engine TOYOTA CELICA 1987 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 120 of 346

EFI SYSTEM - Fuel System

-.

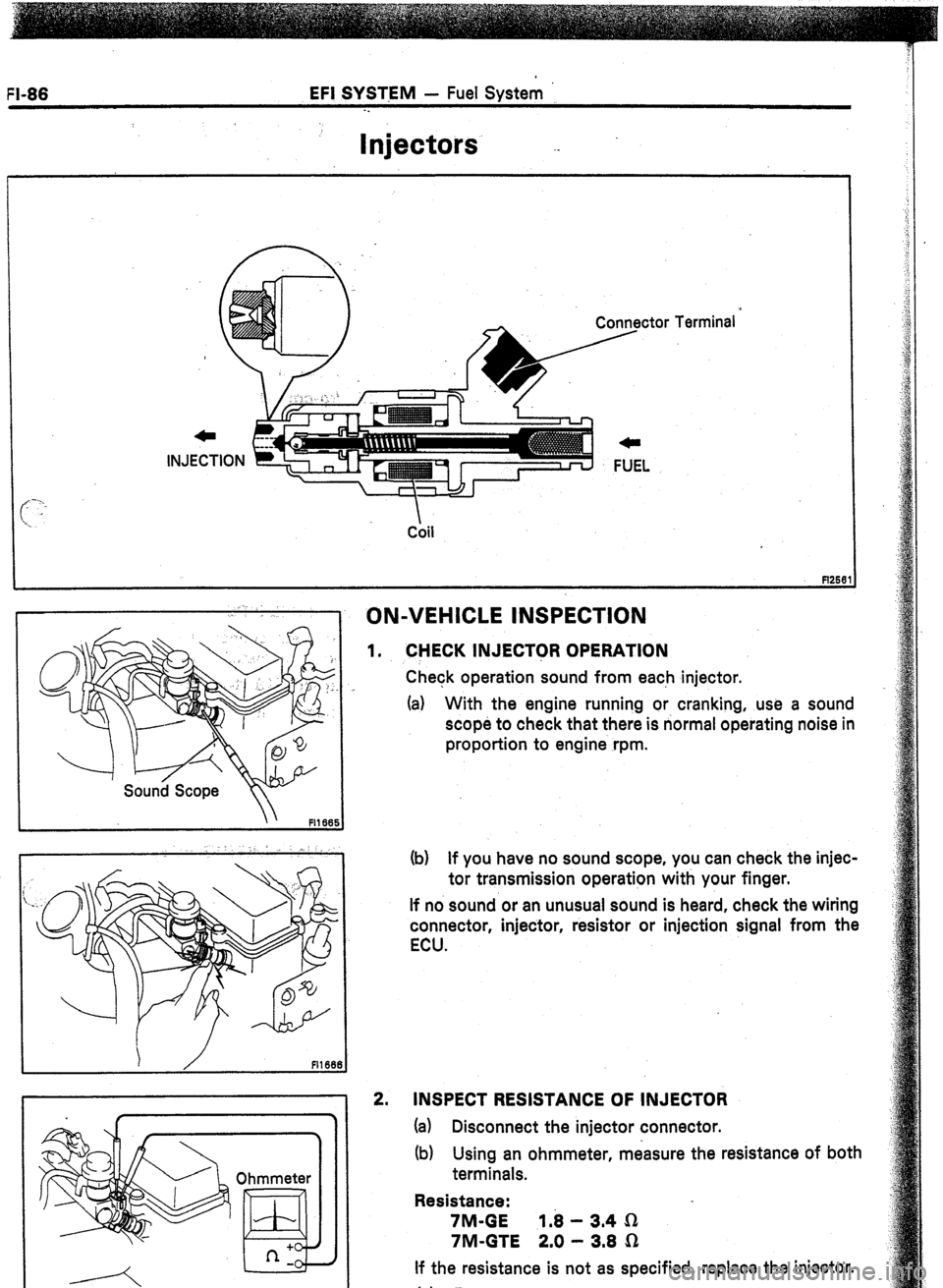

Injectors --

Coil

1 ON-VEHICLE tNSPkTlON

1.

2. CHECK INJECToR OPERATION

Check operation sound from each injector.

(a) With the engine running or cranking, use a sound

scope to check that there is normal operating noise in

proportion to engine rpm.

(b) If you have no sound scope, you can check the injec-

tor transmission operation with your finger.

If no sound or an unusual sound is heard, check the wiring

connector, injector, resistor or injection signal from the

ECU.

INSPECT RESISTANCE OF INJECTOR

(a) Disconnect the injector connector.

(b) Using an ohmmeter, measure the resistance of both

terminals.

Resistance:

7M-GE 1.8 - 3.4 n

7M-GTE 2.0 - 3.8 Q

If the resistance is not as specified, replace the injector.

(c) Reconnect the injector connector.

