engine TOYOTA CELICA 1987 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 42 of 346

-8 EFI SYSTEM -.- Inspection Precautions

IF VEHICLE IS EQUIPPED WITH MOBILE

RADIO SYSTEM (HAM, CB, ETC)

The ECU has been designed so that it will not be affected by

outside interference.

However, if your vehicle is equipped with a CB radio

transceiver, etc. (even one with about 10 W output), it may, at

times, have an affect upon ECU operation, especially if the

antenna and feeder are installed nearby.

Therefore, observe the following precautions:

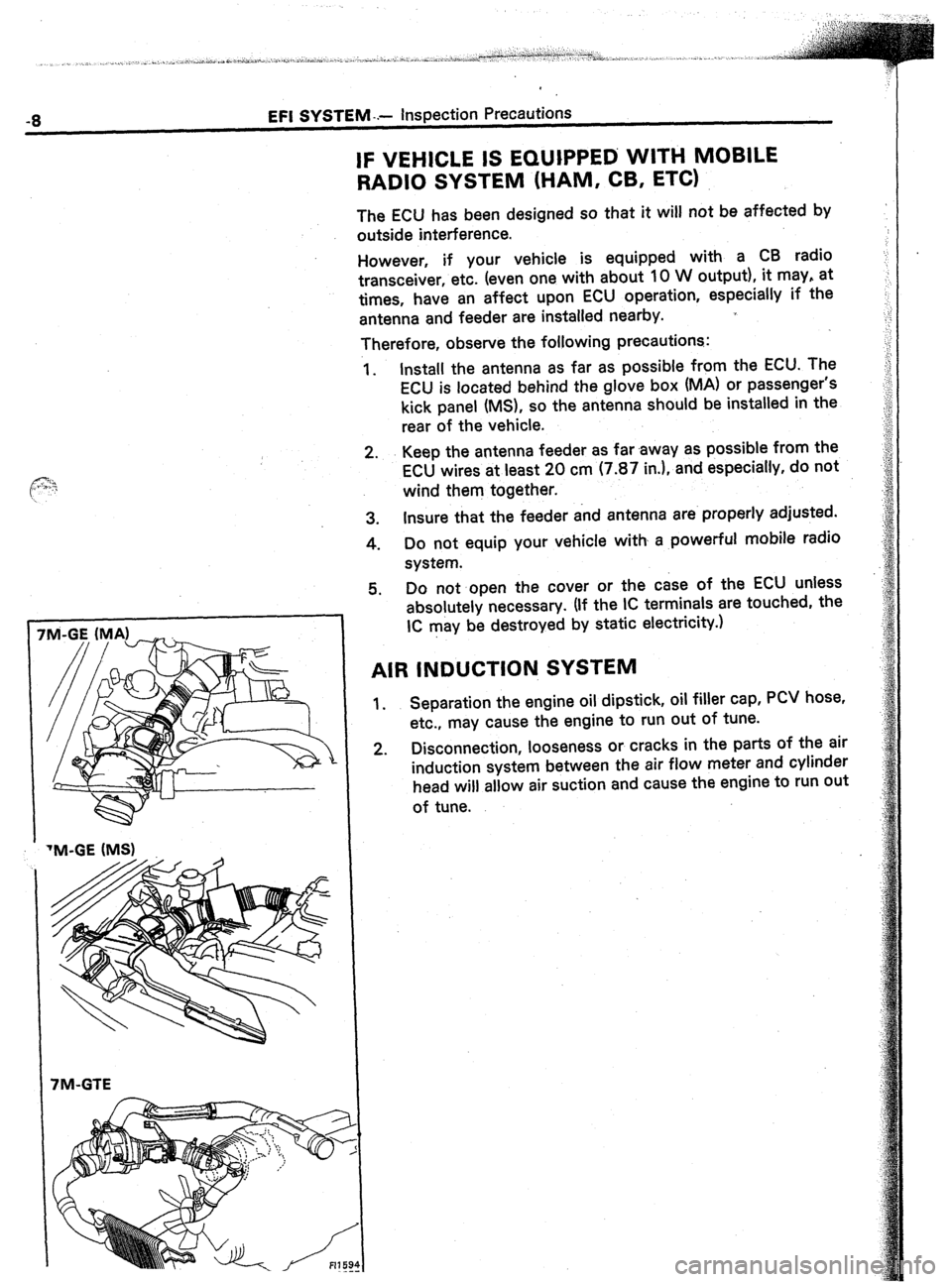

1. Install the antenna as far as possible from the ECU. The

ECU is located behind the glove box (MA) or passenger’s

kick panel (MS), so the antenna should be installed in the

rear of the vehicle.

2. Keep the antenna feeder as far .away as possible from the

ECU wires at least 20 cm (7.87 in.), and especially, do not

wind them together.

3. Insure that the feeder and antenna are properly adjusted.

4. Do not equip your vehicle with a powerful mobile radio

system.

Do not open the cover or the case of the ECU unless

absolutely necessary. (If the IC terminals are touched, the

. . .

IC may be destroyed by static electricity.1

AIR INDUCTION SYSTEM

1.

2. Separation the engine oil dipstick, oil filler cap, PCV hose,

etc., may cause the engine to run out of tune.

Disconnection, looseness or cracks in the parts of the air

induction system between the air flow meter and cylinder

head will allow air suction and cause the engine to run out

of tune.

TM-GE (MS)

7M-GTE

Page 43 of 346

EFI SYSTEM - inspection Precautions

FI-9

FM066

FlOO95 FlOO91

ELECTRONIC CONTROL SYSTEM

1.

2.

