TOYOTA HIGHLANDER 2001 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2001, Model line: HIGHLANDER, Model: TOYOTA HIGHLANDER 2001Pages: 2572, PDF Size: 34.8 MB

Page 271 of 2572

2005 HIGHLANDER (EWD592U)

90

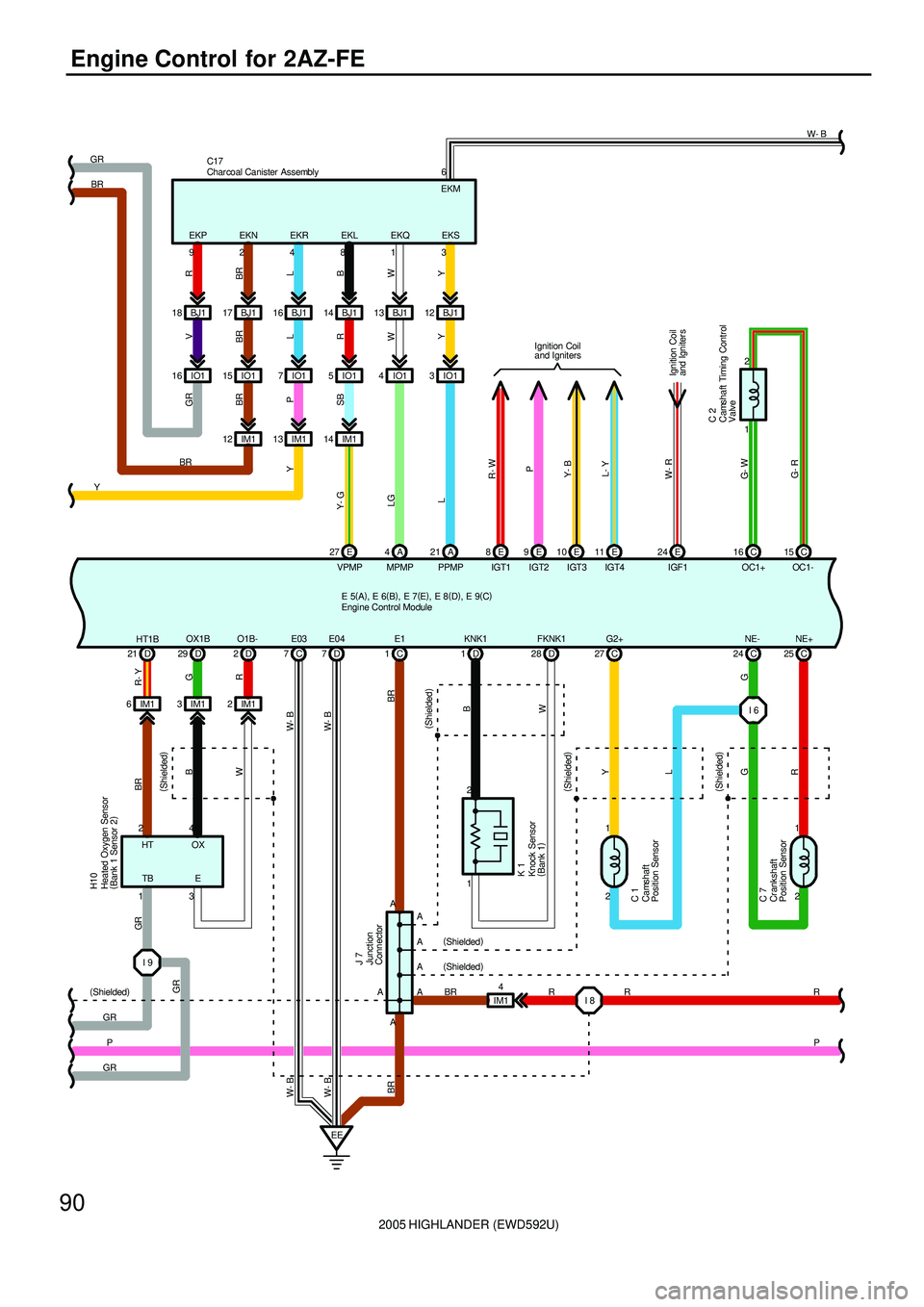

Engine Control for 2AZ-FE

15

27 13 IM1

Y- G

VPMP

IM14

J 7V

Y

14 16 IO1 3 IO1

WR

L

4IO1 BJ1 17

BR

IM1

L P BR

21

L

PPMPA A

MPMP

LG

4 IM1 12IO1 5 IO1

A

YGR

L BR

B

W

Y R

1 E BR

Y GR

BRC17

SB

1

W

D 7IO1

Ignition Coil

and Igniter s

93

Ignition Coil

and Igniters

28 O1B-13

Y (

Shielded)

1

R

8

IM1

G R- Y

W

14 18

H10

2 24

D 225 C 24 C 27 C 1D BJ1 BJ1(

Shielded)

4 2D 21 D29

3 1

B BR GR

BJ1 12 BJ1

(

Shielded)(

Shielded)

