own weight.

If it does not, replace the relief valve. If necessary,

replace

the oil filter bracket assembly.

INSTALLATION OF OIL ASSEMBLY AND

FILTER BRACKET

(See page LU-18)

1. INSTALL RELIEF VALVE

(a) Install the relief valve and spring.

(b) Install and torque the plug with a new gasket.

Torque: 375 kg-cm (27 ft-lb, 37 Nsm)

2.

INSTALL OIL FILTER

(See page LU-8)

3. INSTALL OIL FILTER BRACKET

(a) Install a new O-ring to bracket.

(b) Install a new gasket to union bolt.

(c) Put the oil filter bracket hole over the cylinder block

stud bolt and install the oil filter bracket with the

union bolt.

(d) Torque the union bolt.

Torque: 500 kg-cm (36’ ft-lb, 49 N*mI

Page 303 of 346

A12 : SERVICE SPECIFICATIONS - Enaine.Mechanical

EN$W4~~~WlECHAN~CAL (

‘t&.gy,.::*,. : .,

Speclfrcations

r

: r’

: . .

‘-’ b- ~.

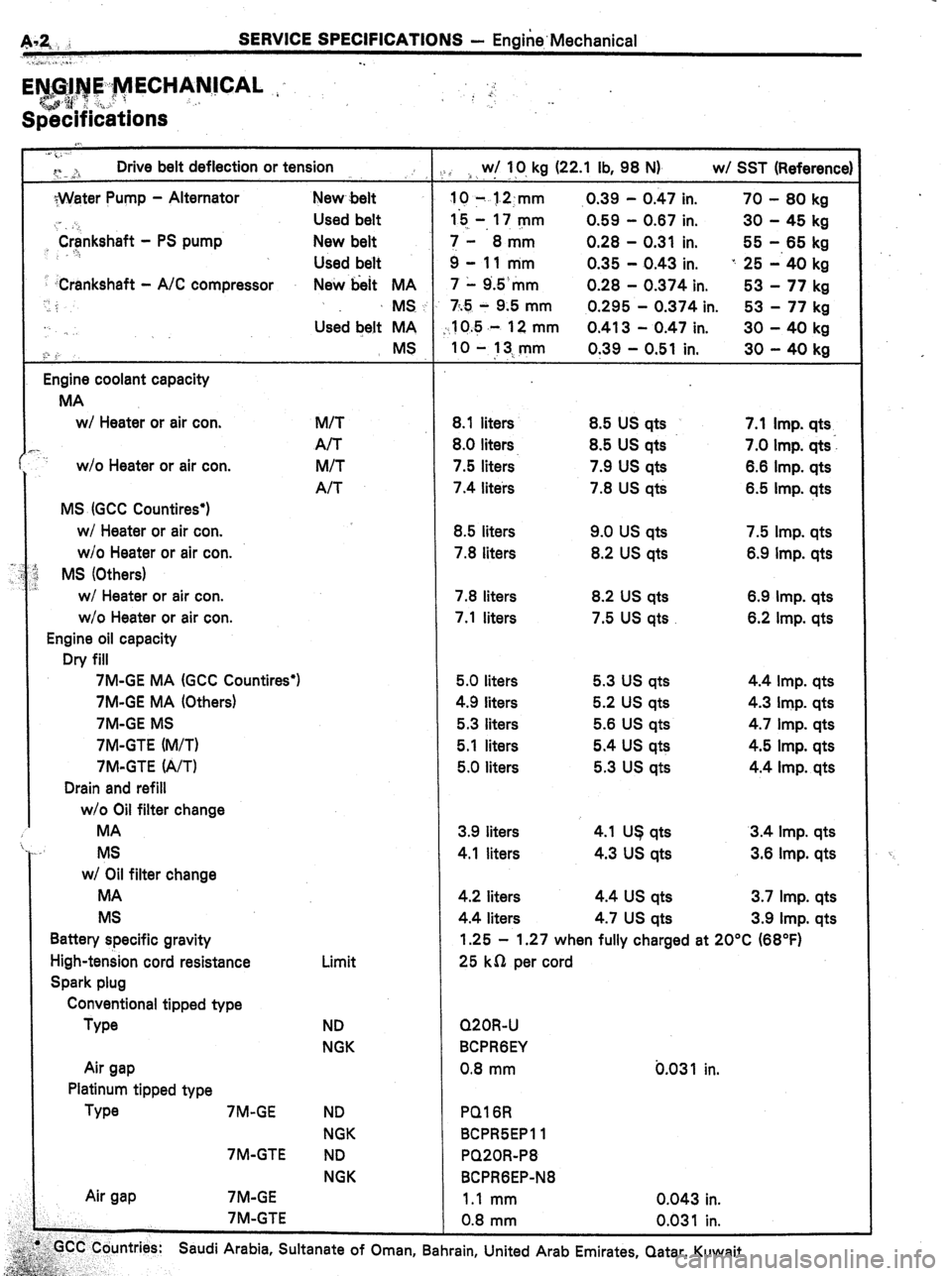

” Drive belt deflection or tension

. . . .,:

;Water Pump - Alternator New belt

,, ‘Crankshaft Used belt

- PS pump New belt

..!

Used belt

-Crankshaft - A/C compressor

New hit MA

,.

‘; MS

Used belt MA

<” : MS

Engine coolant capacity

MA

WI Heater or air con.

,.

w/o Heater or air con.

MS (GCC Countires’)

WI Heater or air con.

w/o Heater or air con.

MS (Others)

w/ Heater or air con.

w/o Heater or air con.

Engine oil capacity

Dry fill

7M-GE MA (GCC Countires’)

7M-GE MA (Others)

7M-GE MS

7M-GTE (M/T)

7M-GTE (A/T)

Drain and refill

w/o Oil filter change

MA

MS

w/ Oil filter change

MA

MS

Battery specific gravity

High-tension cord resistance

Spark plug

Conventional tipped type

We

Air gap

Platinum tipped type

Type 7M-GE

7M-GTE

Air gap 7M-GE

7M-GTE M/T

A/T

M/T

A/T

Limit

ND

NGK

ND

NGK

ND

NGK / w/ IO, kg (22.1 lb, 98 N) w/ SST (Reference)

,. .

