engine TOYOTA CELICA 1987 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 71 of 346

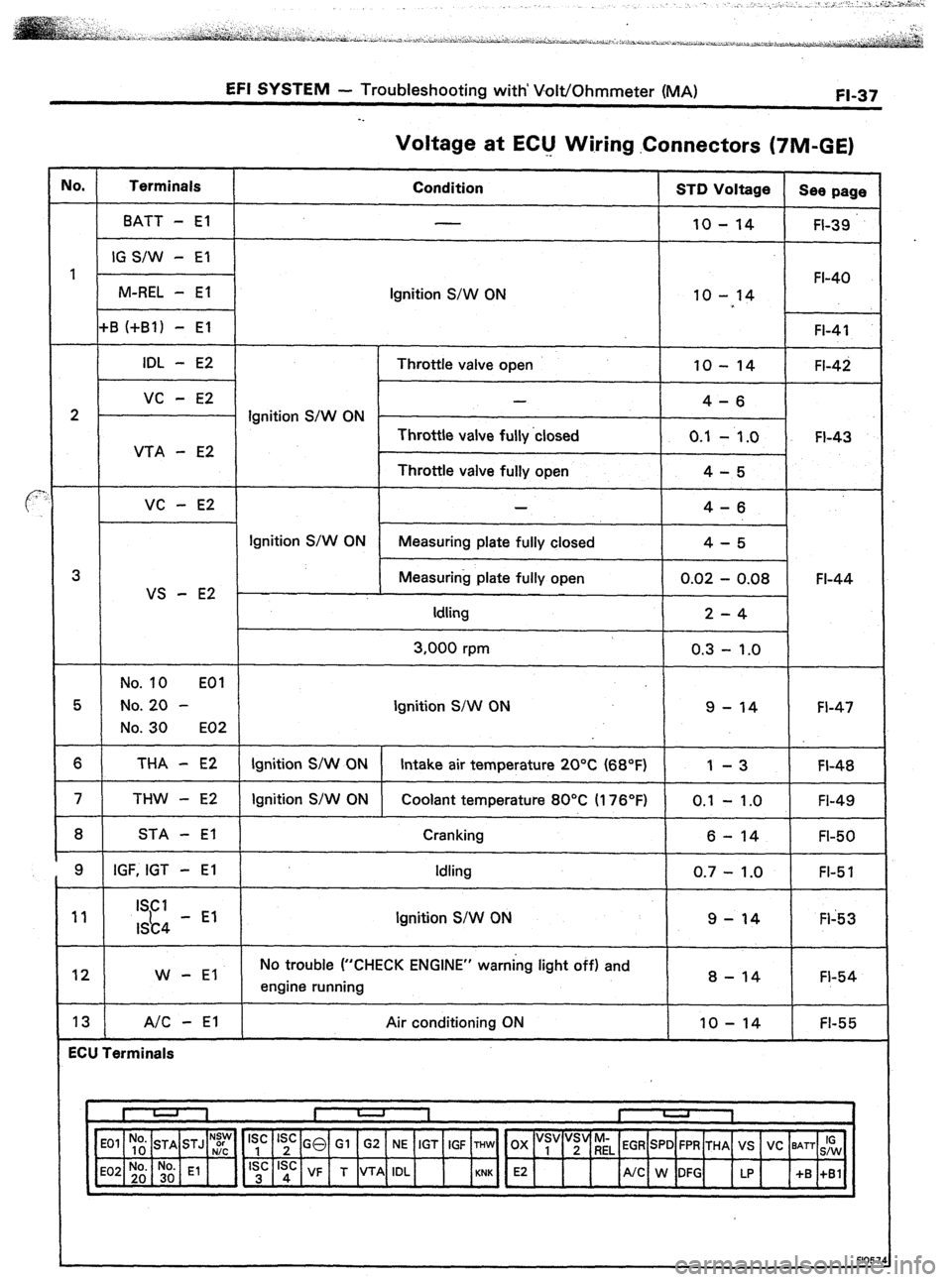

EFI SYSTEM - Troubleshooting with’ Volt/Ohmmeter (MA) FI-37

Voltage at EClJ Wiring .Connectors (TIM-GE)