1

2 1

2

EE

G

GR

C 7 C 1

2B

R FKNK1

G

R

R 16

HT1BOX1B KNK1 G2+ NE- NE+

I 6 3IM1 6IM1IGT1

Y- B

IGF1

R- W

IGT2

P

IGT3

W- R

24 E 11 E 10 E 9E 8E BJ1

IGT4

L- Y

D 7 7C

W- B W- B

E03 E04 E1

C

BR

1 2

C 16 C15

G- W

G- R

OC1+ OC1-

C 2

P (

Shielded)

I 8 R BR A

A

A

A

A

P A(

Shielded)

(

Shielded)

BR W- B W- B

I 9

GR

GR

6W- B

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C)

Camshaft

Position Sensor

Camshaft Timing Control

Valve

Cr ankshaft

Position Sensor

Char coal Canister Assembly

Engi ne Control Module

Heated Oxygen Sensor

(

Bank 1 Sensor 2)

Junction

Connector

EKP EKN EKR EKL EKQ EKSEKM

HT OX

TB E

Knock Sensor

(

Bank 1) K 1

Page 272 of 2572

2005 HIGHLANDER (EWD592U)

91

S15

C 224L 3

B Y- B

O 1

A 292

BR

EPA2 EPA2

12

1+BM

W

B 6A27

VPA2

VPA2

W

210A

ETCS

3

23 A

MOPS

R 4M

A A

B

GY

17 31 24TRC-

C 10

17E 20A

STOP

1E 1

E 6

P 2

TRC+ 1 2

A

Y BR R- L

W- B W- B

E02 E01 PSW

25 STPB 19

EFNEO

V

2

2

E 16

NSW

B- R

E 17

STA

B

54

NP7. 5A

STARTER

EB2 3

E 7

B- R L B- R P 1

R

P PENG+

A30

R

ENG-

A

Skid Control ECU

with Actuator

W- B W- B

A 271

L

VCP2 VCP2

A 285

R

EPA EPA

A 226

B

VPA VPA

A 264

G

VCPA VCPA

B 27

B

IMI

B 26

V

IMO

EFIO EFII67

T1 4 2

IC1 4

R

4C

W- B

ME01

I 6

W- G

G 14C 21RL

L W- BW- B

NC- NC+ NT- NT+

W- GY R- WWT 3

C 6

D 261

2

D 34 35 D 2 1

27 D

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C) Fr om Power Source System (

See Page 62)