Page 136 of 346

EFI ,SY$TEM - Air Inducti& System

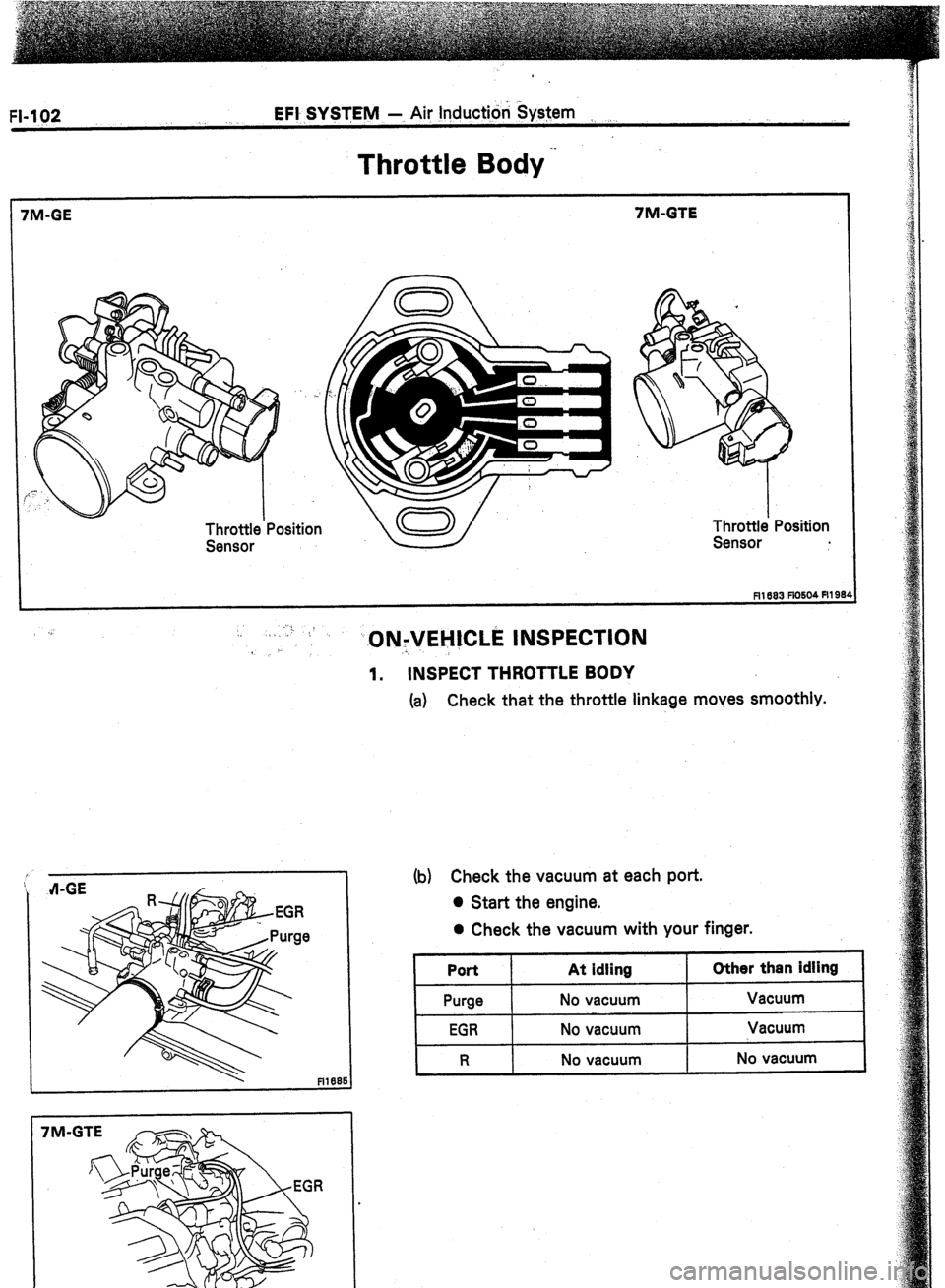

Throttle Body --

‘M-GE 7M-GTE

Throttle’Position

Sensor Throttle’ Position

fl1693 Flo504nl9f

.,.

,. ,F .,’

1 .ON:VEHtCLE INSPECTION

1. INSPECT THROTTLE BODY

(a) Check that the throttle linkage moves smoothly.

(b) Check the vacuum at each port.