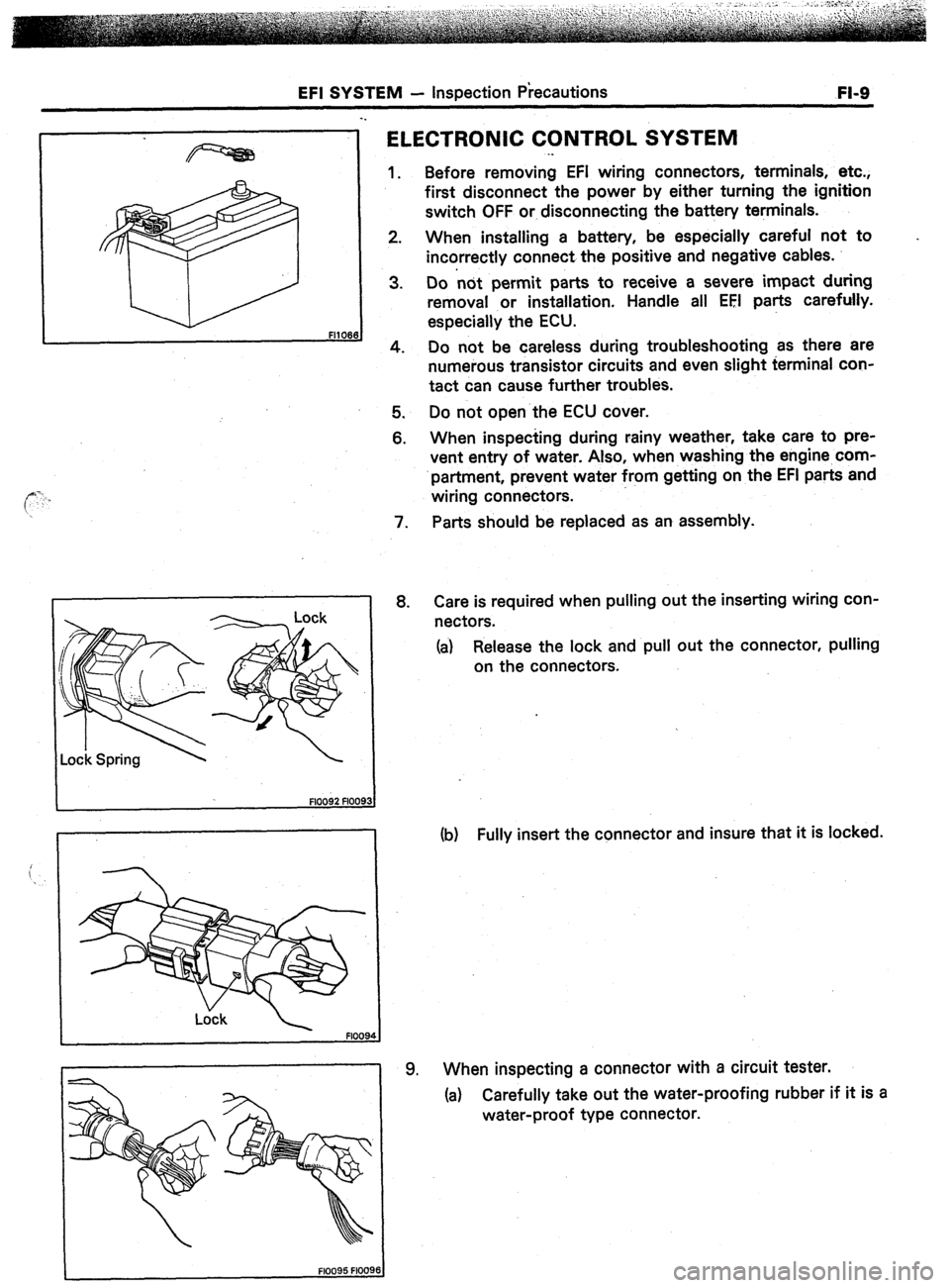

3. Before removing EFI wiring connectors, terminals, etc.,

first disconnect-the power-by either turning the ignition

switch OFF or disconnecting the battery terminals.

When installing a battery, be especially careful not to

incorrectly connect the positive and negative cables.

Do not permit parts to receive a severe impact during

removal or installation. Handle all EEI parts carefully.

especially the ECU.

4. Do not be careless during troubleshooting as there are

numerous transistor circuits and even slight terminal con-

tact can cause further troubles.

5.

6. Do not open the ECU cover.

When inspecting during rainy weather, take care to pre-

vent entry of water. Also, when washing the engine com-

.partment, prevent water from getting on the EFI parts and

wiring connectors.

7. Parts should be replaced as an assembly.

8. Care is required when pulling out the inserting wiring con-

nectors.

(a) Release the lock and pull out the connector, pulling

on the connectors. .

(b) Fully insert the connector and insure that it is locked.

9. When inspecting a connector with a circuit tester.

(a) Carefully take out the water-proofing rubber if it is a

water-proof type connector.

Page 45 of 346

EFI SYSTEM

- inspection Precautions

FI-11

I CORRECT i

Gro

Q * Delivery

Ring pipe

*

Black Ring

Delivew

Pipe -

O-Ring

-Grommet

3.

4.