Accel Position Sensor

Counter Gear Speed

Sensor

Engi ne Control Module

Gen erat or

Oil Pressur e SWPark/Neutral

Position SW

Power Steering Oil

Pressure SW

Stop Light SW

Turbine Speed Sensor

Transponder Key Computer

Page 273 of 2572

2005 HIGHLANDER (EWD592U)

92

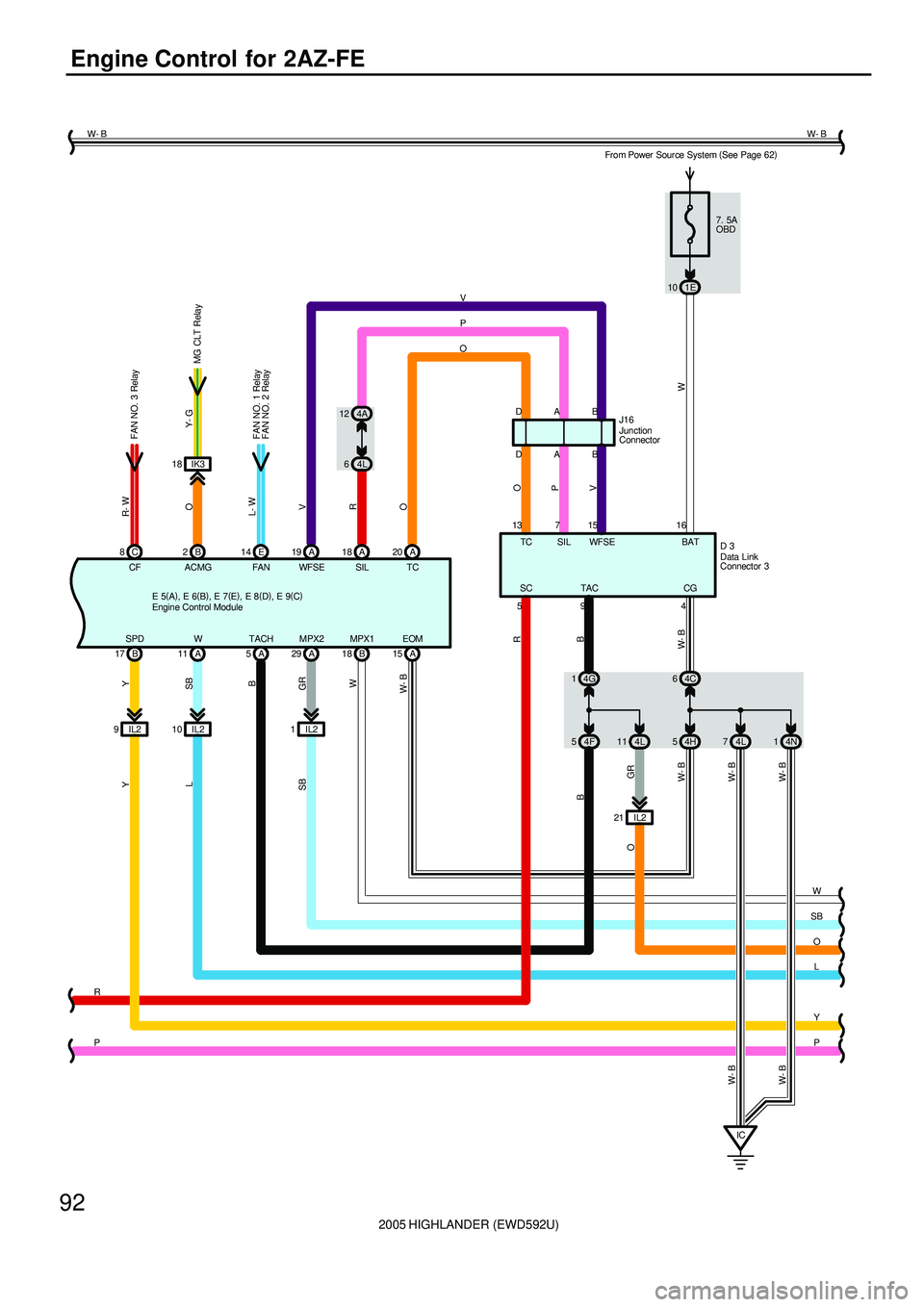

Engine Control for 2AZ-FE

O

L

Y

OGR

TAC

9

B

OP

V

18 IK3

FAN NO. 1 Relay

DJ16

W TC

5

O

V

D

13 7

SIL WFSEB

P

7. 5A

OBD

1E 10

A 18 A20 A 19

ACMG

O

B

4F 5B

IL2 10 IL2 95ATACH

R16

WFSE SIL TC

V

R

O

W SBY Y

L

15

SPD W

B 17 A11BAT

MG CLT Relay

A

A

B 2

5

SB

ICP 4L 74N1

R

SC

W- B

64C

W- B

W- B

CF

R- W

C 8

FAN

L- W

E 14

FAN NO. 3 Relay

4G 1

B

D 3

4CG

Y- G

EOM

A 15

W- B SB

1IL2MPX2

GR

A 29

4H 11 4L

IL2 21 4L 64A 12

W- B

W- B

W- B

MPX1

W

B 18

P W- BW- B

From Power Sour ce System (

See Page 62)