IO. Terminals

Condition STD Voltage

See page

BATT - El

10 - 14 FI-39

IG S/W - El

1 FI-40

M-REL - El

Ignition S/W ON 10 - 14

+B (+Bl) - El FI-41

IDL - E2 Throttle valve open 10 - 14 FI-42

vc - E2 -

4-6

2 Ignition S/W ON -

Throttle valve fully ‘closed 0.1

- 1.0 FI-43

VTA - E2

Throttle valve fully open 4-5

VC - E2 4-6

Ignition S/W ON

Measuring plate fully closed 4-5

3 Measuring plate fully open 0.02 - 0.08 FI-44

VS - E2

Idling 2-4

3,000 rpm 0.3 - 1.0

No. 10 EOI

5 No. 20 - Ignition S/W ON 9 - 14 FI-47

No. 30 E02

6 THA - E2 Ignition S/W ON Intake air temperature 20°C (68°F) 1 -3 FI-48

7 THW - E2 Ignition S/W ON Coolant temperature 80°C II 76’F) 0.1 - 1 .O

FI-49

8 STA - El Cranking

6 - 14 FI-50

9 IGF, IGT - El Idling

0.7 - 1.0 FI-5 1

11 ISCI

I&4 - El Ignition S/W ON 9-14 Fl-53

12 W - El No trouble (“CHECK ENGINE” warning light off) and

engine running 8 - 14 FI-54

13 A/C - El Air conditioning ON IO - 14 FI-55

ECU Terminals

‘~,~] E2 4

/UC W:G up +S :,:I

N:y Is’ Is’ GO Gl G2 NE IGT IGF THW OX “s, “;“riL EGR SPD FPR THA VS VC BATT IG

F1057

Page 72 of 346

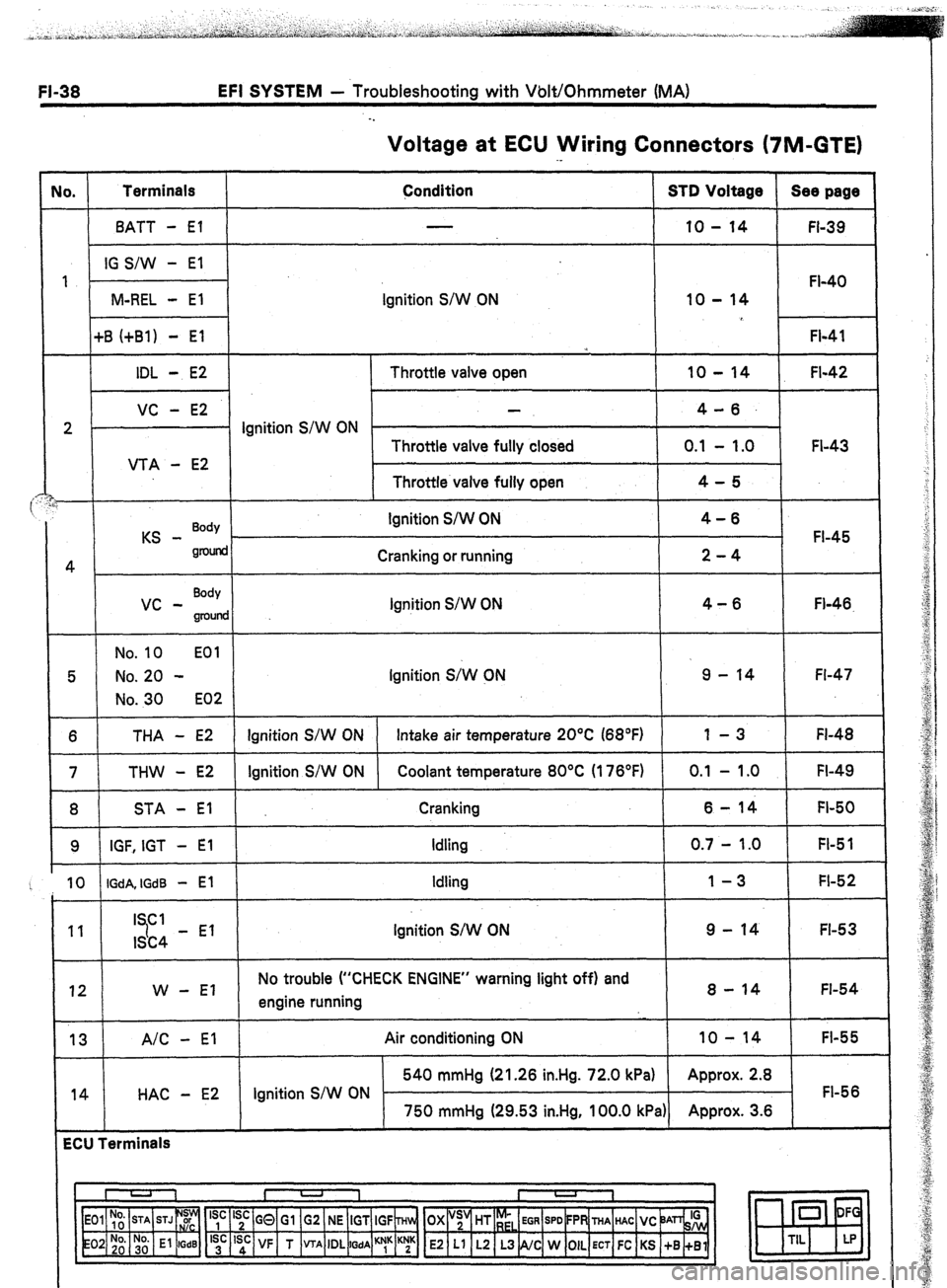

EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MA)

. .

Voltage at ECU Wiring Connectors (7M-GTE)

No. Terminals

Condition STD Voltage Sea page

BATT - El 10 - 14

FI-39

IG S/W - El

1

FI-40

M-REL - El Ignition S/W ON 10 - 14

+B (+Bl) - El

FI-41

*

IDL - E2 Throttle valve open 10 - 14 FI-42

VC - E2 4-6.

2 . Ignition S/W ON

Throttle valve fully closed 0.1 - 1.0 FI-43

VTA - E2

Throttle valve fully open 4-5

i

KS - Body Ignition S/W ON 4-6

FI-45

gnMid

4 Cranking or running 2-4

vc - Body

Ignition S/W ON 4-6

groulld Fl-46.