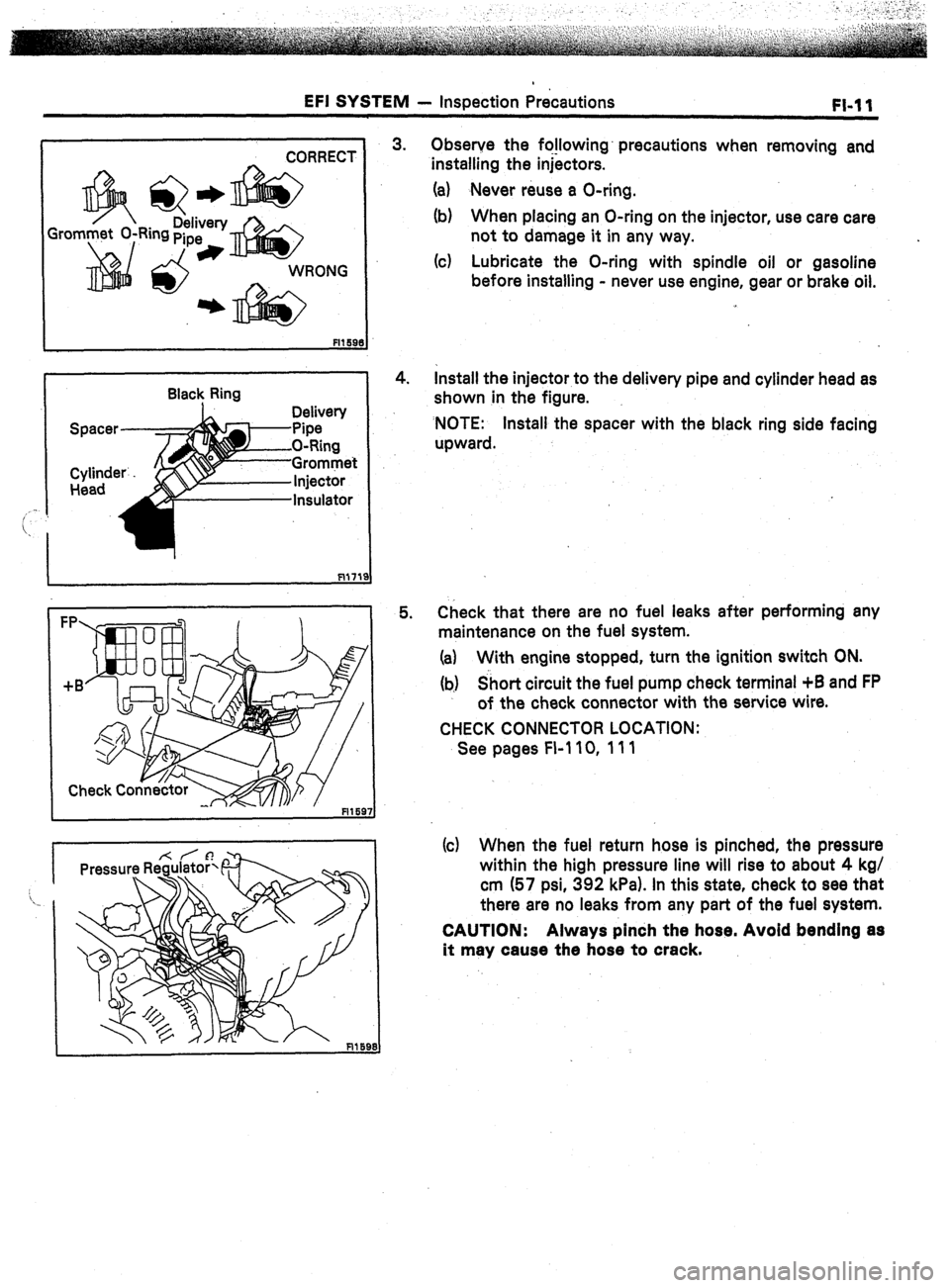

5. Observe the fo!lowing’ precautions when removing and

installing the injectors.

(a) Never reuse a O-ring.

(b) When placing an O-ring on the injector, use care care

not to damage it in any way.

(c) Lubricate the O-ring with spindle oil or gasoline

before installing - never use engine, gear or brake oil.

Install the injector to the delivery pipe and cylinder head as

shown in the figure.

‘NOTE: Install the spacer with the black ring side facing

upward.

Check that there are no fuel leaks after performing any

maintenance on the fuel system.

(a) With engine stopped, turn the ignition switch ON.

(b) Short circuit the fuel pump check terminal +B and FP

of the check connector with the service wire.

CHECK CONNECTOR LOCATION:

See pages FI-110, 111

(c) When the fuel return hose is pinched, the pressure

within the high pressure line will rise to about 4 kg/

cm (57 psi, 392 kPa). In this state, check to see that

there are no leaks from any part of the fuel system.

CAUTION: Always pinch the hose. Avoid bending as

it may cause the hose to crack.

Page 46 of 346

1-12 EFI SYSTEM - Troubleshooting’

FlO48

TROUBLESH~~TI~~G

. .

TROUBLESHOOTING HlhJTS

1. Engine troubles are usually not caused by the EFI system.

When troubleshooting, always first check the condition of

the other systems.

(a) Electronic source

0 Battery

0 Fusible links

0 Fuses

(b) Body ground

(cl Fuel supply

0 Fuel leakage

0 Fuel filter

0 Fuel pump

(d) Ignition system

0 Spark plug

0 High-tension cord

l Distributor (7M-GE) or cam position sensor (7M-

GTE)

0 Igniter and ignition coil

(e) Air induction system

0 Vacuum leaks

(f) Emission control system

0 PCV system

0 EGR system (w/ EGR)

(g) Others

l Ignition timing (ESA system)

0 Idle speed (ISC system)

-r

2. The most frequent cause of problems is simply a bad don-

tact in wiring connectors. Always make sure that connec-

tions are secure.

When inspecting the connector, pay particular attention to

the following points:

(a) Check to see that the terminals are not bent.

(b) Check to see that the connector is pushed in com-

pletely and locked.

(c) Check to see that there is no signal change when the

connector is slightly tapped or wiggled.

3. Sufficiently troubleshoot for other causes before replac-

ing the ECU. The ECU is of high quality and it is expensive.