FAN NO. 2 Relay

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C)Data Link

Connector 3

Engine Control ModuleJunction

Connector

Page 274 of 2572

2005 HIGHLANDER (EWD592U)

93

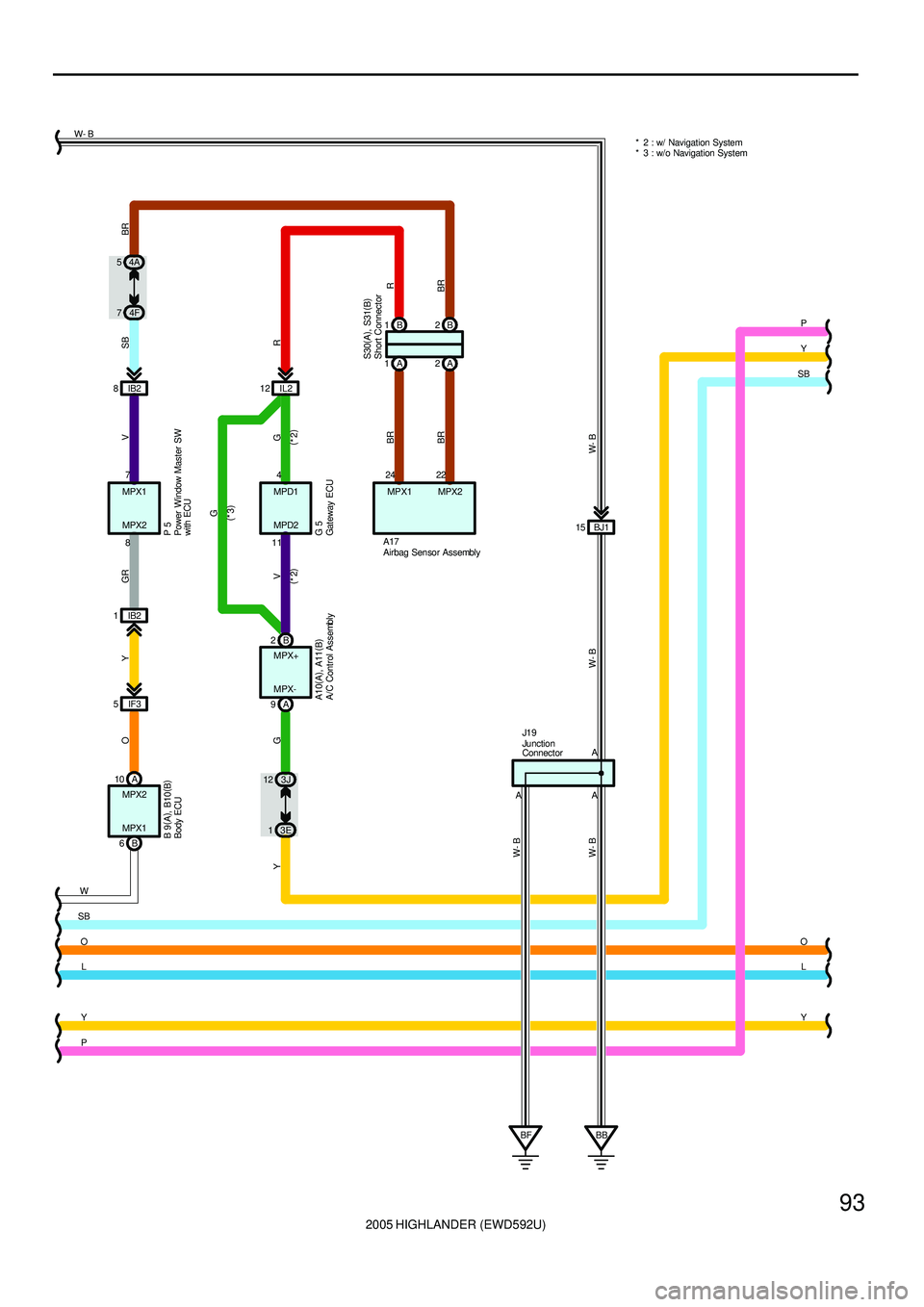

O

L

Y

P5

W

Y

GR

IF3

A 10

B 6MPX2

MPX1

O

L 8

O

SBSBY

7

1IB2MPX1

MPX2

P 5 Y

8IB2

V

4A 5

4F 7

A 2 A 1B 1B2

IL2 12

V

114

MPD1

MPD2G 5G

B 2

A 9MPX+

MPX-A17

13E3J 12

(

*2) G

(

*3)

(

*2)R SB

R

BRBR

G Y

BR

BR

24

MPX122

MPX2P * 2 : w/ Navigation System

* 3 : w/o Navigation System W- B

BB BF AAABJ1 15

W- B W- B W- B

W- B

J1 9

A10(

A)

, A11(

B) B 9(

A)

, B10(

B)

S30(

A)