IO 7 1.2:mm .0.39 - 0.47 in. 70 - 80 kg

I5 -, 17 mm 0.59 - 0.87 in. 30 - 45 kg

I- 8mm 0.28 - 0.31 in. 55 - 65 kg

3-llmm 0.35 - 0.43 in. ” 25 -‘40 kg

7 1 9.5‘mm 0.28 - 0.374 in. 53 - 77 kg

7;.5 - 9.5 mm 0.295 - 0.374 in. 53 - 77 kg

10.5 .- 12 mm 0.413 - 0.47 in. 30 - 40 kg

IO - 13.,mm

0.39 - 0.51 in. 30 - 40 kg

8.1 liters

8.0 liters.

7.5 liters

7.4 liters

8.5 liters

7.8 liters

7.8 liters

7.1 liters 8.5 US qts

8.5 US qts

7.9 us qts

7.8 US qts

9.0 us qts

8.2 US qts

8.2 US qts

7.5 us qts 7.1 Imp. qts

7.0 Imp. qts:

6.8 Imp. qts

6.5 Imp. qts

7.5 Imp. qts

6.9 Imp. qts

6.9 Imp. qts

6.2 Imp. qts

5.0 liters

4.9 liters

5.3 liters

5.1 liters

5.0 liters 5.3 us qts

5.2 US qts

5.6 US qts

5.4 us qts

5.3 us qts 4.4 Imp. qts

4.3 Imp. qts

4.7 Imp. qts

4.5 Imp. qts

4.4 Imp. qts

3.9 liters 4.1 US qts 3.4 Imp. qts

4.1 liters 4.3 us qts 3.6 Imp. qts

4.2 liters 4.4 us qts 3.7 Imp. qts

4.4 liters 4.7 us qts 3.9 Imp. qts

1.25 - 1.27 when fully charged at 20°C (68°F)

25 kn per cord

Q20R-U

BCPRGEY

0.8 mm b.03 1

PQ16R

8CPR5EPll

PQ20R-P8

BCPRGEP-N8 in.

1.1 mm 0.043 in.

0.8 mm 0.031 in.

,:‘GCC Countries:

~~ s; Saudi Arabia, Sultanate of Oman, Bahrain, United Arab Emirates, Qatar, Kuwait.

p;

.5&.,..‘ .,

gg&-&;,., ;.

Page 319 of 346

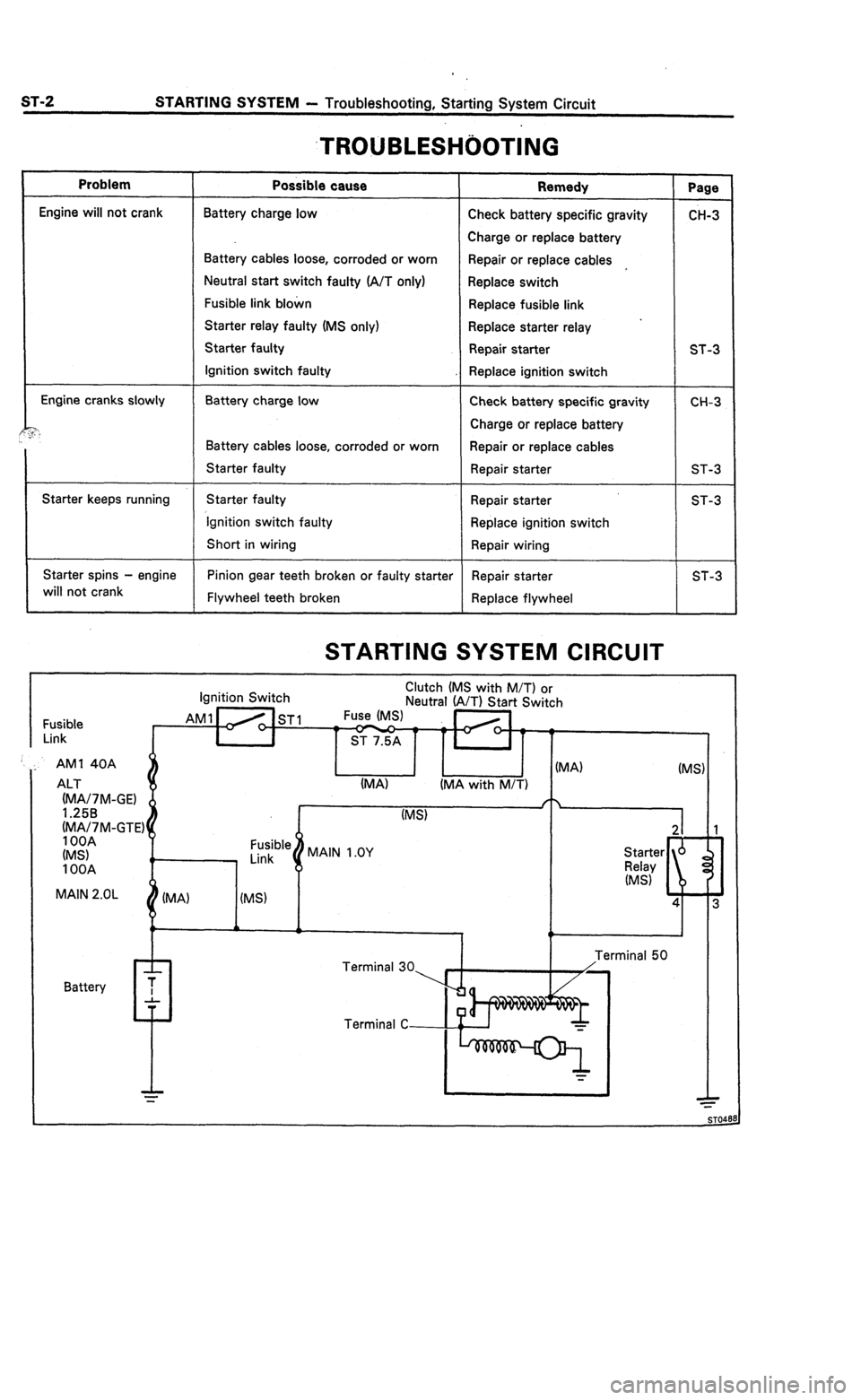

ST-2 STARTING SYSTEM - Troubleshooting, Starting System Circuit

.TROUBLESHi)OTING

Problem

Engine will not crank

Engine cranks slowly

?“.