Page 48 of 346

EFI SYSTEM - Troubleshootina

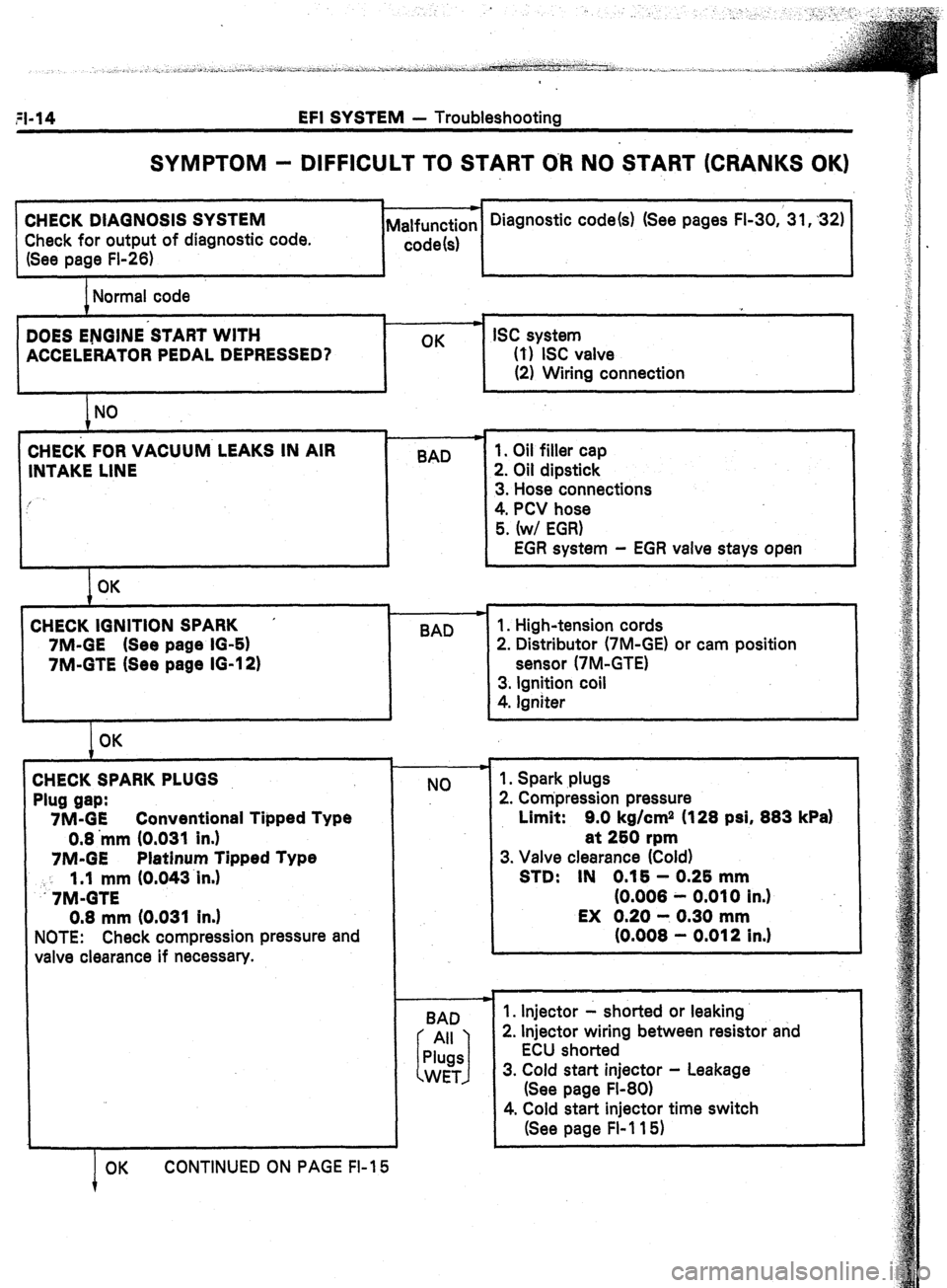

SYMPTOM - DIFFICULT TO START O-R NO START (CRANKS OK)

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page FI-26) Diagnostic code(s) (See pages FI-30,‘31,32)

Normal code

DOES ENGINE’START WITH

ACCELERATORPEDALDEPRESSED? OK ISC system

0) ISC valve

(2) Wiring connection

i NO I

CHECK FOR VACUUM LEAKS IN AIR I

BAD

INTAKE LINE

I OK

CHECK IGNITION SPARK ’

7M-GE (See page IO-61

7M-GTE (See page IG-12)

t OK

CHECKSPARKPLUGS

Plug gap:

7M-GE Conventional Tipped Type

0.8 ‘mm (0.031 In.)

7M-GE Platinum Tipped Type

: : 1.1 mm (0.043~in.)

.7M-GTE

0.8 mm (0.031 In.)

NOTE: Check compression pressure and

valve clearance if necessary.

OK CONTINUED ON PAGE FI-15

!

I

.

BAD 1. Oil filler cap

2. Oil dipstick

3. Hose connections

4. PCV hose

5. (w/ EGR)

EGR system - EGR valve stays open

1. High-tension cords

2. Distributor (‘IM-GE) or cam position

sensor (7M-GTE)

3. Ignition coil

4. Igniter

+

NO

BAD 1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883 kPa)

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.16 - 0.25 mm

(0.008 - 0.010 in.)