0 Start the engine.

0 Check the vacuum with your finger.

Port

Purge

EGR

R

At idling

No vacuum

No vacuum

No vacuum

Other than idling

Vacuum

Vacuum

No vacuum

Page 142 of 346

FI-108 EFI SYSTEM - Air Induction System

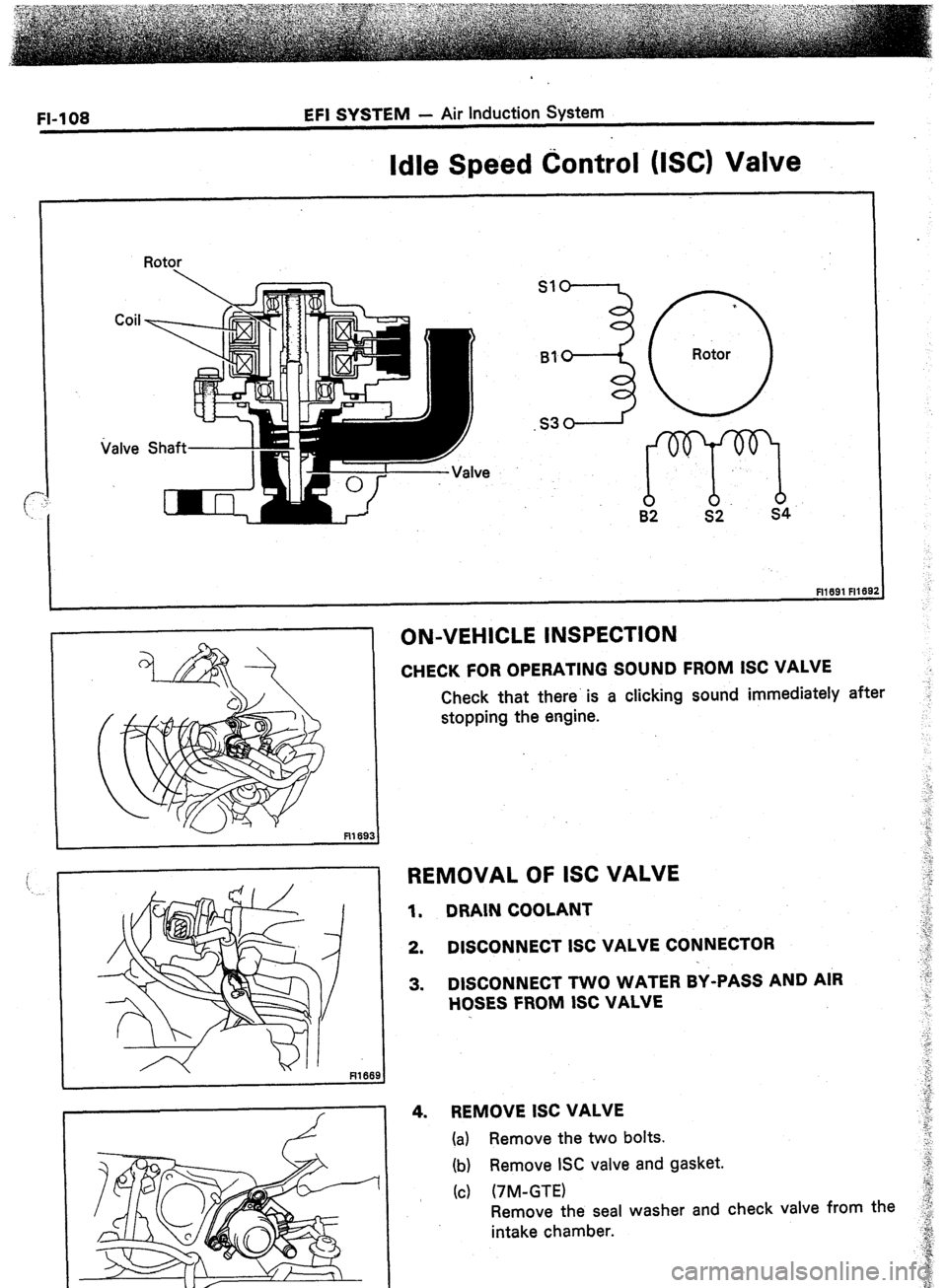

Idle Speed Control (EC) Valve

Rotor

Bl

Q-4

*

0

Rotor

m B2 s2. s4

Fll99lFH6.

,

ON-VEHICLE INSPECTION

CHECK FOR OPERATING SOUND FROM ISC VALVE

Check that there’ is a clicking sound immediately after

stopping the engine.

REMOVAL OF ISC VALVE

1. DRAIN COOLANT

2. DISCONNECT ISC VALVE CONNECTOR

3. DISCONNECT TWO WATER BY-PASS AND AIR

HOSES FROM ISC VALVE

4. REMOVE ISC VALVE

(a) Remove the two bolts.

(b)

Remove ISC valve and gasket.

(cd (7M-GTE)

Remove the seal washer and check valve from the

intake chamber.