Starter keeps running

Starter spins - engine

will not crank

Possible cause

Battery charge low

Battery cables loose, corroded or worn

Neutral start switch faulty (A/T only)

Fusible link blown

Starter relay faulty (MS only)

Starter faulty

Ignition switch faulty

Battery charge low

Battery cables loose, corroded or worn

Starter faulty

Starter faulty

‘Ignition switch faulty

Short in wiring

Pinion gear teeth broken or faulty starter

Flywheel teeth broken

Remedy

Check battery specific gravity

Charge or replace battery

Repair or replace cables

Replace switch

Replace fusible link

.

Replace starter relay

Repair starter

Replace ignition switch

Check battery specific gravity

Charge or replace battery

Repair or replace cables

Repair starter

Repair starter

Replace ignition switch

Repair wiring

Repair starter

Replace flywheel

STARTING SYSTEM CIRCUIT

Page

CH-3

ST-3

CH-3

ST-3

ST-3

ST-3

Ignition Switch Clutch (MS with M/T) or

Neutral (A/T) Start Switch

Fusible

Link AM1 Ho ST1 Fuse (MS)

t ST 7.5A

(MA/7M-GTE) ALT (MA) (MA with M/T)

(MS)

MAIN 2.OL

IMA) I IMS) I

AM1 40A

n I I PA) (MS) 1

Battery

I . I T

Page 328 of 346

STARTING SYSTEM

- Staher Relay (MS)

_. ., ST113

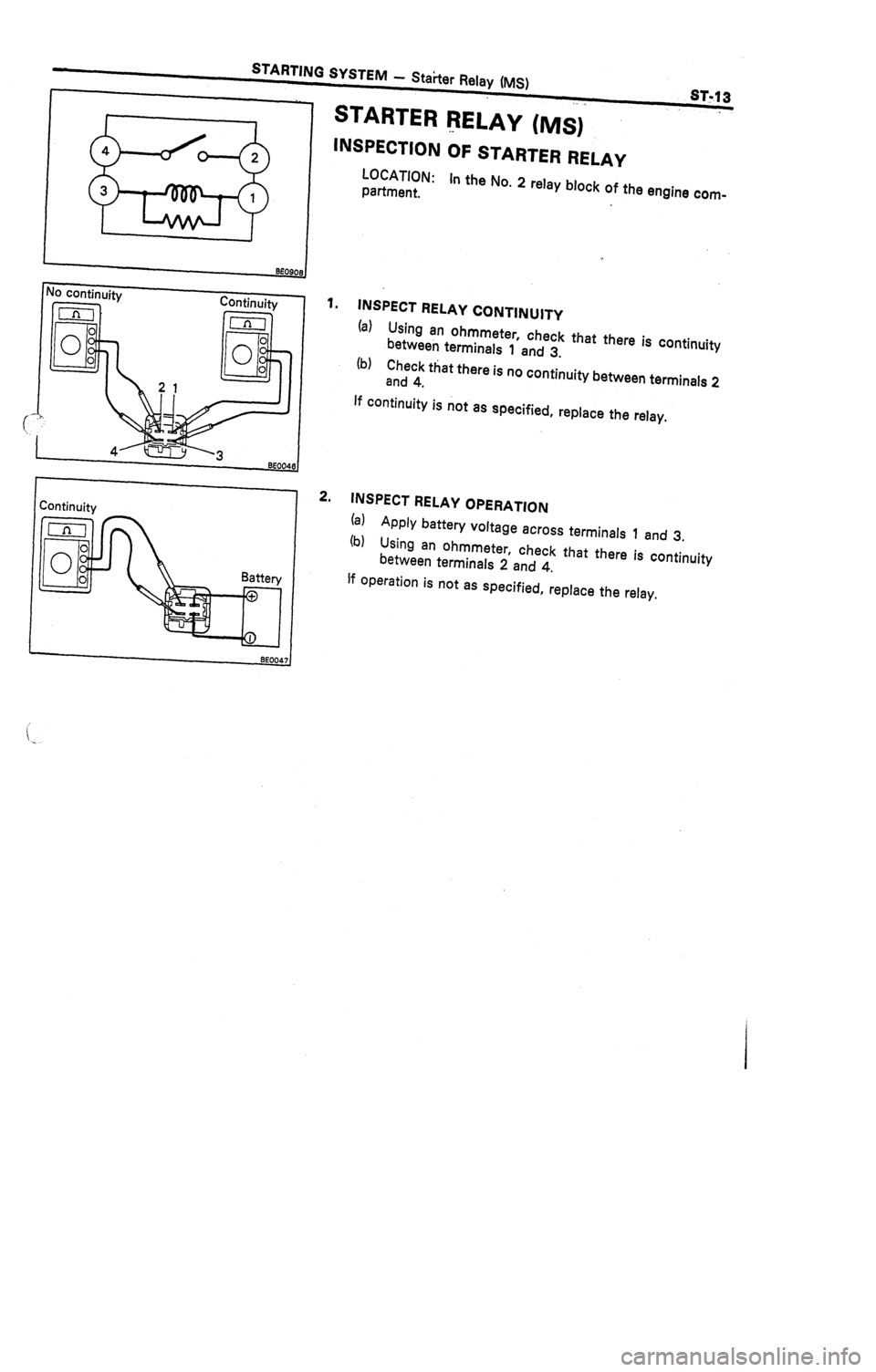

STARTER RELAY (MS)

._

INSPECTION OF STARTER RELAY

LOCATION:

partmen t. In the NO. 2 relay block of the engine com-

Continuity

Inl

Hi

0

0

0

-

Zontinuity

1.

INSPECT RELAY CONTINUITY

(a) Using an ohmmeter, check that there is continuity

lb) between terminals 1 and 3.

zt;cqk that there is no continuity between terminals 2

lf Continuity is not as specified, replace the relay.

2.

INSPECT RELAY OPERATION

(a) Apply battery voltage across terminals 1 and 3.

(b) Using an ohmmeter, check that there

is continuity

between terminals 2 and 4.