EX 0.20 - 0.30 mm

(0.008 - 0.012 in.1

1. Injector - shorted or leaking

2. Injector wiring between resistor and

ECU shorted

3. Cold start injector - Leakage

(See page Fl-80)

4. Cold start injector time switch

(See page Fl-115)

Page 50 of 346

l-16 EFI SYSTEM - Troubleshooting

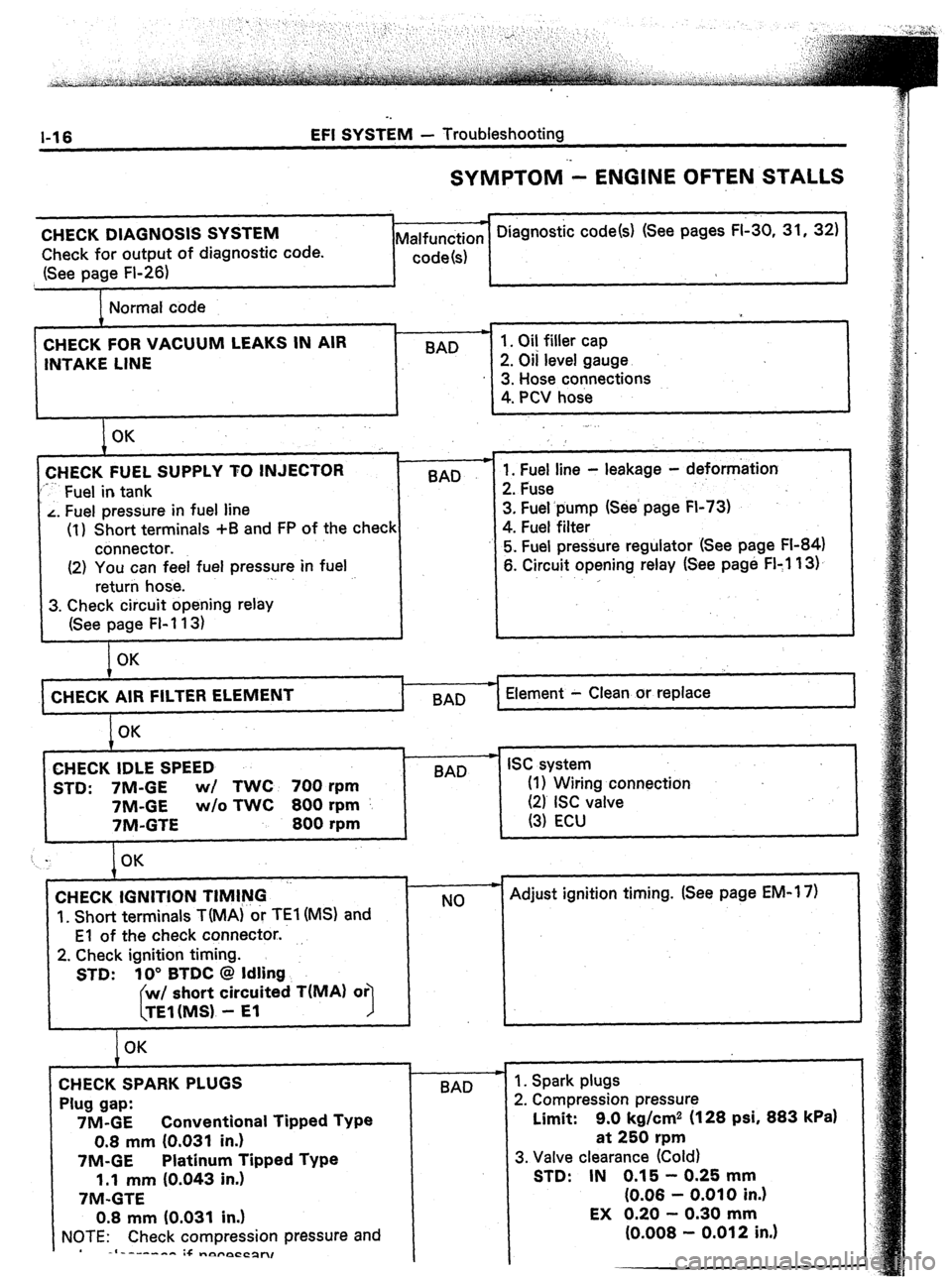

SYMPTOM - ENGINE OFTEN STALLS

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page Fl-26) * Diagnostic code(s) (See pages FI-30, 31, 32)

Malfunction

code(s)

Normal code

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE BAD 1. Oil filler cap

2. Oil level gauge

3. Hose connections

4. PCV hose

I OK

CHECK FUEL SUPPLY TO INJECTOR

‘*-- Fuel in tank BAD

L. Fuel pressure in fuel line

(1) Short terminals +B and FP of the check

connector.

(2) You can feel fuel pressure in fuel

return hose. .

3. Check circuit opening relay

(See page FI-113) .

1. Fuel line - leakage - deformation

2. Fuse

3. Fuel.pump (See’ page FI-73)

4. Fuel filter

5. Fuel pressure regulator (See page FI-84)

6. Circuit opening relay (See page FI:1 13).

,

OK

CHECK AIR FILTER

I BAD Element - Clean or replace

OK

CHECK IDLE SPEED

STD: 7M-GE wl TWC 700 rpm

7M-GE w/o TWC 800 rpm

7M-GTE 800 rpm

t w

BAD ISC system

(I 1 Wiring connection

(21 ISC valve

(3) ECU

CHECK IGNITION TIMING ‘-

‘I. Short terminals TiMA) or TEl (MS) and

El of the check connector..

2. Check ignition timing.

STD: 10” BTDC @ Idling

short circuited T(MA) or

1

OK

CHECK SPARK PLUGS

Plug gap:

7M-GE Conventional Tipped Type

0.8 mm (0.031 in.)

7M-GE Platinum Tipped Type

1.1 mm (0.043 in.)

7M-GTE

0.8 mm (0.031 in.)

NOTE: Check compression pressure and

-I------- :+ -nyrpCCpn, c

NO

-I-

BAD - Adjust ignition timing. (See page EM-1 7)

1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883

kPa)

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.15 - 0.25 mm

(0.06 - 0.010 in.)