No. 10 EOl

5 No. 20 - Ignition S;W CN 9 - 14 Fl-47

No. 30 E02

6 THA - E2 Ignition S/W ON Intake air temperature 20°C (68°F) 1 -3 FI-48

7 THW - E2 Ignition S/W ON Coolant temperature 80°C (176°F) 0.1 - 1 .O FI-49

8 STA - El Cranking 6-14 FI-50

9 IGF, IGT - El Idling 0.7 - 1.0 FI-5 1

10 IGdA, IGdB - El Idling 1-3 FI-52

11 I Cl

7 9 - 14 FI-53

ISC4 - El Ignition S/W ON

12 W - El No trouble (“CHECK ENGINE” warning light off) and

engine running 8 - 14 FI-54

13 A/C - El

14 HAC - E2 Air conditioning ON 10 - 14

FI-55

540 mmHg (21.26 in.Hg. 72.0 kPa) Approx. 2.8

Ignition S/W ON FI-56

750 mmHg (29.53 in.Hg, 100.0 kPa) Approx. 3.6

ECU Terminals

I U 1 I -

I

1

‘yc ‘;c GQ Gl G2 NE IGT IGF ~Hln, OX “;’ HT r;,

EGR SPD FPR THA HAC VC ‘JAn& 0 DF

‘;’ ‘sd: VF T VTA IDL

WA ““1” K;K E2 Ll L2 L3 NC W OIL ECT FC KS +B +Bl m

TIL LP

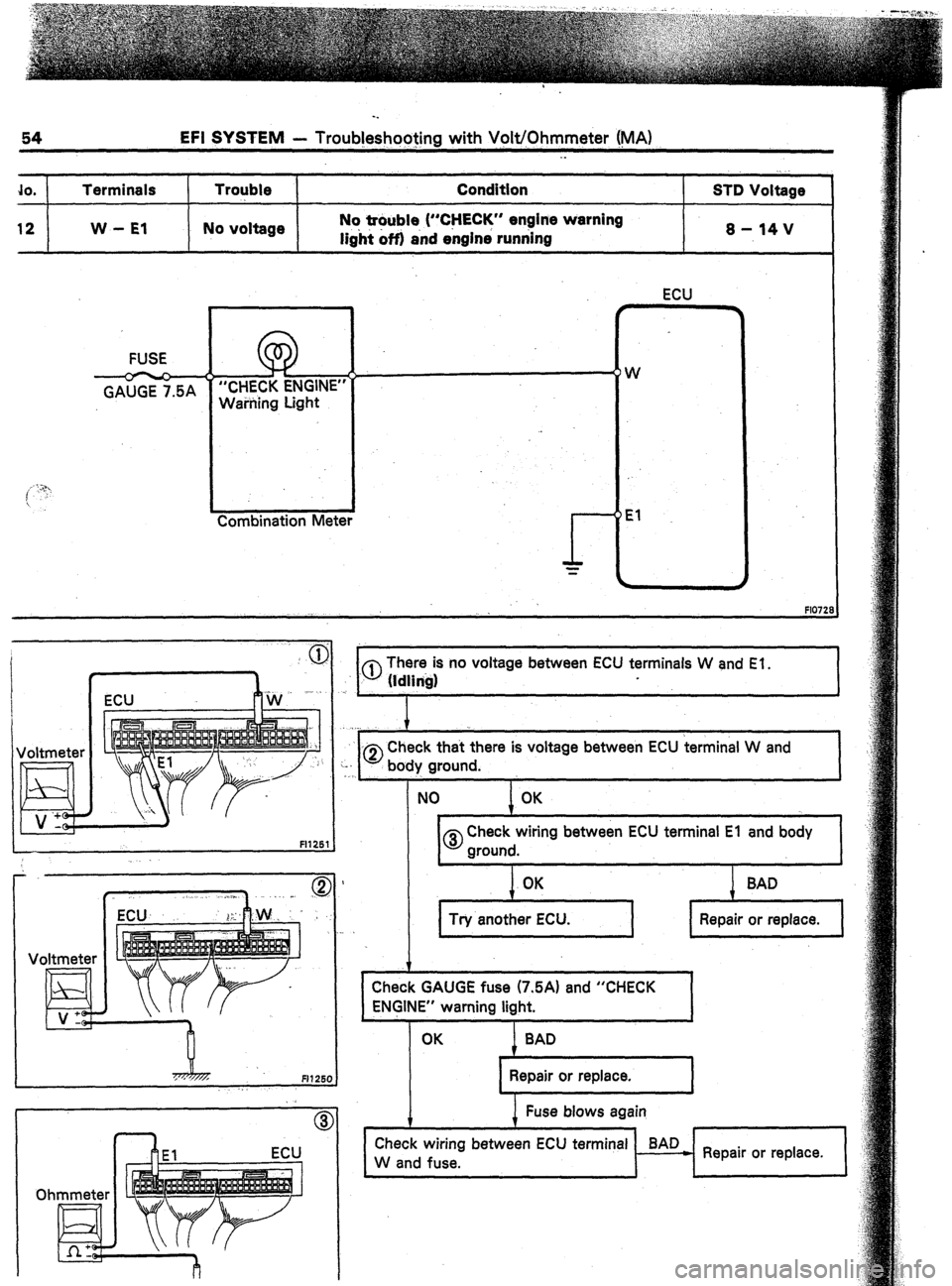

Page 88 of 346

EFI SYSTEM - Troub!eshoo$ng with Volt/Ohmmeter (MA)

. .

JO. Terminals

12 W - El Trouble

No voltage Condition

Nq @uble, (“CHECK” engine warning

light off) and engine running STD Voltage

s-14v

FUSE

GAUGE 7.5A

i

f “CHECK ENGINE”

Wahiing Light

Combination Mete W

El

FlO7

Joltmeter

EL v “_

Fl1251

1

Voltmeter

FH25C

. .

~0 There is no voltage between ECU terminals W and El.

(Idlin$

,

.

I 0

Check that there is voltage between ECU terminal W and

I

hod

Q;

0 Check wiring between ECU terminal El and body

Check GAUGE fuse (7.5A) and “CHECK

ENGINE” warning light.

I I

I Repair or replace.

I

1

Check wiring between ECU terminal BAD

*

W and fuse. Repair or replace.