Page 156 of 346

22 EFI &STEM - Electronic Control S&m

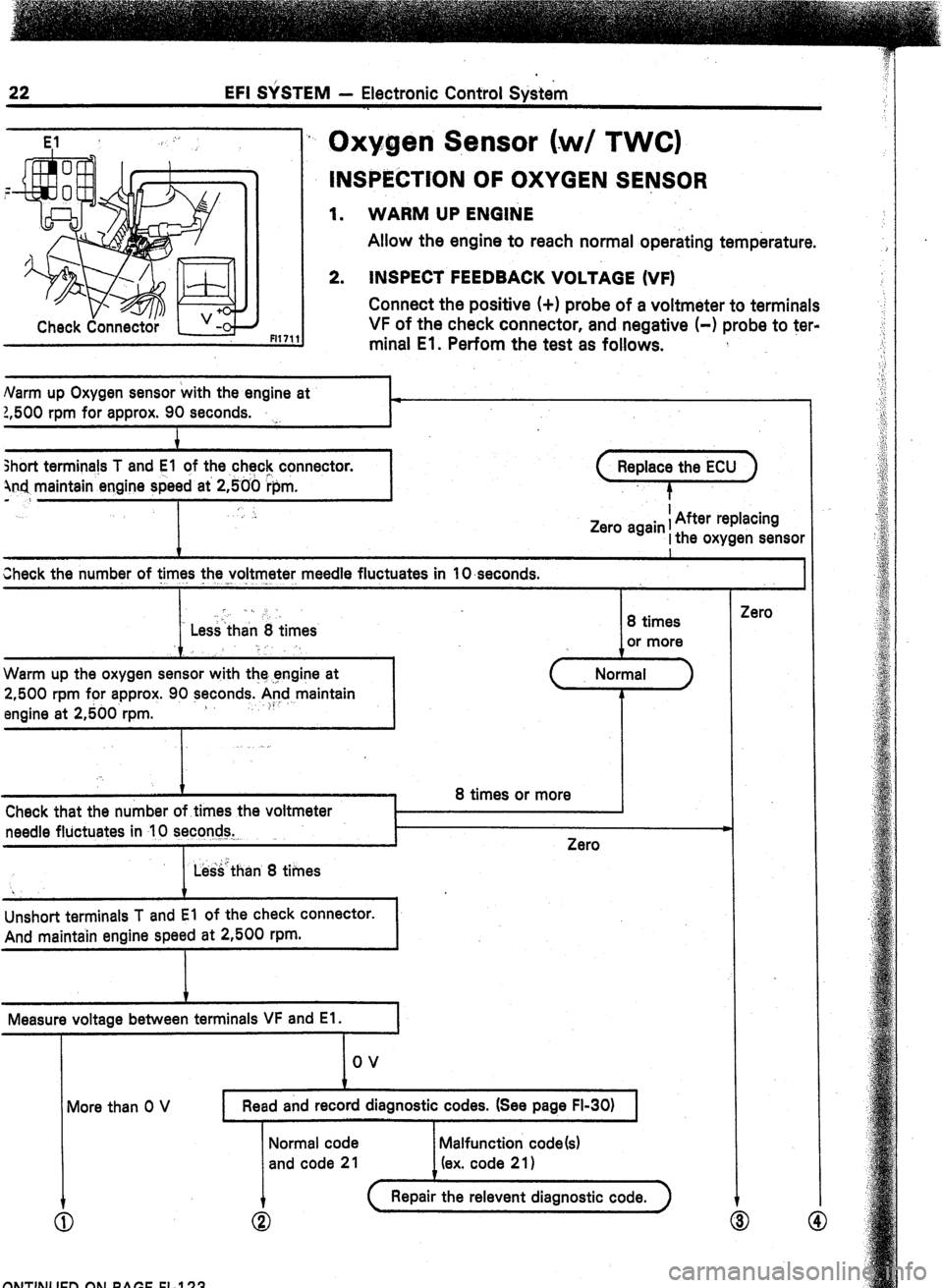

El 7 Oxygen S,ensor (-WI TWC)

INSPECTrON OF OXYGEN SENSOR

1. WARM UP ENGINE

Allow the engine to reach normal operating temperature.

2. INSPECT FEEDBACK VOLTiGE (VFI

Connect the positive (+I probe of a voltmeter to terminals

n1711 VF of the check connector, and negative (-1 probe to ter-

minal El. Perfom the test as follows.

Narm up Oxygen sensor ‘with the engine at

!,500 rpm for approx. 90 seconds.

I

1

short termina!s T and El of the check connector.

4nd maintain engine speed at 2,560 ‘i-pm.

- / (,,,;,,.,,,,

i .

Check the number of times the voltmeter meedle fluctuates in 1 Oseconds. Zero again 1 After replacing

I the oxygen sensor

i ,. ., ;

: . .

Less than 8 times

t. ., .,

Warm up the oxygen sensor with the engine at

,,I

2,500 rpm for approx. 90 seconds. And maintain

engine at 2,500 rpm.

’

I

c

Check that the number of times the voltmeter

needle fluctuates in 10 seconds,

;- 8 times or more

Zero

Leis’~than 8 times

c

Unshort terminals T and El of the check connector.

And maintain engine speed at 2,500 rpm.

Measure voltaae between terminals VF and El.

I

More than 0 V t

Read and record diagnostic codes. (See page FI-30)

I I

Normal code

and code 21 Malfunction code(s)

(ex. code 21)

Repair the relevent diagnostic code.