Page 51 of 346

EFI SYSTEM - Troubleshooting

OK ‘. .CONTINUED FROM PAGE FI-I 6

m

CHECK COLD START INJECTOR

1. Cold start injector

(See page FI-80) BAD

2. Cold start injector time switch

(See page FL11 5)

OK FI-17

CHECK FUEL PRESSURE

(See page FI-74) BAD p 1. Fuel pump (See page FL73)

2. Fuel filter

3. Fuel pressure regulator (See page FI-84)

OK

CHECK INJECTORS

(See page FI-86) c

-

BAD Injection condition

I OK

..I

’ CHECK EFI ELECTRONIC CIRCUIT

USING VOLT/OHMMETER

(See pages FI-34, 57) BAD 1. Wiring connection

2. Power to ECU

(I) Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Injection signal circuit

(I 1 Injector wiring

SYMPTOM - ENGINE SOMETIMES STALLS

I

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

‘I ,. ,dSee page FI-26)

I Normal code

I

CHECK AIR FLOW METER’

Air flow meter

(See pages .Fl-96, 98)

I

OK

CHECK WIRING CONNECTORS AND

RELAYS 1 BAD --

2’ EFI main relay (See page FI 112)

Check for a signal change when the connec- 3. Circuit opening relay (See page FI-113)

tor or relay is slightly tapped or wiggled.

Page 54 of 346

.20 EFI SYSTEM - Troubleshooting __

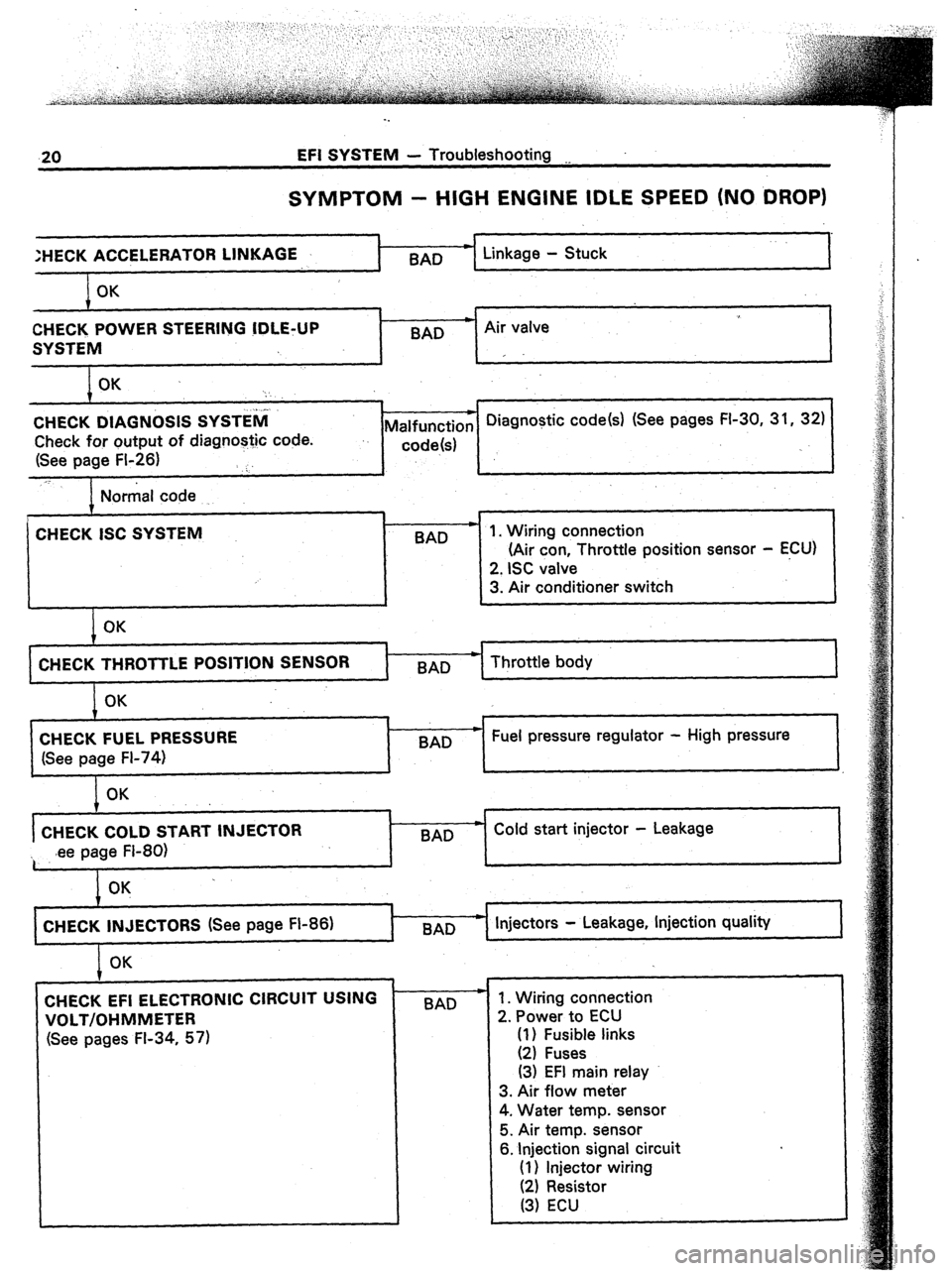

SYMPTOM - HIGH ENGINE IDLE SPEED (NO DROP)

:HECK ACCELERA

OK

CHECK POWER STEERING !DLE+JP

SYSTEM

OK .

‘:

j..l.

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page FI-26) ‘:.

_T I Linkage - Stuck

I

9

BAD * Air valve

I

r

* Diagnostic code(s) (See pages FI-30, 31, 32)

Malfunction

..

code!s)

Normal code

.