I I

1 I

Page 91 of 346

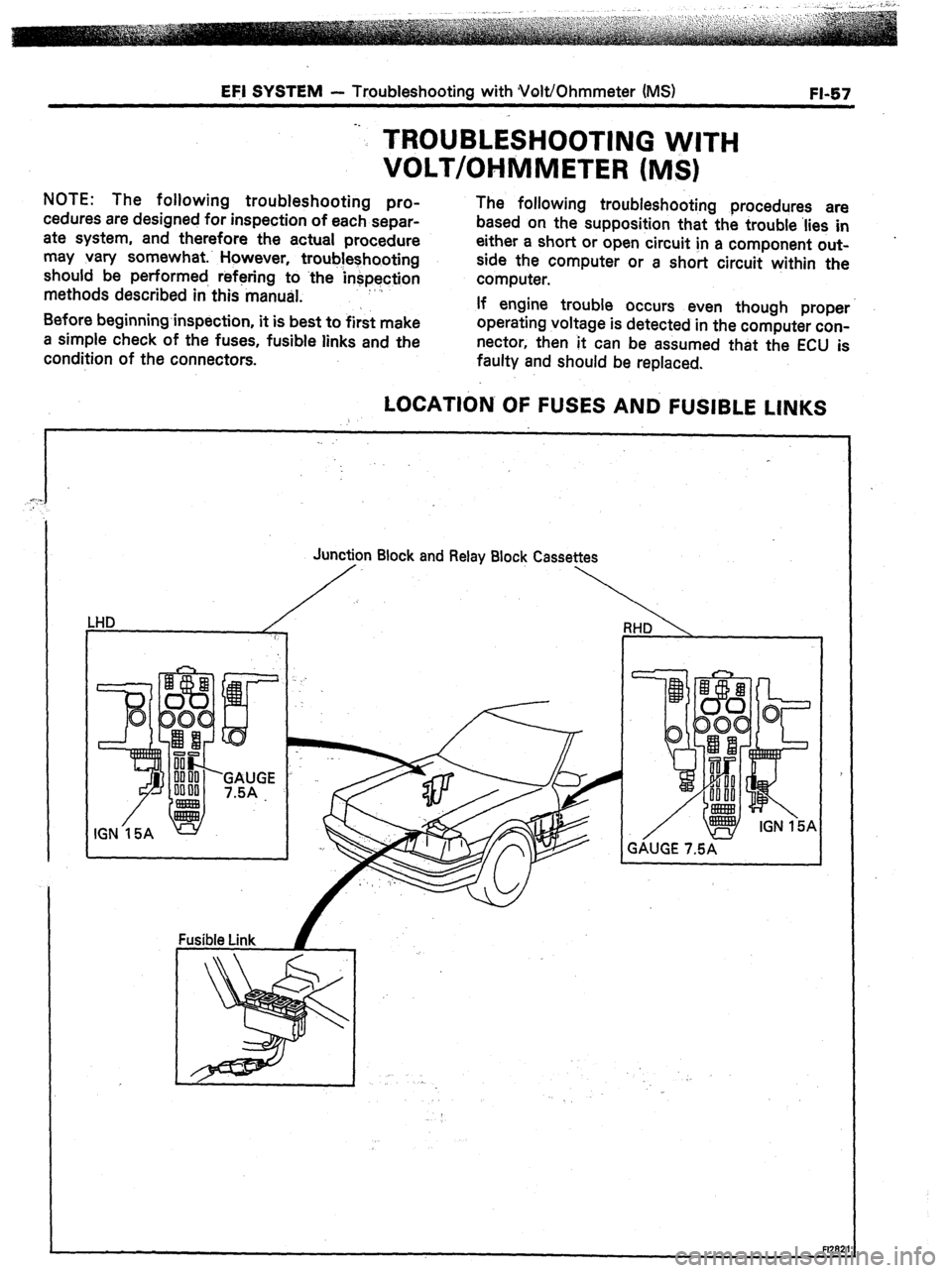

EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MS) FI-57

-.

TROUBLESHOOTING WITH

VOLT/OHMMETER (MS)

NOTE: The following troubleshooting pro-

cedures are designed for inspection of each separ-

ate system, and therefore the actual procedure

may vary somewhat.. However, troubleshooting

should be performed refering to .the inspection

methods described in this manual. .._

Before beginning,inspection, it is best to first make

a simple check of the fuses, fusible links and the The following troubleshooting procedures are

based on the supposition that the trouble ‘lies in

either a short or open circuit in a component out-

side the computer or a short circuit within the

computer.

If engine trouble occurs even though proper.

operating voltage is detected in the computer con-

nector, then it can be assumed that the ECU is

faulty and should be replaced.

LOCATIoN- OF FUSES AND FUSIBLE LINKS

condition of the connectors.

Junction Block and Relay Block Cassettes

Page 93 of 346

EFI SYSTEM - Ttpbleshooting with Volt/Ohmmeter (MS)

FL59

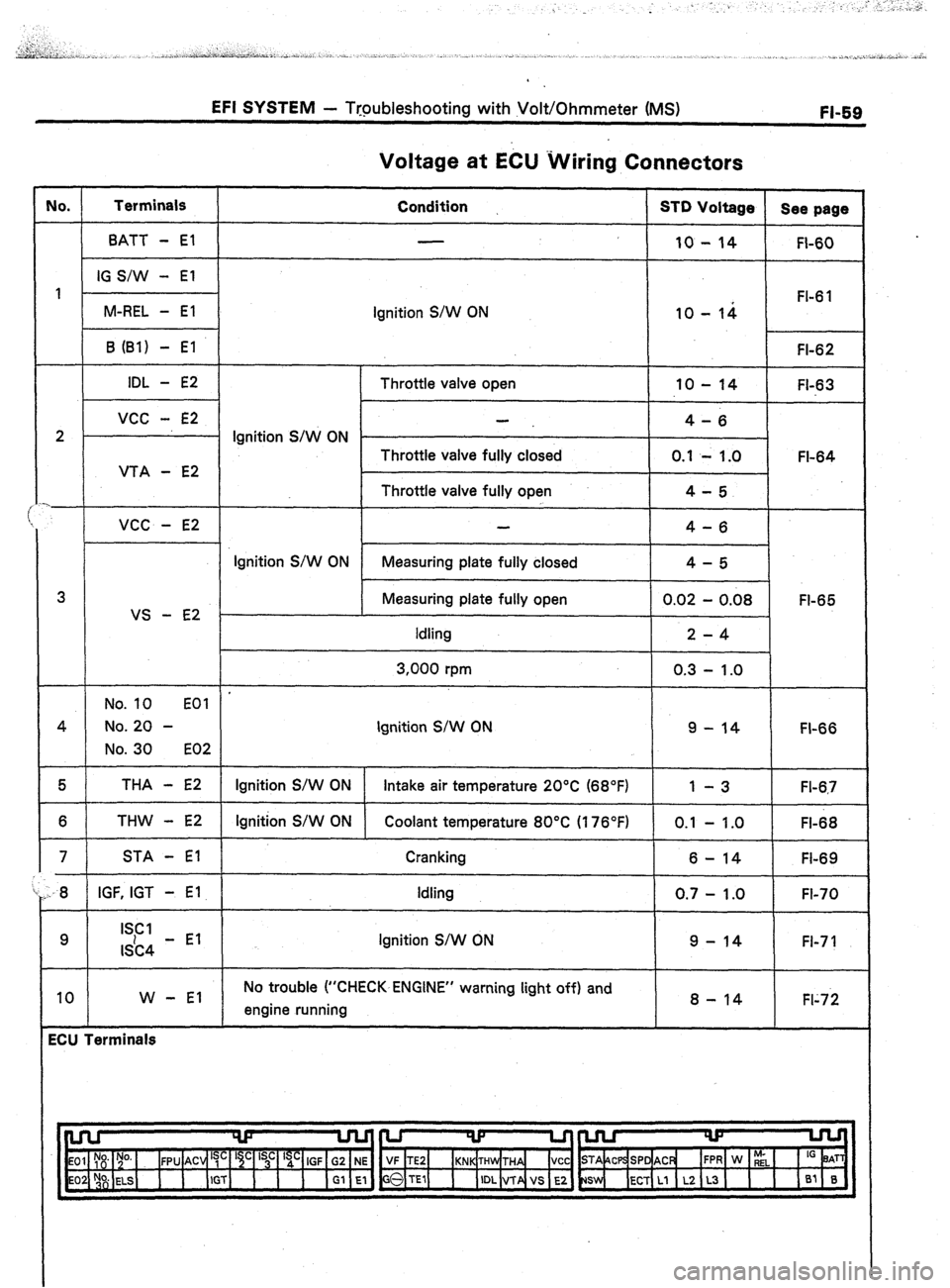

IO.

I Terminals

BATT - El

IG S/W - El

M-REL - El

2P-

I UTA - E2

3

US - E2

THA - E2

THW - E2

.B / IGF, IGT - El

9 ISCI

lSC4 - El

10

I W - El

ECU Terminals

Voltage at ECU Wiring Connectors

Condition STD Voltage ’

10 - 14

ignition S/W ON

10 - 14

Throttle valve open 10 - 14

4-6

Ignition S/W ON .