, S31(

B) A/C Control Assembly

Airbag Sensor Assembly

Body ECU

Gat eway ECU

Ju nctio n

Connector

Power Window Master SW

with ECU

Short Connector

Page 275 of 2572

2005 HIGHLANDER (EWD592U)

94

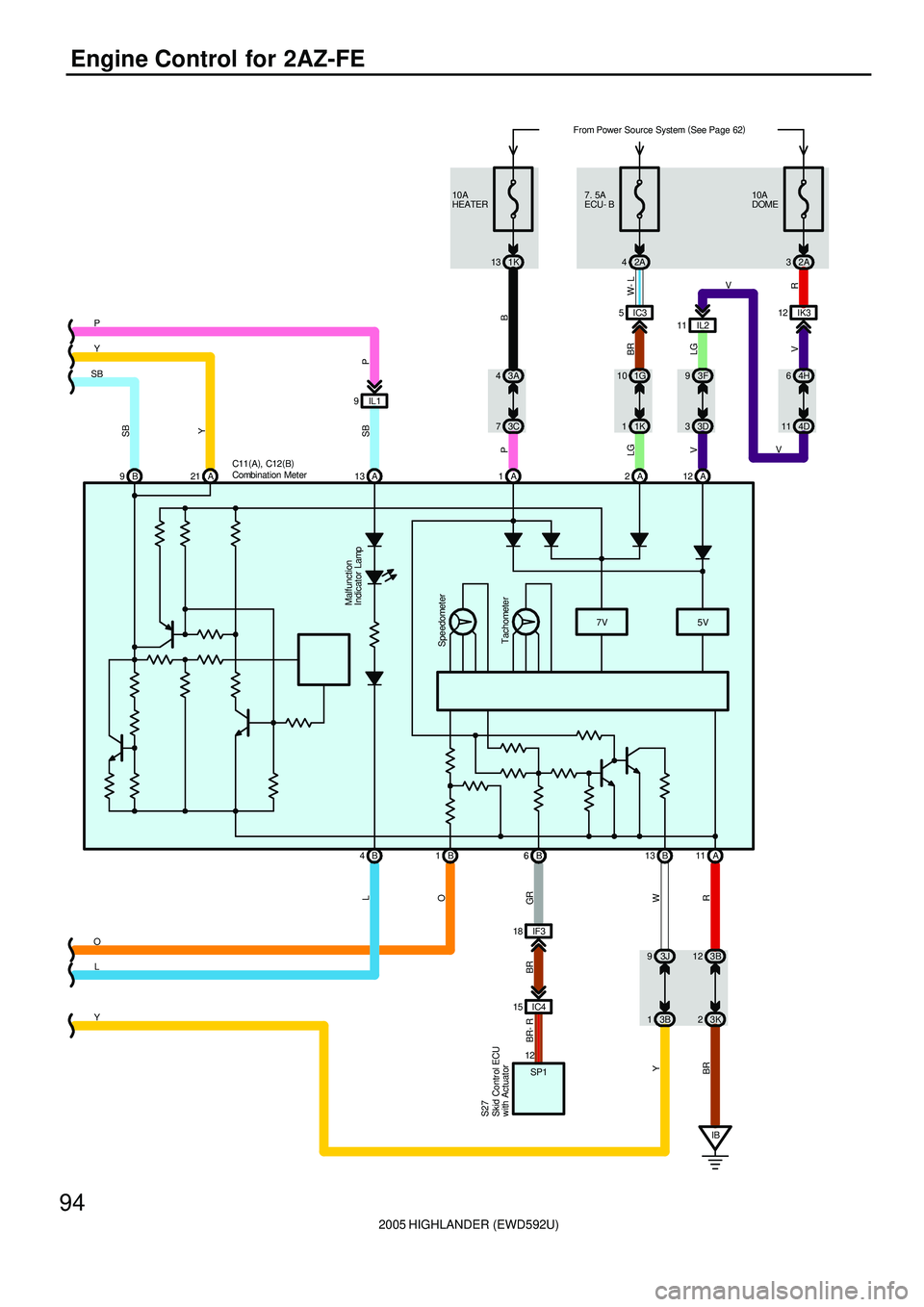

Engine Control for 2AZ-FE

W Y

93J

13B IF3 18

IC4 15

GR BR BR- R

12

SP1

OL

O

YL4B Y

SBP

P SB

IL1 9

A 13

Malfunction

Indicator Lamp

6B

SB

Y

IB 21 A 9BA 12 A 2 A

5V 7V

Tachometer Speedometer

B 13 1

B 6 B 1

R

11 A

3B 12

3K 2 11 IL2IK3 12

V V

VR

32A 10A

DOME

11 4D64H

LG V

33D 93F

BR W- L LGPB

73C 43A

11K 10 1G5IC3 7. 5A

ECU- B

2A 4 13 1K 10A

HEATER

BR

From Power Source System (

See Page 62)

Combination Meter C11(

A)

, C12(

B)

Skid Contr ol ECU

with Actuator S27

Page 276 of 2572

2005 HIGHLANDER (EWD592U)

95

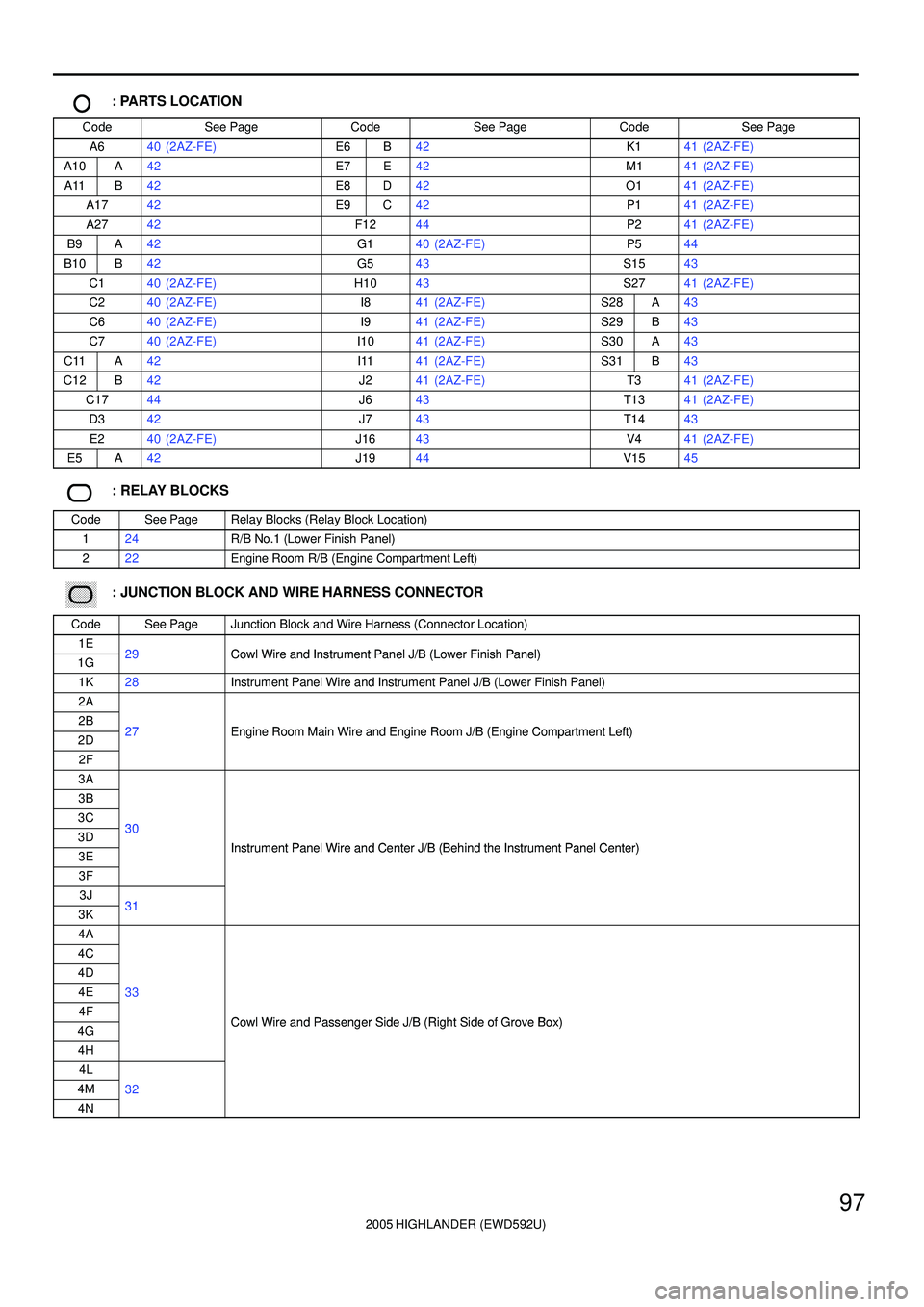

The engine control system utilizes a microcomputer and maintains overall control of the engine, transmission etc. An outline

of the engine control is given here.