ONTINUED ON PAGE FI-123 !ero

Page 157 of 346

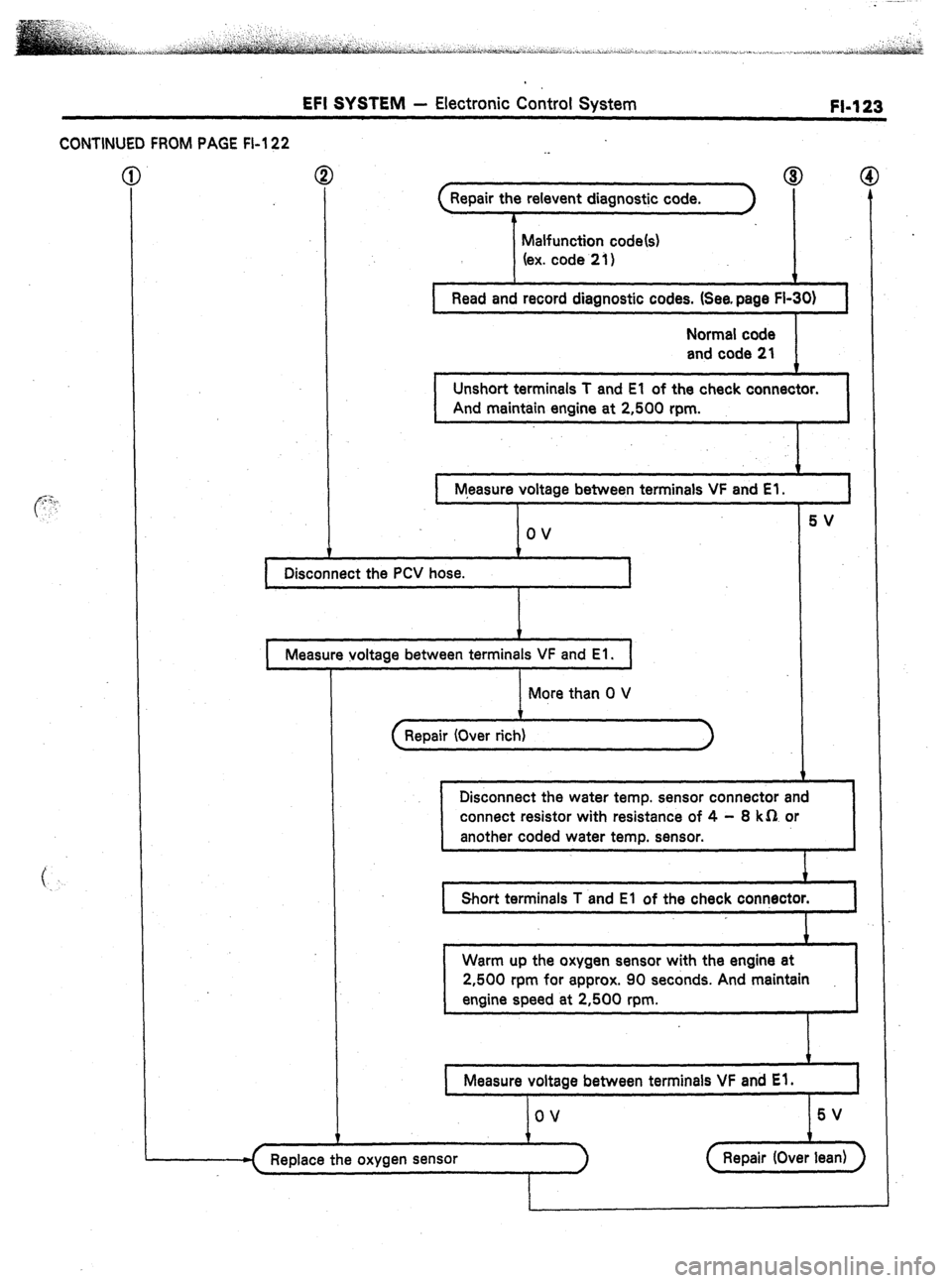

EFI SYSTEM - Electronic Control System FI-123

CONTINUED FROM PAGE FI-122

. .

t

8 (

epair the relevent diagnostic code.

Malfunction code(s)

(ex. code 21)

Read and record diagnostic codes. (See.page FL30)

Normal code

and code 21

t

Unshort terminals T and El of the check connector.

And maintain engine at 2,500 rpm.

I

I

M,easure voltage between terminals VF and El.

ov

t

1

Disconnect the PCV hose.

.

1 Measure voltage between terminals VF and El. 1

t

Replace the oxygen sensor Repair (Over lean) 5V

Disconnect the water temp. sensor connector and

connect resistor with resistance of 4 - 8 kS1 or

another coded water temp. sensor.

1

Short terminals T and El of the check connector.

I

I

Warm up the oxygen sensor with the engine at

I

1 2,500 rpm for approx. 90 seconds. And maintain 1

engine speed at 2,500 rpm.