Throttle valve fully closed 0.1 - 1.0

Throttle valve fully open

4-5

4-6

Ignition S/W ON Measuring plate fully closed

4-5

Measuring plate fully open

0.02 - 0.08

Idling 2-4

3,000 rpm 0.3 - 1 .o

Ignition S/W ON 9

- 14 FI-66

Ignition S/W ON Intake air temperature 20°C (68°F) 1

-3

Ignition S/W ON

Coolant temperature 80°C (176°F) 0.1 - 1.0

Cranking

6 - 14

Idling 0.7 - 1.0

Ignition S/W ON

9 - 14

No trouble (“CHECK-ENGINE” warning light off) and

engine running 8 - 14 See page

FI-60

FI-6 1

FI-62

FI-63

FI-64

Fl-65

Fl-6.7

FI-68

FI-69

Fl-70

FI-7 1

Fl;72

Page 106 of 346

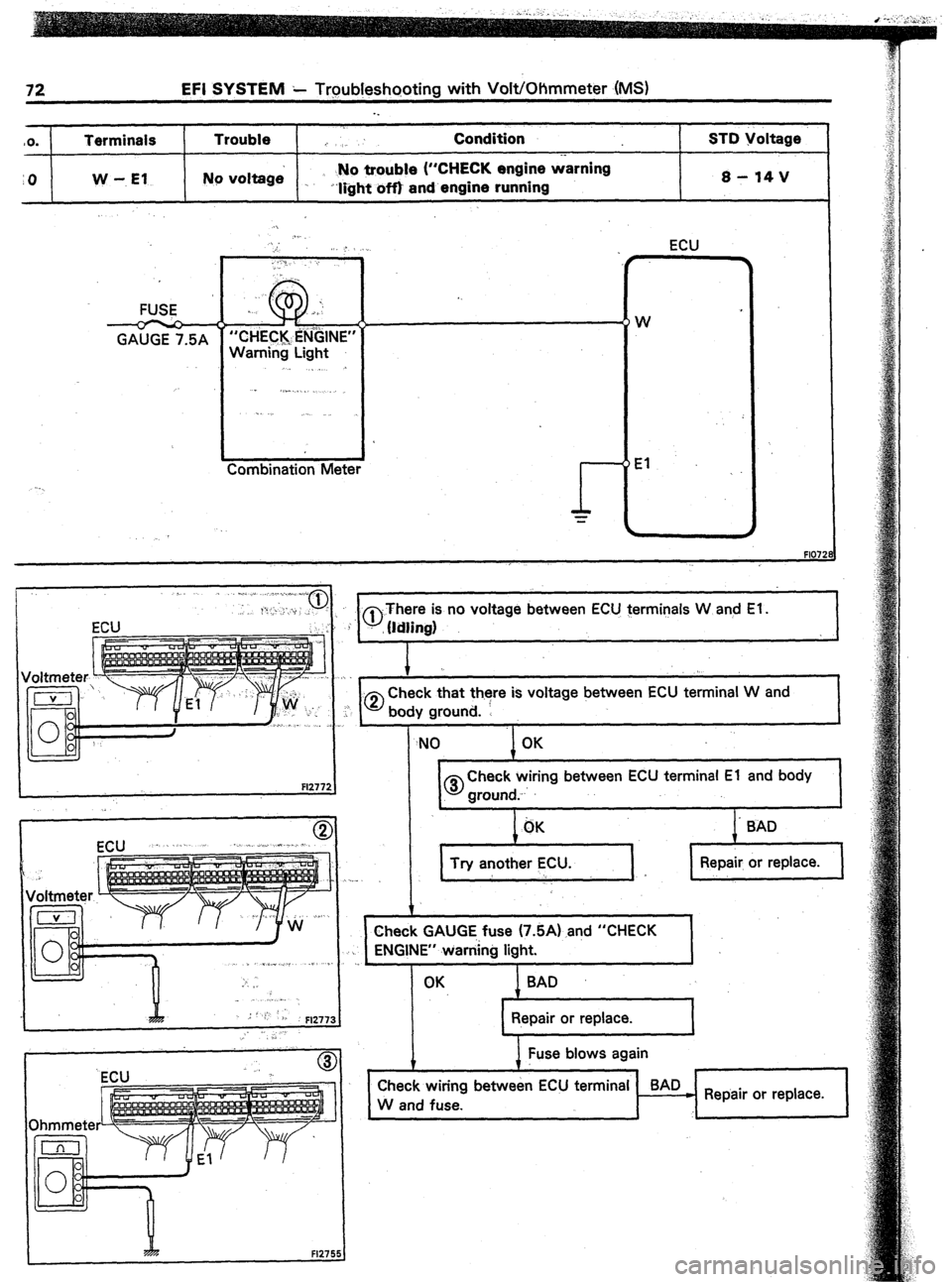

72 EFI SYSTEM ‘- Troubleshooting with Volt/Ohmmeter (MS)

40.

10 Terminals

W - El

. .

Trouble ,, Condition

No voltage _ No trouble (“CHECK engine warning

>‘Iight om and engine running STD Voltage

a-14v

. FUSE

GAUGE 7.5A

f$.; ..

w-im~~

S&INE-

Warning Light ECU

I

W

El

F12772

ECU

__

There is no voltage between ECU terminals W and El. !:, ;,:;:,p i, @

.,..I fldling)

1

,..

‘CD Check that there is voltage between ECU terminal W and

bodv around. ’ 1

_ -

I

NO OK

0 Check wiring between ECU terminal El and body

ground:..

*

OK BAD

Try another ECU.

I. Repair or replace.

: . i’ F1277

d% F12755

Check GAUGE fuse (7.5A) and “CHECK

~ ENGINE” warning light.

,. r

OK BAD

Repair or replace.

t Fuse blows again

Check wiring between ECU terminal

BAD

W and fuse. Repair or replace.