1. Input Signals

(1) Engine coolant temp. signal circuit

The engine coolant temp. sensor detects the engine coolant temp. and has a built-in thermistor with a resistance, which

varies according to the engine coolant temp.. The engine coolant temp. which is input into TERMINAL THW of the

engine control module as a control signal.

(2) Intake air temp. signal circuit

The intake air temp. sensor is installed in the mass air flow meter and detects the intake air temp. which is input as a

control signal to TERMINAL THA of the engine control module.

(3) Vehicle speed signal circuit

The vehicle speed signal is input from the ABS speed sensor to skid control ECU with actuator, and are sent to the

engine control module through communication control.

(4) RPM signal circuit

Camshaft position and crankshaft position are detected by the camshaft position sensor and crankshaft position sensor.

Camshaft position is input as a control signal to TERMINAL G2+ of the engine control module, and engine RPM is input

into TERMINAL NE+.

(5) Throttle position signal circuit

The throttle position sensor detects the throttle valve opening angle as a control signal, which is input into TERMINALS

VTA1 and VTA2 of the engine control module.

(6) Battery signal circuit

Voltage is constantly applied to TERMINAL BATT of the engine control module. With the ignition SW turned on, the

voltage for engine control module start-up power supply is applied to TERMINALS +B and +B2 of the engine control

module via the EFI relay.

The current flowing through the IGN fuse flows to TERMINAL IGSW of the engine control module.

(7) Intake air volume signal circuit

Intake air volume is detected by the mass air flow meter and the signal is input to TERMINAL VG of the engine control

module as a control signal.

(8) Stop light SW signal circuit

The stop light SW is used to detect whether the vehicle is braking or not and the signal is input into TERMINAL STP of

the engine control module as a control signal.

(9) Starter signal circuit

To confirm whether the engine is cranking, the voltage is applied to the starter motor during cranking is detected and the

signal is input into TERMINAL STA of the engine control module as a control signal.

(10) Engine knock signal circuit

Engine knocking is detected by knock sensor and the signal is input into TERMINAL KNK1 as a control signal.

(11) Air fuel ratio signal system

The air fuel ratio is detected and input as a control signal into TERMINAL A1A+ of the engine control module.

(12) Oxygen sensor signal circuit

The oxygen density in the exhaust gases is detected and input as a control signal into TERMINAL OX1B of the engine

control module. To maintain stable detection performance by the heated oxygen sensor, a heater is used for warning the

sensor. The heater is also controlled by engine control module (O1B-).

(13) Fuel cut in a collision

The system receives the collision signal from center airbag sensor assembly in the vehicle has a collision and stops the

fuel pump operation on the side of the engine control module.

System Outline

Page 277 of 2572

2005 HIGHLANDER (EWD592U)

96

Engine Control for 2AZ-FE

2. Control System

*SFI system

The SFI system monitors the engine condition through the signals input from each sensor (Input signals from (1) to (12)

etc.) to the engine control module. And the control signal is output to TERMINALS #1, #2, #3 and #4 of the engine

control module to operate the injector (Inject the fuel). The SFI system controls the fuel injection operation by the engine

control module in response to the driving conditions.

*ESA system

The ESA system monitors the engine condition through the signals input to the engine control module from each sensor

(Input signals from (1) to (12) etc.). The best ignition timing is decided according to this data and the memorized data in

the engine control module and the control signal is output to TERMINALS IGT1, IGT2, IGT3 and IGT4. This signal

controls the igniter to provide the best ignition timing for the driving conditions.

3. Diagnosis System

With the diagnosis system, when there is a malfunction in the engine control module signal system, the malfunctioning

system is recorded in the memory. The malfunctioning system can be found by reading the code displayed by the

malfunction indicator lamp.

4. Fail-safe System

When a malfunction has occurred in any system, if there is a possibility of engine trouble being caused by continued control

based on the signals from that system, the fail-safe system either controls the system by using data (Standard values)

recorded in the engine control module memory or else stops the engine.