If operation is not as specified, replace the relay,

Page 330 of 346

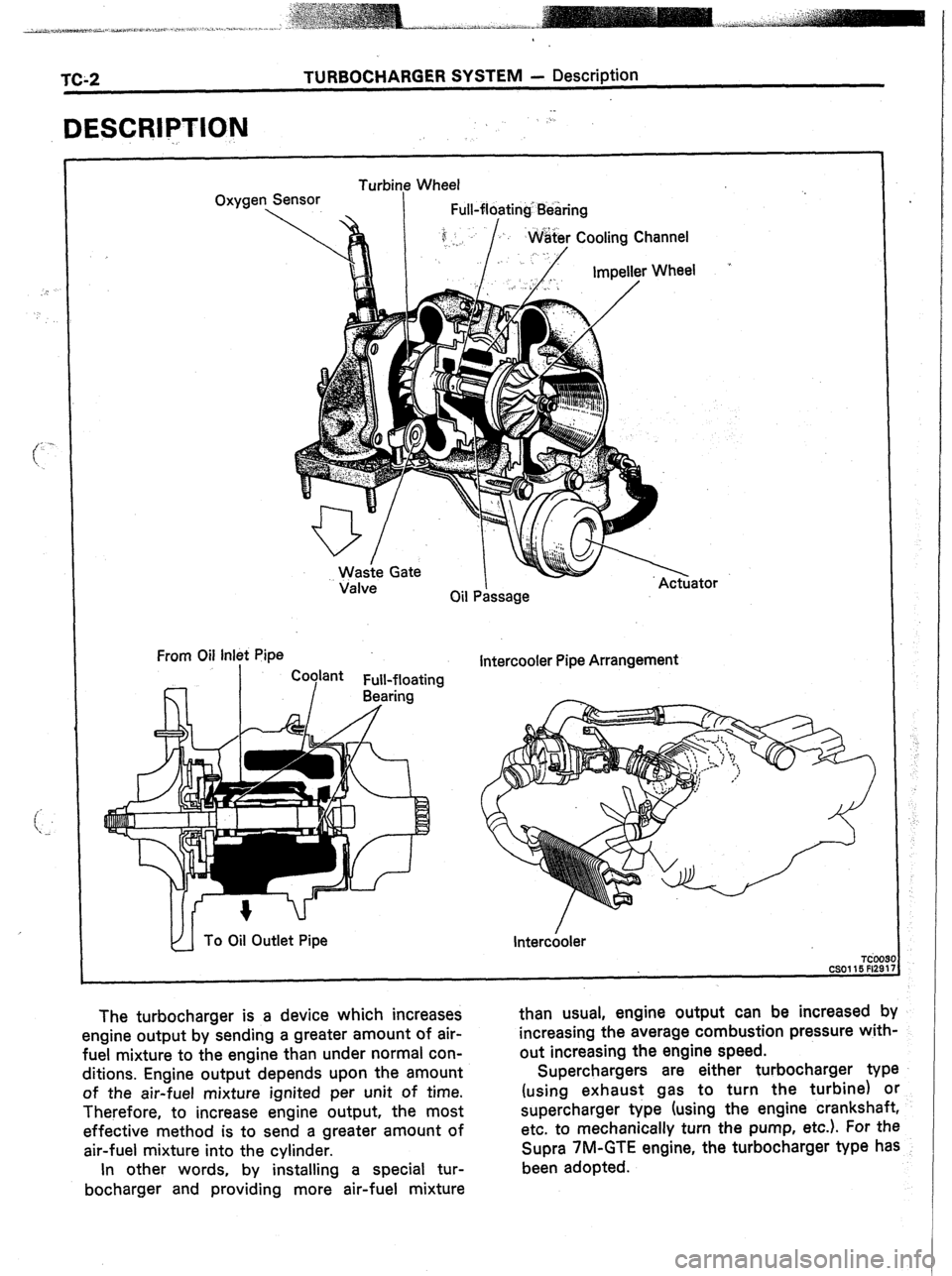

x-2 TURBOCHARGER SYSTEM - Description

.

DESCRIPTION

-.

“

Oxygen

. Turbine Wheel

Sensor

.

I Full-floating Bearing

Valve

Oil P&sage

From Oil Inlet Pipe

Intercooler Pipe Arrangement

TdO

CSOll5 Fl2

The turbocharger is a device which increases

engine output by sending a greater amount of air-

fuel mixture to the engine than under normal con-

ditions. Engine output depends upon the amount

of the air-fuel mixture ignited per unit of time.

Therefore, to increase engine output, the most

effective method is to send a greater amount of

air-fuel mixture into the cylinder. than usual, engine output can be increased by

.

increasing the average combustion pressure with-

out increasing the engine speed.

Superchargers are either turbocharger type

(using exhaust gas to turn the turbine) or

supercharger type (using the engine crankshaft,

etc. to mechanically turn the pump, etc.). For the

Supra 7M-GTE engine, the turbocharger type has

been adopted.