Page 108 of 346

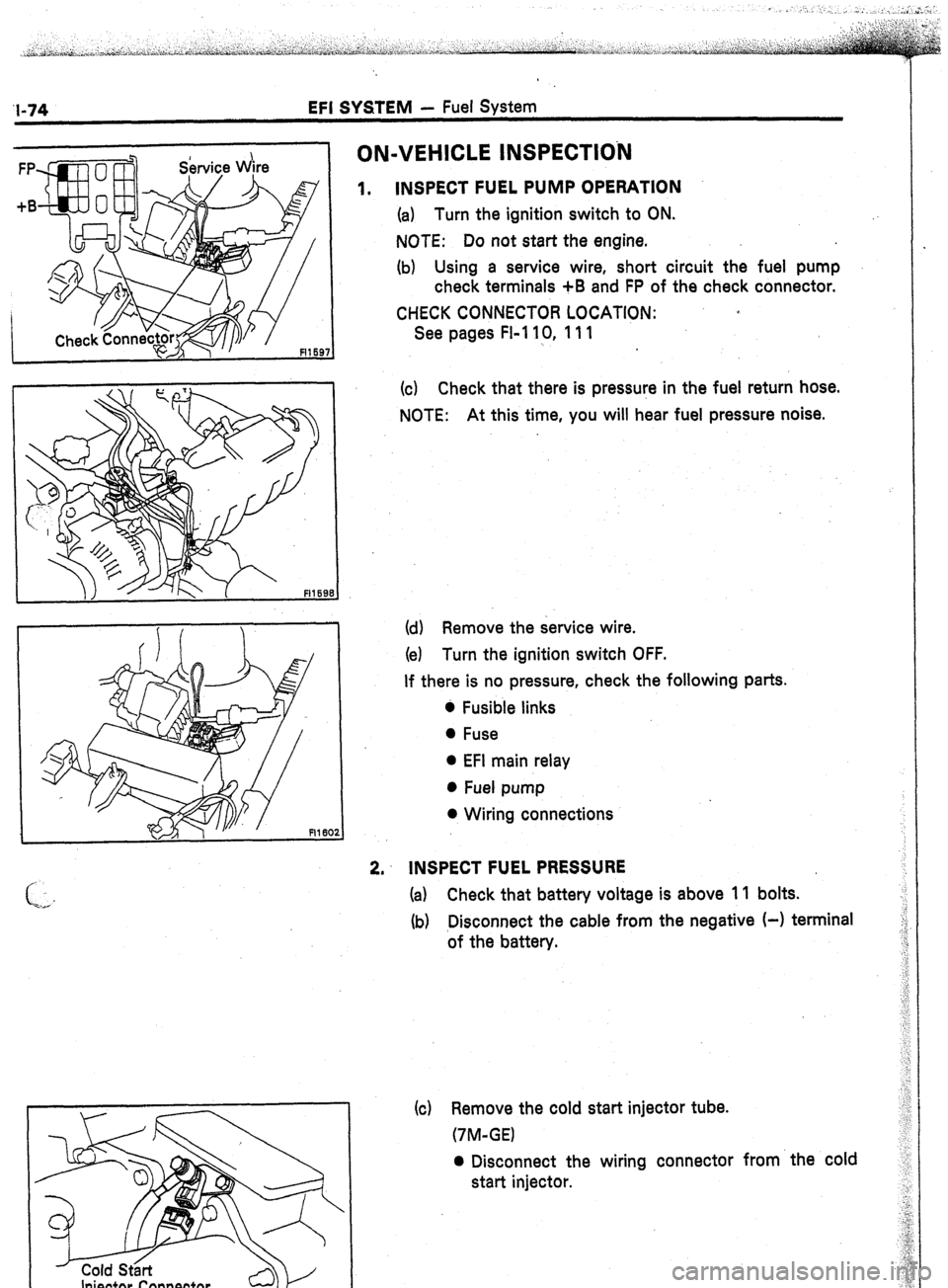

‘I-74 EFI SYSTEM - Fuel System

Fl169

ON-VEHICLE INSPECTlOiU

1.

INSPECT FUEL PUMP OPERATION

(a) Turn the ignition switch to ON. :

NOTE: Do not start the engine.

(b) Using a service wire, short circuit the fuel pump

check terminals +B and FP of the check connector.

CHECK CONNECTOR LOCATION:

See pages FI-1 10, 111

(c) Check that there is pressure in the fuel return hose.

NOTE: At this time, you will hear fuel pressure noise.

(d) Remove the service wire.

(el Turn the ignition switch OFF.

If there is no pressure, check the following parts.

i Fusible links

0 Fuse

0 EFI main relay

0 Fuel pump

0 Wiring connections

2. INSPECT FUEL PRESSURE

(a) Check that battery voltage is above 11 bolts.

(b) Disconnect the cable from the negative (-) terminal

of the battery.

(c) Remove the cold start injector tube.

(7M-GE)

0 Disconnect the wiring connector from the cold

start injector.