CIRCUIT OPENING Relay

5-3 : Closed with the starter running

EFI Relay

5-3 : Closed with the ignition SW at ON or ST position

E5 (A), E6 (B), E7 (E), E8 (D), E9 (C) Engine Control Module

BATT-E1 : Always 9.0-14.0 volts

VC-E2 : 4.5-5.5 volts (Ignition SW at ON position)

VG-EVG : 1.1-1.5 volts (Engine idling and A/C SW off)

THA-E2 : 0.5-3.4 volts (Engine idling and intake air temp. 20°C, 68°F)

THW-E2 : 0.2-1.0 volts (Engine idling and coolant temp. 80°C, 176°F)

IG1-E1 : 4.5-5.5 volts (Ignition SW at ON position)

Pulse generation (Engine idling)

SIL-E1 : Pulse generation (During transmission)

TACH-E1 : Pulse generation (Engine idling)

STA-E1 : 6.0 volts or more (Engine cranking)

FC-E01 : 9.0-14.0 volts (Ignition SW at ON position)

SPD-E1 : Pulse generation (Ignition SW on and rotate driving wheel slowly)

W-E01 : Below 3.0 volts (Ignition SW at ON position)

NSW-E1 : 9.0-14.0 volts (Ignition SW on and other shift position in P or N position)

0-3.0 volts (Ignition SW on and shift position in P or N position)

PRG-E01 : 9.0-14.0 volts (Ignition SW at ON position)

STP-E1 : 7.5-14.0 volts (Ignition SW on and brake pedal depressed)

Below 1.5 volts (Ignition SW on and brake pedal released)

KNK1-E1 : Pulse generation (Engine idling)

PSW-E1 : 9.0-14.0 volts (Ignition SW at ON position)

HA1A-E04 : Below 3.0 volts (Engine idling)

IGSW-E1 : 9.0-14.0 volts (Ignition SW at ON position)

MREL-E1 : 9.0-14.0 volts (Ignition SW at ON position)

G2+, NE+ -NE- :

Pulse generation (Engine idling)

OC1+ -OC1- : Pulse generation (Ignition SW at ON position)

HT1B-E1 : 9.0-14.0 volts (Engine idling)

Below 3.0 volts (Ignition SW at ON position)

A1A+ -E1 : 3.3 volts (Ignition SW at ON position)

OX1B-E1 : Pulse generation (Maintain engine speed at 2500 rpm for 90 sec. after warming up)

IGT1, IGT2, IGT3, IGT4-E1 : Pulse generation (Engine idling)

#1, #2, #3, #4-E01 : 9.0-14.0 volts (Ignition SW at ON position)

Pulse generation (Engine idling)