CHECK ISC SYSTEM

BAD

I

OK

71

(Air con Throttle posrtron sensor - ECU)

1 CHECK THROTTLE POSITION SENSOR

t-x- Throttle body

OK

CHECK FUEL PRESSURE

(See page FI-74) 7

BAD w Fuel pressure regulator - High pressure

OK

CHECK COLD START INJECTOR

~ .ee page FI-80) BAD w Cold start injector - Leakage

CHECK INJECTORS (See page FI-86)

I Injectors - Leakage, Injection quality

I OK

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See pages FI-34, 57) BAD - 1. Wiring connection

2. Power to ECU

(1) Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Injection signal circuit

(1) Injector wiring

(2) Resistor

(3) ECU

Page 55 of 346

EFI SYSTEM - Troubleshooting

FI-21

-.

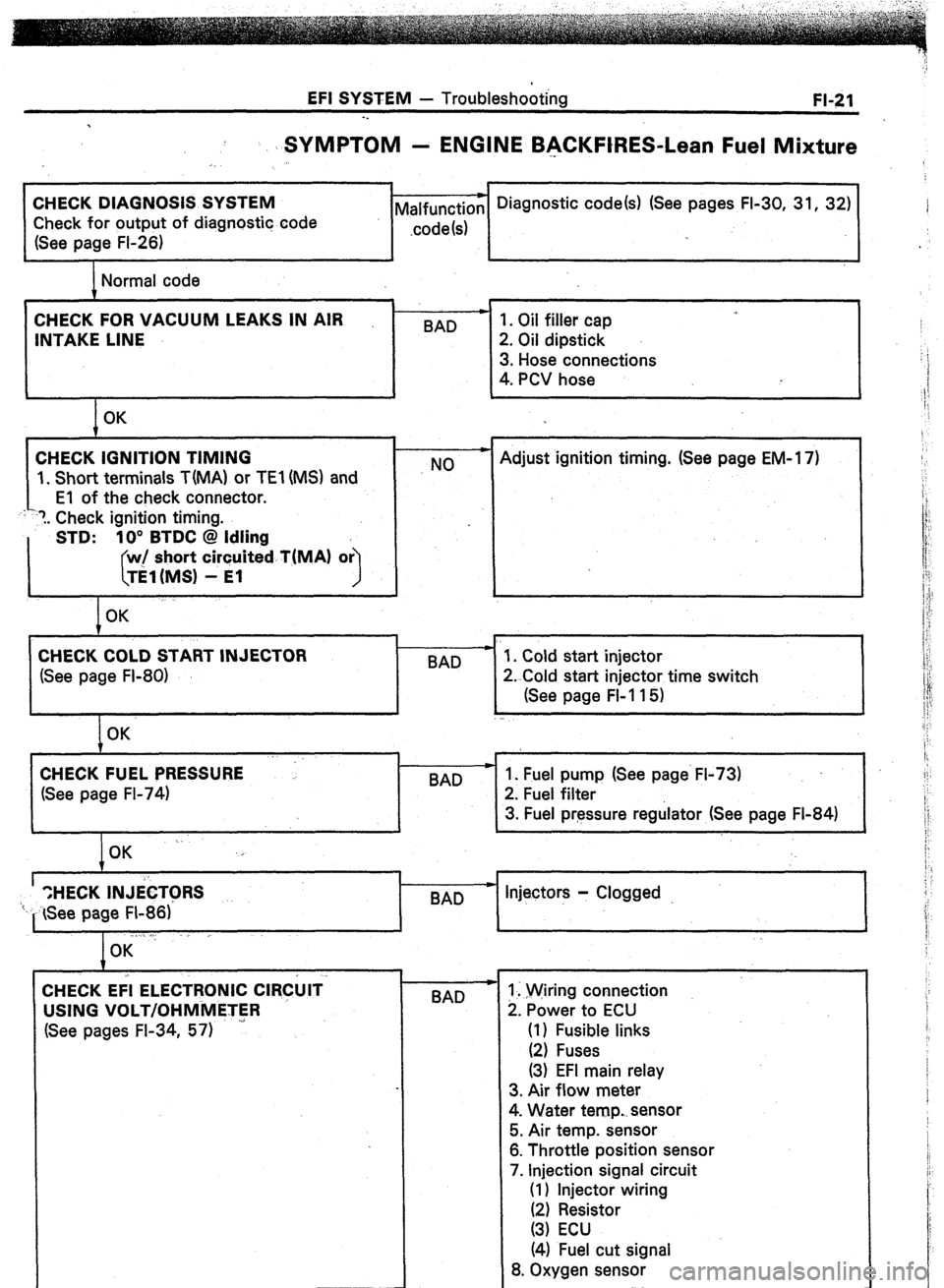

SYMPTOM - ENGINE BACKFtRES-Lean Fuel Mixture

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code

(See page FI-26) Malfunction --) Diagnostic code(s) (See pages FI-30, 31, 32)

.code 1s) j

,

Normal code

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

1. Short terminals T(MA) or TEl (MS) and BAD -

NO 1. Oil filler cap

2. Oil dipstick

3. Hose connections

4. PCV hose

Adjust ignition timing. (See page EM-1 7)

1. Cold start injector

2. Cold start injector time switch

(See page FI-115)

CHECK FUEL PRESSURE

(See page FI-74)

I

I

BAD 1. Fuel pump (See page‘ FI-73)

2. Fuel filter

3. Fuel pressure regulator (See page Fl-84)

I

’ “,HECK INJib

‘I- See page FI-86)’ - Injectors - Clogged

BAD

. ., .l

I OK

CHECK Eii ELECTRONIC ClR&lT

USING VOLT/OHMMETER

(See pages FI-34, 57)