Page 110 of 346

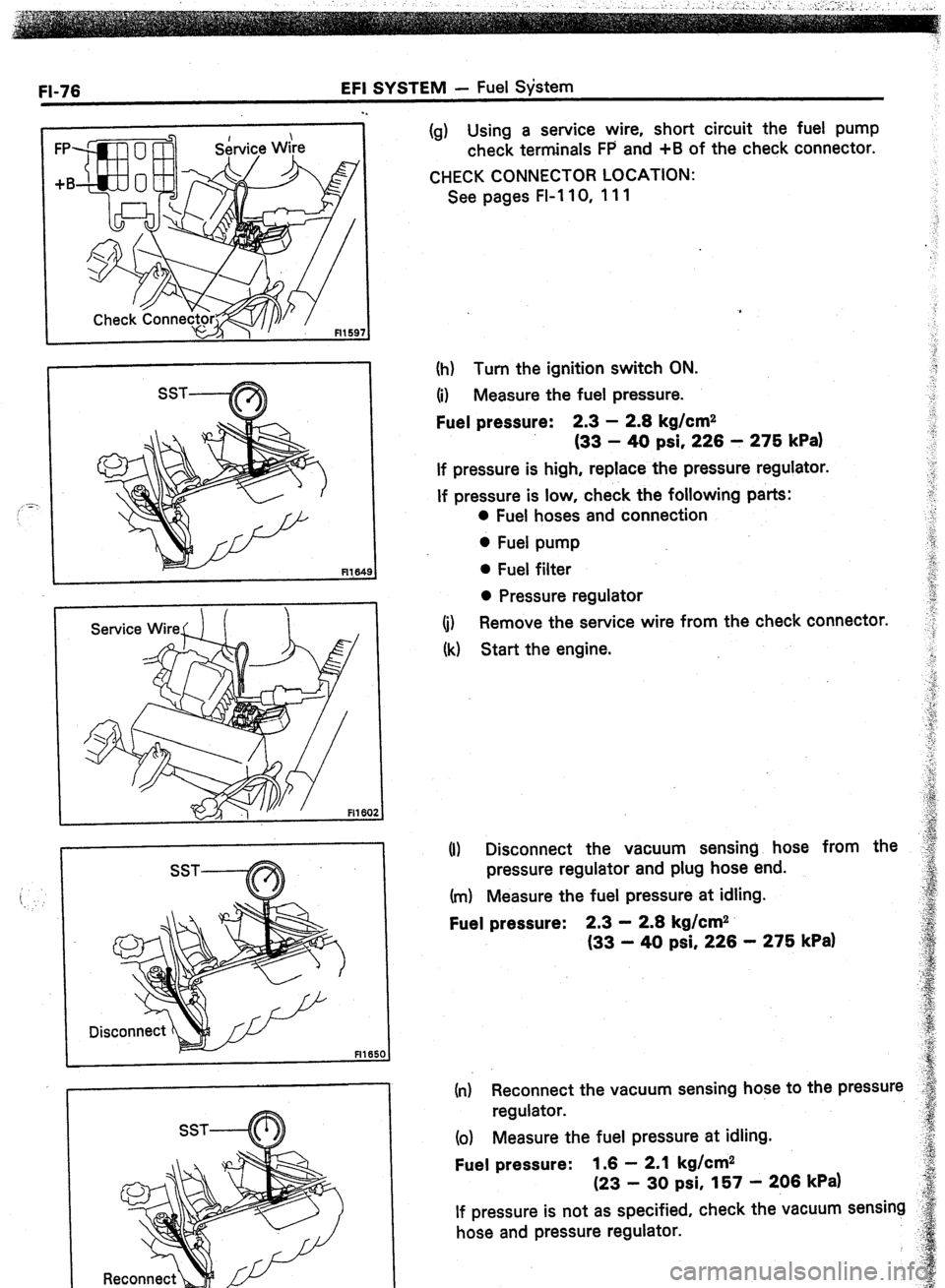

FI-76 EFI SYSTEM - Fuel S$stem

:’ ‘=-

r

Fl165

1

(g) Using a service wire, short circuit the fuel pump

check terminals FP and +B of the check connector.

CHECK CONNECTOR LOCATION:

See pages FI-110, 111

(h) Turn the ignition switch ON.

6) Measure the fuel pressure.

Fuel pressure: 2.3 - 2.8 kg/cm2

(33 - 40 psi, 226 - 275 kPa)

If pressure is high, replace the pressure regulator.

If pressure is low, check the following parts:

0 Fuel hoses and connection

0 Fuel pump

l Fuel filter

0 Pressure regulator

(j) Remove the service wire from the check connector.

(k) Start the engine.

(I) Disconnect the vacuum sensing hose from the

pressure regulator and plug hose end.

(m) Measure the fuel pressure at idling.

Fuel pressure: 2.3 - 2.8 kg/cm2

(33 - 40 psi, 226 - 275 kPa)

(r-r) Reconnect the vacuum sensing hose to the pressure

regulator.

10) Measure the fuel pressure at idling.

Fuel pressure: 1.6 - 2.1 kg/cm2

(23 - 30 psi, 157 - 206 kPa)

If pressure is not as specified, check the vacuum sensing

hose and pressure regulator.

Page 111 of 346

- Fiel System

FI-77

Fl199

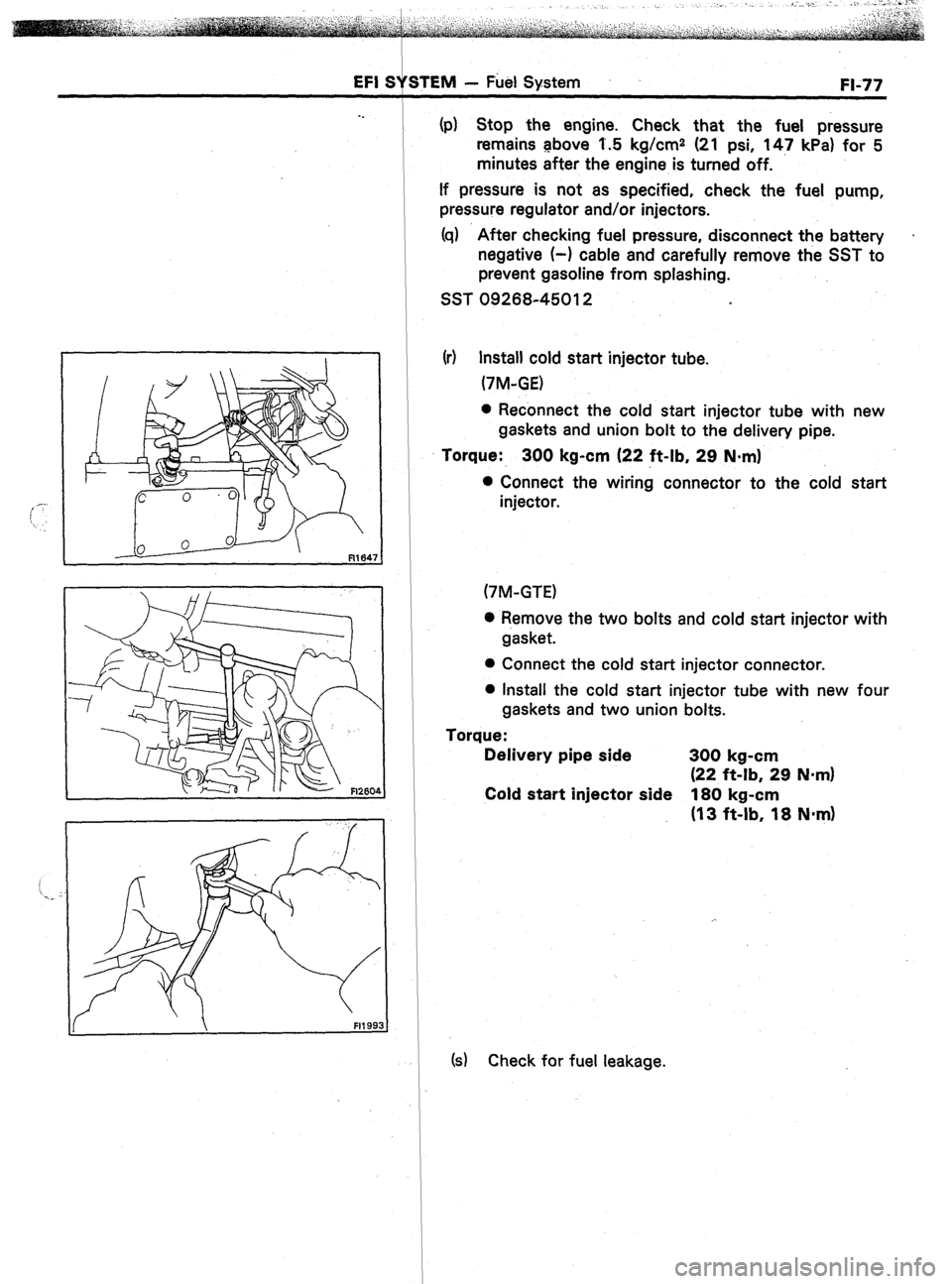

(p) Stop the engine. Check that the fuel pressure

remains above I.5 kg/cm2 (21 psi, 147 kPa) for 5

minutes after the engine is turned off.