Service Hints

Page 278 of 2572

2005 HIGHLANDER (EWD592U)

97

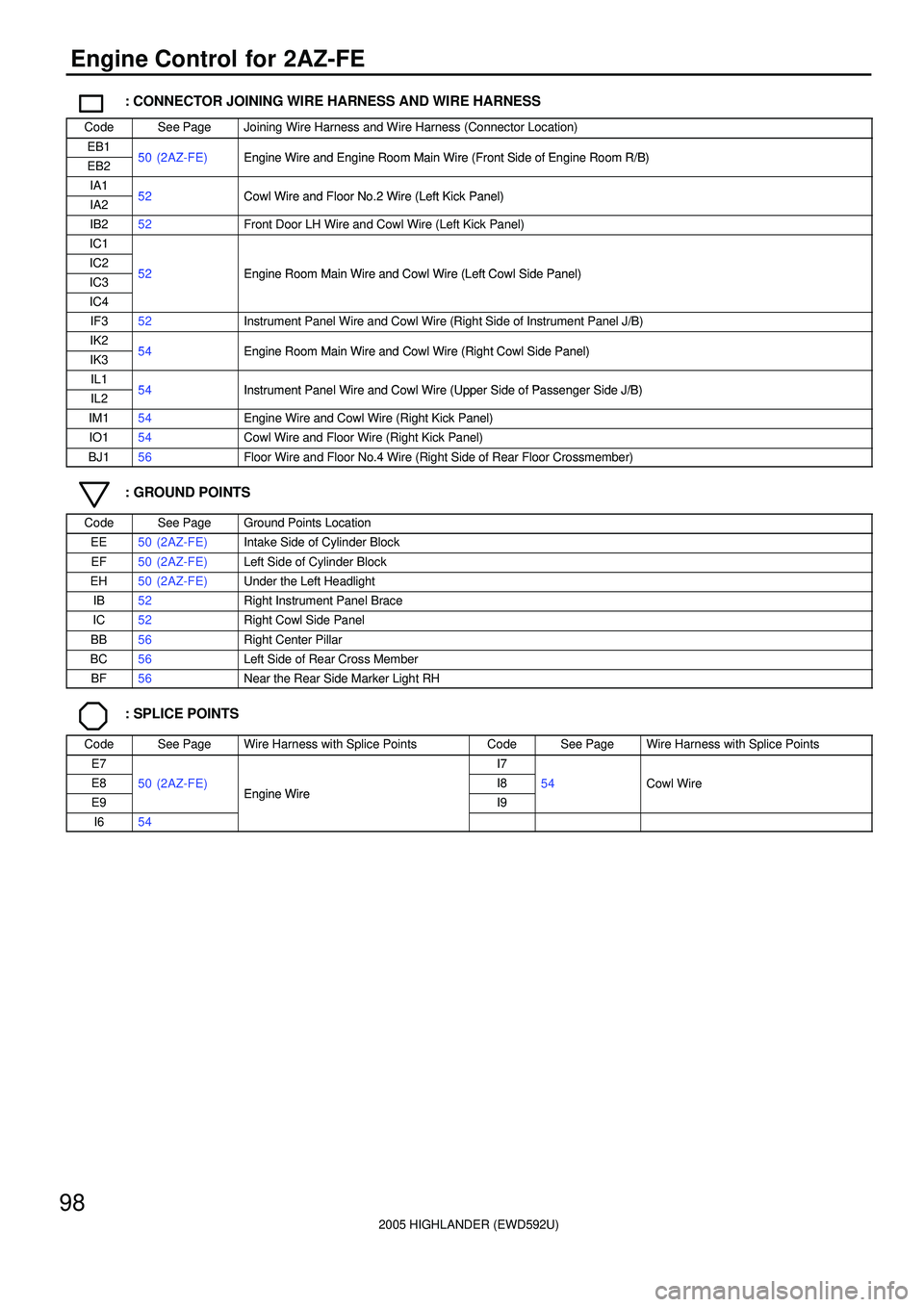

: PARTS LOCATION

CodeSee PageCodeSee PageCodeSee Page

A640 (2AZ-FE)E6B42K141 (2AZ-FE)

A10A42E7E42M141 (2AZ-FE)

A11B42E8D42O141 (2AZ-FE)

A1742E9C42P141 (2AZ-FE)

A2742F1244P241 (2AZ-FE)

B9A42G140 (2AZ-FE)P544

B10B42G543S1543

C140 (2AZ-FE)H1043S2741 (2AZ-FE)

C240 (2AZ-FE)I841 (2AZ-FE)S28A43

C640 (2AZ-FE)I941 (2AZ-FE)S29B43

C740 (2AZ-FE)I1041 (2AZ-FE)S30A43

C11A42I1141 (2AZ-FE)S31B43

C12B42J241 (2AZ-FE)T341 (2AZ-FE)

C1744J643T1341 (2AZ-FE)

D342J743T1443

E240 (2AZ-FE)J1643V441 (2AZ-FE)

E5A42J1944V1545

: RELAY BLOCKS

CodeSee PageRelay Blocks (Relay Block Location)

124R/B No.1 (Lower Finish Panel)

222Engine Room R/B (Engine Compartment Left)

������ ���: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CodeSee PageJunction Block and Wire Harness (Connector Location)

1E29Cowl Wire and Instrument Panel J/B (Lower Finish Panel)1G29Cowl Wire and Instrument Panel J/B (Lower Finish Panel)

1K28Instrument Panel Wire and Instrument Panel J/B (Lower Finish Panel)

2A

2B27Engine Room Main Wire and Engine Room J/B (Engine Compartment Left)2D27Engine Room Main Wire and Engine Room J/B (Engine Compartment Left)

2F

3A

3B

3C303D30

Instrument Panel Wire and Center J/B (Behind the Instrument Panel Center)3EInstrument Panel Wire and Center J/B (Behind the Instrument Panel Center)

3F

3J313K31

4A

4C

4D

4E33

4FCowl Wire and Passenger Side J/B (Right Side of Grove Box)4GCowl Wire and Passenger Side J/B (Right Side of Grove Box)

4H

4L

4M32

4N

Page 279 of 2572

2005 HIGHLANDER (EWD592U)

98

Engine Control for 2AZ-FE

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CodeSee PageJoining Wire Harness and Wire Harness (Connector Location)

EB150 (2AZ FE)Engine Wire and Engine Room Main Wire (Front Side of Engine Room R/B)EB250 (2AZ-FE)Engine Wire and Engine Room Main Wire (Front Side of Engine Room R/B)

IA152Cowl Wire and Floor No 2 Wire (Left Kick Panel)IA252Cowl Wire and Floor No.2 Wire (Left Kick Panel)

IB252Front Door LH Wire and Cowl Wire (Left Kick Panel)

IC1

IC252Engine Room Main Wire and Cowl Wire (Left Cowl Side Panel)IC352Engine Room Main Wire and Cowl Wire (Left Cowl Side Panel)

IC4

IF352Instrument Panel Wire and Cowl Wire (Right Side of Instrument Panel J/B)

IK254Engine Room Main Wire and Cowl Wire (Right Cowl Side Panel)IK354Engine Room Main Wire and Cowl Wire (Right Cowl Side Panel)

IL154Instrument Panel Wire and Cowl Wire (Upper Side of Passenger Side J/B)IL254Instrument Panel Wire and Cowl Wire (Upper Side of Passenger Side J/B)

IM154Engine Wire and Cowl Wire (Right Kick Panel)

IO154Cowl Wire and Floor Wire (Right Kick Panel)

BJ156Floor Wire and Floor No.4 Wire (Right Side of Rear Floor Crossmember)

: GROUND POINTS

CodeSee PageGround Points Location

EE50 (2AZ-FE)Intake Side of Cylinder Block

EF50 (2AZ-FE)Left Side of Cylinder Block

EH50 (2AZ-FE)Under the Left Headlight

IB52Right Instrument Panel Brace

IC52Right Cowl Side Panel

BB56Right Center Pillar

BC56Left Side of Rear Cross Member

BF56Near the Rear Side Marker Light RH

: SPLICE POINTS

CodeSee PageWire Harness with Splice PointsCodeSee PageWire Harness with Splice Points

E7I7

E850 (2AZ-FE)Engine WireI854Cowl Wire

E9

()Engine WireI9

I654

Page 280 of 2572

2005 HIGHLANDER (EWD592U)

99

MEMO