In other words, by installing a special tur-

bocharger and providing more air-fuel mixture

Page 331 of 346

Air

Cleaner

i

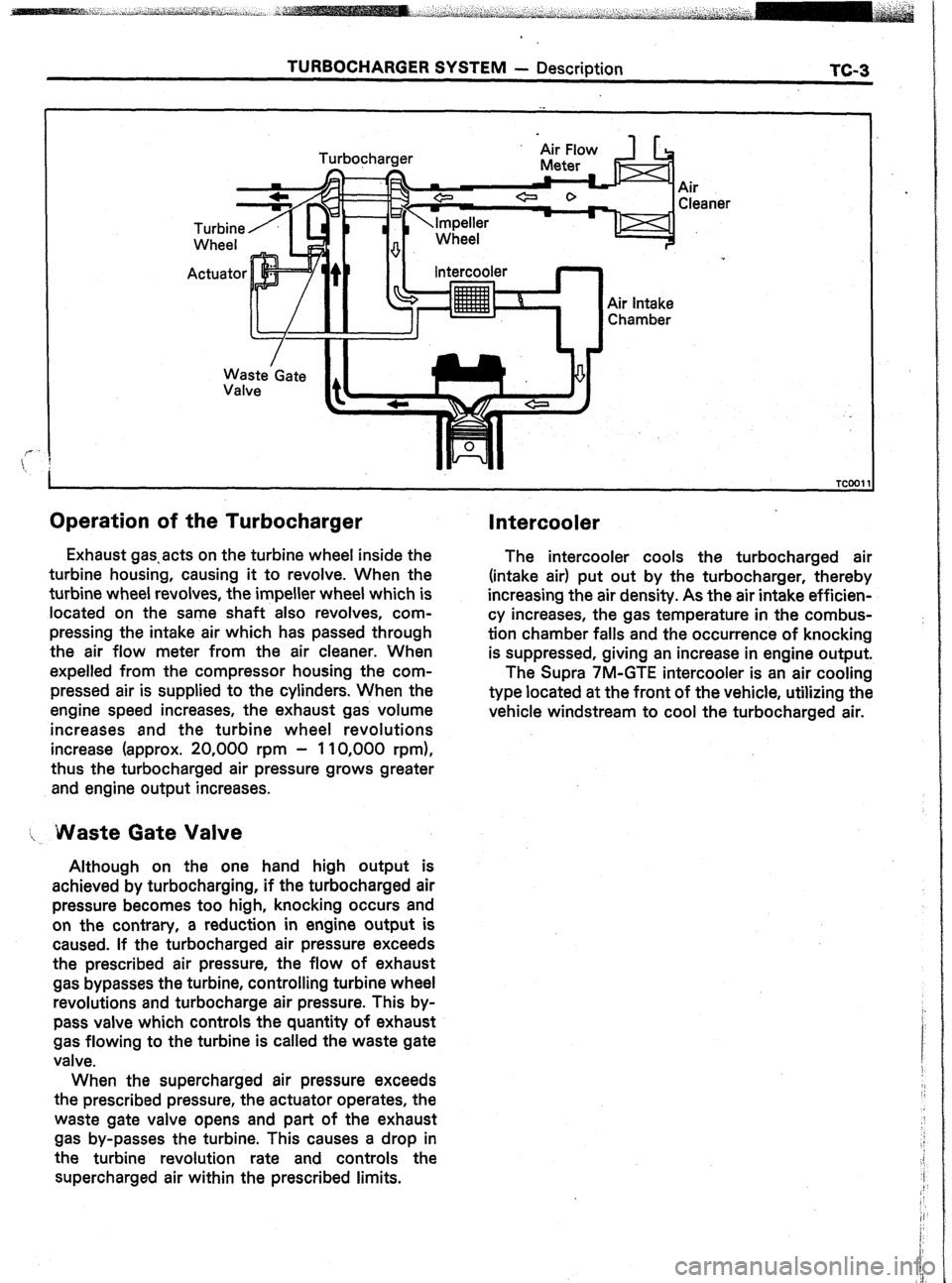

Operation of the Turbocharger

Waste’Gate

Valve Intercooler

Air intake

Chamber

Exhaust gas.acts on the turbine wheel inside the

turbine housing, causing it to revolve. When the

turbine wheel revolves, the impeller wheel which is

located on the same shaft also revolves, com-

pressing the intake air which has passed through

the air flow meter from the air cleaner. When

expelled from the compressor housing the com-

pressed air is supplied to the cylinders. When the

engine speed increases, the exhaust gas volume

increases and the turbine wheel revolutions

increase (approx. 20,000 rpm - 110,000 rpm),

thus the turbocharged air pressure grows greater

and engine output increases.

I, Waste Gate Valve

Although on the one hand high output is

achieved by turbocharging, if the turbocharged air

pressure becomes too high, knocking occurs and

on the contrary, a reduction in engine output is

caused. If the turbocharged air pressure exceeds

the prescribed air pressure, the flow of exhaust

gas bypasses the turbine, controlling turbine wheel

revolutions and turbocharge air pressure. This by-

pass valve which controls the quantity of exhaust

gas flowing to the turbine is called the waste gate

valve.

When the supercharged air pressure exceeds

the prescribed pressure, the actuator operates, the

waste gate valve opens and part of the exhaust

gas by-passes the turbine. This causes a drop in

the turbine revolution rate and controls the

supercharged air within the prescribed limits.

Intercooler

The intercooler cools the turbocharged air

(intake air) put out by the turbocharger, thereby

increasing the air density. As the air intake efficien-

cy increases, the gas temperature in the combus-

tion chamber falls and the occurrence of knocking

is suppressed, giving an increase in engine output.

The Supra 7M-GTE intercooler is an air cooling

type located at the front of the vehicle, utilizing the

vehicle windstream to cool the turbocharged air.