If pressure is not as specified, check the fuel pump,

pressure regulator and/or injectors.

CqI After checking fuel pressure, disconnect the battery

negative (-1 cable and carefully remove the SST to

prevent gasoline from splashing.

SST 09268-45012

(r) Install cold start injector tube.

(7M-GE)

l Reconnect the cold start injector tube with new

gaskets and union bolt to the delivery pipe.

Torque: 300 kg-cm (22 ft-lb, 29 Nsm)

0 Connect the wiring connector to the cold start

injector.

(7M-GTE)

0 Remove the two bolts and cold start injector with

gasket.

0 Connect the cold start injector connector.

l Install the cold start injector tube with new four

gaskets and two union bolts.

Torque:

Delivery pipe side

300 kg-cm

(22 ft-lb, 29 N.m)

Cold start injector side 180 kg-cm

(13 ft-lb, 18 N.m)

(s) Check for fuel leakage.

Page 116 of 346

Fl-82 EFI SYSTEM - Fuel System

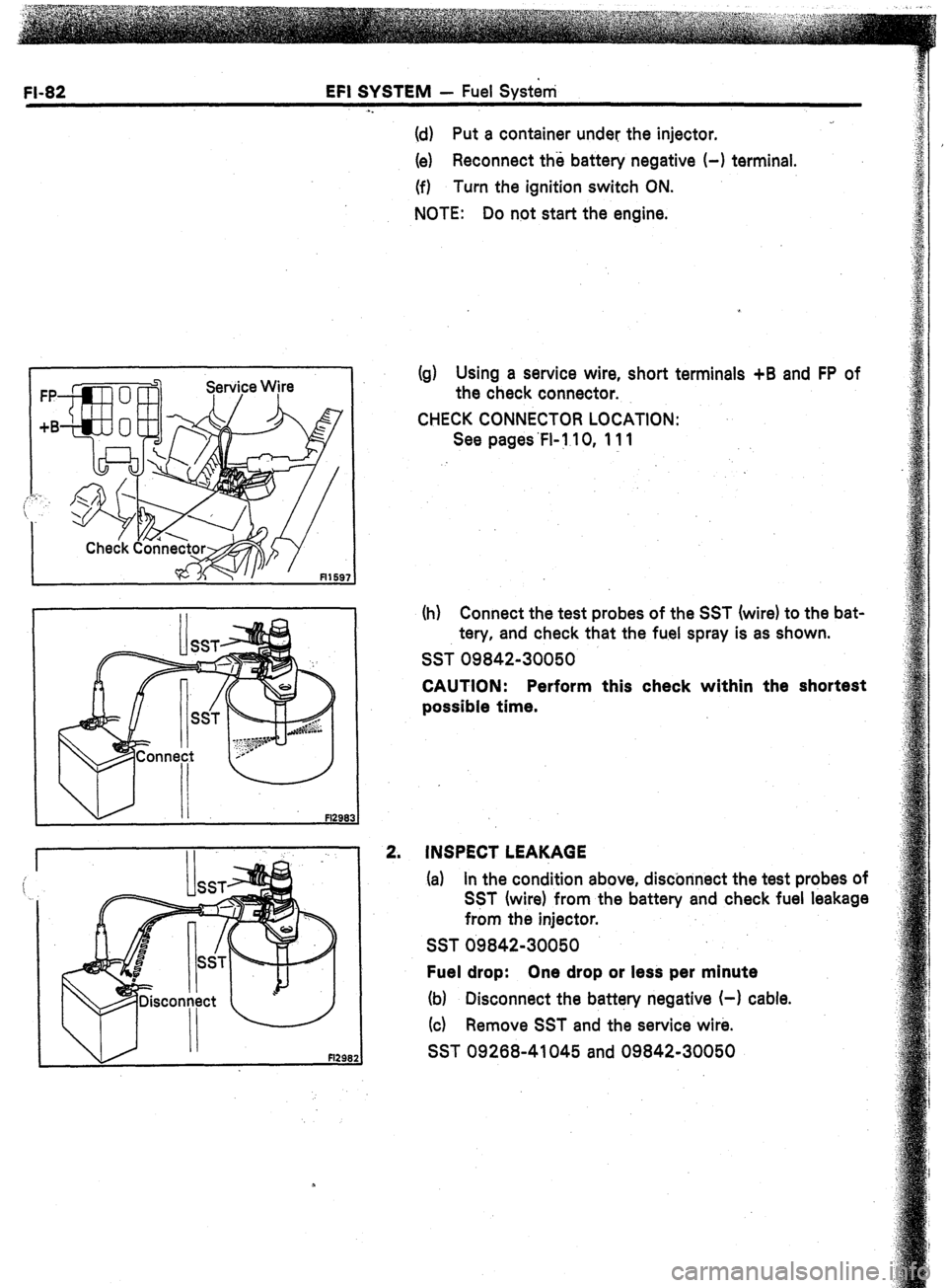

(d) Put a container under the injector.

(e) Reconnect the battery negative (-1 terminal.

(f) Turn the ignition switch ON.

NOTE: Do not start the engine.

Fl298:

!g) Using a service wire, short terminals +B and FP of

the check connector.

CHECK CONNECTOR LOCATION:

See pages ‘FI-j 10, 111

(h) Connect the test probes of the SST (wire) to the bat-

tery, and check that the fuel spray is as shown.

SST 09842-30050

CAUTION: Perform this check within the shortest

possible time.

2. INSPECT LEAKAGE

(a) In the condition above, disconnect the test probes of

SST (wire) from the battery and check fuel leakage

from the injector.

SST 09842-30050

Fuel drop: One drop or less per minute

(b) Disconnect the battery negative (-1 cable.

(c) Remove SST and the service wire.

SST 09268-41045 and 09842-30050