Measure voltage between terminals VF and El.

I

I 5V

Page 160 of 346

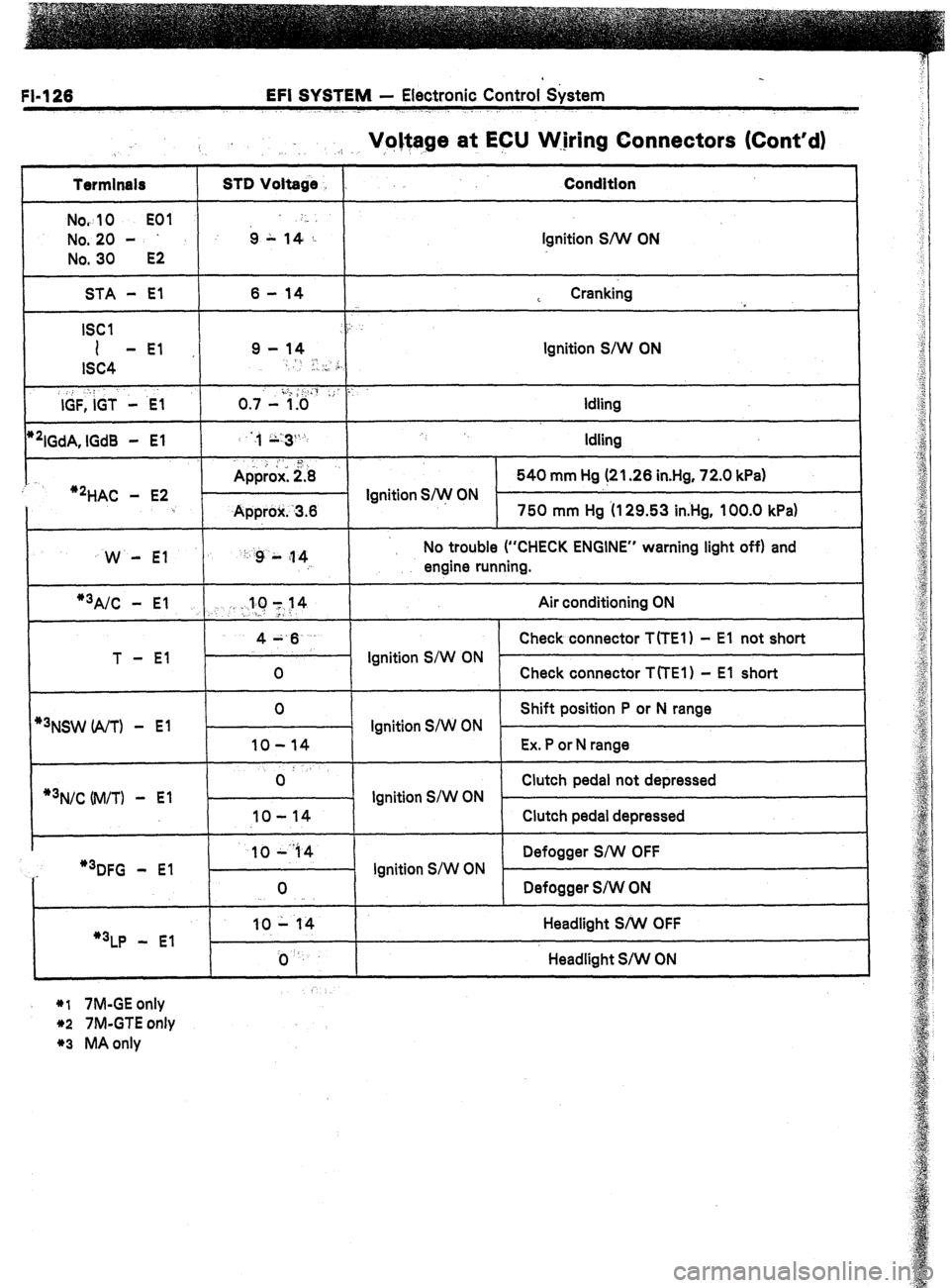

FI-126 EFI SYSTEM - Electronic Control &stem

Voltage at ECU W.jring Connectors (Cont’d)

.:. .I, ,,

Termlnals

Nov

10 EOI

No. 20 -

No. 30

E2

STD Voltage

6 L ,4-,: Condition

Ignition S/W ON

STA - El

ISCI

I -El

ISC4

,, : :

IGF, IGT - .E-1

*‘IGdA, lGd8 - El

:

‘2HAC - E2 6 - 14

9 - 14

-

I, .., ,i,

o .,.- i.;&& ,; ::

:,, ;;:3%

. . 1

Approx: 2.8

- Ignition S/w ON

Approlr. -3.6 L Cranking

,

Ignition S/W ON

Idling

Idling

540 mm Hg (21.26 in.Hg, 72.0 kPa)

750 mm Hg (I 29.53 in.Hg, 100.0 kPa)

W - El ‘: :g L ;I 4

: No trouble (“CHECK ENGINE” warning light off) and

engine running.