Page 332 of 346

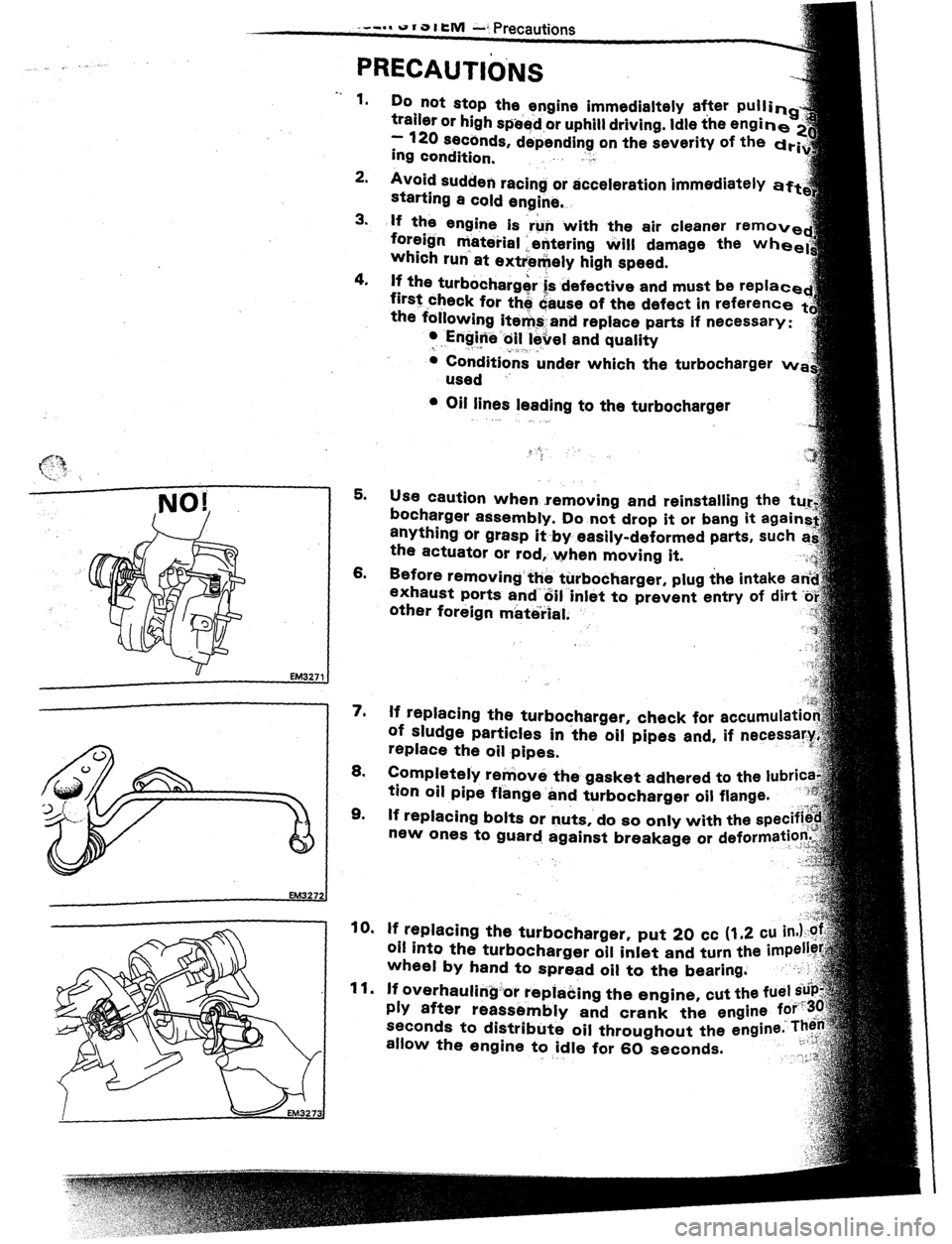

u EM3271

. .

1.

Do not stop the engine immedialtely after pullin

trailer or high speed or uphill driving. Idle the engin

- 126 seccnds, depending on the severity of the drf

ing condition, .,I

2.

Avoid sudden racing or acceleration immediately

starting a cold engine. aft

3.

If the engine is ‘run with the air cleaner remov

foreign material : entering Will damage the whe

which run’ at ext

lf the turbocharger i‘s .defective and must be replac

first check for thd &use of the defect in referent

the foilowing ite&and replace parts if necessary:

l .Engine:oil level and quality

c ,. ,_. .^

. I, .: .’

c Conditions under which the turbocharger MI

used ..

c Oil lines leading to the turbocharger

PRECAUTIO.NS

5.

use caution when .removing and reinstalling the

bocharger assembly. Do not drop it or bang it

anything or grasp it by easily-deformed parts,

the actuator or rod, .when moving it.

6.

other foreign material.

7.

lf replacing the turbocharger, check for accumulati

of sludge particles in the oil pipes and, if necessary

replace the oil pipes.

8.

EM327:

allow the engine

to idle for 60 seconds.

. ,-

Page 333 of 346

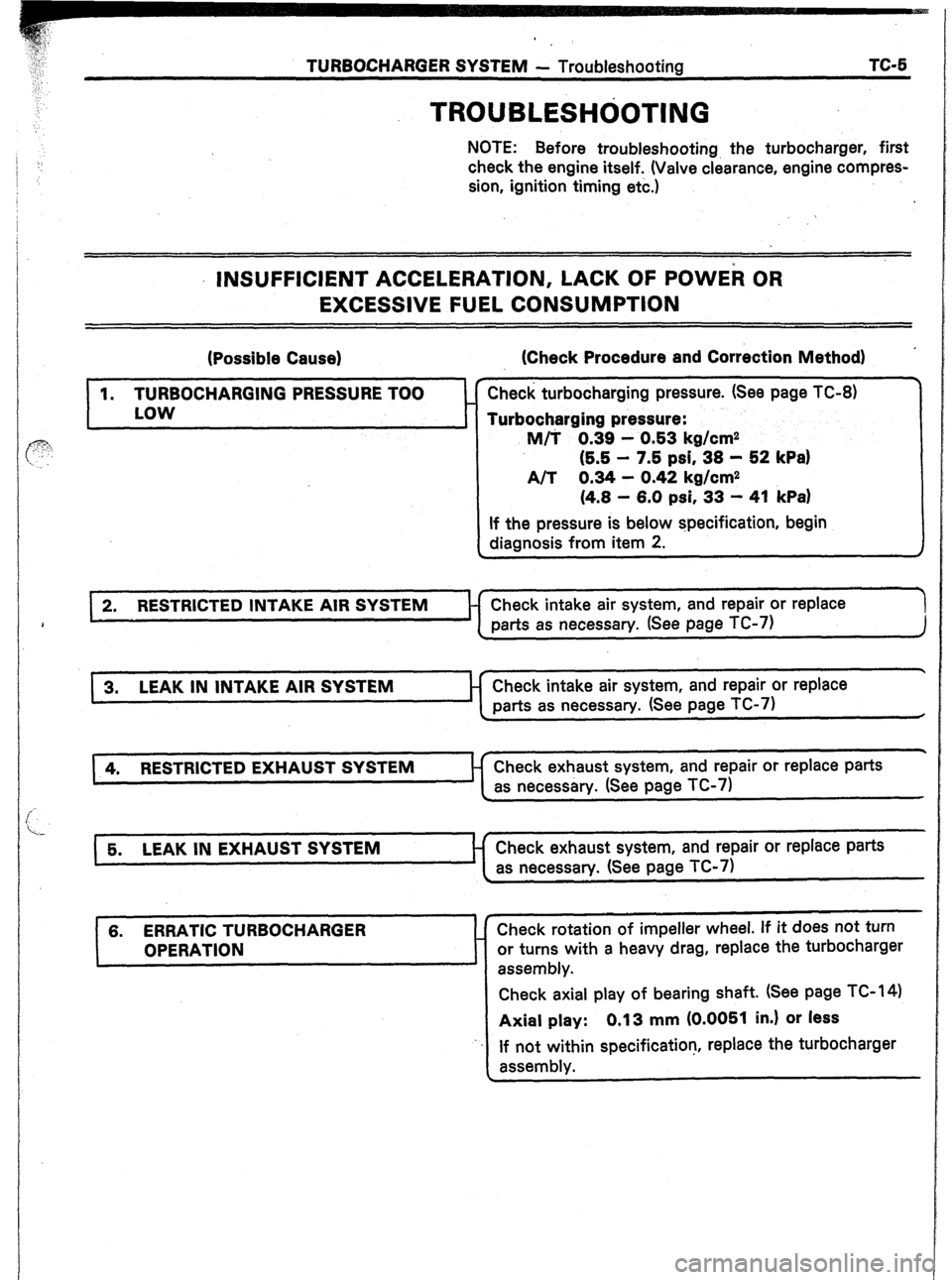

TURBOCHARGER SYSTEM - Troubleshooting TC-5

TROUBLESHdOTlNG

NOTE: Before troubleshooting the turbocharger, first

check the engine itself. (Valve clearance, engine compres-

sion, ignition timing etc.)