4

BAD 1. Wiring connection

2. Power to ECU

(1) Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Throttle position sensor

7. Injection signal circuit

(1) Injector wiring

Ii, zesstor

(4) Fuel cut signal

8. Oxygen sensor

Page 57 of 346

EFI SYSTEM - Troubleshooting

FI-23

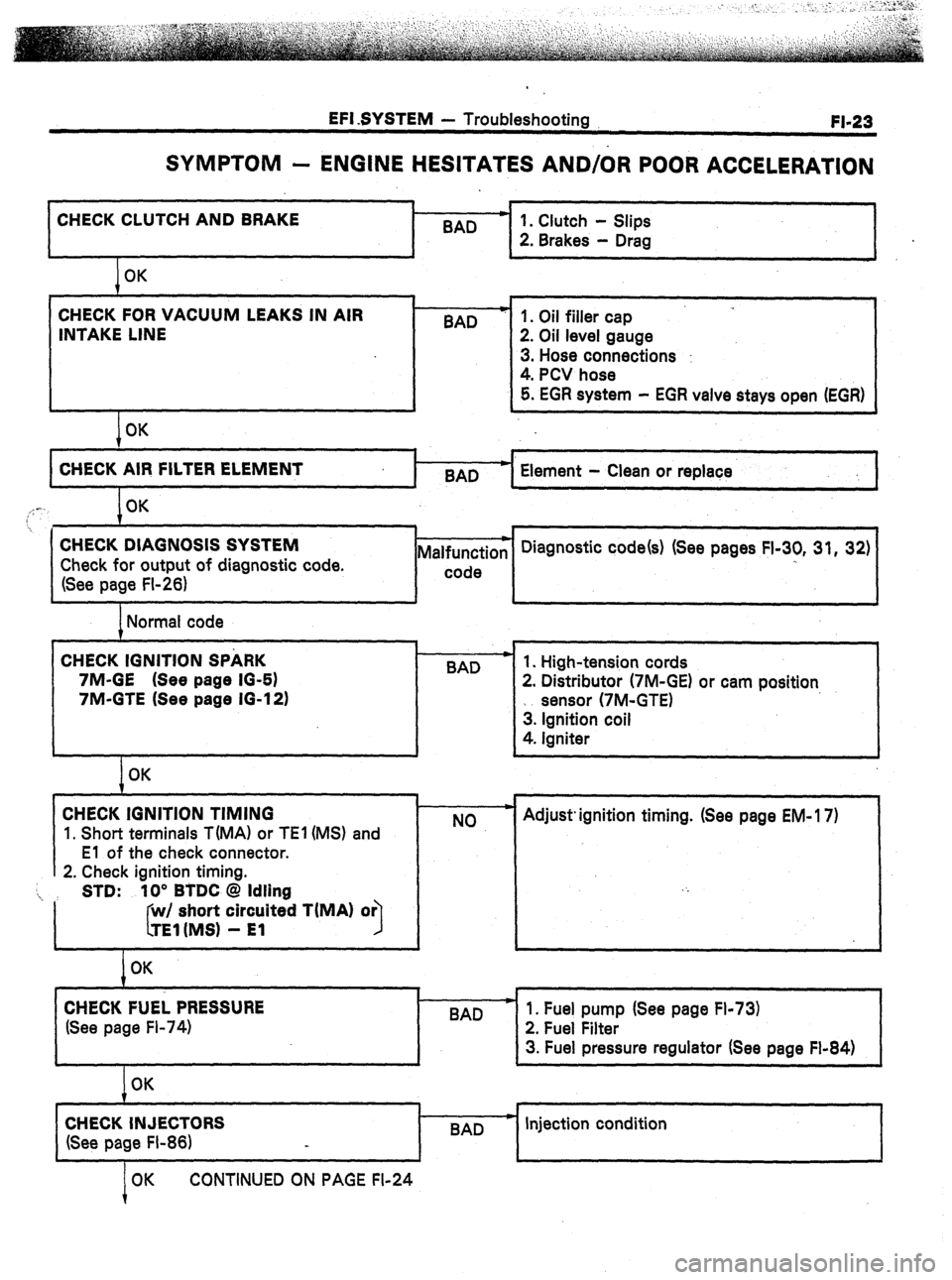

SYMPTOM - ENGINE HESITATES AND/OR POOR ACCELERATION

CHECK CLUTCH AND BRAKE .

BAD

I

I 1

1 OK

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

I OK BAD

I-

1. Clutch - Slips

2. Brakes - Drag

1. Oil filler cap

2. Oil level gauge

3. Hose connections :

4. PCV hose

5. EGR system - EGR valve stays open (EGR)

4

CHECK AIR FILTER ELEMENT

BAD Element - Clean or replace

I

,,: -. OK

7

. . 1 i , 1

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page FI-26) Malfunction

I-- code Diagnostic code(s) (See pages FI-30, 31, 32)

I

I I I J

1 Normal code

CHECK IGNITION SPARK

7M-GE (See page IO-61

7M-GTE (See page 16-12) .

BAD

I

I OK

CHECK IGNITION TIMING

1. Short terminals T(MA1 or TEl (MS) and

El of the check connector.

2. Check ignition timing.

‘i, STD: 10” BTDC @ Idling

I short circuited TiMA) or

I

I OK

CHECK FUEL PRESSURE

(See page Fl-74) 1. High-tension cords

2. Distributor (7M-GE) or cam position

sensor (7M-GTE)

3. Ignition coil

4. Igniter

NO Adjust. ignition timing. (See page EM- 17)

I

I

BAD

I

1. Fuel pump (See page Fl-73)

2. Fuel Filter

3. Fuel pressure regulator (See page Fl-84)

1

OK

CHECK INJECTORS

(See page FI-86) BAD c Injection condition

OK CONTINUED ON PAGE FI-24