1

*3A/C - El .,. . :.llC 1~14 Air conditioning ON

>-

T - El 4A.6

Check connector T(TE1) - El not short

Ignition S/W ON

0 Check connector TfTEl) - El short

*3NSW (A/T) - El

*3N/C Uvl/TI -

El 0

Shift position P or N range

Ignition S/W ON

IO-14 Ex. P or N range

0: Clutch pedal not depressed

- Ignition S/W ON .

IO-14 Clutch pedal depressed

..-

I 1044 1 1 Defogger S/W OFF

I

“3DFG - El

“3LP - El 0

10 - 14

j) ‘. Ignition S/W ON

Defogger S/W ON

Headlight S/W OFF

Headlight S/W ON

*I 7M-GE only

*2 7M-GTE only

*3 MA only

Page 162 of 346

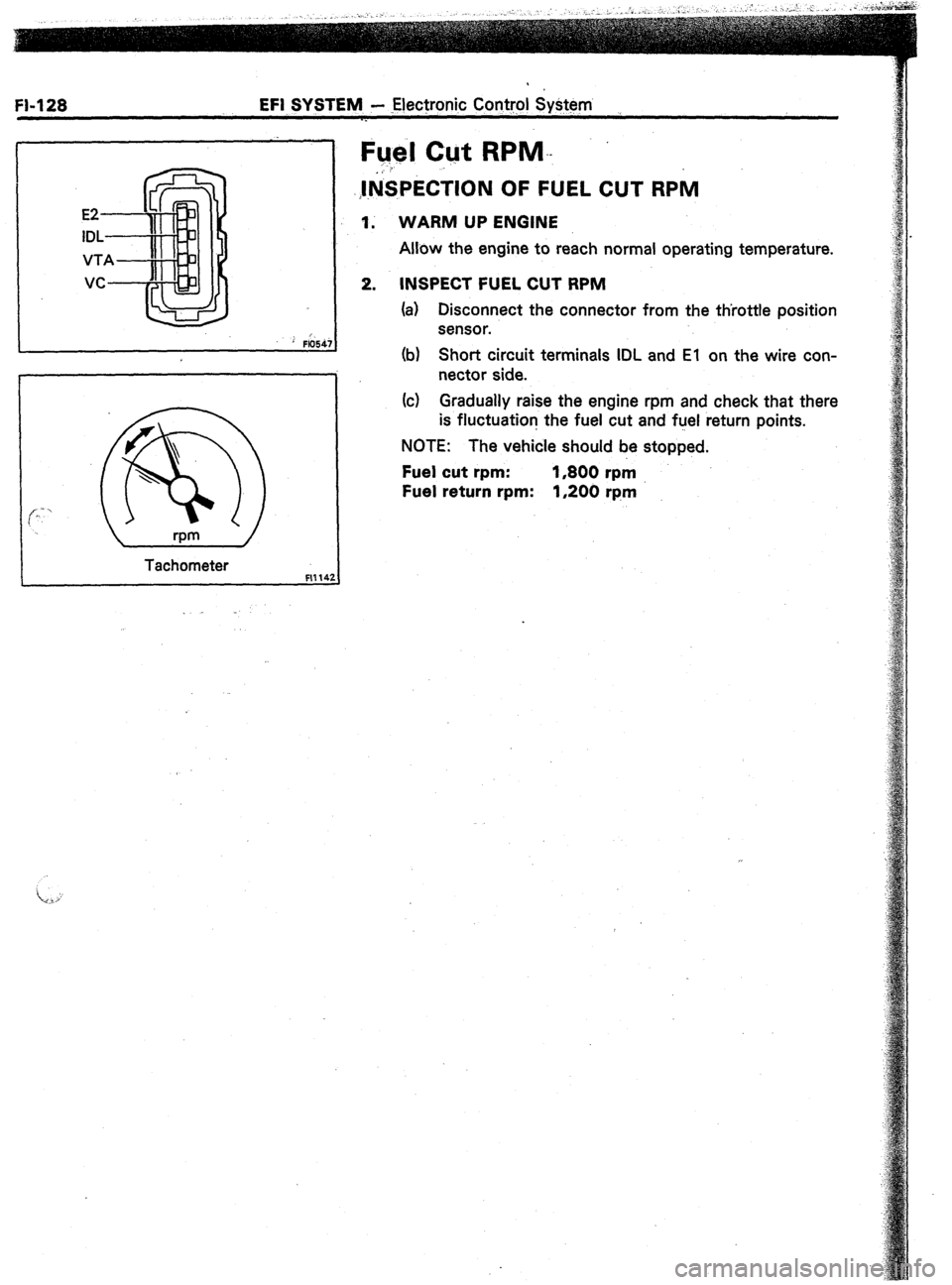

Fl-128 EFI SYSTEM - Electronic Contpl SyStem

c

’ FlO54

Tachometer Fl114:

Fuel Cut RPM--

;INSPECTION OF FUEL CUT RPM

I.