INSUFFICIENT ACCELERATION, LACK OF POWEk OR

EXCESSIVE FUEL CONSUMPTION

(Possible Cause)

I

1. TURBOCHARGING PRESSURE TOO

LOW

t

’ (Check Procedure and Correction Method)

Check turbocharging pressure. (See page TC-8)

Turbocharging pressure:

M/T 0.39 - 0.53 kg/cm2

(5.5 - 7.5 psi, 38 - S2 kPa)

A/T 0.34 - 0.42 kg/cm2

(4.8 - 6.0 psi, 33 - 41 kPa)

If the pressure is below specification, begin

diagnosis from item 2.

2. RESTRICTED INTAKE AIR SYSTEM Check intake air system, and repair or replace

‘1

parts as necessary. (See page TC-7)

J

.

3. LEAK IN INTAKE AIR Check intake air system, and repair or replace

parts as necessary. (See page TC-7)

.

4. RESTRICTED EXHAUST SYSTEM Check exhaust system, and repair or replace parts

as necessary. (See page TC-7)

Check exhaust system, and repair or replace parts

as necessary. (See page TC-7)

6. ERRATIC TURBOCHARGER

OPERATION Check rotation of impeller wheel. If it does not turn

or turns with a heavy drag, replace the turbocharger

assembly.

Check axial play of bearing shaft. (See page TC- 14)

Axial play: 0.13 mm (0.0051 in.) or less

If not within specification, replace the turbocharger

assembly.

Page 336 of 346

TC;8 TUWOCHARGER SYSTEM--- Turbocharger

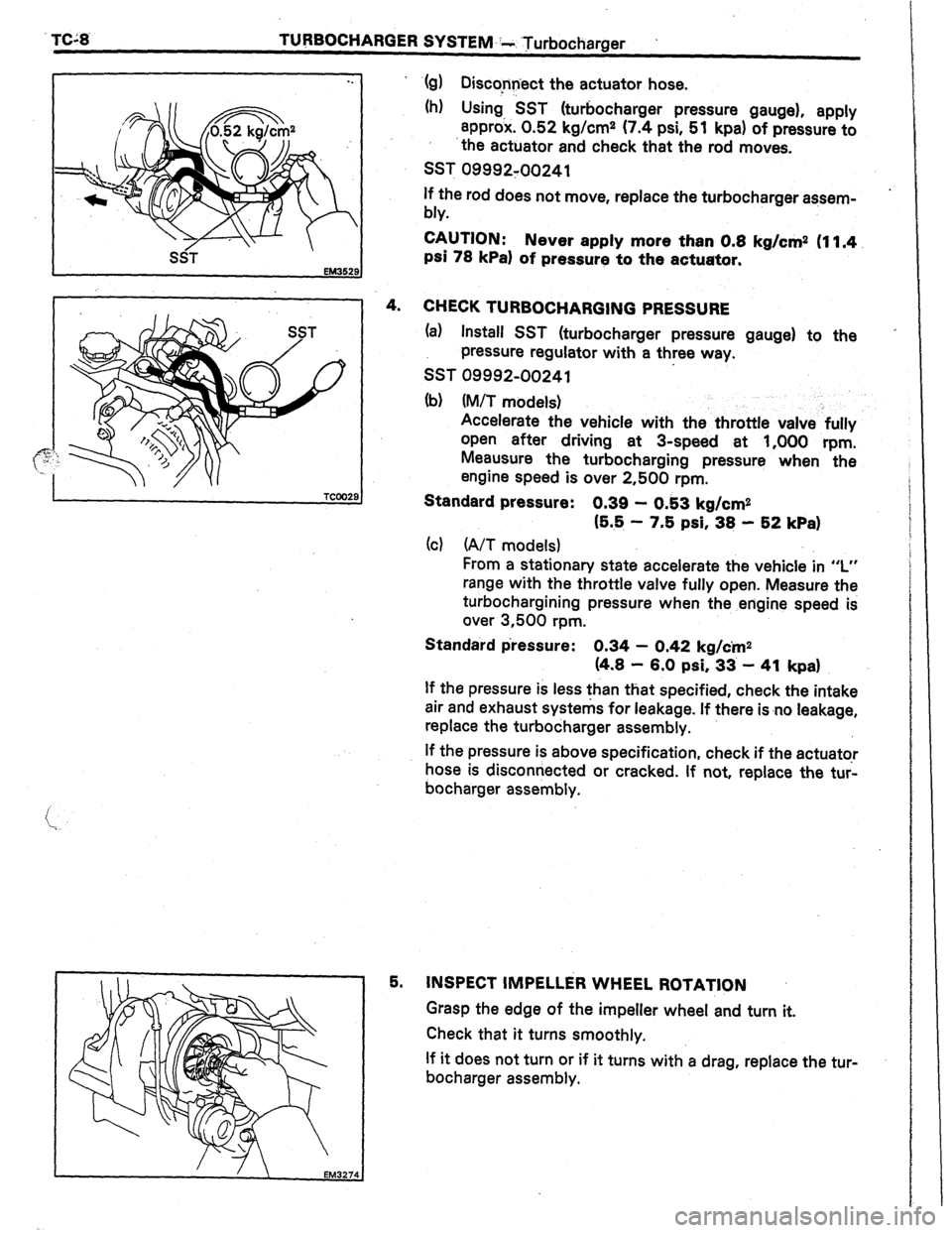

-. ‘(g) Disccnnect the actuator hose.

(h) Using, SST (turbocharger pressure gauge), apply

approx. 0.52 kg/cm2 (7.4 psi, 51 kpa) of pressure to

‘the actuator and check that the rod moves.

SST 09992:00241

SST

EM352!

If the rod does not move, replace the turbocharger aasem-

bly.

CAUTION: Never apply more than 0.8 kg/cm2 (11.4.

psi 78 kPa1 of pressure to the actuator.

4.

CHECK TURBOCHARGING PRESSURE

(a) Install SST (turbocharger pressure gauge) to the

pressure regulator with a three way.

SST 09992-00241

(b) (M/T models)

Accelerate the vehicle with the throttle valve fully

open after driving at 3-speed at 1,000 rpm.

Meausure the turbocharging pressure when the

engine speed is over 2,500 rpm.

Standard pressure:

0.39 - 0.53 kg/cm2

(6.8 - 7.8 psi, 38 - 82 kPa)

(c) (A/T models)

From a stationary state accelerate the vehicle in I”

range with the throttle valve fully open. Measure the

turbochargining pressure when the engine speed is

over 3,500 rpm.

Standard p‘ressure: 0.34 - 0.42 kg/em2

(4.8 - 8.0 psi, 33 - 41 kpa)

If the pressure is less than that specified, check the intake

air and exhaust systems for leakage. If there isno leakage,

replace the turbocharger assembly.

If the pressure is above specification, check if the actuator

hose is disconnected or cracked. If not, replace the turl

bocharger assembly.

I l,Il - 1 5, INSPECT IMPELLiR WHEEL ROTATION

/-L

EM32

Grasp the edge of the impeller wheel and turn it.

Check that it turns smoothly.

If it does not turn or if it turns with a drag, replace the tur

bocharger assembly.

1 :74

Page 344 of 346

TURBOCHARGER SYSTEM - Turbocharaer

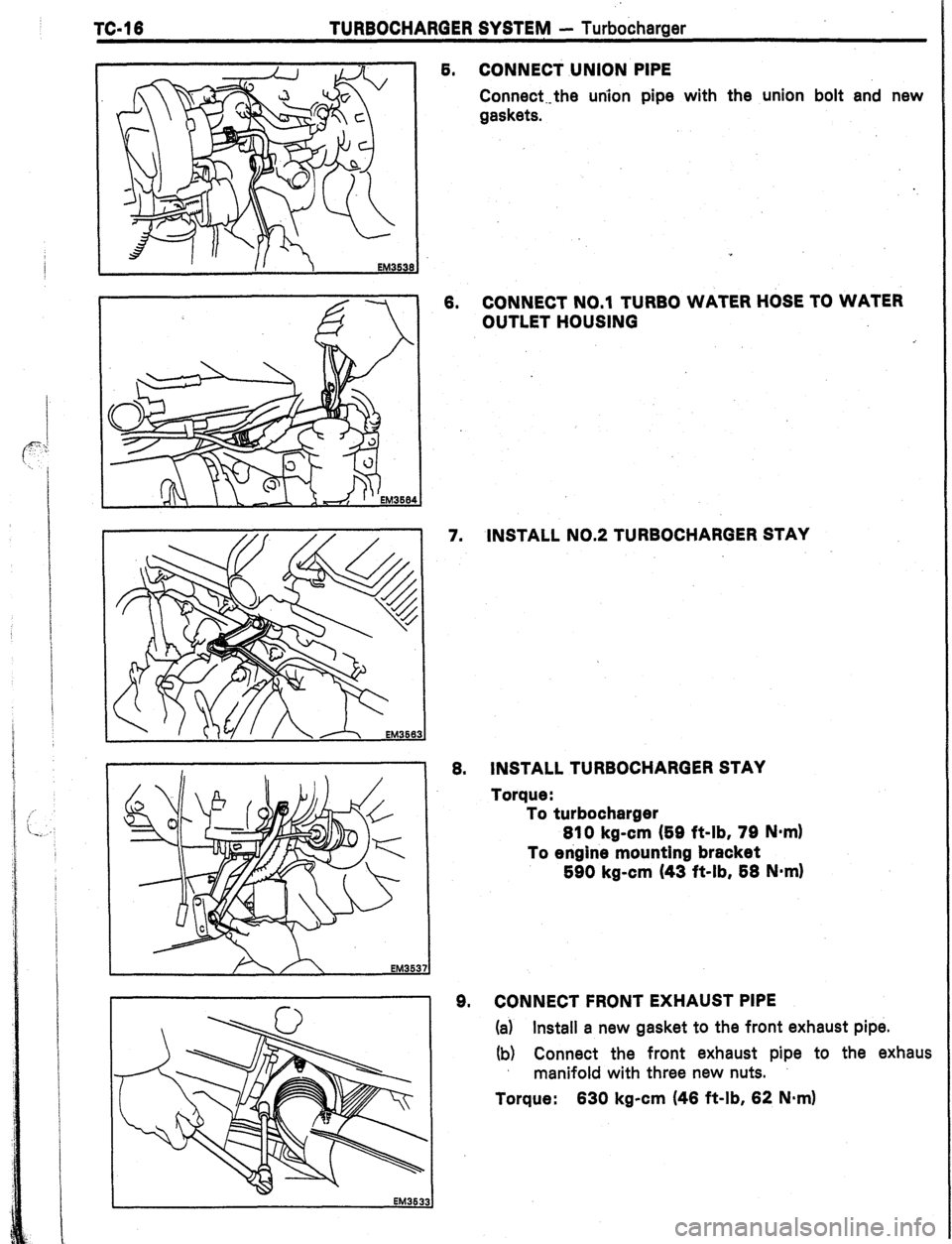

6. CONNECT UNION PIPE

Connect--the uriion pipe with the union bolt and new

gaskets.

’

6-i

6. CONNECT NO.1 TURBO WATER HOSE TO WATER

OUTLET HOUSING

7. INSTALL NO.2 TURBOCHARGER STAY

8. INSTALL TURBOCHARGER STAY

Torque:

To turbocharger

810 kg-cm (59 ft-lb, 70 N-m)

To engine mounting bracket

680 kg-cm (43 ft-lb, 68 N-m)

9. CONNECT FRONT EXHAUST PIPE

(a) Install a new gasket to the front exhaust pipe.

(b) Connect the front exhaust pipe to the exhaus

manifold with three new nuts.

Torque: 630 kg-cm (46 ft-lb, 62 Nem)