2. WARM UP ENGINE

Allow the engine to reach normal operating temperature.

INSPECT FUEL CUT RPM

(a) Disconnect the connector from the throttle position

sensor.

(b) Short circuit terminals IDL and El on the wire con-

nector side.

(c) Gradually raise the engine rpm and check that there

is fluctuation the fuel cut and fuel return points.

NOTE: The vehicle should be stopped.

Fuel cut rpm:

1,800 rpm

Fuel return rpm: 1,200 rpm

Page 163 of 346

-.

EM-1

I

ENGINE MECHANICAL .’ ../_ :.

F&e.

DESCRIPTION

. . . ..1........111.......~....~.~ E+ -;.’

TROUBLESHOOTING

. . . . . . . . . . . . . . . . n . ma m I. I.

EM-4’ ”

ENGINE TUNE-UP

. . . . . . . . . . . . ..~......~.......

COMPRESSION CHECK

s e . . . . . . . . . . . . . , . . . . . . .

TIMING BELT

,,,..,....................*.*...

EM-28

CYLINDER HEAD

. . . . . . . . . . . . . . ..*............

EM-37

CYLINDER BLOCK

1”1......1...............,..

EM-66

Page 164 of 346

EM-2

ENGINE MECHANICAL - Description

-.

DESCRl.PTlON _

.-. ..‘. /,.

: --

+..>r:*. ,, .,. 2 ,-,. j . .:..,. .-

The 7M-GE and 7M-GTE engines are an in-line 6-cylinder 3.0 titer DOHC 24 valve engine. i

‘M:G.E. (MA)

..

: _

7M-GE (MS)

7M-GTE

Page 165 of 346

ENGINE MECHANICAL -, Description

EM-3

The 7M-GE, 7M-GTE engines are an in-line 6-

cylinder engine with the cylinders numbered l-2-

3-4-5-6 from the front. The crankshaft is sup-

ported by 7 bearings specified by the inside of the

crankcase. These bearings are made of kelmet.

.The crankshaft is integrated with 8 weights

which are cast along with it for balancing. Oil holes

‘are built into the crankshaft for supplying oil to the

connecting rods, pistons and other components.

These engine’s ignition order is l-5-3-6-2-4 .

The cylinder head is made of aluminum alloy, with

a cross flow type intake and exhaust layout and

with pent roof type combustion chambers. The

spark plugs are located in the center of the com-

bustion chambers.

Exhaust and intake valves are equipped with

irregular pitch springs with symmetrical ends

made of oil tempered silicon chrome steel wire

which are capable of following the valves even at

,high engine speeds.

Both the exhaust side cam shaft and the. intake

side cam shaft are driven by a single timing belt.

The cam journal is supported at 7 places between

the valve lifters of each cylinder and on the

cylinder head of front end. Lubrication of the cam

journal and cam is accomplished by oil being sup-

plied through the oiler port in the center of the

camshaft.

Adjustment of the valve clearance is done by

means of an outer shim type system, in which

valve adjusting shims are located above the valve

lifters. This permits replacement of the shims

without removal of the camshafts.

The resin timing belt cover is made in 2 pieces.

Pistons are made of highly temperature-resis-

tant aluminum alloy, and depressions are built into

the piston head to prevent interference with

valves.

Piston pins are the full-floating type, with the

pins fastened to neither the piston boss nor the

connecting rods. Instead, snap rings are fitted on

both ends of the pins, preventing the pins from

falling out.

The No. 1 compression ring is made of stainless

steel and the No. 2 compression ring is made of

cast iron. The oil ring is made of a combination of

stainless steel. The outer diameter of each piston

ring is slightly larger than the diameter of the

piston

and the flexibility of the rings allows them

to hug the cylinder walls when they are mounted

on the piston. Compression rings No. 1 and No. 2

work to prevent the leakage of gas from the

cylinder and the oil ring works to scrape oil off the

cylinder walls to prevent it from entering the com-

bustion chamber.

The cylinder block is made of cast iron. It has 6

cylinders which are approximately 1.6 times the

length of the piston stroke. The top of the cylin- ders is closed off by the cylinder head and the

lower end of the cylinders becomes the crankcase,

in which the crankshaft is installed. In addition,- the

cylinder block contains a water jacket, through

which coolant is pumped to cool the cylinders.

The .oil pan is bolted onto the botiom of the

cylinder block. The oil pan is an oil reservoir made .

of pressed steel sheet. A dividing plate’is included

-inside the oil pan to keep sufficient oil in the bot-

tom of the pan even when the vehicle is tilted. This

dividing plate also prevent5 the oil from making

waves when the vehicle is stopped suddenly and

thus shifting the oil away from the oil pump suc-

tion pipe.